Abstract

In this study, wheat flour at different contents was mixed with soy whey and fermented to produce high-quality Suanjiang tofu. The objective was to evaluate the impact of wheat flour supplementation on the physicochemical, structure, and qualitative properties of Suanjiang tofu, and explore the correlation between wheat flour content and bacterial population. The results demonstrated that wheat flour supplementation not only increased tofu yield but also enhanced the formation of a dense and uniform three-dimensional protein network, reduced protein aggregate size, and significantly improved hardness (p < 0.05). Additionally, the hydrophobic interactions and disulfide bonds playing a more critical role than ionic and hydrogen bonds in stabilizing the gel network. Moreover, higher wheat flour concentrations reduced bacterial diversity, with Acetobacter rapidly proliferating and becoming the dominant genus (97% relative abundance). These findings provide valuable insights into the between wheat flour and soy whey and practical guidance for specialty tofu production.

Similar content being viewed by others

Introduction

As a major soybean derivative, tofu is widely consumed worldwide due to its high nutritional value, important physiological functions, and affordability1,2. However, tofu production generates substantial amount of soy whey, a yellow liquid byproduct released during the pressing process3,4. It is estimated that ~9 kg of soy whey is produced for every kilogram of soybeans used in tofu production5. It is worth noting that soy whey contains valuable bioactive compounds, including oligosaccharides, soluble proteins, phenolic acids, and isoflavones6. Despite its nutritional potential, the large-scale discharge of soy whey results in significant nutrient loss and increases both chemical oxygen demand and biological oxygen demand in wastewater, leading to serious environmental pollution7. Consequently, the efficient and sustainable utilization of soy whey has become a critical concern.

One traditional approach to repurposing soy whey is its use as a natural coagulant in tofu production. Fermented soy whey (FSW) has been used for this purpose in China for over 600 years, particularly in rural areas8. The tofu produced using FSW, known as Suanjiang tofu, is valued for its distinctive flavor and enhanced nutritional profile, which are attributed to the presence of lactic acid bacteria and their metabolites9,10. Compared to chemical coagulants such as bittern, gypsum, and glucono-δ-lactone, FSW not only facilitates the recycling of tofu wastewater, but also eliminates chemical pollutants, making it a more sustainable and environmentally friendly alternative. However, despite these advantages, Suanjiang tofu has certain drawbacks, including loose texture and low yield, which have hindered its widespread adoption and industrial-scale production.

To overcome these limitations, researchers have investigated the incorporation of starch to enhance the gel properties of tofu. Studies have demonstrated that starch can strengthen hydrophobic interactions within the gel system and promote heat-induced protein conformational transitions5,11,12, thereby improving gel stability and texture. Since wheat flour is naturally rich in starch, it is reasonable to hypothesize that its addition could influence tofu gel formation and enhance overall quality. Furthermore, wheat flour can serve as a nutrient source for lactic acid bacteria, facilitating fermentation and increasing acid production, which may effectively shorten the fermentation period. In addition, water absorption is a critical quality parameter of wheat flour13, and its incorporation into tofu production may enhance water-holding capacity (WHC), thereby increasing the final yield. Considering these potential benefits, a novel approach was developed in which wheat flour and soy whey were co-fermented to produce Suanjiang tofu with improved characteristics.

During the fermentation process of FSW, a significant amount of organic acids is produced, serving as key coagulating agents in Suanjiang tofu preparation³. These acids play a crucial role in the gelation mechanism by inducing pH-dependent coagulation of soy proteins14,15. We hypothesized that the addition of wheat flour could further influence gel formation by modifying these molecular interactions. Specifically, we proposed that the rapid acid production resulting from the proliferation of lactic acid bacteria in wheat flour-supplemented soybean milk could accelerate tofu gel formation. Furthermore, the formation of hydrophobic structures between starch and gluten proteins in wheat flour and soy proteins in soybean milk may further enhance gel strength. Despite these promising possibilities, research on the effects of wheat flour addition on the gelation mechanism of Suanjiang tofu remains limit.

This study investigated the ratio of soybean whey and wheat flour to evaluated the effects of varying wheat flour addition levels on the gel properties and quality of Suangjiang tofu. Specifically, it examined yield, WHC, texture (TPA), microstructure, and rheological properties. Furthermore, the gelation mechanism was explored through the measurement of intermolecular forces, Fourier transform infrared spectroscopy (FT-IR), and sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE). Finally, high-throughput sequencing was employed to assess the impact of different wheat flour addition levels on the bacterial community composition in Suangjiang tofu. This study is the first to utilize a composite of soybean whey and wheat flour as raw materials for Suangjiang tofu production, which not only improved the utilization of soy whey and reduced the waste of resources but also enhanced the flavor and nutritional value of the product. In addition, this study promotes the high-value utilization of soy whey and reduces the waste of food industry by-products, which is in line with the green, low-carbon, and sustainable development direction of the modern food industry.

