Abstract

Conductive polymer nanocomposites have emerged as essential materials for wearable devices. In this study, we propose a novel approach that combines graph attention networks (GAT) with an improved global pooling strategy and incremental learning. We train the GAT model on homopolymer/carbon nanotube (CNT) nanocomposite data simulated by hybrid particle-field molecular dynamics (hPF-MD) method within the CNT concentration range of 1–8%. We further analyze the conductive network structure by integrating the resistor network approach with the GAT’s attention scores, revealing optimal connectivity at a 7% concentration. The comparative analysis of trained data and the reconstructed network, based on the attention scores, underscores the GAT model’s ability in learning network structural representations. This work not only validates the efficacy of the GAT model in property prediction and interpretable network structure analysis of polymer nanocomposites but also lays a cornerstone for the reverse engineering of polymer composites.

Similar content being viewed by others

Introduction

Conductive polymer nanocomposites (CPNs) are attracting significant attention from researchers owing to their promising applications in advanced technological fields, including flexible electronics, stretchable strain sensors, wearable electronic skins, and soft robotics1,2,3,4,5,6. These materials are typically created by incorporating conductive nanoparticles such as carbon nanotubes, carbon nanofibers, and metal nanoparticles into a polymer matrix. When the concentration of these conductive nanoparticles exceeds the percolation threshold, they interconnect within the polymer matrix to form a conductive network structure, which endows the nanocomposite with certain electrical conductivity. In these materials, a complex coupling interaction exists between the polymer matrix and the conductive nanoparticles, influenced by various factors. The resulting conductive network structure and macroscopic electrical conductivity are governed by the intricate interplay between entropy and enthalpy within the system.

In recent years, researchers have extensively studied the self-assembly behavior, phase structure, and electrical conductivity of conductive polymer nanocomposites through experimental methods. These materials exhibit a remarkable ability to recover their molecular order and electrical properties once the applied strain is removed7. For example, Zhou and colleagues successfully fabricated porous nanofibers featuring mesoporous (~10 nm) and microporous (~0.5 nm) structures via the microphase separation technique of block copolymers. Owing to their interconnected three-dimensional reticulated structure and highly optimized bimodal pore size distribution, these porous nanofibers significantly reduce ion transport resistance and exhibit an ultra-high capacitance of 66 mF·cm−2, which is 6.6 times greater than that of activated carbon8. Additionally, Wang et al. conducted an in-depth investigation into the characteristics of the matrix–particle interface in polymer nanocomposites, a critical factor in understanding the electrical properties of CPNs. The experimental strategies and characterization techniques outlined in this study have established a crucial foundation for the analysis and design of material properties9. While experimental methods can effectively tailor the electrical properties of CPNs across a wide range, they often rely on trial-and-error approaches. Given the extensive parameter space within the CPN composite system, identification of optimal synthesis conditions frequently involves significant economic and time investments.

In recent years, the hybrid particle-field simulation method has emerged as a powerful tool, which combines the strengths of particle-based techniques (such as Monte Carlo, molecular dynamics, and dissipative particle dynamics) with field-based approaches such as self-consistent field theory10,11,12,13,14,15. This method has demonstrated significant potential for multi-scale simulations in the study of conductive polymer nanocomposites (CPNs)10,11,12,13,14,15. For example, the hPF-MD method has been utilized to study CPNs formed by carbon nanotubes (CNTs) embedded in various polymer matrices at a large scale (~1.5 million particles). This method has also enabled molecular dynamics simulations over extended timescales, which span ~4.8 ms13. The conductivity of CPNs can be quantitatively calculated using the resistor network approach. In the electrical conductivity equation: \(\sigma /{\sigma }_{CNT}=\eta {(f-{f}_{c})}^{t}\), where η is a prefactor, f represents the CNT volume percentage, fc is the percolation threshold, and t is the exponent of the power law. These calculations reveal that, in the homopolymer/CNT system, the conductivity exponent t = 1.7, which is consistent with the 3D “dynamic percolation” theory proposed by Bauhofer and Kovacs et al.14. When CNTs are confined within the two-dimensional lamellar templates formed by block copolymers, the resulting co-continuous defect nanostructure significantly enhances the conductivity of CPNs. Furthermore, the simultaneous incorporation of CNTs and carbon black nanoparticles creates a synergistic effect that follows Boltzmann’s nonlinear relationship14. However, the inherent randomness in the conductive network structures formed by conductive nanoparticles poses a significant challenge in establishing predictive relationships between microstructure and macroscopic electrical conductivity in CPNs. While the conductive network structure at the nanoscale can be quantitatively described using parameters such as particle size, geometric shape, and dispersion state, these structural indicators alone do not fully or uniquely determine the electrical conductivity of CPN materials. This limitation arises because these parameters fail to capture the overall structure, which is critical for determining the electrical conductivity of CPNs. Consequently, it is essential to comprehensively quantify the conductive network structure, which incorporates both “local” and “global” structural patterns16.

Graph neural networks (GNNs) have become a prominent focus in deep learning owing to their exceptional capability to process complex structured data. They have been widely applied across various fields, including graph data analysis, physical modeling, and molecular structure characterization17,18,19. GNNs have shown superior accuracy and stronger correlations in describing the relationship between microstructure and macroscopic properties20. In the field of new material development, GNNs have attracted significant attention from both academia and industry. For example, Feng et al. employed GNNs to identify new phases of metastable IrO2, a discovery with profound implications for designing oxygen evolution reaction catalysts21. Similarly, Gao et al. reviewed the application of machine learning in polymer material design and emphasized the critical role of GNNs in advancing materials science22. GNNs effectively incorporate bonding relationships and three-dimensional structural information between atoms by representing compounds as graphs, which aligns closely with the intuition and expertise of chemical scientists. Numerous studies have demonstrated the significant advantages of using GNNs for representing molecules and polymers. For example, the A-Lab system23,24, developed by Lawrence Berkeley National Laboratory in collaboration with Google DeepMind, leverages AI and robotics to accelerate the discovery and synthesis of new materials25, which are applied in the design of automotive batteries and solar cell materials. Additionally, Xie et al. employed GNNs to analyze poly(ethylene oxide) and bis(trifluoromethanesulfonyl)imide composite electrolytes, which predicted lithium ion states and conductivity through clustering analysis25. Qiu et al. developed the PolyNC model to predict the physical properties of polymers26. Zheng et al. used GNNs to predict the self-assembly behavior of molecules on metal surfaces27. Additionally, Du et al. has established a polymer material genomics research platform and developed a set of machine learning-based performance prediction models to forecast the thermal, mechanical, and processing properties of resins28. These studies have significantly advanced our understanding of material properties. However, owing to the complex polydispersity, multi-scale, and multi-level structural characteristics of polymer materials, as well as the limitations of large-scale training sets, the application of artificial intelligence methods in polymer materials research still lags behind that in the fields of inorganic materials and small molecules. Currently, there is limited research on predicting the electrical properties of polymer materials and on the interpretability of structure–property relationships20,29.

