Abstract

The hot corrosion behavior of nickel-based single-crystal superalloy after drilling is investigated at 900 °C. The characteristics of hot corrosion after drilling which are different from normal hot corrosion are reflected in the formation of a more stable oxide layer and less severe spallation. The change of microstructure around the hole is the main reason for the formation of a stable oxide layer during hot corrosion by changing the diffusion process of alloying elements. Subsequently, the formation of a stable oxide layer can reduce the effect of spalling by optimizing surface stress.

Similar content being viewed by others

Introduction

The industrial gas turbines (IGTs), as the most important energy conversion mode for at least 20 years, have served a variety of service environments and conditions1,2. Nickel-based single-crystal superalloy becomes the primary choice of turbine blade material for IGTS because of its excellent mechanical properties, good casting properties, high oxidation resistance, and hot corrosion properties3,4,5. With the increasing requirements for IGTs, increasing turbine inlet temperature becomes a consensus for the development of gas turbines in the future6,7. However, with the continuous increase of turbine inlet temperature, it is far from enough to rely solely on the temperature bearing capacity of nickel-based single-crystal superalloy itself8,9. Therefore, thermal barrier coating technology and gas film cooling technology are proposed and widely used10,11,12,13. Advanced gas film cooling technology is widely adopted because of its extremely high thermal insulation effect14. However, due to the destruction of gas film holes on the overall structure of blades, it is necessary to study the properties of the superalloy after drilling15,16.

So far, the microstructure and properties of drilled superalloys have been studied in part. Sundar Marimuthu et al. have analyzed the change of microstructure of superalloys during the fiber laser drilling17. Umacharn Singh Yadav et al. have studied the process of using electrical discharge machining (EDM) to drill holes and the corresponding microstructure changes18. It can be said that the microstructure changes around the hole obtained by using different drilling methods have been well studied. However, different drilling methods bring different degrees of micro-change19,20. Therefore, the properties change based on different micro-changes caused by drilling is the urgent problem to be solved. Shang et al. observe the high-temperature tensile behavior of Ni-based single-crystal superalloy with cooling hole21. Sanja et al. and Panigrahi et al. have researched the creeping properties of Ni-based superalloys after drilling22,23. Kersey et al. and Liang et al. have investigated the thermal mechanical fatigue and low cycle fatigue of Ni-based superalloy after drilling, respectively24,25. The researches above basically cover all the mechanical properties of superalloy after drilling, but it is worth noting that the change of the structure around the superalloy gas film hole not only brings about change of mechanical properties, but also has a huge impact on the oxidation and hot corrosion performance, and relevant studies on the oxidation and hot corrosion performance are not sufficient26. Dong et al. have conducted a preliminary study on the influence of oxidation behavior on fatigue property of Ni-based superalloy after drilling27. It can be seen that there are great changes in the oxidation behavior of the superalloy after drilling. Therefore, the hot corrosion behavior which is more sensitive to the superalloy structure can undoubtedly be greatly affected due to the drilling, while the research on the hot corrosion behavior after drilling is almost blank. So, it is of great significance and imperative to study the hot corrosion behavior after drilling.

In this study, a low Cr content Ni-based single-crystal superalloy with poor hot corrosion resistance is selected to study the hot corrosion behavior after drilling for a dramatic and intuitive reaction28. Considering the practical service temperature of the first stage turbine blade after drilling and the reaction temperature of type-1 hot corrosion, 900 °C is used for the temperature of hot corrosion experiment29,30. The EDM method and the hole with diameter of 1 mm which commonly used in IGTs are adopted31. A saturated aqueous solution of 75 wt.% Na2SO4 + 25 wt.% NaCl is the molten salt medium for hot corrosion as it can truly reflect the environment where hot corrosion occurs32. In order to better explain the reasons why different characteristics appear between normal hot corrosion and hot corrosion after drilling, diffusion mechanism and finite element stress analysis are applied.

Results

Normal hot corrosion test

The relationship between the thickness of the reaction layer and the hot corrosion time of the alloy sample is shown in Fig. 1. Considering that the blade itself is a structural part of the engine, and the position of the deepest part of the hot corrosion reaction layer will have a great influence on the service of the blade, the thickness of the hot corrosion reaction zone is measured by uniformly selecting the deepest part of the reaction layer and using Scanning electron microscopy (SEM) to calibrate it accurately. It can be seen from the curve that the thickness of the reaction zone of the sample experiences a linear growth period in the first 50 h and a growth deceleration period after 50 h until the end of the experiment. The rapid thickening of the reaction layer in the beginning 50 h reflects the general dynamic law of linear growth, while the variation trend of the thickness of the reaction layer after 50 h needs further observation.

