Abstract

This paper provides a comprehensive review of the research progress in paper-based flexible electronic devices, focusing on key aspects such as the physical and chemical properties of paper substrates, device structures, fabrication methods for electrodes and active layers, and their diverse applications. The paper also identifies current challenges facing paper-based electronic devices, such as issues related to long-term stability and the optimization of large-scale production processes.

Similar content being viewed by others

Introduction

In today’s era of digitalization and intelligence, electronic devices, as the key components for acquiring and processing information, are undergoing profound changes and innovations to meet the growing and diversified needs in various fields1. From environmental monitoring to medical diagnosis, from consumer electronics to industrial automation, the pursuit of electronic devices with high sensitivity, high stability, low cost and easy integration never stops2,3. Paper, as an ancient and widely used material, has gradually become an ideal substrate for the construction of new electronic devices by virtue of its unique physicochemical properties, such as lightweight, porous, biodegradable, flexible, and rich surface chemistry properties4,5,6. The emerging field of paper-based electronic devices, which not only inherits the advantages of paper, but also shows extraordinary application potential through the organic combination with modern electronic technology, opens up a completely new path for the development of electronic devices.

In the research scope of paper-based electronic devices, in-depth investigation of the physical and chemical properties of the paper substrate is the cornerstone. The precise control of its microstructure and macroscopic properties plays a crucial role in the construction of subsequent electronic functional components. As the core components, the optimization and innovation of the preparation process of electrodes and active layers are directly related to the electrical performance and stability of the devices7,8,9,10. By skillfully selecting materials and applying advanced preparation techniques, such as printing, deposition, and surface self-assembly method, researchers are committed to realizing the construction of high-performance electrodes and active layers, thus enhancing the overall performance of paper-based electronic devices. Further, based on the functional principle, paper-based electronic devices can be subdivided into various types, including paper-based mechanical sensors, electrochemical sensors, optical sensors, humidity sensors, photodetectors, and supercapacitors11,12. Each type of device plays a unique role in its specific application scenario, such as flexible mechanical sensors for human movement monitoring, electrochemical sensors for environmental contaminant detection and biomarker analysis, optical sensors for food safety and medical diagnostics, and humidity sensors for intelligent packaging and environmental humidity monitoring. Photodetectors are used for information acquisition in optical communication and optical sensing, and supercapacitors for portable energy storage13,14,15. These diverse applications fully demonstrate the ability of paper electronic devices to solve practical problems in different fields, attracting researchers around the world to optimize the preparation process and performance, which provide more innovative solutions for future smart life, green technology, and precision medicine16,17,18. In this paper, we will discuss in detail the physical and chemical properties of paper substrates, the structural classification of paper-based electronic devices, the preparation and integration of devices, and applications, aiming to sort out the current research status, analyze the existing challenges, and look forward to the future development direction.

Structure of the paper

Paper-based materials, with their unique physical and chemical structure properties, have become ideal substrates for flexible electronic devices. Specifically, the flexibility of paper-based materials gives flexible electronic devices excellent bending and tensile properties, the lightweight characteristics reduce the overall weight of the device, the porous nature of paper-based materials provides an effective channel for electron transport and material exchange, and the characteristics of the cut and print properties greatly enhance the flexibility and precision of the device design and fabrication19,20,21. In addition, the renewability of paper-based materials is in line with the concept of sustainable development, the easy modification and functionalization provide the possibility of device customization and multifunctionality, and the thermal and chemical stability ensures that the devices operate stably in a variety of complex environments22,23. Together, these characteristics constitute the unique advantages of paper-based materials in the field of flexible electronic devices and lay a solid foundation for their wide application in a variety of application scenarios.

Physical properties of the paper base

Paper-based materials show remarkable potential in the field of flexible electronics due to their excellent flexibility, low density and lightweight properties, and excellent biocompatibility. Their outstanding flexibility, i.e., the ability to withstand bending, folding, and even twisting without rupture or loss of structural integrity, makes paper-based an ideal substrate for building flexible electronic devices that require bending or folding applications24,25,26. For example, Marina Sala de Medeiros et al.27, in their 2020 study, successfully prepared a self-powered paper-based flexible electronic device that is not only lightweight and flexible, but even has the ability to be folded. Through 500 folding cycle tests, the resistance change rate is less than 2%, which fully verifies the stability and reliability of paper-based materials in maintaining the electrical performance of the device, which is mainly attributed to the excellent flexibility of paper. In addition, the porous structure of paper-based materials facilitates the permeation of gases and liquids, which is particularly critical in the construction of microfluidic devices. Under the capillary force of fiber cavities, paper can be used as a fluid transport channel without the need for an external power device28,29. In a study by Aoxun Liang et al.30 in 2024, a humidity sensor was successfully prepared by impregnating A4 paper with LiCl solution and combining carbon nanotube-carboxymethyl cellulose composite paper-based fiber. The sensor was able to accurately detect humidity over a relative humidity range of 33% to 98%, with a response time of only 500 ms and a linearity of R2 = 0.960. In terms of human health monitoring, this sensor can continuously monitor respiratory rate and amplitude, as well as non-contact sensing of the humidity status of body parts. These properties are achieved due to the loose porous structure of paper, which allows Li+ ions to easily adsorb water molecules from the air and ionize to generate H+ ions under the action of an electric field.

Another major advantage of paper-based materials is their easy cutting and printing properties, which makes paper-based extremely flexible in the design and fabrication of flexible electronic devices. Xiaoqian Liu et al.31, in their study in 2022, prepared an all-paper touch temperature sensor using direct-write technology. This sensor can be freely cut, folded, or reversibly deformed between two-dimensional and three-dimensional configurations without affecting device functionality. Similarly, Huashuo Ma et al.32 developed an editable flexible wood origami electronic device by combining a transparent wood film (TWF) substrate with cellulose-based conductive ink. This device possesses excellent flexibility, high tensile strength, and good electrical conductivity. It can output stable current signals when making origami and printing patterns of various geometrical shapes. These examples further prove the broad application prospects of paper-based materials in the design and fabrication of flexible electronic devices.

Chemical properties of the paper base

Paper-based materials, whose core constituent is cellulose, a natural polymer from plants with unique physicochemical properties, have significant potential in various applications. As the most abundant natural polymer, cellulose is a major structural component of plant cell walls and many microorganisms (e.g., fungi, bacteria, and algae)33,34. It consists of β-D-glucopyranose units linked by β-(1-4) glycosidic bonds35,36,37,38 (Fig. 1a, b). The good thermal and chemical stability, renewability, and biocompatibility exhibited by cellulose opens up a promising prospect for the application of paper-based materials in the field of flexible electronics, especially in medical and biotechnology39,40,41,42,43. In the cellulose molecular chain of paper-based materials, the presence of hydroxyl groups and other functional groups provides a wealth of chemically active sites that can react with a variety of chemical substances. This enables the customized adjustment of the chemical properties and functions of the materials. Through functionalization, paper-based materials can combine the inherent advantages of paper with the unique properties of modifiers, thereby expanding their application scope44,45,46,47. Specifically, in 2020, Mihut et al.48 successfully deposited silver and copper onto the surface of filter paper using a high-vacuum magnetron sputtering system at room temperature. This modification strategy significantly enhanced the antimicrobial properties of the filter paper and effectively inhibited the growth of common wastewater bacteria. Similarly, Guo et al.49 developed a new type of colorimetric test paper for metal ion detection through a surface esterification process. Guo et al. used esterification reactions to introduce acetoacetyl groups onto cellulose fibers, generating cellulose acetoacetate (CAA) fibers. Due to the excellent chelating ability of acetoacetyl groups for metal ions, the CAA paper shows obvious color changes when capturing Fe3+ and Cu2+. In addition, Zhang et al.50 infiltrated metal ions into lignin-containing cellulose nanopaper (LCNP). This method significantly enhanced the water resistance and optical properties of the lignocellulose nanopaper by constructing cross-linking interactions within the fiber network. This approach not only preserves the lightweight, flexibility, and renewability of the paper-based materials but also gives them a wider application potential, especially in applications requiring high water resistance and excellent optical properties.

a, b Schematic illustration of hierarchical fibril structure and morphologies of lignocellulose and schematics of the crystalline and disordered regions38.

