Abstract

The potential for crevice corrosion of UNS30400 stainless steel in the presence of sulfate-reducing bacteria (SRB) was studied in different media. Immersion studies found crevice corrosion to occur in test media supplemented with high chloride levels and SRB present for crevice gaps of ~3 μm. Electrochemical measurements showed high susceptibility to corrosion in this particular medium, demonstrated by a negative shift of open circuit potential, increased corrosion current and the lowest passivity breakdown potential. Overall, the results showed that test media can play a critical role in the crevice corrosion of stainless steel in the presence of SRB.

Similar content being viewed by others

Introduction

Stainless steel is a widely used material in many industrial applications owing to its high strength and good corrosion resistance properties. The corrosion resistance of stainless steel is due to the formation of a thin, adherent chromium oxide passive film on its surface1. Nevertheless, these passive alloys have been reported to be affected by localized corrosion in the presence of chlorides and reduced sulfur compounds2,3. One of the main concerns with stainless steel alloys in chloride-containing environments is crevice corrosion. Crevice corrosion is a form of localized corrosion that occurs within gaps or at shielded areas where the solution is stagnant and/or its access is restricted4. Such crevices can be formed at metal-metal and/or metal-nonmetal junctions like rivets, bolts, gaskets, irregular penetrating welds, loose surface deposits and areas of marine growth5. The most commonly proposed theories to describe the initiation of crevice corrosion in stainless steel alloys include the critical crevice solution theory6,7,8,9 and the potential drop theory10,11.

The geometry of the crevice, and particularly the gap between the two surfaces that form the crevice, is a critical factor for the initiation and propagation of crevice corrosion. Gaps between 0.1 and 100 µm are typically reported in relation to crevice corrosion, with smaller gaps usually leading to increased corrosion12. A common method for testing crevice corrosion involves using a crevice former, a washer with a series of grooves and plateaus, held in contact with the material of interest with the assembly tested in an appropriate solution13.

The potential role of microorganisms in the corrosion of stainless steel alloys has long been recognized14,15,16,17. Accelerated corrosion attack on stainless steels due to MIC has been reported by a variety of industries such as oil and gas, pulp and paper, power generation, maritime and sewage18,19. It is also interesting to note that many of the field reported failures of MIC of stainless steel tend to occur within obstructed regions and/or crevices, for example, at irregular weldments, threaded/overlapping joints, unsealed gasket or naturally occurring deposits20,21,22. Biofilms have been shown to increase the localized corrosion of stainless steel alloys by lowering their critical pitting potential which is attributed to the physicochemical changes at the metal/biofilm interface23,24. The effect of biofilms on crevice corrosion of stainless steel alloys has also been studied. However, the majority of these studies have focused on natural marine/seawater biofilms containing a wide variety of microbes and physiological characteristics that makes it difficult to explain the underlying mechanisms involved in the corrosion process25,26,27,28. Performing corrosion experiments with a single strain of bacteria can potentially help to provide better understanding of the fundamental mechanisms involved in the MIC process.

Sulfate-reducing bacteria (SRB) have been reported to be the cause or a contributing factor in the MIC of stainless steels29,30,31. Laboratory experiments have attempted to replicate the rapid, sustained corrosion of stainless steels that occur in the field due to the presence of SRB. However, most of these studies have either produced insignificant corrosion rates30,32 or reported that stainless steels are resistant to SRB mediated corrosion attack33,34,35,36. One of the potential reasons for conflicting reports of SBR corrosion of stainless steel may be due to varying test media composition used37,38,39,40,41. Webster and Newman42 investigated the effect of test media constituents on SRB corrosion of Fe-15Cr-10Ni stainless steel crevices. They found that the accelerated corrosion of stainless steel in the presence of SRB would not occur unless chloride were the dominant anions in the test media. The authors further suggested that the concentration of the chloride ions should be at least equivalent to all other anions combined; otherwise, corrosion of the stainless steel was inhibited. In contrast, in our recently published paper43, we investigated the SRB corrosion of 304 stainless steel in test medium with ~2.1× more chloride ions compared to all other anions combined. Despite a high ratio of chloride to all other anions in the test media used, no evidence of SRB corrosion of stainless steel was found. It is important to note that the test arrangement used in the Webster and Newman study42 consisted of creviced stainless steel coupons, whereas, in the later study (i.e. reference43) no crevice was present.

In the current work, experiments were designed to investigate the effect of the test media composition (chloride and iron ions) on the corrosion of UNS30400 stainless steel alloy (from now on referred to as 304 stainless steel) by SRB in the presence of crevices. A detailed analysis of surface profiles of polished steel coupons and crevice washers was performed using a 3D optical profilometer to determine the actual crevice gaps present. The creviced coupons were exposed to two different test media with and without SRB, i.e. modified Baar’s (MB) medium with iron ions and MB medium supplemented with high chloride and no iron ions (MBN) under anaerobic conditions at 30 °C for 32 days. A combination of simple immersion tests, electrochemical tests and surface analysis techniques were used to evaluate the crevice corrosion of 304 stainless steel under both abiotic and biotic test conditions.

Results

Simple immersion tests

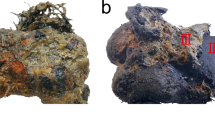

Photos of 304 stainless steel coupons retrieved from MB and MBN media after 32 days of immersion under abiotic and biotic conditions are shown in Fig. 1. Under abiotic conditions, the coupons were observed to be free of corrosion products and/or biofilms and there were no visual signs of attack on the surface of the coupons. Under biotic conditions, the coupons retrieved from MB medium were covered with a dense black colored biofilm outside the creviced areas and within the 1 mm gap rectangular slots of the crevice washer. However, there was no biofilm present where the triangular wedges of the crevice washers touched the surfaces of the stainless steel coupons. After removal of the biofilm, no attack was seen on the coupons recovered from the biotic MB medium. In comparison, the coupons immersed in the MBN medium only showed a greyish, less-dense biofilm between the 1 mm gap rectangular slots. No biofilm was seen outside the crevice washer or where the triangular wedges touched the stainless steel coupons. The cleaned coupons recovered from biotic MBN medium clearly showed visible signs of crevice corrosion attack at the location of the triangular wedges of the crevice washer. It is worth mentioning here that crevice corrosion attack was seen on all the 72 sites of multiple crevice assembly attached on the triplicate stainless steel coupons tested in the MBN biotic medium. These results indicated that there is a very high probability of crevice corrosion attack on 304 stainless steel coupons in the biotic MBN medium at 30 °C after 32 days of immersion for the smaller ~3 μm crevices that arise due to the machining marks on the crevice washers.

SEM analysis

Figure 2 shows SEM images of the surface of the coupons after exposure in abiotic/biotic MB and MBN media for 32 days. Under abiotic conditions, no corrosion products were found on the surface of metal coupons exposed to MB (Fig. 2a) and MBN (Fig. 2c) media. Likewise, no corrosion attack was observed on the surface of the coupons exposed to MB (Fig. 2b) and MBN media (Fig. 2d) under abiotic conditions. The coupons exposed to biotic MB medium, however, were covered with a relatively dense biofilm comprising a network of SRB and extracellular polymeric substances (EPS) (Fig. 2e). Rather than a dense biofilm, the coupons exposed to biotic MBN medium were covered with isolated SRB cells without the additional EPS or corrosion products seen for the biotic MB test (Fig. 2g). SEM images of cleaned coupons showed no signs of corrosion on the coupons exposed to the MB medium (Fig. 2f). Whereas, crevice corrosion in the form of small (submicrometer) shallow continuous pits was found on the coupons exposed to MBN medium in the regions where the crevice formers were in contact with the surface of the stainless steel (Fig. 2h). Additional SEM images are provided in Fig. 3 and Fig. 4 indicating where each of the images shown in Fig. 2 were captured on the surface of the stainless steel coupons.

