Abstract

Metal corrosion poses significant economic and safety challenges across industries, necessitating efficient cathodic protection strategies. Triboelectric nanogenerator (TENG) offers a promising self-powered solution by harvesting ambient mechanical energy. This study presents the design of TENG based on fluorinated ZIF-67/PDMS (F-ZIF-67/PDMS) composites for enhanced cathodic protection of 304 stainless steel (304SS). The present study integrates dual regulation of microstructure and surface energy to synergistically enhance the triboelectric performance. While loading 5 wt.% ZIF-67, the TENG achieved remarkable output performance with an open-circuit voltage of 187.14 V, short-circuit current of 37.46 μA, and transferred charge of 72.54 nC, delivering a peak power of 3.08 mW. When integrated with a cathodic protection system, the TENG significantly reduced the open-circuit potential (OCP) and the corrosion rate. This work advances the integration of MOF-based triboelectric materials with energy harvesting technologies, offering a sustainable approach to mitigating metal corrosion.

Similar content being viewed by others

Introduction

Metal corrosion is a common challenge in the construction, marine, and automotive industries, causing considerable global losses and safety hazards, making it a major issue of concern. Corrosion has been identified as a pressing issue, with economic losses associated with this phenomenon estimated to be approximately 4% of the global GDP. This highlights the urgent need for effective strategies to address the corrosion issue. Among the various approaches, cathodic protection is recognized as an efficient anti-corrosion method that has garnered considerable attention. Traditionally, cathodic protection has primarily relied on the sacrificial anode protection method or impressed current protection systems1. While both of these methods require external devices to provide electrons to the metal, so the search for reliable energy sources has become an urgent problem.

Traditional generators, including electromagnetic generators (EMGs), are characterized by their complex structures, substantial volume and weight, and limited adaptability to diverse operational environments. Most notably, EMGs have encountered challenges in effectively harvesting energy under low-frequency working conditions. In 2012, the TENG was first introduced to the scientific community as an innovative technology for energy harvesting2,3,4. Advantages such as a simple structure5,6, high power density7,8, and low cost9 distinguish TENGs, while their working environment requirements are notably more favorable compared to other emerging energy technologies10,11. Consequently, this technology has garnered considerable interest from the scientific research community12. Furthermore, TENGs exhibit exceptional capabilities in energy harvesting and conversion, as they can efficiently transform various forms of small-scale mechanical energy into electrical power13,14,15. It can function as an external power sources, providing continuous electricity for cathodic protection systems, particularly suited for corrosion prevention in remote areas or regions with limited access to electricity16. TENGs have been successfully utilized to develop advanced cathodic protection systems17,18,19. Liu et al.20 constructed a wind-driven TENG with a bilayer comprising polyvinylidene fluoride (PVDF) and polyaniline (PANI), which effectively delivered cathodic protection to damaged metal coatings, significantly mitigating the risk of localized corrosion. Similarly, Sun et al.21 utilized a flexible PTFE film to construct a TENG as an energy source for a self-powered anticorrosion system. This novel approach led to a significant 590 mV decrease in the OCP of carbon steel, demonstrating its effectiveness in improving corrosion resistance. Ji et al.22 developed a multi-layer grating synergistic TENG (MLGS-TENG) with a high peak power output. The electrochemical anti-corrosion system constructed with this TENG effectively transmitted early warning signals and prevented corrosion in offshore facilities. While TENGs have made significant advancements in the realm of cathodic protection, further improvements in output performance—particularly regarding energy harvesting and conversion efficiency—are essential to facilitate large-scale applications. Therefore, new methodologies must be explored to ensure the maintenance of excellent performance and stable output in TENGs during operation, which holds considerable significance for the advancement of triboelectric nanogenerators and corrosion protection technologies.

Modifying the micro-nano structure of triboelectric materials has been proven to greatly improve the efficiency of TENGs23. Recently, metal-organic frameworks (MOFs) have received considerable attention for their exceptional adaptability and wide-ranging properties, enabling their broad utilization in multiple scientific fields24,25,26,27,28. These materials are synthesized through the precise construction of linkages between organic ligands and metal ions, resulting in high crystallinity, exceptional specific surface area, unique morphological structures, and excellent chemical stability. The porous nature of MOFs substantially increases their specific surface area, thereby optimizing the output response of TENGs, making MOFs highly regarded in the field of TENG research29,30,31. By carefully selecting MOFs as the triboelectric layer material for TENG, the device’s overall performance can be significantly enhanced, a performance parameter critical for optimizing TENG functionality. The extensive variety of MOFs primarily arises from the diverse combinations of metal centers and organic ligands, as well as the flexibility in synthesis conditions, which collectively provide extensive opportunities for material innovation. Among the different types of MOFs, zeolitic imidazolate frameworks (ZIFs) have gained prominence in TENG research due to their distinctive characteristics. These frameworks consist of metal ions coordinated with organic ligands, creating a unique three-dimensional network structure that enhances charge transfer and separation efficiency during the triboelectric process32. The nitrogen-containing heterocyclic ligand (2-methylimidazole) in ZIF-67 has a relatively high electronegativity. It has a highly ordered porous structure and an extremely large specific surface area, which can provide a large effective contact area. When in contact with other materials through friction, more surface atoms participate in the charge transfer process, significantly increasing the charge density at the friction interface. In short, the core role of ZIF-67 in TENG from its inherent high electron affinity (as a strong electron acceptor) and its extremely large nanostructural specific surface area. When ZIF-67 is dispersed in a flexible polymer to form a composite friction layer, the ZIF-67 particles act as the main charge generation and capture centers. Consequently, ZIFs are considered ideal candidates for improving the efficiency of triboelectric nanogenerators.

To ensure a continuous power supply for the cathodic protection of metals, this study successfully prepared an F-ZIF-67/PDMS film through the implementation of straightforward physical doping and surface modification strategies, realizing the synergistic optimization of microstructural and surface energy. The film was designed as a negative triboelectric material and was subsequently applied in the construction of ta riboelectric nanogenerator (F-ZIF-67/PDMS TENG). The ZIF-67 powder employed in this investigation exhibited a consistent rhombic dodecahedral structure. When incorporated into the ZIF-67/PDMS composite material via physical doping, it significantly enhanced surface roughness. This improvement in surface texture is a critical parameter for increasing the efficiency of power generation. Additionally, to enhance the TENG’s output performance more effectively, 1H,1H,2H,2H-perfluorooctyltriethoxysilane (FAS) was applied to the surface of ZIF-67/PDMS via an immersion technique, the F-ZIF-67/PDMS film was formed. After the film was integrated into the TENG, the TENG showed excellent output performance. Notably, high stability was maintained by the TENG after 2000 cycles of durability testing. An anti-corrosion system was developed by combining TENG technology with electrochemical cathodic protection. This system successfully lowered the OCP and corrosion potentials of the 304SS by 210 mV and 390 mV, respectively, illustrating a significant improvement in corrosion resistance. The TENG presented in this study features a straightforward design and cost-effectiveness, showcasing significant potential for practical applications in the protection of metals against corrosion.

