Abstract

Numerous studies have aimed to improve the mechanical flexibility of thin-film encapsulation, a key obstacle in commercializing wearable organic light-emitting diodes (OLEDs). This study develops a silbione-blended organic/inorganic hybrid epoxy polymer (hybrimer) with high toughness as an organic barrier to enhance the flexibility of organic-inorganic multi-barriers. The optimal silbione-blended hybrimer (SBH) films exhibit superior mechanical properties, including increased elongation and tensile strength, compared to the hybrimer. The 3.5-dyad SBH-based encapsulation achieves a water vapor transmission rate of 7.83 × 10−6 g/m2/day and 9.45 × 10−5 g/m2/day before and after bending at a strain of 2%, respectively. In addition, the SBH barrier effectively protects the inorganic barrier by forming a robust aluminate phase at the interface between the inorganic and organic barrier, even under harsh conditions of 85 °C/85% relative humidity, demonstrating its potential for wearable applications. As a result, SBH-based encapsulations offer mechanical and environmental stability, making them ideal for wearable OLEDs.

Similar content being viewed by others

Introduction

The fourth industrial revolution encompasses several key components, including artificial intelligence, the Internet of Things (IoTs), cloud computing, big data, and mobile technology. Among these, the IoTs can foster a hyperconnected society, allowing users to remotely control interconnected objects. Furthermore, objects can independently analyze and learn information, enhancing user convenience. As electronic devices increasingly integrate with the human body, the need for flexible displays that can accommodate various shapes and movements is rising1,2,3,4. Flexible organic light-emitting diodes (OLEDs) that can be bent, folded, or rolled up are gaining market interest, necessitating the enhancement of their mechanical flexibility. Thin-film encapsulation (TFE) technology, crucial for OLEDs, poses considerable challenges to achieving this flexibility5,6,7,8,9,10,11,12. Therefore, advanced thin-film encapsulation technologies that can provide high-performance gas-diffusion barriers and excellent mechanical characteristics are considered critical for commercializing next-generation OLEDs, including wearable and stretchable OLEDs.

Wearable displays that can be worn or attached to the body present a higher growth potential than foldable displays13,14,15. Wearable displays are highly effective platforms for leveraging various content and functions. This new class of displays extends beyond traditional devices, such as TVs, phones, and monitors, to include fiber-based displays that can be worn on the body and biocompatible-based biomedical wearable displays that can be attached to or implanted in the body16,17,18,19,20,21,22. Especially, commercializing highly reliable wearable OLEDs depends on advanced multifunctional encapsulation technology, which is considered a key enabling technology. This encapsulation must have gas barrier and flexibility properties as well as exceptional waterproofing for underwater use, maintaining stability in harsh environments23,24,25,26. Various organic-inorganic encapsulation technologies have been reported for wearable OLEDs; however, prior techniques have focused on improving the mechanical properties of brittle inorganic barriers or inserting a thick organic barrier into the encapsulation structure5,6,7,27. Consequently, these techniques either resulted in thick structures exceeding several micrometers, which reduces mechanical flexibility, or showed significant WVTR increases at bending strains near 1% due to limited improvement of brittle inorganic films. In addition, the low toughness of the organic barrier significantly deteriorates the barrier performance of encapsulation at mechanical strains exceeding 2%, making it challenging to meet the mechanical properties required for wearable devices5,28.

Key mechanical factors influencing the flexibility of hybrid organic-inorganic multilayer barriers include the neutral axis control, residual stress, elongation, and Young’s modulus2,6,28,29. However, no functional organic barriers comprehensively addressing these mechanical factors in encapsulation structures have been proposed. Han et al. studied highly flexible encapsulation structures and designed flexible OLEDs by applying buffer barriers to control the neutral axis28. However, they utilized brittle Al2O3 as the inorganic barrier, and no analysis was performed considering the physical properties of the organic barrier. Lee et al. developed a multilayer barrier with an elongation of 2.8% by structurally designing silane-based hybrid inorganic-organic polymers (silamers)2. However, they failed to examine changes in barrier performance regarding the water vapor transmission rate (WVTR) with respect to elongation or analyze the residual stress of the entire encapsulation structure. As such, recent studies on hybrid organic-inorganic multilayer barriers have focused on specific mechanical factors, failing to ensure the flexibility required for ultraflexible and wearable OLEDs. Therefore, we aimed to develop an organic barrier with a reduced crack driving force owing to high elongation and high Young’s modulus with long elastic behavior, as well as verify the effect of residual stress by calculating the residual stress and membrane force of the entire encapsulation structure.

The polymer blending technique is widely recognized for addressing the trade-off between Young’s modulus and elongation by mixing two polymers to improve overall mechanical properties30,31. Polymer blending can enhance mechanical properties by altering the polymer matrix, chemical structure, or degree of crosslinking. However, the range of materials that can be blended is limited by their miscibility. Most polymers are immiscible owing to differences in their spatial arrangement and chemical repulsion. Therefore, the selection of appropriate material combinations is critical for successful blending. Epoxy and elastomers are well-known examples of miscible material pairs and can compensate for each other’s weaknesses, making them effective blending materials32. Epoxy exhibits excellent heat, chemical, and corrosion resistance, electrical insulation, and mechanical properties, making it suitable as an organic layer in multilayer encapsulation structures. However, they are brittle and prone to failure under sudden or repeated mechanical stress. For instance, a hybrimer, an epoxy-based cycloaliphatic siloxane material, demonstrated brittleness under an elongation of 1.22% in freestanding tensile tests. Owing to their exceptional elasticity and high elongation, elastomers can enhance the mechanical properties of epoxy polymers. This study aimed to improve the flexibility of multilayer organic-inorganic encapsulation structures by increasing the degree of crosslinking of the organic layer by adding silbione, an elastic polymer, to the epoxy hybrid solution.