General layout and processing technology of paper-based devices

Paper-based electronic devices can be divided into two categories based on their functional characteristics: electronic devices and optical devices, each of which exhibits a unique structural configuration and functional principle. As for optical devices, they are classified into colorimetric devices and fluorescent devices based on different optical response mechanisms. Colorimetric devices are based on the difference in light absorption properties of substances, through color changes to reflect the information to be measured or signal detection. Fluorescent devices rely on the fluorescence emission phenomenon of substances, through changes in fluorescence intensity or fluorescence wavelength migration to transmit and detect signals. Considering that electronic devices generally have complex device structures, the following will take electronic devices as an example to introduce the functional composition and device structure of different electronic devices, in order to facilitate the review of device preparation methods.

Electronic device structure

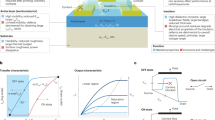

Within the realm of paper-based electronic devices, they can primarily be categorized into resistive, capacitive, photoelectric, field-effect transistor types and diode types. The structure of paper-based resistive electronic devices typically includes paper-based materials, conductive layers, electrode materials, resistive layers, and encapsulation layers. Paper-based resistive devices usually use paper as the substrate material, and conductive layers are formed on the paper through printing or coating methods. The electrode layer is generally composed of metallic materials or carbon-based materials with good electrical conductivity and stability. The resistive layer is usually achieved through the incorporation or coating of specific materials25,51,52. Paper-based resistive devices respond to external stimuli through changes in resistance. Their basic structure typically involves the integration of conductive materials with a paper substrate53 (Fig. 2a). This structural design allows the device to maintain the flexibility and lightweight nature of paper while achieving precise control over resistance changes52,54.

a Schematic illustration of the proposed all-paper-based flexible pressure sensor53. b Schematic representation of thick paper electrode supercapacitor55. c Schematic illustration of the fabrication process of paper-based WS2 photodetectors via abrading WS2 crystals and penciling graphite electrodes on paper substrates60. d Schematic illustration of paper-based POFET flash memory consisting of a trilayer gate dielectric structure and artificially-colored TEM image of the flash memory64. e The Device Structure of Paper-based OLEDs and their Luminescence at 5 V71.

Paper-based capacitive electronic devices use paper as the substrate, with the core structure being a parallel-plate capacitor configuration. The upper and lower electrode layers are made of flexible conductive materials. Between the two electrode layers is a dielectric layer, which can be selected from polymers (such as polyimide and polyvinyl alcohol) or dielectric structures modified from the paper itself (e.g., impregnated with dielectric liquid or coated with dielectric nanocomposite coatings). Some devices utilize the porous structure of the paper to fill in dielectric materials in order to optimize the dielectric constant. The entire structure is sealed with a polymer encapsulation layer. The electrode leads are connected using flexible conductive traces55 (Fig. 2b). The total thickness of the device is usually controlled within 50–150 μm to balance flexibility and capacitive performance55,56. The principle of capacitive electronic devices is mainly based on the charge storage mechanism of capacitors. A capacitor is an element capable of storing electrical charge. Its fundamental principle involves applying a voltage between two conductive plates, causing the accumulation of charge on the plates57.

Paper-based photoelectric electronic devices include a core functional layer, electrode layers, and an encapsulation layer. The core functional layer varies depending on the type of device. For example, in paper-based solar cells, a sandwich-like structure is adopted (Fig. 2c), which includes a light absorption layer (composed of organic semiconductor materials or perovskite materials) and electron/hole transport layers58. In paper-based photodetectors, the structure can be planar or vertical, containing a photosensitive layer (made of inorganic semiconductors or organic-inorganic hybrid materials)59,60. Photovoltaic devices are those that convert optical signals into electrical signals through the photoelectric effect. The photoelectric effect refers to the phenomenon where the irradiation of light onto the surface of a metal or semiconductor causes the emission or excitation of surface electrons. These excited electrons are known as photoelectrons. When the energy of a photon exceeds the bandgap width of the material, the photon can excite an electron from the valence band to the conduction band, thereby generating conductive electron-hole pairs61.

The typical representative of field-effect transistor-type electronic devices is the paper-based organic thin-film transistor (OTFTs). The structure of OTFTs uses paper as the flexible substrate, and from bottom to top, it integrates the gate electrode (such as aluminum, gold, or a conductive polymer layer), the gate insulating layer (using high-dielectric-constant organic/inorganic materials such as polyvinyl alcohol (PVA), polymethyl methacrylate (PMMA), or aluminum oxide (Al2O3)), the organic semiconductor layer (formed by solution-processable deposition of p-type or n-type materials such as pentacene or C60), and the source and drain electrodes (composed of metals or conductive polymers)62,63,64 (Fig. 2d). The core mechanism is essentially the dynamic regulation of the conductivity of the organic semiconductor channel by the electric field65,66,67.

The paper-based diode is a general term for various diode devices that use natural paper or modified paper as a flexible substrate. The basic structure of an OLED consists of a thin, transparent electrode layer and another metal cathode, forming a sandwich-like structure. The entire structural layer includes a hole transport layer (HTL), an emissive layer (EL), and an electron transport layer (ETL)68,69. In general, OLEDs need to be fabricated on smooth substrates. Smooth substrates help reduce surface defects and inhomogeneities, thereby improving the luminous efficiency and uniformity of the devices70. However, the rough surface structure of paper can lead to uneven film coverage and pinhole defects during device fabrication, which in turn affects the transport and recombination efficiency of carriers. Therefore, it is relatively rare to directly fabricate OLEDs on paper surfaces. To successfully fabricate diodes on paper, targeted surface treatment of the paper is required. For example, Teng Pan et al.71 fabricated a paper-based OLED for high-security anti-counterfeiting applications (Fig. 2e) by using dip-coating treatment and multi-material deposition on commercial paper. This OLED has excellent brightness (maximum brightness of 71,346 cd/m²), efficiency (maximum current efficiency of 64 cd/A), and a half-life of over 4000 h.

Preparation and Integration Methods

Although these devices follow very different physical mechanisms in their functional realization, they show some commonality in structural composition. As shown in Fig. 3. they all contain core components such as paper substrates, electrode materials and active materials. In view of the key role of these basic components in the device performance, the preparation process and integration technology of the electrode part and the active layer are particularly important and constitute the core issues in the research work. Specifically, the selection of electrode materials, structural design, as well as the synthesis of active layer materials, thin film deposition technology, etc., have a decisive impact on the overall performance of the device, so an in-depth study of these preparation and integration technologies is of vital significance to enhance the performance and application scope of paper-based electronic devices. In the selection of electrode materials, carbon family materials (e.g. carbon nanotubes, graphene, carbon black, etc.) are favored due to their excellent electrical conductivity and chemical stability72, at the same time, metallic materials (e.g. gold, silver, copper, etc.) are also widely used, in which gold electrodes are known for their excellent chemical stability and electrical conductivity73,74, silver electrodes are competitive due to their relatively low cost, and copper electrodes are of great interest due to their ease of processing75. As for the photoelectrically active materials, they cover a wide range of types such as carbon materials and their derivatives, metal oxide semiconductors (MOS), and organic materials76. The diverse integration methods of paper-based electronic devices and their structural commonalities provide a broad research space for the selection and preparation techniques of electrode materials and active materials.

The preparation and integration methods of paper-based electronic devices constitute a diversified and technology-intensive field, which mainly includes, but is not limited to, the following high-precision and high-efficiency preparation technologies: screen printing, inkjet printing, electrochemical deposition, vacuum filtration technology, drop casting, and water surface self-assembly method. Each of these technologies has its own unique advantages, and can be flexibly selected and combined according to the specific application requirements and performance indicators of the paper-based electronic devices, in order to achieve high performance, low cost and large-scale device preparation.