Results and discussion

Characterization of samples

The morphology of ZIF-67 was characterized using SEM, as shown in Fig. 1a, and the inset Fig. shows the low magnification of the samples. It can be seen that the prepared ZIF-67 exhibited a uniform rhombic dodecahedral shape, demonstrating a high degree of geometric consistency. Moreover, the regular geometric morphology manifested as sharp edges and protrusions at the microscale. To acquire a more profound understanding of its chemical composition, elemental mapping (Fig. 1b) was utilized to analyze the spatial distribution of carbon (C), nitrogen (N), cobalt (Co), and oxygen (O). Compositional analysis was performed using EDS, which unveiled the distribution patterns of Co, C, N, and O elements, confirming the phase purity of the ZIF-67 material, as presented in Fig. 1c, along with detailed atomic percentage composition data (shown in the inset Fig.). In addition, as shown in Fig. S1, the particle size distribution curve showed the highest peak at 722.4 nm with an intensity of 71%, demonstrating that the particle size distribution of the particles in this sample was highly concentrated and uniform. In general, an increase in surface roughness enhances the surface area of triboelectric materials, offering more sites for charge accumulation, thereby improving the density of charge carriers. This phenomenon, in turn, augments the performance of the TENG33. Furthermore, fluorination treatment, in conjunction with the construction of surface roughness, exhibited marked effects in synergistically enhancing TENG power output34,35. Based on these findings, ZIF-67 was incorporated into the polydimethylsiloxane (PDMS) matrix, and surface fluorination modification was applied to the ZIF-67/PDMS composite in this investigation. The series of SEM images in Fig. 1d illustrates the microstructural evolution of the fluorinated ZIF-67/PDMS films as the doping concentration of F-ZIF-67 varied from 0 wt.% to 10 wt.%. Additionally, to facilitate a clearer observation of the ZIF-67 powder distribution, cross-sectional SEM images of F-ZIF-67/PDMS composites with varying ZIF-67 weight percentages were presented in Fig. S2. Since ZIF-67 nanoparticles were insoluble in the PDMS matrix and existed as dispersoids within PDMS, it could be observed in Fig. S2 that when ZIF-67 particles were introduced onto the PDMS surface, the sharp edges and protrusions increased the surface roughness. Furthermore, optical images of F-ZIF-67/PDMS films with F-ZIF-67 loadings ranging from 0 wt.% to 10 wt.% were provided in Fig. S3. As the amount of ZIF-67 increased, the surface color changed from transparent to violet, and achieving uniform dispersion at 5 wt.%. However, continuous increases in concentration led to particle aggregation. This observation aligned with the electrical measurement data, indicating that 5 wt.% represented the optimal doping concentration for maximizing TENG output performance, beyond which performance degradation was observed. Fig. S4 and Video S1 illustrate the exceptional flexibility exhibited by film with the addition of 5 wt.% particles, as evidenced by its ability to readily undergo bending, stretching, and twisting without fracture. It enables the film to effectively accommodate the diverse and complex motions encountered during the operation of TENGs, thereby mitigating potential damage resulting from mechanical deformation. Supplementary energy spectrum analysis and elemental composition measurements verified the synthesis of ZIF-67/PDMS (Fig. S5a) and fluorinated ZIF-67/PDMS (Fig. S5b) films, while showing that the fluorination treatment had little effect on the surface morphology of the composite material.

a SEM of ZIF-67 powder, the inset Fig. showed the low magnification, b Elemental color mapping of ZIF-67 showed the distribution of different elements, c EDS spectra with the corresponding atomic percentages of elements in ZIF-67. d SEM of F-ZIF-67/PDMS composites with varying ZIF-67 weight percentages.

High-precision XPS was systematically utilized to analyze the surface chemical composition of various materials. Figure 2a displays the XPS spectra of ZIF-67, ZIF-67/PDMS, and F-ZIF-67/PDMS films, highlighting key peaks attributed to ZIF-67. These include Co 3p (binding energy: 61.08 eV), Co 2p (binding energy: 781.08 eV), C 1 s (binding energy: 284.08 eV), N 1 s (binding energy: 399.08 eV), and O 1 s (binding energy: 531.08 eV). Additionally, a new Si 2p peak at 102 eV in the ZIF-67/PDMS spectrum suggests the presence of the PDMS component. In the F-ZIF-67/PDMS sample, fluorination treatment introduced a distinct F 1 s peak at 689 eV, confirming successful fluorination and effective fluorine attachment to the surface. A detailed analysis of the XPS data indicates that the relatively low concentration of ZIF-67 in the composite material resulted in less pronounced characteristic peaks associated with ZIF-67 in the XPS spectra of both ZIF-67/PDMS and F-ZIF-67/PDMS. This finding highlights the role of ZIF-67 in the overall elemental composition of the composite. Specifically, the Co 2p XPS spectrum of ZIF-67 (Fig. 2b) shows two significant peaks at 780.5 eV and 795.8 eV, which correspond to the Co 2p3/2 and Co 2p1/2 energy levels, respectively, with an energy separation of around 15 eV, which is typical for Co. Additionally, weak satellite peaks at 784.6 eV (Sat. 1) and 800.7 eV (Sat. 2) further confirm the identification of the Co 2p3/2 and Co 2p1/2 states36,37,38,39. Interestingly, the Co 2p3/2 energy level splits into two sub-peaks at D1 = 779.1 eV and D2 = 789.3 eV, while the Co 2p1/2 energy level splits into a doublet centered at D3 = 795.2 eV and D4 = 796 eV. In XPS analysis, Co²⁺ and Co³⁺ ions typically show similar binding energy peak shapes, with significant peaks around 780 eV for the 2p3/2 level and around 796 eV for the 2p1/2 level. However, the energy splitting (ΔE) caused by spin-orbit coupling differs between the two, with theoretical ΔE values of about 15.0 eV for Co³⁺ and 15.7 eV for Co2+ 40,41. For the ZIF-67 sample, peak separations of 16.7 eV and 16.1 eV were identified, corroborating the coexistence of Co²⁺ and Co³⁺ cation states. The C 1 s spectrum shown in Fig. 2c was analyzed and deconvoluted into three separate peaks at binding energies of 283.4, 284.6, and 285.4 eV. These peaks are attributed to C–C, C–N, and C–O bonds, respectively42. The O 1 s spectrum is presented in Fig. 2d, while the N 1 s spectrum in Fig. 2e was deconvoluted into two distinct peaks. The peak at 398.08 eV is related to C–N bonds, while the peak at 399.28 eV corresponds to Co–N and N–O groups43. The deconvoluted O 1 s spectra reveal bonding states associated with Co–O (528.98 eV), C–O (531.38 eV), and C=O (532.58 eV)44,45.

XRD analysis was conducted to investigate the crystallographic characteristics of the composite materials over a 2θ range of 5°–90°. Figure 3a displays the XRD patterns of ZIF-67, pure PDMS, and ZIF-67/PDMS films, highlighting distinct structural features. The sharp, prominent peaks observed in ZIF-67 confirm its high crystallinity, consistent with prior studies46. In comparison, the incorporation of ZIF-67 into PDMS (at 5 wt.%) disrupted the crystalline structure of PDMS. Distinct diffraction peaks at 2θ values of 7.31°, 12.72°, 18.04°, 26.7°, 29.67°, and 31.55° in the ZIF-67/PDMS composite confirmed the successful incorporation of both materials. The decreased intensity of the ZIF-67 peaks in the composite is due to the lower mass loading of ZIF-67. The pattern of F-ZIF-67/PDMS closely mirrored that of ZIF-67/PDMS, showing no significant changes in the crystal structure. This indicated that the fluorosilane treatment did not affect the crystalline morphology of the composite.

