Abstract

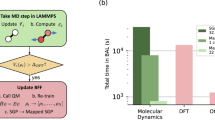

Silicon carbide (SiC) is an important technological material, but its high-temperature phase diagram has remained unclear due to conflicting experimental results about congruent versus incongruent melting. Here, we employ large-scale machine learning molecular dynamics (MLMD) simulations to gain insights into SiC decomposition and phase transitions. Our approach relies on a Bayesian active learning workflow to efficiently train an accurate machine learning force field on density functional theory data. Our large-scale simulations provide direct indication that melting of SiC proceeds incongruently via decomposition into silicon-rich and carbon phases at high temperature and pressure. During cooling at high pressures, carbon nanoclusters nucleate and grow within the homogeneous molten liquid. During heating, the decomposed mixture reversibly transitions back into a homogeneous SiC liquid. The full pressure-temperature phase diagram of SiC is systematically constructed using MLMD simulations, providing new understanding of the nature of phases, resolving long-standing inconsistencies from previous experiments and yielding technologically relevant implications for processing and deposition of this material.

Similar content being viewed by others

Data availability

The data and scripts are available on Zenodo: https://doi.org/10.5281/zenodo.14648292 and https://doi.org/10.5281/zenodo.15066527.

Code availability

Post-processing scripts are available on Github: https://github.com/YuuuXie/SiC_MLMD_phase_diagram. For the machine learning force field, this work utilizes FLARE (version 1.3.0) for training and deployment, available at https://github.com/mir-group/flare.

References

Madar, R. Silicon carbide in contention. Nature 430, 974–975 (2004).

Madhusudhan, N., Lee, K. K. & Mousis, O. A possible carbon-rich interior in super-earth 55 Cancri e. Astrophys. J. Lett. 759, L40 (2012).

Katoh, Y. & Snead, L. L. Silicon carbide and its composites for nuclear applications–historical overview. J. Nucl. Mater. 526, 151849 (2019).

Matsunami, H. & Kimoto, T. Step-controlled epitaxial growth of SiC: High quality homoepitaxy. Mater. Sci. Eng. R Rep. 20, 125–166 (1997).

Yi, J., He, X., Sun, Y. & Li, Y. Electron beam-physical vapor deposition of SiC/SiO2 high emissivity thin film. Appl. Surf. Sci. 253, 4361–4366 (2007).

Zhang, W. & Van Duin, A. C. Atomistic-scale simulations of the graphene growth on a silicon carbide substrate using thermal decomposition and chemical vapor deposition. Chem. Mater. 32, 8306–8317 (2020).

Ekimov, E. et al. A high-pressure cell for high-temperature experiments in a toroid-type chamber. Instrum. Exp. Tech. 47, 276–278 (2004).

Togaya, M. & Sugiyama, S. Melting behavior of β-sic at high pressure. Rev. High. Press. Sci. Technol. 7, 1037–1039 (1998).

Daviau, K. & Lee, K. K. Decomposition of silicon carbide at high pressures and temperatures. Phys. Rev. B 96, 174102 (2017).

Bhaumik, S., Divakar, C., Mohan, M. & Singh, A. A modified high-temperature cell (up to 3300 k) for use with a cubic press. Rev. Sci. Instrum. 67, 3679–3682 (1996).

Bhaumik, S. Synthesis and sintering of monolithic and composite ceramics under high pressures and high temperatures. Met. Mater. Process. 12, 215–232 (2000).

Dolloff, R. T. & Sara, R. Research study to determine the phase equilibrium relations of selected metal carbides at high temperatures, vol. 60 (Aeronautical Systems Division, Air Force Systems Command, US Air Force, 1961).

Hall, H. T. High temperature studies: Final Report U.S. Army Ordnance. Tech. Rep. DA 04 493 495 ORD 792, Brigham Young University 36 (1956).

Sokolov, P. S., Mukhanov, V. A., Chauveau, T. & Solozhenko, V. L. On melting of silicon carbide under pressure. J. Superhard Mater. 34, 339–341 (2012).

Finocchi, F., Galli, G., Parrinello, M. & Bertoni, C. M. Microscopic structure of amorphous covalent alloys probed by ab initio molecular dynamics: SiC. Phys. Rev. Lett. 68, 3044 (1992).

Saiz, F. An ab initio study on liquid silicon carbide. J. Phys. Chem. Solids 137, 109204 (2020).

