Abstract

Iridium oxide is commonly used as a catalyst for the oxygen evolution reaction (OER) in various electrolysers. In this study we investigate the impact of organic compounds, such as ethanol, in the accelerated dissolution of iridium oxide, particularly in amorphous form, across a wide pH range. Our findings suggest that organic compounds produced via electrochemical reaction, including CO2 reduction, can severely compromise the stability of Ir based catalysts during OER. In situ/operando analysis reveals that this degradation is driven by aldehyde oxidation, where dual-lattice oxygen from acetate occupies the oxide lattice of Ir, leading to the collapse of the iridium oxide matrix. This observation highlights the need to find alternative anodic reactions or materials to avoid crossover induced deactivation of the anodic catalyst.

Similar content being viewed by others

Introduction

Despite considerable efforts to develop electrocatalysts, Ir is the only commercially available catalyst material for use in the oxygen evolution reaction (OER) in an acidic media1,2,3,4. The OER is pivotal in various clean electrochemical technologies, such as water splitting, electrochemical CO2 reduction (CO2RR), and other electrolyser systems5,6,7. However, its sluggish kinetics, which involve the multistep transfer of four protons and four electrons, result in a high anodic overpotential and harsh reaction environment, limiting the choice of catalyst in reducing the inevitable catalyst dissolution. Ir-based oxides display superior electrochemical activities and stabilities in the OER over a wide pH range, and they exhibit slight levels of dissolution during the OER compared to those of other materials8. Even with a small amount of Ir dissolution, its high cost and scarcity render the minimisation of dissolution and thorough investigation of the dissolution mechanism necessary9.

Based on numerous studies, Ir-based oxides can be classified into two categories based on their structures, catalytic activities, and stabilities: crystalline rutile IrO₂ and amorphous IrOx10,11,12,13,14. Generally, rutile IrO₂ exhibits well-ordered IrO₆ octahedra, whereas amorphous IrOx contains iridium vacancies and a highly distorted structure, which results in the presence of more electrophilic oxygen species. Electrophilic oxygen species facilitate nucleophilic attack for OER, thereby promoting the participation of lattice oxygen. This induces distinct catalytic mechanisms, which cause amorphous IrOx to display higher OER catalytic activity and lower electrochemical stability relative to crystalline IrO₂. The OER mechanism of IrO2 is the adsorbate evolution mechanism (AEM), wherein the OER occurs on the surface of the oxide because the rigid oxide structure inhibits the involvement of lattice O15,16. Conversely, amorphous IrOx exhibits a lattice O participation mechanism (LOM), which promotes the involvement of lattice O in the OER17,18. The LOM pathway typically provides favourable electronic structures for the OER by changing the binding energies of the intermediates, leading to an enhanced OER activity19,20. However, it also generates numerous O vacancies and weakens the amorphous structure, thus accelerating Ir dissolution21,22,23,24. Amorphous IrOx can be synthesised during electrochemical processes25, including the OER, indicating that the amorphous and crystalline phases can coexist, even within crystalline IrO₂, and thus, the inevitable dissolution of Ir-based catalysts can occur during the OER.

Herein, we report the critical phenomenon of accelerated electrochemical Ir dissolution during the OER in the presence of certain organic compounds. The accelerated dissolution of iridium in the presence of organic compounds was firstly reported by L. Moriau et al.26. This phenomenon was thoroughly studied in our work, addressing both its fundamental mechanisms and practical implications. We observed that ethanol produced via the CO2RR crosses over and significantly accelerates Ir dissolution, particularly that of amorphous IrOx, over a wide pH range. Recently, the electrochemical production of valuable organic compounds, e.g., via the CO2RR, has drawn considerable interest in the push toward a carbon-neutral society27,28,29. However, our observations suggest that the use of Ir to produce several organic compounds should be limited. Based on in situ/operando analysis, aldehyde oxidation accelerates Ir dissolution. Furthermore, we propose a mechanism for the accelerated dissolution during aldehyde oxidation.

Results and discussion

Accelerated Ir dissolution phenomenon

Accelerated Ir dissolution is observed in a zero-gap CO2 electrolyser with an anion exchange membrane (AEM, Fig. 1a)30. The IrOx and IrO2 electrodes are respectively fabricated via electrodeposition and thermal treatment31,32. When using an Ag electrode as the cathode, the cell voltage and Faradaic efficiency for CO (FECO) are maintained well when using both anodes, i.e., IrOx and IrO2 (Fig. 1b and d)33,34. However, when using a Cu cathode, which can generate various C2 products, such as ethanol, ethylene, and acetate, the IrO2 anode displays stable cell voltages and FEs for CO and ethylene35,36. Conversely, the IrOx anode exhibits a rapid increase in cell voltages and decreases in the FEs for CO and ethylene (Fig. 1c and e). Furthermore, IrOx almost disappeared after the test. Ethanol and acetate resulting from crossover were identified in the solution on the anode side (Supplementary Fig. S1). Therefore, we expected that several chemicals, such as ethanol, cross over from the cathode to accelerate the degradation of the IrOx electrode.

a Schematic of the CO2 reduction reaction MEA system with IrOx and IrO₂ at the anode and Ag and Cu at the cathode. The cell voltage and Faradaic efficiencies for CO, C₂H₄, and H2 of (b) IrOx at the anode with (b) Ag or (c) Cu at the cathode and IrO₂ at the anode with (d) Ag or (e) Cu at the cathode in 0.1 M KHCO₃ at 300 mA cm–² for approximately 2 h (CP).