In this study, a mechanically and environmentally robust wearable encapsulation method was developed using a silbione-blended hybrimer (SBH). The developed encapsulation recorded a WVTR of 10−6 and 9.45 × 10−5 g/m2/day with a thickness of only 510 nm, without and with a 2% bending strain, respectively. In addition, by applying optimized encapsulation and adding an organic buffer layer for neutral axis control, the flexible OLED demonstrated robustness when applying a maximum effective strain of 3.29% to the top layer of the buffer, indicating its potential as a wearable, foldable OLED. Moreover, the textile-based wearable OLED with the developed encapsulation barrier demonstrated potential as a washable OLED by enabling long-term OLED operation underwater and high-strain conditions.

Results

Preparation and characteristics of silbione-blended hybrimers

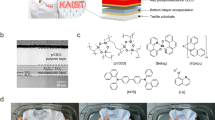

The inorganic layer of multi-barrier encapsulation is critical for moisture protection; however, it is extremely vulnerable to mechanical destruction when the barrier is subjected to an external bending strain. It has been widely reported that single inorganic layers demonstrate a critical strain of approximately 1%33,34,35. To address this problem, researchers have focused on improving the flexibility of inorganic layers6,27,28,36,37,38,39,40,41,42,43,44. In this study, we attempted to improve the flexibility of the barrier by focusing on improving the intrinsic mechanical properties of the organic barrier and chemical interface interactions between the inorganic and organic barriers. Among the polymers used as the organic layer of the sealing film, epoxy materials are highly compatible with elastomers. Therefore, we aimed to improve the mechanical performance by blending elastomers in an epoxy solution. A sol–gel-synthesized hybrimer was used as the epoxy material, with silbione as the elastomer (Fig. 1a). Since silbione has a density similar to that of the hybrimer, miscibility should be excellent. Polymer blending can change the chemical structure or crosslinking degree of the polymer matrix, and when mixed in an appropriate ratio, can improve the overall mechanical properties. Fig. 1b illustrates the cross-sectional transmission electron microscopy (TEM) and energy dispersive spectrometer (EDS) images of the SBH layer. The clear cross-sectional image without chemical aggregation demonstrates the excellent miscibility of silbione and hybrimer. The miscibility of the two substances is determined by the density, shape of the functional groups, polarity, viscosity, and glass transition temperature30. Epoxy and elastomers are representative pairs of materials with high miscibility owing to their similar densities. Therefore, the mechanical flexibility of the organic-inorganic multi-barrier was improved by utilizing a highly attractive organic layer, which was blended between silbione, with an extremely low Young’s modulus and high elongation, and a hybrimer, which provides remarkable heat resistance, electrical insulation, and chemical resistance. Fig. 1c shows the silbione-hybrimer blending process, which offers an improved degree of crosslinking compared to that achieved with a two-step crosslinking reaction. First, when the silbione elastomer is inserted into cycloaliphatic epoxy oligosiloxane and cured by UV light, only the epoxy material hardened through the crosslinking reaction, as illustrated in Fig. 1b. In the second step, the silbione elastomer is hardened via a heat polymerization reaction, improving the degree of crosslinking and increasing the number of crosslinking networks. In a structure with laminated organic and inorganic compounds, the highly crosslinked organic layer prevents crack formation in the brittle inorganic film, thereby improving the mechanical performance of the entire organic-inorganic multi-barrier.

Silbione gel 4717 was formed via a polyaddition reaction of 4717A and 4717B. When liquids 4717A and 4717B are mixed and placed close, different functional groups react and harden into a semi-solid state. In this chemical reaction, no additional activation energy is required; thus, the polymerization reaction progresses directly, even at room temperature. Cycloaliphatic epoxy oligosiloxane, a hybrimer component that exists as a nano-block before curing, could conduct the polymerization reaction under UV activation. Based on these results, a method was developed to address the different curing speeds of the hybrimer and silbione (Fig. 2a). First, Silbione 4717A and B were injected into the hybrimer solution and stored. To form a thin film, the two solutions are mixed and directly sprayed using a pipette during spin coating. The hybrimers are hardened through exposure to UV light for 120 s. Meanwhile, silbione gradually undergoes polymerization. The UV-cured thin film is stored inside a high-temperature chamber to completely cure the silbione. Finally, an SBH thin film with a crosslinked network is fabricated via a two-step curing reaction.

Figure 2b illustrates the glass transition temperature (Tg) of the SBH film as a function of the silbione concentration. Hybrimers possess a higher Tg than that of silbione. Therefore, blending films containing excessive silbione causes miscibility deterioration, causing phase separation and lowering Tg. Poor miscibility reduces the functionality of the hybrimer, which exhibits high barrier performance, good adhesion, and stable surface tension properties45,46. In the SBH film, with silbione concentration over 4 wt%, phase separation occurs and Tg decreases. Therefore, the optimal blending concentration that provides high functionality of silbione and hybrimer is 4 wt%.

The materials and mechanical properties of the SBH thin films were analyzed and compared with those of the individual polymer thin films. Figure 3a illustrates Young’s moduli of the hybrimer and SBH layers, measured using the nanoindentation method, at 9.75 ± 0.75 and 10.68 ± 0.81 MPa, respectively. The increase in Young’s modulus is attributed to the increased crosslinked networks inside the SBH.

Figure 3b illustrates the measured densities of the hybrimer, silbione, and SBH films as 1.51, 0.98, and 1.67 g/cm3, respectively. SBH has a higher density than hybrimer and silbione, indicating that the molecular network became denser and experienced volume shrinkage due to crosslinking during SBH formation.

Figure 3c illustrates the residual stress of the hybrimer and SBH. The hybrimer exhibits a compressive residual stress, whereas SBH exhibits a tensile residual stress. These results can be explained by the volume shrinkage results described earlier. As the volume of the polymer shrinks, SBH experiences physical stress that pulls it from both sides, changing the compressive residual stress to tensile residual stress.

