Abstract

We present an upgraded version of the model GRAAL (Glass Reactivity with Allowance for the Alteration Layer model) to predict nuclear glass alteration. GRAAL2 accounts for the formation and diffusion properties of the gel which constitutes a passivating alteration layer at the interface between the pristine glass and the aqueous environment, as well as the feedbacks between the gel chemistry and passivation properties. Solubility and apparent diffusion of the gel end members are optimized thanks to geochemical equilibrium calculations and Newton-Raphson and bisection methods, respectively. Modelling reliability is analyzed through the root mean square deviation of the model to the experimental data. A sensitivity analysis based on the propagation of the analytical uncertainties to the modelling parameters is also provided. The model is applied to alteration experiments on simple glass CJ2 at 90 °C, pH 9, and different surface-to-volume ratios and solutions compositions (pure water and solutions spiked with Si or Na).

Similar content being viewed by others

Introduction

Glass matrices are reference materials for the immobilization of radionuclides contained in high-level (HLW) and intermediate-level long-lived (ILW-LL) nuclear waste1. In the deep geological disposal facility for radioactive waste under study in France, the Cigéo project2,3, HLW and some ILW-LL waste packages are vitrified in a glass matrix, and will be placed in a container and stored in the Callovo-Oxfordian clay formation located in the North-East border of the Paris basin4,5,6. After the containers corrode and break, the glass will be put in contact with interstitial water and undergo alteration.

The glass matrix is the first barrier for containing radioactive waste, ensuring the safety and stability of nuclear waste management over time. Estimation of the long-term glass alteration rate is based on laboratory leaching experiments and characterization of altered glass. Modeling the behavior of glass in the laboratory is of paramount importance, not only for immediate understanding of the experiments but also for long-term predictions. This involves considering both microscopic and macroscopic models, each with their own limitations. Microscopic models delve into the intricate mechanisms of glass alteration, while macroscopic models provide a broader perspective by allowing interaction with the environmental materials of the waste package.

The behavior of glass results from a complex interplay between chemical reactions and diffusive transport processes. For chemical reactions, the rate-limiting step is often the kinetics of specific dissolution and precipitation processes, described by the Transition State Theory (TST)7,8. For transport, diffusion within the passivating gel layer is critical, and can be characterized by an apparent diffusion coefficient. The focus here is on the passivating gel layer, which chemical composition evolves through time, thus influencing its thickness and transport properties.

The GRAAL model solves the Eqs. for the gel formation and for diffusion through the gel (refs. 9,10). The main assumption in the model lies in a thermodynamic equilibrium between the gel and the solution. The model has offered significant advances in understanding of the complex dynamics of glass alteration. GRAAL is designed to bridge the gap between microscopic and macroscopic models11,12,13, by capturing the essential aspects of glass passivation without accounting for an exhaustive description of all the physical processes involved or underlying mechanisms details. The passivation process is implemented in a reactive transport code, and allows for coupling dissolution reactions and reactive transport in the glass matrix in contact with the aqueous environment.

The GRAAL model has demonstrated its ability to predict certain major effects involved during glass alteration, related for instance to the glass surface area, solution volume, solution renewal rate14,15, pH, time and glass composition16,17, aqueous environment composition18 and secondary phase formation, including carbonates and zeolites10,19,20.

However, GRAAL has some limitations. Certain aspects of glass alteration dynamics are not fully captured by the model, leaving room for improvement. One limitation of the first version of GRAAL is that it accounts only for one phase, i.e., one of the gel end members, to bear the passivating capacity. This means that the other end members have no effect on passivation. As a result, the model cannot account for how the passivating properties evolve with the gel composition. Therefore, the ability of GRAAL to account for the effect of chemical complexity of the aqueous environment on the glass alteration rate is limited. Incorporation of chemical elements from the environment into the gel is possible, but their effects on passivation is not accounted for.

Thus, the original GRAAL model has been upgraded to GRAAL2, with two aims: (1) to better incorporate in the gel composition not only the elements forming the glass, but also the elements provided by the aqueous environment, and (2) to enable the feedback between the gel composition evolution and passivation properties. Additionally, GRAAL2 includes an optimized calculation of solubility product and apparent diffusion coefficient (Dapp) of the end-members. The finality here is to ensure that the parameterization is as objective and independent as possible from the modeler.

This article describes the new potentialities offered by the GRAAL2 formalism and revisits the very foundations of the model GRAAL. Compared to GRAAL, the equilibrium between the gel and the solution in GRAAL2 is now described through a system of end members. The model accounts for the kinetics of glass dissolution, which is dependent to the saturation state, and for the kinetics of gel formation at the expense of the glass, which is driven by the diffusive transport of species through the passivating layer.

The model is applied to an experimental data set obtained from leaching experiments (see section “Experiments” for details) on the simple 4-oxide (Si-B-Na-Al) glass CJ221 at 90 °C, pH 9 and different volume to surface (S/V) ratios. These experiments are used to illustrate the response of the model, and to present and illustrate the methods associated with parameterization.

Simple chemical systems are first considered to qualify the model, i.e., to assess the relevance of the most important assumptions behind the model, i.e., the gel-solution equilibrium, the gel end-members, and the passivation properties. These simple chemical systems were chosen because the composition of the gel can be deduced using mass balance from the composition of the solution, as no precipitation of new solid phases is possible under these experimental conditions. Varying ratios between the glass surface and the volume of solution (S/V) is helpful to assess the model ability to account for the feedback of the glass forming elements and the solution composition on the alteration process. By systematically varying the experimental conditions, such as surface area-to-volume ratio and the composition of the leaching solutions, we can evaluate the robustness of the model parameterization. This approach ensures that the model predictions remain consistent and reliable across a range of experimental scenarios, demonstrating that the model parameterization not overly sensitive to changes in the experimental conditions.

Four replicate experiments are also used in a repeatability study to evaluate how the experimental uncertainties propagate to the modeling parameters. The use of statistical tools, such as regression analysis, root mean square deviation (RMSD) and uncertainty propagation, enables the evaluation of the modeling quality. Regression analysis helps to analyze the links between the model inputs (i.e., the experimental data) and outputs (i.e., the modeling data), while RMSD identifies the sources of variability in the model predictions. Uncertainty propagation assesses how uncertainties associated to the input experimental data affect the model results, providing a comprehensive evaluation of the modeling quality. The propagation of the uncertainties gives an estimation of the influence of the experimental uncertainties on the modeling parameters calculated, and it is therefore possible to study the repeatability of the parameterization method. In addition, it enables an estimation of the uncertainty for the responses given by the model based on the parametric uncertainties.

In addition, two experimental series are dedicated to studying the ability of the model to reproduce aqueous environments initially spiked with elements, i.e., silicon or sodium, which are also included in the gel composition. The objective is to assess the model’s ability to account for variations in solution composition by evaluating their impact on gel composition and solubility, as well as on glass alteration.

