Abstract

The desire for cost-effective strategies for producing organic electronic devices has led to many new methods for the organic semiconductor layer deposition; however, manufacturing contacts remains an expensive technique due to the high cost of both the materials used and the processing necessary for their patterning. In this work, we present a method for contact deposition and patterning, which overcomes these limitations and allows fabrication of all-printed organic thin-film transistors on paper. The method relies on depositing contacts using aerosol spray and patterning them with a digitally printed mask from an office laser printer, at ambient temperature and pressure. This technique, which we have denoted aerosol spray laser lithography, is cost-effective and extremely versatile in terms of material choice and electrode geometry. As the processing temperature does not exceed 155 °C, it is compatible with a variety of substrates, including plastic or paper. The success of this method marks an opportunity for a rapid, scalable, and low-cost alternative to current electrode-manufacturing techniques for development of flexible, large-area, electronic applications.

Similar content being viewed by others

Introduction

Organic electronics are at the forefront of the industry for large-area, low-cost flexible electronic applications, and provide an opportunity to incorporate electronics in non-traditional areas, such as clothing, electronic paper, bio-integrated applications, and more.1,2,3,4,5,6 Their key benefits include chemical versatility and the ability to be processed at ambient temperature and pressure.7,8,9,10 Processing techniques such as spray coating, ink-jet printing, blade coating, or laser printing, are scalable to an industrial setting and have made it possible to manufacture the various device layers in a cost-effective manner.11,12,13,14,15,16 Although significant progress has been achieved in the development of organic semiconductor (OSC) materials compatible with processing at or near room temperature, patterning and deposition of electrodes under ambient conditions remain a challenge. With a few exceptions, most device contacts are based on metals such as gold or silver, which require complex deposition methods such as sputtering, electron beam, or thermal evaporation, in conjunction with shadow masks or photolithography for patterning. These methods are not only expensive, but their scalability and compatibility with flexible substrates are limited.

To reduce the processing intricacy for contact fabrication, there has been a great effort in developing solution processable contacts. Examples include carbon nanotubes,17 graphene electrodes,18,19,20,21,22 and poly(3,4-ethylenedioxythiophene) doped with polystyrene sulfonic acid.23 Metallic charge-transfer complexes such as tetrathiafulvalene-7,7,8,8-tetracyanoquinodimethane can be casted from solutions, but this process involves complex steps due to the low solubility characteristic to these compounds.24,25 Typically, they are deposited using thermal evaporation and shadow masks, making the process expensive and time consuming.26 Clearly, there has been notable progress in the development of contact deposition methods and materials for cost-effective manufacturing of organic devices, but the issue of contact patterning remains. Solutions offered for this problem include the use of ink-jet printing21,27,28 or chemical processes involving orthogonal solvents,29 but the low resolution and need of hazardous chemicals limit their adoption and scalability to an industrial setting.

Herein we introduce a method for contact deposition and patterning—aerosol spray laser lithography—which involves pattern definition using laser printer toner and electrode deposition by aerosol jet. We demonstrate its compatibility with several solution-deposited electrode materials with a remarkable tolerance to bending and folding, and then successfully apply it to fabricate all-printed organic thin-film transistor (OTFT) devices on paper. The method has several clear advantages. First, it uses an aerosol to spray-coat the contacts, thus eliminating the need for metal evaporation. Second, the patterning is done via a lithography method that utilizes a laser printer and conventional toner to design the pattern. This allows for making many different geometries (sizes and shapes) possible, with no necessity for changes in the physical infrastructure and without requiring the pre-fabrication of masks or stamps. Third, it is cost-effective, scalable, and suitable for integration with roll-to-roll manufacturing. Lastly, as the processing conditions do not exceed 155 °C, it is compatible with flexible substrates such as paper or plastic. These attributes make the process both environmentally friendly and cost-effective.

