Abstract

This study investigated the corrosion and oxidation mechanism of the Cr-free Fe-40Ni-15Co superalloy with exposure to a tropical marine atmosphere for one year and a subsequent high temperature of 650 °C for 300 h. The degradation behavior of the samples was evaluated based on surface characterization and analysis. In the tropical marine atmospheres, the corrosion process of the Fe-40Ni-15Co superalloy presented an initial localized type after one month of exposure and gradually developed into uniform. The corrosion products were mainly comprised of Fe2O3 and NiO, suppressing the pitting process. During the high-temperature oxidation process, all samples presented super-parabolic oxidation kinetics. Except for the initial active oxidation due to salt deposits, the corrosion products after atmospheric exposure could significantly enhance the oxidation resistance at 650 °C. An explanation for the degradation mechanism of the Fe-40Ni-15Co superalloy was developed based on the synergistic effects of atmospheric corrosion and high-temperature oxidation.

Similar content being viewed by others

Introduction

As the precision requirement for aerospace materials in manufacturing aircraft turbine engines, Incoloy 900-series superalloys have been designed with a low thermal expansion coefficient and almost constant elastic modulus at elevated temperatures1,2. The superalloys in this series are Fe-Ni-Co based alloys with the additions of Nb, Ti, and Si. It is known that the excellent corrosion and oxidation resistance of superalloys at room and high temperatures are attributed to the presence of coherent oxide layers such as Cr2O3 on the alloy surface, acting as a barrier for the diffusion of oxygen and corrosive species3,4,5. For this reason, although the elimination of Cr from the composition provides the Fe-Ni-Co superalloys with low expansion characteristics, the absence of Cr makes them susceptible to corrosion and oxidation under practical service conditions2. Consequently, it is important to understand the degradation of Cr-free Fe-Ni-Co superalloys under atmospheric and high-temperature conditions to ensure the safety of turbine engines.

When the aircraft stays in the parking state, atmospheric corrosion is considered the predominant environmental degradation of Cr-free Fe-Ni-Co superalloys6,7,8. For instance, when the airports and hangers are located in the coastal areas, the significant proportions of sea salts such as NaCl contained in the marine atmospheres are expected to induce the destruction of the passive films and make the alloy suffer from serious corrosion attacks9,10,11,12,13,14,15,16. As a result, localized corrosion will occur and introduce a layer of corrosion products to the alloy surface. In particular, the corrosion products are accompanied by salt deposits as the corrosion takes place in the marine atmosphere. Therefore, the corroded Fe-Ni-Co superalloys with adherent corrosion products will suffer from elevated temperatures during the flight cycle of aircraft, presenting a potential risk to the durability of high-temperature components.

The oxidation characteristics of superalloys are usually related to the properties of the surface scale17,18. Based on the alloy composition, the scale will consist of different oxide phases during the oxidation process at high temperatures, exhibiting different abilities to suppress the inward diffusion of oxygen or the outward diffusion of metal elements19,20,21. Moreover, the oxidation performance of superalloys is expected to vary depending on the presence of voids and cracks inside the surface scale22,23. Accordingly, instead of coherent passive film as surface scale, the presence of corrosion products with the salt deposits after atmospheric exposure is supposed to affect the oxidation kinetics of the Fe-Ni-Co superalloys, associated with the changes in the diffusivity and solubility of oxygen and the physical properties of the surface scale at elevated temperatures.

A previous study24 reported that the corrosion products after atmospheric corrosion exhibited an acceleration effect on the oxidation rate of Fe-25Ni-15Cr superalloy, attributing to the destruction of Cr2O3 layer by the deposited salts, high growth stress of oxide film and film defects caused by the corrosion products. As for the effect of salt deposits, numerous studies focusing on the oxidation behavior of traditional metals or alloys indicated that the solid NaCl deposits accelerated the oxidation rates of most metallic materials at high temperatures (500–700 °C)25,26,27,28,29,30,31,32,33,34. Cao et al.35 reported that the oxidation rate of the Fe-20Cr alloy in the NaCl solution spray environment was greatly amplified by NaCl particles and water vapor. Pradhan et al.36 investigated the oxidation behavior of the Cr-containing IN718 superalloy under NaCl coated condition at 600 °C and found that NaCl coated sample exhibited higher weight gain after exposure of 100 h as compared to the uncoated sample. Although the studies have demonstrated the significant effect of salts on the oxidation kinetics of Cr-containing superalloys, the role of corrosion products with salt deposits in the oxidation behavior of Cr-free superalloys remains uncertain.

The objective of this study was to understand the degradation mechanism of Cr-free Fe-Ni-Co superalloy during marine atmospheric exposure and high-temperature oxidation process. A one-year marine atmospheric corrosion (MAC) test was first conducted to investigate the corrosion behavior of Cr-free superalloys during long-term exposure to tropical marine atmospheres. Subsequently, a high-temperature oxidation (HTO) test was performed to investigate the influence of atmospheric corrosion on the oxidation kinetics of Cr-free superalloys. In addition, a salt-fog corrosion (SFC) test followed by the HTO test was conducted to evaluate the role of salt deposits in the HTO process, facilitating the understanding of the effect of salt deposits contained in the corrosion products on the oxidation of Cr-free superalloys.