Rapid Ir dissolution during the OER

To investigate the rapid degradation, the OER stabilities of various Ir electrodes were evaluated in various electrolytes in the presence of ethanol, which is a representative product generated via the CO2RR using the Cu electrode37. The degradation of the IrOx electrode accelerates with increasing ethanol content, indicating that ethanol degrades the anode within the zero-gap CO2 electrolyser (Fig. 2a and Supplementary Fig. S2). Notably, Ir dissolution was significantly accelerated even at an ethanol concentration of 0.1%, which is lower than the level detected in the MEA test. The commercial IrO2 nanoparticles with various binders (Nafion and polyvinylidene fluoride) also display similar trends (Supplementary Fig. S3–6). Regardless of the substrate, the IrOx electrode degrades in the presence of ethanol (Fig. 2b and Supplementary Fig. S7–10). To verify the universality of this phenomenon in a wide pH range, the stabilities of the IrOx and IrO2 electrodes were further evaluated under acidic, neutral, and alkaline conditions with 10% ethanol (Fig. 2c and Supplementary Fig. S11–18). IrOx degradation is clear in acidic, neutral, and alkaline media, suggesting that this phenomenon can occur over a wide pH range, and IrOx and IrO2 degrade in acidic electrolytes. This phenomenon was consistently observed even when the pH was fixed and the cation/anion composition was varied (Supplementary Fig. S19). Scanning electron microscopy (SEM) images of IrOx and IrO2 before and after evaluation in the presence of ethanol are shown in Fig. 2d–g and Supplementary Fig. S20, and Supplementary Fig. S21. After conducting the OER for 1 h in 1 M KHCO3 electrolyte with 10% ethanol, IrOx is no longer observed, whereas IrO2 persists. Clearly, Ir degradation may be attributed to the presence of ethanol rather than the electrode components and electrolyte environment, such as local pH, CO2 concentration and species of cation and anion.

Chronopotentiometry (CP) of the (a) IrOx electrodes on Ti substrates in 1 M KHCO₃ with ethanol concentrations of 0%, 0.1%, 1%, and 10%, applying an iR correction of 3 Ω. b CP of the IrO₂ and IrOx electrodes on Pt-coated Ti or Ti substrates in 1 M KHCO₃ containing 10% ethanol at a constant current density of 300 mA cm⁻² for 1 h, with iR correction of 3.5 Ω. c CP of the IrOx and IrO₂ electrodes on Pt-coated Ti substrates in 0.5 M H₂SO₄, 1 M KHCO₃, and 1 M KOH, each containing 10% ethanol, at a constant current density of 300 mA cm⁻² for 1 h, with iR correction of 1.5, 3.5, and 1.5 Ω, respectively. d–g SEM images with EDS elemental maps showing the distributions of Ir, Ti, and O of the IrOx and IrO2 electrodes on Ti substrates after CP for 1 h at 300 mA cm⁻² in 1 M KHCO₃ containing 0% or 10% ethanol.

Various spectroscopic analyses were performed to further confirm the degradation of Ir in the presence of ethanol. In the Raman spectra, the peaks representing IrO2 remain after the OER, regardless of the presence of ethanol, but the peak representing IrOx is no longer observed after the OER in the presence of ethanol (Fig. 3a and Supplementary Fig. S22). In the IrOx with 10% ethanol, the appearance of a Raman peak associated with the substrate indicates the complete removal of the surface IrOx. Ir 4 f X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), and near-edge X-ray absorption fine structure (NEXAFS) analysis also reveal a similar trend (Fig. 3b and Supplementary Figs. S23, S24). Previous studies have shown that amorphous IrOx contains more electrophilic oxygen than crystalline IrO₂, which is attributed to its higher oxidation state12. In our XPS results, IrOx initially shows a higher oxidation state than IrO₂, but this is no longer observed after OER in the presence of ethanol. Since the surface of commercial IrO₂ also exists in the form of IrOx, the observed severe Ir dissolution is likely attributed to this surface state Supplementary Fig. S25. To remove the uncertainty of test consistency, IrOx@IrO2 was produced via the electrodeposition of IrOx on the IrO2 electrode. No peaks representing IrOx are observed after the OER in the presence of ethanol, with only peaks representing IrO2 observed, confirming the dissolution of IrOx by ethanol during the OER (Fig. 3c and Supplementary Fig. S26).

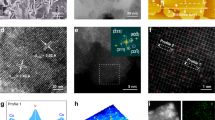

a Raman and (b, c) Ir 4 f XP spectra of the (a, b) IrO₂ and IrOx electrodes and the (c) IrOx@ IrO2 electrode on a Ti substrate as the initial sample. The electrodes were subjected to 1 h of 300 mA cm⁻² chronopotentiometry (CP) in 1 M KHCO₃ containing 0% or 10% ethanol. X-ray absorption near-edge structure (XANES) spectra of the Ir L-edges of the (d) IrOx and (e) IrO₂ electrodes in 1 M KHCO₃ containing 0% or 10% ethanol, with the insets showing the oxidation state of each electrode after the OER. f Amounts of Ir in the solutions (1 M KHCO3 containing 0% or 10% ethanol) after 1 h of 300 mA cm⁻² CP of the IrOx electrodes and IrO₂ electrodes calcined at 400 or 600 °C. g–j High-magnification HR-TEM images of IrO₂ calcined at 400 °C after 1 h of 300 mA cm⁻² CP in 1 M KHCO₃ containing 0% or 10% ethanol.