Vashishta, P., Kalia, R. K., Nakano, A. & Rino, J. P. Interaction potential for silicon carbide: A molecular dynamics study of elastic constants and vibrational density of states for crystalline and amorphous silicon carbide. J. Appl. Phys. 101, 103515 (2007).

Tersoff, J. Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B 39, 5566 (1989).

Tersoff, J. Chemical order in amorphous silicon carbide. Phys. Rev. B 49, 16349 (1994).

Yan, W., Gao, T., Guo, X., Qin, Y. & Xie, Q. Melting kinetics of bulk SiC using molecular dynamics simulation. Sci. China Phys. Mech. Astron. 56, 1699–1704 (2013).

Devanathan, R., Gao, F. & Weber, W. J. Atomistic modeling of amorphous silicon carbide using a bond-order potential. Nucl. Instrum. Methods Phys. Res. B 255, 130–135 (2007).

Kubo, A. & Umeno, Y. Machine-learning-based atomistic model analysis on high-temperature compressive creep properties of amorphous silicon carbide. Materials 14, 1597 (2021).

MacIsaac, M., Bavdekar, S., Spearot, D. & Subhash, G. A genetic algorithm trained machine-learned interatomic potential for the silicon–carbon system. J. Phys. Chem. C. 128, 12213–12226 (2024).

Liu, Y. et al. Deep learning inter-atomic potential for irradiation damage in 3C-SiC. Comput. Mater. Sci. 233, 112693 (2024).

Ishimaru, M., Bae, I.-T. & Hirotsu, Y. Electron-beam-induced amorphization in sic. Phys. Rev. B 68, 144102 (2003).

Vandermause, J. et al. On-the-fly active learning of interpretable bayesian force fields for atomistic rare events. npj Comput. Mater. 6, 1–11 (2020).

Xie, Y., Vandermause, J., Sun, L., Cepellotti, A. & Kozinsky, B. Bayesian force fields from active learning for simulation of inter-dimensional transformation of stanene. npj Comput. Mater. 7, 1–10 (2021).

Larsen, P. M., Schmidt, S. & Schiøtz, J. Robust structural identification via polyhedral template matching. Model. Simul. Mater. Sci. Eng. 24, 055007 (2016).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2009).

Gayler, M. Melting point of high-purity silicon. Nature 142, 478–478 (1938).

Dozhdikov, V., Basharin, A. Y. & Levashov, P. Two-phase simulation of the crystalline silicon melting line at pressures from –1 to 3 GPa. J. Chem. Phys. 137, 054502 (2012).

Xie, Y. et al. Uncertainty-aware molecular dynamics from bayesian active learning for phase transformations and thermal transport in sic. npj Comput. Mater. 9, 36 (2023).

Krieger, F. J. The Thermodynamics of the Silicon Carbide/Silicon-Carbon Vapor System. Technical Report (1968).

Daviau, K. & Lee, K. K. Zinc-blende to rocksalt transition in sic in a laser-heated diamond-anvil cell. Phys. Rev. B 95, 134108 (2017).

Kidokoro, Y., Umemoto, K., Hirose, K. & Ohishi, Y. Phase transition in sic from zinc-blende to rock-salt structure and implications for carbon-rich extrasolar planets. Am. Mineralogist J. Earth Planet. Mater. 102, 2230–2234 (2017).

Miozzi, F. et al. Equation of state of SiC at extreme conditions: New insight into the interior of carbon-rich exoplanets. J. Geophys. Res. Planets 123, 2295–2309 (2018).

Vandermause, J., Xie, Y., Lim, J. S., Owen, C. J. & Kozinsky, B. Active learning of reactive Bayesian force fields applied to heterogeneous catalysis dynamics of h/pt. Nat. Commun. 13, 5183 (2022).

Batzner, S. et al. E (3)-equivariant graph neural networks for data-efficient and accurate interatomic potentials. Nat. Commun. 13, 2453 (2022).

Musaelian, A. et al. Learning local equivariant representations for large-scale atomistic dynamics. Nat. Commun. 14, 579 (2023).

Kimoto, T. Bulk and epitaxial growth of silicon carbide. Prog. Cryst. Growth Charact. Mater. 62, 329–351 (2016).

Snead, L., Zinkle, S., Hay, J. & Osborne, M. Amorphization of SiC under ion and neutron irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B: Beam Interact. Mater. At. 141, 123–132 (1998).

Zhou, J., Odqvist, J., Thuvander, M. & Hedström, P. Quantitative evaluation of spinodal decomposition in fe-cr by atom probe tomography and radial distribution function analysis. Microsc. Microanal. 19, 665–675 (2013).