Interestingly, lower magnification SEM images showed that the corrosion attack on the biotic MBN samples was similar in dimensions to the pattern of the machining grooves observed on the triangular wedges of the crevice washers (Supplementary Fig. 1). The average width of the regions in which crevice attack was observed on stainless steel coupons (i.e. ~35 ± 5 µm) was found to be quite similar to that of the average width of the machining grooves/crevice gap on the surfaces of the triangular wedges of the crevice washers (i.e. ~48 ± 4 µm).

EDS analysis

Examples of EDS spectra of the surface of stainless steel coupon before and after 32 days of exposure in the MB and MBN test media inoculated with SRB are shown in Fig. 5. Figure 5a shows an EDS spectrum of a freshly polished 304 stainless steel surface for comparison. Figure 5b shows an elemental composition of the biofilm formed on the surface of the coupons after 32 days of exposure in the biotic MB medium. The EDS results showed that the biofilm predominantly consists of a relatively high concentration of sulfur and iron, indicating the presence of iron sulfide (FeS, a black color surface film). The FeS film formed on the coupons immersed in the MB medium is likely due to a reaction between the sulfide ions produced during the metabolic activity of SRB and the free soluble Fe+2 ions present in the MB medium. Figure 5c shows the elemental composition of the general surface of metal coupons exposed to the biotic MBN medium for 32 days. No sulfur was found in this case indicating the absence of a FeS film on the surface of these coupons. This is to be expected because there were no soluble Fe+2 ions present in the MBN medium (see Table 3), there was no black colour FeS film formed on the coupon surface in this medium. This was also confirmed by SEM images, which showed a dense biofilm on the surface of the samples immersed in biotic MB medium (Fig. 2e), but no biofilm and only isolated SRB cells on the samples immersed in biotic MBN medium (Fig. 2g). The absence of FeS film formation in MBN media could be attributed to the lower concentration of Fe+2 produced by crevice corrosion in MBN medium over the course of 32 days. While it was beyond the scope of the current investigation it may be interesting in future studies to identify the changes in the composition of the passive film present on the stainless steel samples in different test media and SRB combination using techniques such as X-ray photoelectron spectroscopy, X-ray diffraction and/or Raman spectroscopy.

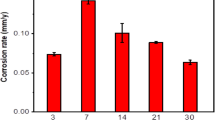

Corrosion rates (mass loss)

The corrosion rates calculated from mass loss of metal coupons after 32 days of immersion in MB and MBN media under abiotic and biotic conditions are shown in Fig. 6. The corrosion rates of the coupons immersed in the abiotic and biotic MB medium were found to be similar (p > 0.05). The average corrosion rates of the coupons were found to be 0.08 ± 0.01 µm y−1 and 0.09 ± 0.01 µm y−1 after 32 days of exposure in the abiotic and biotic MB medium, respectively. In contrast, a significant difference (p < 0.05) was found in the corrosion rates of the coupons exposed to the abiotic and biotic MBN medium. While the rates are still relatively low, as would be expected for the localized type of corrosion observed, the average corrosion rates of the coupons were found to be significantly higher in the biotic MBN medium (0.23 ± 0.02 µm y−1) compared to the abiotic MBN medium (0.11 ± 0.02 µm y−1).

pH and viable bacterial counts

The pH of the test media (MB and MBN) was measured at the start and end of the simple immersion tests for 32 days. For the abiotic test conditions, minimal change in the pH was observed between the start and end of the test (constant at ~6.5). On the other hand, for biotic test conditions, the pH of both the media increased to more alkaline values, i.e. ~7.9, by the end of the test.

The number of viable SRB cells (CFU mL−1) was measured at the end of the experiment to see if there was any correlation between the numbers of SRB present in the different media used and the observed crevice corrosion of stainless steel. Supplementary Fig. 2 shows an example of typical black color SRB colonies grown on agar plate. The estimated number of viable SRB cells was similar in both the MBN and MB medium i.e. 107 CFU mL−1. During the plating tests, no evidence of microbes other than the SRB being tested was found, indicating that the tests were free of contamination. No growth of SRB or other cells was found in any of the abiotic media, as evidenced by spread plating at the conclusion of the tests. Furthermore, in both the biotic and abiotic test media, additional plates incubated under aerobic conditions also showed no bacterial cell growth.

Open circuit potential vs. time

Figure 7 shows the OCP versus time data of the creviced 304 stainless steel coupons exposed to the MB and MBN test media at 30 °C under abiotic and biotic conditions over 10 days. In the case of the abiotic MB medium, the OCP values of 304 stainless steel increased slightly from −250 mV to about −150 mV after 1.5 days of exposure and then remained relatively stable throughout the testing period. In contrast, in the biotic MB medium, the 304 stainless steel coupons showed a gradual negative shift in the OCP from 1.5 days until the end of the test. The final OCP was found to be ~150 mV more negative than the initial OCP. In the case of abiotic and biotic MBN medium, the OCP in both the test conditions dropped from −120 mV to about −400 mV after 1.5 days of immersion. Following this, the OCP values continued to drop with the OCP in the biotic MBN medium ending up being more negative, on an average by ~100 mV lower, compared to the abiotic MBN medium.

Potentiodynamic polarization curves

Potentiodynamic polarization scans were conducted on the creviced 304 stainless steel coupons at the end of the OCP tests. Examples of potentiodynamic polarization curves obtained for each of the test configurations are shown in Fig. 8. It is worth noting that relative to the other test conditions, the current did not decrease after reaching a passivation potential for the case of the MB abiotic test. The previous work44 observed that biogenic sulfides in chloride-containing solutions can affect the shape of potentiodynamic polarization curves of stainless steels in the region of transition from active to passive states. Standard electrochemical parameters, including corrosion potential (Ecorr) and corrosion current density (icorr) were evaluated for the coupons from all the test conditions, which were performed in triplicate, with the results summarized in Table 1.

A significant difference was seen in the Ecorr values of 304 stainless steel immersed in the different media under abiotic and biotic situations. The Ecorr values of 304 stainless steel in both of the media under biotic conditions are found to be more negative compared to their respective abiotic controls. A difference of ~300 mV was found between the Ecorr values in the biotic and abiotic MB medium. In the MBN medium, the difference between Ecorr values in biotic and abiotic media was ~80 mV. The overall trend in the Ecorr values of 304 stainless steel in all of the tested conditions is in the following order: MB-AB >> MB-B > MBN-AB > MBN-B.

The icorr values of 304 stainless steel showed a significant difference between abiotic and biotic MB medium. No significant difference, however, was seen between icorr values of 304 stainless steel coupons tested in MBN medium under abiotic and biotic conditions. The values for the MBN tests were also quite similar to the icorr values found in the biotic MB medium. The overall trend in the icorr values of 304 stainless steel in different tested conditions is in the following order: MB-AB << MB-B ≈ MBN-AB < MBN-B.