According to computational simulation data, we can construct a pre-trained model for polymer nanocomposites30 by leveraging GNNs for deep learning training. This approach lays a crucial foundation for material property analysis and predictive design31,32. Graph convolutional networks (GCN), an efficient technology for processing graph-structured da ta, offer an innovative solution for unraveling the conductive performance mechanisms of CPNs through their unique network architecture and exceptional learning capabilities. This application of GCN not only significantly broadens the scope of material property research but also ushers in a new era of material design and application. Graph attention mechanism network models, a sophisticated deep learning strategy33,34,35, offer a new perspective for the in-depth exploration of key characteristics of conductive polymer materials, owing to their dynamic attention capabilities on graph-structured data. The graph attention mechanism can more accurately identify the core elements influencing material performance by assigning personalized weight parameters to different edges, which provides unprecedented insight and efficiency in the study and application of conductive polymer materials. The objective of this research is to elucidate the complexities of CPNs. A combination of hPF-MD with resistor network analysis led to the development of a physics-informed artificial intelligence (AI) model. This model is built upon an incremental graph neural network (IGNN) capable of extracting and learning structural patterns directly from hPF-MD simulation trajectories. Our goal is to uncover the relationship between the microstructural features and the electrical properties of conductive polymer networks (CPNs) by systematically analyzing how varying concentrations of conductive nanoparticles within a uniform polymer matrix affect the electrical behavior of the system. This comprehensive approach not only provides a theoretical foundation for understanding CPNs but also establishes a practical framework for predicting material properties and guiding experimental efforts in the field of CPNs.

Results

Experimental protocol

This experiment utilizes the open-source machine learning framework PyTorch (https://pytorch.org) and the improved GCN/GAT models built on the Hugging Face library (https://huggingface.co). All experiments are conducted on an Ubuntu 20.04.4 LTS operating system with an Intel(R) Xeon(R) Gold 6226R CPU (32 cores, 2.9 GHz, 128 GB memory) and a single 4090 GPU (24 GB memory).

Attribute prediction results and discussion

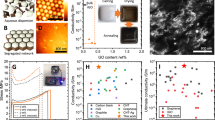

In the study of screening conductive network structures of polymer composites, we employed a data-driven strategy utilizing GCN17,36 and GAT33,37,38, which are improved graph neural network methods, to predict the electrical properties of polymer materials. To examine the similarity of data distributions between the training and validation sets, we randomly split the data into 80% for training and 20% for validation and then visualized the spatial distribution at different concentrations, as shown in Fig. 1. Using the 1% CNT concentration as an example, as shown in Fig. 1a, we first standardized each frame of data to generate a 3D coordinate matrix of carbon particles. This matrix was then reduced to a 1 × 3 vector using singular value decomposition (SVD), resulting in a 1000 × 3 matrix composed of data from 1000 frames. Subsequently, we applied t-distributed Stochastic Neighbor Embedding (t-SNE) to further reduce the dimensionality to a 1000 × 2 matrix, where each row represents the 2D coordinates after dimensionality reduction. Finally, we mapped these 2D coordinates into the feature space and plotted the distributions of the training and validation sets, which enabled a visual assessment of the data distribution and the generalization ability of the model. We observe that the samples in both the training and validation sets for CP1–CP8 are rich and diverse and fill the entire space. Their distributions in the feature space are roughly consistent and provide reliability for the validation set in assessing the model. Furthermore, for better visualization, we cluster the data and annotate the centroids, as shown in the supporting file, Supplementary Fig. S1.

a–h Carbon nanotube concentrations ranging from 1% to 8%. The spatial comparison between concentrations is performed using SVD and t-SNE dimensionality reduction. The distributions of the training and validation sets for CP1–CP8 are uniform and representative, which ensures the reliability of the model evaluation.

Throughout the training and evaluation process, we set the batch size to 8 and performed 20 iterations per epoch to ensure the model could fully learn the data characteristics. After training and fine-tuning, the model is applied to predict the properties of polymer materials. The mean absolute error (MAE) and root mean square error (RMSE) are used as evaluation metrics39,40; smaller values of these indicators indicate that the predictions of the model are closer to the true values.

According to the results in Table 1 and the predicted distribution scatter plot in Fig. 2a, b, our proposed improved GAT model performs excellently in the regression prediction of conductivity. Specifically, the prediction error of the GAT model is maintained within the range of 0 to 0.0001 for all concentrations, which indicates very high prediction accuracy. Compared with the similarly improved GCN model, the GAT model exhibits smaller errors in predicting the conductivity of polymer composites, which suggests that the GAT model is better at capturing the key features of the conductive network structure, thus leading to more accurate conductivity predictions. Therefore, in the process of screening the conductive network structures of polymer composites, our improved GAT model plays a crucial role. It not only effectively learns the structural features of the conductive network from the data but also accurately predicts the conductivity of polymer composites at various concentrations. This capability enables us to identify network structures with optimal conductivity, which provides a scientific foundation and guidance for the design and preparation of new polymer composite materials.

Analysis of graph network structure changes based on statistical features

Network topological indices are essential in modern computational chemistry and complex network modeling, particularly for describing the connectivity and transmission efficiency of network structures. These indices effectively capture the intricate connectivity characteristics and topological arrangements within networks. In this study, we selected six key network topological indices, listed in Table 2, to characterize important features of the network structure. These indices include average degree (AD)41,42, clustering coefficient (CC)43, network density (ND)44,45, shortest path (SP)46, global efficiency (GE)47,48, and connected component (CC)49,50. In polymer composites, the connectivity of conductive particles (C) within the network is directly related to their ability to form an effective conductive network. Therefore, we calculate these topological indices to assess the connectivity of the conductive network and provide a deeper understanding of the complexity and heterogeneity of the nanomaterial network under varying concentration conditions.

The connectivity of conductive particles (C) in the network is not only crucial for the formation of the conductive network structure but is also influenced by the concentration of C particles. To further explore the relationship between the conductive network structure and the concentration of C particles, we use the traditional resistance network method to construct complex networks within the training set. At each concentration, we extract one network every 100 frames, resulting in 10 network samples per concentration. We analyze the variations in network performance by calculating the average of the six topological indices for these 10 network samples. The specific analysis results are shown in Fig. 3, which illustrates the network performance at different concentrations.

a Trend of average degree with CNT concentration; b Trend of connected components with CNT concentration; c Trend of global efficiency with CNT concentration; d Trend of clustering coefficient with CNT concentration; e Trend of network density with CNT concentration; f Trend of the shortest path length of the largest connected component with CNT concentration.

In the process of screening the conductive network structures of polymer composites, we focus on the changes in the average degree of the network based on the data shown in Fig. 3a. The data indicate that as the concentration of C particles increases, the average degree of the network rises, which suggests an increase in the average number of connections between nodes and enhanced interactions and connectivity among nanoparticles. This is crucial for the formation of effective conductive pathways. During the screening process, we observe that while the overall trend of the average degree remains stable, slight fluctuations occur at specific concentration points, such as CP4, CP6, and CP7. These fluctuations reflect local reorganization within the network structure, which may cause short-term variations in electrical conductivity. As a result, we prioritize datasets that exhibit minimal fluctuation in the average degree with changes in concentration to ensure the effectiveness and stability of the conductive pathways. The stable trend of the average degree also suggests that in the Apr20.2 system, the nanomaterials maintain good structural stability once a certain concentration is reached, which preserves a relatively constant level of connectivity even as the concentration increases. This demonstrates the robustness of the system at the macro level. Combining the analysis of conductivity, we conclude that the stability of the average degree is a key indicator of both good conductivity and stability in the material network after reaching a certain concentration. Therefore, during the screening process, we focus on selecting samples that maintain a stable average degree at higher concentrations to achieve the optimal conductive network structure.

From the results in Fig. 3b, we observe that as the concentration increases from CP1 to CP8, the number of connected components in the network decreases significantly. After CP6, the number of connected components stabilizes at 1, which indicates that the network structure rapidly transitions from multiple independent small groups to a single, highly connected large network. This suggests that the material exhibits strong self-organization capabilities and structural adaptability as the concentration increases. During the material selection process, we place particular emphasis on the reduction of connected components, as this is directly related to the enhancement of the material’s electrical conductivity. A fully connected network is crucial for achieving optimal conductivity. Therefore, we prioritize datasets with the fewest connected components at higher concentrations, as these are more likely to exhibit superior conductivity characteristics. The number of connected components and their trend with concentration changes serve as key indicators for understanding and predicting the conductivity properties of the material.