Finally, Fig. 3d illustrates the Fourier transform infrared spectroscopy (FTIR) measurements of the hybrimer and SBH layers. The hybrimer shows a hydroxyl peak at 2900 cm−1, whereas the SBH shows no such peak. During polymerization, the hybrimer requires water molecules. UV irradiation provides the chemical energy for polymerization, enabling the polar nanoblocks of hybrimer to undergo cationic ring-opening polymerization. Water molecules are added to the polar nanoblocks to terminate the polymerization reaction. Water molecules, used as agents in the polymerization process, penetrate the epoxy and increase the volume of the polymer system. Therefore, the volume of hybrimer expands after polymerization. By contrast, the volume of SBH shrinks as crosslinking increases, preventing water molecules from penetrating the empty spaces between the networks of SBH. Hence, a hydroxyl peak is observed in the hybrimer, but not in SBH.

Gas barrier performances and mechanical properties of SBH-based multi-barrier

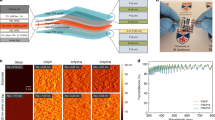

The WVTRs of various types of 3.5-dyad inorganic/organic multi-barriers were measured by changing the organic barriers (Fig. 4a and Table 1). To verify the mechanical factors affecting the mechanical properties of the multi-barrier, an organic barrier called a silamer was added and compared. A 30 nm thick Al2O3/ZnO nanolaminate film based on atomic layer deposition (ALD) was used as the inorganic barrier in all the multi-barriers. All multi-barriers using hybrimers, silamers, and SBHs demonstrate similar WVTR values of 7–8 × 10−6 g/m2/day, indicating that the performance of inorganic/organic multilayer barriers containing organic barriers is highly dependent on the WVTR of the inorganic barrier. Bending tests were then conducted to compare the flexibility of the multi-barriers according to the organic barrier. The 3.5-dyad multi-barrier with 120 nm thick SBHs (SBH-TFE) achieved a WVTR of 9.45 × 10−5 g/m2/day at a strain of 2%. This result is similar to the WVTR value of the multi-barrier that intentionally used a high-elongation silamer. The SBH-TFE, which is 510 nm thick, less than half that of the 1275 nm thick silamer-based multi-barrier, exhibits a similar level of flexibility. Additionally, we evaluated the mechanical properties to verify the mechanism that enhances the mechanical flexibility of the SBH-based TFE. To obtain the elastic modulus, elongation, and tensile strength, a tensile test on water (TOW) was performed to evaluate the mechanical behavior of the film without relying on the substrate (Fig. 4b)47,48. TOW can reliably measure the mechanical properties of a film by floating the film on water without a supporting substrate, utilizing the high surface tension of water. Figure 4c and Table 2 show the representative stress-strain curves and measured mechanical properties of the various organic barriers. The hybrimer and silamer single layers exhibit Young’s moduli of 1.46 and 0.02 GPa, and elongations of 1.216% and 8.75%, respectively. The Young’s modulus of the SBH is 1.54 GPa, similar to that of the hybrimer; however, the elongation increases to approximately 2.36% owing to the high elasticity of the silbione. Although the elastic modulus or elongation of SBH did not significantly differ from those of the hybrimer, its tensile strength is 9.66 MPa, which is slightly higher than that of the hybrimer (8.36 MPa), and considerably higher than that of silamer (1.60 MPa). Because the target strain of the encapsulation barrier in this study is 2–3%, which is the strain level required for foldable and wearable displays, we determined whether SBH exhibits sufficient strain for use as an organic barrier for multi-barriers. The analyses of the mechanical properties obtained through TOW show that SBH alleviates the driving force of cracks with a higher Young’s modulus, tensile strength, and elongation after blending. In particular, the mechanical properties of the SBH improved overall without any trade-off between the elastic modulus and elongation. Furthermore, the toughness of the SBH is 185.54 GPa, more than twice that of the hybrimer and silamer, recorded at 68.80 and 70.48 GPa, respectively (Fig. 4d). In other words, the SBH produced using the blending technique comprehensively improved the mechanical performance indices. The WVTR results before and after the bending test of the 3.5-dyad multi-barrier with each organic barrier are sufficiently explained by the measured mechanical properties. The multi-barrier using the SBH demonstrates the best results, even with the lowest total thickness, because of the high toughness of the SBH. In other words, because SBH has a higher toughness than the other two organic barriers, it exhibits similar mechanical properties despite its relatively small thickness. Compared to the encapsulation films reported thus far, the SBH-based TFE exhibits the best flexibility in terms of WVTR according to strain. Particularly, the WVTR range required for OLED encapsulation is 10−6–10−4 g/m2/day, and the SBH-based multi-barrier remarkably maintains the order of 10−5 g/m2/day at 2% bending strain.

a Water vapor transmission rate (WVTR) change according to bending strain in 3.5-dyad multi-barriers fabricated using hybrimer, silamer, and SBH as organic barriers. b Process for freestanding tensile testing of barrier samples on water. c Stress-strain curves and d calculated toughness of hybrimer, silamer, and SBH measured on tensile test on water (TOW). e Changes in WVTR of various encapsulation barriers as a function of bending strain. f Comparison of elongation of A/SBH, aged A/SBH, and (aged A)/SBH samples under 85 °C/85% RH for 10 h. g Schematic explaining improved environmental stability of Al2O3/SBH bilayer.