Passivity breakdown potentials (Eb)

The passivity breakdown potential (Eb) was determined from the potentiodynamic polarization curves. The values of Eb for 304 stainless steel in MB and MBN media under abiotic and biotic conditions are shown in Fig. 9 (left-hand side). The Eb of the coupons were found to be significantly different in the biotic medium compared to the abiotic medium. The Eb in both of the biotic media shifted in the negative direction compared to their respective abiotic control media, suggesting that the SRB decreased the Eb of the passive film. The average Eb of the metal coupons exposed to the biotic MB medium (553 ± 19 mV) was ~1.9 times lower compared to the abiotic MB medium (1038 ± 38 mV). Similarly, for coupons exposed to the MBN medium, the Eb in the biotic medium (61 ± 16 mV) was ~3.1 times lower than the abiotic medium (191 ± 35 mV).

Another critical parameter that shows the tendency of a metal to pitting/crevice corrosion is the difference between the Eb and Ecorr values. The lower the difference, the higher is the tendency for pit initiation45,46. In this respect, the differences between Eb and Ecorr were calculated for the creviced 304 stainless steel in different test media conditions studied (Fig. 9, right-hand side). The difference (Eb − Ecorr) for 304 stainless steel was found to be the lowest in the biotic MBN medium. These observations suggest that the most detrimental effects of crevice corrosion of 304 stainless steel coupons emerge from the interactions of SRB and relatively high salt levels in the test media, i.e. biotic MBN medium. These findings also correlate well with the immersion test results from this study which showed crevice corrosion attack to occur only in the biotic MBN medium after 32 days of immersion at 30 °C.

Discussion

The effect of test media composition on the onset of crevice corrosion of 304 stainless steel was studied with and without SRB using a combination of simple immersion, electrochemical and surface inspection tests. Stainless steel coupons with crevice assemblies were exposed to two different test media with different chloride and iron ions concentrations (i.e. MB and MBN) at 30 °C under anaerobic conditions with and without SRB. The results obtained revealed that the test media composition played a significant role in the overall susceptibility of the 304 stainless steel to crevice corrosion in the presence of SRB. It is worth mentioning that in the previous work43 using similar testing conditions to that used in the current paper but without crevices, no corrosion of 304 stainless steel was observed after 42 days of testing incorporating SRB.

The simple immersion test (32 days duration, Fig. 6) showed no difference in the crevice corrosion rates of 304 stainless steel in the MB medium for both abiotic and biotic conditions. Significantly higher corrosion rates, however, were observed for tests performed in the MBN medium in biotic conditions compared to abiotic conditions. These results are consistent with previous studies suggesting that the composition of test media can play an important role in the corrosion of stainless steel with SRB38,42,47. The critical factors in the composition of the test media are reported to be: (i) the presence of chloride ions and (ii) the relative concentration of inhibiting anions to aggressive anions. Literature has indicated that the relative concentration of the aggressive anions to inhibiting anions (i.e. the ratio of chlorides to the sum of all other anions) is very important for the abiotic as well as biotic corrosion of stainless steel39,42. Chlorides are known to be aggressive to stainless steel, including when crevices are present. The crevice and/or pitting potential for stainless steel tends to drop as the concentration of chloride ions increases48. However, there are several anions present in common test media used for laboratory-based SRB corrosion studies that can act as inhibitors to the corrosion of stainless steel, such as sulfates, hydroxides, phosphates, carbonates, nitrates and acetates38,49. Webster et al.42 showed that a relatively high ratio of chlorides to inhibiting anions is required to consistently produce rapid corrosion of stainless steel with SRB in the laboratory. The ratio of chloride to inhibiting anions in the MBN medium is 2.1:1, which is relatively higher compared to the MB medium with a ratio of 0.2:1.

The OCP tests showed more negative (active) values of the stainless steel coupons exposed to both of the biotic MB and MBN media with increasing exposure time compared to their respective abiotic control media. In the case of MB medium, the drop of OCP to more active values in biotic conditions compared to abiotic conditions is likely due to the formation of bacterial biofilm on the metal surface. These results are consistent with previous studies which showed a decrease in the free corroding potential of the stainless steel in the presence of bacterial biofilm50,51. In case of the MBN abiotic medium, the shift of OCP to negative values could be due to the depolarization effect of absorbed chloride ions on the metal surface thus promoting open circuit dissolution of surface oxide films26,52. For the MBN biotic medium, although there was no thick biofilm present on the metal surface, studies have shown that the single aggregates of bacterial cells on discrete locations on the metal surface are capable of shifting the potential of stainless steel in the active directions26,53.

The results of the potentiodynamic polarization test showed that the icorr values for the coupons exposed to the biotic MB medium were significantly higher than for the abiotic MB medium. Interestingly, no significant difference was found in the icorr values for the coupons exposed to the biotic MB medium and the abiotic/biotic MBN medium. However, the Ecorr values were found to be considerably different and more negative in the biotic MBN, abiotic MBN, biotic MB and abiotic MB media, respectively. Similarly, a significant difference in Eb values was seen for the coupons exposed to the different test conditions, with the trend indicating that the lowest values were found in the biotic MBN, abiotic MBN, biotic MB, and abiotic MB media, respectively. These findings suggest that of all the test media studied, the susceptibility to crevice corrosion for any given time interval was greater for the biotic MBN medium.

It has been proposed that the crevice corrosion of stainless steel occurs through the mechanism of passive film dissolution in a neutral chloride-containing solution5,7,54. This theory suggests that when the crevice corrosion is initiated, the passive film inside the crevice is broken while the passive film outside the crevice remains intact. According to previous studies, one of the potential reasons for the breakdown of the passive film could be the increasing concentration of H+ and Cl- ions inside the crevice48,55. Figure 10 shows a schematic diagram of the proposed mechanism of crevice corrosion of 304 stainless steel in MBN biotic medium based on passive film dissolution theory. This assumes that initially, some corrosion of stainless steel occurs over the entire surface of the stainless steel, including the surface within the crevice. In terms of the mixed potential theory, the electrode reaction at the anodic region is the dissolution of Fe (Eq. (1)), i.e.

The electrode reactions at the cathodic region is the reduction of sulfate by SRB into hydrogen sulfide either electrically via extracellular electron transfer (EET-MIC) (Eq. (2)) or chemically from the sulfidogenic degradation of organic matter (simplified here as carbohydrate-building unit CH2O) (Eq. (3))56,57,58 i.e.

There are conflicting reports in the literature on the role of H2S in the SRB MIC. Several studies indicated that metabolically produced H2S is not a significant contributor in SRB MIC of steel at near-neutral pH and the dominant corrosion mechanisms are EET-MIC rather than chemical-MIC caused by H2S59,60. Similarly, Wang et al.61 demonstrated that there was no significant difference in the headspace H2 concentration profiles with and without steel coupons tested in the presence of SRB, thus supporting the same conclusion that metabolically produced H2S is not directly involved in the MIC of steel. In contrast, however, there are various studies62,63,64 which suggested that metabolically produced H2S acts as an additional cathodic reduction reaction (Eq. (4)). The H2 produced will act as an electron donor for SRB, resulting in the production of more H2S56.