According to the data shown in Fig. 3c, we observe that the global efficiency of network connections generally increases as the concentration rises. This increase indicates an improvement in the overall transmission efficiency of the network and an enhancement in the effectiveness of the average shortest path between nodes, which facilitates the rapid spread of resources or information within the network. Since global efficiency is directly related to the optimization of material conductivity, it is important to closely monitor changes in global efficiency when screening materials. Notably, a sharp increase in global efficiency occurs between specific concentration points, such as CP3 and CP5, which marks a key shift in the network structure. This could represent a crucial stage in the formation of conductive pathways. Therefore, we prioritize specific concentrations that show a large increase in global efficiency as the concentration rises. At the same time, we also pay attention to the minor fluctuations in global efficiency between CP6 and CP8, as these fluctuations may indicate internal structural adjustments within the network. While these adjustments might temporarily affect conductivity, they are part of the network’s self-optimization process. Thus, during the screening process, we consider both the overall trend of global efficiency and its fluctuations at specific concentration points to identify conductive networks that maintain efficient transmission and structural stability despite concentration changes.

The data in Fig. 3d illustrate the structural evolution of conductive polymer nanocomposites at different concentrations, with a particular focus on the trend of the clustering coefficient. This provides crucial insights into the conductivity of the material. Overall, while the clustering coefficient shows a downward trend, this change indicates that the network reaches a dynamic balance between conductivity and structural stability. Through self-adaptive structural adjustments, the network becomes more uniform and connected, which promotes the formation of global conductive paths and enhances the conductivity of the material. Since self-organization is essential for optimizing electrical conductivity, we prioritize this ability during the screening process. Consequently, we tend to select samples that show a moderate decrease in the clustering coefficient under concentration changes, while maintaining the uniformity and connectivity of the network structure. This ensures that the selected conductive network structures remain stable and maximize electrical conductivity, which provides reliable candidate structures for the development of high-performance conductive polymer nanocomposites.

According to the data in Fig. 3e, we observe the dynamic changes in the network density of conductive polymer nanocomposites as the concentration increases, which provides important insights into the conductivity of the material. Network density measures the ratio of the actual number of connections in the network to the maximum possible number of connections. The observed decreasing trend indicates a significant reduction in network compactness during the initial stages (from CP1 to CP3), which reflects adjustments in the interactions between carbon particles and the preliminary formation of conductive pathways. As the concentration increases from CP4 to CP8, the slower decline in network density suggests that the network adapts to the increasing particle numbers through internal reorganization and structural optimization to form more optimized conductive paths in certain areas. In the screening process, we note that although the network density generally decreases, this change does not lead to a decrease in conductivity. Instead, the network optimizes its conductive channels through self-organization, which maintains or even enhances electron transport efficiency. Notably, at CP8, when the network density reaches its lowest point, conductivity remains stable or slightly increases, which indicates that the optimization of the internal network structure plays a key role in improving conductivity. Therefore, during the screening process, we prioritize samples that maintain or improve conductivity while reducing network density. These samples exhibit excellent conductivity through network structure optimization and are ideal candidates for the development of high-performance conductive polymer nanocomposites.

Figure 3f shows the change curve of the shortest path length of the largest connected component, a parameter closely related to network connectivity and conductivity. During the initial formation stage of the nanomaterial network, as the concentration increases from CP1 to CP3, the rapid increase in the shortest path length indicates the initial establishment of network connectivity. The network self-organizes, forms more connections, and gradually becomes a connected whole. As the concentration continues to rise, the shortest path length starts to decrease after reaching its peak, which signals a significant enhancement in network connectivity. The newly added particles effectively fill network gaps, create more efficient connections, and reduce path lengths, which is essential for optimizing conductive pathways. This phenomenon indicates that the network can improve its electrical conductivity through internal structural adjustments. Therefore, during the screening process, we focus on datasets where the shortest path length effectively decreases as the concentration increases. At the highest concentration (CP8), the stable downward trend of the shortest path length signifies that the network has achieved strong connectivity at high concentrations. This is associated with higher electrical conductivity, as electrons are transported through shorter and more direct paths, which further improves the network’s conductivity. Consequently, we prioritize datasets that show both a decrease in shortest path length and a maintenance or improvement in electrical conductivity. The optimization of network structure in these datasets enhances electrical performance, which makes them ideal candidates for the development of efficient conductive polymer nanocomposites.

In summary, during the process of screening conductive network structures of polymer composites, we focus on changes in six key indicators: average degree, number of connected components, global efficiency, clustering coefficient, network density, and shortest path length. These indicators help identify network structures with optimal conductivity and structural stability. The stability of the average degree and the reduction in connected components suggest improved network connectivity, while the increase in global efficiency and the moderate decrease in the clustering coefficient reflects enhanced transmission efficiency and a balanced structural dynamic. Additionally, the continuous decrease in network density, along with the reduction in shortest path length at high concentrations, indicates optimization of the network structure and the formation of conductive pathways. The combination of these indicators allows us to prioritize datasets that maintain the effectiveness and stability of conductive paths while demonstrating efficient transmission and strong structural adaptability under varying concentrations.

Dynamic characterization of graph networks based on attention scores

To further elucidate the impact of different CNT concentrations on the conductive network structure and how these structural changes influence the overall conductivity of polymer composites, we conduct an interpretable analysis based on attention scores. In the “Attribute prediction results and discussion” subsection, we use a GAT model to perform regression predictions on the conductivity of polymer composites with CNT concentrations ranging from 1% to 8%. During this process, through incremental training, we not only obtain models for concentrations from 1% to 8% but also obtain the corresponding attention score matrices. Specifically, we first calculated the attention scores for each node pair at different concentrations. Then, we organized the attention scores between all node pairs into a matrix and created an attention score matrix that reflected the relationships between the nodes and their impact on conductivity. These matrices provide valuable information about the connection weights between pairs of nodes (edges) in the CNT network (i.e., C particle network), which are essential for understanding changes in the conductive network structure.

As shown in Fig. 4a, we first calculate the average conductivity of the composites at different concentrations. From CP1 to CP3, the conductivity of the composites is nearly zero, which indicates that within this concentration range, CNTs fail to form an effective conductive network. Beginning with CP4, the conductivity rises gradually and exhibits a pronounced inflection at CP7, aligning closely with the percolation theory51,52. This suggests that the conductive network structure undergoes substantial changes, leading to enhanced conductivity. Although the precise percolation threshold is sensitive to CNT dispersion, fictionalization and processing conditions, every system follows the same universal rule based on percolation theory: conductivity increase sharply once a continuous filler network spans the insulating matrix. Our model quantitatively reproduces this statistical percolation transition, and its physical fidelity is confirmed by independent experimental measurements53,54. To gain a deeper understanding of this structural change, we further analyze the attention score matrices. We extract the attention scores for pairwise CNT edges from these matrices and calculate their variance and coefficient of variation, as shown in Fig. 4b.