Finally, we evaluate the model capacity to predict a whole set of experimental data with a unique set of parameters. The modeling choices are then discussed, with a focus on the parameterization methods.

Modeling of glass alteration with GRAAL2

Principles

The GRAAL2 model aims to predict the alteration22 of nuclear waste conditioning glasses in contact with aqueous solutions in geological repository conditions23. It has been implemented in the reactive transport code HYTEC24,25, and uses the thermo-kinetics formalism of Chess24 with the database Thermochimie v926.

Compared to the original GRAAL model9,14, GRAAL2 takes into account the feedback of the evolution of the alteration gel composition on the transport of chemical species through a passivation effect, i.e. a reduction of the diffusive flux of chemical species. It describes the chemical interactions between the major elements released by the glass or brought by the aqueous solution19,27, and account for the composition of the newly formed minerals and amorphous gel20,28,29.

In GRAAL2, the chemical composition and solubility of the gel is described through a system of end members. This description allows the gel properties, i.e., composition, solubility and transport properties, to evolve through time. Each end member is described by a chemical Eq. of dissociation and a solubility product. In addition, each end member is attributed a specific, apparent diffusion coefficient to account for the feedback of the alteration gel composition on its passivation properties. Provided that porosity and molar volumes are known, the volume and thickness of the gel layer can be calculated. It is important to note that GRAAL2 does not explicitly model reactive transport within the passivating layer. Diffusion is accounted implicitly in the rate of glass alteration (Eq. (2)). Therefore, the representation of glass alteration process in Fig. 1 with the existence of three phases, in between the pristine glass and the solution, i.e., alkali-free glass, protective gel and non protective gel, does not formally exist in GRAAL2. Only the associated mass balance is accounted for. This representation will be useful for large-scale modeling of the alteration of fractured glass containers, as it will be possible to account for the alteration of the glass as a function of the position in space, and particularly the distance to the reactive environment.

The glass alteration process summarized in Fig. 1 includes three successive steps: (1) after contact between the glass and the aqueous environment, the surface atoms of the glass hydrolyze rapidly, as the bonds that link them to the rest of the network are weaker. The surface becomes depleted in alkalis, which are replaced by protons. Hydrolysis of additional alkalis requires both water and alkalis to pass through a network formed by elements, e.g. Si, whose dissolution is slower. Therefore, the rate of this reaction is quickly limited by a diffusion process, known as the exchange reaction between alkalis of the glass and protons in solution14,30,31,32. In the model, this step leads to the formation of the alkali-free glass. It is assumed that the reorganization of this layer is limited and that it occupies the volume of the glass from which it originates; (2) the layer depleted in alkalis reorganizes in situ through local dissolution-condensation processes to form a gel33,34. The kinetic rate of this reorganization is implemented in the model. Its maximal value correspond to the maximum hydrolysis rate (see further Eq. (3)). The molar volume of this gel is a parameter of the model that can be adjusted so that its volume differs from the volume of the glass from which it originates. However, experimental data show that the hypothesis of isovolumetry is a good approximation9,35,36,37. The assumption is made that this layer also participates in slowing down the hydrolysis of the weaker bonds, similarly to was happens for the alkali-free glass. The model describes that this process also involves other atoms in the glass whose bonds are fragile and do not participate in the formation of the gel, such as boron. A fraction of the gel does not participate in the passivation unless it reaches a sufficient density threshold to allow passivation, represented in Fig. 1 as the non-protective gel; (3) the gel hydrolyzes, forming the dissolved gel zone. The resulting thickness of the protective gel is taken into account at each time step to calculate the flux of elements diffusing through the gel.

These three steps are described in GRAAL2 through two main kinetic laws. The first kinetic law (Eq. (2)) is a rate of transformation of the glass into the alkali-free glass, r1 (m s−1).The rate is limited by diffusion through both the alkali-free glass and the protective gel, and depends also on the gel composition. The gel consists in several end members, which are used to describe both the protective (i.e., passivating) and non-protective gel. The non-protective gel constitutes only a fraction of the protective gel. There is no chemical distinction between the two in the model. The amount of the end members is not limited in the model as long as they are enough to frame and describe the compositional variations of the gel. Each end-member i has its own apparent diffusion coefficient Dapp_i (m s−2). The glass alteration rate is then a function weighted by the amount and the diffusion properties of each gel end member. Formally, in the model, r1 applies to the reaction transforming the pristine glass into alkali-depleted glass. Therefore, it drives the release of sodium into the solution. However, it also leads to the congruent dissolution of boron alongside sodium if the thickness of the alkali-free glass is negligible compared to the thickness of the gel (long-term condition) or the thickness of the dissolved gel (forward rate conditions).

The pristine glass alteration rate r1 is given by:

where x0 is the thickness of the alkali-free glass and Dapp_0 is its the apparent diffusion coefficient, n is the total number of gel end members, xi is the thickness of each end-member i, and Dapp_i their apparent diffusion coefficient. The thickness of each end member is calculated based on the normalized quantities of each end member relative to the glass surface and the molar density of the end member.

The second kinetic law (Eq. (3)) corresponds to dissolution-precipitation rates of the gel at their boundaries, i.e. the alkali-free glass-passivating gel interface and the non-protective gel-solution interface. The dissolution rate drives the gel-forming elements to pass into solution, especially silicon. The gel solubility limit is described by Eq. (3), where Ksp_i is the solubility product of each gel end member, and IAP is the ionic activity product. At equilibrium, IAP = Ksp_i and the rate is equal to zero. Far from equilibrium (at t = 0, pure water), IAP = 0 and the rate ri is maximum, and equal to the gel kinetic rate r0 for dissolution. r0 is commonly referred to as the initial glass alteration rate9, but in the GRAAL model, it represents rather the dissolution rate of the alkali-free layer (Fig. 1). The dissolution kinetics of the alkali-free layer does drive the forward rate. In contrary, the kinetics implemented for the other end members only come into play in exceptional situations, such as when a previously formed gel is brought back into contact with a solution of pure water. These kinetics also drive the reorganization of the alkali-free layer into a gel, a process that is experimentally difficult to access due to the complexity of the glass network reorganization. By default, r0 is applies to all end-members. In practice, the evolution of the gel composition occurs close to equilibrium, under conditions where r0 is no longer a significant parameter in Eq. (3):

The rate constant \({r}_{0}\) varies depending on the power law as a function of the pH, and on an Arrhenius law depending on the temperature. Numerical values are given for ISG glass in ref. 10.