It is worth mentioning here that there are some proteins (c-cytochrome) in the cytomembrane of SRB which have been shown to play an important role in direct electron transport from conductive surfaces, a process known as direct electron transfer MIC (DET-MIC)65,66,67. In addition, hydrogenase enzymes present in SRB species is also capable of hydrogen-cycling, in which H2 act as an electron shuttle between the metal surface and microbes, resulting in a mediated electron transfer MIC (MET-MIC)68,69. Although H2 is frequently used as an electron carrier between the metal surface and microbes during MIC of iron, however, this process is found to be unlikely for MIC of stainless steel which has a passive film on its surface. Tang et al.70 recently investigated whether anaerobic MIC of stainless steel could occur using H2 as an electron carrier, or through direct electron transfer at the metal/microbe interface. They used genetically modified strains of Geobacter sulfurreducens as well as wild-type Geobacter metallireducens, a species that cannot use H2. They found that H2 is unlikely to be an efficient electron shuttle for microbial corrosion of stainless steel and proposed for direct metal-to-microbe electron transfer as a potential route for MIC of stainless steel. This is an active area of research, and additional work is needed to better understand the processes involved in the MIC of stainless steels and develop mitigation strategies to combat it.

It is well-known that the narrow gaps of crevices can restrict the diffusion of ionic species between the bulk solution and solution within a crevice5,71. As the corrosion proceeds, the sulfate consumed in the cathodic reactions is not replenished, and the cathodic reaction within the crevice ceases and shifts outside the crevice where sulfate is plentiful. The anodic reaction, however, continues within the crevice resulting in the build-up of high concentration of positively charged metal ions. In order to maintain electroneutrality, the negatively charged ions, particularly chloride ions, transfer from the bulk solution into the crevice solution. The chloride ions form complexes with metal ions, which are then quickly hydrolyzed and lower the pH inside the crevice through the production of hydrogen ions (Eq. (5))5,72:

Therefore, with the extension of immersion time, the solution within the crevice undergoes two major changes, i.e. acidification (lower pH values) and higher Cl− ion concentration, enhancing the degradation of the passive film inside the crevice, resulting in a decreased breakdown potential and an increased susceptibility to crevice corrosion (Fig. 9). Other potential factors that could be responsible for the lower breakdown potential values observed in the biotic MBN medium are: (i) the consumption of the inhibiting anions such as sulfates by SRB, which leads to a relatively high concentration of aggressive anions (e.g. Cl−) to inhibiting anions (e.g. SO42−), and (ii) the increased production of biogenic sulfides (e.g. H2S/HS−) as there are no iron ions present in this medium. Both of these factors have been shown to make stainless steel susceptible to localized corrosion at lower potentials and increase the likelihood of corrosion continuing once initiated42,73,74. It is interesting to note that increased cathodic reactions occurring outside the crevice seem to be one of the key reasons for the initiation of crevice corrosion of the coupons in biotic MBN medium. This aspect could be investigated further in future studies using two separate electrodes setup with and without crevice, as demonstrated in a recently published study on crevice corrosion of carbon steel with SRBs75.

In the case of the abiotic MBN medium (Supplementary Fig. 3), despite a relatively high chloride ion concentration, no evidence of crevice corrosion was observed after 32 days of immersion. The only cathodic reaction possible in this case (i.e. anaerobic abiotic MBN), to sustain the anodic dissolution of metal ions, is the reduction of hydrogen (Eq. (6)), i.e.

The above reaction is kinetically very slow, particularly at pH values greater than 6, where the availability of protons is limiting58,63. The pH values of the bulk abiotic MBN medium in this study remained constant at ~6.5 throughout the immersion period. Due to slower kinetics of the electrode reaction of the reduction of protons, the concentration of the ions (H+, Cl- and Fe2+) within the crevice would be far below the critical level to cause the passive film breakdown by 32 days of immersion. This is in agreement with the potentiodynamic polarization results, which showed relatively higher values of breakdown potential of stainless steel in abiotic MBN medium compared to biotic MBN medium (Fig. 9).

In the case of the biotic MB medium (Supplementary Fig. 4), the free iron ions react with the metabolically produced sulfide ions and form black iron sulfide film on the surface of stainless steel63,64. Since there are no additional chloride ions present in the MB medium and the relative ratio of Cl− ions to inhibiting anions is low (i.e. 0.2:1), the solution inside the crevice would be unlikely to undergo changes which would destabilize the passive film, resulting in relatively higher breakdown potentials values (Fig. 9). Previous studies have shown that the likelihood of rapid and sustained pitting of stainless steel is increased in the test media with high Cl- to inhibiting anion ratios42,73. Finally, for the MB abiotic medium (Supplementary Fig. 5), the conditions are least favorable for crevice corrosion of 304 stainless steel due to (i) the low Cl− to inhibiting anion ratio (i.e. 0.2:1) and (ii) slow reduction of protons (2H+ + 2e− → H2) which is the only cathodic reaction possible under anaerobic condition in the absence of SRB as discussed earlier. The breakdown potential values are also found to be highest in this MB abiotic medium (Fig. 9).

The measurements performed showed that the bulk pH of the abiotic test media remained relatively constant throughout the test (stabilizing at ~6.5) whereas the pH of the biotic test media showed an increase by the end of the immersion test i.e. from ~6.5 to ~7.9. The increase in the pH with SRB is considered to be due to the oxidation of lactate (an electron donor) into bicarbonate with the simultaneous reduction of sulfate (a terminal electron acceptor) by SRB into sulfide by-products. Similar findings have been reported in the literature, which showed an increase in the pH during the growth and metabolic activity of SRB76,77. Interestingly, although similar pH values were recorded in the biotic MB and MBN media, a significant difference was observed in the corrosion of the 304 stainless steel in the two tested media. This suggests that in the presence of bacteria, the bulk pH of the media cannot be used reliably to predict the corrosion of the substrate, which could be reasonably different from the local pH values found inside the crevices and/or at substrate-biofilm interface78,79.

The number of viable planktonic SRB cells in the media were determined using the spread plate method and found to be similar in both media types tested at the end of the 32-day immersion test. This indicates that the relatively high chloride levels used in the MBN medium did not affect the viability of the SRB. There was no correlation found between the viable SRB counts and the crevice corrosion of 304 stainless steel coupons in the two tested media. Interestingly, although there was similar viable SRB cells in the two MB and MBN media, a considerable difference was seen qualitatively in the number of attached SRB cells and the formation of the biofilm on the stainless steel surface in the two test media. A dense biofilm was seen in case of the MB medium (Fig. 2e), whereas only isolated SRB cells were observed for the stainless steel surface in the case of the MBN medium (Fig. 2g). These observations were consistent with previous studies which showed that the composition of the test media can affect the attachment of bacterial cells and the formation of biofilms on a metal substrate80,81. In future work, it would be interesting to investigate the potential role (if any) of the number of SRB cells attached on the surface of the stainless steel coupons and the subsequent MIC of these alloys.

From immersion tests, electrochemical measurements and surface analysis of creviced 304 stainless steel samples exposed to two different test media, i.e. MB and MBN, under abiotic and biotic conditions at 30 °C for 32 days, the following conclusion can be drawn:

-

1.

Simple immersion tests showed crevice corrosion of the 304 stainless steel to occur only in the medium with a high chloride ion concentration (i.e. MBN medium) and the presence of SRB, for crevice gaps of ~3 μm.

-

2.

Electrochemical measurements confirmed that the susceptibility of 304 stainless steel to crevice corrosion was highest in the biotic MBN medium, which was demonstrated by the lowest OCP, Ecorr and Eb values.

-

3.