Results

Corrosion morphology during marine atmospheric exposure

Figure 1 shows the surface changes of the Fe-40Ni-15Co superalloy samples during one-year exposure to the tropical marine atmosphere. After the atmospheric exposure for 1 month, brownish-yellow corrosion products are present and distributed scatteringly on the sample surface, which indicates the initiation of corrosion attack from a localized type. With the increase in exposure time, the corrosion area presents a significant increase at the initial corrosion sites, and the corrosion products tend to merge with the adjacent ones. From the SEM images of the corroded regions, the corrosion products exhibit a cracked texture and gradually cover the entire surface. The surface changes of samples demonstrate the occurrence of localized corrosion on the Fe-40Ni-15Co superalloy during exposure to tropical marine atmospheres.

To corroborate the finding that localized corrosion occurred on the samples during the exposure tests, an analysis of the corrosion area and depth of the corroded samples after removing the corrosion products was conducted as shown in Fig. 2. The surface confocal images confirm the presence of localized corrosion after exposure for 1 month. Additionally, the initial corrosion presents a tendency to occur along the direction of scratches on the sample surfaces, which indicates that the scratches are considered the preferred sites for corrosion to initiate. With the extension of exposure time to 12 months, the corrosion area exhibits a distinct expansion from the initial localized area to the entire surface. According to the calculation of the corrosion area and depth (Fig. 2b), the maximum corrosion depth shows a slight increase during the exposure for one year, in contrast to the pronounced increase in the corrosion area. These results corroborate the corrosion characteristics of the Fe-40Ni-15Co superalloy from initial localized to uniform types during one-year exposure to the tropical marine atmosphere.

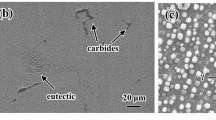

Cross-sectional analysis after one year of atmospheric exposure

Prior to the HTO test, a section analysis of the corroded sample after one year of exposure was conducted to facilitate the understanding of the role of corrosion products in high-temperature environments. As shown in Fig. 3, the sample surface is covered by the corrosion products with some cracks and voids. The corroded area is relatively shallow, and no localized deep pits appear on the surface. It is noteworthy that the corrosion products present a bilayer structure, consisting of a thick outer layer with relatively compact products and a thin inner layer with relatively larger amounts of cracks and voids. Since the sample was exposed to the tropical atmospheric environment, the daily wet-dry cycle (thermal effect) and internal growth stress of the product layer might be the reason why some cracks and voids appeared inside the corrosion products. Based on the EDS elemental mapping, the corrosion products are mainly composed of Fe and Ni compounds. Fe is particularly abundant in the outer layer of the corrosion products rather than other elements. Since Fe has a lower corrosion resistance than the other elements such as Ni and Co, the initial anodic dissolution of the sample introduced Fe-containing corrosion products to the surface, followed by the corrosion of other metals. This is supposed to be the reason why a higher content of Fe appears in the outer corrosion products.

High-temperature oxidation kinetics after atmospheric corrosion

Figure 4 shows the isothermal oxidation kinetic curves of the as-received and MAC samples during the HTO test at 650 °C for 300 h. According to the mass change as a function of the oxidation time in Fig. 4a, the mass gain of both samples presents a significant increase in the early stage of oxidation (40 h) and then a relatively gentle increase with the extension of oxidation time. This result suggests the presence of a parabolic relationship between the oxide growth and oxidation time for the Fe-40Ni-15Co superalloy. Compared with the as-received sample, the MAC sample exhibits a higher inhibition effect on the high-temperature oxidation after the initial period (5 h). After 300 h of oxidation, the mass gain per unit area of the MAC sample is about 2.4 mg/cm2, which is about 1.5 times less than the as-received samples (3.6 mg/cm2).

In an attempt to evaluate the oxidation kinetics of the samples with the empirical models37,38,39,40, the mass change and oxidation time are expressed in logarithm as plotted in Fig. 4b:

where y is the mass gain per unit area, n is the mass gain exponent, k is the oxidation rate constant, and t is the oxidation time. The fitted lines (after oxidation for 20 h) indicate a linear relationship between the log (mass gain) and log (oxidation time), with a slope of about 0.3 for the both as-received and MAC samples. The mass gain exponent n, therefore, is approximately 3, suggesting that the oxidative kinetics of the two kinds of samples follow the cubic law at 650 °C.

Surface characterization during the HTO tests

SEM-EDS and XRD characterizations were performed on the samples after HTO for 20 h and 300 h. Figure 5a shows a dense oxide layer on the surface of the as-received sample after oxidation at 650 °C for 20 h. With the oxidation time extending to 300 h, some cracks appear in the oxide layer. The EDS analysis (Fig. 5c) presents that the surface oxide layer mainly consists of O, Fe, and Co compounds. Combined with the XRD analysis results in Fig. 5d, the surface layer formed during HTO is mainly composed of CoFe2O4 with a spinel structure. As for the MAC sample (Fig. 5b), the oxide layer presents two areas with different morphologies rather than a uniform and dense layer. The area with a large number of cracks has a higher content of Ni (Fig. 5c), indicating the presence of NiO according to the XRD analysis in Fig. 5d. Combined with the surface morphology of the corroded samples (Fig. 1), the cracked area corresponds to the existence of corrosion products. After oxidation for 300 h, the surface morphology and EDS results indicate that the area around the cracked corrosion product layer was subjected to serious oxidation, forming an oxide layer with a similar morphology and composition (CoFe2O4) to the as-received sample. However, the cracked area remains a high content of Ni, and its morphology shows no obvious change, which indicates that the corrosion products retarded the formation of the oxide scale at 650 °C.