To explain the effects of ethanol on the Ir catalyst, in situ/operando X-ray absorption near-edge structure (XANES) measurements of the Ir L3-edge were performed (Fig. 3d, e). The white-line position of IrOx increases during the OER without ethanol, which is consistent with previous research38,39. However, the white-line positions of IrOx under the OCV and OER conditions are similar in the presence of ethanol, and it decreases after the OER. This suggests that the IrOx produced in situ with abundant electrophilic O species is dissolved by ethanol during the OER. In contrast, IrO2 exhibits a similar white-line position with or without ethanol. To confirm Ir dissolution, we directly measured the amount of Ir in the electrolyte after the OER using inductively coupled plasma optical emission spectroscopy (ICP-OES, Fig. 3f). The amount of dissolved IrOx in the presence of ethanol significantly exceeds that in its absence, providing direct evidence for the acceleration of IrOx dissolution by ethanol. IrOx is no longer observed after the OER with ethanol (Supplementary Fig. S27, S28). Remarkably, the amount of Ir dissolved when using IrO2 also increases in the presence of ethanol, and IrOx can be produced at the IrO2 electrode during the OER. An amorphous layer is observed on the IrO2 surface after the OER (Fig. 3g, h and Supplementary Fig. S29, S30). With ethanol, IrO2 displays an abraded surface without the amorphous layer, indicating the dissolution of the amorphous layer (Fig. 3i and j and Supplementary Fig. S31, S32). Therefore, these observations suggest that the acceleration of the dissolution of Ir-based oxide catalysts during the OER in the presence of ethanol is inevitable.

Origin of the accelerated Ir dissolution

To determine the origin of the accelerated dissolution by ethanol, we tracked the possible pathways of electrochemical ethanol oxidation (Fig. 4a). Ethanol is typically oxidised sequentially to acetaldehyde and then acetic acid40,41,42. All organic chemicals can be directly oxidised to CO2 after C–C bond cleavage. We anticipate that one step in the electrochemical ethanol oxidation pathway shall trigger considerable Ir dissolution. Therefore, we investigated the dissolution of the IrOx electrodes in the presence of ethanol, acetaldehyde, and acetic acid (Fig. 4b and Supplementary Fig. S33). In acetic acid, IrOx displays a stable performance. Notably, IrOx rapidly degrades in the presence of acetaldehyde compared to that in ethanol, suggesting that the accelerated dissolution of Ir may be attributed to electrochemical aldehyde oxidation. Distinguishing between the effects of ethanol and acetaldehyde is challenging using conventional analyses because aldehydes can be produced from ethanol. First, we compared 1-propanol (which is oxidised to an aldehyde) and 2-propanol (which is oxidised to a ketone) (Supplementary Fig. S34). As a result, accelerated Ir dissolution was observed only in the case of 1-propanol, confirming that aldehyde is the key chemical species driving this degradation. To further realise this, in situ/operando inductively coupled plasma mass spectrometry (ICP-MS) analysis of the IrOx electrode was performed using an electrochemical flow cell, which minimised the effects of the produced chemicals (Fig. 4c)43,44. Without organic chemicals (H2O), Ir dissolution is proportional to the applied potential, exhibiting dissolution due to lattice O participation for the OER. When ethanol is present in the electrolyte, a broad peak is observed after the highest potential, but it displays a similar height to that of H2O. In the case of acetaldehyde, the amount of Ir dissolved significantly exceeds that in the presence of ethanol, confirming that the accelerated Ir dissolution is due to electrochemical aldehyde oxidation. Two dissolution peaks are observed, the first occurring a few seconds after the potential reaches its maximum, and the second after its return to 0 V. The current density results for in situ/operando ICP analysis suggest that the accelerated Ir dissolution comprises two processes (Supplementary Fig. S35): an electrochemical reaction with slow kinetics during aldehyde oxidation, and a non-electrochemical reaction after aldehyde oxidation.

a Electrochemical oxidation mechanism of ethanol on an Ir electrode in an electrolyte. b Chronopotentiometry (CP) of the IrOx electrodes on Pt-coated Ti substrates in 1 M KHCO₃ containing 1% acetic acid, ethanol, or acetaldehyde at a constant current density of 300 mA cm⁻² for 1 h, with iR correction of 1.8 Ω. c Ir dissolution profiles of the IrOx electrodes during cyclic voltammetry measured using on-line ICP-MS in solutions containing 1% H2O, ethanol, or acetaldehyde. d Electrochemical oxidation mechanism of acetaldehyde on an Ir electrode in an electrolyte. e Compositions of the gases (%, compared without chemical) generated during the reactions in 1 M K₂SO₄ containing 1% acetic acid, formaldehyde, ethanol, or acetaldehyde at a constant current density of 300 mA cm⁻² for 6 min. f CP of the IrOx electrodes on Pt-coated Ti substrates in 1 M KHCO₃ containing 1% butyraldehyde, acetaldehyde, or formaldehyde at a constant current density of 300 mA cm⁻² for 1 h, with iR correction of 4 Ω.

Based on the mechanism of electrochemical aldehyde oxidation, the pathways of aldehyde oxidation can be categorised into three distinct routes: (1) oxidation and protonation, (2) deprotonation after hydrate formation, and (3) the formation of CO2 after C–C bond cleavage (Fig. 4d)40. To directly confirm pathway (3), gas analysis was performed in the presence of 1% chemical, and the results were compared with those observed using the pure electrolyte (Fig. 4e). Acetic acid exhibits a gas component similar to that of the pure electrolyte, indicating that the electrochemical oxidation of organic chemicals ceases at acetic acid. Only formaldehyde produces abundant CO2, suggesting pathway (3) for C1. The lower amount of O2 gas generated using ethanol and acetaldehyde compared to that generated using the pure electrolyte explains the occurrence of organic oxidation instead of the OER. To investigate pathways (1) and (2), OER evaluations of the IrOx electrode were performed using three aldehydes with different alkyl chain lengths and hydration tendencies (Fig. 4f)45,46,47. Remarkably, despite using the same aldehyde, the stability of the IrOx electrode varies significantly. In butyraldehyde, the IrOx electrode degrades drastically, whereas it displays a stable performance in formaldehyde. Formaldehyde is almost completely hydrated within the electrolyte, indicating pathways (2) and (3)48,49. Butyraldehyde exhibits a longer alkyl chain, which decreases hydrate formation, suggesting that the main pathway for aldehyde oxidation is pathway (1). Therefore, the accelerated Ir dissolution can best be described by pathway (1).