The synthesized samples were analyzed through FT-IR spectroscopy, as depicted in Fig. 3b (400–4000 cm−1). In the FT-IR spectrum of ZIF-67, a prominent absorption band at 428 cm−1 corresponds to the Co–N bond stretching vibration, reflecting the coordination between Co ions and the nitrogen atoms of the 2-methylimidazole linker47. Additional bands included out-of-plane C-H bending vibrations at 997 cm−1 and 752 cm−1, in-plane C-H bending at 1136 cm−1, and C-N stretching at 1381 cm−1. The stretching vibrations of the C=C and C=N bonds were observed at 1573 cm−1, while the C-H stretching vibration appeared at 2916 cm−1. A broad peak at 3208 cm−1 was attributed to N-H stretching48,49. For pure PDMS, characteristic peaks included O-H stretching at 3641 cm−1, indicative of surface hydroxyl groups. C-H stretching vibrations at 2968 cm−1 and 2907 cm−1 were attributed to -CH₃ and -CH₂- groups in the polymer, while a peak at 2158 cm−1 corresponded to Si-H stretching, indicating the presence of unreacted silane groups. Additional peaks included -CH₃ bending at 1409 cm−1 and Si-CH₃ wagging at 1285 cm−1. The ZIF-67/PDMS composite retained several key FT-IR features. The peak at 3641 cm−1, corresponding to the N-H stretching vibration of ZIF-67, verified its inclusion in the matrix. C-H stretching vibrations at 2968 cm−1 and 2907 cm−1 were maintained, representing contributions from both ZIF-67 and PDMS. Notably, a new peak at 1607 cm−1, shifted from the 1573 cm−1 band of PDMS, was attributed to the C=C and C=N bonds of ZIF-67, further validating the framework’s structural integrity. The Si-CH₃ wagging vibration shifted slightly from 1285 cm−1 to 1294 cm−1 in the composite. In the F-ZIF-67/PDMS composite, the peaks at 3641 cm−1, 2968 cm−1, and 2907 cm−1 were unchanged, confirming the preservation of the N-H and C-H stretching vibrations. Likewise, the peak at 1607 cm−1 remained, suggesting that the fluorosilane treatment did not alter the C=C and C=N bonds of ZIF-67. The Si-CH₃ wagging vibration at 1294 cm−1 reaffirmed the structural integrity of the composite. These results suggest that the fluorination process primarily altered other functional groups or the chemical environment, leaving the characteristic absorption peaks unaffected.

The dielectric constant is a critical property influencing the performance of TENGs, as a higher dielectric constant enhances charge trapping and boosts output efficiency50,51,52. Figure 3c shows that incorporating ZIF-67 nanoparticles into PDMS significantly increased the dielectric constant of the composites. Similarly, the dielectric constant of F-ZIF-67/PDMS composites improved further, leading to notable enhancements in the output performance of TENGs based on these materials.

Surface roughness analysis surface roughness, a key factor affecting the effective contact area and output performance53 of triboelectric materials, was analyzed for PDMS, ZIF-67/PDMS, and F-ZIF-67/PDMS composites. The average surface roughness values are detailed in Table S1. Pure PDMS (Fig. S6a) exhibited pronounced peak-valley structures, indicative of high roughness. Embedding ZIF-67 nanoparticles into the PDMS matrix (Fig. S6b) created a more uniform micro-nanostructure, visually enhancing surface flatness. However, microscopic analysis revealed increased height fluctuations, as evidenced by higher root mean square (Sq) and arithmetic mean height (Sa) values, caused by the dispersion of ZIF-67 particles. In comparison, the F-ZIF-67/PDMS composite displayed enhanced surface smoothness (Fig. 3d). The fluorosilane treatment formed a low-surface-energy coating on the ZIF-67/PDMS surface, filling the original rough structures and reducing both Sq and Sa values. Excessive surface roughness can negatively impact charge separation efficiency and reduce the stability and durability of TENGs by causing uneven charge distribution. These effects will be further discussed in subsequent sections on electrical performance evaluation.

Working principle of the prepared TENG

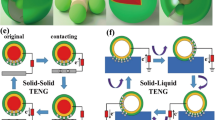

The operating principle of the F-ZIF-67/PDMS TENG is illustrated in Fig. 4a. Initially, when the F-ZIF-67/PDMS and PTFE materials—possessing opposite triboelectric polarities—are separated, no current or potential is generated (Fig. 4aI). Upon applying an external load, the two materials are pressed together, initiating triboelectric charging. This process creates a balance between the negative triboelectric charge on the F-ZIF-67/PDMS composite film and the positive electrostatic charge on the PTFE surface, leading to a potential difference (Fig. 4aII). Upon separation of the materials, charge transfer occurs between two electrodes as electrons move through the external circuit until electrostatic equilibrium is achieved (Fig. 4aII–III). During re-compression, the positive charge on the bottom electrode returns to the top electrode, generating a reverse current (Fig. 4aIV).

To conduct a thorough analysis, this study utilized COMSOL Multiphysics finite element simulation software to precisely calculate the output voltage of the TENG. According to theoretical derivations, the voltage can be expressed by the following equation33,54,55:

In this context, V represents the potential difference, while ε, σ, and x(t) correspond to the dielectric constant, charge density, and the time-varying gap distance between the electrodes, respectively. The triboelectric potential, derived from simulation calculations and depicted in Fig. 4b, demonstrated a significant enhancement attributable to the optimized treatment of the frictional material’s surface. This result suggests that a greater number of charges can be accumulated on the surface of the F-ZIF-67/PDMS composite film, and the trend predicted by the simulation was highly consistent with the results of subsequent experimental investigations.

Output performance of F-ZIF-67/PDMS TENG

The TENG device was initially tested using fixed ZIF-67/PDMS composites as one friction layer, paired with four different materials as counter layers. The electrical performance of the device was evaluated at a frequency of 2 Hz. Figure 5a–c display the voltage, current, and charge transfer characteristics of the TENG, with aluminum (Al), paper, polyethylene terephthalate (PET), and PTFE used as counter layers. The results demonstrated that the TENG with PTFE as the counter layer achieved the highest output performance among the materials tested. Moreover, at a ZIF-67 content of 5 wt.%, the TENG demonstrated outstanding output features, including a voltage of 165.57 V, a current of 33.31 μA, and a charge of 55.5 nC, outperforming devices with other composite concentrations.

a Voc, b Isc, and c Q plots after triboelectric charging of ZIF-67/PDMS with different concentrations and various materials, d Voc, e Isc, and f Q plots after triboelectric charging of F-ZIF-67/PDMS with different concentrations and various materials. Comparison of g open-circuit voltage, h short-circuit current, and i transferred charge for pure PDMS, ZIF-67/PDMS, and F-ZIF-67/PDMS after triboelectric charging with PTFE.

The output performance of the F-ZIF-67/PDMS triboelectric nanogenerator (TENG) was subjected to further examination, as illustrated in Fig. 5d–f. The performance trends observed in the F-ZIF-67/PDMS TENG were remarkably consistent with those of the unmodified ZIF-67/PDMS TENG. In particular, when PTFE was used as the counter layer, the F-ZIF-67/PDMS TENG exhibited the best output performance among the four materials tested, outperforming the original ZIF-67/PDMS TENG. Additionally, the output performance achieved its peak when the ZIF-67 content was at 5 wt.%. An increase in ZIF-67 content beyond this point led to a gradual decline in output performance; this phenomenon is likely attributable to the overexposure of ZIF-67 at the surface, which hinders effective contact between the F-ZIF-67/PDMS composite and PTFE. It is noteworthy that while fluorination significantly enhanced performance under specific conditions, the anticipated substantial improvement was not observed with counter materials other than PTFE. In fact, the output performance either remained constant or decreased, suggesting that the effects of fluorination may be material-specific, particularly regarding the selection of counter materials. The fluorination process may have diminished the adhesion between ZIF-67/PDMS and materials other than PTFE, resulting in increased slippage during friction and leading to an incomplete contact with each other, hence a consequent reduction in output performance. In short, PTFE, as a highly fluorinated polymer characterized by extremely low surface energy and excellent lubrication properties, likely contributes to a more stable friction interface with fluorinated ZIF-67/PDMS because of the chemical affinity, thereby facilitating enhanced charge generation and transfer. For more intuitive comparison of the amplitudes of open-circuit voltage, short-circuit current, and transferred charge, all waveform data plots have been provided in Fig. S7.