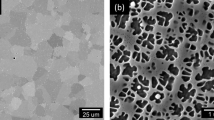

Figure 2 shows the surface and cross-section morphologies of the sample after normal hot corrosion at 900 °C. The surface morphology of the sample after 200 h normal hot corrosion at 900 °C is shown in Fig. 2a. It can be seen that the surface integrity of the sample is seriously damaged, with huge cracks all over the surface of the sample. A large amount of dispersed tiny oxides can be found on the surface of the sample. Combined with the weight change of the sample during hot corrosion after drilling and the surface new tiny oxides, it can be found that when the hot corrosion is carried out after 200 h, severe spallation occurs. An observation about the cross-section is made regarding the behavior of the hot corrosion after 50 h as reflected in Fig. 1 above. Figure 2b shows the cross-section morphology of the sample after 50 h normal hot corrosion. The surface of the sample still remains an oxide layer which is mainly composed of NiO. Below the oxide layer, some diffuse Al2O3 and sulfides are distributed in the reaction zone. The presence of these hot corrosion products is not very significant at 50 h. Figure 2c displays the cross-section morphology of the hot corrosion sample at 100 h. Compared with the hot corrosion morphology at 50 h, the hot corrosion morphology at 100 h changes dramatically. First, the surface oxide layer (NiO) does not thicken with the reaction time, but its thickness and integrity decrease slightly. Second, the thickness of the reaction zone increases, and the oxide and sulfide in the reaction zone increase significantly. Finally, the size of the internal oxide increases, and the interface of the reaction zone appears obvious irregularities. As the reaction continues, the cross-section morphology changes to a certain extent when the hot corrosion reaches 200 h as shown in Fig. 2d. The oxide layer is still not thickened but the surface roughness is aggravated. At the same time, the reaction products inside the alloy are remarkable, and the thickness of the reaction layer increases.

Hot corrosion test after drilling

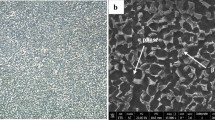

The original structures around the hole of the specimens after drilling are shown in Fig. 3. The overall morphology and the partial magnification morphology around the hole are shown in Fig. 3a, b, respectively. It can be seen that the structure around the hole is relatively complete, but there are also some relatively small bulges here. By further energy dispersive spectroscopy (EDS) analysis, the bulges are identified as Al2O3 which can be shown in Fig. 3c, d. At the same time, a burning loss zone (Al-lean Ni-rich) which is about 15-μm-thick can also be found on the surface of the sample. These specimens are then used for hot corrosion experiment.

The normal hot corrosion kinetic curves of the samples at 900 °C after drilling are illustrated in Fig. 4. A severe hot corrosion occurs during the test to the sample undoubtedly. The mass gain and sample weight change (the effective area is 216.56 mm2) keep rising during the experiment. At the beginning 40 h, the increase of weight is not drastic. After 40 h, the increasing trend of sample mass gradually becomes stronger and there is a significant increase in weight after 100 h until the finish of the test. However, no apparent spallation can be found compared to normal hot corrosion (the effective area is 239.52 mm2) through the curves as the gap of mass gain and sample weight change increases a little bit (only about 10 mg cm−2) at the end of the experiment.

The X-ray diffraction (XRD) patterns of the surface corrosion products after hot corrosion after drilling for 20, 50, 100, and 200 h are shown in Fig. 5. It can be seen that NiO is always the main component of surface reaction products and with the extension of experiment time, its dominant position becomes more and more significant. Na2Ta4O11 and NaTaO3 are always present, but as the degree of hot corrosion deepened, the content of them on the surface of the specimens become less and less. At the meantime, Ta2O5 can only be observed on the surface at the beginning (the first 20 h) of the experiment as an initial product. Of course, from the perspective of the products and conditions of the whole reaction process, the hot corrosion experiment is largely explained by the nature of the oxidation reaction: the formation of (Ni, Co)Cr2O4, Al2O3, and NiO rather than the sodium salt.

The surface morphologies around the hole after hot corrosion are displayed in Fig. 6. Figure 6a shows that the oxide layer has begun to form and some cracks in the surface layer can be clearly observed at the initial stage (20 h) of hot corrosion. Cracks also appear around the hole but do not appear to cause significant damage to the overall structure of the oxide layer. When the hot corrosion time reaches 50 h, the reaction degree on the sample’s surface and around the hole increases slightly as shown in Fig. 6b. Some small surface oxides tend to flake off, but surface cracking is not worse. At the same time, no obvious cracking is found around the hole. As the reaction time increases to 100 h, a severe hot corrosion reaction occurs on the surface of the sample as shown in Fig. 6c. A partial oxide layer that has been removed and a larger piece of the oxide that is about to spall can be found on the sample surface. Surprisingly, though, cracks appear around the hole at this time, the oxide layer integrity around the hole remains intact. In other words, the cracking and spallation around the hole are not very serious compared with the sample surface (position away from the hole). When the reaction continues and reaches 200 h, a relatively dense and continuous oxide layer is formed on the surface of the sample as shown in Fig. 6d. Therefore, the sample does not show a very serious spallation phenomenon. Although cracks appear in some areas, the part around the hole is very intact.