Additionally, we conducted comparative experiments to verify the environmental stability of the developed multi-barrier system. Fig. 4e presents the TOW results, demonstrating the capping effect of the SBH layer in an environment of 85 °C/85% relative humidity (RH). ALD-based Al2O3 films, known for their susceptibility to degradation in harsh environments but offering sufficient elongation, were used in the experiment. The SBH-coated Al2O3 sample (A/SBH) exhibited an elongation of 0.79 ± 0.05%, only slightly higher than that of the Al2O3 single layer (0.72%). Remarkably, after exposure to the 85 °C/85% RH environment for 10 h, the aged A/SBH structure maintains an elongation of 0.77 ± 0.02%, nearly identical to its pre-exposure value, confirming its superior environmental stability. To further validate this analysis, the (aged A)/SBH structure was evaluated, where the Al2O3 layer was environmentally aged prior to forming the SBH layer. Notably, the high-elongation SBH layer exhibits a minimal reduction in elongation under these conditions. The (aged A)/SBH structure, however, achieves an elongation of only 0.33 ± 0.06%, demonstrating a significant decrease in the overall barrier structure’s elongation. This protective effect is attributed to the formation of robust Al–O–Si bonds at the interface between Al2O3 and the SBH layer during silicification (Fig. 4f).

Reliability of flexible OLEDs encapsulated with ultraflexible TFE

The flexible OLED devices were fabricated in three steps. First, the PET (75 μm) to be used as the flexible substrate was cleaned. Subsequently, an SBH-TFE was formed as the bottom encapsulation on the PET substrate. Finally, the OLED devices and SBH-TFE layer were deposited. The OLED devices were deposited via thermal evaporation in a vacuum chamber at 7.0 × 10−6 Torr. Ag, which serves as an anode in red-emitting OLED devices, was first deposited. Molybdenum oxide (MoO3) served as the hole-injection layer, and N,N′-Di(1-naphthyl)-N,N′diphenyl-(1,1′biphenyl)-4,4′-diamine (NPB) served as the hole-transport layer. The emitting and electron transport layers were made of bis (10-hydroxybenzo [h] quinolinato) beryllium (Bebq2) doped with 8 wt% tris[1-phenylisoquinolinato-C2,N]iridium(III)(Ir(piq)3). 8-hydrosyquinolinolato-lithium(Liq) was used as the electron injection layer, and Al as the final cathode. The reliability of the encapsulation process was verified using a flexible RED OLED with the structure of Ag (30 nm)/MoO3 (5 nm)/NPB (68 nm)/Bebq2:Ir(piq)3 (70 nm)/Liq (1 nm)/Al (100 nm). Following the completion of the upper encapsulation, a buffer encapsulation layer (BEL) was laminated on the upper encapsulation layer to prevent scratches caused by physical damage and position the entire structure’s neutral axis on the OLED element (Fig. 5a). BEL is coated with a high-viscosity hybrimer solution with the solvent amount reduced to 1/10 of the previously used hybrimer barrier. The thickness optimization of BEL was calculated, as shown in Supplementary Figure 1. When the entire structure is divided into PET substrate, upper/lower encapsulation films, OLED elements, and BEL, the upper/lower encapsulation films form a symmetrical structure with respect to the OLED elements. Each component layer constituting the OLED element is thin compared to the PET substrate and BEL. Therefore, the effects of the encapsulation film and OLED element on the thickness calculation of the BEL are minimal. Consequently, the structure was simplified, and the neutral axis was determined to be on the PET substrate surface, with BEL placed on the PET substrate. The equation used is as follows:

When using the lower part of the PET substrate as the starting point, the height of the neutral axis is \(\bar{Y}\), and that of the substrate and BEL centers are \({y}_{1}\) and \({y}_{2}\), respectively; the product of \(\bar{Y}\) and the total area \(\sum {A}_{i}\) equals the sum of the product of the center height of each layer \({y}_{i}\) and area \({A}_{i}\). The Young’s modulus of the PET substrate and BEL is \({E}_{1}\) and \({E}_{2}\), respectively. The width of the BEL with respect to the width b of the substrate was set as \(\frac{{E}_{2}}{{E}_{1}}b\) to reflect the effect of the difference in Young’s modulus in the calculation. Calculations indicated a BEL thickness of 66.1 μm for the height \(\bar{Y}\) to become 75 μm, the surface height of PET. Therefore, an undiluted hybrimer of 66.1 μm thickness was formed on the upper encapsulation film using a bar coater. The BEL lowers the stress applied to the upper and lower encapsulation films by positioning the neutral axis on the OLED, enabling the OLED and encapsulation elements to withstand high strain. The J-V-L characteristics of the OLED device were measured sequentially after performing encapsulation, BEL, and bending tests (Fig. 5b, c). The J-V-L characteristics before and after applying the SBH-TFE remain consistent, confirming that the encapsulation process did not affect the electro-optical performance of the device. The OLED device with SBH-TFE/BEL structure also exhibits similar electro-optical characteristics. Finally, a bending test with a curvature radius of 2 mm was conducted on the OLED device encapsulated with SBH-TFE/BEL to verify flexibility and reliability. The strain at the top of the BEL reaches 3.29%. The J-V-L characteristics of the devices remain almost the same before and after the bending test, demonstrating significant improvements in the flexibility of the OLED device via neutral axis engineering. This was confirmed by emitting cell images of the device before and after the bending test. To verify the mechanical reliability of the flexible OLED, the lifetimes of the OLED devices subjected to TFE and bending tests were compared (Fig. 5d). Neutral axis engineering confirmed the long-term reliability of flexible OLEDs under a 3.29% strain, exceeding the 2% strain typically withstood by the encapsulation film. The device lifetime was determined by measuring the shelf lifetime of the encapsulated OLED devices and through bending tests at room temperature at regular intervals. The lifetime was measured at a luminance of 500 cd/m2. The unencapsulated OLED device has a short half-life of approximately 12 days; however, the OLED device encapsulated with an SBH-TFE maintained its luminance for 50 days. The encapsulated device with an additional BEL lamination on top also maintained its luminance for the same period. Moreover, the luminance is maintained for the same period after a 3.29% bending test on the encapsulated device. The results confirm that the multi-barrier encapsulation, including the BEL, can effectively protect the OLED device while maintaining reliability even under strain conditions exceeding 3%.