It is noteworthy that in this study, the output performance of the TENG when paired with PTFE exceeded expectations. According to the traditional triboelectric series, both PDMS and PTFE are negative materials, theoretically resulting in a small triboelectric potential difference and low output. However, regardless of the fluorination modification, the ZIF-67/PDMS composite material exhibited relatively high output when paired with PTFE. In contrast, when paired with aluminum, a typical positive triboelectric material, the output remained consistently the lowest, which was inconsistent with the anticipated trend. This phenomenon may be attributed to multiple factors. Firstly, the aluminum surface is prone to forming a dense oxide film, whose dielectric effect inhibits interfacial charge transfer and reduces the triboelectric charging efficiency. Secondly, the high rigidity and smoothness of the aluminum surface limit the actual contact area with the flexible PDMS composite film, thereby restricting charge generation. Moreover, the introduction of ZIF-67, especially when in contact with conductive electrodes (such as aluminum), may create charge recombination or leakage pathways within the composite material, further weakening the output. In contrast, the PTFE surface, with its flexibility and roughness, can form a closer contact with the PDMS matrix, and its excellent insulating properties facilitate the retention and accumulation of surface charges. Thus, the output performance of the TENG depends not only on the relative positions of the materials in the triboelectric series but also is significantly influenced by the composite structure, surface modification, and interfacial contact mechanisms.

Furthermore, the frequency response characteristics of the device were evaluated, with results presented in Fig. S8. The output performance showed little change when the contact frequency was adjusted from 0.5 Hz to 3 Hz, suggesting that key parameters are not highly influenced by frequency variations. This is primarily attributed to the fact that the materials employed possess high charge-trapping and storage capabilities. Moreover, the structural design ensures a sufficient and stable contact-separation process, enabling the charge generation and transfer in a single cycle to approach saturation. Consequently, variations in frequency only affect the time intervals between oscillations, while having a limited impact on the voltage and charge quantity output each time. This ultimately leads to a weak overall frequency response.

The output performance of pure PDMS TENG, ZIF-67/PDMS TENG, and F-ZIF-67/PDMS TENG devices was systematically compared, as illustrated in Fig. 5g–i. The incorporation of ZIF-67 into the PDMS composite resulted in a significant enhancement of its electrical output performance. Notably, following fluorination, the ZIF-67/PDMS TENG demonstrated peak performance, with maximum recorded values of voltage, current, and charge reaching 187.14 V, 37.46 μA, and 72.54 nC, respectively. Subsequent research will concentrate on optimizing the 5 wt.% ZIF-67/PDMS TENG, utilizing PTFE as the counter material. The notable improvement in the TENG’s output performance is primarily attributed to the enhanced surface roughness of the PDMS composite film resulting from the incorporation of ZIF-67 powder. This increased roughness results in a greater effective contact area during friction, promoting better charge transfer and accumulation. As a result, this factor contributes substantially to enhancing the overall output performance of the TENG. Additionally, the fluorination process may have intensified the frictional interaction between PDMS and PTFE by altering the microstructure or chemical characteristics of the PDMS surface. Such an enhancement could stem from the increased surface roughness of the PDMS following fluorination or could arise from strengthened interactions between the fluorine atoms present on the PDMS surface and those in the PTFE.

A thorough study was conducted to explore the correlation between the TENG’s output power and different external load resistances, aiming to enhance the understanding of its electrical performance. The device’s output performance was carefully assessed by varying the load resistance across a wide range from 10 kΩ to 1000 MΩ, while recording electrical output data at each resistance level to determine the maximum power. The circuit diagram used for voltage and current measurements is shown in Fig. 6a. A more in-depth analysis, presented in Fig. 6b, indicated that the output voltage of the TENG gradually increased as the load resistance rose, eventually stabilizing at around 200 MΩ. Conversely, the output current diminished in response to the increase in load resistance, a behavior that is consistent with the predictions of Ohm’s law due to Ohmic losses. To gain a deeper insight into the device’s performance, the instantaneous power was computed using the formula (P = UI), where/stands for the instantaneous current and U represents the instantaneous voltage, derived from the data shown in Fig. 6b. The results, shown in Fig. 6c, indicated that the instantaneous power initially rose with the increase in load resistance, reaching a peak of around 3.08 mW at a resistance of 10 MΩ, before gradually decreasing as the resistance continued to rise. Additionally, Fig. S9 specifically presents the instantaneous voltage and current waveforms under a 10 MΩ load resistance, with recorded values of 123.77 V and 24.87 μA, respectively, thereby further substantiating the accuracy of the aforementioned analysis.

a Circuit diagram for electronic devices, b Voc and Isc characteristics at different load resistances, c Power curves of the TENG corresponding to various load resistances, d TENG rectifier circuit diagram, e A schematic diagram of the panel equipped with 111 LED lamps under the conditions where the TENG was in both the ON and OFF states, f Charging profiles of various capacitors, g The energy stored within the various capacitors, h Capacitor charging and discharging curves of 1 μF, i Stability response of the TENG after 2000 cycles, with insets displaying the TENG response at 1000 and 2000 cycles.

The F-ZIF-67/PDMS TENG produced AC powered by a motor. To address the incompatibility between the AC output of the TENG and the DC requirements of most electronic components, a rectifier bridge circuit was devised. This circuit effectively converted the AC output of the TENG into DC, as illustrated in the configuration presented in Fig. 6d. The resultant DC electrical energy could be directly supplied to light-emitting diodes (LEDs). The experimental results demonstrated that the system was capable of driving a panel with 111 LED lights, and the visual effect of switching between the OFF and ON states was shown in Fig. 6e (Video S2). Furthermore, the TENG successfully charged capacitors of varying capacitances, specifically 1 μF, 3.3 μF, and 10 μF. Figure 6f illustrates the charging curves for each capacitor, highlighting that the 1 μF capacitor exhibited optimal charging performance, attaining 118 V in just 300 s (Video S3). Moreover, Fig. 6g depicts the energy accumulated in commercial capacitors following 300 s of charging. Utilizing the energy calculation formula E = ½CV2 (where C represents capacitance and V denotes charging voltage), the maximum stored energy when the load capacitor was optimized to 1 μF was approximately 6.76 mJ. Figure 6h presents the charging and discharging curves for the 1 μF capacitor, which was derived from the F-ZIF-67/PDMS TENG, showing that the capacitor quickly regained its charge after discharge, ensuring consistent and dependable power output from the F-ZIF-67/PDMS TENG over prolonged periods.

When assessing the practical application performance of the manufactured devices, stability emerges as a critical parameter that warrants careful consideration. To evaluate these characteristics, stability tests were conducted in which the contact and separation motions were repeated at a frequency of 2 Hz over more than 2000 cycles, as shown in Fig. 6i. During the tests, the device exhibited exceptional stability in peak current response, with no significant fluctuations, thereby effectively maintaining the continuous operation and dependability of the TENG. Additionally, the inset images in Fig. 6i specifically illustrate the output current at 1000 and 2000 cycles, revealing no noticeable signs of fluctuation. These results robustly demonstrate the excellence and reliability of the TENG as an energy-harvesting device, emphasizing its prolonged lifespan for practical industrial applications.