Results

Contact deposition and pattering

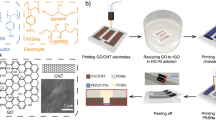

The aerosol spray laser lithography process is summarized in Fig. 1. Depending on the sequence of the processing steps and the chemistry of the conductor spray, the toner can define either a negative or positive mask, as detailed below. To obtain the patterned electrodes, we first printed a circle of black toner onto a printer paper, placed a thin sheet of a polymer layer over it, and secured it with Kapton tape. The polymer was either mylar or Etnom (by Chemplex), and played the role of the dielectric in the organic field-effect transistor devices. This stack was passed through the laser printer using a blank printed image and the heat generated by the fusing roller in the laser printer promoted the lamination of the polymer layer on the paper. For the negative lithography (Fig. 1a–d), we printed the desired pattern onto the substrate from a laser printer toner and then sprayed the conductor onto the substrate (Fig. 1a), allowing it to cure on a hotplate between each layer. It is noteworthy that the pattern can be defined using any design software and its resolution is given by the specifications of the laser printer used, as well as the particle size of the conductive ink and the laser toner. We then placed the substrate, pattern side up, onto a hotplate set to 155 °C and covered it with an aluminum foil. This step softened the toner, making it tacky. An aluminum cylinder acted as a transfer roller to gently roll the foil off (Fig. 1b). Next, the aluminum foil was peeled off (Fig. 1c). As the adhesion of the toner on the polymer is weaker compared with that of the electrode spray, this process resulted in removal of the areas covered with the toner pattern, leaving behind a pattern of contacts on the mylar (Fig. 1d). A single pass was generally sufficient for transfer. For the positive lithography process (Fig. 1e–h), the complementary image of the contacts was printed on the substrate using standard toner and the conductor was sprayed on top (Fig. 1e). After curing the conductor using a material-specific temperature (Fig. 1f), the substrate was soaked in acetone to release off-contact areas (Fig. 1g). The patterned electrodes are schematically depicted in Fig. 1h. The aerosol spray laser lithography method was tested using three different commercially available sprayable conductors: graphite (Bonderite L-GP by Henkel), nickel (841AR by MGChemicals), and silver (842AR by MGChemicals).

Aerosol spray lithography process. a–d Negative lithography. a Print the negative pattern of the contacts with standard toner (shown here in cyan), then spray on layer of aerosol conductor (shown here as metal ink). b Heat substrate at 65 °C to cure the conductive layer; increase the temperature to 155 °C and apply pressure onto aluminum foil and roll with cylinder. c Remove aluminum foil while on hotplate at 155 °C. d Reveal contact pattern on dielectric material. e–h Positive lithography. e Print positive of contacts with standard toner (shown here in cyan), then spray on layer of aerosol conductor (shown here as metal ink). f Heat substrate at 65 °C to cure conductive layer. g Soak in acetone to release off-contact areas. h Reveal contact pattern

An optical microscopy image of a sprayed silver electrode array on a 3 inch paper/mylar stack substrate is shown in Fig. 2a, whereas in Fig. 2b, c we include both low-magnification and high-magnification scanning electron microscopy (SEM) images of the contacts. These images confirm that the paper, mylar, and electrode layers maintained a good mechanical contact throughout the processing steps, but the edge and the surface of the of the contacts has a roughness on the order of several micrometers. This could be a potential drawback of the proposed method, but fortunately it can be minimized with fine tuning the toner removal step and we are actively pursuing this task.

Optical (left, a) and scanning electron (right b, c) microscopy images of aerosol spray lithography contact patterns. The scale bar in b corresponds to 200 μm; the scale bar in c corresponds to 10 μm. The device has a channel length of 200 μm. The contacts are defined by a positive toner mask and a coat of silver conductive spray. This device was printed on a piece of standard printer paper

Electrical properties of aerosol-sprayed contacts defined by laser lithography

Prior to incorporation in devices, we evaluated the electrical properties of the contacts processed via the aerosol spray laser lithography and their tolerance to folding. In Fig. 3 we include the sheet resistances of the graphite, nickel, and silver films as a function of number of layers. The reduction in resistance (increase in conductance) is a consequence of a more continuous and uniform film resulting from a larger number of layers. The obtained values agree well with previous reports on similar sprayable inks.30,31,32 A clear advantage of electronics on paper is its portability resulting from its low weight and the reduction of footprint upon folding. To test the mechanical robustness to bending, we evaluated the relative change in electrode resistance upon repeated folding and unfolding cycles; the results for graphite and silver are displayed in Fig. 4 for the inward (black) and outward (red) bend over a bending radius of 3.25 mm. We could not complete this test with the Nickel-based spray as the dried film would crack and no longer conduct when stressed. The resistance of the graphite electrodes decreased by 85% after 300 cycles, probably as graphite flakes assumed a more compact and laminar arrangement. On the contrary, the silver electrodes become 150% more resistive, most likely due to strain and some fractures generated in the films. These changes, although not negligible, are smaller than what has been previously observed for electrodes on paper, in spite of the very small bending radius.33,34,35