Proposed route of rapid Ir dissolution

The chemical concentrations of various chemicals after the OER were determined to gain insight into the origin of the accelerated Ir dissolution during pathway (1). The acetic acid remaining after the OER further supports no acetic acid oxidation over the iridium oxide electrode (Supplementary Fig. S36). Remarkably, although only IrOx converts to IrO2, the chemical composition changes after the OER in the presence of acetaldehyde. Despite the low CO2 production during the OER, a missing sum of chemicals is observed when using IrOx with acetaldehyde. In contrast, the sum of the chemicals of IrO2 and acetaldehyde is almost 100%. The ultraviolet (UV) spectrum of the electrolyte with various chemicals after OER evaluation using the IrOx and IrO2 electrode was measured to identify the missing chemicals (Supplementary Fig. S37–S39). The broad peak at 500–700 nm is assigned to IrOx nanoparticles, suggesting that IrOx is partially physically detached50,51. The large peak at 300 nm is not consistent with the Ir(III) and Ir(IV) ions, and it exhibits a similar position to those of peaks representing other Ir complexes with organic ligands. Based on these results, we carefully suggest that Ir dissolved via aldehyde oxidation occurs as an Ir complex with an organic compound52,53,54.

Based on various observations, we propose a mechanism for the accelerated Ir dissolution via organic compound oxidation. Based on the OER mechanism, iridium intermediates and their oxidation states undergo dynamic transformations during OER55,56. In this process, the involvement of the lattice O of IrOx weakens the oxide matrix, increasing Ir dissolution (Fig. 5a). The dual-LOM in the presence of aldehydes may explain the accelerated Ir dissolution (Fig. 5b). Unlike pathway (2), electrochemical aldehyde oxidation via pathway (1) electrochemically forms di-oxygen without hydrates. We anticipate that this dual oxygen is adsorbed and occupies the IrO6 lattice to form an Ir-acetate complex. This leads to the severe collapse of the oxide matrix, accelerating the detachment of IrOx. The observations in this study are consistent with this mechanism. According to previous literature, iridium typically exhibits lower durability under alkaline conditions56. However, in the presence of aldehydes, accelerated iridium dissolution is more pronounced under acidic conditions. This can be explained by that aldehyde stability is lower in an alkaline medium because of aldol condensation and oxidation, which mitigates this phenomenon at high pH. The proposed mechanism was further supported via ICP results in Fig. 3f and in situ/operando ICP study in Fig. 4c. Based on the ICP analysis, 1 mg of Ir was lost from the electrode, whereas only 0.4 mg was detected as dissolved Ir species. This discrepancy is presumed to be due to IrOx particles that detached from the electrode. In in situ/operando ICP results, the first dissolution peak can be explained by the electrochemically formed Ir-acetate complex, and the second dissolution peak is associated with the detachment of IrOx (a non-electrochemical reaction). Our proposed mechanism demonstrates how accelerated Ir degradation occurs, even in the presence of trace amounts of aldehyde.

In this study, we discovered and identified a phenomenon: the acceleration of electrochemical Ir dissolution under anodic conditions in the presence of certain organic compounds. These organic compounds are restricted to aldehydes with C numbers of >2, or compounds with the capacity to produce such aldehydes. This phenomenon was prominently observed for IrOx, and it was also observed for IrO₂, indicating that all iridium oxides could be drastically dissolved via organic compounds. We unveil that the electrochemical formation of di-oxygen without hydration during electrochemical aldehyde oxidation is the primary cause of this phenomenon. Taking this a step further, we propose a dual-LOM, wherein the dual oxygen of acetate occupies the lattice O sites of Ir and collapses its oxide matrix. These results demonstrate that the acceleration of Ir dissolution during the OER in the presence of certain organic compounds is inevitable.

Various organic compounds produced via electrochemical reactions, such as the CO2RR, have emerged as promising solutions in realising a sustainable net-zero society. In these technologies, the anode material may be Ir, owing to its good OER activity and stability, despite its high cost. However, the observations in this study suggest that the electrochemical production of organic compounds that can be oxidised to aldehydes should be reconsidered. Recently, conversion has been regarded as the dominant factor in determining economic viability57,58,59. Thus, realising a high concentration of the product is a target of numerous studies. However, high compound concentrations increase the possibility of crossover to the anode. While cation exchange membrane (CEM)-based systems have recently gained attention, it should be noted that ethanol crossover can also occur through thick CEMs, although to a lesser extent than that observed with AEMs. (Supplementary Fig. S40–42)60. Therefore, the electrochemical production of chemicals, such as ethanol, can be accompanied by the severe degradation of the Ir catalyst, drastically reducing its economic viability. In this sense, we suggest directions for research regarding the electrochemical production of organic compounds: (1) focusing on the production of gaseous organic compounds or organic compounds that are not converted to aldehydes, (2) identifying alternative reactions to replace the OER, such as hydrogen evolution reaction and (3) developing alternative catalysts to replace Ir including oxide material with strong lattice oxygen. We hope that the analysis of our findings will aid in identifying a realistic route for use in developing electrochemical technology to contribute to a sustainable society.