Results

pH and the number of lactic acid bacteria analysis

The changes of pH and number of lactic acid bacteria with fermentation time are presented in Fig. S1a, b. As displayed in Fig S1, the pH value of all samples decreased rapidly to ~4 after 12 h fermentation. Due to the rapid growth of LAB during this period, the number in all samples increased rapidly from 7.78–18.11 log CFU/mL to 9.11–19.23 log CFU/mL, generating a rapid decrease in pH. Yongtao et al. also found that Lactobacillus secreted large amount of organic acid by consuming glucose, fructose, and most sucrose at the first 12 h fermentation3. After fermentation for 24 h, the number of lactic acid bacteria added with wheat flour (10% and 15%) has reached a stable period (9.26 log CFU/mL and 9.15 log CFU/mL), while the addition of 5% wheat flour presented a small downward trend (from 9.15 to 8.70 log CFU/mL). The decrease is more pronounced without adding flour (from 9.11 to 8.15 log CFU/mL), because the nutrients in soy whey have been used up by lactic acid bacteria. In this case, the pH of all samples reached below 4. After fermentation for 24 to 48 h, the number of lactic acid bacteria added with wheat flour remained roughly the same, and the pH decreased gradually. Most of the lactic acid bacteria without adding wheat flour entered the decline phase, and thus the pH hardly decreased. The final pH was 3.79 ± 0.026. The pH of adding wheat flour continued to decrease slowly, and the wheat flour content of 5% finally fell to 3.55 ± 0.012. Both 10% and 15% were 3.43 ± 0.006. The reasons might contribute to adding wheat flour, which could supply nutrients for lactic acid bacteria, realize high and rapid acid production, and shorten the fermentation period16. Nevertheless, if we continue to add wheat flour, the ability of lactic acid bacteria to produce acid by using carbohydrates and other substances has reached its limit. As a result, the pH value will no longer decrease.

The yield and WHC analysis

The yield of tofu gel with varying wheat flour contents was investigated as illustrated in Table S1. The yield of tofu gel without wheat flour was 170.23 ± 10.30 g/L, and the yield was elevated with the supplementation of wheat flour (p < 0.05), while adding 5% and 10% wheat flour exerted no significant impact on the yield. The yield reached 250.11 ± 8.05 g/L with 15% wheat flour content. It demonstrates that adding wheat flour can effectively increase the yield of tofu, probably because adding wheat flour affects the formation of the three-dimensional network structure of the gel. In addition, the added flour particles were also gelatinized to a certain extent during processing, and remained in the network structure of tofu after swelling with water, playing the role of filling and improving the yield of tofu.

As a measure of protein–water interactions, the water holding capacity refers to another important indicator of tofu quality15. Table S1 shows WHC of tofu gels. Results demonstrated that WHC was notably (p < 0.05) influenced by the ratio of the added wheat flour. WHC increased (p < 0.05) from 73.63% ± 1.39 to 79.50% ± 2.43 as the wheat flour concentration increased from 0% to 15%. This result is similar to the findings of Kao et al.3. The above phenomenon is due to the wheat flour contains a significant amount of starch, which has the ability to absorb and retain water through the formation of hydrogen bonds with water molecules. This helps to increase the water retention in the tofu matrix. Secondly, wheat flour contains gluten proteins, which, upon hydration and mixing, form a network that can further trap water and improve the texture of the tofu. This gluten matrix likely interacts with soy proteins, enhancing the overall structure and stability of the gel, thus contributing to an increase in WHC. Additionally, the presence of starch and gluten in wheat flour may also affect the porosity and water retention capacity of the gel, allowing for more efficient retention of water during the pressing process17,18. Therefore, in the current work, with the increasing wheat flour content, water can bind to more functional groups of polysaccharides and proteins, generating the improvement of water holding capacity.