It is worthwhile to note that some salt-forming elements such as Na, Mg, and K can be detected from the corrosion product layer, which might be introduced from the sea salt aerosols during the marine atmospheric exposure period. The presence of such sea salt particles is also considered an important factor causing the distinct difference in the surface characteristics between the as-received and MAC samples. A detailed investigation of the salt effect on the oxidation behavior of the sample will be discussed in the following sections.

Cross-sectional analysis during the HTO tests

To investigate the role of corrosion products after field exposure in the high-temperature environment, elemental mapping of the cross-section of the as-received and MAC samples after oxidation for 20 h and 300 h are provided in Fig. 6. As shown in Fig. 6a, a relatively uniform oxide layer was formed on the as-received sample after oxidation for 20 h. The results of EDS mapping reveal that the oxide layer has a multilayer structure, consisting of an outmost layer containing CoFe2O4, a medium layer containing Fe2O3, and an internal oxidation zone (IOZ) with poor Fe content. After oxidation for 300 h in Fig. 6b, the thickness of the oxide scale presents a significant increase from approximately 7.8 µm to 22.1 µm, exhibiting a noticeable stratification from the outmost CoFe2O4-containing layer to a medium Fe2O3-containing layer and then to the IOZ with a relatively low content of Fe. The thickness of the IOZ is greater than the outer oxide scale, suggesting a large quantity of oxygen diffused through the surface scale into the alloy matrix after oxidation for 300 h. In addition, some penetrating cracks appear in the oxide layer with the extension of the oxidation time.

By contrast, the oxide layer of the MAC sample after oxidation for 20 h presents a distinctly different structure compared with the as-received sample, as shown in Fig. 6c. The oxide scale exhibits an irregular thickness and a dendritic structure interlacing with the alloy substrate. In addition to the outer CoFe2O4 and Fe2O3-containing products, a noticeable Ni-rich zone is interwoven with the oxide layer. As the oxidation time extends to 300 h in Fig. 6d, the thickness of the oxide scale shows a relatively slight increase compared to the as-received sample. In addition, the Ni-rich zone seems to suppress the inward thickening of the oxide scale and the development of IOZ on the MAC sample. The IOZ layer is significantly thinner (about 9.3 µm) than that of the as-received sample. The thinner IOZ means that the outer surface scale retards the diffusion of oxygen to the internal alloy matrix. This phenomenon suggests the inhibition effect of the corrosion product layer on the oxidation process, which is consistent with the result of oxidation kinetic curves.

Corrosion and oxidation with exposure to salt deposition

As mentioned in Section “Surface characterization during the HTO tests”, the sea salt deposited inside the corrosion products is another consideration for investigating the effect of field exposure on the subsequent oxidation of samples in high-temperature environments. NaCl is the main component of sea salt aerosol, therefore it was chosen as a corrosive agent for the SFC test. Figure 7a shows the surface morphology of the sample after the SFC test for 300 h. The density of deposited NaCl on the sample surface was about 0.11 mg/cm2. Apart from several obvious corrosion sites, the sample surface remains relatively intact along with the deposition of cubic salt particles. During the subsequent HTO test, the change in the mass gain of the sample as a function of oxidation time is plotted in Fig. 7b. Compared with the as-received sample, the SFC sample exhibits a higher oxidation rate at the initial oxidation stage (5 h). With the extension of oxidation time to 100 h, the rate of mass gain of the SFC samples gradually becomes relatively identical to that of the as-received sample.

To compare the oxidation behavior of the SFC sample with the as-received and MAC samples, Fig. 7c shows the cross-sectional morphology of the SFC sample after oxidation for 5 h, 20 h, and 100 h. In the presence of salt deposits, the oxide scale exhibits a similar morphology to the MAC sample (Fig. 6c) in the initial oxidation period, exhibiting a cracked structure with a large number of voids. Moreover, there is no obvious IOZ under the surface scale in the initial 20 h. This phenomenon indicates that the oxygen was hindered or consumed before diffusing deep into the alloy matrix. After oxidation for 100 h, the oxide layer is arched and flaked along with the formation of an inner IOZ. In summary, the SFC test demonstrates that the deposited salts contribute to a rapid oxidation rate and the formation of irregular oxide scales with abundant cracks and voids in the initial oxidation period (20 h). Therefore, similar phenomena in the MAC samples support the important role of salt particles in the oxidation process after marine atmospheric exposure.