OTFTs with contacts patterned by laser lithography

The resilience of our samples to layer delamination, significant cracking, or other catastrophic changes provided robust perspectives for incorporation in flexible printed electronics. To confirm the process compatibility of the aerosol-spray laser lithography method with device fabrication, where multiple layers are necessary, we used it in defining the source and drain electrodes of OTFTs. We fabricated transistors on a paper substrate with two different device configurations: bottom-gate, bottom-contact and bottom-gate, top-contact.36 The bottom-contact OTFTs were achieved by spray coating the mylar gate dielectric with a metallic gate electrode layer prior to fusing it to paper, and defining the source and drain electrodes using aerosol spray laser lithography. We created a grid of transistor devices with channel lengths ranging from ~70–280 µm, at the surface of the paper/mylar substrate. A SEM image taken on one of the devices with the shortest channel lengths is shown in the Supplementary Information, Supplementary Fig. 1. The debris present in the channel results from inefficient lift-off during the patterning process and further optimization of this step will result in the enhancement of device properties by reducing the leakage currents and scattering at the semiconductor/dielectric interface. The OSC layer was 2,7-dioctyl[1]benzothieno[3,2-b][1]benzothiophene (C8-BTBT), a material that is extensively used in the literature because of its good environmental stability and excellent performance.37,38 C8-BTBT has a melting point of 130 °C and therefore melts in the fusing roller of an office laser printer without needing any modifications in its construction.39 By covering the device with a powder of C8-BTBT we then fused the C8-BTBT to the device in a bottom-gate, bottom-contact orientation by sending the paper through the laser printer fusing roller, which resulted in melting of the semiconductor layer, followed by recrystallization after exiting the paper feed of the printer. This deposition is in fact a simplified version of the laser-printing technique for OSC devices that we developed recently, and was adopted here with no further optimization.16 Figure 5a illustrates the device geometry, whereas in Fig. 5b we show the dependence of the source–drain current (ID) on the drain-source voltage (VDS) for different gate-source voltages, VGS, confirming the p-type transport in this material. Using the current–voltage dependence in the transfer curve of Fig. 5c, the device parameters were calculated, resulting in a mobility µ = 0.02 cm2 V−1 s−1, a current on/off ratio of 1.6 × 105, and threshold voltage VT = −8.8 V. The average mobility obtained on 25 devices was µavg = 0.04 ± 0.04 cm2 V−1 s−1. The modest values for the device properties may be impacted by high surface roughness of the contacts, as discussed earlier, and the relatively large contact resistance of RC = 20 kΩm, as calculated from the gated-transmission line method (TLM). In addition, we recognize that there is an energetic barrier at injection as a result of the mismatch between the work function of the graphite electrode and the highest-occupied molecular orbital (HOMO) level of C8-BTBT. Using a Kelvin probe equilibrated to the contact potential of highly ordered pyrolitic graphite (HOPG ϕ = 4.48 eV) we determined that the graphite aerosol has a work function of −4.53 eV,36 as reference (the HOMO level of C8-BTBT is −5.45 eV).40,41 Other factors responsible for reduced performance include the fact that the OSC and the gate layer were not patterned, which resulted in significant leakage currents in our devices.

I–V characteristics for a C8-BTBT semiconductor, mylar dielectric graphite spray device. a Schematic of bottom-gate, bottom-contact device on paper. Here, OSC is C8-BTBT, dielectric is mylar, and the source, drain, and gate are graphite. b Transport curves. The lines are colored by the voltage applied at the gate as the source–drain voltage is modulated. c Transfer curve for this device. The left y axis shows the square root of the drain current, the right y axis shows the drain current plotted on a logarithmic scale in blue with a VDS of −50 V

The aerosol spray laser lithography method is not restricted to the bottom-contact geometry. Top-contact OTFTs were fabricated by using silver spray on an Etnom film by first printing the contact pattern using conventional laser toner, but this time as a positive pattern. The silver was sprayed on top of the toner and then the contacts were developed by soaking and rinsing in acetone, as seen in Fig. 1 e–h. The areas of silver that were in contact with the Etnom released from the dielectric, leaving behind the silver patterned on the toner. The Etnom film, now with contacts, was removed from the carrier paper, which served as a temporary substrate, and flipped onto a previously prepared bottom-gate of sprayed nickel with the polymer dielectric. C8-BTBT was then melted on as the semiconductor. Figure 6a shows the device structure, with silver serving the role of the top source/drain electrodes. In Fig. 6b we include the transport curve showing the drain current dependence on VDS with varying VGS, and the transfer characteristics are shown in Fig. 6c. The mobility was µ = 0.02 cm2 V−1 s−1 with a current on/off ratio of 1.2 × 105 and VT = −25 V. The average mobility obtained upon testing 50 devices was 0.02 ± 0.01 cm2 V−1 s−1 and the threshold voltages ranged from VT = −8 V to −30 V.