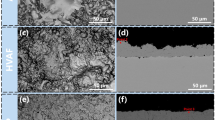

The cross-section morphologies around the hole after different hot corrosion time at 900 °C are presented in Fig. 7. With hot corrosion lasting for 20 h, it can be seen that the surface of the hole occurs a non-dense outer oxide layer and the internal reaction zone as shown in Fig. 7a, b. Further observation suggests that the surface oxides are not so stable because some pits can be found. Meanwhile, internal sulfides and oxides also appear. Although this phenomenon is not serious, but the trend of the oxides to the internal expansion is still relatively obvious. Of course, the sulfides are mainly distributed in the reaction zone near the side of the substrate. Compared with the morphology at 20 h, when the reaction is conducted to 50 h, the change degree around the sample hole is not obvious as shown in Fig. 7c, d. There are no significant structure or product differences, except for some spallation of the surface oxides and a slight increase in the internal products. When the hot corrosion continues and reaches 100 h, the microstructure around the hole has undergone relatively dramatic changes, which can be seen in Fig. 7e, f. First, the thickness of the reaction layer around the hole increases significantly with the extension of reaction time. Second, the top layer of loose oxide is consumed, but at the same time, a relatively dense layer of Al2O3 is quietly formed beneath it. Third, hot corrosion reactions involving Cr, Mo, and S occur33. Cr–S compounds are formed earlier than Mo–S compounds because of the strong external diffusion behavior of Cr and the lower Gibbs generating energy of Cr–S compounds. Subsequently, with the consumption of Cr caused by long-term hot corrosion, Mo appears more in the reaction zone and forms a phase with S. This long, white phase is more central to the reaction zone. Finally, the Al2O3 in the reaction zone extended toward the matrix shows no obvious growth trend compared with that at 50 h. In consideration of the reaction zone (γ′-depleted zone) expanding, the formation of dense Al2O3 on the surface can be verified. At the last stage of the hot corrosion, the hot corrosion reaction zone is expanded to a large scale at 200 h as shown in Fig. 7g, h. The relatively dense oxide layer mainly composed of Al2O3 which still remains at 100 h of hot corrosion reaction reaches a considerable scale equal to about 40 μm at the end of the experiment. Compared to 100 h, the oxide layer around the sample hole is obviously thicker and its continuity is also complete at 200 h. There are no apparent penetrating cracks around the hole. Certainly, with the deepening of the reaction degree, more and more Mo–S phase appears in the reaction zone.

The cross-section morphologies of the surfaces near the holes after different hot corrosion time at 900 °C are shown in Fig. 8. From the point of view of reaction products only, there is no significant difference between the surface products near the hole and the products around the hole at the same reaction time. But it can still be seen that the difference in the distribution of the products appears. When the reaction comes to 20 h, a thin layer of Al2O3 begins to form, and the internal distribution of Al2O3 is not very obvious as shown in Fig. 8a. Then, when the reaction continues to 50 h, the reaction degree is significantly intensified, the Al2O3 layer becomes thicker, and the internal dispersion of Al2O3 is much more variable which can be seen in Fig. 8b. As the reaction continues, although the Al2O3 layer still exists at 100 h, the reaction layer has significantly thickened, and it becomes very loose. Large amounts of internal oxides appear as dispersion as shown in Fig. 8c. When the hot corrosion lasts for 200 h, the dispersed oxides show a layered structure and begin to become dense. The thickness of the Al2O3 layer also increases to a certain extent. Although there are still more loose oxides near the matrix which can be found in Fig. 8d.

Discussion

The spallation is the most direct and obvious difference between normal hot corrosion and hot corrosion after drilling. The reasons for this difference will be analyzed in detail. Whether it is oxidation or hot corrosion, the structure of the oxide layer on the surface is the most direct factor to reflect the root cause of its spallation34. It can be found from the experimental results above that the surface structures of the samples with normal hot corrosion and hot corrosion after drilling are quite different. Under normal hot corrosion conditions, the surface oxide layer is mainly composed of loose and easily spalling NiO, while around the hot corrosion hole is composed of relatively dense and stable Al2O3. It leads to the difference in the degree of reaction and spallation between the different hot corrosions.

According to the above experimental results, as shown in Fig. 3, the surface morphology of the sample after drilling shows the characteristics of burning loss zone (Al-lean Ni-rich) and dispersed Al2O3 particles. The particular morphology is related to the drilling behavior. EDM is a hot discharge process that causes a remelting layer forming around the hole. Because of the high temperature in the EDM process, the element-burning phenomenon is obvious in the remelting layer. Due to its relatively active nature, the Al element suffers more serious loss in the process of burning than other elements, which results in the formation of the burning loss zone with the characteristics of Al-lean. At the same time, there are micro-area arc discharges in the EDM process. The random discrete arc discharges cause the Al element to be oxidized rapidly and form Al2O3 particles deep into the matrix. The above discharge and high-temperature processes contribute to the formation of the particular morphology shown in Fig. 435,36,37. Based on this situation, the formation of the subsequent oxide layer also shows the particularity. Both oxidation and hot corrosion in the narrow sense can be considered as controlled by diffusion processes, including the external diffusion of alloying elements and the internal diffusion of oxygen elements as shown in Supplementary Fig. 1.