Corrosion performance after the MAC and HTO tests

To evaluate the corrosion performance of the samples after the MAC and HTO tests, potentiodynamic polarization was carried out using the as-received and MAC samples before and after HTO for 20 h and 300 h, as illustrated in Fig. 8. The electrochemical results of corrosion potential (Ecorr) and corrosion current density (icorr) of the samples are listed in Table 1. Before the HTO test, the MAC sample exhibited lower Ecorr and higher icorr than the as-received sample, indicating that the corrosion resistance of the as-received sample is higher than the MAC sample that suffered one year of atmospheric exposure in the tropical marine environment. The presence of cracks and voids in the corrosion products layer (Fig. 3) promotes the anodic dissolution of the MAC sample, leading to the negative shift of Ecorr and increasing icorr compared with the as-received sample. As for the as-received sample, the anodic polarization current presents a slight passive region ranging from −0.25 VSCE to −0.05 VSCE. The inapparent passivation might be due to the absence of Cr in the sample, thereby preventing the formation of a protective passive film such as Cr2O3 on the sample surface.

After HTO for 20 h, although the samples display a positive shift in Ecorr, the increasing rate of cathodic reaction leads to the rising icorr, as listed in Table 1. This result suggests that the surface oxide layer after HTO presents a lower inhibition effect on the corrosion process than the initial passive film. As the oxidation time extends to 300 h, although the thickness of the surface scale presents an apparent increase (Fig. 6), the increasing anodic reaction makes the samples a negative shift in Ecorr and increasing icorr, which indicates that the extended oxidation period accelerates the corrosion processes of the samples. This phenomenon might be related to the formation of cracks and voids in the surface layer after long-term oxidation, which makes the electrolytes readily accessible to the metal/oxide interface for the anodic dissolution of the metal substrate.

In order to investigate the corrosion resistance of the surface films formed on the samples further, EIS measurement was performed using the as-received and MAC samples before and after oxidation for 20 h and 300 h. Figure 9a–d illustrates the Nyquist and Bode diagrams of the as-received and MAC samples before and after HTO. From Bode diagrams (Fig. 9b, d), the impedance moduli of the samples before HTO vary linearly with the frequency with a slope of about -1 in the middle and low-frequency range, and the corresponding phase angles evolve between 60° and 85°, implying that the surface films formed before HTO are mainly capacitive. After HTO, the as-received and MAC samples present two-time constants, including two capacitive peaks appeared in Bode diagrams. The impedance moduli and the radii of the capacitive loops decrease with increasing oxidation time, which suggests that the surface films after HTO are too loose to protect the substrate from corrosion in the 3.5 wt.% NaCl solution.

Two equivalent electric circuits (EEC) were established to fit the EIS data, as shown in Fig. 9e, f. In particular, the EEC in Fig. 9f was used to fit the results of the as-received samples after HTO for 300 h. In the EEC, Rs is the solution resistance; R1 and CPE1 represent the resistance and the constant phase element of the surface passive/oxide layers, respectively; R2 and CPE2 represent the charge transfer resistance of the corrosion process and the constant phase element of the electrochemical double-layer, respectively; and W is the Warburg diffusion impedance at the interface of the oxide layer and substrate.

According to the fitted EIS results as listed in Table 2, the resistance of the surface oxide layer, R1, of the MAC sample is lower than the as-received one before HTO, corresponding to the increased ipass and decreased Eb of the sample after field exposure as shown in Table 1. After oxidation at 650 °C for 20 h, the values of R1 of the as-received and MAC samples exhibit a decrease, indicating that the HTO process degraded the resistance of the passive films and corrosion products on the samples after field exposure. After oxidation for 300 h, the resistance of the surface films exhibits a slight increase, which is supposed to be related to the increasing thickness of the oxide layers with the extension of oxidation time (Fig. 6). In addition, the R2 values display a significant decrease, while the CPE2 values show a slight increase as the oxidation time extends from 20 h to 300 h. This phenomenon might be attributed to the presence of a perceptible number of pores at the interface of the oxide layer and alloy substrate (Fig. 6).

Discussion

In comparison with the Cr-containing superalloy, the present study demonstrates that the Cr-free Fe-40Ni-15Co superalloy is susceptible to marine atmospheric corrosion and high-temperature oxidation. After the same one-year field exposure and high-temperature oxidation of 300 h, the Fe-40Ni-15Co superalloy presented a thicker oxide scale (about 12.7 µm) and greater mass gain (about 2.4 mg/cm2) than those of the Fe-25Ni-15Cr superalloy, which were about 2.4 µm and 0.3 mg/cm2, respectively24. However, in contrast to the promotion effect of atmospheric exposure on the oxidation of Cr-containing superalloy as reported in the previous work, this study found that the corrosion products produced during atmospheric exposure inhibited the oxidation kinetics of the Cr-free superalloy at an elevated temperature. These findings suggest that when the superalloy lacks Cr to form a protective passive film, an atmospheric corrosion product film will assume responsibility for the protection of superalloys in response to the high-temperature oxidation.