Definition of the end members defining the gel

The gel composition is defined as the sum of end members weighted by their respective formed quantities16. The composition of end members is chosen to encompass the variations in the gel composition through time and leaching conditions. For gels of composition Si-Al-Na with an (Al/Na)gel ratio equal to one, a set of two end members is sufficient to reproduce the variations in gel composition (Fig. 2). One of the end members inherits of the Al/Si ratio in the glass ((Al/Si)glass, lower bound), while the other is more enriched in Al (upper bound). It is worth noting that there is no theoretical or numerical limitation on the number of end members. Their optimal number is up to the model designers, and depends on the availability and accuracy of the experimental data, the range of gel compositions, and the degree of complexity of the chemical interactions accounted for.

Each gel end member SiAlNacj2_i is defined in a database by an equation of dissociation (Eqs. (3) and (4), for i = 1 or i = 2, respectively) and a solubility product Ksp_i. Note that the end member composition can be retrieved from the equation of dissociation. Note that the composition given in Eqs. (3) and (4) is defined to encompass the variations in gel composition. Note that the basis components of the Thermochimie v926 database used for the calculation of log K are those of the following equations:

Two methods are implemented in GRAAL2 to calculate the solubility of the gel end members from: (1) the ion activity product given the species concentrations in solution or (2) the gel composition. The first method is the straightforward way to calculate the solubility, by definition whereas the second method is based on an estimation of the gel composition rather than directly accounting from the concentrations in solution. The advantage of the second method is that the modeled gel composition varies around the composition of the intermediate end member. It is particularly suitable to calculate the solubility of the end members when most of Al is retained in the gel.

Determination of the solubility product of the end members (K sp_i) using the ion activity product (IAP)

The solubility of the end members is determined from the geochemical analysis of the concentrations of Si, Al and Na is solution. The ion activity product IAP is calculated through time for each end member by the geochemical model Chess24. The assumption is made that the end member is at equilibrium with the leaching solution when it presence is expected9 (in the same way than in the GRAAL original model). Considering the duration of the experiments, formation of the gel is expected. At this time, the ratio Ω = log(Ksp_i/IAP) is equal to 0 and the equilibrium constant Ksp_i becomes equal to IAP. Practically Ksp_i is calculated from the average of IAP values in the time lapse the end member presence is expected. In this article, the presence of the end-members is assumed at all time steps.

It is worth noting that calculation of Ksp_i requires the concentration of [H+] and so the pH to be known. The pH can be recalculated based on the solution electroneutrality assumption by setting the charge balance on the ions H+. For the experiments in initially pure water, the pH is determined from the charge balance, with better accuracy and lower uncertainties than the pH measured experimentally. However, for the series of experiments spiked with Na or Si, the uncertainty associated with Na concentration approaches the order of magnitude of the hydroxide ion concentration. In this case, it was more relevant to use the pH measured in solution rather than the pH calculated by the model.

Determination of the solubility product of the gel end members (K sp_i) focusing on fitting the gel composition (Al/Si)gel ratio rather than the ions activities in solution

The determination of the solubility of the gel end members described above is based on the species concentration in solution. These concentrations can also be used to calculate the average composition of the gel from the mass balance, i.e., the difference between the glass and solution compositions, given the absence of precipitation of secondary phases:

with n(Al) and n(Si) the amount of aluminum and silicium (mol), and t the time.

An alternative method is implemented in GRAAL2 to calculate the solubility of the gel end members from the gel composition evolution through time. This method aim to better reproduce the gel stoichiometry rather than the ions activities in solution. During alteration of the CJ2 simple glass in pure water, the (Al/Na)gel ratio remains equal to 116 and only the (Al/Si)gel ratio varies, so that a minimum of two end members are required. The method is described as follow. First, a third end member of intermediate composition between the two end members that bound the gel composition is created temporary. For the two bounding end members SiAlNacj2_1 (Eq. (3)) and SiAlNacj2_2 (Eq. (4)), the third end member created is SiAlNacj2_3 (Fig. 3), and its solubility is determined with CHESS using the method described above (section “Determination of the solubility product of the end members (Ksp_i) using the ion activity product (IAP)”). In this study, an Al/Si ratio equal to 0.16549 is used for the third end member, which is an intermediate value of the (Al/Si)gel ratio in the gel during the experiment. A modeling is performed with GRAAL2, in which only the intermediate end member is allowed to precipitate. The time tint at which the gel composition is equal to the intermediate end member composition is searched. The solubility of the bounding end members is then defined from the saturation index calculation at the numerical timesteps just before and after tint, using the method described above (section “Determination of the solubility product of the end members (Ksp_i) using the ion activity product (IAP)”). The intermediate end member SiAlNacj2_3 is finally removed from the database and only the two bounding end members are kept (Fig. 4).

Determination of the apparent diffusion coefficient D app_i of the gel end members

GRAAL2 defines the passivation ability of each end member through their apparent diffusion coefficient, whose determination is based on the boron concentration evolution.

The apparent diffusion coefficient through the gel, Dapp_i (m2 s−1) of for each end member i is an important parameter to calculate, as it defines the ability of the gel to passivate the glass alteration process. The determination of Dapp_i is two-steps. First, an approximate value of Dapp_i is determined from the assumption the gel occupies all the volume of the altered glass (isovolumicity hypothesis) using the equation:

where eth(t) is the equivalent altered glass thickness (m) at time t. Secondly, Dapp_i is recalculated from the amount of boron released during the experiments, the boron in solution being considered as chemically inert and so a good tracer of glass dissolution, and also a good indicator of the diffusive flux from the pristine glass to the solution. Determination of Dapp_i is optimized for each end member using the Newton-Raphson approximation method to minimize the differences existing between the experimental and modeled values, and a bisection method to get the best fit by minimizing the square of the deviations.

Qualification method for the modeling results

This article focuses on the comparison between modeled data and experiment data and the differences existing between them. The differences between the two for a given variable (concentration in this paper) is estimated by using the root mean square deviation (RMSD) (Eq. (5)):

where Xexp and Xsim are the experimental and predicted values, respectively, and N is the number of data points.

Sensitivity analysis and uncertainty associated with modeling

For the experiments, only the analytical uncertainties from the analyses by inductively coupled plasma atomic emission spectroscopy (ICP-AES) have been considered. Their repercussions on the modeling results are studied. For a given element, the relative uncertainty is calculated by varying the experimental concentrations in the range of the analytical uncertainty (10% for Si, Na, B and 20% for Al) before recalculating the corresponding modeling parameters, i.e. the solubility products Ksp_i and the apparent diffusion coefficients Dapp_i. For each experimental datapoint, a million values are generated according a normal distribution to evaluate the uncertainties associated to the experimental concentration on the modeling parameters (Dapp_i et log Ksp_i). The same procedure is applied on the modeling parameters by generating a million values for each parameter to evaluate the uncertainties of the parameters on the model responses.