I–V characteristics for a C8-BTBT semiconductor, Etnom dielectric silver spray device. a Schematic of bottom-gate, top-contact device on paper. Here, OSC is C8-BTBT, dielectric is Etnom, and the source, drain, and gate are silver. b Transport curves. The lines are colored by the voltage applied at the gate as the source–drain voltage is modulated. c Transfer curve for this device. The left y axis shows the square root of the drain current, the right axis shows the drain current plotted on a logarithmic scale in blue with a VDS of −100 V

We have shown that the aerosol spray lithography can be effectively used for defining and depositing contacts with lateral contact separation of minimum 70 μm. This channel dimension is rather large for commercial applications and several routes can be pursued in parallel to reduce it. The resolution is given by the composition of the conductive inks, the nature of the toner particles, and the instrumentation used in printing. Reducing the sprayable ink particle size (both of the conductive particles and the filler materials used for improving their cohesion) and/or designing a toner with smaller grains would allow the definition of smaller features in the printed pattern. Our printer was limited to a 600 × 600 dpi resolution, which equates to a diameter of ~40 μm for each dot. This feature size is in agreement with our minimum channel dimmension. However, with a 1200 × 1200 dpi standard office printer one would be able to print channel widths of 20 μm and with a professional printer specified at 9600 dpi the resolution can become as low as 3 μm, if a perfect alignment of the dots and small toner particle size are reached.

Discussion

In summary, we introduced a device electrode-manufacturing method using aerosol spray for deposition and a laser toner for patterning. The aerosol spray laser lithography process is performed at ambient temperature and pressure, making this method low-cost, easily scalable to a manufacturing level, and compatible with any substrate types. We adopted it for the fabrication of all-printed OTFTs on commercially available paper, with no additional treatment, and discussed its compatibility with different device structures. Our results provide an example of the use of laser printing for contact definition and expand the library of electronic devices on paper available to date,42,43,44,45,46,47 while also providing additional advantages such as reduced complexity processing and high-throughput, versatile electrode design. The method was successfully adopted for manufacturing different types of electrode materials (graphite, silver, and nickel), which showed an excellent tolerance to extreme bending, confirming its potential for emerging printed electronics applications.

Methods

Characterization of the contacts

The SEM images were obtained using a JEOL JSM6330F Scanning Electron Microscope. The instrument was operated at an accelerating voltage of 10 kV. Sheet resistance was determined using van der Pauw, four-point measurements. Electrodes were placed at the four corners of square coupons of half-inch side lengths, which were cut out of larger samples. An Agilent 4155C Semiconductor Parameter Analyzer was configured to apply current through two adjacent electrodes, while measuring the voltage across the opposite electrodes. The pairs of active electrodes were programmatically switched to address each combination of four sides as well as reversing the direction of the injected current, resulting in a total of eight current/voltage measurements per coupon. The bend tests were accomplished using a home-made apparatus capable of clamping a sample between two electrodes separated by a gap of 10 cm. The samples were cut into half-inch strips from a larger sheet. An aluminum rod of radius 3.25 mm was placed in the middle, wrapped in insulating Kapton tape, and gently held in position with an elastic cord. The apparatus was hinged in the middle, allowing the two halves to rotate 180° about the rod using a computer-controlled servo motor. After each folding event, the resistance was measured using a Keithley 2200-30-5 Programmable Power Supply by applying a fixed voltage and measuring the resulting current.