Assuming that the thermodynamic equilibrium is established at each interface during hot corrosion, the process can be analyzed as follows38,39,40. The outward element flux, \(j_{\mathrm{M}},\) can be expressed as in Eq. 1,

where \(x\) is the reaction zone thickness, \(D_{\mathrm{M}}\) is the diffusion coefficient for alloy element, and \(C_{\mathrm{M}}^\prime\) and \(C_{\mathrm{M}}^{\prime\prime}\) are the element concentrations at the reaction zone- molten salt and reaction zone- substrate interfaces, respectively.

Furthermore, there is also a correlation between diffusion and the reaction products as shown in Eq. 2,

where \(V_{{\mathrm{r}}x}\) is the molar volume of the reaction products. Then,

Integrating that \(x\) = 0 and \(t\) = 0, Eq. 4 can be obtained,

By analyzing the above equations, the value of \((C_{{\mathrm{Al}}}^{\prime\prime} - C_{{\mathrm{Al}}}^\prime )\) is constant in normal hot corrosion. However, after the sample is drilled, the value of \((C_{{\mathrm{Al}}}^{\prime\prime} - C_{{\mathrm{Al}}}^\prime )\) decreases continuously due to the existence of surface burning loss zone (Al element spontaneously diffuses from the substrate to the surface through burning loss zone, as the burning loss zone itself has the characteristic of poor Al) which means that the hot corrosion reaction zone on the surface is smaller. Further, the hot corrosion reaction can be simplified to two parts: one is the fluxing of Ni and molten salt in the upper layer of the burning loss zone, and another is the oxidation of inner diffused O and outer diffused Al in the lower layer of the burning loss zone. Therefore, the Al2O3 layer can be formed under the protection of the concentration gradient and the outer layer of Ni. This is why the abnormal hot corrosion can occur.

Figure 9 shows the schematic diagram of oxide layer formation of hot corrosion after drilling and oxide layer formation on different shaped surfaces after hot corrosion. Except that the diffusion process of the elements mentioned above can be reflected in Fig. 9a, Al2O3 particles also play a role in the oxide layer formation of the hot corrosion after drilling. As mentioned above, the Ni in the burning loss zone on the surface of the sample will react with molten salt priority (fluxing process), to a certain extent, for the formation of Al2O3 layer provides a possibility. But when the reaction is catastrophic, that is, if the reaction product of NiO is extremely loose and easy spalling, then it will lose its protection effect, even accelerate the degree of hot corrosion. At this point, the effect of Al2O3 particles will be displayed. When hot corrosion occurs, NiO begins to form, and the solid phase reaction as shown in Eq. 5 occurs41,42.

The solid phase reaction product \({\rm{NiAl}}_{2} O_{4}\) has a stable bond, existing in the substrate and the hot corrosion product, connecting the two parts like nails, which slows down the spallation of the surface oxide layer to a certain extent, and provides an opportunity for the formation of Al2O3 layer43.

The above explains why Al2O3 layer can be formed; its compactness is also briefly analyzed below. Figure 9b displays the schematic diagram of oxide layer formation on different shaped surfaces after hot corrosion. It can be seen that the growth of the oxide layer is different for different surfaces. For a flat plane, the growth of oxide layer is uniform, while for a circular plane, the growth of oxide layer is convergent. It is assumed that the size of the hole after hot corrosion is \(r_i\) = 470 μm and the oxide layer thickness is h = 30 μm. Compared with a plane oxide layer of the same size, its volume shrinks (\({\rm{Vol}_{s}}\)) by 3% as shown in Eq. 6.

Considering that the Pilling–Bedworth ratio of Ni3Al after oxidation is 1.71–1.88 normally, its influence on oxide density is more than 5%44,45. Moreover, the ratio increases with the decrease of hole size and the increase of oxide layer thickness. That is to say, under the same conditions, the oxide layer formed on the inner wall of the hole is denser than the planar oxide layer and less likely to spall.