An analysis of the changes in the coefficient of variation and variance of the attention score matrices in Fig. 4b reveals a deeper understanding of the impact of CNT concentration on the conductive network structure and its electrical performance. In the concentration range from 1% to 4%, we observe a gradual decrease in the coefficient of variation, which suggests that the importance of edges between nodes in the conductive network is becoming more balanced, thereby enhancing the stability of the network structure. As the concentration increases from CP4 to CP6, the rise in the coefficient of variation coincides with an increase in conductivity and indicates that the interaction between certain node pairs becomes more influential in improving conductivity. These node pairs become critical in the conductive network and play a decisive role in improving conductivity. At the CP7 concentration, the coefficient of variation of the attention score matrices reaches a local minimum and conductivity peaks, which indicates that the distribution of edge importance among network nodes has achieved balance, with each edge contributing relatively evenly, resulting in fewer ineffective edges. As a result, the overall stability and conductivity efficiency of the network are at their optimal state. Therefore, during the screening process, we prioritize the conductive network structure at CP7 concentration, as it exhibits the highest conductivity efficiency and the most balanced network connectivity. At the CP8 concentration, although the coefficient of variation increases again, the decrease in conductivity indicates a change in the network structure. Some node connections contribute less to the conductive network, resulting in weakened network connectivity, which suggests that network restructuring due to excessively high concentrations should be avoided to maintain the efficient connectivity of the conductive network. In summary, by analyzing the coefficient of variation and variance in the attention score matrices, we can effectively identify the conductive network structures of polymer composites that exhibit the highest conductivity efficiency and the most balanced network structure. These statistical data reveal how the distribution of connecting edges in the conductive network is reorganized as CNT concentration increases and how this local structural reorganization impacts overall conductivity performance. Through this interpretable analysis based on attention scores, we can observe the evolution of the conductive network structure and identify the optimal conductive network structure. This provides a theoretical basis for the design and development of efficient polymer composite conductive materials.

To identify the network structures most conducive to conductivity at different concentrations, we extract the attention scores for the same CNT at each concentration and visualize the changes in the attention score matrices, as shown in Fig. 5. From Fig. 5a, we observe that as the CNT concentration increases from CP1 to CP4, more node pairs (edges) approach an attention score of 1. This increase indicates that within the low concentration range, the node pairs in the network are increasingly contributing to the formation of the conductive network, and network connectivity is gradually strengthening.

a 1–4%; b 4–6%; c 6–8%. The x and y axes represent node indices, with values ranging from 1 to 25 corresponding to the carbon particle numbers on a single carbon nanotube. The colors progressively darken indicating a stronger impact of the nodes on conductivity, with yellow indicating no connection.

The upward trend in the coefficient of variation shown in Fig. 5b reveals a differentiation in the importance of node pair connections within the network, which indicates that some connections become more critical while others become relatively less important. Combined with the gradual increase in conductivity from CP4 to CP6, we infer that within this concentration range, the conductive network transitions from gradual expansion at low concentrations to self-organization and optimization of the connection structure at medium concentrations. This evolution results in a more efficient network structure with enhanced connectivity.

In Fig. 5c, the changes from CP6 to CP8 show a trend where the number of important node pairs in the conductive network first increases and then decreases, which corresponds to the observed conductivity increase followed by a decrease. Compared with CP6, at CP7, a greater number of node pairs exhibit significant attention scores, which indicates that the connectivity efficiency of the conductive network reached its peak and that the network structure may have reached an optimal state. However, compared with CP7, at CP8, the significance of some node pairs decreases, which suggests that as the concentration further increases, the network’s connectivity efficiency begins to decline. This decrease may be due to overly dense network connections or excessive connectivity between certain nodes, leading to structural redundancy and a reduction in conductivity efficiency.

In summary, when screening the conductive network structures of polymer composites, we prioritize the network structures at the CP7 concentration because they exhibit the highest connectivity efficiency and optimal network structure. An analysis of the changes in attention scores and coefficients of variation identifies the node pairs that contribute most to the increase in conductivity and ensures that these critical connections are retained and optimized in the final network structure. At the same time, we avoid the redundancy and decrease in connectivity efficiency caused by excessively high concentrations, which selects conductive network structures that are both highly conductive and structurally stable. These findings provide valuable insights into the relationship between CNT network structure and conductivity at the microscopic level, guiding the design of more efficient conductive polymer nanocomposites.

Additionally, we calculate the attention score graphs and coefficients of variation for four other CNTs and observe similar patterns of change. These results are provided in the supporting materials, Supplementary Figs. S2–S4.

Analysis of the differences in graph structural feature space before and after GAT model training

To further explore the interpretability of attention scores in analyzing CNT conductive network structures, we compare the initial distribution of 1000 frames of training data for CP1–CP8 with the spatial distribution obtained after nonlinear transformation and mapping by the GAT model. In the main text, we present the spatial distribution comparison for CP1-CP4, as shown in Fig. 6. Comparisons for the other concentrations are provided in the supporting materials, Supplementary Fig. S5.

a–d Distribution at a concentration of 1–4% carbon nanotubes. Blue circles represent the distribution of original features after SVD and t-SNE dimensionality reduction, while orange circles represent the distribution after network reconstruction using the top 200 edges based on attention scores extracted from the GAT model.

To redefine the CNT network connections using attention scores, we utilize a GAT model trained on CP1 data to extract attention scores from the second layer of the CNT network. Node connections are redefined, and the network is reconstructed using the top 200 edges with the highest score values; their maximum length is used as the threshold. Subsequently, t-SNE dimensionality reduction and min–max normalization are applied to generate a low-dimensional spatial distribution plot, represented by green triangles. Moreover, starting with the three-dimensional spatial coordinates of CP1 as the initial data, we use SVD to extract feature vectors. After applying t-SNE dimensionality reduction and normalization, we produce another low-dimensional spatial distribution plot, which is represented by orange circles.

From Fig. 6, a noticeable difference emerges between the distribution of the blue and orange sample points, which highlights the spatial distinction between the original input features and the features transformed by the GAT model. The orange sample points exhibit a more concentrated distribution around distinct centers, which demonstrates clear clustering characteristics, while the blue sample points are more continuously distributed and lack easily identifiable clusters, which indicates that the GAT model, through learning attention scores within the CNT network, effectively reconstructs the samples’ feature representations and optimizes their distribution in low-dimensional space for classification or clustering analysis. This finding underscores the ability of the GAT model to identify critical connections within the CNT network structure and emphasizes the pivotal role of the learned attention scores in accurately predicting conductivity. Therefore, we conclude that the GAT model, utilizing its attention mechanism, effectively captures the structure–property relationships between the network structure of polymer composite materials and their conductivity. This establishes the model as a powerful tool for analyzing and optimizing conductive network structures.

In addition to Fig. 6, we calculate and compare the distributions for concentrations CP5–CP8, which are presented in the supporting file (Supplementary Fig. S5). The results show that the new embedded features learned by the model offer a more accurate representation of network node relationships which exhibit a more distinct clustering effect compared with the original spatial representation. This further confirms that the model effectively captures the structure–property relationships (QSPR) within the network and reinforces the reliability and credibility of our interpretable analysis based on attention scores.

Discussion

In this study, we utilized hPF-MD simulations to examine the dynamics of CNT/homopolymer systems with an aspect ratio of 20.2 across concentrations ranging from 1% to 8%. Electrical conductivity for each simulation frame was calculated via the macroscopic resistance method, and 1000 equilibrium frames were selected as training data and split into 80% for training and 20% for validation. We determined that the GAT model provided the highest accuracy for conductivity regression predictions by incrementally training GCN and GAT.