The loss of passivity and/or drop of Eb of 304 stainless steel in the biotic MBN medium could be attributed to the combine effect of (i) relatively high chloride ions concentration and (ii) production of biogenic sulfide by-products by SRB during metabolic activity.

-

4.

The test media composition (i.e. the high ratio of chloride to all other anions) was found to be critical in crevice corrosion of stainless steel with SRB.

The present results show the importance of test media composition and crevices in the MIC susceptibility of stainless steel with SRB. It is worth noting that the surface area of the coupons used in this work were somewhat small, with an estimated cathode-to-anode ratio of ~14:1. It is well known that a small cathode surface area will reduce the likelihood of crevice corrosion82, and may have contributed to the relatively low levels of crevice corrosion observed in this work. Increasing the relative cathode surface area would likely raise the chances for crevice corrosion and possibly even lead to crevice corrosion for the test conditions other than just the SRB and relatively high chloride levels. This is definitely something worthy of future study. In addition, it would be useful in future studies to investigate the effect of other testing parameters on SRB corrosion of stainless steel, for example, using different crevice geometries (gap/width), cathode to anode area ratios, measuring the potential differences between inside/outside crevices and resulting galvanic corrosion driving force in the test solution, monitoring sessile cells counts, headspace hydrogen concentration, localized changes of pH and/or oxygen concentration inside/outside crevices, chemical changes in the test solution (e.g. relative biogenic sulfides levels) and its effect on the active-passive transition of passive alloys, different anaerobic systems, using different grades of stainless steels, using different chloride ion concentrations as well as extended test durations. Studies are currently in progress to investigate these test parameters and are expected to provide additional information to help understand the potential mechanisms involved in the SRB corrosion of stainless steels.

Methods

Coupon preparation

Coupons of 304 stainless steel in the as-received annealed condition were used in this study. Microstructural analysis showed that the stainless steel consisted of a single austenite phase (Supplementary Fig. 6). The chemical composition of the stainless steel was determined via the ICP-AES technique (Table 2).

Stainless steel coupons with dimension 25 mm × 25 mm (L × W) were cut from a 3 mm thick plate sample. These coupons were used to prepare two different types of crevice test assemblies (as discussed in more detail below) for use in simple immersion and electrochemical testing. In each case the exposed coupon surface was successively ground with a series of SiC papers with different grit sizes up to a 1200 grit finish. After grinding, the coupons were degreased with acetone, thoroughly washed with water and absolute ethanol and finally dried with nitrogen gas.

Crevice assembly preparation

The crevices on each coupon (Fig. 11) were formed using two crevice washers, each containing multiple gaps, made using TFE-fluorocarbon as per the ASTM G48-11 standard13. The individual crevice washers consist of 12 raised triangular wedges (that contact the test sample) and 12 rectangular slots (Supplementary Fig. 7). A schematic diagram of one of these washers is shown in Fig. 11b. Each rectangular slot has a width and height of ~1.5 mm and ~1 mm, respectively. A 3D optical profilometer was used to scan the surfaces of a number of the triangular wedges (to determine the crevice heights) and stainless steel coupons (to determine surface roughness). The results obtained showed that stainless steel coupon consists of a relatively smooth surface profile with an average surface roughness of 0.087 ± 0.003 µm (Supplementary Fig. 8a, b). The triangular wedges included a series of microscale machining grooves on the surface (Supplementary Fig. 8c, d) with an average height (crest to trough distances) of 3.3 ± 0.3 µm and an average width (trough to trough distance) of 48 ± 4 µm. This means that when the crevice washers come into contact with the stainless steel coupons there are effectively two sets of crevices present. This includes the relatively large (~1 mm) gaps and smaller (~3.3 µm height) crevices due to the machining profiles on the washer surfaces (Supplementary Fig. 9).

(a) Crevice assembly used in simple immersion testing, (b) schematic illustration of crevice washer with multiple crevice assembly (not to scale). For more detail about the crevice washer areas that are directly in contact with the surface of the stainless steel samples please see Supplementary Figs. 7 and 9.

The washers, thread bolts and nuts used to join the crevice washers with the stainless steel coupon were made of commercially pure titanium. The titanium bolt passing through the coupon was covered with Teflon tape to prevent any galvanic coupling between the coupon and the crevice assembly. A constant torque of 1.58 Nm was applied on all the tested coupons using a torque wrench as per ASTM G48-11 standard13. The stainless steel coupons and all pieces of crevice assembly were sterilized by immersing in 70% ethanol and then drying aseptically within a PC2 biosafety cabinet before assembly and corrosion testing.

Test media preparation

Crevice corrosion tests were conducted in MB and MBN test media (Table 3). The MB medium is the standard ATCC 1249 medium commonly used for growing the SRB strain used in this study, i.e. Desulfovibrio desulfuricans (D. desulfuricans, ATCC 27774), with iron ions included. The composition of the MBN medium is the same as the standard MB medium except that it was supplemented with NaCl and had no iron ions added. The two different test media were used to see the effect of the composition, i.e. chlorides and iron ions in this case, on the SRB biofilm formation and the subsequent crevice corrosion of stainless steel coupons. The chloride to anion ratio of standard MB medium is ~0.2 whereas in case of MBN medium it is ~2.1.

After preparing, the pH of the individual test media components (I, II and III) were adjusted to 7.5 ± 0.1. These components were then autoclaved separately for 30 min at high temperature and gauge pressure, i.e. 121 °C and 103 kPa, respectively. The autoclaved media components were mixed and allowed to cool to room temperature, after which a 20 mL of 5% filtered sterilized (NH4)2Fe(SO4)2 was added per liter of the MB medium only.

Bacterial culture preparation

The SRB was cultured from −80 °C in MB medium under anaerobic conditions at 37 °C for four days as described in detail in Javed et al.43. Anaerobic sachets (AN0025A, Oxoid) and sealed pouches (AG0060C, Oxoid) were used for maintaining anaerobic conditions. An anaerobic redox indicator (BR005B, Oxoid) resazurin was used to verify the anaerobic conditions. A 1 mL aliquot of the initial SRB culture was inoculated into 400 mL of each test media type (i.e. MB and MBN). Corrosion tests were performed using this inoculated (biotic) test media. Abiotic control tests were performed using the same test media without SRB inoculation. The pH of the media was checked using a pH meter (PHM210, Meter-Lab, USA) at the start and end of the immersion test. The spread plate method (n = 6) was used to estimate the number of viable bacterial counts in the media at the end of the immersion test. The spread plates were made with tryptic soy agar plus essential salts medium (Supplementary Table 1)83. The plates were incubated for four days under anaerobic conditions at 37 °C before being analyzed to estimate the number of bacterial cells. Furthermore, plates were also incubated under aerobic conditions to see the presence of aerobic contamination (if any) in the tested system.

Simple immersion tests

A schematic illustration of the coupon used for simple immersion crevice corrosion tests is shown in Fig. 11a. For these coupons a 2 mm diameter hole was drilled on each coupon close to the edge. A Nylon string was passed through the drilled hole so that they could hang vertically during the corrosion studies carried out via simple immersion testing. Another hole of 7 mm diameter was drilled in the center of the coupons for the attachment of the crevice testing assembly. All the coupons and crevice assemblies were sterilized by immersing them in 70% ethanol for ~1 h and then aseptically dried within level 2 physical containment (PC2) cabinet.