Texture analysis

Texture is one of the most important indexes that indicate the quality of tofu, and it also directly reflects the gelation of tofu. As shown in Table S2, the texture features of tofu gel with different Suanjiang tofu are explored. As for hardness, it elevated initially and subsequently lowered with the increase of wheat flour content, while it significantly increased from 129.33 ± 42.12 (p < 0.05) to 288.00 ± 41.58 when only 5% wheat flour was added. Nevertheless, there existed no obvious difference between 10% and 5%. With wheat flour content reaching 15%, the hardness decreased, which shows that adding flour can form stiffer tofu gel, while adding too much will cause the gel to become soft. The chewiness, adhesiveness and hardness of tofu gel showed the same trend, which elevated initially and subsequently lowered with the content of wheat flour. With the increase of wheat flour content, the viscosity gradually increased (p < 0.05), probably due to the starch and gluten proteins contained in wheat flour. Kon considered that the gluten protein formed a small molecular gluten structure after hydration, possessing greater viscosity19. Granules of starch swell when hydrated and gelatinize when heated, usually increasing viscosity and helping form and stabilize the gel-like structure20. Therefore, when the addition amount reached 15%, the viscosity of tofu increased obviously (p < 0.05). However, no obvious impact on the elasticity and cohesion of tofu gel was found in adding wheat flour samples. The hardness, springiness, and cohesiveness of our fermented tofu were comparable to those reported for traditional fermented tofu varieties21,22. Consumer acceptability of tofu is strongly influenced by its textural properties, particularly hardness and adhesiveness. Excessive hardness may lead to a dense, dry mouthfeel, reducing palatability, whereas tofu that is too soft may lack structural integrity. A moderate level of hardness is generally preferred, as it ensures a balance between firmness and tenderness. Likewise, adhesiveness plays a key role in mouthfeel perception. While excessive adhesiveness may be undesirable, a slight degree of adhesiveness can contribute to a smooth and cohesive texture that enhances the overall eating experience. In conclusion, adding 5 ~ 10% flour can significantly improve the hardness, chewiness, and adhesiveness of tofu gel, but has little effect on elasticity, viscosity, and cohesion.

SEM analysis

SEM was adopted for observing the microstructure of tofu gel with varying wheat flour content, as shown in Fig. 1. The tofu gel formed by the Suanjiang tofu (0%) has a rough and uneven surface and a large protein aggregate size, also explaining the fragile nature of Suanjiang tofu. However, with the addition of 5% wheat flour, a relatively dense and uniform three-dimensional network structure was formed with the protein aggregates being small in size, which is also the reason why the addition of flour increases the hardness, strength, and yield of tofu gel. With the wheat flour content reaching up to 10%, the three-dimensional structure and texture of tofu gel are more uniform. Small grains of starch are wrapped by protein, while the pores are larger than 5%wheat flour content. Thus, the water content is higher, which is also one of the reasons for the increasing tofu production. When the addition of wheat flour reached 15%, the gel network structure became loose, porous, and uneven, and the large starch particles were almost completely bare or slightly wrapped with protein. In particular, the pore area of the Suanjiang tofu in the 15% treatment group was 28 µm2, the other treatment groups did not observe significant pore. Therefore, tofu is featured by low strength and hardness, and lacks elasticity and toughness.

FT-IR analysis

Fig. S2a, b and Table S3 present the FT-IR spectra and the secondary structure for all the four groups sample. The Amide I region (1700–1600 cm−1) was chosen since it is well-known, and is the most sensitive spectral region to changes in the secondary protein structure23. The analyzed major components correspond to α-helix (1650–1660 cm-1), β-turn (1660–1700 cm−1), β-sheet (1618–1640 cm−1), and random structures (1640-1649 cm-1)24. The textural properties of protein gels show association with the relative content of varying secondary structures, while the relative content of β-sheets was 32.51% ± 0.79–135.61% ± 0.81, β-turns was 29.95% ± 0.62–134.73% ± 0.47, random coil structurewas21.74% ± 1.08–123.60% ± 0.49, and α-helix was 11.02% ± 0.087–111.87% ± 0.37 (Table S3). Then, it can be found that the secondary structure of protein in the bean curd is mostly β structure. With the addition of wheat flour, there is basically no change in the content of random coil and α-helix, but mainly the mutual conversion between β-sheets and β-turns. With the increasing wheat flour, β-sheet content increased from 32.51 ± 0.79 to 35.61 ± 0.81 (p < 0.05), and β-turns decreased from 34.73 ± 0.47 to 30.20 ± 0.64 (p < 0.05). β-Sheets are stabilized by extensive intermolecular hydrogen bonding, which enhances protein-protein interactions and facilitates the formation of a dense, ordered gel matrix. Studies have shown that a higher β-sheet content contributes to increased gel strength, rigidity, and WHC due to the improved structural integrity of the network25,26. The dominance of β-sheet structures enhances gel elasticity by promoting a more interconnected and resilient protein network, thereby reducing syneresis and improving textural properties27. Additionally, the structural transformation from random coils or α-helices to β-sheets may result in stronger hydrophobic interactions and disulfide bond formation, further stabilizing the gel network28. In addition, Xiaojing also found that the addition of wheat protein in soybean protein gel increased the β-sheet content of protein structure29. Adding wheat flour can promote the transformation of protein β-sheet structure, which may be caused by the role of gluten protein in wheat flour. Moreover, β-sheet and random conformations were the leading secondary structures in the unhydrated gluten.