The previous section explains why a stable and dense layer of Al2O3 is formed around the hole. This section will focus on the role of the Al2O3 layer. After hot corrosion, it is observed that although the mass gain of the whole drilled sample is not much different from that of the undrilled sample, the degree of spallation is greatly reduced, in particular, the inner wall of the hole does not appear obvious spalling phenomenon as shown in Fig. 6. Hot corrosion is catastrophic mainly because it is difficult to form a stable oxide layer (due to severe spallation), and the spallation of the oxide layer is closely related to the stress state46. The result indicates that the stability of the oxides on the surface of the sample has been improved to some extent. In order to better illustrate the hot corrosion process after drilling and explore the role of oxides in hot corrosion, finite element simulation software ABAQUS is used to analyze the surface oxides stress state47,48. In view of the experimental results in the previous section, NiO has significant consumption during hot corrosion while Al2O3 layer keeps stable, so the simulated microstructure around the hole is simplified: an Al2O3 layer is established in accordance with the experimental results and the parabolic growth with time. For detailed simulation parameters, please refer to the Supplementary Notes. Figure 10a–d displays the stress state on the oxide layer (Al2O3 layer) of the inner wall of the hole. It can be seen that, for the oxidation layer on the inner wall of the hole without the other surface oxidation layer and the substrate, the radial direction is subject to smaller compressive stress, while the tangential direction is subject to greater compressive stress with the growth of Al2O3 layer. Combined with the hot corrosion process, which causes the oxidation layer to loose, a stable compressive stress helps to alleviate this phenomenon, increases the density, and to some extent inhibits the catastrophic hot corrosion caused by diffusion. It indicates that the oxide layer (Al2O3 layer) on the inner wall of the hole tends to exist stably on the surface of the substrate because of the compressive stress state of the surface oxide layer on the samples.

a initial state, b the overall stress condition at 100 h, c the stress state in the X direction, and d the stress state in the Y direction. And the simulations of the stress distribution of the overall oxide layer of the alloy changing with time: e 20 h (initial state), f 50 h, g 100 h, and h 200 h. (In the figures, the compressive stress is negative; X, Y direction is parallel to the surface, Z direction is perpendicular to the surface).

The structural stability of the Al2O3 layer on the inner wall of the hole is described above. Subsequently, the simulations of the stress state of the overall oxide layer of the alloy changing with time are shown in Fig. 10e–h. Considering that when the hot corrosion goes on for 20 h, the inner wall Al2O3 layer has formed stably, and the reaction state of 20 h is set as the initial state for simulation. Then the stress state of the whole-experiment process is analyzed. It can be seen from the simulation results that the Al2O3 layer on the surface of the sample is always subjected to the compressive stress pointing to the direction of the matrix, and the stress level increases with reaction time which even does not take into account the tendency of the oxides growth on the inner wall of the hole to converge outward (the space is smaller and the volume is compressed cause the Al2O3 layer to become dense and stable). In other words, the compressive stress increases with the thickness of the oxide layer caused by the prolonged reaction time. This increased compressive stress caused by the oxide layer on the inner wall over time can provide structural stability to the oxide layer on the overall surface, which can be reflected by the large stress zone around the hole to some extent. Combined with the overall structure of the oxide layer, it is enough to show that the formation of Al2O3 layer on the inner hole can reduce the oxides spallation of the alloy. This enhance effect is attenuated on the undrilled sample surface (open state) because of the oxides’ spallation, but it can be better reflected at the convergent interface of the inner wall of the hole49. It shows that Al2O3 plays a significant role during the hot corrosion experiment after drilling.

Combined with the two sections above, drilling provides the possibility for the formation of stable Al2O3 layer in the hot corrosion process, and the existence of a stable Al2O3 layer can well prevent the oxidation layer from spallation. This positive facilitation process leads to this unusual hot corrosion behavior.

The hot corrosion behavior of nickel-based single-crystal superalloy is studied after drilling at 900 °C above. The normal hot corrosion experiment and the hot corrosion experiment after drilling are compared. The changes of different oxide layers and the corresponding spallation are analyzed. The main conclusions are as follows:

-

1.

For nickel-based single-crystal superalloy with low Cr content, severe hot corrosion occurs at 900 °C, and the oxide layer continuously spalls and cannot be formed stably.

-

2.

Al-lean zone and Al2O3 bugle structure are formed around the hole of nickel-based single-crystal superalloy after drilling, which can improve the hot corrosion performance to some extent.

-

3.

Compared with normal hot corrosion, a relatively stable and dense Al2O3 layer forms around the hole after hot corrosion, which depends on the different element diffusion effect of the Al-lean layer and the stability effect of Al2O3 bugle structure on the oxide layer.

-

4.

In addition to the influence of the change of microstructure on the formation of Al2O3 layer, the convergence effect brought by the shape of holes also improves the density of the Al2O3 layer.

-

5.

When the stable Al2O3 layer is formed, it produces stress pointing to the direction of the matrix, so as to maintain the stable existence of the oxide layer and reduce the spallation caused by hot corrosion.

Methods

Preparation of materials

The nominal composition of the experimental alloy is listed in Table 1.