Simple immersion tests were carried out in 500 mL Duran glass bottles containing ~400 mL of the specific test media (i.e. MB and MBN), under abiotic and biotic conditions (Supplementary Fig. 10). All the glass bottles used were sterilized by autoclaving at high temperature and gauge pressure, i.e. 121 °C and 103 kPa, respectively. Five separate sterilized stainless steel coupons (2 coupons for corrosion product/biofilm analysis and 3 coupons for weight loss/surface attack analysis) were studied for each testing condition. All immersion tests were performed at 30 °C in a water bath under anaerobic conditions (created using the anaerobic gas generating sachets and sealed pouches previously discussed) for 32 days.

SEM and EDS analysis

A scanning electron microscope (SEM, SUPRA 40VP-25-38, Zeiss, Germany) was used to examine the surfaces of the stainless steel coupons after the immersion tests. Before the surface inspection, the crevice washers were carefully removed to avoid disrupting any biofilm/corrosion products present. Two coupons (of five) retrieved from each test media type were fixed for 30 min at room temperature with glutaraldehyde solution (2.5 vol. %, electron microscopic grade) in phosphate buffer saline. The coupons were then dehydrated stepwise in an increasing ethanol concentration up to 100% ethanol. Finally, the coupons were aseptically air-dried and examined under SEM. The elemental composition of the surfaces of coupons, including any biofilm and/or corrosion products present, was determined via energy-dispersive X-ray spectroscopy (EDS) coupled with the SEM. The EDS spectra were collected at three random locations where biofilm and corrosion products were present on duplicate samples (n = 6) with scanned areas of 270 µm x 200 µm each.

To evaluate the extent of crevice corrosion of stainless steel, the additional coupons used for this purpose (n = 3) were cleaned in an ultrasonic bath for 1–2 min using a passive cleaning solution (25 vol. % solution nitric acid in water)30,84. After ultrasonic cleaning, the coupons were first rinsed with distilled water then with absolute ethanol and finally dried using nitrogen gas. Afterwards, the coupons were inspected using the SEM.

Corrosion rate (mass loss)

The coupons were weighed before and after the immersion tests using a high accuracy analytical balance (Mettler Toledo MS205DU, readability 0.01 mg). The corrosion rates were determined via mass loss, as per ASTM G1-03 standard85, using the following Eq. (7):

Electrochemical measurements

A standard three-electrode glass cell was used to carry out electrochemical measurements with a crevice assembly (Fig. 12). Each glass cell was sterilized just before the test by thoroughly rinsing and filling them with 100 mL of 70% isopropyl alcohol for ~1 hour, followed by aseptic drying in a laminar flow cabinet. Each glass cell was filled with ~600 mL of sterile test media (i.e. either MB or MBN). Tests were performed in triplicate for coupons under biotic and abiotic conditions with each test media type. For the biotic tests, a 1.5 mL aliquot of SRB culture, which had been freshly grown from −80 °C in the MB medium for four days, was added in the specific test media. Anaerobic conditions were maintained by periodically purging filtered (0.22 μm pore) pure nitrogen gas (i.e. one hour per day) through the headspace of each glass cell. A pressure outlet (fitted with a 0.22 μm pore filter) tube passed any excess gas into a bleach trap. To help maintain sterility and anaerobic conditions, all unused openings of the electrochemical cells were sealed using paraffin film. A water bath was used to maintain a constant incubation temperature of 30 °C during the tests (Supplementary Fig. 11).

The reference electrode used was a Ag/AgCl saturated with 3.8 M KCl. The reference electrode was connected to the glass cell via a Luggin capillary filled with specific testing media (i.e. MB or MBN). A graphite rod was used as the counter electrode. The working electrode was prepared by soldering copper wire to the rear side of the 304 stainless steel coupons which were then cold mounted with epoxy resin leaving an exposed surface area of 625 mm2. A hole of 7 mm was then drilled through the center of the coupon and epoxy resin in order to attach the crevice assembly. Afterwards, the surfaces of the stainless steel were ground to 1200 grit finish as described earlier in section ‘coupon preparation’. All the electrodes were sterilized by fully immersing in 70% isopropyl alcohol for ~1 hour and then aseptically dried in laminar flow cabinet.

Open-circuit potential (OCP) and potentiodynamic polarization tests were run using a multichannel potentiostat (VMP3, BioLogical science instruments, France). The working electrodes were left in the OCP mode for 10 days, during which relatively steady free corrosion potential values were reached. The potentiodynamic polarization scans were then run at a scan rate of 0.166 mV s−1 from −250 mV to 1500 mV versus OCP.

Statistical analysis

Statistical analysis of the data obtained in this study was performed using one way of analysis of variance (ANOVA) with Origin Pro 9.0 software. Any p values greater or equal to 0.05 were considered significant.

Data availability

All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials. Additional data related to this paper are available from the corresponding author upon reasonable request.

References

Blair, M. Cast stainless steels, in: Properties and selection: irons, steels, and high performance alloys, in: ASM Handbook, Vol 1: Metal 1409–1442 (2005).

Antony, P. J., Singh Raman, R. K., Kumar, P. & Raman, R. Corrosion of 2205 duplex stainless steel weldment in chloride medium containing sulfate-reducing bacteria. Metall. Mater. Trans. A 39, 2689–2697 (2008).

Yuan, S., Liang, B., Zhao, Y. & Pehkonen, S. O. Surface chemistry and corrosion behaviour of 304 stainless steel in simulated seawater containing inorganic sulphide and sulphate-reducing bacteria. Corros. Sci. 74, 353–366 (2013).

Kennell, G. F., Evitts, R. W. & Heppner, K. L. A critical crevice solution and IR drop crevice corrosion model. Corros. Sci. 50, 1716–1725 (2008).

Sedriks, A. J. Crevice corrosion in corrosion of stainless steel, 2nd edn, (John Wiley and Sons Inc., 1996).

Oldfield, J. & Sutton, W. Crevice corrosion of stainless steels: i. a mathematical model. Br. Corros. J. 13, 13–22 (1978).

Jakobsen, P. & Maahn, E. Temperature and potential dependence of crevice corrosion of AISI 316 stainless steel. Corros. Sci. 43, 1693–1709 (2001).

Alavi, A. & Cottis, R. The determination of pH, potential and chloride concentration in corroding crevices on 304 stainless steel and 7475 aluminium alloy. Corros. Sci. 27, 443–451 (1987).

Sridhar, N. & Dunn, D. Effect of applied potential on changes in solution chemistry inside crevices on type 304L stainless steel and alloy 825. Corrosion 50, 857–872 (1994).

Pickering, H. W. The significance of the local electrode potential within pits, crevices and cracks. Corros. Sci. 29, 325–341 (1989).

Shaw, B., Moran, P. & Gartland, P. The role of ohmic potential drop in the initiation of crevice corrosion on alloy 625 in seawater. Corros. Sci. 32, 707–719 (1991).

Kelly, R. G. Crevice corrosion, in: ASM Handbook, Volume 13A: Corrosion 2003. 242-247.

ASTM, Standard test methods for pitting and crevice corrosion resistance of stainless steels and related alloys by use of ferric chloride solution [standard G48-11(2020)e1], in: ASTM Hnadbook 3.02 Corrosion of Metals, Wear and Erosion, West Conshohocken, PA, 2020 1–11.

Videla, H. A. Electrochemical aspects of biocorrosion, in Bioextraction and Biodeterioration of Metals (Cambridge University Press,1995).