To demonstrate the commercial potential of wearable displays using SBH-TFE, we fabricated a practical fabric-based wearable OLED, as illustrated in Fig. 6a, and evaluated the waterproofing properties of the encapsulation barrier. A simple and highly reliable surface planarization process was developed to smooth the surface of the fiber substrate. CVD-based parylene-C, known for its eco-friendly and biocompatible properties, was selected for textile planarization. Parylene-C is ideal for replacing polymer substrates because of its controllable thickness and transparency. Furthermore, the adhesion between the substrate and thin film is insufficient for easy removal through hydrophobic treatment of the substrate surface. To ensure the stable debonding of parylene-C from the hydrophilic glass substrate, a hydrophobic film was first coated to make the glass surface hydrophobic, allowing for the stable detachment of parylene-C. The glass was coated with 3 M™ Novec™ 1700 solution, which forms a transparent film with excellent hydrophobic properties. Consequently, the glass surface became strongly hydrophobic, with a water contact angle (WCA) of 87°. Subsequently, a 1-μm-thick layer of parylene-C was applied. Next, Solaris, a Si-based elastomer that connects the parylene-C layer to the fabric, was formed with a thickness of approximately 10 μm. The fabric substrate was then attached and thermally cured under uniform pressure. The flattened fabric substrate was then peeled off from the glass substrate. The flattened fabric showed root-mean-square and peak-to-valley roughnesses of 0.48 and 4.54 nm, respectively, confirming effective planarization of the fabric substrate with microscale surface roughness (Supplementary Fig. 2). SBH and nanolaminate were alternately laminated on the flattened fabric to form a 3-dyad encapsulation as a bottom layer, and then a top-emission red OLED was fabricated. Finally, the top encapsulation layer was formed as a 3-dyad multi-barrier with the same structure as the bottom layer. Thus, a highly reliable wearable OLED was fabricated by applying fabric planarization and ultraflexible wearable encapsulation technologies.

a Fabrication process for a reliable wearable OLED. b Water contact angles of the hybrimer, silbione, and SBH layers. c Electrical characteristics of wearable OLEDs encapsulated with SBH-based multi-barrier exposed to water immersion and bending test. d Photograph of a wearable OLED operating stably in deionized water.

To create a waterproof encapsulation barrier for wearable devices, the outermost thin-film surface must exhibit hydrophobicity. The hydrophobicity of the SBH layer was assessed using WCA analysis. As illustrated in Fig. 6b, the SBH film has a WCA of 92.736°, indicating hydrophobicity, whereas the hybrimer surface is hydrophilic, with a WCA of 78.435°. Single-layer silbione exhibited an enhanced WCA of 117.825°. Moreover, the WCA of the SBH film increases proportionally with the amount of silbione blended into the hybrimer solution, confirming that the enhanced WCA of SBH results from silbione. Consequently, SBH serves as an effective organic barrier for achieving a highly hydrophobic waterproof encapsulation layer. The encapsulated wearable OLED operated stably after fabric planarization and maintained stable performance for over two weeks underwater (Fig. 6c). Additionally, it maintained electrical characteristics and electroluminescence spectra after 1000 folds at an extreme bending radius of 1 mm (Supplementary Fig. 3). As illustrated in Fig. 6d, the SBH-TFE exhibits almost no environmental degradation when exposed to water, and the encapsulated wearable OLED operates stably for a long time. In summary, we developed a high barrier, highly flexible, and highly water-resistant encapsulation through material design and applied it to wearable OLED, confirming the commercialization possibility of real wearable OLED.

Discussion

In conclusion, we presented a facile and effective method for mechanically flexible and environmentally friendly encapsulation by comparing organic and inorganic multilayered encapsulation structures based on various organic barriers. An SBH with exceptional toughness was developed as an organic barrier to improve the flexibility of organic-inorganic multi-barriers. Optimized SBH films demonstrated enhanced mechanical properties, including elongation and tensile strength, compared to those of hybrimers. The 3.5-dyad SBH-based encapsulation achieved a WVTR of 7.83 × 10−6 g/m2/day, remaining as low as 9.45 × 10−5 g/m2/day under 2% bending strain. The SBH barrier effectively protected the inorganic barrier by forming a robust aluminate phase at the interface under extreme conditions of 85 °C/85% RH, highlighting their suitability as wearable encapsulation materials. When integrated into OLEDs with thick BELs for neutral axis engineering, SBH-based encapsulations enabled ultraflexible OLEDs to sustain strains up to 3.29% while maintaining a stable luminance and lifespan. The exceptional mechanical and environmental stability makes SBH-based encapsulation a promising solution for realizing flexible and wearable OLEDs.

The SBH-TFE developed in this study demonstrates significant potential as a TFE technology for the commercialization of ultraflexible and wearable OLEDs. The encapsulation method presented here offers strong applicability for enabling wearable displays across various applications. However, additional functionalities need to be integrated into the proposed technology to make it suitable for real-world wearable display encapsulation. Future research will focus on advancing this technology by creating a multifunctional wearable encapsulation. This will involve embedding it in a highly stretchable epoxy polymer based on blending techniques and incorporating an inorganic barrier to protect against UV radiation and infrared (heat) from sunlight.