Our analysis of the attention score matrices, variance, and coefficient of variation for the CNT network at various concentrations revealed a clear correlation between the conductive network structure and conductivity. At a concentration of 7% (CP7), the attention score matrix exhibited the lowest coefficient of variation and peak conductivity, which indicated that the conductive network spontaneously formed at this concentration achieved the highest connectivity efficiency. Conductivity was observed to initiate at 4% concentration (CP4) and increased steadily, but at 8% concentration (CP8), connectivity efficiency declined. This decline was attributed to over-connectivity and excessive density, which not only hindered regulation but also increased material costs.

Analysis of the coefficient of variation of the CNT network’s attention score matrix alongside conductivity and six structural indicators derived from traditional resistance network models helped us trace the evolution of the conductive network across varying concentrations. This analysis underscored the structural optimization occurring at medium concentrations and the limitations posed by dense or over-connected networks at higher concentrations. We concluded that the CP7 concentration achieved the optimal balance of connectivity efficiency, whereas concentrations at CP8 and above exhibited diminishing returns in research value due to increased costs and regulatory challenges.

Reconstructing the network using the top 200 attention scores from the third layer of the GAT model and comparing it with the input data’s feature space confirmed the reliability of GAT’s attention scores in the interpretable analysis of conductive networks. This study highlighted the potential of interpretable graph neural networks as a powerful tool for property prediction and network structure analysis in polymer composite materials.

Looking ahead, we aim to explore graph generation models, particularly graph diffusion convolution models, for the inverse structural design of polymer composites with varying components and concentrations. This research will lay a crucial foundation for the application of interpretable graph neural networks and graph generation models in the study of polymer conductive and thermal conductive composite materials. These approaches will enable more effective screening and optimization of conductive network structures, which ultimately enhances the overall performance of the materials.

Methods

Constructing graph network structural features for polymer materials

Translating the structure of polymer materials into a graph network input data format is the first step in developing GNN models. Since the original polymer simulation data are typically presented as particle trajectories, we retrieval the particles’ coordinate information from the trajectories data. This conversion facilitates the construction of a standardized graph network dataset, which enables subsequent model training and further applications.

In this study, coarse-grained models are used to simulate the self-assembly behavior of CNTs in a homopolymer matrix, as shown in Fig. 7a. Each homopolymer chain is represented by 25 beads, with a bond length of 1.4 nm between them. Each CNT is modeled with 25 beads, where the bond length between beads is 1.12 nm and the diameter is 1.4 nm. The interaction parameter between CNTs and homopolymers was constructed using the Flory–Huggins theory55 based on solubility parameter56. In refs. 55,57, the solubility parameters for CNTs and PS are 18.9 and 18.7 (J/cm3)1/2, respectively. The interaction parameters \(\chi\) (CNT-PS) ~ 20.0 kJ/mol can be obtained and applied in the hPF-MD simulations. The \({\rm{\kappa }}\) value for the incompressibility condition is set by 0.1 to keep the density homogeneous in the space in the hPF-MD simulation10. The same parameterization approach has been successfully applied in our previous studies13,15 as well as in related work by Canan Atilgan et al.58. We generated a dataset for CNT/homopolymer systems through a multiscale simulation technique that combines hybrid particle-field molecular dynamics9 with a macroscopic resistance network method based on this model. The dataset consists of eight samples with CNT concentrations ranging from 1% to 8%. The CNT concentration is adjusted by varying the ratio of carbon particles to homopolymer matrix particles. For each concentration, we extracted 1000 structures from the equilibrium state, with each frame containing 440,000 particles.

a Shows the complete process of constructing the CPNs and generating its network model. The self-assembly behavior of CNTs in a homopolymer matrix is simulated using a coarse-grained model combined with hPF-MD simulations, which generates the self-assembled structure of the nanocomposite. From this structure, the bonding relationships between particles and their spatial coordinates are extracted, forming the network model and providing input for subsequent GNN analysis to predict conductivity; b Shows the process of extracting graph embeddings from the graph structure built by particles and their interactions in one frame of data for a system with an aspect ratio of 20.2 using a GNN. Specifically, a chain structure consisting of 25C or P particles is selected for detailed explanation. The graph structure is constructed using node and edge feature matrices as well as the adjacency matrix, and the GNN learns the interactions between nodes through the message-passing mechanism. Finally, a graph embedding is generated to represent the entire frame of data and support conductivity prediction.

Based on these simulation data, we further extracted information such as the bonding relationships and spatial coordinates between particles to construct a self-assembly network model for CPNs, providing support for subsequent GNN analysis. Specifically, the particles in the network are divided into two types: CNT particles (C:1) and homopolymer matrix particles (P:2). For each concentration, a node data file is generated for each frame of the simulation data, while a unified edge relationship file is created for that concentration, applicable to all frames at that concentration. The node data file records information such as particle ID (NID), particle type (Type), particle XYZ coordinates, carbon nanotube aspect ratio (AR), and concentration (Conc). The edge relationship file records attributes such as the source node (Src Node), target node (Tgt Node), and edge type (Type). Based on these files, we constructed a network model containing both node features and edge features, which accurately represents the particle properties and their connections. This model is used as input for the GNN, which then extracts the key characteristic graph representation of the CPNs, providing foundational data and structural support for conductivity prediction.

According to the structural characteristics at different concentrations, we constructed corresponding graph network data formats to better analyze the relationship between the electrical conductivity of the material and its network structure. Figure 7b illustrates the process of building the graph network data format for polymer materials. First, for one frame in the polymer trajectory file, we extracted key feature information, including the position coordinates of each particle, sequence number, particle type, and bonding relationships. Subsequently, all nodes are arranged based on their sequence IDs, which creates a node matrix where each row represents the feature information of a node. This arrangement constitutes the node feature matrix. Additionally, an N × N zero matrix is constructed based on the total number of nodes N, where the positions corresponding to connected nodes are set to 1, which creates the adjacency matrix. This process is repeated for all frames in the dataset.

A chain-like structure consisting of 25C or P particles was specifically selected as an example for a detailed explanation. In this structure, particles are treated as nodes, and the bonding or interaction relationships between particles are treated as edges. The corresponding graph structure is constructed by extracting key features from the node data file and the edge relationship file. The node feature matrix contains the characteristic information of each node, including the node ID, node type, and the XYZ coordinates of the node. The node types (C:1, P:2) are represented using one-hot encoding: C is represented as [1, 0, 0, 0, 0], and P is represented as [0, 1, 0, 0, 0]. One-hot encoding is a method of converting categorical variables into binary vectors, where each type is represented by a unique binary vector, allowing the neural network to efficiently handle categorical information. The adjacency matrix A is used to represent the connectivity between nodes, where Aij = 1 indicates that nodes i and j are connected, and Aij = 0 otherwise. The edge attribute matrix represents the type of the edge; in this study, all edge types are “interacts” and are encoded as [1, 0, 0, 0, 0]. The resulting node feature matrices, adjacency matrices and edge attribute matrices are then input into the GNN model for training, which enables the model to learn the complex interactions between nodes and facilitates the analysis of the topological structure of the entire network. Ultimately, our attention mechanism-based incremental graph neural network model learns the structure–property relationships that influence changes in conductivity at different CNT concentrations and explains the network structure changes at varying concentrations.

Improved GNN strategy for screening the network structure of conductive polymer composites

At the forefront of materials science, the development of conductive polymer nanocomposites is becoming a key driver of technological innovation. However, many mysteries remain regarding the complex relationships between the microstructure and macroscopic properties of these materials. Traditional, experimental, and computational methods have faced significant challenges in unraveling these connections. In this context, GCN, a novel deep learning technology capable of efficiently processing graph-structured data, offers an innovative solution for uncovering the performance mechanisms of conductive polymer nanocomposites. With its unique network architecture and exceptional learning capabilities, GCN has greatly expanded the depth and scope of material property research and opened a new chapter in material design and application. The GAT model36,59, a more advanced deep learning strategy, opens new possibilities for the in-depth exploration of key features in conductive polymer materials, especially in handling complex graph-structured data and enhancing prediction accuracy. The graph attention mechanism can more precisely identify the core elements influencing material performance by assigning personalized weight parameters to different edges. This identification brings unprecedented insight and efficiency to the study and application of conductive polymer materials.