TENGs, as a viable approach for energy harvesting and conversion, not only provide consistent power to small electronic devices but also show potential in protecting metallic materials from corrosion. Figure 7a provides a detailed illustration of the schematic structure of a TENG based on F-ZIF-67/PDMS within a cathodic protection system. In this configuration, the TENG is externally actuated, facilitating the transfer of positive and negative triboelectric charges from its upper and lower electrodes, respectively, to a rectifier bridge circuit. Next, the 304SS is attached to the negative terminal, and the platinum (Pt) electrode is connected to the positive terminal of the rectifier bridge. To assess the performance of the self-powered cathodic protection system, the reduction in the OCP was used as a primary indicator of effectiveness56. A more pronounced negative shift in the OCP of the connected metallic material signifies an increased transfer of external electrons to its surface. This enhanced electron flow contributes to a more efficient cathodic protection mechanism57. Figure 7b illustrates the OCP of 304SS, both with and without the integration of the TENG. When the TENG is not connected to the 304SS, the OCP stabilizes at approximately −0.12 V. In contrast, upon connection of the TENG to the steel, the OCP experiences a sharp decline to -0.33 V, indicating a significant reduction of approximately 210 mV. This implies that the polarization of the generated electrons from TENG enhances the electrochemical reaction at the interface of the 304SS, which causes the metal to lose its tendency to spontaneously transform from the atomic state to the ionic state. Consequently, the propensity of the metal to undergo corrosion is diminished, thereby, to a certain extent, decelerating the corrosion rate and facilitating the long-term protection of the metal. Additionally, when the TENG is detached from the 304SS, the OCP nearly reverts to its original value, confirming the process’s reversible nature. The periodic fluctuations noted in the OCP further emphasize the reproducibility of the system, while the marked voltage reduction highlights its exceptional performance in providing cathodic protection to 304SS. To evaluate the stability of the cathodic protection system, Fig. S10 presented the OCP curve of 304SS protected by TENG over a continuous 1-hour period. The experimental results demonstrate that the protective potential of 304SS remains consistently stable below −0.35 V throughout the entire testing cycle. This phenomenon confirms the reliability and durability of the system.

a Diagram of the cathodic protection system, b OCP of 304SS powered by the TENG, c Nyquist plots comparing the electrochemical performance of 304SS when powered by the TENG versus when not powered, d Equivalent circuit model representing the electrochemical behavior of 304SS without the TENG connection, e Equivalent circuit model illustrating 304SS with the TENG connection, f Impedance-frequency and phase-frequency Bode plots, g Tafel diagram with and without TENG, h Optical images of 304SS samples immersed in a NaCl solution for 4 and 8 h, with and without TENG integration.

The electrochemical EIS technique was employed to thoroughly examine the interfacial charge transfer behavior of 304SS in specific solution environments. This analysis aimed to assess the performance and reliability of the F-ZIF-67/PDMS TENG in cathodic protection applications. Figure 7c presents Nyquist plots showing the electrochemical response of 304SS, both with and without the TENG’s coupling effect. The impedance values of 304SS were significantly reduced under TENG-provided cathodic protection compared to the condition without TENG protection. Additionally, as illustrated in Fig. 7f, the impedance modulus of 304SS in the low-frequency region was nearly reduced by an order of magnitude when the TENG was applied. Significantly, when the TENG was applied, a decline in the phase angle of 304SS was observed, with the range narrowing. These changes were attributed to the influence of externally supplied electrons. By employing curve-fitting methods, the equivalent circuit model for the TENG protection system was accurately determined, along with the specific numerical values of its components. This approach facilitated a comprehensive qualitative and quantitative analysis of the underlying electrochemical reaction mechanisms and dynamic kinetic processes. Figures 7d and e illustrate the equivalent circuit diagrams of 304SS in with and without of TENG coupling, respectively. The constant phase element (CPE), typically representing capacitance, is characterized by the formula Y = Y0 (jω)n, where admittance Y and the power exponent n serve as key parameters. The value of n ranges between specific limits: n = 0 represents a pure resistor, while n = 1 corresponds to a pure capacitor. Generally, 0 < n < 158. Figure 8d depicts the equivalent circuit of 304SS, excluding the influence of the TENG, which comprises solution resistance (Rs), a phase element (Ql), and charge transfer resistance (Rct), denoted as Rs(QlRct). Figure 8e illustrates the equivalent circuit model of 304SS under the influence of the TENG. This circuit was enhanced by incorporating additional components, specifically the double-layer capacitance (Cdl) and the interfacial resistance (Rf) at the boundary between the 304SS and the solution. This modified circuit configuration is expressed as Rs(QlRct)(CdlRf), where each element represents a specific electrochemical characteristic of the system. In this representation, Cdl denotes the double-layer capacitance, while Rf reflects the interfacial resistance of the 304SS/solution layer. The electrochemical parameters for the equivalent circuit are listed in Table 1, revealing a notably lower Rct value for 304SS when coupled with the TENG, which aligns with the observations from the Nyquist plot. Since Rct directly corresponds to charge transfer resistance, the smaller Rct value indicates an accelerated rate of electron transfer into the metal under the reciprocating motion of the TENG, resulting in increased electron density on the 304SS steel surface59. These findings demonstrate that the F-ZIF-67/PDMS TENG serves as an efficient power source for cathodic protection systems, effectively suppressing metal corrosion.

The analysis of Tafel polarization curves is a widely utilized technique for accurately determining Ecorr and Icorr. This method is critical for assessing the corrosion rates of various materials. In this study, the Tafel polarization curves of 304SS were investigated under two conditions: with and without connection to the F-ZIF-67/PDMS TENG. The electrochemical parameters were presented graphically in Fig. 7f and summarized in Table 2. Notably, within the cathodic protection systems, the corrosion potential exhibited a negative shift, indicating an increase in electron transfer to the 304SS surface. This phenomenon suggested an enhancement in the effectiveness of the cathodic protection mechanism. Specifically, the corrosion potential of 304SS steel, when connected to the F-ZIF-67/PDMS TENG, was approximately −0.32 V, in contrast to approximately 0.07 V when disconnected, demonstrating a clear negative shift. During the cathodic polarization process, the decrease in corrosion potential directly indicated that the ease with which the metal undergoes corrosion was reduced, and the tendency for the corrosion reaction to occur was diminished, which in turn led to a reduction in the corrosion rate. In practical applications, a lower corrosion rate meant that the mass loss of the metal during long-term use was relatively small, thereby extending the service life of the metal structure. This negative shift trend was consistent with the OCP results shown in Fig. 8b, which confirmed the anti-corrosion performance of the TENG. The research findings revealed that the F-ZIF-67/PDMS TENG-driven cathodic protection system effectively enhances the corrosion resistance of 304SS steel. Furthermore, as indicated in Table 2, a significant increase of approximately 12 times in the corrosion current density of 304SS steel with the F-ZIF-67/PDMS TENG was observed compared to that without the TENG, suggesting accelerated electrochemical reactions. This acceleration was attributed to the efficient injection of electrons generated by the F-ZIF-67/PDMS TENG onto the surface of 304SS steel. In conclusion, it was clearly demonstrated through Tafel polarization curve analysis that the corrosion resistance of 304SS is markedly enhanced by the F-ZIF-67/PDMS TENG-driven cathodic protection system, which efficiently injects a substantial number of electrons onto its surface. Table 3 shows the comparison between the previous cathode-protection works and the work of this study in detail. It can be clearly observed that the corrosion potential in this study exhibited a decrease of 390 mV, which represents a remarkable improvement over previously reported cathode-protection works. This significant performance enhancement highlights the promising potential of this approach in the field of corrosion prevention and protection.