Screen printing

Screen printing has become a widely used method for preparing paper electronic devices because of its low cost, good pattern ability and suitable for mass production. The technology is based on precisely transferring ink containing conductive particles to a paper substrate through a screen template, and drying and curing to form conductive patterns. In 2011, Dungchai et al.77 used solid wax-based screen printing technology to prepare paper-based microfluidic channels. They rubbed solid wax onto a filter paper substrate through a nylon silk mesh and then melted the wax by heating it, allowing it to permeate the paper substrate and form a hydrophobic barrier. Since then, the application of screen printing methods in paper electronic products has become increasingly popular among researchers. (Fig. 4a). Compared with photolithography, the paper-based microfluidic channel prepared by screen printing has a lower background signal, which is convenient for qualitative and semi-quantitative paper-based colorimetric analysis. Thinikan Thongkam78 screen-printed an epoxy resin solution with an optimized concentration onto filter paper to form hydrophobic patterns. This process enabled the development of a simple and low-cost 3D paper-based analysis device (3D PAD) for detecting soil available phosphate (Fig. 4b), which exhibits high reproducibility, separability, and stability. The developed PAD shows excellent tolerance to common acids, bases, and organic solvents. Jaruwan Mettakoonpitak et al.79 prepared a paper-based chip using an acetone solution of polycaprolactone (PCL) as a printing ink for the quantification of the important metal Cr3+ and the essential anion Cl-. The chip achieved patterning resolution with hydrophilic channels measuring 510 ± 40 μm and hydrophobic edges measuring 490 ± 30 μm. Compared with the other polymer ink, the proposed PCL screen-printed chip achieves approximately 33.3-fold enhancement in the average resolution of hydrophilic channels and hydrophobic edges. Mazzaracchio et al.80 prepared a paper-based electrochemical sensor (Fig. 4c) for detecting iron ions in serum. They used graphite conductive ink for screen printing to create the working electrode and counter electrode. The detection limit for iron ions using the Square Wave Voltammetry (SWV) method is as low as 0.05 mg/L. Sun et al.81 used conductive carbon paste as the screen-printing ink to prepare two sets of working electrodes and counter electrodes. Silver/silver chloride ink was used to prepare reference electrodes for constructing a multifunctional self-driven origami-type paper-based microfluidic chip for detecting C-reactive protein (CRP) and prealbumin (PAB) in whole blood (Fig. 4d). The device diverts blood samples separated by plasma separation membranes to the surface of the two sets of working and counter electrodes via capillary force, enabling aptamer-based electrochemical detection of CRP and antibody-based electrochemical detection of PAB. Nair et al.82 prepared paper-based organic electrochemical transistor (OECT) biosensors by screen-printing an OECT on paper with the ability to detect halide ions (Fig. 4e). Paper-based OECTs provide a versatile and cost-effective platform for customizable electronic applications and have the potential to be used in disposable devices. This innovative approach offers a new direction for developing recyclable and biodegradable printed OECTs.

a Constructing paper-based hydrophobic barriers using solid wax-based screen printing technology77. b Procedure for making PAD in one step using screen printing method78. c Screen-printed paper-based electrochemical sensor for detection of iron ion in serum80. d Screen-printed origami paper-based electrochemical chip for detection of C-reactive protein and prealbumin in whole blood81. e Screen-printed OECT based on paper substrate82.

Screen-printed paper-based electrodes can realize diverse pattern designs and can be applied to a variety of electrode composites, which helps to prepare electrode systems with different styles and functions, based on which paper-based electrochemical sensors can be constructed with good specific recognition performance, stability and sensitivity. At present, in the field of paper-based electronic devices, exploring new high-performance, green and environmentally friendly screen-printed electrode materials to further improve the accuracy, sensitivity, and stability of paper-based electrodes is the future direction of development. At the same time, the multifunctionality of the electrode materials needs to be considered in order to expand the scope of its application and better meet the application needs.

Inkjet printing

Inkjet printing is another promising technique for the fabrication of paper-based electronic devices, which allows for the fine design of pattern structures by precisely controlling the position and number of ink droplet jets and shows great potential in the preparation of paper-based electronic devices83. Xu et al.84 developed paper-based electronic devices using an alkyl vinyl ketone dimer-heptane solution as inkjet ink to create hydrophilic and hydrophobic patterns on paper in 2010. Since then, inkjet printing has attracted researchers’ interests, especially in the preparation of paper-based electronic devices, due to its advantages of low cost, high speed, digital control, ease of operation, and low ink consumption. Kento Maejima et al.85 used an EPSON PX-101 inkjet printer to print UV-curable acrylic ink onto untreated filter paper surfaces, forming microfluidic structural patterns in less than 5 min. After UV curing for 60 s, a hydrophobic barrier was formed, enabling sensitive detection of H2O. The printed patterns retained their aqueous liquid orientation for at least 6 months at room temperature and for at least 72 h at 50 °C. Yafeng Deng et al.86 developed an all-inkjet printing method by mixing three kinds of fluorescent carbon dots (R-CDs, B-CDs, Y-CDs) (Fig. 5a). They explored hydrophilic and hydrophobic ink formulations suitable for inkjet printing. The resulting sensor can be used to detect vitamin C (AA), NO2-, and sunset yellow (SY), achieving good visual detection results. Yanqi Li et al.87 developed a novel paper-based colorimetric sensor array (Fig. 5b) by inkjet printing pH indicators onto MCE paper using a PEG 400 immobilization system. This method allows for direct pH detection with relatively high resolution due to the precise control of droplet technology and inkjet printing. Compared to other colorimetric-based pH sensors, this sensor array provides a fast, microliter, inexpensive, and accurate method for detecting the pH of normally colorless aqueous solutions. Binghuan Zhang88 prepared an inkjet-printed cellulose-based biosensor (IPB) by printing a cellulose-based carbon electrode (PCE) on A4 cellulose paper using an Epson R330 inkjet printer (Fig. 5c). They found that the IPB performed better than a drop-coated cellulose paper-based biosensor (DPB). The IPB’s response current in the detection range (0–10 mM) was twice that of the DPB. The faster electron transfer rate, flexibility, and repeatability make it an ideal glucose sensor, establishing a new high-performance and biodegradable platform for future single-use glucose detection technologies in daily life.

While the preparation of electronic devices on paper substrates using inkjet printing offers significant advantages, it also faces challenges such as substrate limitations, conductivity issues, and process complexity. For example, different types of substrates may affect print quality and electrode performance. Additionally, a variety of conductive inks, such as silver nanoparticles, graphene, and PEDOT:PSS, have stability and dispersion issues that limit their application. Moreover, inkjet printing requires precise control of ink jet characteristics and post-processing to achieve the desired performance.

Direct drawing method

Preparation of electrode patterns by drawing directly on paper with a pencil is a simple and economical method for paper-based electronic devices. This method is based on the fact that the graphite material in the pencil core has good electrical conductivity, and the electrodes can be formed by directly drawing the desired electrode patterns on the paper. Specifically, the pencil core is mainly composed of a mixture of graphite, clay and wax, of which graphite is the key component for electrical conductivity89. When a pencil is used to draw on paper, graphite particles adhere to the surface of the paper and are embedded in the fiber structure of the paper. As the drawing process proceeds, the graphite particles form continuous conductive paths on the paper90. In the early days, Li et al.91 prepared micro-supercapacitors by using medical tape as a flexible and stretchable substrate, using MnO2 as an active material, and drawing with the pencils, since then, direct pencil drawing on paper has become a common method for preparing paper-based electrodes due to its low cost, simplicity, and fairly good conductivity obtained. For example, Sabina Yeasmin et al.92 prepared an all-solid-state supercapacitor (SCs) by applying 8B pencil on A4 paper as electrodes and modified paper-based graphite (GP) electrodes with polyaniline nanofibers (Fig. 6a). This SCs now exhibits excellent electrochemical performance and linear variation of the surface resistance of the graphite layer drawn by the pencil with distance (Fig. 6b). Danielly S. Rocha et al.93 developed a new electrochemical paper-based analytical device (ePAD) (Fig. 6c) by rubbing a graphite pencil directly against the surface of sandpaper for the square-wave voltametric measurement of midazolam maleate used as a “date-rape drug” in beverages. This ePAD provides high accuracy for midazolam maleate, used as a “date rape drug” in beverages. At 95% confidence level, there was no statistical difference from the data recorded by High Performance Liquid Chromatography (HPLC).

a Schematic diagram of preparation of electrodes and fabrication of all-solid-state SCs and (b) variation of resistance with distance on the GP electrode surface92. c The layout of the electrode (left) and the electrical contacts and reference electrode coated with silver ink are drawn in pencil on the sandpaper substrate (right)93.