Methods

Material preparation

Sol–gel organic-inorganic hybrid nanocomposites (S-H nanocomposites) containing silica nanoparticles were prepared as reported in our previous study46. UV-curable cycloaliphatic epoxy hybrid materials synthesized by the sol–gel reaction between [2-(3,4-epoxycyclohexyl)ethyl]trimethoxysilane (ECTS) and diphenylsilanediol (DPSD) were stirred with Nanopox® E600 (Nanoresins, Germany) based on methyl-terminated silica nanoparticles dispersed in a reactive diluent of 3,4-epoxycyclohexyl methyl 3,4-epoxycyclohexane carboxylate. Arylsulfonium hexafluorophosphate salts used for photoinitiated polymerization were used as initiators. The viscosity was controlled by adding propylene glycol monoether acetate. We also investigated the effect of silica content on the average particle diameter and dispersion morphology of S-H nanocomposites. A 100% silica content with an average particle diameter of 19 nm was used for uniform dispersion in the oligosiloxane resin. S-H nanocomposites exhibited high transmittance and low WVTR values due to low light scattering and complex diffusion paths at high silica content, respectively.

Silbione® RT GEL 4717A&B is a two-component silicone elastomer that crosslinks at room temperature by polyaddition reaction. Polymerization can be accelerated by heating. Silicone is available as two low-viscosity liquid components that transform into elastic and durable gels when mixed and cured. Polymerization occurs without heat generation.

Fabrication of the encapsulation barrier

Inorganic and organic layers were stacked to form a 1-dyad multi-barrier structure. A 3.5-dyad multi-barrier using Al2O3/ZnO nanolaminate films as the inorganic layer was fabricated on a 75 μm-thick PET substrate. The inorganic layers were deposited at 70 °C via ALD. Trimethylaluminum (TMA) and dimethylzinc (DEZ) were selected as precursors for Al2O3 and ZnO, respectively. Deionized water was used as a reactant precursor, which reacted with TMA to form Al2O3 or DEZ to form ZnO. The deposition rates were measured to be 0.87 and 1.11 Å cycle−1 for Al2O3 and ZnO, respectively. A 3 nm thick Al2O3 and ZnO was cross-stacked to form a 30 nm thick nanolaminate inorganic layer. SBH as the organic layer was deposited by spin coating and then UV-cured with I-line UV light (λ = 365 nm, light power density = 20 mW/cm2) for 100 s. Additionally, it was stored in a 70 °C chamber for 20 min to cure silbione completely.

Fabrication of flexible OLEDs

Bottom-emitting OLEDs were fabricated on 75 μm PET substrates with a 3.5-dyad AZ (Al2O3/ZnO) multi-barrier coating. The following structures were used in these devices: Ag (30 nm)/MoO3 (5 nm)/NPB (68 nm)/Bebq2:Ir(piq)3 (70 nm)/Liq (1 nm)/Al (100 nm). The devices were fabricated by thermal evaporation, maintained at an average vacuum level of 1 × 10−6 Torr. A semitransparent Ag layer was used as the anode. MoO3 and NPB were used as the hole-injection and hole-transport layers, respectively. The emitting layer was co-injected with Bebq2 and Ir(piq)3 as 8% red-emitting dopants. Liq, together with the Al cathode, was used as the electron injection layer. A 3.5-dyad AZ multi-barrier was deposited on the device for OLED encapsulation.

Fabrication of textile-based wearable OLEDs

The fabrication process of the wearable OLED is described in detail in Results and Discussion. After performing a hydrophobic treatment on the surface of the guide glass, parylene-C was deposited using a parylene coater (OBT-PC300, OBANG TECHNOLOGY). The parylene-C powder was vaporized at 80–175 °C, and the resulting gaseous parylene dimer was pyrolyzed into a monomer at 680 °C. Subsequently, the Solaris elastomer was applied via spin coating, followed by thermal curing in a 70 °C chamber for 15 min under constant pressure. The fabric/parylene-C/Solaris composite was then stably peeled off the guide glass. Finally, the bottom encapsulation, red OLED, and top encapsulation layers were sequentially formed to complete the wearable OLED.

Freestanding tensile testing system

Thin films were fabricated on 1 mm-thick Cu-coated Si wafers. A femtosecond laser (Pharos, Light Conversion) was used to shape the films into dog bone specimens suitable for tensile testing. The laser was operated with a pulse duration of 230 fs and a repetition rate of 100 kHz. The stage was moved at a speed of 5 mm/s, and a 20× magnification objective lens was used. The laser output power varied between 5 and 15 mW. The patterned bone-shaped thin film samples were first immersed in water to ensure stable floating and then immediately transferred into a diluted (NH4)2S2O8 solution. After the Cu film was completely etched, the remaining barrier films were floated on the water again for tensile tests. The PDMS-coated aluminum grips were attached to the edges of each barrier specimen using van der Waals adhesion.

Characterization of the barrier films

Electrical Ca tests were performed for WVTR measurements49. A 100 nm thick Al layer, which was used as an electrode, was deposited on the glass via thermal evaporation. Subsequently, a 250 nm thick Ca layer was prepared. The Ca pad on the glass substrate has an area of 1.5 cm2. A 75 μm-thick PET was used as the substrate for the test sample barrier. The Ca pad was sealed with a test barrier-coating film using a UV-curable sealant (XNR5570-Ba; Nagase Chemtex, Japan) dispensed from a dispenser. All steps were implemented in a nitrogen-filled glove box. The Ca test was performed at 30 °C/90% RH. Resistance was measured using a four-point probe field system (Keithley 2750, USA) in a climate chamber. A spectrophotometer (UV-2550, Shimadzu, Japan) was used to measure light transmittance. Each encapsulation barrier was observed in detail using an HR-TEM (Tecnai F30 ST, FEI Company, USA). The J-V-L characteristics of the OLEDs were characterized using a spectrophotometer (CS-2000, Konica Minolta, Japan) and a source meter (Keithley 2400, USA). A lifetime test system (Polaronix M600, McScience, Korea) was used to record the lifetimes of the OLEDs. FTIR (Nicolet iN 10 MX, Thermo Scientific) measurements were conducted to identify the hydroxyl peaks of the hybrimer and SBH layers.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Yokota, T. et al. Ultraflexible organic photonic skin. Sci. Adv. 2, 1–9 (2016).