Uncertainty associated with the determination of gel composition

As boron is not retained in the gel, it is possible to deduce the composition of the gel from the differences in concentrations [B]-[Al] and [B]-[Si] in solution. The [B] concentration increases progressively in solution, as a function of diffusive transport and of the thickness of the amorphous layer which develops between the pristine glass and the solution. The equivalent thickness of the altered glass at a given time, eth(t) (m) is calculated from the fraction of altered glass (faltered glass) using the shrinking core model27. The model is based on the assumption that the grains are spheres, whose radius can be calculated from the BET specific surface (SBET):

where dglass is the glass density.

The Al/Si ratio in the CJ2 simple glass, (Al/Si)glass, is equal to 0.1273. Then, the Al/Si ratio in the gel, (Al/Si)gel (Eq. (5)), can be written more explicitly:

where eth(k) is the equivalent thickness of the altered glass considering element k in solution.

It should be noted that the (Al/Si)gel ratio can be calculated from mass balance because no precipitation of secondary phases occurs in the experiments. In the present case, the use of the CJ2 simple glass is thus precious for the construction of end member model.

The uncertainty associated with the (Al/Si)gel ratio determined from the experiments is expressed using the uncertainty propagation formula38:

The uncertainty associated with the calculation of the equivalent thickness of the altered glass is given by38:

Where dglass is the glass density, m the mass of glass, V the volume of solution and C(k) the concentration of element k in solution.

Modeling of simple glass alteration with GRAAL2

Model parameterization from the experiments at S/V = 16 cm−1 in pure water

The two experiments performed in pure water at S/V = 16 cm−1 were chosen to illustrate the parameterization of GRAAL2 (section “Definition of the end members defining the gel”). The optimal parameters obtained for the two end members, i.e., the solubility products and the apparent diffusion coefficients are given in Table 1. It should be noted that here the same apparent diffusion coefficient was used for both end members. The use of two diffusion coefficients would not improve the experimental model deviations given the uncertainty.

The parameters setup method used in this study was based on a common diffusion coefficient for the two end members of the gel. This hypothesis is justified here because the gel composition variations during the experiments were moderate, and therefore the two end member compositions are close. Here, the effect of the composition on the diffusion coefficient is within the order of magnitude of the experimental uncertainty. If, for example, the glass had been altered in a solution containing potassium or cesium in sufficient quantities to replace sodium in the gel, it would then have been essential to give much lower diffusion coefficients to the end members containing K and Cs39.

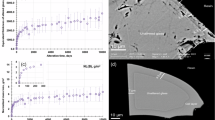

The modeling results for the concentrations of [B], [Si], [Al] and [Na] are shown in Fig. 5. The modeling qualification and uncertainties are estimated according to the methods described in “Qualification method for the modelling results” and “Sensitivity analysis and uncertainty associated with modelling”. Modeling is highly satisfactory, with almost all of the experimental data points included in the modeling uncertainty range, thus enabling validation of the modeling for these two experiments.

Some parameters do not need to be determined because they have no effect on the calculations under the present experimental conditions. This is the case for instance for the solubility product of the dealkalized glass and the rate constant relative to the end members. The dealkalized glass must be sufficiently soluble to allow its transformation into the gel, through a dissolution/reprecipitation process that occurs at the initial, maximum rate k, which is not limiting. The dissolution/precipitation kinetics specific to each end member are assumed to be as rapid as that of the dealkalized glass. Its hydrolysis at the dealkalized glass/gel interface drives, without additional hindrance, the kinetics at which the gel can reorganize without further limitation throughout its volume.

Generalization to the experiment series in pure water

The optimal modeling parameters for the six experiments in pure water are determined in a similar way that in the previous section for the two experiments in pure water at S/V = 16 cm−1. They are summarized in Table 2.

Figure 6 compares the difference in the solubility product (Ksp) between a given experiment SVj and the reference experiment SV1_PW (S/V = 1 cm−1), and the evolution apparent diffusion coefficient (Dapp) depending on the S/V ratio. The end member solubilities or apparent diffusion coefficient are meant to be constant. By observing whether these parameters change from one experiment to another beyond the uncertainty range, it is possible to identify the limits of the model. Results show that the solubility of end members seems to increase when the solution-to-volume ratio increase (higher Log Ksp_i). Moreover, the apparent diffusion coefficient increases with increasing S/V. It can be supposed that there is a faster transfer of species from the pristine glass to solution, and thus a faster saturation of the solution.

It is worth noting that the difference in Dapp for the replicate experiments also increases with the S/V ratio. This trend will be analyzed in section “Evaluation of the modelling reliability and management of the model uncertainties and deviations for pure water experiments” when accounting for the analytical uncertainties, in order to qualify whether these differences are significant or not.

Evaluation of the modeling reliability and management of the model uncertainties and deviations for pure water experiments

Table 3 shows the root mean square deviation (RMSD) values between experimental and modeled data (Eq. (7)) for the four elements in solution, i.e. Si; B, Na and Al. For all elements, the RMSD decreases with increasing S/V. The high S/V experiment at 16 cm−1 is better modeled, with smaller experiment-model differences.

The RMSD values assess the deviation between the experimental and the predicted results. However, this criteria this is not sufficient to conclude whether a given experiment is well modeled. Assessing the quality of a model requires a study of the sources of discrepancies between experimental and modeled data and an assessment of uncertainties.

In the present study, only the analytical uncertainties related to the determination of concentrations were considered. They can be quantified, and we assume they represent the main experimental uncertainty. Given the maximum analytical uncertainties of 10% for silicon, boron, and sodium concentrations, and 20% for aluminum concentration, propagation of these uncertainties to the solubility and apparent diffusion coefficient of the end members, and to the concentration of the different elements (Si, Al, Na, B) gives the following results (Tables 4 and 5).

The uncertainties range from 15 to 20% for the apparent diffusion coefficients, and are equal to ±0.025 for the solubility products. For the different concentrations, the uncertainties range from 9% to 43%. In details, the accuracy on [Si] is about 20%. As the main component of the gel, its concentration is therefore greatly influenced by the uncertainties associated with the end-members solubility. It is also sensitive to pH in a basic solution. The accuracy on aluminum is the lowest, with uncertainties up to 67%. It bears the analytical uncertainties, and is also sensitive to the pH.

Figure 7 shows the concentrations of [Si], [Al], [Na] and [B] (normalized to the maximum concentration of the modeling for each experiment). For the experiments at high S/V = 16 cm−1 (shown in dark and light blue), the experimental and modeled uncertainty ranges are fairly well overlapped. For the experiments at intermediate S/V = 4 cm−1 (shown in green), the accuracy of the model is slightly lower, with some experimental data out of the modeling uncertainty ranges. However, it seems that this difference is preferentially related to the dispersion of the experimental data rather than to a real drift in the modeling. It suggests that the initial hypothesis according to which only the analytical uncertainties make up much of the total uncertainty is appropriate, without being perfect. The poorest accuracy of the modeling is obtained for the experiments at low S/V = 1 cm−1 (shown in pink and violet). The first question that arises concerns the reliability of the experimental results. Indeed, a large increase in the experimental concentrations of sodium can be observed after 20 days in experiments SV1_PW and SV1_PW_GB, without any apparent reason, i.e., no secondary phase formation. In addition, there is a wide dispersion of the concentrations in [Al], particularly in the first experimental series. Overall, in these experiments, [Si] concentrations are in a fairly bad agreement ([Si] keeps increasing in the experiment, while it reaches a plateau in the modeling), although [B] and [Na] concentrations seem correctly modeled on the long term.