The electrochemical behavior of 304SS was assessed using Tafel curves, allowing for a comparison of the material’s performance with and without the TENG. The performance of the steel was assessed in both coupled and uncoupled states with the F-ZIF-67/PDMS TENG. These tests were designed to visually demonstrate the efficacy of cathodic protection afforded by the constructed TENG to 304SS. In Fig. 7h, microscopic morphologies of 304SS were captured using optical microscopy following immersion periods of 4 and 8 h. It was observed that for the uncoupled 304SS samples, indications of corrosion pits began to manifest on the surface after merely 4 h. As the immersion time was extended to 8 h, the pitting became particularly pronounced. In contrast, the coupled 304SS samples exhibited no discernible signs of corrosion after 4 h, and even after 8 h, only minimal distribution of corrosion pits was noted. This phenomenon was attributed to the continuous electron supply from the TENG to the 304SS, effectively mitigating the electron loss from the steel itself. Such a mechanism conferred oxidative and corrosion resistance, thus providing preventive protection. The corrosion dynamics of 304SS in a high-concentration solution can be expressed as follows60,61:

Under natural corrosion conditions, the cathodic and anodic reaction processes were evidenced by 304SS, corresponding to reaction stages (2) and (3), respectively. Upon connecting to the TENG, the device’s continuous electron generation effectively hindered the progression of the reaction in stage (4), resulting in a significant reduction in the steel’s corrosion rate. Additionally, during stage (5), oxygen naturally migrated to the steel surface. This migration, coupled with the ongoing electron interaction, facilitated the formation of a considerable amount of OH−. This phenomenon enhanced the resistance of stainless steel to chloride-induced corrosion. In summary, the experimental data conclusively demonstrated the substantial improvement in the corrosion resistance of 304SS when treated with the TENG in a simulated seawater environment.

In this study, a F-ZIF-67/PDMS-based triboelectric nanogenerator (TENG) was successfully developed for efficient cathodic protection of 304 stainless steel (304SS). By incorporating ZIF-67 nanoparticles into a PDMS matrix and applying fluorination via FAS, the composite achieved enhanced surface roughness and dielectric properties, significantly boosting triboelectric charge generation and transfer. At an optimal ZIF-67 concentration of 5 wt.%, the F-ZIF-67/PDMS TENG demonstrated exceptional output performance, generating a voltage of 187.14 V, a current of 37.46 μA, and a charge transfer of 72.54 nC, with a peak power of 3.08 mW. The device exhibited remarkable stability over 2000 operational cycles and efficiently charged capacitors, achieving 118 V for a 1 μF capacitor within 300 s. When integrated into a self-powered cathodic protection system, the TENG reduced the open-circuit potential (OCP) of 304SS by 210 mV and the corrosion potential by 390 mV in 3.5 wt.% NaCl. Electrochemical analyses confirmed the system’s efficacy in suppressing corrosion by sustaining electron transfer to the steel surface. Optical microscopy further validated the protective effect, revealing minimal corrosion pits on TENG-coupled 304SS after 8 h of immersion, in stark contrast to severe pitting in unprotected samples. This work not only advances the utilization of MOF-based triboelectric materials in energy harvesting but also provides a sustainable strategy for combating metal corrosion, bridging the gap between self-powered technologies and electrochemical protection systems.

Methods

Reagents

Cobalt nitrate hexahydrate (Co(NO3)2·6H2O), 2-methylimidazole (2-MIM), sodium chloride (NaCl), and methanol were procured from Nanjing Chemical Reagent Co., Ltd., whereas polydimethylsiloxane (PDMS) and 1H,1H,2H,2H-Perfluoroalkyltriethoxysilane (FAS) were obtained from Aladdin, USA. All purchased chemicals were utilized as received, with no additional purification.

Synthesis of ZIF-67

The formation of ZIF-67 was performed following the standard procedures outlined in the literature62. First, 3.3 g of Co(NO3)2·6H2O was fully dispersed in 45 mL of methanol. Then, 90 mL of methanol containing 3.7 g of 2-methylimidazole was quickly added to the solution. The mixture was magnetically stirred for 2 h, and then aged at room temperature for 24 h in an aging chamber. Following this aging period, a purple precipitate was formed and was subsequently washed six times with methanol through centrifugation. The obtained product was subjected to drying for 12 h at 60 °C in a vacuum oven, resulting in the formation of ZIF-67 powder. A detailed schematic of the preparation process is illustrated in Fig. 8a.

Synthesis of F-ZIF-67/PDMS

The ZIF-67 was first blended into the PDMS precursor, which consisted of a mixture of elastomer and curing agent in a 9:1 mass ratio. The resulting blend was stirred and underwent ultrasonic dispersion for 30 min to achieve uniform ZIF-67/PDMS solutions with concentrations varying from 1 wt.% to 10 wt.%. To eradicate any entrained air bubbles, the solutions were degassed using a vacuum pump. The resulting mixture was spread onto glass substrates using a 200 μm drawdown bar and then cured at 80 °C for 2 h. This procedure culminated in the formation of a composite film of ZIF-67/PDMS, measuring 200 μm in thickness, on the glass surface. Figure 8b shows the procedure details, while Fig. 1c illustrates the prepared composite film. The composite film was then cut into 4 × 4 cm² sections and immersed in a 1 wt.% FAS ethanol solution for fluorination modification. As a consequence, the F-ZIF-67/PDMS was successfully fabricated.

Fabrication of F-ZIF-67/PDMS TENG

Copper foil tape with double-sided conductive property was attached to the acrylic substrate surface as the top and bottom electrodes. Copper wires were then connected to the electrodes for the purpose of measuring triboelectric signals. PTFE, acting as the positive triboelectric material, was adhered to the surface of the adhesive copper foil tape (form the top electrode), while the F-ZIF-67/PDMS composite film, serving as the negative material, was also attached to the copper foil tape surface (function as the bottom electrode), as depicted in Fig. 8c. The substrates were fabricated through laser machining, comprising two acrylic plates, each measuring 4 × 4 × 0.5 cm³. Both the friction layers and electrodes were dimensioned at 4 × 4 cm² with a thickness of 200 μm (Fig. 8d).

Electrical measurement and material characterization

The surface morphology and elemental distribution of the composite materials were analyzed using scanning electron microscopy (SEM) coupled with energy dispersive spectroscopy (EDS). The crystalline structure of the synthesized composites was examined by X-ray diffraction (XRD), while Fourier transform infrared spectroscopy (FTIR) was used to investigate the surface functional groups. X-ray photoelectron spectroscopy (XPS) was employed to assess the chemical composition in the samples. Additionally, dielectric properties were measured at room temperature over a frequency range of 10 Hz to 10⁶ Hz using broadband dielectric spectroscopy. Surface morphology and roughness were assessed using a profilometer. Linear motion was controlled via a speed-adjustable stepper motor, and a force of 20 N was applied to the TENG via this motor, while voltage, charge, and current were recorded using an electrometer (Keithley 6514, input impedance > 200 TΩ).