In this study, we developed an advanced graph attention mechanism learning model, as shown in Fig. 8. The model effectively integrates an end-to-end graph neural network framework, which is designed to model and analyze the complex relationship between the three-dimensional structure of conductive polymer nanocomposites and their electrical conductivity. The architecture processes input data; including node features, adjacency matrices, and edge attributes; and autonomously extracts key features for accurate predictions through an automated learning process. Specifically, the model iteratively aggregates the features of neighboring nodes and progressively captures the global graph structure. This process allows the model to automatically identify and learn complex relationships between features and generate optimal feature representations. During training, the model simultaneously optimizes all parameters using the Adaptive Momentum (Adam) gradient descent algorithm. The Adam optimizer combines the benefits of momentum and adaptive learning rates, which makes parameter updates more efficient at each layer. The goal of optimization is to minimize the loss function by continuously adjusting the weight of the model. Through backpropagation, the model uses the chain rule to propagate errors backward through the network layers and gradually adjusts the weights and biases of each layer to reduce prediction errors and improve overall performance. Additionally, to enhance training efficiency and prevent overfitting, an early stopping strategy is implemented. This strategy monitors performance metrics on the validation set after each iteration. If the predetermined accuracy threshold is reached or if there is no significant performance improvement over several consecutive iterations, training is automatically halted to prevent overtraining and overfitting. This approach effectively simplifies the training process while significantly improving the model’s ability to understand and predict the structure–performance relationships of materials.

a Shows the input graph data of the model. The model first receives 1000 frames of network data at a 1% CNT concentration for training, providing solid initialization parameters for subsequent incremental training. This ensures that the model has good generalization capabilities when processing network data at other concentrations; b Illustrates the optimization mechanism of the model in the feature representation learning and message aggregation process. This module iteratively computes the relationships between nodes and their first-order neighbors using the multi-head attention mechanism, aggregating features with edge attributes. Subsequently, the TopKPooling layer selects and retains the most representative nodes based on their importance, enhancing feature extraction efficiency. Finally, the PairNorm normalization technique is applied to normalize node features, ensuring consistency in feature scales, improving the model’s stability and convergence speed, and further enhancing its performance in complex networks; c Presents the improved pooling strategy, which combines the advantages of global average pooling and global max pooling. First, global average pooling and global max pooling are applied to all nodes in each graph. Then, the results are concatenated to generate a more comprehensive graph-level embedding. This dual-pooling strategy captures both the global information of the graph structure and the significant features of key nodes, thereby improving the model’s representational power and generalization ability; d Demonstrates the workflow of the Estimator block. The input graph embedding is first processed with layer normalization and then undergoes a nonlinear feature transformation through a fully connected layer. Afterward, a dropout strategy is applied to enhance the model’s robustness, followed by another layer of normalization to optimize the feature distribution. Finally, after introducing non-linearity through a ReLU activation function, the output layer is used to make an accurate conductivity prediction. These steps progressively optimize the feature representation and ensure an effective mapping from high-dimensional graph embeddings to the target property space.

Incremental learning mode for graph feature data

In material property prediction, the size of the dataset plays a crucial role in determining the effectiveness of model training. In this experiment, we only have 1000 frames of data for each concentration, which presents a challenge due to data scarcity. To address this issue, we implemented an incremental learning strategy. This approach enables us to gradually optimize the model under limited data conditions, improve its generalization capability, and enhance its predictive accuracy for material property prediction tasks.

Specifically, we began by training the model using 1000 frames of data at concentration CP1, which allowed the model to capture the basic characteristics of the conductive network structure at this concentration. Through this initial training, the model learned key features of the conductive network and we saved the pre-trained model. Then, when processing data at concentration CP2, we loaded the previously trained model and fine-tuned its parameters. Moreover, we randomly froze certain network parameters that had changed significantly during the CP1 training to preserve the learned network structure features and improve the robustness of the model. In this way, the model can incorporate new features from the CP2 data, retain the knowledge gained from the CP1 data, and gradually develop a more comprehensive and in-depth understanding of the conductive network structure.

This process continues from CP3 to CP8, with each new concentration of data being fine-tuned and optimized based on the previous model. Through this incremental learning strategy, we gradually accumulate feature information from different concentrations under limited data conditions, which enables the model to adapt flexibly to the network structure variations caused by changes in concentration. This method not only addresses the issue of limited data but also, through continuous model iteration and optimization, maximizes the potential of the available data, and enhances the robustness and reliability of the model in screening conductive network structures of polymer composites. Ultimately, through incremental learning, our model can identify the network structural features that significantly impact electrical conductivity at different concentrations, which offers an effective tool for screening polymer composite conductive network structures with optimal electrical conductivity.

Graph embedding block

In the process of screening the conductive network structures of polymer composites, we employed an enhanced GNN model. This model efficiently transmits and aggregates information between nodes and their neighbors using multi-head attention mechanisms and cascaded graph convolutional layers, which effectively capture the complex relationships within the CNT network.

The model dynamically assigns different weights to each neighbor by calculating attention scores between nodes and their neighbors and performs weighted aggregation of node features. In this model, the calculation of attention scores takes into account both node features and edge attributes. This design allows the attention mechanism to rely not only on node features but also to dynamically model edge attribute information. For carbon nanotubes, for example, the edge attribute vector effectively represents the physical connection characteristics between nodes, which further enhances the flexibility and accuracy of the model and enables the model to capture the relationships between nodes with greater precision. The formula for calculating the attention score αi,j is as follows:

where hi and hj represent the features of node i and its neighboring node j, W is the learned feature transformation matrix, a is the attention weight, LeakyReLU is the activation function, and ei,j denotes the edge attribute between node i and node j. The symbol || indicates concatenation. This formula captures the complex relationship between nodes and their neighbors by concatenating and transforming both node features and edge attributes.

Furthermore, using the multi-head attention mechanism, each attention head k independently calculates the attention coefficient \({\alpha }_{i,j}^{(k)}\) and the feature transformation matrix W(k). Then, the k-th head aggregates the features of the neighbors through weighted summation:

Finally, the outputs of all attention heads are concatenated along the feature dimension to produce the updated node feature representations:

where K denotes the number of attention heads, \(\sigma\) is the activation function, and || represents the concatenation operation along the feature dimension. This mechanism enables the model to capture the complex relationships between nodes from multiple perspectives, thereby improving its generalization ability and stability. The formal description of GAT is as shown in the supporting file.

Our model processes node features, edge indices, and edge attributes through three cascaded graph convolutional layers. This step not only considers the characteristics of the nodes themselves but also fully incorporates the interactions between nodes and edge attributes and provides rich information for screening conductive network structures. We incorporated the TopKPooling layer to dynamically select and retain the most important nodes based on this step. TopKPooling identifies the most significant nodes by calculating their significance scores, typically derived by weighting the node features. The nodes are ranked according to their importance and the top K nodes are retained. To control the proportion of retained nodes, the TopKPooling layer uses a ratio to determine how many important nodes to keep. In our model, the ratio is set to 0.75, which means that 75% of the nodes are retained during the pooling operation. This approach not only improves the efficiency of feature extraction and computational performance but also ensures that the information from key nodes in the conductive network structure is effectively preserved, which allows for better capture of critical structural features in the carbon nanotube network.