The single-crystal superalloy bars are directionally solidified by the liquid metal cooling method. The (001)-oriented René-N5 seed crystal is used to ensure the growth from rod crystal into single-crystal. Then, a solution heat treatment is applied. After solution heat treatment, an aging heat treatment is carried out for the alloy bars successively. Electro-spark wire-electrode cutting is used to cut the hot corrosion samples with a size of ø10 × 3 mm and then machines cylindrical sides by a lathe process. The surfaces of all alloy samples are ground by grinding from #60 to #1000 emery papers and washed with alcohol to remove dirt subsequently50.

Drilling and hot corrosion testing

In order to study the hot corrosion behavior of the microstructure near the alloy cooling hole, drilling, and then hot corrosion tests are carried out. Due to the severe hot corrosion, the surface reaction is intense, and the low Cr content alloy is used to conduct an experiment for the most obvious result. First, the hole with a diameter of 1 mm is machined by electric spark (ZGDC406 EDM numerical control punch Suzhou Zhonggu Machine & Electronic Technology Co. Ltd) at the center of the prefabricated alloy samples as shown in Supplementary Fig. 251. Subsequently, the normal hot corrosion tests are carried out. Each sample is sprayed with a saturated aqueous solution of 25 wt.% NaCl + 75 wt.% Na2SO4 (simulation of actual hot corrosion environment) through a little spray bottle and followed by drying. At the same time, to ensure that the inner surface of the hole is also sprayed with salt, a micron tube is used to assist in spraying the salt solution into the inside of the hole. After that, each specimen is weighted to ensure that a 0.3–0.5 mg cm−2 salt is existed on the surface of the sample. Each sample is placed into a crucible separately, and all the crucibles are put into a furnace at 900 °C for hot corrosion, and the kinetics of hot corrosion is studied. The experiment is suspended every 5 h to weigh the weight change with both “mass gain” (including the weight of the corrosion spallation in the crucible) and “sample weight change” (referring just the weight of the specimen) and then the salt is added to make sure enough salt for the subsequent reaction. Before each cycle of the weigh and salt replenishment, the samples surfaces are cleaned simply by sitting in deionized water for 5 min to ensure the accuracy of hot corrosion test to a certain extent. When the tests last for 20, 50, 100, and 200 h, specimens are taken out of the furnace to observe the microstructure.

Analyzing methods

An analytical balance with a minimum sensitivity of 0.01 mg is used to weigh the weight changes of the samples and prepare salt solution. XRD is used to identify the hot corrosion products. SEM with SE and BSE detectors, an EDS, and electron backscattered diffraction (EBSD) is used to study the surfaces and cross-section morphologies, characterize the elements distribution, and analyze the sulfides information.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study. All relevant data can be available from the authors if required.

References

Emami, M. D., Shahbazian, H. & Sunden, B. Effect of operational parameters on combustion and emissions in an industrial gas turbine combustor. J. Energy Resour. 141, 12202 (2019).

Gusarov, V. A. & Godzhaev, Z. A. Development of low-power gas turbine plants for use at industrial facilities. J. Mach. Manuf. Reliab. 47, 500 (2018).

Sass, V., Glatzel, U. & Feller-Kniepmeier, M. Anisotropic creep properties of the nicle-base superalloy CMSX-4. Acta Mater. 44, 1967 (1996).

Betteridge, W. & Shaw, S. W. K. Development of superalloys. Mater. Sci. Technol. 3, 682 (1987).

Yang, S. et al. Oxidation behavior of Al/Y co-modified nanocrystalline coatings with different Al content on a nickel-based single-crystal superalloy. Corros. Sci. 170, 108700 (2020).

Aminov, R. Z., Moskalenko, A. B. & Kozhevnikov, A. I. Optimal gas turbine inlet temperature for cyclic operation. J. Phys. Confer. Ser. 1111, 12046 (2018).

Lujn, J., Serrano, J., Piqueras, P. & Diesel, B. Turbine and exhaust ports thermal insulation impact on the engine efficiency and after treatment inlet temperature. Appl. Energy 240, 409 (2019).

Swaina, B., Mallick, P., Patel, S., Roshan, R. & Behera, A. Failure analysis and materials development of gas turbine blades. Mater Today Proc. 33, 5143 (2020).

Frąckowiak, A., Wolfersdorf, J. V. & Ciałkowski, M. Optimization of cooling of gas turbine blades with channels filled with porous material. Int. J. Therm. Sci. 136, 370 (2019).

Evans, A. G., Mumm, D. R., Hutchinson, J. W., Meier, G. H. & Pettit, F. S. Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater. Sci. 46, 505 (2001).

Miller, R. A. Current status of thermal barrier coatings—an overview. Surf. Coat. Technol. 30, 1 (1987).

Wang, J., Liu, C., Zhao, Z., Balet, J. & Sundén, B. Effect and optimization of backward hole parameters on film cooling performance by Taguchi method. Energy Convers. Manag. 214, 112809 (2020).

Singh, K., Premachandran, B. & Ravi, M. R. Effect of thermal barrier coating and gas radiation on film cooling of a corrugated surface. J. Heat Trans. 140, 94504 (2018).