In the presence of a Cr2O3-free passive film, the mass change (Fig. 4) and cross-sectional analysis (Fig. 6) of the as-received superalloy indicate that the chemical reaction between oxygen and metal elements is rapid under a cubic power law rather than diffusion-controlled oxidation kinetics17. According to Wagner’s theory of oxidation in metals37,38, the growth mechanism of the oxide scale on the Cr-free Fe-40Ni-15Co superalloy is illustrated in Fig. 10. Due to the poor oxidation resistance of the passive film, oxygen is readily available at the interface of metal/oxide for the growth of the oxide scale. Considering the Gibbs free energy and reaction requirements at a certain temperature, the possible oxidation reactions are as follows:

Based on the Richardson-Ellington diagram and HSC Chemistry software database41,42, the Gibbs free energies (ΔG) of the above reactions at 650 °C are −578.33 kJ mol−1 (\(\Delta {\text{G}}_{{\text{Fe}}_{2}{\text{O}}_{3}}\)), −204.09 kJ mol−1 (\(\Delta {\text{G}}_{\text{FeO}}\)), −812.46 kJ mol−1 (\(\Delta {\text{G}}_{{\text{Fe}}_{3}{\text{O}}_{4}}\)), −168.87 kJ mol−1 (\(\Delta {\text{G}}_{\text{CoO}}\)), −554.70 kJ mol−1 (\(\Delta {\text{G}}_{{\text{Co}}_{3}{\text{O}}_{4}}\)), and −155.27 kJ mol−1 (\(\triangle {\text{G}}_{\text{NiO}}\)), respectively. All the oxidation reactions exhibit negative ΔG values, implying that these reactions will occur spontaneously at 650 °C. In addition, as a more negative value of ΔG represents greater stability of the product, Fe2O3 and CoO are considered more stable than other oxidation products. Subsequently, the oxides of Fe2O3 and CoO are supposed to produce CoFe2O4 spontaneously as follows:

where the ΔG is −73.44 kJ mol−1 (\(\Delta {\text{G}}_{{\text{CoFe}}_{2}{\text{O}}_{4}}\)) at 650 °C.

Given the XRD patterns and cross-sectional analysis (Figs. 5 and 6), the inward-diffused oxygen reacts with the outward-diffused Fe and Co, leading to the growth of the surface oxide scale. Since the high content of Fe and lower diffusion efficiency of Ni in the alloy matrix43, the oxide scale is mainly composed of Fe2O3 and CoFe2O4. As the oxidation kinetics follow a cubic power law, the inward quantity of oxygen is significantly larger than the outward contents of metal elements at the metal/oxide interface. As a result, oxygen will diffuse into the alloy matrix and react with Fe and Co before the metal elements diffuse to the metal/oxide interface, forming the IOZ character under the oxide scale (Fig. 10b). With the consummation of Fe and Co cations, the residual vacancies provide a driving force for the diffusion of surrounding Ni to replace the Fe/Co positions, reducing the formation of a Ni-rich layer under the surface scale (Fig. 6). In addition, the internal stress gradually increases with the growth of the oxide scale and results in penetrated cracks, which makes oxygen travel into the superalloy and accelerates the formation of IOZ (Fig. 10c).

Regarding the superalloy suffering from marine atmospheric corrosion, the presence of corrosion products plays a critical role in the growth mechanism of the oxide scale at high temperatures. The degradation processes of the Cr-free Fe-40Ni-15Co superalloy under atmospheric and high-temperature exposures are illustrated in Fig. 11. During long-term exposure to tropical marine atmospheres (Fig. 11a), the initial passive film cannot provide sufficient resistance to atmospheric corrosion, resulting in the localized dissolution of the substrate and the formation of corrosion products on the superalloy surface, as demonstrated in Sections “Corrosion morphology during marine atmospheric exposure” and “Cross-sectional analysis after one year of atmospheric exposure”. As for the corroded alloys after marine exposure, it is generally accepted that some corrosive species such as NaCl will be introduced to the alloy surface and exhibit an acceleration role in the oxidation process at high temperatures24,25,26,27,28,29. A series of chemical reactions at high temperatures will take place according to44:

which introduces an “active corrosion” to the oxidation processes of superalloys28,29,44.

In this study, the SFC test suggests that the Cr-free Fe-40Ni-15Co superalloy follows the so-called “active corrosion” before depleting deposited NaCl particles. As schematically illustrated in Fig. 11b, although the corrosion product layer is considered an oxygen barrier at high temperatures, the cracks provide a pathway for oxygen to reach the alloy substrate and react with Fe and Co cations. In particular, the introduced NaCl from marine atmospheres will react with the corrosion products (Fe2O3) and the diffused oxygen from the cracks. The produced chlorine diffuses to the metal/oxide interface and accelerates the formation of the oxide scale along with oxygen. Whereafter, the consumption of Fe and Co promotes the enrichment of Ni under the surface oxide scale. This mechanism might be the reason for the rapid mass gain in the initial 5 h (Fig. 4) and the similar cross-sectional morphology of the oxide scale (Fig. 6c) compared with the NaCl-accelerated oxidation process (Fig. 7c).

After the initial active oxidation period, the corrosion product layer represents an inhibition effect on the oxidation kinetics compared with the presence of passive film. Based on the surface characterization (Fig. 5) and cross-sectional analysis (Fig. 6), the corrosion product layer mainly composed of NiO and Fe2O3 is considered to obstruct the inward diffusion of oxygen, resulting in the sluggish growth of the oxide scale. The oxides of Fe2O3 and CoFe2O4 will be formed under the corrosion products and in the surrounding area without covering by the corrosion products, as illustrated in Fig. 11c. Similarly, the void and crack within the surface scale provide the transport pathways for oxygen to react with the internal metal elements Fe and Co, leading to the formation of a thin IOZ and a Ni-rich layer above the substrate.