Beech, I. B. & Gaylarde, C. C. Recent advances in the study of biocorrosion - An overview. Rev. de. Microbiologia 30, 177–190 (1999).

Javed, M. A., Borges, B., Cirino, V., Osman A. & Wade, S. A. Effect of metal substrate on initial attachment of E. coli bacteria and subsequent microbiologically influenced corrosion. Corrosion and Prevention 2015, ACA, Adelaide, Australia, 2015. Paper049.

Little, B. et al. Microbially influenced corrosion–any progress? Corros. Sci. 170, 108641 (2020).

Little, B., Lee, J. & Ray, R. Microbiologically influenced corrosion: global phenomena, local mechanisms. Corros. Mater. 36, 46–51 (2011).

Flemming, H. C. Biofouling in water systems-cases, causes and countermeasures. Appl. Microbiol. Biotechnol. 59, 629–640 (2002).

Bernasovský, P. et al. Case studies from industrial failures. Mater. Sci. Forum 844, 59–64 (2016).

Elshawesh, F., Abusowa, K., Mahfud, H. & ElAgdel, E. Case history: Microbiologically influenced corrosion of type 304 austenitic stainless steel water pipe. Mater. Perform. 42, 54–57 (2003).

Liu, W. Rapid MIC attack on 2205 duplex stainless steel pipe in a yacht. Eng. Fail. Anal. 42, 109–120 (2014).

Javed, M. A., Stoddart, P. R. & Wade, S. A. Corrosion of carbon steel by sulphate reducing bacteria: initial attachment and the role of ferrous ions. Corros. Sci. 93, 48–57 (2015).

Neville, A. & Hodgkiess, T. Corrosion of stainless steels in marine conditions containing sulphate reducing bacteria. Br. Corros. J. 35, 60–69 (2000).

Zhang, H. J. & Dexter, S. C. Effect of biofilms on crevice corrosion of stainless steels in coastal seawater. Corrosion 51, 56–66 (1995).

Machuca, L. L. et al. Effect of oxygen and biofilms on crevice corrosion of UNS S31803 and UNS N08825 in natural seawater. Corros. Sci. 67, 242–255 (2013).

Liao, J., Fukui, H., Urakami, T. & Morisaki, H. Effect of biofilm on ennoblement and localized corrosion of stainless steel in fresh dam-water. Corros. Sci. 52, 1393–1403 (2010).

Kain, R. Crevice corrosion behavior of stainless steel in seawater and related environments. Corrosion 40, 313–321 (1984).

Brennenstuhl, A., Gendron, T. & Cleland, R. Mechanisms of underdeposit corrosion in freshwater cooled austenitic alloy heat exchangers. Corros. Sci. 35, 699707–705711 (1993).

Sheng, X., Ting, Y. P. & Pehkonen, S. O. The influence of sulphate-reducing bacteria biofilm on the corrosion of stainless steel AISI 316. Corros. Sci. 49, 2159–2176 (2007).

Castaneda, H. & Benetton, X. D. SRB-biofilm influence in active corrosion sites formed at the steel-electrolyte interface when exposed to artificial seawater conditions. Corros. Sci. 50, 1169–1183 (2008).

Zhang, P., Xu, D., Li, Y., Yang, K. & Gu, T. Electron mediators accelerate the microbiologically influenced corrosion of 304 stainless steel by the desulfovibrio vulgaris biofilm. Bioelectrochem 101, 14–21 (2015).

Lutterbach, M. T. S. & De França, F. P. Biofilm formation in water cooling systems. World J. Microbiol. Biotechnol. 12, 391–394 (1996).

Ortiz, C., Guiamet, P. S. & Videla, H. A. Relationship between biofilms and corrosion of steel by microbial contaminants of cutting-oil emulsions. Int. Biodeter. Biodegrad 26, 315–326 (1990).

Javed, M. A., Neil, W. C., McAdam, G. & Wade, S. A. Effect of sulphate-reducing bacteria on the microbiologically influenced corrosion of ten different metals using constant test conditions. Int. Biodeterior. Biodegrad. 125, 73–85 (2017).

Wang, J. et al. Comparison of 304 SS, 2205 SS, and 410 SS corrosion by sulfate reducing Desulfovibrio ferrophilus. J. Chem. 2021, 1–10 (2021).

Foley, R. Role of the chloride ion in iron corrosion. Corrosion 26, 58–70 (1970).

Ismail, A. The corrosion attack on stainless steel 316L and WC-Co in high sulphate-chloride ratio. Adv. Mater. Res. 1087, 410–414 (2015).

Little, B. J. A perspective on the use of anion ratios to predict corrosion in Yucca Mountain. Corrosion 59, 701–704 (2003).

Ortíz, M. R., Rodríguez, M., Carranza, R. & Rebak, R. Oxyanions as inhibitors of chloride-induced crevice corrosion of Alloy 22. Corros. Sci. 68, 72–83 (2013).

Salvarezza, R., De Mele, M. & Videla, H. Mechanisms of the microbial corrosion of aluminum alloys. Corrosion 39, 26–32 (1983).

Webster, B. J. & Newman, R. C. Producing rapid sulfate-reducing bacteria (SRB)-influenced corrosion in the laboratory, in: Microbiologically Influenced Corrosion Testing, ASTM Int. 1994 28–41.

Javed, M. A., Neil, W. C., McAdam, G., Moreau, J. & Wade, S. A. Microbiologically influenced corrosion of stainless steel by sulfate reducing bacteria: A tale of caution. Corrosion 76, 639–653 (2020).

Moreno, D. A., Ibars, J. R., Ranninger, C. & Videla, H. A. Use of potentiodynamic polarization to assess pitting of stainless steels by sulfate-reducing bacteria. Corrosion 48, 226–229 (1992).

Dastgerdi, A. A., Brenna, A., Ormellese, M., Pedeferri, M. & Bolzoni, F. Experimental design to study the influence of temperature, pH, and chloride concentration on the pitting and crevice corrosion of UNS S30403 stainless steel. Corros. Sci. 159, 108160 (2019).

Pardo, A. et al. Influence of pH and chloride concentration on the pitting and crevice corrosion behavior of high-alloy stainless steels. Corrosion 56, 411–418 (2000).

Lee, J. S., Ray, R. I. & Little, B. J. Are sulfate reducing bacteria important to the corrosion of stainless steels?, in: Proceeding of 17th International Corrosion Congress: Corrosion Control in the Service of Society, 2009 paper no. 11351.

Hospadaruk, V. & Petrocelli, J. V. The pitting potential of stainless steels in chloride media. J. Electrochem. Soc. 113, 878–883 (1966).

Uhlig, H. H. & Gilman, J. R. Pitting of 18-8 stainless steel in ferric chloride inhibited by nitrates. Corrosion 20, 289t–292t (1964).

Zhao, Y. et al. Comparison of different electrochemical techniques for continuous monitoring of the microbiologically influenced corrosion of 2205 duplex stainless steel by marine Pseudomonas aeruginosa biofilm. Corros. Sci. 126, 142–151 (2017).

Videla, H. A. Microbially induced corrosion: an updated overview. Int. Biodeterior. Biodegrad. 48, 176–201 (2001).

Ambat, R., Aung, N. N. & Zhou, W. Studies on the influence of chloride ion and pH on the corrosion and electrochemical behaviour of AZ91D magnesium alloy. J. Appl. Electrochem 30, 865–874 (2000).