In conclusion, the direct mapping method has significant advantages. It is low cost, easy to handle, environmentally degradable, and requires no complex equipment or processes94. Moreover, due to the flexibility of paper, the electrodes are also flexible and suitable for the preparation of various flexible electronic devices. However, the roughness and non-uniformity of the paper surface may lead to differences in the conductivity of the electrodes. Furthermore, the limited precision of pencil drawing may not meet the preparation requirements for certain high-precision electrodes. Overall, the pencil-on-paper drawing method for electrode preparation is a simple and practical method for a variety of low-cost, low-precision electrode preparation requirements.

Electrochemical deposition

Electrochemical deposition is a technique in which a material is deposited on a conductive substrate by an electrochemical reaction to prepare a film or coating95. Electrochemical deposition usually involves an electrolytic cell containing an electrolyte solution, an anode and a cathode. In the presence of an electric current, ions in the electrolyte solution undergo a redox reaction on the surface of the electrodes, resulting in the deposition of the desired material formed96. In the case of paper substrates, they need to be made electrically conductive first, then they can be used as cathodes or anodes for electrochemical deposition97. Compared to other electrode preparation methods, the electrochemical deposition method does not require expensive equipment and complex processes, and the production cost is low. Moreover, the electrochemical deposition method is able to control the deposition thickness to form a good bond between the deposited layer and the conductor, which helps to improve the performance of the electrode98,99. However, electrodeposition does face two key issues: the dependence of electrodeposition on the conductive substrate and the controllable electrodeposition area. To solve this problem, one approach is to first electrodeposit the desired metal pattern on a conductive substrate, incorporate photolithography, and then transfer it to an insulating substrate100,101. Another approach is to first form patterned conductive channels on the insulating substrate by chemical plating, and then electrodeposit them to form a continuous metal film102,103. However, these methods either increase the complexity of the process or involve environmentally unfriendly chemicals, which limits their application. On this basis, Xuanzhang Li et al.104 proposed a new transverse electrodeposition method called “CCB edge-guided metal transverse electrodeposition (EG-MLED)”. In this method, an electroactivated carbon patterned layer is sprayed onto the substrate surface to effectively guide the rapid deposition of copper ions on the insulating substrate (Fig. 7a). This EG-MLED method eliminates the dependence of conventional electroplating on conductive substrates and is particularly suitable for the preparation of metal films on insulating substrates (cellulose paper) with complex surface structures (Fig. 7b), and paper-based light-emitting diode and photodetector devices prepared using this method demonstrate potential applications in flexible electronics.

a Schematic of the patterned metal film prepared by EG-MLED on CCB template. b Paper-based LED device prepared by EG-MLED104.

Laser induction

Laser-induced graphene (LIG) is a simple one-step low-cost method for producing graphene and designing devices directly on carbon-based substrates. Under laser irradiation, the carbon-hydrogen bonds on the surface are cleaved and SP3 carbon atoms are converted to SP2 carbon atoms through a photothermal conversion process. As a result, LIG consists of a network of conductive porous interconnections with a high surface area for enhanced electrochemical performance and charge transport. In addition, LIG is formed directly on the substrate, simplifying the device fabrication process as it can be used as both a collector and an active material105,106,107,108. In the early days, Zang et al.109 produced conductive molybdenum carbury-graphene (MCG) composites directly on the paper substrate, and since then, the generation of LIG on the surface of the paper and the simultaneous realization of accurate cutting of the paper and clever construction of the device have been extensively studied. For example, Maykel dos Santos Klem et al.110 prepared MSC (micro-supercapacitors) with high energy density by preparing LIG electrodes on a wax-coated paper substrate and electrodepositing MnO2 on the LIG (Fig. 8a). Upon laser heating, paper cellulose fibers were transformed into highly porous LIG structures, increasing the area available for MnO2 deposition, and MSCs with a capacitance of 86.9 mF cm−2 could be produced by tuning the laser parameters and deposition time. Rodrigo Abreu et al.111 laser processed paper fibers embedded with MnOx precursor converted to graphene to form MnOx-LIG to obtain MnOx-LIG-MSC (Fig. 8b). Since MnOₓ can promote pseudo-capacitive charge storage to increase the overall capacitance, and LIG has unique porous and conductive properties that provide a favorable substrate for efficient charge transport, the obtained MnOx - LIG-MSCs have high specific capacitance, high energy density, and good cycling and electrochemical stability. Tomá s Pinheiro et al.112 achieved photothermal conversion to porous laser-induced graphene (LIG) on paper through appropriate chemical treatment using sodium tetraborate as a flame retardant (Fig. 8c). In addition, by manipulating the operating parameters of the laser, they have created a high-throughput, easy-to-adapt disposable electrochemical sensor, a low-cost material and manufacturing technique with potential applications in bioelectronics and wearable devices.

In conclusion, applications in the field of paper-based microfluidics and wearable devices are promising, but the requirements for laser equipment are relatively stringent, the operation process is relatively complex, and precise control of the laser parameters is required to ensure that the quality and homogeneity of the active layer are optimized113,114,115,116. In addition, during the laser induction process, some by-products may be generated, which may adversely affect the performance of the active layer117,118. Therefore, in practical applications, it is necessary to further optimize the laser parameters and improve the subsequent treatment process to minimize the influence of by-products and ensure the performance and stability of the devices.

Drop casting

Drop casting is a simple method for preparing paper-based electronic device films without the need for complex equipment. The basic principles include the preparation of liquid precursors, the formation and deposition of droplets, and the curing and forming of films. Each of these steps in the process has a decisive impact on the quality and performance of the final film. The drop-casting method can realize high-precision and high-uniformity film preparation by precisely controlling the volume and deposition position of droplets, and is especially suitable for the fabrication of small-area and complex-structure films, with higher flexibility and process controllability. In recent years, the drop-casting method has been favored by researchers due to its simplicity and speed. For example, Christopher J. Valentine et al.119 drop-cast CNT suspensions into laser-cut electrode areas in multiple steps to build a series of different conductive networks in paper (Fig. 9a). By defining this geometry, CNT suspensions can be simply drop-cast onto paper without the need for additional patterning methods (e.g., inkjet printing or screen printing) to define the electrode regions. Papamatthaiou et al.120 drop-cast graphene ink to form a transistor channel, and immobilized a PNA probe onto the graphene channel to prepare an electrolyte-gated field effect transistor (FET) biosensors (Fig. 9b) for selective detection of complementary DNA sequences. The results showed that FET sensors have the potential to be effortlessly integrated into Lab-on-PCB diagnostic platforms, promising to further reduce the time for DNA amplification and detection modules.

In summary, drop-coating is easy to manipulate but can lead to inhomogeneous deposition and limited control over the thickness of the active layer. Drip-casting method for preparing the active layer on paper substrate has the advantages of easy operation and lower cost, but it also has the disadvantages of difficulty in controling the film quality, weak bonding between the active layer and the paper substrate, and difficulty in preparing large-area homogeneous films.