Mishra, S. & Sanjay Energy and exergy analysis of air-film cooled gas turbine cycle: effect of radiative heat transfer on blade coolant requirement. Appl Therm. Eng. 129, 1403 (2018).

Tian, K., Wang, J., Liu, C., Yang, L. & Sunde, N. B. Effect of blockage configuration on film cooling with and without mist injection. Energy 153, 661 (2018).

Hu, C., Kong, Z., Liu, X. & Tao, C. Effects of gas film hole on mechanical property and oxidative damage of turbine blades. Mater. Sci. Forum 944, 421 (2019).

Marimuthu, S., Antar, M. & Dunleavey, J. Characteristics of micro-hole formation during fibre laser drilling of aerospace superalloy. Precis. Eng. 55, 339 (2019).

Yadav, U. S. & Yadava, V. Experimental modeling and multiobjective optimization of electrical discharge drilling of aerospace superalloy material. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 229, 1764 (2015).

Garofano, J. K. M., Marcus, H. L. & Aindow, M. Characterization of microstructural effects in a percussion laser-drilled powder metallurgy Ni-based superalloy. J. Mater. Sci. 44, 680 (2009).

Garofano, J. K. M., Marcus, H. L. & Aindow, M. Extraction replication studies of near-surface microstructures in laser-drilled samples of the powder metallurgy Ni-based superalloy IN100. Mater. Charact. 61, 929 (2010).

Shang, Y., Zhang, H., Hou, H., Ru, Y. & Pei, Y. L. High temperature tensile behavior of a thin-walled Ni based single-crystal superalloy with cooling hole In-situ experiment and finite element calculation. J. Alloy. Compd. 782, 619 (2019).

Petronic, S., Milosavljevic, A., Burzić, M., Eric-Cekic, O. & Jovicic, R. The influence of laser drilling process on the microstructural changes of nickel based superalloy. Adv. Mater Res. 1146, 134 (2018).

Panigrahi, R. R., Panda, A., Sahoo, A. K. & Kumar, R. Machining performance measures of high temperature heat resistant super alloys: a review. Mater. Today Proc. 18, 4524 (2019).

Kersey, R., Staroselsky, A., Dudzinski, D. & Genest, M. Thermomechanical fatigue crack growth from laser drilled holes in single crystal nickel based superalloy. Int. J. Fatigue 55, 183 (2013).

Liang, J., Ai, X., Wen, Z. & Yue, Z. Experimental investigation on low cycle fatigue of DZ125 with film cooling holes in different processes of laser drilling. Eng. Fail Anal. 59, 326 (2016).

Leigh, S., Sezer, K., Li, L., Grafton-Reed, C. & Cuttell, M. Recast and oxide formation in laser-drilled acute holes in CMSX-4 nickel single-crystal superalloy. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 224, 1005 (2010).

Dong, T. et al. Effect of substrate orientations on microstructure evolution and stability for single crystal superalloys in rapid solidification process. Mater. Des. 128, 218 (2017).

Chang, J. X., Wang, D., Zhang, G., Lou, L. H. & Zhang, J. Interaction of Ta and Cr on Type-I hot corrosion resistance of single crystal Ni-base superalloys. Corros. Sci. 117, 35 (2017).

Rehman, A., Bidabadi, M. H. S., Liang, Y., Yu, Z. & Yang, Z. G. Hot corrosion behaviour of yttrium and aluminium modified wear resistance coating alloy in mixed sulphate at 900 °C. Corros Sci. 165, 108369 (2020).

Zhang, P., Li, X., Moverare, J. & Lin Peng, R. The iron effect on hot corrosion behaviour of MCrAlX coating in the presence of NaCl at 900 °C. J. Alloy. Compd. 815, 152381 (2020).

Yadav, U. S. & Yadava, V. Experimental investigation on electrical discharge diamond drilling of nickel-based superalloy aerospace material. Proc. Inst. Mech. Eng. B-J. Eng. Manuf. 231, 1160 (2017).

Zhu, L., Zhu, S. & Wang, F. Hot corrosion behaviour of a Ni plus CrAlYSiN composite coating in Na2SO4-25 wt.% NaCl melt. Appl. Surf. Sci. 268, 103 (2013).

Birks, N., Meier, G. H. & Pettit, F. S. Introduction to the High-Temperature Oxidation of Metals. (Cambridge University Press, United States of America by Cambridge University Press, New York, 2006).

Evans, H. E. & Taylor, M. P. Creep relaxation and the spallation of oxide layers. Surf. Coat. Technol. 94-95, 27 (1997).

Ay, M., Çaydaş, U. & Hasçalık, A. Optimization of micro-EDM drilling of inconel 718 superalloy. Int. J. Adv. Manuf. Technol. 66, 1015 (2013).