Acuña, N., Ortega-Morales, B. O. & Valadez-González, A. Biofilm colonization dynamics and its influence on the corrosion resistance of austenitic UNS S31603 stainless steel exposed to Gulf of Mexico seawater. Mar. Biotechnol. 8, 62–70 (2006).

Brossia, C. S. & Yang, L. Studies of microbiologically influenced corrosion using a coupled multielectrode array sensor, in: Corrosion 2003, NACE Int. 2003 1–8.

Arab, S. T., Abdulsalam, M. I. & Alghamdi, H. M. Susceptibility of 254 SMO alloys to crevice corrosion in NaCl solution. Arabian. J. Sci. Eng. 39, 5405–5412 (2014).

Enning, D. & Garrelfs, J. Corrosion of iron by sulfate-reducing bacteria: new views of an old problem. Appl. Environ. Microbiol. 80, 1226–1236 (2014).

Dinh, H. T. et al. Iron corrosion by novel anaerobic microorganisms. Nature 427, 829–832 (2004).

Kato, S. Microbial extracellular electron transfer and its relevance to iron corrosion. Microb. Biotechnol. 9, 141–148 (2016).

Jia, R. et al. Effects of biogenic H2S on the microbiologically influenced corrosion of C1018 carbon steel by sulfate reducing Desulfovibrio vulgaris biofilm. Corros. Sci. 130, 1–11 (2018).

Jia, R. et al. Effects of ferrous ion concentration on microbiologically influenced corrosion of carbon steel by sulfate reducing bacterium Desulfovibrio vulgaris. Corros. Sci. 153, 127–137 (2019).

Wang, D. et al. Distinguishing two different microbiologically influenced corrosion (MIC) mechanisms using an electron mediator and hydrogen evolution detection. Corros. Sci. 177, 108993 (2020).

Morse, J. W., Millero, F. J., Cornwell, J. C. & Rickard, D. The chemistry of the hydrogen sulfide and iron sulfide systems in natural waters. Earth. Sci. Rev. 24, 1–42 (1987).

Enning, D. et al. Marine sulfate‐reducing bacteria cause serious corrosion of iron under electroconductive biogenic mineral crust. Environ. Microbiol. 14, 1772–1787 (2012).

Blackwood, D. J. An electrochemist perspective of microbiologically influenced corrosion. Corros. Mater. Degrad. 1, 59–76 (2020).

Fan, Y. et al. Early corrosion behavior of X80 pipeline steel in a simulated soil solution containing Desulfovibrio desulfuricans. Bioelectrochem 141, 107880 (2021).

Deng, X., Dohmae, N., Nealson, K. H., Hashimoto, K. & Okamoto, A. Multi-heme cytochromes provide a pathway for survival in energy-limited environments. Sci. Adv. 4, eaao5682 (2018).

Nealson, K. H. & Little, B. Breathing manganese and iron: solid-state respiration. Adv. Appl. Microbiol 45, 213–240 (1997).

Li, Y. et al. Anaerobic microbiologically influenced corrosion mechanisms interpreted using bioenergetics and bioelectrochemistry: a review. J. Mater. Sci. Technol. 34, 1713–1718 (2018).

Xu, D. & Gu, T. Carbon source starvation triggered more aggressive corrosion against carbon steel by the Desulfovibrio vulgaris biofilm. Int. Biodeter. Biodegrad 91, 74–81 (2014).

Tang, H. et al. Stainless steel corrosion via direct iron-to-microbe electron transfer by Geobacter species. ISME J. 15, 3084–3093 (2021).

Hu, Q., Zhang, G., Qiu, Y. & Guo, X. The crevice corrosion behaviour of stainless steel in sodium chloride solution. Corros. Sci. 53, 4065–4072 (2011).

Ahmad, Z. Principles of corrosion engineering and corrosion control. (Elsevier, 2006).

Newman, R., Isaacs, H. & Alman, B. Effects of sulfur compounds on the pitting behavior of type 304 stainless steel in near-neutral chloride solutions. Corrosion 38, 261–265 (1982).

de Mele, M. F. L., Moreno, D. A., Ibars, J. R. & Videla, H. A. Effect of inorganic and biogenic sulfide on localized corrosion of heat-treated type 304 stainless steel. Corrosion 47, 24–30 (1991).

Zhang, T., Wang, J., Li, G. & Liu, H. Crevice corrosion of X80 carbon steel induced by sulfate reducing bacteria in simulated seawater. Bioelectrochem 142, 1–14 (2021).

Hamilton, W. A. Sulphate-reducing bacteria and anaerobic corrosion. Annu. Rev. Microbiol. 39, 195–217 (1985).

Postgate, J. R. The Sulphate Reducing Bacteria, 2nd edn., (Cambridge University Press, 1984).

Dexter, S. C. & Chandrasekaran, P. Direct measurement of pH within marine biofilms on passive metals. Biofouling 15, 313–325 (2000).

Salvago, G., Taccani, G. & Funmaglli, G. Review of effect of biofilms on the probability of localized corrosion of stainless steels in seawater, in: Microbiologically Influenced Corrosion Testing, ASTM Int. 70–95 (1994).

Javed, M. A., Stoddart, P. R., Palombo, E. A., McArthur, S. L. & Wade, S. A. Inhibition or acceleration: bacterial test media can determine the course of microbiologically influenced corrosion. Corros. Sci. 86, 149–158 (2014).

Marsden, A. E., Grudzinski, K., Ondrey, J. M., DeLoney-Marino, C. R. & Visick, K. L. Impact of salt and nutrient content on biofilm formation by vibrio fischeri. PloS one 12, e0169521 (2017).

Anderson, D. B. Statistical aspects of crevice corrosion in seawater, in: Galvanic and pining corrosion - field and laboratory studies, ASTM STP 576 1976 231–242.

Iverson, W. P. Growth of desulfovibrio on the surface of agar media. Appl. Microbiol. 14, 529–534 (1966).

Javed, M. A. et al. The influence of chemical cleaning methods on pitting morphology attributed to microbially influenced corrosion of stainless steels. Corrosion 77, 276–286 (2020).

ASTM, Standard practice for preparing, cleaning, and evaluating corrosion test specimens [standard G1-03], in: ASTM Int. ASTM Handbook 3.02 Corrosion of Metals, Wear and Erosion, 2011 20−28.

Acknowledgements

This research project was financially supported by the Commonwealth of Australia through the Defence Science and Technology Group, Melbourne, Australia.

Author information

Authors and Affiliations

Contributions

M.A.J. Conceptualization, Methodology, Formal Analysis, Investigation, Writing Original Draft. W.C.N. Formal Analysis, Writing – Review & Editing, Funding Acquisition S.A.W. Conceptualization, Methodology, Writing – Review & Editing, Supervision, Funding Acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Javed, M.A., Neil, W.C. & Wade, S.A. Effect of test media on the crevice corrosion of stainless steel by sulfate reducing bacteria. npj Mater Degrad 6, 40 (2022). https://doi.org/10.1038/s41529-022-00250-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41529-022-00250-4

This article is cited by

-

Biodegradation of materials: building bridges between scientific disciplines

npj Materials Degradation (2023)

-

Insights into the various mechanisms by which Shewanella spp. induce and inhibit steel corrosion

npj Materials Degradation (2023)