In summary, the absence of Cr makes the Fe-40Ni-15Co superalloy susceptible to atmospheric corrosion and high-temperature oxidation. Although the passive film exhibits a higher corrosion resistance than the corrosion product layer at room temperature, the latter composed of NiO and Fe2O3 acts as an oxygen barrier and exhibits a good oxidation resistance at high temperatures. The oxidation processes are mainly driven by salt-induced “active oxidation” and the diffusion of oxygen through the cracks and voids inside the corrosion product layer. During high-temperature oxidation, the corrosion resistance of the surface oxide scale is lower than that of the passive film and corrosion product layer. The destruction of the oxide scale with the formation of cracks and voids will be responsible for decreasing corrosion resistance over long-term high-temperature exposure.

Methods

Sample preparation

The material used was a commercial Fe-40Ni-15Co superalloy (Fushun Special Steel Co. Ltd., Fushun, China) with a chemical composition (wt.%) of 0.03 C, 38.28 Ni, 13.70 Co, 5.12 Nb, 1.74 Ti, 0.49 Mn, 0.36 Si, and Fe in balance. The material with a thickness of 2 mm was machined into samples with dimensions of 150 mm × 75 mm and was degreased with acetone and deionized water before the field exposure test.

MAC and SFC tests

The MAC test was carried out in an exposure site (112°20’ E, 16°50’ N) with a tropical marine climate, experiencing an annual average temperature of about 27 °C, a high mean relative humidity of about 77%, a salt deposition rate of about 113 mg·m−2·y−1, and an annual solar radiation dose of 6210 MJ·m−2 8. The samples were fixed at an angle of 45° to the horizontal on an open-air shelf according to ASTM G-5045. After exposure for 1, 3, 6, and 12 months, the samples were collected from the exposure site for the subsequent tests.

The SFC test was performed according to ASTM B117-0946. The as-received material was cut into samples with dimensions of 10 mm × 10 mm × 2 mm. The samples were ground with SiC grinding papers up to 2000 grit and cleaned with acetone and deionized water. The salt solution used to create fog droplets was a 5.0 wt.% NaCl solution with a near-neutral pH (6.5–7.2). The salt fog test was conducted in a cabinet chamber at a constant temperature of 35 °C for 300 h.

HTO test

The HTO test was conducted in a muffle furnace with a temperature of 650 °C and the test procedure was illustrated in Fig. 12. Three groups of samples were used in the HTO test, including the as-received samples, the samples after MAC test, and the samples after SFC test. Each sample was placed in a corundum crucible, which was dried to a constant weight at 650 °C before the high-temperature oxidation test. The oxidation time was 100 h for the SFC sample and 300 h for the as-received and MAC samples. The weight change of the sample was measure by a balance offering a precision of 0.1 mg (Sartorius, BP211D, Germany). The time intervals of the weight measurement were 5 h, 20 h, 40 h, 60 h, 80 h, 100 h, 150 h, 200 h, 250 h, and 300 h during the HTO text. Data from at least three parallel samples were recorded for each experimental group.

Electrochemical measurements

The corrosion performance of the samples was studied by electrochemical measurements, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS). All the measurements were performed in 3.5 wt.% NaCl solution on an electrochemical workstation (VersaSTAT 3F, Princeton, USA) with a three-electrode system, consisting of a saturated calomel electrode (SCE) as the reference electrode, a Pt plate as the counter electrode, and the sample as the working electrode. In the polarization test, the starting potential was set at 300 mV below the open circuit potential (OCP) of the sample. The measurement was carried out at a scan rate of 20 mV·min−1 and ended after the anodic current density reached 1 mA·cm−2. The EIS test was performed after the samples achieved a stable OCP in the 3.5 wt.% NaCl solution. The frequencies ranged from 105 Hz to 10−2 Hz with an amplitude of 10 mV. A commercial software ZSimpWin was used to analyze the produced EIS data. All the measurements were carried out at room temperature (25 °C) and repeated at least two times to ensure reproducibility.

Surface characterization and analysis

A stereomicroscope (Stemi 508, Zeiss, Germany) was used to observe the micrographs of the samples after atmospheric corrosion for 1, 3, 6, and 12 months. After removing the corrosion products on the corroded samples using an ultrasonic bath, the surface morphology and pit depth were measured and calculated using confocal laser scanning microscopy (CLSM; VK-X250, KEYENCE, Japan). At least five different areas of each sample were measured to ensure reliability. Microstructure observation and composition analysis of the corrosion products and oxide films were conducted using scanning electron microscopy (SEM; MIRA3, TESCAN, Czech Republic) and energy dispersive spectrometry (EDS; Ultim MaxN, Oxford, England) with an accelerating voltage of 20 kV. Phase structure of the corrosion products and oxide films was identified by X-ray diffraction (XRD; X’pert Pro, PANalytical, Netherlands) with a Cu-Kα radiation scanned in the 2θ range of 10°–90° at a scan step size of 0.02 s−1. The cross-sectional analysis was performed using SEM-EDS for the samples after MAC and HTO tests. The samples were initially embedded into an epoxy resin, then ground with SiC papers and polished with the buffing compound under water cooling. The polished samples were cleaned with acetone and deionized water before the cross-sectional analysis.