Methods

Preparation of the Ir anodes

IrO2 electrode

The IrO₂ electrode was prepared by dissolving 400 mg of IrCl3.xH2O (99.9% trace metals basis, 203491, Sigma-Aldrich, St. Louis, MO, USA) in 1 mL of 36% HCl (4090-4400, Daejung Chemicals, Siheung, Republic of Korea), followed by the addition of 9 mL of isopropyl alcohol (99.5%, 5035-4410, Daejung Chemicals, Siheung, Republic of Korea). The solution was stirred continuously for 24 h. Subsequently, Pt-Ti (5GDL05N-035, 0.35 mm, Bekaert, Zwevegem, Belgium) or Ti felt (5GDL05N-035S, 0.35 mm, Bekaert) was immersed in the solution, removed, and heated in a box furnace at 600 °C for 1 h to form the IrO₂ electrodes. When preparing the Ti felt, pretreatment was required, which involved etching the Ti felt in a solution of 60 mL of deionised (DI) H2O mixed with 5 mL of HCl at 150 °C for 40 min. In this study, whereas the IrO₂ samples were primarily calcined at 600 °C, the experimental results of ICP-optical emission spectrometry (ICP-OES) and transmission electron microscopy (TEM) also include analyses of IrO₂ calcined at 400 and 600 °C. The IrO₂ electrode displayed an Ir loading of approximately 1 mg cm–².

IrOx electrode

The IrOx electrode was prepared by dissolving 0.81 g of H₂IrCl₆ (99.9% trace metals basis, 455962, Sigma-Aldrich) and 0.71 g of oxalic acid (98%, 194131, Sigma-Aldrich) in 175 mL of DI H2O, followed by the addition of 2 mL of 30% H2O2 (4104-4400, Daejung Chemicals). In a separate vessel, 11.05 g of K₂CO₃ (99.9%, 209619, Sigma-Aldrich) was dissolved in 25 mL of DI H2O and added dropwise to the H₂IrCl₆ mixture with stirring. The mixture was then stirred at 30 °C for 3 d. The Pt-Ti or Ti felt was then immersed in the solution, and chronopotentiometry (CP) was applied at 20 mA for 5 min to fabricate the IrOx electrode with an Ir loading of ~ 1 mg cm–².

IrO2 @ IrOx electrode

The IrO₂@IrOx electrode was prepared via a two-step process. First, an IrO₂ electrode was fabricated, which served as the base layer, and then IrOx was electroplated onto the surface of the IrO₂ electrode to form the final composite structure.

IrO2 NP electrode

The IrO₂ NP electrode was prepared by spraying a catalyst ink onto a platinised Ti screen placed on a hot plate at 70 °C. The catalyst ink was prepared by mixing 60 mg of commercial iridium oxide (Alfa Aesar, Haverhill, MA, USA) with 60 mg of a 5 wt.% Nafion ionomer solution and 2 mL of IPA. The catalyst loading of the IrO₂ NP electrode was set to 1 mg cm⁻².

Preparation of the Ag and Cu cathodes

The Ag and Cu electrodes, which were used as cathodes during the CO2RR activity studies, were prepared by spraying their respective catalyst inks onto gas diffusion layers (Sigracet 39BB, SGL Carbon, Wiesbaden, Germany) at 70 °C. For the Ag electrode, the Ag ink was prepared by mixing an Ag nanopowder (99.9%, APS 20–40 nm, Alfa Aesar) with a 5% Nafion solution and IPA, followed by ultrasonication. Similarly, the Cu electrode ink was prepared by dispersing a Cu nanopowder (60 mg, Chempur, Karlsruhe, Germany) in 2 mL of IPA and a 5 wt.% Nafion solution via sonication. The catalyst loadings of the Ag and Cu electrodes were set to 1 mg cm⁻².

Electrochemical OER study

Half-cell OER electrochemical measurements were performed using a three-electrode setup within an electrochemical cell, with only 1 cm² of each electrode submerged during the study. The studies were performed at room temperature. Electrolyte solutions were prepared by dissolving the appropriate amount of high-purity reagent-grade salts in deionised water under magnetic stirring until fully homogeneous. Prepared solutions were then transferred into airtight polypropylene bottles and stored at room temperature. In the OER studies, a graphite rod served as the counter electrode, and the reference electrode was selected based on the electrolyte solution. Hg/HgSO₄, Ag/AgCl, and Hg/HgO reference electrodes were used with 0.5 M H₂SO₄, 1 M KHCO₃, and 1 M KOH, respectively, and were calibrated versus RHE in H₂-saturated electrolyte using a Pt wire. The pH is approximately 0 ± 0.3 for 0.5 M H₂SO₄, 7.5 ± 0.3 for 1 M KHCO₃, and 14 ± 0.3 for 1 M KOH. All measured potentials were converted to the reversible hydrogen electrode (RHE) scale using the Eq. (1):

A graphite rod was used as the counter electrode, and cyclic voltammetry tests were conducted using 200 mL of electrolyte. The performance of the OER electrode (1 cm²) was first evaluated in an electrolyte containing 0% ethanol using cyclic voltammetry (CV, within the range 0.5–2.0 V vs. the reversible hydrogen electrode (RHE)) at a scan rate of 10 mV s⁻¹ for 3 cycles. After the initial measurement, the electrode was immersed in an electrolyte containing x% ethanol, and CP was performed at a constant current of 300 mA for 1 h. Upon completion of the CP evaluation, the electrode was rinsed once with DI H2O and then reimmersed in the electrolyte without ethanol. CV was then repeated under the same conditions to assess the performance degradation caused by the presence of ethanol. The CV, CP and EIS measurements were performed using a multichannel potentiostat (BioLogic EC-Lab).