To further enhance the stability of the model and accelerate convergence, we introduced the PairNorm normalization technique after the pooling operation. Specifically, PairNorm normalizes node features while considering the relative differences between them, rather than standardizing each node’s features individually. This approach helps prevent issues such as vanishing or exploding gradients, which can arise from significant differences in feature scales across nodes and makes the model more stable during training. With this normalization strategy, the model effectively maintains consistency in feature scales during training and reduces potential numerical instability. This strategy enables the model to more efficiently capture critical information in the CNT network, consequently enhancing its predictive capability, especially in complex network structures and allowing it to more accurately identify features that significantly impact conductivity.

Improved global pooling

In building material property prediction models, model training often depends on the precise extraction of key information from the graph. Material properties are influenced by their complex microstructures and interactions, hence, efficiently capturing these features during training is crucial. However, traditional global pooling methods commonly used in graph neural networks (such as global average pooling and global max pooling) can capture some information from the graph structure but still have inherent limitations. Global average pooling often overlooks key information from locally significant nodes, which reduces the sensitivity of the model to important features. While global max pooling preserves the most important node features, it may discard overall information and fail to fully represent the entire graph. As a result, a single pooling strategy often struggles to balance the relationship between local and global features.

To address this issue, we propose a novel global pooling strategy that combines the advantages of both global average pooling and global max pooling. Specifically, we first apply global average pooling and global max pooling to the node features of each graph and then concatenate the results of these two operations to create a richer graph-level embedding. This improved approach effectively combines the strengths of both pooling strategies, which enables the model to capture not only the overall trend of node features in the graph but also focus on the significant features of key nodes. As a result, it enhances the representational power and generalization ability of the model across various tasks. The enhanced graph neural network model can more comprehensively represent graph structures by applying this dual-pooling strategy, particularly when handling highly complex and heterogeneous graph data, leading to significant performance improvements.

Estimator block

The Estimator block is a key component of the model, responsible for receiving graph embedding representations and accurately predicting the conductivity of conductive polymer nanocomposites. This module performs a nonlinear mapping from the feature space to the target property space through layer-by-layer processing of high-dimensional graph embeddings, which effectively transforms the global structural information contained in the embeddings into conductivity predictions. The module enhances the expressiveness and prediction accuracy of the model through iterative optimization by fully leveraging the global structural information in the graph embeddings.

First, the input graph embedding representation is treated as the initial feature and undergoes standardization through the first layer normalization. Layer normalization computes the mean and standard deviation of the input features on a per-layer basis and performs a linear transformation on each feature to ensure it has zero mean and unit variance. The specific operation follows the formula:

where x is the input feature and \(\mu\) and \({\sigma }^{2}\) represent the mean and variance of the input features at the current layer, respectively. \(\epsilon\) is a smoothing factor to prevent division by zero, and \(\gamma\) and \(\beta\) are learnable scales and shift parameters. This process eliminates imbalances in the input feature distribution and ensures that feature values across different dimensions fall within the same range. This elimination helps mitigate the risk of vanishing or exploding gradients and improves the stability of the training process. Subsequently, the normalized features are passed to a fully connected layer, which captures the complex relationships between features through a linear transformation. This step performs a linear mapping from the high-dimensional vector to the hidden layer features, reduces the dimensionality of the input features, and provides input for subsequent nonlinear modeling. To further enhance the generalization ability of the model, the features after the linear transformation pass through a dropout layer, which randomly drops neurons with a probability of p = 0.2 to prevent overfitting during training. Subsequently, the features that have undergone dropout are optimized by a second layer normalization to further balance the feature distribution, stabilize the training process, and ensure that the nonlinear-transformed features remain within an appropriate numerical range. Finally, the ReLU activation function introduces nonlinearity to the model, which enables it to learn more complex relationships between features. The activated features are then passed through the output layer, which is a single-neuron linear layer that generates the final conductivity prediction. The Estimator block systematically extracts and transforms the global information from the input graph embedding representation through a series of steps, which enables accurate predictions of conductivity from high-dimensional features. As a key component of the model, it ensures an effective mapping between the input graph embedding and the target attribute while maintaining training stability, ultimately yielding precise predictions of material conductivity.

In summary, our improved GNN model, when used to screen the conductive network structures of polymer composites, offers a more comprehensive consideration of the microstructure and interactions within the CNT network. Through efficient attention mechanisms and pooling strategies, the model effectively identifies network structures that significantly impact conductivity and provides strong theoretical support and guidance for the design and development of polymer composites with superior conductive properties.

Data availability

The data that support the findings of this study are available from: https://github.com/TANG-77777/GAT-PolymerNanocomposites.

Code availability

The code that support the findings of this study are available from: https://github.com/TANG-77777/GAT-PolymerNanocomposites.

References

Wang, S. et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature 555, 83–88 (2018).

Kim, J., de Mathelin, M., Ikuta, K. & Kwon, D.-S. Advancement of flexible robot technologies for endoluminal surgeries. Proc. IEEE 110, 909–931 (2022).

Liu, L. et al. Highly stretchable, sensitive and wide linear responsive fabric-based strain sensors with a self-segregated carbon nanotube (CNT)/Polydimethylsiloxane (PDMS) coating. Prog. Nat. Sci. Mater. Int. 32, 34–42 (2022).

Steck, J., Kim, J., Kutsovsky, Y. & Suo, Z. Multiscale stress deconcentration amplifies fatigue resistance of rubber. Nature 624, 303–308 (2023).

A‹t Hocine, N., Miranda, C., Nauman, S. & Langlet, A. Electrical properties of elastomer-based composites reinforced with carbon nanotubes-A review. Polym. Adv. Technol 35, e6299 (2024).

Jiang, X. et al. The connotation and key research areas of the new application code “computational physics” of the National Natural Science Foundation of China. Sci. Sin. Phys. Mech. Astron 54, 247102 (2024).

Wu, H.-C. et al. Highly stretchable polymer semiconductor thin films with multi-modal energy dissipation and high relative stretchability. Nat. Commun 14, 8382 (2023).

Zhou, Z., Liu, T., Khan, A. U. & Liu, G. Block copolymer-based porous carbon fibers. Sci. Adv. 5, eaau6852 (2019).

Wang, S. et al. Polymer nanocomposite dielectrics: understanding the matrix/particle interface. ACS Nano 16, 13612–13656 (2022).

Milano, G. et al. Hybrid particle-field molecular dynamics: a primer. In Comprehensive Computational Chemistry (eds Yanez, M. & Boyd, R. J.) 636–659 (Oxford: Elsevier, 2024).

Milano, G. & Kawakatsu, T. Hybrid particle-field molecular dynamics simulations for dense polymer systems. J. Chem. Phys. 130, 214106 (2009).

Zhao, Y., De Nicola, A., Kawakatsu, T. & Milano, G. Hybrid particle-field molecular dynamics simulations: parallelization and benchmarks. J. Comput. Chem. 33, 868–880 (2012).

Zhao, Y. et al. Self-assembly of carbon nanotubes in polymer melts: simulation of structural and electrical behaviour by hybrid particle-field molecular dynamics. Nanoscale 8, 15538–15552 (2016).

Zhao, Y. et al. Self-assembled morphologies and percolation probability of mixed carbon fillers in the diblock copolymer template: hybrid particle-field molecular dynamics simulation. J. Phys. Chem. C. 119, 25009–25022 (2015).