Sarkar, S. K., Ray, D., Sen, D. & Biswas, A. Nucleation–growth versus spinodal decomposition in fe–cr alloys: An experimental verification by atom probe tomography and small-angle neutron scattering. Microsc. Microanal. 29, 437–450 (2023).

Herrero, C. P., Ramírez, R. & Herrero-Saboya, G. Cubic silicon carbide under tensile pressure: Spinodal instability. Chem. Phys. 573, 112005 (2023).

Maras, E., Trushin, O., Stukowski, A., Ala-Nissila, T. & Jonsson, H. Global transition path search for dislocation formation in ge on si (001). Comput. Phys. Commun. 205, 13–21 (2016).

Li, W., Yao, X. & Zhang, X. Planar impacts on nanocrystalline sic: a comparison of different potentials. J. Mater. Sci. 53, 6637–6651 (2018).

Branicio, P. S. et al. Shock-induced microstructural response of mono-and nanocrystalline sic ceramics. Journal of Applied Physics123 (2018).

Li, W., Yao, X., Branicio, P., Zhang, X. & Zhang, N. Shock-induced spall in single and nanocrystalline sic. Acta Mater. 140, 274–289 (2017).

Bartók, A. P. & Csányi, G. Gaussian approximation potentials: a brief tutorial introduction. Int. J. Quantum Chem. 115, 1051–1057 (2015).

Thompson, A., Swiler, L., Trott, C., Foiles, S. & Tucker, G. Spectral neighbor analysis method for automated generation of quantum-accurate interatomic potentials. J. Comput. Phys. 285, 316–330 (2015).

Drautz, R. Atomic cluster expansion for accurate and transferable interatomic potentials. Phys. Rev. B 99 (2019).

Thompson, A. P. et al. LAMMPS-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 271, 108171 (2022).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558 (1993).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Ramakers, S. et al. Effects of thermal, elastic, and surface properties on the stability of SiC polytypes. Phys. Rev. B 106, 075201 (2022).

Trott, C. R. et al. Kokkos 3: programming model extensions for the exascale era. IEEE Trans. Parallel Distrib. Syst. 33, 805–817 (2022).

Johansson, A. et al. Micron-scale heterogeneous catalysis with Bayesian force fields from first principles and active learning. Preprint at: https://doi.org/10.48550/arXiv.2204.12573 (2022).

Sekine, T. & Kobayashi, T. Shock compression of 6h polytype sic to 160 GPa. Phys. Rev. B 55, 8034 (1997).

Tracy, S. et al. In situ observation of a phase transition in silicon carbide under shock compression using pulsed X-ray diffraction. Phys. Rev. B 99, 214106 (2019).

Yoshida, M., Onodera, A., Ueno, M., Takemura, K. & Shimomura, O. Pressure-induced phase transition in sic. Phys. Rev. B 48, 10587 (1993).

Acknowledgements

We acknowledge Cameron Owen and Anders Johansson for discussions and help with the large simulation setup and computational resources. We acknowledge Evelyn Hu for helpful discussions and feedback. Y.X. is supported by the "Design & Assembly of Atomically-Precise Quantum Materials & Devices" grant DE-SC0020128 of the Department of Energy. M.W. is supported by the National Science Foundation, Office of Advanced Cyberinfrastructure (OAC), under Award No. 2118201. B.K. and F.S. are supported by the Harvard University Materials Research Science and Engineering Center funded by the National Science Foundation grant DMR-2011754. The simulation and analysis are done on the Harvard Cannon cluster. This research used resources of the National Energy Research Scientific Computing Center (NERSC), a DOE Office of Science User Facility supported by the Office of Science of the U.S. Department of Energy under Contract No. DE-AC02-05CH11231 using NERSC award BES-ERCAP0024206.

Author information

Authors and Affiliations

Contributions

Y.X. initiated the project, performed the training of the ML force field, phase transition simulations and post-analysis. M.W. contributed to the dataset and code preparation, phase transition simulations and post-analysis. S.R. contributed to the DFT settings and the collection of experimental results. F.S. guided the analysis of nucleation and decomposition. B.K. supervised all aspects of the project. All authors contributed to the writing of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xie, Y., Wang, M., Ramakers, S. et al. Incongruent melting and phase diagram of SiC from machine learning molecular dynamics. npj Comput Mater (2026). https://doi.org/10.1038/s41524-026-01976-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41524-026-01976-4