Device fabrication

After cleaning a 3 inch diameter circle of 2.5 µm-thick mylar with isopropyl alcohol, we sprayed graphite onto one side of the mylar to form the gate electrode of the device. The graphite aerosol spray, Bonderite L-GP, was purchased from Ted Pella and the mylar was manufactured by Chemplex; other solvents were purchased from Sigma Aldrich. We sprayed three layers of graphite, allowing the it to cure on a hotplate at 65 °C between sprays. To adhere the graphite gate on mylar to the paper, we printed a circle of black toner onto printer paper and taped the substrate, gate side down to this paper. The gate electrode was not patterned and, although this reduces the complexity of processing by removing the need of alignement of subsequent layers, it will contribute to the leackage currents through the parasitic effects that it introduces. To be able access the gate for characterization, we placed a 1 inch piece of Cu tape underneath the mylar sheet (in contact with the sprayed graphyte). By sending the mylar/paper stack through the laser printer, we fused the graphite side of the mylar to the black toner on the paper, causing it to adhere to the paper. The laser printer used for patterning contacts was a Brother HL-2270D with black toner. This method defined source/drain electrodes for OTFTs with channel-width dimensions limited only by the resolution of the laser printer, which in this case was as low as 70 μm. A laser printer with 600 dpi resolution, such as the one used in this study, is quoted to produce lines on the order of 40 μm; however, variability in software and hardware makes this minimum line width fluctuate from printer to printer.48

To pattern the source and drain contacts, we printed a grid of a desired contact device pattern onto the mylar (Fig. 1a). The toner grid is intended to define the channels and the blank space the contacts. We then sprayed graphite spray onto the substrate from a distance of ~50 cm. To get full coverage, we sprayed three layers. The substrate was kept on a hotplate set to 65 °C in between each spray to allow the graphite to cure. We then used a piece of aluminum foil, which was smoothed out with a Kimwipe, as the transfer material. We placed the substrate with the toner grid facing up onto a hotplate set to 155 °C (Fig. 1b), placed the aluminum foil on top of the substrate, and applied pressure by rolling a 1.6 kg aluminum cylinder over the substrate to allow the aluminum foil to stick to the parts of the grid where we had printed the channels. By applying pressure to the foil by hand with Kimwipe on the hotplate, and using the cylinder to roll the foil off smoothly, we could remove the areas where toner was present underneath the graphite (Fig. 1c), leaving behind a pattern of graphite contacts on the mylar dielectric. Heating the substrate to 155 °C allowed the toner to selectively adhere to the aluminum foil rather than the mylar, so we could remove the areas in which toner was applied to the mylar. The final device structure was a bottom-gate, bottom-contact device, printed onto paper (Fig. 1d).

A positive toner pattern was also used in which the source and drain contacts were defined by the areas of printed toner, whereas all blank areas were channels and off-contact. Here, Etnom was used as the dielectric film and silver as the conductive spray (Fig. 1e–h). The bottom-gate conductor was applied as above. In this case, we also demonstrated the ability to apply top contacts by patterning on a second Etnom film. The toner was printed in the positive pattern followed by spraying three coats of silver (Fig. 1e) with 65 °C heat applied by hotplate in between coats to aid in drying and curing (Fig. 1f). Instead of using the peel-off method, the film was soaked in acetone, which released the silver from the Etnom, but the silver-coated toner areas remained adhered (Fig. 1g). This resulted in silver contacts on top of toner (Fig. 1h) with which the film could be laminated contacts side down on a layer of semiconductor to create top source and drain contacts (Fig. 6).

OTFT characterization

To measure the I–V characteristics of the OTFTs with graphite aerosol spray lithography defined contacts, we used the Agilent 4155 Semiconductor Parameter Analyzer in ambient air. The saturation mobility μ was calculated from the transfer characteristics with a VDS of −50 V using the equation:

in which ID is the drain current, W is the channel width, L is the channel length, Ci is the areal capacitance of the dielectric, VGS is the gate-source voltage, and VT is the threshold voltage calculated by determining the x-axis intercept of the \(I_D^{1/2}\) curve. The contact resistance was calculated using the TLM method.49 The work function was measured using a Kelvin Probe with respect to the work function of ϕ = 4.48 eV for HOPG.

Data availability

The experimental data referenced in this text is available from the authors upon reasonable request.

References

Arias, A. C., MacKenzie, J. D., McCulloch, I., Rivnay, J. & Salleo, A. Materials and applications for large area electronics: solution-based approaches. Chem. Rev. 110, 3–24 (2010).

Khodagholy, D. et al. In vivo recordings of brain activity using organic transistors. Nat. Commun. 4, 1575 (2013).