Data availability

Data is provided within the manuscript and is available from the corresponding author on reasonable request.

References

Carpenter, H. W. Alloy 903 helps space shuttle fly. Met. Prog. 8, 25–29 (1976).

Ernst, S. C. Weldability of high-strength, low-expansion superalloys. Weld. J. 61, 418–430 (1989).

Croll, J. E. & Wallwork, G. R. The design of iron-chromium-nickel alloys for use at high temperatures. Oxid. Met. 1, 55–71 (1969).

Croll, J. E. & Wallwork, G. R. The high-temperature oxidation of iron-chromium-nickel alloys containing 0-30% chromium. Oxid. Met. 4, 121–140 (1972).

Cheng, C. Q. et al. Two typical oxidation models on nickel-based superalloys under different initial surface roughness. Corros. Sci. 176, 108942 (2020).

Eliaz, N., Shemesh, G. & Latanision, R. M. Hot corrosion in gas turbine components. Eng. Fail. Anal. 9, 31–43 (2002).

Prashar, G. & Vasudev, H. Hot corrosion behaviour of super alloys. Mater. Today. Proc. 26, 1131–1135 (2020).

Zhang, W. et al. Research on the evolution of corrosion products of 17-4 PH martensitic stainless steel in the tropical marine environment. J. Mater. Res. Technol. 29, 3849–3865 (2024).

Sun, S., Zheng, Q., Li, D. & Wen, J. Long-term atmospheric corrosion behaviour of aluminium alloys 2024 and 7075 in urban, coastal and industrial environments. Corros. Sci. 51, 719–727 (2009).

Cui, Z., Li, X., Xiao, K. & Dong, C. Atmospheric corrosion of field-exposed AZ31 magnesium in a tropical marine environment. Corros. Sci. 76, 243–256 (2013).

Luo, H., Li, X. G., Dong, C. F. & Xiao, K. Degradation of austenite stainless steel by atmospheric exposure in tropical marine environment. Corros. Eng. Sci. Technol. 48, 221–229 (2013).

Cui, Z. Y. et al. Corrosion behaviour of Field-Exposed zinc in a tropical marine atmosphere. Corrosion 70, 731–748 (2014).

Cui, Z. Y. et al. Corrosion behaviour of Field-Exposed 7A04 aluminum alloy in the Xisha tropical marine atmosphere. J. Mater. Eng. Perform. 24, 2885–2897 (2015).

Wu, W., Cheng, X., Zhao, J. & Li, X. Benefit of the corrosion product film formed on a new weathering steel containing 3% nickel under marine atmosphere in Maldives. Corros. Sci. 165, 108416 (2020).

Han, X. & Sakairi, M. The promotion effect of aluminium ion on hydrogen entry into steel during atmospheric corrosion. Electrochim. Acta 458, 142505 (2023).

Han, X. & Sakairi, M. Role of hygroscopic chloride salts on corrosion performance and hydrogen absorption of steel under cyclic wet-dry conditions. Corros. Sci. 231, 111993 (2024).

Wagner, C. Theoretical analysis of the diffusion processes determining the oxidation rate of alloys. J. Electrochem. Soc. 99, 369–380 (1952).

Foley, R. T. Oxidation of Iron‐Nickel Alloys: VI. A Survey of Kinetics and Mechanism,. J. Electrochem. Soc. 109, 1202 (1962).

Dalvi, A. D. & Smeltzer, W. W. The Kinetics and Morphological Development of the Oxide Scale on Nickel‐Iron Alloys (0–25 w/o Fe) at 1000° C. J. Electrochem. Soc. 118, 1978 (1971).

Piscitelli, R. A., Rhee, S. K. & Bradley, F. N. Oxidation of Fe‐29Ni‐17Co Alloy. J. Electrochem. Soc. 123, 929 (1976).

Zhang, S., Hayashi, S., Ukai, S. & Oono, N. H. Effect of Co addition on the high-temperature oxidation behavior of oxide-dispersion-strengthened FeCrAl alloys. Corros. Sci. 184, 109391 (2021).

Ohl, B., Owen, L., Stone, H. & Dunand, D. C. Microstructure and mechanical properties of L12-strengthened Co–Ni–Fe-based superalloys. Mater. Sci. Eng. A. 884, 145276 (2023).

Wang, Y., Tan, Y., Liu, L., Li, P. & Li, X. Oxidation behavior and mechanism of GH4975 superalloy prepared electron beam smelting between 900° C and 1100° C in air,. Vacuum 219, 112752 (2024).

Sun, Q. et al. Corrosion of the Fe–25Ni–15Cr superalloy under the combined effects of marine atmospheric exposure and high-temperature oxidation,. Mater. Charact. 201, 112885 (2023).

Shinata, Y. Accelerated oxidation rate of chromium induced by sodium chloride. Oxid. Met. 27, 315–332 (1987).