Lee, S. W. et al. Highly reliable and ultra-flexible wearable OLEDs enabled by environmentally and mechanically robust hybrid multibarrier encapsulation layers. Adv. Funct. Mater. 35, 2411802 (2025).

Choi, S. et al. Highly flexible and efficient fabric-based organic light-emitting devices for clothing-shaped wearable displays. Sci. Rep. 7, 1–8 (2017).

Wang, S., Oh, J. Y., Xu, J., Tran, H. & Bao, Z. Skin-inspired electronics: an emerging paradigm. Acc. Chem. Res. 51, 1033–1045 (2018).

Kwon, J. H. et al. Design of highly water resistant, impermeable, and flexible thin-film encapsulation based on inorganic/organic hybrid layers. ACS Appl. Mater. Interfaces 11, 3251–3261 (2019).

Kwon, J. H. et al. Functional design of highly robust and flexible thin-film encapsulation composed of quasi-perfect sublayers for transparent, flexible displays. ACS Appl. Mater. Interfaces 9, 43983–43992 (2017).

Oh, S. J. et al. Nanolaminate-induced mechanically and environmentally robust Al2O3/TiO2 thin film encapsulation by low-temperature atomic layer deposition: toward flexible and wearable OLEDs. Adv. Mater. Technol. 9, 2400381 (2024).

Lee, S. M., Kwon, J. H., Kwon, S. & Choi, K. C. A review of flexible OLEDs toward highly durable unusual displays. IEEE Trans. Electron Devices 64, 1922–1931 (2017).

Jeon, Y., Lee, H., Kim, H. & Kwon, J. H. A review of various attempts on multi-functional encapsulation technologies for the reliability of OLEDs. Micromachines 13, 1478 (2022).

Kwon, J. H. et al. Functional design of dielectric-metal-dielectric-based thin-film encapsulation with heat transfer and flexibility for flexible displays. ACS Appl. Mater. Interfaces 9, 27062–27072 (2017).

Kwon, J. H., Jeon, Y., Choi, S., Kim, H. & Choi, K. C. Synergistic gas diffusion multilayer architecture based on the nanolaminate and inorganic-organic hybrid organic layer. J. Inf. Disp. 0, 1–8 (2018).

Kwon, J. H., Jeon, Y. & Choi, K. C. Robust transparent and conductive gas diffusion multibarrier based on Mg- and Al-doped ZnO as indium tin oxide-free electrodes for organic electronics. ACS Appl. Mater. Interfaces 10, 32387–32396 (2018).

Choi, S. et al. Wearable photomedicine for neonatal jaundice treatment using blue organic light-emitting diodes (OLEDs): toward textile-based wearable phototherapeutics. Adv. Sci. 9, 1–10 (2022).

Kim, W. et al. Reliable actual fabric-based organic light-emitting diodes: toward a wearable display. Adv. Electron Mater. 2, 1–7 (2016).

Hwang, Y. H. et al. High-performance and reliable white organic light-emitting fibers for truly wearable textile displays. Adv. Sci. 9, 2104855 (2022).

Natali, M. et al. Engineering of keratin functionality for the realization of bendable all-biopolymeric micro-electrode array as humidity sensor. Biosens. Bioelectron. 141, 111480 (2019).

Prontera, C. T. et al. Fabrication and biocompatibility analysis of flexible organic light emitting diodes on poly(lactic acid) substrates: toward the development of greener bio-electronic devices. Polym. Adv. Technol. 33, 1523–1532 (2022).

Kong, D., Zhang, K., Tian, J., Yin, L. & Sheng, X. Biocompatible and biodegradable light-emitting materials and devices. Adv. Mater. Technol. 7, 2100006 (2022).

Keum, C. et al. A substrateless, flexible, and water-resistant organic light-emitting diode. Nat. Commun. 11, 1–9 (2020).

Kwon, S. et al. High luminance fiber-based polymer light-emitting devices by a dip-coating method. Adv. Electron Mater. 1, 1–8 (2015).

Woo Park, J., Kwon, S., Hyun Kwon, J., Young Kim, C. & Cheol Choi, K. Low-leakage fiber-based field-effect transistors with an Al2O3–MgO nanolaminate as gate insulator. ACS Appl. Electron Mater. 1, 1400–1407 (2019).

Sim, J. H. et al. OLED catheters for inner-body phototherapy: a case of type 2 diabetes mellitus improved via duodenal photobiomodulation. Sci. Adv. 9, 1–13 (2023).

Lee, S. et al. Study of mechanical degradation of freestanding ALD Al2O3 by a hygrothermal environment and a facile protective method for environmentally stable Al2O3: toward highly reliable wearable OLEDs. Mater. Horiz. 10, 4488–4500 (2023).

Nam, M. et al. Highly reliable and stretchable OLEDs based on facile patterning method: toward stretchable organic optoelectronic devices. npj Flex. Electron. 8, 17 (2024).

Natali, M. et al. Stable organic solar cells with enhanced efficiency built on sodium alginate. Adv. Sustain. Syst. 9, 2401026 (2025).

Kwon, J. H. et al. Low-temperature and corrosion-resistant gas diffusion multi-barrier with UV and heat rejection capability – a strategy to ensure reliability of organic electronics. ACS Appl. Mater. Interfaces 11, 16776–16784 (2019).

Jeong, S. Y. et al. Foldable and washable textile-based OLEDs with a multi-functional near-room-temperature encapsulation layer for smart e-textiles. npj Flex. Electron. 5, 15 (2021).

Han, Y. C. et al. Reliable thin-film encapsulation of flexible OLEDs and enhancing their bending characteristics through mechanical analysis. RSC Adv. 6, 40835–40843 (2016).

Jeon, Y. et al. Highly efficient and reliable organic light–emitting diodes enabled by a multifunctional hazy substrate for extreme environments. Adv. Funct. Mater. 34, 2310268 (2024).