Dilip, D. G., Panda, S. & Mathew, J. Characterization and parametric optimization of micro-hole surfaces in micro-EDM drilling on Inconel 718 superalloy using genetic Algorithm. Arab. J. Sci. Eng. 45, 5057 (2020).

Imran, M., Mativenga, P. T., Gholinia, A. & Withers, P. J. Assessment of surface integrity of Ni superalloy after electrical-discharge, laser and mechanical micro-drilling processes. Int. J. Adv. Manuf. Technol. 79, 1303 (2015).

Birks, N., Meier, G. H. & Pettit, F. S. Introduction to the High-Temperature Oxidation of Metals. (Cambridge University Press, the United States of America, 2006).

Karabela, A., Zhao, L. G., Lin, B., Tong, J. & Hardy, M. C. Oxygen diffusion and crack growth for a nickel-based superalloy under fatigue-oxidation conditions. Mater. Sci. Eng. A 567, 46 (2013).

Smialek, J. L., Jayne, D. T., Schaeffer, J. C. & Murphy, W. H. Effects of hydrogen annealing, sulfur segregation and diffusion on the cyclic oxidation resistance of superalloys—a review. Thin Solid Films 253, 285 (1994).

Jokisaari, A. M., Naghavi, S. S., Wolverton, C., Voorhees, P. W. & Heinonen, O. G. Predicting the morphologies of γʹ precipitates in cobalt-based superalloys. Acta Mater. 141, 273 (2017).

Zhang, L. N. & Ojo, O. A. Corrosion behavior of wire arc additive manufactured Inconel 718 superalloy. J. Alloy. Compd. 829, 154455 (2020).

Nychka, J. A., Clarke, D. R. & Meier, G. H. Spallation and transient oxide growth on PWA 1484 superalloy. Mat. Sci. Eng. A 490, 359 (2008).

Xu, C. & Gao, W. Pilling-Bedworth ratio for oxidation of alloys. Mater. Res. Innov. 3, 231 (2000).

Huntz, A. M., Zhao, J. G. & Boumaza, A. Parameters affecting oxide adherence in nickel based alloys and techniques allowing estimation of adherence. Mater. Sci. Technol. 4, 470 (1988).

Hancock, P. & Hurst, R. C. eds. The Mechanical Properties and Breakdown of Surface Oxide Films at Elevated Temperatures (NY, Plenum Press, New York, 1974).

Chai, Y. J., Lin, C. & Li, Y. M. Growth trend of thermal grown oxide in TBCs under chemical oxidation effect. Appl. Math. Mech. 36, 404 (2015).

Lin, C. & Li, Y. M. A coupled mechanical-chemical model for reflecting the influence of stress on oxidation reactions in thermal barrier coating. J. Appl. Phys. 123, 215305 (2018).

Nakajo, A., Wuillemin, Z., Van Herle, J. & Favrat, D. Simulation of thermal stresses in anode-supported solid oxide fuel cell stacks. Part II: Loss of gas-tightness, electrical contact and thermal buckling. J. Power Sources 193, 216 (2009).

Bondarenko, Y. A., Kablov, E. N. & Morozova, G. I. Effect of high-gradient directed crystallization on the structure and phase composition of a high-temperature alloy of the type RENE-N5. Metal Sci. Heat. Treat. 41, 61 (1999).

Rahul & Datta, S. Electrical discharge machining performance of deep cryogenically treated Inconel 825 superalloy: emphasis on surface integrity. Metallogr. Microstruct. Anal. 8, 212 (2019).

Acknowledgements

This research is sponsored by the National Natural Science Foundation of China (Grant Nos. 51771007, 51671015 and 92060301), National Key Research and Development Program of China under Grant No. 2017YFA0700700, the National Science and Technology Major Project 2017-VI-0012-0084, R & D Program in Key Field of Guangdong Province 2019B010936001, and the Academic Excellence Foundation of BUAA for Ph.D. Students.

Author information

Authors and Affiliations

Contributions

Z.C.: conceptualization, methodology, software, investigation, data curation, writing—original draft. M.W.: software, formal analysis. Y.P.: resources. S.L.: validation, resources, funding acquisition. S.G.: supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, Z., Wu, M., Pei, Y. et al. Study on abnormal hot corrosion behavior of nickel-based single-crystal superalloy at 900 °C after drilling. npj Mater Degrad 5, 21 (2021). https://doi.org/10.1038/s41529-021-00167-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-021-00167-4

This article is cited by

-

Hot Corrosion and Oxidation Behavior of Pt–Aluminide and Pt–Rh–Aluminide Coatings Applied on Nickle-Base and Cobalt-Base Substrates

Metals and Materials International (2024)

-

Solid/Molten Na2SO4-Induced Hot Corrosion Behaviors of Mar-M247 Alloy with CVD Aluminide Coatings

High Temperature Corrosion of Materials (2024)

-

Study on the oxidation resistance mechanism of self-healable NiAl coating deposited by atmospheric plasma spraying

npj Materials Degradation (2023)