Analysis of the gel composition for pure water experiments

Prediction of the quantities formed for each end member enables an estimation of the gel composition. For the gels formed during alteration of the CJ2 simple glass that contain as much Na as Al, the (Al/Si)gel ratio is enough to represent the variations in the gel composition, which can be derived from the experimental concentrations in solution (see section “Uncertainty associated with the determination of gel composition”).

It is therefore possible to evaluate the model ability to correctly represent the gel composition using the statistical methods presented in section “Uncertainty associated with the determination of gel composition”. Table 6 shows the experimental and the modeling uncertainties associated with the gel composition, i.e., the (Al/Si)gel ratio, together with and evaluation of the RMSD between experiment and modeling. The level of confidence for the experimental estimation of the gel compositions is good ( < 3%). The RMSD values, however, are high compared to the relative errors Δ (Al/Si)gel-experimental and Δ (Al/Si)gel-modeled. This phenomenon can be also seen in Fig. 8, which shows an overestimation of the aluminum concentration (or an underestimation of the silicon concentration) in the gel. Although the experimental values are fairly close at high S/V ratios (which could be expected, given the previous RMSD calculation), there is a real difference at low S/V ratio, with modeling and experimental uncertainty domains that only coincide occasionally. It can be noted, however, that there is a good repeatability between the replicate experiments, both for the modeling and experimental data. For the higher S/V experiments, the gel compositions tends rapidly towards the (Al/Si)glass stoichiometric ratio of the glass. Their modeling parameters varied much less, as was illustrated by the experiment at S/V = 16 cm−1.

Evaluation of gel solubility over a given period of time for pure water experiments

Previous results (Sections “Generalization to the experiment series in pure water” and “Evaluation of the modeling reliability and management of the model uncertainties and deviations for pure water experiments”) have shown that differences exist between the experimental and modeled data, especially for [Si], in the experiments at S/V = 1 cm−1.

It should be noted that the parameters for the six experiments were set in the same way, using the method from section “Determination of the solubility product of the end members (Ksp_i) using the ion activity product (IAP)” by taking all of the experimental points into account. However, the method described in this section foresees the use of Log Ksp_i only during a period of time the saturation index associated with the end member is constant. This is the case for all the time lapses in the experiments with S/V = 4 and 16 cm1. Applying the method to the experiments at S/V = 1 cm−1, the modeled concentrations of silicon and aluminum reflect the experimental points much better on the long term (Fig. 9).

The model-experiment discrepancy decreases at the end of the experiment, but is high at the beginning. Meanwhile, the RMSD value does not vary. The modeling method is however better in the sense it suppresses the dependence of the Log Ksp_i onto the S/V ratio. This suggests the existence of a mechanism revealed at low S/V, which would explain a slower transfer of silicon in solution. Moreover, it should be noted that this method improves the modeling accuracy of the gel for the experiment SV1_PW, with the opposite effect on the experiment SV1_PW_GB (Figs. 8 and 10). As the two experiments are replicates, this difference must be attributed to experimental variability in the concentrations of [Al], whose uncertainty propagates onto the modeling.

Although it provides significant improvements, this method is not applied to the rest of the article in order to allow a consistent comparison of the experiments treated using the method described in section “Determination of the solubility product of the end members (Ksp_i) using the ion activity product (IAP)”.

Alternative model parameterization using the gel composition ((Al/Si)gel ratio) for pure water experiments

In this section, we apply the alternative method based on the (Al/Si)gel ratio (section “Determination of the solubility product of the gel end members (Ksp_i) focusing on fitting the gel composition (Al/Si)gel ratio rather than the ions activities in solution”) to the experiments in pure water at S/V = 1 cm−1. Modeling better fits with respect to the gel composition (Fig. 11).

Table 7 qualifies the method, as the prediction of the gel composition is much better (RMSD is divided by two to three), but the gain in accuracy for the gel composition is detrimental to the aluminum concentration in solution, whose RMSD then reaches about 145%. However, as the measurement of [Al] in solution is not very accurate, this method is justified. For the other elements, the RMSD remains about equal ( ± 3%).

Evaluation of repeatability

Evaluation of repeatability is achieved based on four experiments performed in pretty identical conditions and can be considered as replicates (SV1_PW, SV1_PW_GB, SV1_0Si, and SV1_0.4Na). The surface-to-volume ratio S/V is equal to 1 cm−1 and the only differences are the mass of glass and volumes of solution, whose effects on the alteration process are considered as negligeable.

Figure 12 shows the concentrations in silicon for the four experiments. It can be clearly seen that the SV1_0.4Na experiment stands out from the others. This experiment belongs to a series with high sodium concentrations (up to 40 mmol L−1). The entire series was analyzed with a sample dilution by to avoid polluting the ICP-AES, and the dilution led to lower accuracy and greater uncertainty. The result illustrates the importance of the chemical analysis step in the global experimental uncertainty. Due to the uncertainty associated to these values, it appears better to exclude this experiment of the modeling.

Table 8 gives the parameters calculated for the three remaining experiments. Results show that the gel solubility parameterization is consistent within the uncertainties, but the apparent diffusion coefficient value shows slightly greater variations.

Modeling of the experimental series spiked with silicon and sodium

Modeling is extended to the experimental series for which the aqueous environment, i.e. the composition of the leaching solutions, is more complex. This applies to the experiment series spiked with Si or Na (see section “experiments”). The objective here is to determine if the model is suitable for predicting the chemical interactions between elements that lead to changes both in the solution composition, the gel composition, and the glass alteration rate.

The nine spiked experiments were carried out with a S/V ratio of 1 cm−1, so that in a first approach, we use the modeling parameters determined for the similar experiments in pure water (SV1_PW and SV1_PW_GB, Table 2) to test the model response. Figure 13 shows that this approach gives erroneous results, i.e., boron is greatly underestimated, and silicon is either underestimated or overestimated depending on the initial content of Si in the solution.

Aluminum concentration in solution for the glass alteration experiments in water spiked with (left) sodium and (right) silicon, using the average parameters (solubility product and apparent diffusion coefficient shown in Table 2) parameterized from the experiments in pure water SV1_PW and SV1_PW_GB.