Pierre, A., Gaikwad, A. & Arias, A. C. Charge-integrating organic heterojunction phototransistors for wide-dynamic-range image sensors. Nat. Photonics 11, 193–199 (2017).

Park, S. et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 561, 516–521 (2018).

Tee, B. C.-K. et al. A skin-inspired organic digital mechanoreceptor. Science 350, 313–316 (2015).

Lochner, C. M., Khan, Y., Pierre, A. & Arias, A. C. All-organic optoelectronic sensor for pulse oximetry. Nat. Commun. 5, 5745 (2014).

Klauk, H. Organic thin-film transistors. Chem. Soc. Rev. 39, 2643–2666 (2010).

Gundlach, D. J. et al. Contact-induced crystallinity for high-performance soluble acene-based transistors and circuits. Nat. Mater. 7, 216–221 (2008).

Sirringhaus, H. 25th Anniversary article: organic field-effect transistors: the path beyond amorphous silicon. Adv. Mater. 26, 1319–1335 (2014).

Minemawari, H. et al. Inkjet printing of single-crystal films. Nature 475, 364–367 (2011).

Klauk, H. et al. High-mobility polymer gate dielectric pentacene thin film transistors. J. Appl. Phys. 92, 5259–5263 (2002).

Park, S. K., Jackson, T. N., Anthony, J. E. & Mourey, D. A. High mobility solution processed 6,13-bis(triisopropyl-silylethynyl) pentacene organic thin film transistors. Appl. Phys. Lett. 91, 063514 (2007).

Azarova, N. A. et al. Fabrication of organic thin-film transistors by spray-deposition for low-cost, large-area electronics. Org. Electron. 11, 1960–1965 (2010).

Sowade, E. et al. All-inkjet-printed thin-film transistors: manufacturing process reliability by root cause analysis. Sci. Rep. 6, 33490 (2016).

Niazi, M. R. et al. Solution-printed organic semiconductor blends exhibiting transport properties on par with single crystals. Nat. Commun. 6, 8598 (2015).

Diemer, P. J. et al. Laser-Printed Organic Thin-Film Transistors. Adv. Mater. Technol. 2, 1700167 (2017). https://doi.org/10.1002/admt.201700167

Du, J., Pei, S., Ma, L. & Cheng, H.-M. 25th Anniversary article: carbon nanotube- and graphene-based transparent conductive films for optoelectronic devices. Adv. Mater. 26, 1958–1991 (2014).

Liu, Z. et al. Transparent conductive electrodes from graphene/PEDOT:PSS hybrid inks for ultrathin organic photodetectors. Adv. Mater. 27, 669–675 (2015).

Secor, E. B., Prabhumirashi, P. L., Puntambekar, K., Geier, M. L. & Hersam, M. C. Inkjet printing of high conductivity, flexible graphene patterns. J. Phys. Chem. Lett. 4, 1347–1351 (2013).

Zhang, L. et al. Inkjet printing high-resolution, large-area graphene patterns by coffee-ring lithography. Adv. Mater. 24, 436–440 (2012).

Hyun, W. J. et al. All-printed, foldable organic thin-film transistors on glassine paper. Adv. Mater. 27, 7058–7064 (2015).

Wöbkenberg, P. H. et al. Reduced graphene oxide electrodes for large area organic electronics. Adv. Mater. 23, 1558–1562 (2011).

Leem, D.-S. et al. Micron-scale patterning of high conductivity poly(3,4-ethylendioxythiophene):poly(styrenesulfonate) for organic field-effect transistors. Org. Electron. 11, 1307–1312 (2010).

Hiraoka, M. et al. On-substrate synthesis of molecular conductor films and circuits. Adv. Mater. 19, 3248–3251 (2007).

Georgakopoulos, S. et al. Spray-coated contacts from an organic charge transfer complex solution for organic field-effect transistors. Org. Electron. 48, 365–370 (2017).

Takahashi, Y. et al. Tuning of electron injections for n-type organic transistor based on charge-transfer compounds. Appl. Phys. Lett. 86, 063504 (2005).

Ha, J. et al. One-step interface engineering for all-inkjet-printed, all-organic components in transparent, flexible transistors and inverters: polymer binding. ACS Appl. Mater. Interfaces 9, 8819–8829 (2017).

Sirringhaus, H. et al. High-resolution inkjet printing of all-polymer transistor circuits. Science 290, 2123–2126 (2000).

Zhang, S. et al. Water stability and orthogonal patterning of flexible micro-electrochemical transistors on plastic. J. Mater. Chem. C. 4, 1382–1385 (2016).