Vacuum filtration

Vacuum filtration is an effective method for preparing thin films for paper-based electronic devices, which is easy to operate and master, and can prepare uniform and dense films. It is suitable for the preparation of a variety of electronic materials, such as conductive polymers, nanoparticles and so on. The basic principle is to use a vacuum pump to generate negative pressure, so that the solution or dispersion through the filter membrane, the solvent in the solution or dispersed media pumped out, while the solute or dispersed material is deposited on the filter membrane to form a thin film. In the preparation of paper-based electronic devices, this method is commonly used in such as conductive polymers, nanoparticles uniformly deposited on the paper substrate to form a film with a specific function. In the early stage, Wu Z et al.121 deposited carbon nanotubes on the filter membrane by vacuum filtration method to prepare carbon nanotube films, which had excellent electrical conductivity and light transmission (Fig. 10a). Since then, the vacuum filtration method has been increasingly applied to the preparation of paper-based electronic devices. For example, Kanyawan Ponlamuangdee et al.122 modified ordinary laboratory filter paper with the cationic poly (diallyldimethylammonium chloride) (PDADMAC) and used a simple vacuum filtration method to develop a paper-based Surface enhanced Raman scattering (SERS) substrate (Fig. 10b) for the detection of pesticides, including paraquat, diquat, thiophanate and parathion. This substrate exhibited excellent inter-spot reproducibility with a relative standard deviation (RSD) of 5.03% and low detection limits of 0.51 μM (0.13 ppm) for paraquat and 0.38 μM (0.09 ppm) for thiophanate. Ru Chen et al.123 prepared composite films based on whisker-carbon nanotubes (w-CNTs) by vacuum filtration using Triton-100 as a surfactant (Fig. 10c). The films obtained by this method have uniform and dense surfaces, and w-CNT exhibits excellent electrothermal properties due to the more complete and higher crystallinity of the w-CNT structure. Tuoyi Su et al.124 prepared MXene (Ti3C2Tx)/Bacterial cellulose (BC) film by mixing MXene and BC with a mass ratio of 1:4 and vacuum filtration (Fig. 10d). MXene can be used as a binder to provide film-forming ability and improve the conductive ability of the film due to its multiple chemical bonds. In addition, BC expands the layer spacing of MXene nanosheets and increases the mechanical strength of the material by combining adjacent nanosheets, so that the film exhibits great flexibility and foldability.

In summary, vacuum filtration for preparing active layers on paper substrates offers advantages such as high efficiency, scalability, high material utilization, and controllable preparation processes. However, there is a risk of clogging, which can affect filtration efficiency and layer quality, potentially leading to unstable performance and incomplete filtration. Additionally, the adhesion between the active layer prepared by vacuum filtration and the paper substrate may be weak, necessitating subsequent treatment to enhance bonding. Therefore, this technology presents both potential and challenges. Optimizing filtration conditions and improving processes can further enhance the quality and performance of the active layer, providing strong support for the development of paper-based electronic devices.

Surface self-assembly method

The water surface self-assembly method involves two steps, first, self-assembly on the water surface using the intermolecular interaction forces of the nano-dispersion to form an ordered layer of nano-film, then, this layer of already self-assembled nano-film is transferred from the initial water surface to another target substrate for further application or treatment of the film. This approach combines the advantages of both self-assembly and film transfer techniques and provides a new way to prepare high-quality, ordered-structured films. However, the self-assembly process of nanofilms on aqueous interfaces still faces several challenges and dilemmas that hinder the successful preparation of desirable films. Therefore, it is crucial to optimize and refine the preparation process of self-assembled thin films. In recent years, extensive and in-depth research has been conducted in academia on preparing thin films via self-assembly strategies using water surfaces as templates. This research aims to overcome existing limitations and promote technological advancement and application expansion in this field. For example, Shan Li et al.125 first employed an ethanol-assisted carbon material suspension, which was skillfully applied on top of the water surface by the spraying technique. They also adjusted the position of the sprayer in order to ensure the homogeneity of the resulting film. Immediately thereafter, the siphoning effect of the microporous sponge was utilized to effectively remove the water, a process that not only significantly reduced the area of the film, but also facilitated the tight alignment of the film’s internal structure. Through the above steps, they successfully prepared a uniformly spread carbon nanotube (CNT) film, which was then further transferred onto a polydimethylsiloxane (PDMS) substrate (Fig. 11a). Notably, because the film was prepared in a free-support environment, it is highly transferable and can be easily transferred to other substrate materials such as paper without compromising its original properties. This discovery not only broadens the application scope of self-assembled films, but also provides new ideas and strategies for the development of high-performance and multifunctional film materials. Wei Zhou et al.126 prepared graphene/carbon sphere films (GCH) by self-assembling on the water surface. They then sprayed Ecoflex on them to increase the mechanical flexibility of the films to form graphene/carbon sphere/Ecoflex elastic films (GCEF) (Fig. 11b). Finally, leveraging the free-supporting nature of the liquid substrate, they easily transferred the GCEF to a PET substrate. Similarly, the GCEF prepared by this method can also be transferred to a paper substrate while retaining its original properties, due to its free-supporting nature. Shuai Wang et al.127 prepared a graphene film (GF) by spraying a graphene-ethanol dispersion onto a water surface using a self-assembly method. The GF was then transferred onto an Ecoflex film/PET substrate using a lift-and-transfer method. Subsequently, an additional Ecoflex layer was spin-coated to create a sandwich-structured a-G@E sensor (Fig. 11c). The free-standing film prepared by this method not only enhances the mechanical flexibility of the film but also allows for multiple retransfers several times to prepare films with different thicknesses. Furthermore, it can be transferred to paper substrates.

Physical vapor deposition (PVD) method

When fabricating paper-based electronic devices using Physical Vapor Deposition (PVD), materials are first vaporized into atoms or molecules through evaporation, sputtering, or other methods, and then transported to the surface of the paper substrate to deposit a film in a vacuum environment128. The paper substrate needs to undergo surface pre-treatment (e.g., coating with PMMA) to fill pores and reduce roughness to adapt to the PVD process. This method faces the challenge of insufficient thermal stability of paper, as paper typically decomposes at temperatures below 200 °C, while the high temperatures in PVD processes can lead to carbonization or deformation of the paper. Additionally, the rough surface of the paper substrate can easily cause defects such as pinholes and uneven coverage in the deposited film, leading to device short-circuiting or performance degradation. Therefore, research in this direction is limited by process compatibility, and there are relatively few published papers. However, in recent years, there have still been representative studies focusing on this direction. For example, Ihalainen et al.129 prepared ultrathin gold film electrodes on a nanostructured latex-coated paper substrate using PVD (Fig. 12a). The device exhibits conductivity comparable to that of bulk gold (with a 6 nm thick gold film), and shows good mechanical stability, maintaining performance unchanged through multiple bending and repeated folding-unfolding cycles. Moreover, the electrode demonstrates excellent stability in electrochemical experiments (Fig. 12b), making it suitable for the development of paper-based electrochemical platforms, such as for biosensing applications.

a A schematic illustration of the structure of the multi-layer coated paper used as the coating substrate for nanostructured two-component latex coating. b Capacitance vs frequency log-log curves for the bare and coated UTGF electrodes129.

Applications of paper-based electronic devices

In the research field of paper-based electronic devices, a series of innovative applications are gradually revealing their promising potential. These devices mainly include paper-based mechanical sensors for monitoring and responding to external mechanical stress changes130, paper-based electrochemical sensors for detecting the presence or concentration of specific chemicals through electrochemical principles131, paper-based optical sensors, which utilize optical effects to achieve sensing and conversion of light signals132, paper-based humidity sensors, which measure and monitor environmental humidity changes133, paper-based photodetectors, which combine optical and electronic properties for detecting optical signals and converting them into electrical signals134, and paper-based supercapacitors, which serve as highly efficient energy storage elements to provide the necessary electrical support for paper-based electronic systems135. These diverse paper-based electronic devices not only expand the functional boundaries of paper beyond its traditional role as an information carrier, but also bring revolutionary technological advances to fields such as wearable devices, environmental monitoring, and healthcare136.