Shinata, Y. & Nishi, Y. NaCl-induced accelerated oxidation of chromium. Oxid. Met. 26, 201–212 (1986).

Shu, Y., Wang, F. & Wu, W. Corrosion behaviour of Ti60 alloy coated with a solid NaCl deposit in O2 plus water vapor at 500–700 °. C. Oxid. Met. 52, 463–473 (1999).

Wang, F. H. & Shu, Y. H. Influence of Cr content on the corrosion of Fe−Cr alloys: The synergistic effect of NaCl and water vapor,. Oxid. Met. 59, 201–214 (2003).

Wang, C., Jiang, F. & Wang, F. Corrosion inhibition of 304 stainless steel by nano-sized Ti/silicone coatings in an environment containing NaCl and water vapor at 400-600 °C. Oxid. Met. 62, 1–13 (2004).

Liu, L., Li, Y., Zeng, C. & Wang, F. Electrochemical impedance spectroscopy (EIS) studies of the corrosion of pure Fe and Cr at 600°C under solid NaCl deposit in water vapor. Electrochim. Acta 51, 4736–4743 (2006).

Tang, Y., Liu, L., Li, Y. & Wang, F. Evidence for the occurrence of electrochemical reactions and their interaction with chemical reactions during the corrosion of pure Fe with solid NaCl deposit in water vapor at 600 °C. Electrochem. Commun. 12, 191–193 (2010).

Karlsson, S., Pettersson, J., Johansson, L. G. & Svensson, J. E. Alkali induced high-temperature corrosion of stainless steel: the influence of NaCl, KCl and CaCl2. Oxid. Met. 78, 83–102 (2012).

Mahobia, G. S., Paulose, N. & Singh, V. Hot corrosion behaviour of superalloy IN718 at 550 and 650. C. J. Mater. Eng. Perform. 22, 2418–2435 (2013).

Fan, L. et al. Effect of streaming water vapor on the corrosion behaviour of Ti60 alloy under a solid NaCl deposit in water vapor at 600 °C. Corros. Sci. 160, 108177 (2019).

Cao, M. et al. Studies on the corrosion behaviour of Fe–20Cr alloy in NaCl solution spray at 600 ◦C. Corros. Sci. 133, 165–177 (2018).

Pradhan, D., Mahobia, G. S., Chattopadhyay, K. & Singh, V. Salt induced corrosion behaviour of superalloy IN718. Mater. Today.: Proc. 5, 7047–7054 (2018).

Wagner, C. Reaktionstypen bei der Oxydation von Legierungen. Z. Elektrochem. 63, 772–782 (1959).

Wagner, C. The distribution of cations in metal oxide and metal sulphide solid solutions formed during the oxidation of alloys. Corros. Sci. 9, 91–109 (1969).

Yang, L. L. et al. Diffusion of Ta and its influence on oxidation behavior of nanocrystalline coatings with different Ta, Y and Al contents. Corros. Sci. 126, 344–355 (2017).

Yang, L. L. et al. Oxidation of duplex coatings with different thickness ratio of the inner nanocrystalline layer to the outer NiCrAlY one. Corros. Sci. 143, 136–147 (2018).

Robino, C. V. Representation of mixed reactive gases on free energy (Ellingham–Richardson) diagrams. Metall. Mater. Trans. B 27, 65–69 (1996).

Hasegawa, M. Chapter 3.3 - Ellingham Diagram. In Treatise on Process Metallurgy (ed Seetharaman, S.) 507–516 (Elsevier, Boston, 2014).

Anento, N., Serra, A. & Osetsky, Y. Effect of nickel on point defects diffusion in Fe–Ni alloy. Acta Mater. 132, 367–373 (2017).

Zahs, A., Spiegel, M. & Grabke, H. J. Chloridation and oxidation of iron, chromium, nickel and their alloys in chloridizing and oxidizing atmospheres at 400−700 °C. Corros. Sci. 42, 1093–1122 (2000).

ASTM. G–50, Standard practice for conducting atmospheric corrosion tests on metals (ASTM International, 2015).

ASTM. B117–09: Standard practice for operating salt spray (fog) apparatus (ASTM International, 2009).

Acknowledgements

This research is financially supported by Special Scientific Research Program for Civil Aircraft (MJ-2017-J-99), the National Natural Science Foundation of China (Grant No. 11872053 and Grant No. 51971190).

Author information

Authors and Affiliations

Contributions

Q.S.: Investigation, Formal analysis, Writing-original draft; H.Y.: Resources, Methodology; Y.W.: Data curation, Formal analysis; B.Z.: Conceptualization, Funding acquisition; X.H.:Formal analysis, Visualization, Writing-original draft; X.W.: Methodology, Resources; D.Z.: Supervision, Funding acquisition; J.L.: Supervision, Funding acquisition; Y.Y.: Conceptualization, Investigation, Methodology, Funding acquisition, Writing–review & editing; F.W.: Supervision. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, Q., Yu, H., Wang, Y. et al. Insights into the degradation mechanism of Fe-40Ni-15Co superalloy exposed to marine atmospheric and high-temperature conditions. npj Mater Degrad 8, 113 (2024). https://doi.org/10.1038/s41529-024-00531-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-024-00531-0