Liu, S.-L. et al. Strategic regulation of carbon nanotube dispersion with triblock copolymer phase domains: insights from molecular simulations. Chin. J. Polym. Sci. 43, 517–532 (2025).

Vecchio, D. A., Mahler, S. H., Hammig, M. D. & Kotov, N. A. Structural analysis of nanoscale network materials using graph theory. ACS Nano 15, 12847–12859 (2021).

Kipf, T. & Welling, M. J. A. Semi-supervised classification with graph convolutional networks. In International Conference on Learning Representations (ICLR, 2016).

Gilmer, J., Schoenholz, S. S., Riley, P. F., Vinyals, O. & Dahl, G. E. Neural message passing for quantum chemistry. In Proceedings of the 34th International Conference on Machine Learning, 70, 1263–1272 (PMLR, 2017)

Schütt, K. T., Arbabzadah, F., Chmiela, S., Müller, K. R. & Tkatchenko, A. Quantum-chemical insights from deep tensor neural networks. Nat. Commun. 8, 13890 (2017).

Gong, X.-R. J. Y. Advances and challenges of machine learning in polymer material genomes. Acta Polym. Sin 53, 1287–1300 (2022).

Feng, J., Dong, Z., Ji, Y. & Li, Y. Accelerating the discovery of metastable IrO2 for the oxygen evolution reaction by the self-learning-input graph neural network. JACS Au 3, 1131–1140 (2023).

Gao, L., Lin, J., Wang, L. & Du, L. Machine learning-assisted design of advanced polymeric materials. Acc. Mater. Res. 5, 571–584 (2024).

Merchant, A. et al. Scaling deep learning for materials discovery. Nature 624, 80–85 (2023).

Szymanski, N. J. et al. An autonomous laboratory for the accelerated synthesis of novel materials. Nature 624, 86–91 (2023).

France-Lanord, A. et al. Effect of chemical variations in the structure of poly(ethylene oxide)-based polymers on lithium transport in concentrated electrolytes. Chem. Mater. 32, 121–126 (2019).

Qiu, H. et al. PolyNC: a natural and chemical language model for the prediction of unified polymer properties. Chem. Sci. 15, 534–544 (2024).

Zheng, F. et al. Predicting molecular self-assembly on metal surfaces using graph neural networks based on experimental data sets. ACS Nano 17, 17545–17553 (2023).

Du, S. et al. Polymer genome approach: a new method for research and development of polymers. Acta Polym. Sin. 53, 592–607 (2022).

Liu, L. Y., Ding, F. & Li, Y. Q. Big data approach on polymer materials: fundamental, progress and challenge. Acta Polym. Sin. 53, 564–580 (2022).

Qiu, H., Wang, J., Qiu, X., Dai, X. & Sun, Z. Y. Heat-resistant polymer discovery by utilizing interpretable graph neural network with small data. Macromolecules 57, 3515–3528 (2024).

Shi, X., Zhou, L., Huang, Y., Wu, Y. & Hong, Z. A review on the applications of graph neural networks in materials science at the atomic scale. Mater. Genome Eng. Adv 2, e50 (2024).

Tran, H. et al. Design of functional and sustainable polymers assisted by artificial intelligence. Nat. Rev. Mater. 9, 866–886 (2024).

Veličković, P. et al. Graph attention networks. In International Conference on Learning Representations(ICLR) (ICLR, 2018).

Liu, Z. & Zhou, J. Graph attention networks. In Introduction to graph neural networks. 39–41 (Springer International Publishing, 2020).

Vrahatis, A. G., Lazaros, K. & Kotsiantis, S. Graph attention networks: a comprehensive review of methods and applications. Fut. Internet 16, 318 (2024).

Fang, Z. & Yan, Q. Towards accurate prediction of configurational disorder properties in materials using graph neural networks. npj Comput Mater. 10, 91 (2024).

Hamilton, W. L., Ying, R. & Leskovec, J. Inductive representation learning on large graphs. In Proceedings of the 31st International Conference on Neural Information Processing Systems (NIPS, 2017).

Thekumparampil, K. K., Wang, C., Oh, S. & Li, L.-J. Attention-based graph neural network for semi-supervised learning. arXiv https://arxiv.org/abs/1803.03735 (2018).

Willmott, C. J. & Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 30, 79–82 (2005).

Chai, T. & Draxler, R. R. Root mean square error (RMSE) or mean absolute error (MAE)? – Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 7, 1247–1250 (2014).

Newman, M. E. J. The structure and function of complex networks. SIAM Rev. 45, 167–256 (2003).

Ai, J. et al. Node-importance identification in complex networks via neighbors average degree. 2016 Chinese Control and Decision Conference (CCDC), 1298–1303 (2016).

Watts, D. J. & Strogatz, S. H. Collective dynamics of ‘small-world’ networks. Nature 393, 440–442 (1998).

Intanagonwiwat, C., Estrin, D., Govindan, R., Heidemann, J. Impact of network density on data aggregation in wireless sensor networks. Proc. 22nd Int. Conf. Distrib. Comput. Syst., 457–458 (2002).

Barrat, A., Barthelemy, M., Pastor-Satorras, R. & Vespignani, A. The architecture of complex weighted networks. Proc. Natl Acad. Sci. USA 101, 3747–3752 (2003).

Newman, M. E. The structure of scientific collaboration networks. Proc. Natl Acad. Sci. USA 98, 404–409 (2001).

Latora, V. & Marchiori, M. Efficient behavior of small-world networks. Phys. Rev. Lett. 87, 198701 (2001).

Boccaletti, S. et al. The structure and dynamics of multilayer networks. Phys. Rep. 544, 1–122 (2014).

Newman, M. E. J. Finding community structure in networks using the eigenvectors of matrices. Phys. Rev. E 74, 036104 (2006).

Berenbrink, P., Krayenhoff, B. & Mallmann-Trenn, F. Estimating the number of connected components in sublinear time. Inf. Process. Lett. 114, 639–642 (2014).

Grossiord, N. et al. High-conductivity polymer nanocomposites obtained by tailoring the characteristics of carbon nanotube fillers. Adv. Funct. Mater. 18, 3226–3234 (2008).

Dufresne, A. et al. Processing and characterization of carbon nanotube/poly(styrene-co-butyl acrylate) nanocomposites. J. Mater. Sci. 37, 3915–3923 (2002).

Xie, Y. et al. Microwave-assisted foaming and sintering to prepare lightweight high-strength polystyrene/carbon nanotube composite foams with an ultralow percolation threshold. J. Mater. Chem. C. 9, 9702–9711 (2021).

Shrivastava, N. K. & Khatua, B. B. Development of electrical conductivity with minimum possible percolation threshold in multi-wall carbon nanotube/polystyrene composites. Carbon 49, 4571–4579 (2011).

Maiti, A., Wescott, J. & Kung, P. Nanotube–polymer composites: insights from Flory–Huggins theory and mesoscale simulations. Mol. Simul. 31, 143–149 (2005).

Howell, J. S., Stephens, B. O. & Boucher, D. S. Convex solubility parameters for polymers. J. Polym. Sci. Part B53, 1089–1097 (2015).

Mieczkowski, R. The determination of the solubility parameter components of polystyrene by partial specific volume measurements. Eur. Polym. J. 24, 1185–1189 (1988).

Sema Özen, A., Sen, U. & Atilgan, C. Complete mapping of the morphologies of some linear and graft fluorinated co-oligomers in an aprotic solvent by dissipative particle dynamics. J. Chem. Phys. 124, 1–10 (2006).

Choudhary, K. et al. Recent advances and applications of deep learning methods in materials science. npj Comput Mater 8, 59 (2022).

Acknowledgements