Aluminum is consumed by the gel formation, and according to the mass action law, the more silicon or sodium in the solution, the more aluminum should be consumed. This phenomenon is perfectly taken into account in the modeling, with lower and lower aluminum concentrations as the quantity of silicon or sodium present at the start of the experiment increases (Fig. 13).

These results show that the model consumes silicon or sodium present in solution to form the gel (Fig. 13). As a result, the gel forms more rapidly than in the pure water experiments, i.e., as soon as aluminum is available, and this leads to an early passivation that makes the diffusion of species into solution more difficult. Optimized modeling (shown in Appendix A) results in an increase in the gel solubility when [Si] increases in solution (Fig. 14). However, the initial [Si] concentration in solution has no effect on the apparent diffusion coefficient Dapp. Consequently, silicon in solution does not seem to affect the passivation properties of the gel. Such observations are not made for experiments with the addition of Na, so that it can be concluded that sodium has a minor effect on glass alteration but a great influence on the aluminum concentration. It can also be noted that the model is able to predict the evolution of aluminum concentration in these sodic solutions. This confirms the model ability to reproduce the interaction between sodium and aluminum.

Table 9 gives the RMSD values calculated for the experiments spiked with silicon. The SV1_0Si experiment is identical to those carried out in pure water at a S/V of 1 cm−1 (SV1_PW and SV1_PW_GB). An incomplete amorphous silica dissolution during the preparation of the most concentrated solutions probably explains the underestimation of silicon concentration in the experiments, and therefore the high value of the associated RMSD. Table 10 lists the RMSD values calculated for the experiments in this series. The results of experiments SV1_4Na and SV1_40Na are close to those for the pure water experiments at the same S/V.

Modeling the whole set of experiments using of a single set of parameters

In this section, we propose and qualify a single set of parameters to model all the experiments. The optimal parameters, i.e., the mean of optimum parameters for the experiments in pure water, are Ksp_1 = 0.3052 and Ksp_2 = 0.0064 for the solubility of the gel end members with the highest silicon and aluminum content, respectively, and Dapp = 7.3·10−22 m2 s−1. Figure 15 shows the comparison between all the experiment data and modeling for [Al] and [Si] normalized concentrations.

The data are normalized to the maximum concentration of the element reached during modeling. The gray beam represents the uncertainty range associated to modeling using the mean solubilities and apparent diffusion coefficient obtained from the experiments in pure water SV1_PW and SV1_PW_GB (black curves).

Although some experimental data lie outside the uncertainty domains, more than 80% of the data points are correctly represented on the long run for the Si concentration and more than 70% for the Al concentration. It therefore seems possible to model all the experiments with a single set of solubility products.

Figure 16 (left) shows the evolution of [B] concentrations. We observe that a single apparent diffusion coefficient is, however, not able to capture the evolution of [B] for all the experiments. The modelled values are underestimated for the experiments at S/V = 16 cm−1 and overestimated for the experiments at S/V = 1 cm−1. In the current state, the description of a surface-to-volume ratio dependent mechanism which would affect the passivation properties of the gel is lacking. It should be pointed out that optimization using different apparent diffusion coefficients depending on the S/V ratio improves modeling of [B] (Fig. 16 (right)) but also of [Si] and [Al] concentrations, because of their dependence both on [Na] concentration and pH.

The experimental (dots) and modeling (curves) concentrations are normalized to the maximum [B] reached during modeling. The gray beam represent the uncertainty associated to modeling using the mean solubilities and apparent diffusion coefficient obtained from the experiments is pure water SV1_PW and SV1_PW_GB (black curves).

Discussion

In this article, we have presented the GRAAL2 model. Experimental series corresponding to leaching experiments of the simple 4-oxide CJ2 glass were used to test the model ability to reproduce specific environmental changes, such as variations in the volume of solution in contact with the glass and the presence or absence of certain elements in the aqueous environment, specifically Si and Na. Several parameterization methods have been designed to determine the optimal parameters i.e., solubility products Ksp_i of the end members and apparent diffusion coefficient Dapp_i in the gel for each experiment. Comparing the optimal parameters has provided insights into their dependence on the experimental conditions. All the methods calculate the optimal parameters for the experiments in pure water simply and rigorously. These can therefore be automated, thus allowing for rapid comparison of the modeling parameters obtained, i.e., the solubility products of the end members and their apparent diffusion coefficients.

In addition to solubility product parametrization based on the ion activity product averaged over all experimental data points (section “Determination of the solubility product of the end members (Ksp_i) using the ion activity product (IAP)”), two alternative methods have been proposed. One method exploits the composition of the gel (section “Determination of the solubility product of the gel end members (Ksp_i) focusing on fitting the gel composition (Al/Si)gel ratio rather than the ions activities in solution”), while the other calculates the ionic products over a given period of time (section “Evaluation of gel solubility over a given period of time for pure water experiments”).

Aluminum is difficult to predict by GRAAL2. This can be explained by the low concentration of Al in solution and the wide range of analytical results. The alternative parameterization method based on the (Al/Si)gel ratio in the gel has proven to be as efficient than the one based on the determination of solubility products of the end members from the solution composition, at least for the experiment with a low S/V ratio. However, it can be noted that even if aluminum may remain difficult to model, modeling of the global evolution of this element as the function of the aqueous environment composition (e.g., considering the presence of silicon or sodium) is possible. The model reproduces the trend of decreasing [Al] concentration when sodium or silicon is added to the aqueous solution. Consequently, the mass action law applied to the end members that define the gel composition has proved to be effective. While further verification is required for more complex chemical systems, the results carry an important corollary: increasing the complexity of the model by introducing a large number of end members or a solid solution model is not justified given the accuracy of the experimental data on which the model is based.

The modeling of experiments with high S/V ratios gives accurate results, with overlapping uncertainty domains between experimental and modelled data. However, at low S/V ratios (1 cm–¹), larger discrepancies were observed, with higher RMSD values and continuous silicon increase in solution, contrary to model predictions of a plateau. Mechanistic hypotheses, including diffusive transport of silicon, are being investigated to explain the observed trends. Additionally, the experiment duration at low S/V may have been insufficient. To address initial gel composition variations, equilibrium with the gel was assumed only at the end of the experiment, improving long-term predictions despite initial deviations. Studying the temporal evolution of the ionic products of ions in solution, which are associated with the composition of each end-member, is extremely meaningful. Automating a rigorous method to define the moment when these ionic products can be considered constant for calculating a solubility product is however complex. If this method has not been systematically used in the article, it appears promising and will be used in future work. Additionally, we have chosen the method based on all experimental data points to allow for a rigorous comparison of the experiments with different S/V ratios. This does not diminish the relevance of the method focussing a given period of time.