The recorded potentials were adjusted to the RHE scale. Furthermore, the corrected potentials were iR-compensated to account for the potential drop. The ohmic resistance was determined using electrochemical impedance spectroscopy conducted at 1.63 V (vs. RHE) over the frequency range 100 kHz–1 Hz.

Electrochemical CO2RR study

Electrochemical studies were conducted using a 10 cm² MEA setup. The AEM (Sustanion X37-50 grade 60, Dioxide Materials, Boca Raton, FL, USA) was pretreated by immersing it in a 1 M KOH solution at 55 °C for 3 h. Thereafter, the membrane was thoroughly rinsed several times with DI H2O to eliminate any remaining KOH. The AEM was then placed between the anode and cathode to form the MEA, which was subsequently assembled between the serpentine-type anode and cathode plates. Humidified CO2 gas (100 sccm) was supplied to the cathode plate, which was maintained at 55 °C, whereas 1 M KHCO3 (Sigma-Aldrich) with or without 10% ethanol was pumped to the anode plate at varying flow rates. Electrochemical CO2RR studies were conducted using a custom-built station (CNL Energy, Seoul, Republic of Korea) equipped with a potentiostat (Sorensen XG 20-76, Ametek, Berwyn, PA, USA), and all MEA electrochemical measurements were conducted once per condition. The outlet gases were passed through an H2O trap and analysed using gas chromatography (GC, Agilent Technologies, Santa Clara, CA, USA) with flame ionisation (FID) and thermal conductivity detection (TCD). FID detected CO and C2H4, whereas TCD was used in H2 detection. The FEs of the products are calculated using the following Eq. (2):

where F, i, Vproduct, Q, T, and R are the Faraday constant (96 485 C mol–1), current (mA), volume fraction of the gaseous product in the outlet gas, flow rate of the outlet gas, room temperature (298 K), and ideal gas constant (8.314 J mol K–1), respectively. The CO2RR measurements were conducted three times to ensure accuracy.

Physical characterisation

Field emission SEM (Regulus8230, Hitachi, Tokyo, Japan) combined with energy-dispersive X-ray spectroscopy (EDS) and elemental analysis was utilised to visualise the electrode surfaces before and after the OERs in electrolytes containing 0% and 10% ethanol. XPS (Nexsa, Thermo Fisher Scientific, Waltham, MA, USA) with an Al Kα X-ray source (1486.6 eV) was utilised to analyse the chemical states on the surfaces of the IrO₂@IrOx electrodes, including the initial electrode and those reacted in solutions containing 0% and 10% ethanol. Raman spectroscopy was employed to characterise the various Ir electrodes before and after the OER, and it was conducted at room temperature using a 532 nm laser (Renishaw, Wotton-under-Edge, UK). The concentration of the degraded Ir in the electrolyte after the reaction was determined using ICP-OES (iCAP 7000, Thermo Fisher Scientific) to provide quantitative insights into the Ir degradation. In addition, UV-visible (UV-Vis) spectroscopy was performed to analyse the colour changes in the electrolyte, providing data regarding the Ir within the solution during the reaction. To further probe the structural properties of the Ir on the electrodes, synchrotron-based NEXAFS measurements were performed at the 10D beamline of the Pohang Accelerator Laboratory in Pohang, Republic of Korea. The molecular mechanism underlying the catalytic behaviour of Ir in an ethanol-containing solution was elucidated using in situ/operando XANES.

Data availability

Source data for the figure are provided with the paper.

References

Reier, T., Oezaslan, M. & Strasser, P. Electrocatalytic oxygen evolution reaction (OER) on Ru, Ir, and Pt catalysts: a comparative study of nanoparticles and bulk materials. Acs Catal. 2, 1765–1772 (2012).

Pfeifer, V. et al. Reactive oxygen species in iridium-based OER catalysts. Chem. Sci. 7, 6791–6795 (2016).

Wu, H. et al. Recent developments of iridium-based catalysts for the oxygen evolution reaction in acidic water electrolysis. J. Mater. Chem. A 10, 13170–13189 (2022).

Beni, G., Schiavone, L., Shay, J., Dautremont-Smith, W. & Schneider, B. Electrocatalytic oxygen evolution on reactively sputtered electrochromic iridium oxide films. Nature 282, 281–283 (1979).

Fabbri, E. & Schmidt, T. J. Oxygen evolution reaction—the enigma in water electrolysis. ACS Catal. 8, 9765–9774 (2018).

Suen, N.-T. et al. Electrocatalysis for the oxygen evolution reaction: recent development and future perspectives. Chem. Soc. Rev. 46, 337–365 (2017).

Shi, Q., Zhu, C., Du, D. & Lin, Y. Robust noble metal-based electrocatalysts for oxygen evolution reaction. Chem. Soc. Rev. 48, 3181–3192 (2019).

Cherevko, S. Electrochemical dissolution of noble metals native oxides. J. Electroanal. Chem. 787, 11–13 (2017).

Geiger, S. et al. The stability number as a metric for electrocatalyst stability benchmarking. Nat. Catal. 1, 508–515 (2018).

Choudhury, D., Das, R., Maurya, R., Kumawat, H. & Neergat, M. Kinetics of the oxygen evolution reaction (OER) on amorphous and crystalline iridium oxide surfaces in acidic medium. Langmuir 39, 13748–13757 (2023).