Voigt, M. M. et al. Polymer field-effect transistors fabricated by the sequential gravure printing of polythiophene, two insulator layers, and a metal ink gate. Adv. Funct. Mater. 20, 239–246 (2010).

Blake, P. et al. Graphene based liquid crystal device. Nano Lett. 8, 1704 (2008).

Black, K. et al. Silver ink formulations for sinter-free printing of conductive films. Sci. Rep. 6, 1–7 (2016).

Siegel, A. C. et al. Foldable printed circuit boards on paper substrates. Adv. Funct. Mater. 20, 28–35 (2010).

Tai, Y.-L. & Yang, Z.-G. Fabrication of paper-based conductive patterns for flexible electronics by direct-writing. J. Mater. Chem. 21, 5938 (2011).

Yang, C. et al. Silver nanowires: from scalable synthesis to recyclable foldable electronics. Adv. Mater. 23, 3052–3056 (2011).

Lamport, Z. A., Haneef, H. F., Anand, S., Waldrip, M. & Jurchescu, O. D. Tutorial: organic field-effect transistors: materials, structure and operation. J. Appl. Phys. 124, 071101 (2018).

Liu, C. et al. Solution-processable organic single crystals with bandlike transport in field-effect transistors. Adv. Mater. 23, 523–526 (2011).

Kumatani, A. et al. Solution-processed, self-organized organic single crystal arrays with controlled crystal orientation. Sci. Rep. 2, 393 (2012).

Matsushima, T., Sandanayaka, A. S. D., Esaki, Y., Adachi, C. & Sitter, H. Vacuum-and-solvent-free fabrication of organic semiconductor layers for field-effect transistors. Sci. Rep. 5, 14547 (2015).

Zhu, M. et al. Effect of a MoO3 buffer layer between C8-BTBT and Co(100) single-crystal film. RSC Adv. 6, 112403–112408 (2016).

Lyu, L. et al. Orientation-dependent energy level alignment and film growth of 2,7-diocty[1]benzothieno[3,2-b]benzothiophene (C8-BTBT) on HOPG. J. Chem. Phys. 144, 034701 (2016).

Eder, F. et al. Organic electronics on paper. Appl. Phys. Lett. 84, 2673–2675 (2004).

Zschieschang, U. & Klauk, H. Low-voltage organic transistors with steep subthreshold slope fabricated on commercially available paper. Org. Electron. 25, 340–344 (2015).

Zschieschang, U. et al. Organic electronics on banknotes. Adv. Mater. 23, 654–658 (2011).

Lessing, J. et al. Inkjet printing of conductive inks with high lateral resolution on omniphobic “RF paper” for paper-based electronics and MEMS. Adv. Mater. 26, 4677–4682 (2014).

Kim, D.-H. et al. Ultrathin silicon circuits with strain-isolation layers and mesh layouts for high-performance electronics on fabric, vinyl, leather, and paper. Adv. Mater. 21, 3703–3707 (2009).

Thiemann, S. et al. Cellulose-based ionogels for paper electronics. Adv. Funct. Mater. 24, 625–634 (2014).

Saito, G. et al. in Multifunctional Conducting Molecular Materials 237–301 (Royal Society of Chemistry, 2007).

Luan, S. & Neudeck, G. W. An experimental study of the source/drain parasitic resistance effects in amorphous silicon thin film transistors. J. Appl. Phys. 72, 766–772 (1992).

Acknowledgements

This work was supported by the National Science Foundation under award CMMI-1537080. We thank Dr. Corey Hewitt from Wake Forest University Center for Nanotechnology and Molecular Materials for assistance with the SEM measurements.

Author information

Authors and Affiliations

Contributions

P.J.D. and O.D.J. designed and planned the project. A.F.H. and P.D.J. fabricated and characterized the samples, analyzed the data, and prepared the figures. All authors contributed to writing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Harper, A.F., Diemer, P.J. & Jurchescu, O.D. Contact patterning by laser printing for flexible electronics on paper. npj Flex Electron 3, 11 (2019). https://doi.org/10.1038/s41528-019-0055-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-019-0055-3

This article is cited by

-

Pressure-constrained sonication activation of flexible printed metal circuit

Nature Communications (2024)

-

Liquid metal-based paper electronics: Materials, methods, and applications

Science China Technological Sciences (2023)