Paper-based mechanical sensors

In the field of flexible electronics and wearable technologies, paper-based mechanical sensors have garnered extensive attention due to their unique advantages. These sensors come in a variety of types, mainly including paper-based resistive sensors, paper-based capacitive sensors, and paper-based piezoelectric sensors. With the advancement of material science and micro/nano-fabrication technologies, the performance and application scope of paper-based mechanical sensors are expected to be further expanded, offering more possibilities for the design of future intelligent systems.

Paper-based resistive stress sensors

In recent years, piezoresistive flexible devices that directly convert pressure into electrical resistance signals have become a research focus due to their excellent mechanical properties, simple device structure, and ease of obtaining output signals. In order to significantly enhance the sensitivity of the sensors, Chao Ji et al.137 skillfully combined the permeability of a paper substrate with the electrical conductivity of graphene, and successfully prepared graphene-based piezoresistive pressure sensors by utilizing multilayer structured cellulose paper as a substrate (Fig. 13a). Notably their seven-layer cellulose paper sensor designed by them demonstrated an excellent sensitivity, with specific values as high as 44 kPa−1 (Fig. 13b), which opens up new avenues for sensor sensitivity enhancement. Xiaoqian Liu et al.31 developed a new foldable touch pressure sensor by coating carbon black ink on cellulose paper (Fig. 13c), which can be freely shaped and reversibly deformed between 2D and 3D configurations without losing functionality, Owing to the significant resistance variation and air-gap effect under compression, the sensor exhibits a high sensitivity of 2.36 kPa−1, along with fast response and recovery characteristics (Fig. 13d). Muhammad Hasnain et al.138 created a strain sensor by drawing directly on cellulose paper with a pencil, and SEM showed that the micro-nano structure of graphite penetrated into the void of the fiber frame of cellulose paper, significantly improving the overall electrical conductivity of the film (Fig. 13e). The sensor exhibits good stability and high sensitivity of 122,701 kPa−1 (Fig. 13f), as well as excellent performance at 3.23% bending strain, with response and recovery times of 0.59 s and 0.69 s, respectively (Fig. 13g).

a Fabrication flow chart of graphene–paper-based pressure sensor. b Sensitivity and response range137. c Schematic illustration, photos for the fabrication of the touch–temperature sensor. d Based on kirigami art and landscape ink painting for touch sensors234. e SEM micrographs of graphite coated cellulose paper frameworks. f Response of sensor upon provision of bending strain up to 3.23% for inward. g Graph showing the response and recovery time of the demonstrated sensor138. h Schematic illustration of fabricating an all-paper pressure sensor by integrating a blade-coated top sensing electrode and a screen-printed bottom copper electrode. i Sensitivity and sensing range of all-paper pressure sensor compared to other paper-based and textile-based sensors reported in literatures139. j ECR variation mechanism for tactile sensing. k Sensitivity data of scaled down devices140. l Schematic diagram of the fabrication process of graphite-based e-skin developed by PGF approach. m Sensitivity of five different e-skins141.

To further improve the sensitivity, Bowen Zheng et al.139 prepared an ultra-high sensitivity resistive pressure sensor with a sensitivity of 1014 kPa−1 (Fig. 13h) and a wide sensing range of 300 kPa (Fig. 13i) by squeegee coating and screen printing techniques. This sensor was used to effectively monitor various physiological signals, including pulse, body acoustics, joint flexion, and finger tapping. Rajat Subhra Karmakar et al.140 developed a pressure sensor by combining and folding conductive paper substrates face-to-face, optimized for wearable devices for monitoring teething disorders and neck posture. The average surface roughness of the graphene ink film was 0.634 μm, which created multiple electrical contacts at the interface (Fig. 13j), the sensor achieved a high sensitivity of 3.75 kPa−1 in the 0-0.05 kPa range (Fig. 13k). In the same year, Qin-Teng Lai et al.141 prepared pressure sensors with embossed microstructures using the pencil graphite friction (PGF) method (Fig. 13l). This method is simple, cost-effective, and environmentally friendly. The resulting graphite paper-based sensors exhibited a maximum sensitivity of 7202.2 kPa−1 (Fig. 13m) and were capable of real-time detection of human physiological signals such as wrist pulse and finger joint flexion, providing valuable information for disease prevention and diagnosis.

Paper-based resistive pressure sensors offer significant advantages in terms of low cost, flexibility, wearability, and environmental friendliness. However, they face challenges in terms of environmental adaptability. Additionally, improving immunity to interference is an area that requires further development. While current research has focused on enhancing sensitivity and stability, minimizing the impact of external environmental factors on sensor performance remains a crucial topic142,143. For example, improving moisture and corrosion resistance while maintaining sensitivity is a key direction for future research.

Paper-based capacitive stress sensors

Compared with resistive sensors, capacitive sensors demonstrate significant advantages in multiple aspects, such as high impedance, low power consumption, good temperature stability, simple structure, strong adaptability, good dynamic response, and the ability for non-contact measurement. These advantages make capacitive sensors widely applicable in various fields and hold great promise for future applications. For example, Pengfei Zhao et al.144 realized for the first time an all-paper shape designable capacitive pressure sensor by using multilayer thin paper as dielectric and flexible polypyrrole (PPy) printed paper as electrodes (Fig. 14a). This innovative design not only reduces cost but also provides unique features such as stretchability and 3D sensing. It outputs a stable capacitive response under dynamic pressure (Fig. 14b), demonstrating excellent pressure sensing performance and proximity sensing capability. Hua Xue et al.145 constructed a capacitive pressure sensor with a double electric layer (EDL) structure by introducing ionic liquids (ILs) (Fig. 14c). This sensor achieves ultra-high sensitivity (Fig. 14d) and an ultra-low detection limit of 2 Pa (Fig. 14e). Azmal Huda Chowdhury et al.146 further simplified the sensor fabrication process by preparing a thin, paper-based capacitive pressure sensor using textiles (Fig. 14f), which is easy and inexpensive to produce, and achieving a high sensitivity of 2.9 kPa−1 over the pressure range of 0–16 kPa and a wide detection range (Fig. 14g), which can effectively measure pulse waveforms. Myda Arif et al.147 developed a capacitive sensor-based mouse pad using a sensing array on paper (Fig. 14h). This design allows for mouse operations including up, down, left, right, and left and right buttons. Additionally, it addresses the issue of high pressure required by resistive mouse pads while providing fast response, high durability, and excellent optical performance. In order to further reduce the manufacturing cost of the sensor and simplify the preparation process, Haozhe Zhang et al.54 utilized the inherent micro-nano structure of paper to prepare a capacitive paper-based pressure sensor, using paper as both a flexible substrate and a sensitive element (Fig. 14i). This sensor achieved a high sensitivity of 1.623 kPa−1 (Fig. 14j), a fast response time of 240 ms (Fig. 14k), and a minimum pressure resolution of 4.1 Pa (Fig. 14l). It also maintained a stable capacitive output over multiple load cycles, enable accurate and stable real-time monitoring of human wrist movements.

a Schematic diagram of capacitive sensors. b Reversible and subtle pressure responses144. c Schematic diagram of the fabrication process and optical photos of the i-PBP sensors. d Sensor in different pressure ranges of sensitivities. e Response-recovery curve of i-PBP sensor under pressure of 2 Pa145. f Schematic of the tissue-paper-based supercapacitive pressure sensor. g Detailed relative capacitance changes over pressure for the sensor with the highest electrolyte concentration146. h Side view representation of a flexible hybrid design capacitive sensor147. i Fabrication process of capacitive pressure paper-based sensors. j Comparison of sensitivity curves of capacitive pressure sensors made from four types of paper materials. k Response time curve of the rice paper-based capacitive pressure sensor. l Minimum pressure resolution curve of the rice paper-based capacitive pressure sensor54.