Willinger, E., Massué, C., Schlögl, R. & Willinger, M. G. Identifying key structural features of IrOx water splitting catalysts. J. Am. Chem. Soc. 139, 12093–12101 (2017).

Pfeifer, V. et al. The electronic structure of iridium oxide electrodes active in water splitting. Phys. Chem. Chem. Phys. 18, 2292–2296 (2016).

Lee, W. H. et al. Carbon-supported IrCoOx nanoparticles as an efficient and stable OER electrocatalyst for practicable CO2 electrolysis. Appl. Catal. B Environ. 269, 118820 (2020).

Liang, C. et al. Unravelling the effects of active site density and energetics on the water oxidation activity of iridium oxides. Nat. Catal. 7, 1–13 (2024).

Cherevko, S. et al. Dissolution of noble metals during oxygen evolution in acidic media. ChemCatChem 6, 2219–2223 (2014).

Jovanovic, P. et al. Electrochemical dissolution of iridium and iridium oxide particles in acidic media: transmission electron microscopy, electrochemical flow cell coupled to inductively coupled plasma mass spectrometry, and X-ray absorption spectroscopy study. J. Am. Chem. Soc. 139, 12837–12846 (2017).

Massué, C. et al. Reactive electrophilic OI− species evidenced in high-performance iridium oxohydroxide water oxidation electrocatalysts. ChemSusChem 10, 4786–4798 (2017).

Nong, H. N., Gan, L., Willinger, E., Teschner, D. & Strasser, P. IrOx core-shell nanocatalysts for cost-and energy-efficient electrochemical water splitting. Chem. Sci. 5, 2955–2963 (2014).

Nong, H. N. et al. A unique oxygen ligand environment facilitates water oxidation in hole-doped IrNiO x core–shell electrocatalysts. Nat. Catal. 1, 841–851 (2018).

Grimaud, A. et al. Activation of surface oxygen sites on an iridium-based model catalyst for the oxygen evolution reaction. Nat. Energy 2, 1–10 (2016).

Ooka, H. et al. Legitimate intermediates of oxygen evolution on iridium oxide revealed by in situ electrochemical evanescent wave spectroscopy. Phys. Chem. Chem. Phys. 18, 15199–15204 (2016).

Lee, W. H. et al. High crystallinity design of Ir-based catalysts drives catalytic reversibility for water electrolysis and fuel cells. Nat. Commun. 12, 4271 (2021).

Cherevko, S., Geiger, S., Kasian, O., Mingers, A. & Mayrhofer, K. J. Oxygen evolution activity and stability of iridium in acidic media. Part 2.–Electrochemically grown hydrous iridium oxide. J. Electroanal. Chem. 774, 102–110 (2016).

Cherevko, S., Geiger, S., Kasian, O., Mingers, A. & Mayrhofer, K. J. Oxygen evolution activity and stability of iridium in acidic media. Part 1.–Metallic iridium. J. Electroanal. Chem. 773, 69–78 (2016).

Li, T. et al. Atomic-scale insights into surface species of electrocatalysts in three dimensions. Nat. Catal. 1, 300–305 (2018).

Moriau, L. et al. Towards electrochemical iridium recycling in acidic media: effect of the presence of organic molecules and chloride ions. RSC Adv. 13, 7980–7987 (2023).

Chapman, A. et al. Achieving a carbon neutral future through advanced functional materials and technologies. Bull. Chem. Soc. Jpn. 95, 73–103 (2022).

Yang, X. et al. Achievements, challenges, and perspectives on nitrogen electrochemistry for carbon-neutral energy technologies. Angew. Chem. Int. Ed. 62, e202215938 (2023).

Lee, W. H. et al. The green-ol (green-alcohol) economy. Nano Energy 110, 108373 (2023).

Lim, C. et al. Breaking the current limitation of electrochemical CO 2 reduction via a silica-hydroxide cycle. Energy Environ. Sci. 17, 6215–6224 (2024).

Wu, D., Wang, X. & Wu, X. Galvanostatic electrodeposition of durable IrO x films on low-iridium-supported titanium for an acidic oxygen evolution reaction. Ind. Eng. Chem. Res. 61, 16924–16934 (2022).

Park, Y. J. et al. Electrodeposition of high-surface-area IrO(2) films on Ti felt as an efficient catalyst for the oxygen evolution reaction. Front Chem. 8, 593272 (2020).

Wu, X. et al. Fast operando spectroscopy tracking in situ generation of rich defects in silver nanocrystals for highly selective electrochemical CO2 reduction. Nat. Commun. 12, 660 (2021).

Jiang, K. et al. Silver nanoparticles with surface-bonded oxygen for highly selective CO2 reduction. ACS Sustain. Chem. Eng. 5, 8529–8534 (2017).

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Choi, W. et al. Exploring the influence of cell configurations on Cu catalyst reconstruction during CO2 electroreduction. Nat. Commun. 15, 8345 (2024).

Karapinar, D., Creissen, C. E., Rivera de la Cruz, J. G., Schreiber, M. W. & Fontecave, M. Electrochemical CO2 reduction to ethanol with copper-based catalysts. ACS Energy Lett. 6, 694–706 (2021).

Pedersen, A. F. et al. Operando XAS study of the surface oxidation state on a monolayer IrO x on RuO x and Ru oxide based nanoparticles for oxygen evolution in acidic media. J. Phys. Chem. B 122, 878–887 (2018).

Hillman, A. R., Skopek, M. A. & Gurman, S. J. X-Ray spectroscopy of electrochemically deposited iridium oxide films: detection of multiple sites through structural disorder. Phys. Chem. Chem. Phys. 13, 5252–5263 (2011).