Uncertainties provided by GRAAL2 after optimization are in the range ±0.025 for the solubility products Log Kps_i, and ±15–20% for the apparent diffusion coefficients Dapp_i. when evaluating the repeatability. Overall, this study demonstrates that, although the predictions are generally accurate, they slightly exceed the experimental uncertainties. It would be too restrictive to attribute this solely to the model, as the analytical uncertainties for aluminum are visibly higher than those reported by the chemical analysis, and because analytical uncertainties represent only part of the experimental uncertainties. In addition, it was possible to propose a single set of optimized parameters associated with an appropriate uncertainty (section “Modeling the whole set of experiments using of a single set of parameters”). However, the dependence of the modeling parameters on the experimental conditions illustrates a limitation of the model. There is therefore a second order mechanism that is missing or even inappropriate, which seems to be a feature of the experiments at the lowest S/V ratio. Although it is worth exploring modeling of the long-term behavior of glass alteration at low S/V experiments in more details, the GRAAL2 model appears to be a reliable modeling tool to predict glass alteration in solution fairly accurately.

The model structure does not rely solely on Eqs. (1) and (2), and a number of second-order refinements are allowed. Two important mechanisms implemented in GRAAL2 still need to be exploited. First, the model ability to account for a specific diffusion coefficient for each end member. Second, the possibility to define a non-passivating fraction of the gel, meaning the ability to set a density threshold beyond which the gel becomes passivating, rather than assuming that all condensed matter contributes to passivation. These two mechanisms should be particularly useful for improving predictions in experiments with a low glass surface to solution volume ratio (S/V), where the gel dissolves significantly and its composition evolves over time. Among the second-order refinements, the model also allows for a more accurate estimation of the relationship between the amount of gel and the thickness of the gel layer. This is based on the estimation of the molar volumes of the end members, as well as the water content of the passivating gel. This estimation is not accessible through GRAAL2, but it can be achieved through solid characterizations and models specifically designed to explicitly model the alteration film at smaller scales, such as molecular models, Monte Carlo simulations, and mesoscopic models at the scale of the alteration film.

In the future, applying the model to other glass compositions or different chemical environments will allow for testing and validating GRAAL2 on more complex chemical systems. The main objective of the GRAAL2 model is to account for compositional effects to improve predictions. While the effects of S/V and ions from both the glass and the solution have been studied here, many other compositional effects remain to be explored. The GRAAL2 equations are ready to incorporate variations in glass composition as well as the role of ions introduced by the surrounding environment.

Experiments

Experiments of glass alteration were carried out on the 4-oxide simple glass CJ221 (Table 11), using ground glass powder in the range 40–100 µm washed with absolute ethanol.

A total of 15 experiments divided in four different experimental series were performed in 180 mL teflon reactors placed in a laboratory oven at temperature T = 90 ± 2 °C for 70 days, by varying the glass powder surface to the solution volume ratio (i.e., the surface-to-volume ratio, S/V (cm−1)), the atmospheric environment, or by spiking with Si or Na the reference leaching solution, which is ultrapure water (18.2 MΩ cm) to which 0.4 mmol L−1 of sodium hydroxide has been added to stabilize the pH at 9.

In the first series, the surface to volume ratio was varied in the reactor (S/V = 1, 4 or 16 cm−1). These experiments are referenced as “SVj_PW”, with j the value of the S/V ratio, and PW standing for pure water. The second series was carried out in a glove box under a controlled nitrogen atmosphere, in order verify that there was no contamination of the solutions of the first series by atmospheric CO2. As no contamination was noticed, the series can be considered is a replicate of the first series These experiments therefore had GB (for glove box) added to their name, “SVj_PW_GB”. Finally, two additional experimental series were carried out with the addition of either Si or Na to the leaching solution. Si is introduced from dissolution from amorphous silica at five different concentrations (1, 2, 3, 5, and 7 mmol L−1). Na is introduced from a sodium chloride solution at three different concentrations (0.4, 4 and 40 mmol L−1). These experiments were all carried out at S/V = 1 cm−1. These experiments are referenced as either “SV1_kNa” or “SV1_kSi”, with k the concentration of silicon or sodium in solution in mmol L−1.

Regular sampling was performed (aliquots of 2–3 mL) and solutions analyzed by ICP-AES to monitor the [Si], [Na], [B], and [Al] concentrations over time. The pH was also measured during each sample collection with a precision of ±0.1 unit.

The analytical uncertainties range from 5 to 20% and depend on the element and on the S/V ratio of the experiment. For sake of simplicity, an uncertainty of 10% is associated with the concentrations of silicon, boron, and sodium, whereas an uncertainty on aluminum concentration determination is 20%. These values represent indeed the maximum uncertainty (upper bound) for a given element. The higher uncertainty on aluminum is explained by its low concentration in solution, close to the quantification limits of the ICP-AES.

All the experimental data are presented in Supplementary information. Experimental results show that an increase in S/V (decrease in volume) leads to an increase in solution concentrations. The addition of sodium or silicon at the beginning of the experiment leads to a decrease in aluminium concentrations in the solution.

Data availability

The authors declare that the data supporting the findings of this study are available from the corresponding author.

Code availability

The code generated during the current study is not publicly. However, it is available from the corresponding author on reasonable request.

References

Caurant, D. & Majérus, O. Glasses and glass-ceramics for nuclear waste immobilization. In Encyclopedia of Materials: Technical Ceramics and Glasses (ed. Pomeroy, M.) 762–789 (Elsevier, 2021).

Tran, N.-T. et al. Kriging-based reliability analysis of the long-term stability of a deep drift constructed in the Callovo-Oxfordian claystone, Journal of Rock Mechanics and Geotechnical Engineering, S1674775521000949, juill, https://doi.org/10.1016/j.jrmge.2021.06.009 (2021).

Mekki, S. Main repository projects worldwide. In Encyclopedia of Nuclear Energy (ed. Greenspan, E.) 616–649 (Elsevier, 2021).

Descostes, M. et al. Diffusion of anionic species in Callovo-Oxfordian argillites and Oxfordian limestones (Meuse/Haute–Marne, France). Appl. Geochem. 23, 655–677 (2008).

Wang, H., Cui, Y.-J., Vu, M. N. & Talandier, J. Modelling the viscoplastic behaviour of Callovo-Oxfordian claystone with consideration of damage effect. J. Rock Mech. Geotech. Eng. S1674775523002469, https://doi.org/10.1016/j.jrmge.2023.09.001 (2023).

Trouiller, A. Le Callovo-Oxfordien du bassin de Paris: du contexte géologique à la modélisation de ses propriétés. Comptes Rendus Géoscience 338, 815–823 (2006).

Aagaard, P. & Helgeson, H. C. Thermodynamic and kinetic constraints on reaction rates among minerals and aqueous solutions. I. Theoretical considerations. Am. J. Sci. 282, 237–285 (1982).