Evaluation of the self-powered cathodic protection system

To evaluate the effectiveness of corrosion protection, 304SS with an integrated cathodic protection system was immersed in a 3.5 wt.% NaCl solution. Electrochemical tests, including open circuit potential (OCP) fluctuations, alternating current (AC) impedance, and Tafel polarization measurements, were performed using a three-electrode system (CHI 660E, Chenhua, China) to compare the behavior of 304SS with and without TENG integration. A saturated calomel electrode (SCE) was used as the reference electrode, while a Pt electrode acted as the counter electrode, and a 3.5 wt.% NaCl solution served as the electrolyte. Electrochemical impedance spectroscopy (EIS) was performed at a scan rate of 2 mV·s−1, within a frequency range of 10−2–10⁵ Hz, and with a 5 mV sinusoidal perturbation. Tafel plots were obtained at a scan rate of 1 mV·s−1 to determine the corrosion current density (Icorr) and corrosion potential (Ecorr). Before testing, the samples were immersed in the electrolyte for 1 h to allow the OCP to stabilize.

Data availability

Data supporting the findings of this study are available from the corresponding author upon reasonable request and in the supplementary materials accompanying this article.

References

Wu, M. et al. A hybrid triboelectric nanogenerator for enhancing corrosion prevention of metal in marine environment. npj Mater. Degrad. 6, 73 (2022).

Fan, F. R., Tian, Z. Q. & Wang, Z. L. Flexible triboelectric generator. Nano Energy 1, 328–334 (2012).

Luo, J. et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 10, 5147 (2019).

Zhang, W. et al. Self-powered triboelectric-responsive microneedles with controllable release of optogenetically engineered extracellular vesicles for intervertebral disc degeneration repair. Nat. Commun. 15, 5736 (2024).

Lin, H. et al. Seesaw structured triboelectric nanogenerator with enhanced output performance and its applications in self-powered motion sensing. Nano Energy 65, 103944 (2019).

Lu, W. et al. A self-powered biosensor based on triboelectric nanogenerator for dual-specificity bacterial detection. InfoMat 6, e12508 (2024).

Yuan, M. et al. Triboelectric nanogenerator metamaterials for joint structural vibration mitigation and self-powered structure monitoring. Nano Energy 103, 107773 (2022).

Zi, Y. et al. Standards and Fig.-of-merits for quantifying the performance of triboelectric nanogenerators. Nat. Commun. 6, 8376 (2015).

Li, Y. et al. Low-cost, environmentally friendly, and high-performance triboelectric nanogenerator based on a common waste material. ACS Appl. Mater. Interface 13, 30776–30784 (2021).

Jiang, W. et al. Design of triboelectric nanogenerators featuring motion form conversion, motion rectification, and frequency multiplication for low-frequency ocean energy harvesting. Energy Environ. Sci. 16, 6003–6014 (2023).

Zhao, L. & Yang, Y. Toward Small-scale wind energy harvesting: Design, enhancement, performance comparison, and applicability. Shock Vib. 2017, 3585972 (2017).

Li, J. et al. Collaborative optimization design of self-powered sterilizer with highly efficient synergistic antibacterial effect. ACS Appl. Mater. Interface 16, 16232–16242 (2024).

Long, L. et al. High performance floating self-excited sliding triboelectric nanogenerator for micro mechanical energy harvesting. Nat. Commun. 12, 4689 (2021).

Cheng, B. et al. High performance temperature difference triboelectric nanogenerator. Nat. Commun. 12, 4782 (2021).

Rana, S. M. S. et al. Cobalt-nanoporous carbon functionalized nanocomposite-based triboelectric nanogenerator for contactless and sustainable self-powered sensor systems. Adv. Funct. Mater. 31, 2105110 (2021).

Xiang, T. et al. Advances in liquid-solid triboelectric nanogenerators and its applications. J. Mater. Sci. Technol. 214, 153–169 (2025).

Tan, B., Liu, X., Liao, Y., Ruan, H. & Li, Y. Multi-layered roating disk-based triboelectric nanogenerators for self-powered cathodic anticorrosion. J. Mater. Sci. 59, 14766–14776 (2024).

Zhou, H. et al. Enhanced triboelectric nanogenerator performance based on mechanical imprinting PDMS microstructures. Adv. Mater. Interfaces 9, 2201525 (2022).

Xu, H. et al. Flexible sponge-based nanogenerator for energy harvesting from land and water transportation. Adv. Funct. Mater. 33, 2304723 (2023).

Liu, C. et al. A new facile strategy for addressing the localized corrosion issue at damaged coating via a wind-driven triboelectric nanogenerator. Nano Energy 128, 109961 (2024).

Sun, W. et al. Humidity-resistant triboelectric nanogenerator and its applications in wind energy harvesting and self-powered cathodic protection. Electrochim. Acta 391, 138994 (2021).

Ji, X. et al. Efficient self-powered cathodic corrosion protection system based on multi-layer grid synergistic triboelectric nanogenerator and power management circuits. Chem. Eng. J. 485, 149753 (2024).

Li, J. et al. Enhancing the output performance of triboelectric nanogenerator through regulation of its internal nano-architecture. Small 20, 2400041 (2024).

Babu, A. et al. Facile direct growth of ZIF-67 metal–organic framework for triboelectric nanogenerators and their application in the internet of vehicles. ACS Sustain. Chem. Eng. 11, 16806–16817 (2023).

P K, N. & Chandrasekhar, A. Fingerprint-mimicking, ZIF-67 decorated, triboelectric nanogenerator for IoT cloud-supported self-powered smart glove for paralyzed patient care. ACS Appl. Electron. Mater. 6, 5314-5327 (2024).

Hajra, S. et al. Significant effect of synthesis methodologies of metal-organic frameworks upon the additively manufactured dual-mode triboelectric nanogenerator towards self-powered applications. Nano Energy 98, 107253 (2022).

Mohan, B. et al. Advancements in metal-organic, enzymatic, and nanocomposite platforms for wireless sensors of the next generation. Adv. Funct. Mater. 34, 2405231 (2024).

Rajaboina, R. K. et al. Crystalline porous material-based nanogenerators: recent progress, applications, challenges, and opportunities. Small 20, 2306209 (2024).

Sohel Rana, S. M. et al. Recent advances in metal-organic framework-based self-powered sensors: A promising energy harvesting technology. Coord. Chem. Rev. 507, 215741 (2024).

Sohel Rana, S. M. et al. Metal-organic framework and molybdenum oxide-doped highly negative hybridized triboelectric material for self-powered and continuous monitoring of biosignals. Chem. Eng. J. 473, 144989 (2023).

Wang, Y.-M. et al. Remarkable improvement of MOF-based triboelectric nanogenerators with strong electron-withdrawing groups. Nano Energy 107, 108149 (2023).

Barsiwal, S. et al. ZIF-67-metal–organic-framework-based triboelectric nanogenerator for self-powered devices. Nanoenergy Adv. 2, 291–302 (2022).

Ren, X. et al. Triboelectric nanogenerators based on fluorinated wasted rubber powder for self-powering application. ACS Sustain. Chem. Eng. 5, 1957–1964 (2017).

Feng, H. et al. Triboelectric nanogenerator based on direct image lithography and surface fluorination for biomechanical energy harvesting and self-powered sterilization. Nano Energy 98, 107279 (2022).

Rana, S. M. S. et al. Zirconium metal-organic framework and hybridized Co-NPC@MXene nanocomposite-coated fabric for stretchable, humidity-resistant triboelectric nanogenerators and self-powered tactile sensors. Nano Energy 104, 107931 (2022).

Qin, J., Wang, S. & Wang, X. Visible-light reduction CO2 with dodecahedral zeolitic imidazolate framework ZIF-67 as an efficient co-catalyst. Appl. Catal. B Environ. 209, 476–482 (2017).

Yang, Q. et al. Selective separation of methyl orange from water using magnetic ZIF-67 composites. Chem. Eng. J. 333, 49–57 (2018).