Lai, S. C. & Koper, M. T. Electro-oxidation of ethanol and acetaldehyde on platinum single-crystal electrodes. Faraday Discuss. 140, 399–416 (2009).

Heinen, M., Jusys, Z. & Behm, R. J. Ethanol, acetaldehyde and acetic acid adsorption/electrooxidation on a Pt thin film electrode under continuous electrolyte flow: an in situ ATR-FTIRS flow cell study. J. Phys. Chem. C 114, 9850–9864 (2010).

Del Colle, V. & Tremiliosi-Filho, G. Electrochemical and spectroscopic studies of ethanol and acetaldehyde oxidation onto Pt(110) modified by osmium. Electrocatalysis 2, 285–296 (2011).

Kasian, O., Geiger, S., Mayrhofer, K. J. & Cherevko, S. Electrochemical on-line ICP-MS in electrocatalysis research. Chem. Rec. 19, 2130–2142 (2019).

Kim, H. et al. Operando stability of platinum electrocatalysts in ammonia oxidation reactions. ACS Catal. 10, 11674–11684 (2020).

Hilal, S., Bornander, L. & Carreira, L. Hydration equilibrium constants of aldehydes, ketones and quinazolines. QSAR Comb. Sci. 24, 631–638 (2005).

Smith, P. W. G. & Tatchell, A. R. in Fundamental Aliphatic Chemistry (eds P. W. G. Smith & A. R. Tatchell) 147–176 (Pergamon, 1965).

Perez-Puyana, V., Jiménez-Rosado, M., Escribano, D., Romero, A. & Martínez, I. Influence of the aliphatic chain length on the crosslinking properties of aldehydes on sustainable bioplastics obtained from pea protein. J. Polym. Environ. 30, 5163–5172 (2022).

Sutton, H. C. & Downes, T. M. Rate of hydration of formaldehyde in aqueous solution. J. Chem. Soc. Chem. Commun. https://doi.org/10.1039/C39720000001 (1972).

Batista, E. & Iwasita, T. Adsorbed intermediates of formaldehyde oxidation and their role in the reaction mechanism. Langmuir 22, 7912–7916 (2006).

Karade, S. S., Sharma, R., Hedegaard, M. A. B. & Andersen, S. M. Stepwise understanding on hydrolysis formation of the IrOx nanoparticles as highly active electrocatalyst for oxygen evolution reaction. Electrocatalysis 15, 291–300 (2024).

Khalil, M., Liu, N. & Lee, R. L. Super-Nernstian potentiometric pH sensor based on the electrodeposition of iridium oxide nanoparticles. Int. J. Technol. 9, 446–454 (2018).

Ahn, S. H. et al. Self-terminated electrodeposition of iridium electrocatalysts. Energy Environ. Sci. 8, 3557–3562 (2015).

Lu, G.-Z., Tu, Z.-L., Liu, L., Zhang, W.-W. & Zheng, Y.-X. Fast synthesis of iridium (iii) complexes with sulfur-containing ancillary ligand for high-performance green OLEDs with EQE exceeding 31%. J. Mater. Chem. C7, 7273–7278 (2019).

Nguyen, T. L. A. & Dao, D. Q. From green to near-infrared emission of cyclometalated Iridium (III) complexes modified with flavonoids: a theoretical insight. Mol. Phys. 120, e2026509 (2022).

Kasian, O., Grote, J. P., Geiger, S., Cherevko, S. & Mayrhofer, K. J. J. The common intermediates of oxygen evolution and dissolution reactions during water electrolysis on iridium. Angew. Chem. Int. Ed. Engl. 57, 2488–2491 (2018).

Zlatar, M. et al. pH dependence of noble metals dissolution: Iridium. Electrochim. Acta 513, 145450 (2025).

Lee, S. et al. Techno-economic analysis and life-cycle assessment of the electrochemical conversion process with captured CO 2 in an amine-based solvent. Green. Chem. 25, 10398–10414 (2023).

Kuang, Y. et al. High-concentration electrosynthesis of formic acid/formate from CO2: reactor and electrode design strategies. Energy Environ. Mater. 6, e12596 (2023).

Zhu, P. & Wang, H. High-purity and high-concentration liquid fuels through CO2 electroreduction. Nat. Catal. 4, 943–951 (2021).

Papangelakis, P. et al. Scaled CO electroreduction to alcohols. Nat. Commun. 16, 4969 (2025).

Acknowledgements

This work was supported by the Research Project for ‘Carbon Upcycling Project for Platform Chemicals’ of the National Research Foundation (NRF) funded by the Ministry of Science and ICT, Republic of Korea. (grant number: 2022M3J3A1050053) This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (RS-2024-00431568). We are grateful to institutional programme grants from the Korea Institute of Science and Technology. We wish to thank the 1D XRS KIST-PAL beamline and 10D beamline for measuring the XAS and NEXAFS, respectively.

Author information

Authors and Affiliations

Contributions

S.K. designed/conducted the experiments, analysed the data and wrote the manuscript. Y.L. performed the analysis of GC. C.L., E.-D.K., and H.-S.B. contributed to the electrochemical cell tests and product analysis. W.K. and J.-Y.C. provided an idea for the electrochemical analysis. H.-S.O. and W.H.L. supervised the research and wrote the manuscript. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Hongwen Huang, and the other anonymous reviewers for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ka, S., Lee, Y., Lim, C. et al. Accelerated dissolution of iridium anode in the presence of organic compounds. Nat Commun 16, 8946 (2025). https://doi.org/10.1038/s41467-025-63992-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41467-025-63992-0