Helgeson, H. C., Murphy, W. M. & Aagaard, P. Thermodynamic and kinetic constraints on reaction rates among minerals and aqueous solutions. II. Rate constants, effective surface area, and the hydrolysis of feldspar. Geochim. Cosmochim. Acta 48, 2405–2432 (1984).

Frugier, P. et al. SON68 nuclear glass dissolution kinetics: current state of knowledge and basis of the new GRAAL model. J. Nucl. Mater. 380, 8–21 (2008).

Frugier, P. et al. Modeling glass corrosion with GRAAL. npj Mater. Degrad. 2, 35 (2018).

Arab, M. et al. Aqueous alteration of five-oxide silicate glasses: experimental approach and Monte Carlo modeling. J. Non-Cryst. Solids 354, 155–161 (2008).

Kerisit, S. & Du, J. Monte Carlo simulation of borosilicate glass dissolution using molecular dynamics-generated glass structures. J. Non-Cryst. Solids 522, 119601 (2019).

Ledieu, A., Devreux, F. & Barboux, P. Monte Carlo simulations of borosilicate glass corrosion: predictions for morphology and kinetics. J. Non-Cryst. Solids 715–719 https://doi.org/10.1016/j.jnoncrysol.2004.08.152 (2004).

Frugier, P., Chave, T., Gin, S. & Lartigue, J.-E. Application of the GRAAL model to leaching experiments with SON68 nuclear glass in initially pure water. J. Nucl. Mater. 392, 552–567 (2009).

Minet, Y., Bonin, B., Gin, S. & Frugier, P. Analytic implementation of the GRAAL model: application to a R7T7-type glass package in a geological disposal environment. J. Nucl. Mater. 404, 178–202 (2010).

Rajmohan, N., Frugier, P. & Gin, S. Composition effects on synthetic glass alteration mechanisms: part 1. Experiments. Chem. Geol. 279, 106–119 (2010).

Debure, M., Frugier, P., De Windt, L. & Gin, S. Borosilicate glass alteration driven by magnesium carbonates. J. Nucl. Mater. 420, 347–361 (2012).

Jollivet, P. et al. Effect of clayey groundwater on the dissolution rate of the simulated nuclear waste glass SON68. J. Nucl. Mater. 420, 508–518 (2012).

Debure, M., Frugier, P., De Windt, L. & Gin, S. Dolomite effect on borosilicate glass alteration. Appl. Geochem. 33, 237–251 (2013).

Frugier, P., Fournier, M. & Gin, S. Modeling resumption of glass alteration due to zeolites precipitation. Procedia Earth Planet. Sci. 17, 340–343 (2017).

Gin, S. et al. Effect of composition on the short-term and long-term dissolution rates of ten borosilicate glasses of increasing complexity from 3 to 30 oxides. J. Non-Cryst. Solids 358, 2559–2570 (2012).

Zanini, R., Franceschin, G., Cattaruzza, E. & Traviglia, A. A review of glass corrosion: the unique contribution of studying ancient glass to validate glass alteration models. npj Mater. Degrad. 7, 38 (2023).

Schumacher, S. et al. Key phenomena governing HLW glass behavior in the French deep geological disposal. MRS Proc. 1744, 127–138 (2015).

van der Lee, J., De Windt, L., Lagneau, V. & Goblet, P. Module-oriented modeling of reactive transport with HYTEC. Comput. Geosci.29, 265–275 (2003).

Steefel, C. I. et al. Reactive transport codes for subsurface environmental simulation. Comput. Geosci.19, 445–478 (2015).

Giffaut, E. et al. Andra thermodynamic database for performance assessment: ThermoChimie. Appl. Geochem. 49, 225–236 (2014).

Chave, T., Frugier, P., Gin, S. & Ayral, A. Glass–water interphase reactivity with calcium rich solutions. Geochim. Cosmochim. Acta 75, 4125–4139 (2011).

Brunswic, L. et al. Altération des verres industriels en milieux aqueux et atmosphérique: mécanismes, cinétiques, caractérisations. Matér. Tech. 110, 402 (2022).

Gin, S., Delaye, J.-M., Angeli, F. & Schuller, S. Aqueous alteration of silicate glass: state of knowledge and perspectives. npj Mater. Degrad. 5, 42 (2021).

Ojovan, M. I., Hand, R. J., Ojovan, N. V. & Lee, W. E. Corrosion of alkali–borosilicate waste glass K-26 in non-saturated conditions. J. Nucl. Mater. 340, 12–24 (2005).

Ojovan, M. I., Pankov, A. & Lee, W. E. The ion exchange phase in corrosion of nuclear waste glasses. J. Nucl. Mater. 358, 57–68 (2006).

Ojovan, M. I. On alteration rate renewal stage of nuclear waste glass corrosion. MRS Adv. 5, 111–120 (2020).

Gin, S. et al. Origin and consequences of silicate glass passivation by surface layers. Nat. Commun. 6, 6360 (2015).

Gin, S. et al. Dynamics of self-reorganization explains passivation of silicate glasses. Nat. Commun. 9, 2169 (2018).

Rebiscoul, D. et al. X-ray reflectometry characterization of SON 68 glass alteration films. J. Non-Cryst. Solids 325, 113–123 (2003).

Gin, S. et al. Atom-probe tomography, TEM and ToF-SIMS study of borosilicate glass alteration rim: a multiscale approach to investigating rate-limiting mechanisms. Geochim. Cosmochim. Acta 202, 57–76 (2017).

Chave, T., Frugier, P., Ayral, A. & Gin, S. Solid state diffusion during nuclear glass residual alteration in solution. J. Nucl. Mater. 362, 466–473 (2007).

Williams, A. et al. EURACHEM/CITAC Guide. Quantifying Uncertainty in Analytical Measurement—Third Edition. [En ligne]. https://www.eurachem.org/index.php/publications/guides (2012).

Collin, M. Géochimie en milieu nanoporeux: Application aux verres nucléaires. (Université de Montpellier; Ecole Doctorale Information Structures Systèmes, 2018).

Acknowledgements

The author wish to thank Maxime Fournier and Sylvain Peuget for their proofreading and advices. This work was made possible by funding from CEA, ORANO, EDF and Framatome, which are acknowledged for their support.

Author information

Authors and Affiliations

Contributions

M.D.: modeling, methodology of parameterization, uncertainty studies, numerical tools, report writing. P.F.: model conceptualization and proof reading. E.G.: experiments. C.N.: coordination and proof reading.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Delcroix, M., Frugier, P., Geiger, E. et al. The GRAAL2 glass alteration model: initial qualification on a simple chemical system. npj Mater Degrad 9, 38 (2025). https://doi.org/10.1038/s41529-025-00589-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00589-4

This article is cited by

-

Mechanistic insights on the alteration of nuclear waste glass from passivation to reactive diffusion in the environment

npj Materials Degradation (2025)