Zhang, Y., Liu, H., Zhu, P., Yang, M. & Jin, Z. In situ XPS proved effective charge transfer over ZIF-67@CoFe LDH S-scheme heterojunctions for efficient visible light-driven hydrogen evolution. Int. J. Hydrog. Energ. 48, 32631–32641 (2023).

Du, X.-D. et al. Extensive and selective adsorption of ZIF-67 towards organic dyes: performance and mechanism. J. Colloid Interf. Sci. 506, 437–441 (2017).

Thota, S. et al. Magnetic compensation, field-dependent magnetization reversal, and complex magnetic ordering in Co2TiO4. Phys. Rev. B. 92, 214434 (2015).

Cao, J. et al. An ultrathin cobalt-based zeolitic imidazolate framework nanosheet array with a strong synergistic effect towards the efficient oxygen evolution reaction. J. Mater. Chem. A. 6, 18877–18883 (2018).

Fang, W. et al. Metal-organic framework-derived Fe-Co-CN/reduced graphene oxide for efficient HER and OER. Electrochim. Acta 365, 137384 (2021).

Zhang, K. et al. Multifunctional textiles/metal−organic frameworks composites for efficient ultraviolet radiation blocking and noise reduction. ACS Appl. Mater. Interface 12, 55316–55323 (2020).

Sun, X. et al. ZIF-67@Cellulose nanofiber hybrid membrane with controlled porosity for use as Li-ion battery separator. J. Energy Chem. 52, 170–180 (2021).

Xuan, K. et al. Hydroxyapatite modified ZIF-67 composite with abundant binding groups for the highly efficient and selective elimination of uranium (VI) from wastewater. J. Hazard. Mater. 426, 127834 (2022).

Salauddin, M. et al. Laser-carbonized MXene/ZIF-67 nanocomposite as an intermediate layer for boosting the output performance of fabric-based triboelectric nanogenerator. Nano Energy 100, 107462 (2022).

Mohamed, A. M., Abbas, W. A., Khedr, G. E., Abass, W. & Allam, N. K. Computational and experimental elucidation of the boosted stability and antibacterial activity of ZIF-67 upon optimized encapsulation with polyoxometalates. Sci. Rep. 12, 15989 (2022).

Archana, K., Pillai, N. G., Rhee, K. Y. & Asif, A. Super paramagnetic ZIF-67 metal organic framework nanocomposite. Compos. Part B Eng. 158, 384–389 (2019).

Gupta, N. & Murthy, Z. V. P. Synthesis and application of ZIF-67 on the performance of polysulfone blend membranes. Mater. Today Chem. 23, 100685 (2022).

Meng, X. et al. Nanopillar-and nanocone-structured SrTiO3/PDMS films for triboelectric nanogenerators. ACS Appl. Nano Mater. 7, 14193–14202 (2024).

Fang, Z. et al. Modulating crystallinity and dielectric constant of chitosan film for triboelectric polarity shift and performance enhancement in triboelectric nanogenerators. Nano Energy 117, 108923 (2023).

Shao, Y., Feng, C.-p. Deng, B.-w. Yin, B. & Yang, M.-b. Facile method to enhance output performance of bacterial cellulose nanofiber based triboelectric nanogenerator by controlling micro-nano structure and dielectric constant. Nano Energy 62, 620–627 (2019).

Lee, B.-Y., Kim, S.-U., Kang, S. & Lee, S.-D. Transparent and flexible high power triboelectric nanogenerator with metallic nanowire-embedded tribonegative conducting polymer. Nano Energy 53, 152–159 (2018).

Moradi, F., Karimzadeh, F. & Kharaziha, M. Rational micro/nano-structuring for high-performance triboelectric nanogenerator. J. Alloy Compd. 960, 170693 (2023).

Fang, Z., Chan, K. H., Lu, X., Tan, C. F. & Ho, G. W. Surface texturing and dielectric property tuning toward boosting of triboelectric nanogenerator performance. J. Mater. Chem. A. 6, 52–57 (2018).

Liu, X. et al. A synergistic anti-corrosion system based on durable superhydrophobic F-SiO2/epoxy coatings and self-powered cathodic protection. J. Mater. Chem. A. 10, 18616–18625 (2022).

Sun, W., Luo, N., Liu, Y., Li, H. & Wang, D. A new self-healing triboelectric nanogenerator based on polyurethane coating and its application for self-powered cathodic protection. ACS Appl. Mater. Interface 14, 10498–10507 (2022).

Sun, W. et al. Liquid-solid triboelectric nanogenerators array and its applications for wave energy harvesting and self-powered cathodic protection. Energy 217, 119388 (2021).

Guo, W. et al. Electrochemical cathodic protection powered by triboelectric nanogenerator. Adv. Funct. Mater. 24, 6691–6699 (2014).

Wang, M. et al. Droplet energy harvesting system based on MXene/SiO2 modified triboelectric nanogenerators. Chem. Eng. J. 477, 146832 (2023).

Xu, H. et al. Construction of MXene/PDMS-based triboelectric nanogenerators for high-performance cathodic protection. Adv. Mater. Interface 9, 2102085 (2022).

Zhao, X. et al. Electrostatically assembling 2d nanosheets of MXene and MOF-Derivatives into 3D hollow frameworks for enhanced lithium storage. Small 15, 1904255 (2019).

Zhu, P. et al. Ultrahigh current output from triboelectric nanogenerators based on UIO-66 materials for electrochemical cathodic protection. Nano Energy 108, 108195 (2023).

Cui, S. et al. A new synergetic system based on triboelectric nanogenerator and corrosion inhibitor for enhanced anticorrosion performance. Nano Energy 91, 106696 (2022).

Nan, Y. et al. Highly porous and rough polydimethylsiloxane film-based triboelectric nanogenerators and its application for electrochemical cathodic protection. iScience 26, 108261 (2023).

Shao, Z. et al. A double-helix metal-chain metal-organic framework as a high-output triboelectric nanogenerator material for self-powered anticorrosion. Angew. Chem. Int. Ed. 61, e202208994 (2022).

Shao, Z. et al. A high-spintronic helix metal-organic chain as a high-output triboelectric nanogenerator material for self-powered anticorrosion. Chem. Eng. J. 455, 140865 (2023).

Acknowledgements

This work was supported by the National Natural Science Foundation Project of China (No.52201056), College Excellent Young Foundation of Anhui Province (No. 2023AH030029), Excellent Young Talents Fund Program of Higher Education Institutions of Anhui Province (No. YQYB2024016) and College Student Innovation and Entrepreneurship Training Program Project (No. 202410360052).

Author information

Authors and Affiliations

Contributions

Xiang T. F. and Chen X.X.: Writing–original draft, investigation, and data curation. Wang J. H., Liu D., Cui L. J.: Writing–review and editing, resources. Chen X. X., Wang J. H., Liu D., and Wang T.: Conceptualization, investigation, and methodology. Zhang Z. Y. and Yang Y.: Writing–review and editing. Zhang S.H.: Writing–review and editing, and supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xiang, T., Chen, X., Wang, J. et al. Design of F-ZIF-67/PDMS-based triboelectric nanogenerator for enhanced cathodic protection. npj Mater Degrad 9, 110 (2025). https://doi.org/10.1038/s41529-025-00662-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41529-025-00662-y

This article is cited by

-

Nonlinear dynamic modeling of an unsealed capacitive pressure sensor with a viscoelastic PDMS gap-filled dielectric

Journal of Umm Al-Qura University for Applied Sciences (2025)