Paper-based capacitive stress sensors offer advantages such as high accuracy, good stability, fast dynamic response, low power consumption, and easy integration. However, they also have disadvantages, including high output impedance, poor loading capability, parasitic capacitance effects, and stringent requirements for paper-based materials132. Therefore, when selecting and using paper-based capacitive pressure sensors, these factors need to be considered comprehensively and weighed against specific application scenarios.

Paper-based piezoelectric stress sensors

Paper-based piezoelectric stress sensors are attracting attention in the field of flexible electronics due to their unique properties. These sensors utilize the principle of charge generation by piezoelectric materials to convert mechanical stress into electrical signals148,149. They have gained the attention of researchers due to their high sensitivity, fast response time, and wide range of applications in microstress detection and human motion monitoring. In recent years, several studies have focused on developing paper-based piezoelectric sensors. In 2023, Chenxu Yu et al.150 constructed a paper-based piezoelectric sensor with an irregularly porous structure using a polycarbonate (PC) film as the outer protective layer of a BPP-PC sensor (Fig. 15a), which was capable of sensing an external micro-pressure of at least 0.1 mg and has a sensitivity of 0.13 V/kPa, a pressure range of 0–20 kPa, and a response time of 78 ms (Fig. 15b, c). Additionally, it demonstrated excellent detection of water droplets and sensitively captured human motions such as footsteps, hand clapping, wrist and finger bending, showing potential for detecting minute pressures and monitoring human motions (Fig. 15d). However, the piezoelectric coefficients of organic piezoelectric materials and piezoelectric composites are significantly lower than those of conventional piezoelectric ceramics, which limits the sensitivity of pressure sensor arrays151. Furthermore, despite the superior electromechanical properties of piezoelectric ceramics such as lead zirconate titanate (PZT), their inherent stiffness and brittleness restrict their application in flexible electronics152. Therefore, although paper-based piezoelectric pressure sensors hold great potential in flexible electronics, further research is needed to overcome these challenges and enable wider applications.

BPP-PC sensor picture (a), sensitivity (b), response time (c), output voltage (d) at different low voltages150.

Paper-based mechanical sensors, a new type of sensor with unique advantages, show broad application prospects in wearable devices, health monitoring, and environmental monitoring153,154. However, different types of paper-based mechanical sensors have their own limitations. Moreover, gases, humidity, and strain often coexist and interact with each other. Since paper itself is hydrophilic and flexible, developing high-performance paper-based sensors remains challenging. Although paper-based mechanical sensors have great potential for application in various fields, continuous improvement and optimization of material selection, structural design, and manufacturing processes are needed to better meet real-world demands.

Paper-based gas sensor

Gas sensors are widely applied in various fields such as industry, homes, and environmental monitoring because they can detect the types and concentrations of gases in the environment. To reduce health risks and protect the environment, it is necessary to develop gas sensors that are highly responsive, sensitive, selective, and stable, while also maintaining low cost and low power consumption155. Paper-based gas sensors typically use active materials (such as metal oxides, carbon-based materials, and composite materials) as sensing elements. When gas molecules come into contact with these active materials, chemical or physical reactions occur, leading to changes in the materials’ resistance, conductivity, or other properties156. In recent years, paper-based gas sensors have been extensively studied in many fields. For example, Ronil J. Rath et al.157 prepared a paper-based gas sensor by coating polystyrene sulfonate (PSS) on paper to detect and distinguish between ammonia and carbon dioxide gases (Fig. 16a). Due to the interaction between PSS and gas molecules, when NH3 or CO2 comes into contact with PSS in a humid environment, chemical reactions occur, leading to changes in the sensor’s resistance. The sensor exhibited significant resistance changes to ammonia and carbon dioxide under high humidity conditions (>85%), achieving high selectivity detection and a wide detection range (ammonia 0.25 ppm to 2500 ppm) in complex environments, providing an important foundation for gas detection in practical applications (Fig. 16b). Xiao Ye et al.158 prepared a fully inkjet-printed chemiresistive sensor array by coating molecularly imprinted sol-gel (MISG) active material and Ketjen black (KB) ink on paper (Fig. 16c) to detect and distinguish volatile organic acids (VOAs). Due to the molecular imprinting effect of the HA-MISG layer for recognizing target HA vapor, the expansion effect caused by recognition increases the distance between conductive KB particles, leading to an increase in resistance. When the HA-MISG/KB sensor is cleaned, air removes the target molecules from the imprinted cavities of the HA-MISG layer, thus reducing the resistance. The sensor achieved highly cross-selective detection of VOAs at room temperature with high sensitivity and selectivity, as well as low detection limits (Fig. 16d). Additionally, the proposed sensor array demonstrated strong sensor robustness, with excellent stability, flexibility, and humidity resistance. Guh-Hwan Lim et al.159 developed a paper-based sensor for self-activated chemiresistive gas detection by fabricating boron nitride/carbon nanotube (BNCNT) composite paper to detect nitrogen dioxide (NO2) gas (Fig. 16e). The sensor achieves highly sensitive detection of gases through the self-heating effect and changes in electrical conductivity of the boron nitride/carbon nanotube composite paper. The sensor exhibited high sensitivity, selectivity, and fully reversible response characteristics, achieving highly selective detection of NO2 gas at room temperature with a detection limit as low as 3.41 ppb. Moreover, the sensor showed excellent long-term stability and environmental adaptability, providing a promising platform for environmental monitoring in smart clothing and wearable electronic devices.

a Schematic set-up for testing PSS sensor performance in the gas phase. b PSS sensor response to humidified nitrogen, carbon dioxide, and ammonia gas157. c HA-MISG/KB sensors for selective HA vapor detection. d Response curve of HA-MISG/KB sensor to different concentrations of Hexanoic Acid (HA)158. e Schematic illustration for the fabrication process of the BNCNT hybrid papers159.

Paper-based gas sensors have shown promising applications in several fields due to their low cost, biodegradability and high sensitivity. However, despite their significant advantages in providing fast response and high sensitivity, these sensors still face challenges in terms of stability and environmental adaptability. For example, paper-based sensors have poor durability, are susceptible to humidity variations, and can fail in high humidity or underwater environments160. Therefore, future research needs to optimize material selection and sensor design and explore new materials and technologies to enhance the performance and utility of paper-based humidity sensors.

Paper-based humidity sensors

Humidity is a key factor in many fields including ecology, industry, medicine and indoor/outdoor environmental monitoring. Additionally, high humidity levels can make breathing difficult and cause coughing and wheezing in asthmatics. High levels of humidity can create a favorable environment for dust mites and mold to thrive in the home, which can be harmful to human health161. Due to their low cost, biodegradability, and environmental compatibility, paper-based humidity sensors have become a hot research topic in flexible electronic devices. Recent research advances have shown that paper-based humidity sensors have significantly improved in terms of response speed, sensitivity, and stability. For example, Penghui Zhu et al.162 prepared a paper-based bilayer humidity sensor (PBHS) (Fig. 17a) with high sensitivity and good durability. The large number of hydrophilic hydroxyl groups on the surface of CNF and paper fibers allows rapid exchange of water molecules between the moisture-sensitive material and the external environment through hydrogen bonding, the prepared sensor has a 95% relative humidity with a 65.0% maximum response value (Fig. 17b), and also exhibited a bendability with a maximum curvature of 22.2 cm−1 and up to 50-fold folding durability (Fig. 17c). Zhi Song et al.163 developed a paper-based capacitive humidity sensor based on graphene oxides (Fig. 17d). This sensor achieves ultra-high sensitivity (Fig. 17e) with an optimized structural design and fast response/recovery times of 170/40 s (Fig. 17f). It is suitable for respiratory monitoring, non-contact applications, and food safety monitoring. Xiaoqiang Li et al.164 prepared a self-powered humidity sensor using drawing carbon ink (CI), cellulose filter paper (FP), and polyester conductive tape (Fig. 17g). This sensor generates a humidity-dependent voltage by adsorbing water molecules in a humid environment. It exhibits excellent humidity-voltage responsiveness and cycling performance over a wide humidity monitoring range (11–98%) (Fig. 17h), making it suitable for monitoring human health, air humidity, and non-contact humidity sensing. A.S.R.A. Subki et al.165 prepared resistive humidity sensors based on rGO/ZNP nanocomposites (rZNP) with different rGO loadings (Fig. 17i). The presence of oxygen vacancy defects and oxygen-related chemical bonding on the surface of rZNP enhances the sensor’s sensitivity to water molecules, resulting in higher sensitivity compared to conventional humidity sensors. These sensors also demonstrate excellent repeatability and good stability.