Qi, S. et al. An EPDM/MVQ polymer blend based magnetorheological elastomer with good thermostability and mechanical performance. Soft Matter 14, 8521–8528 (2018).

Yu, M., Qi, S., Fu, J., Yang, P. A. & Zhu, M. Preparation and characterization of a novel magnetorheological elastomer based on polyurethane/epoxy resin IPNs matrix. Smart Mater. Struct. 24, 045009 (2015).

Varganici, C. D., Rosu, L., Rosu, D. & Simionescu, B. C. Miscibility studies of some semi-interpenetrating polymer networks based on an aromatic polyurethane and epoxy resin. Compos. B Eng. 50, 273–278 (2013).

Bulusu, A. et al. The mechanical behavior of ALD-polymer hybrid films under tensile strain. Adv. Eng. Mater. 17, 1057–1067 (2015).

Shin, S. M., Yoon, H. W., Jang, Y. S. & Hong, M. P. Stoichiometric silicon nitride thin films for gas barrier, with applications to flexible and stretchable OLED encapsulation. Appl. Phys. Lett. 118, 181901 (2021).

Kim, K. et al. Optimizing crack onset strain for silicon nitride/fluoropolymer nanolaminate barrier films. ACS Appl. Nano Mater. 2, 2525–2532 (2019).

Park, Y. C. et al. A highly bendable thin film encapsulation by the modulation of thermally induced interfacial residual stress. Appl. Surf. Sci. 598, 153874 (2022).

Chen, G. et al. Improved barrier and mechanical properties of Al2O3/acrylic laminates using rugged fluorocarbon layers for flexible encapsulation. Org. Electron. 97, 106263 (2021).

Kwon, B. H. et al. Organic/inorganic hybrid thin-film encapsulation using inkjet printing and PEALD for industrial large-area process suitability and flexible OLED application. ACS Appl. Mater. Interfaces 13, 55391–55402 (2021).

Shin, Y. J. et al. Stretchable Fabric Organic Light-Emitting Diodes Based on Transferable Laser Pattern for Wearable Photodiagnostic Applications. Adv. Fiber Mater. 7, 908–925 (2025).

Kim, E. et al. Thin film encapsulation for organic light emitting diodes using a multi-barrier composed of MgO prepared by atomic layer deposition and hybrid materials. Org. Electron. 14, 1737–1743 (2013).

Kwon, J. H., Jeon, Y., Choi, S., Kim, H. & Choi, K. C. Synergistic gas diffusion multilayer architecture based on the nanolaminate and inorganic-organic hybrid organic layer. J. Inf. Disp. 19, 135–142 (2018).

Kang, K. S., Jeong, S. Y., Jeong, E. G. & Choi, K. C. Reliable high temperature, high humidity flexible thin film encapsulation using Al2O3/MgO nanolaminates for flexible OLEDs. Nano Res. 12, 2716–2725 (2020).

Kim, Y. W. et al. Wearable quantum dots organic light-emitting diodes patch for high-power near infra-red photomedicene with real-time wavelength control. Chem. Eng. J. 499, 156121 (2024).

Jeong, S. Y. et al. Highly air-stable, flexible, and water-resistive 2D titanium carbide MXene-based RGB organic light-emitting diode displays for transparent free-form electronics. ACS Nano 17, 10353–10364 (2023).

Choi, G. M. et al. Flexible hard coating: glass-like wear resistant, yet plastic-like compliant, transparent protective coating for foldable displays. Adv. Mater. 29, 1700205 (2017).

Jin, J. et al. Silica nanoparticle-embedded sol-gel organic/inorganic hybrid nanocomposite for transparent OLED encapsulation. Org. Electron. 13, 53–57 (2012).

Oh, S. J., Lee, S., Choi, K. C., Kwon, J. H. & Kim, T. S. Elucidating the effect of Ag interlayer formation on the intrinsic mechanical properties of free-standing ITO/Ag/ITO thin films. J. Mater. Chem. C. 11, 7262–7271 (2023).

Oh, S. J., Kwon, J. H., Lee, S., Choi, K. C. & Kim, T. S. Unveiling the annealing-dependent mechanical properties of freestanding indium tin oxide thin films. ACS Appl. Mater. Interfaces 13, 16650–16659 (2021).

Carcia, P. F., McLean, R. S., Reilly, M. H., Groner, M. D. & George, S. M. Ca test of Al2O3 gas diffusion barriers grown by atomic layer deposition on polymers. Appl. Phys. Lett. 89, 031915 (2006).

Acknowledgements

This work was supported by the Technology Innovation Program (20017569, Development of substrate materials that can be stretched more than 50% for stretchable displays & 20018379, Development of high-reliability light-emitting fiber-based woven wearable displays) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea). This was also supported by the BK21 FOUR (Connected AI Education & Research Program for Industry and Society Innovation, KAIST EE, No. 4120200113769). In addition, this work was supported by the Technology Development Program (RS-2023-00270443 and RS-2024-00469790) funded by the Ministry of SMEs and Startups (MSS, Korea).

Author information

Authors and Affiliations

Contributions

K.S.K., S.Y.J., and Y.J. contributed equally to this work. K.S.K. and S.Y.J. mainly conducted the experiments and analyses, and prepared figures and the manuscript. Y.J. designed the research object and specific experimental methods. J.H.K. and K.C.C. analyzed the experimental data, organized the manuscript contents, and contributed to the manuscript completion.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kang, K.S., Jeong, S.Y., Jeon, Y. et al. Enhancing flexibility and reliability in wearable OLEDs through silbione-blended hybrimer-based encapsulation. npj Flex Electron 9, 49 (2025). https://doi.org/10.1038/s41528-025-00423-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-025-00423-6

This article is cited by

-

Highly efficient, reliable, and ultraflexible bio-organic light-emitting diode patch

npj Flexible Electronics (2025)