a Schematics illustrating the mechanism of CNF/CNT dual network-enabled flexible humidity sensors with high sensitivity and good durability. b Dynamic response and recovery curves of the PBHS with various CNF/CNT loadings between 11 and 29, 43, 57, 75, and 95% RH. c Current-time curves of human nose breathing under bending states with curvatures of 2.1 and 22.2 cm−1, respectively162. d Fabricated sensor. e Sensitivity at different operation frequencies. f Response/ recovery at different operation frequencies for the GO sensor with concentrations of 1 mg/mL163. g Fabrication process of self-powered CI/FP humidity sensor. h The sensor dynamic voltage response curve increases with RH from 11% to 98% and then decreases to 11%164. i Cross-sectional image based on rZNP humidity sensor165. j Screen-printed G-P-C humidity sensor. k Stability analysis plot166. l Sensor schematic diagram of graphene ink inkjet printing paper167. m Manufacturing process of pen and paper hydration sensor168.

Disposable sensors play a crucial role in monitoring respiratory and ambient humidity. Parthasarathy P et al.166 fabricated cost-effective and flexible disposable humidity sensors using biocompatible and conductive graphene-polypyrrole-carbon black (G-P-C) inks on paper substrates (Fig. 17j). These sensors exhibit high flexibility, stability, and repeatability (Fig. 17k), and can be used to monitor soil moisture and space humidity. In addition, Lim W Y et al.167 designed an inexpensive, disposable, and sensitive capacitive humidity sensor using a fork-finger electrode (IDE) configuration for respiratory sensing (Fig. 17l). This sensor can continuously and real-time monitor respiration in three different scenarios (e.g., normal breathing, deep breathing, and coughing) and exhibits a short response and recovery time of less than 5 s. Guangyu Niu et al.168 prepared a highly sensitive disposable paper-based humidity sensor by treating a hand-drawn graphite electrode on cellulose paper with a saturated NaCl solution (Fig. 17m). The resultant sensor features high sensitivity, and a wide relative humidity (RH) range from 5.6% to 90%, enabling convenient monitoring of respiratory rate and non-contact finger position. Moreover, the preparation method is simple and low-cost.

Paper-based electrochemical sensors

Paper-based electrochemical sensors utilize a paper substrate as an electrochemical sensing platform. These sensors are inexpensive, portable, user-friendly, and are suitable for implementation in resource-limited environments, such as emerging economies or field environments169,170. Electrochemical sensors typically consist of three electrodes: a working electrode, a counter electrode, and a reference electrode. The working electrode, where the reaction occurs, can be modified to enhance recognition and sensitivity to specific substances. For example, immobilizing functional groups or biorecognition elements (e.g. antibodies or enzymes) on the working electrode enables the electrochemical detection of specific species171,172. The working principle is based on the redox reaction of the target substance on the electrode surface, generating electrochemical signals such as current, potential, or charge. These signals are closely related to the concentration or nature of the target substance, and by detecting changes in these signals, qualitative and quantitative analyses can be achieved173,174. In the early stage, Dungchai et al.175 described the paper electrochemical analysis device. Since then, the paper electrochemical analysis device has been widely popularized due to its advantages such as simple, low power consumption, low detection limit and easy quantification. Compared to conventional high-pressure liquid chromatography and gas chromatography coupled with mass spectrometry, paper-based electrochemical sensors achieve high analytical sensitivity due to the many nanoparticles that can increase the loading capacity and the wide surface area of reactant mass transfer176. Wearable paper-based electrochemical sensors have potential applications in monitoring temperature177, pressure178, humidity and respiration179, and healthcare (e.g., monitoring specific analytes, diabetes, or cardiovascular diseases)180. Paper-based electrochemical biosensors can be categorized into three main types based on their operating principles: amperometric (current-based), potentiometric (potential-based), and impedimetric (resistance-based). Each type has its own characteristics and is suitable for different detection needs and application scenarios. Amperometric sensors focus on current changes, potentiometric sensors on potential changes, and impedimetric sensors on resistance changes. These differences allow for the selection of the most suitable sensor type for specific applications. These sensors can be used in clinical diagnosis, environmental monitoring, and food safety181.

Paper-Based Current-Based Electrochemical Sensors

The operating principle of paper-based current-based electrochemical sensors primarily relies on electrochemical reactions. When the measured substance reacts with the sensitive electrode inside the sensor, a change in current is generated, which is directly related to the concentration or nature of the measured substance. By measuring this change in current, quantitative or qualitative analysis of the measured substance can be achieved182. In recent years, paper-based current-based electrochemical sensors have demonstrated significant scientific value and application potential in the field of electrochemical detection and analysis due to their low cost, simple preparation process, high scalability, and good sustainability. For example, Christopher J. Valentine et al.183 used laser cutting to define the electrode region, cleverly fabricating a paper-based electrochemical sensor (Fig. 18a). The sensor leverages the porosity of paper to provide microchannels that respond differently to varying glucose concentrations. Changing the paper’s porosity results in nearly a 2-fold increase in current change (Fig. 18b). Cheng Wang et al.170 prepared functional composite paper for electrochemical detection using traditional papermaking methods (Fig. 18c). This composite paper exhibits good controllability, stability, and reproducibility. It shows similar cyclic voltammetry (CV) curves for electrodes that are folded or even cut at different angles (Fig. 18d). The sensor demonstrates remarkable sensitivity, capable of accurately detecting phenolic compounds at low concentrations. Specifically, the detection limits are as low as 0.045 mg/L for hydroquinone (HQ), 0.093 mg/L for p-chlorophenol (CP), and 0.571 mg/L for p-nitrophenol (NP). These low detection limits highlight the sensor’s significant potential for trace analysis applications. Mohammad Ali Farzin et al.184 developed a highly sensitive and selective electrochemical current-based sensor using conductive graphite nanocrystals (GNC) (Fig. 18e). The sensor demonstrates high stability, low limit of detection (LOD), and high recoveries of spiked sputum samples for the determination of the SARS-CoV-2 RdRP gene. The use of GNC effectively improves the paper surface and increases electrical conductivity. Prasongporn Ruengpirasiri et al.185 integrated a graphene pseudo-reference electrode (GPRE) with a paper-based electrochemical device (PED) to create an electrochemical sensor for the sensitive and selective detection of heavy metals cadmium (Cd) and lead (Pb) (Fig. 18f). The sensor demonstrates remarkable analytical performance. For cadmium ions (Cd2+) and lead ions (Pb2+), the detection limits are as low as 0.69 ng/mL and 5.77 ng/mL, respectively, with electrochemical sensitivities of 70.16 μA mL μg−1 cm−2 for Cd2+ and 38.34 μA·mL μg−1 cm−2 for Pb2+.

a Overall architecture of the electrochemical sensors developed in this work. b Change in current as a function of glucose concentration183. c Fabrication of CF/GO/cellulose paper. d CV of potassium ferricyanide170. e Schematic diagram of GNCs/ paper electrochemical gene sensor electrodes184. f Comparison of electrochemical properties and stability of GPRE and conventional Ag/AgCl PRE185.

Paper-based potentiometric electrochemical sensors