Rheological behavior analysis

Frequency sweeps offer the mechanical spectra which have been called the “fingerprint” of food gels30. As presented in Fig. 2a, b represent the curves of G’ (elastic modulus) and G” (viscous modulus) of tofu gels formed under different flour contents as the role of angular frequency (0.1–100 rad/s). The result shows that with the increasing angular frequency, G’ and G” are increasing, and when 5% flour is added, the value of G’ and G” of the gel is the largest, followed by 10%. However, adding 15% wheat flour content is similar to the tofu gel without flour. It is indicated that the gel network structure formed by 5% Suanjiang tofu is the strongest, conforming to the findings of the microstructure observed under the scanning electron microscope. Moreover, G’ > G” in all samples can also be observed from these data, suggesting that the solid property in these gels is much stronger when compared with that in liquid property24.

Frequency dependence of storage modulus (G’) in tofu gels from 0.1 to 100 rad/s (a); Frequency dependence of loos modulus (G”) in tofu gels from 0.1 to 100 rad/s (b); Temperature dependence of storage modulus (G’) in tofu gels from 25 to 85 °C (c); Temperature dependence of loss modulus (G”) in tofu gels from 25 to 85 °C (d).

In Fig. 2c, d are the variation curves of G’ and G” with temperature, respectively. It is shown from the results that the storage modulus and the loss modulus of all samples lowered with the increasing temperature. When the temperature increased, the gel strength lowered. As the heating temperature reached the highest of 85 °C, G’ and G” reduced to the lowest level. With the increasing temperature, the decreasing trend of all samples was basically the same, indicating that the addition of flour generated little effect on the thermal stability of tofu gel. These findings suggest that the rheological behavior of our product follows expected gelation patterns observed in other tofu-based systems, further supporting its structural integrity and potential for industrial application.

Intermolecular forces analysis

The chemical interactions engaged in protein gels mostly include ionic bonds, hydrogen bonds, disulfide bonds, and hydrophobic interactions31. The relative amounts of hydrogen bonding, ionic bonding, hydrophobic interactions, and disulfide bonding in the proteins are shown in Fig. 3, respectively. The results shown that the disulfide bond contributes the most in the gel forming force, followed by the hydrophobic interaction. The hydrogen bond and the ionic bond are relatively small. Similar results were found in this study. Li et al. revealed that hydrophobic interactions and disulfide bonds in mixed plant proteins gels were obviously higher than nonspecific associations, ionic bonds, and hydrogen bonds32. Nevertheless, ionic bonds and hydrogen bonds primarily exist between the polar groups of protein molecules. During the process of heating, the hydrogen and ionic bonds that maintain the protein conformation are broken. The protein molecular chain is expanded. The internal hydrophobic groups and sulfhydryl groups are exposed. The hydrophobic force on the protein surface is enhanced. The exposed sulfhydryl group causes the proteins to cross-link, forming strong disulfide bonds.

By adding wheat flour, the contents of hydrogen bonds and ionic bonds were decreased (p < 0.05), whereas those of hydrophobic bonds and disulfide bonds were elevated (p < 0.05). This may be due to the introduction of wheat flour components, particularly starch and gluten proteins, alters the gel network by increasing hydrophobic interactions while reducing the availability of polar groups for ionic and hydrogen bonding33. Starch competes with soy proteins for water, leading to reduced hydrogen bonding between protein molecules and instead promoting hydrophobic associations, which contribute to gel stabilization34. Second, gluten proteins in wheat flour may interfere with the electrostatic interactions among soy proteins, limiting the formation of ionic bonds crucial for gelation31,35. In addition, this is also illustrated by the enhancement in the β-sheet structure in the FT-IR. According to the results, the concentration of flour had a direct impact on the hydrogen bond, ionic bond, hydrophobic interaction, and disulfide bond between tofu gels. Hydrophobic interactions and disulfide bonds may be more vital than ionic bonds and hydrogen bonds in keeping the structure of the gel network.

SDS-PAGE analysis

Approximately 90% of soybean protein exists in the form of storage protein. According to different sedimentation coefficients, its components can be divided into 2S, 7S, 11S and 15S, among which 11S (glycinin) and 7S (β-conglycinin) occupy over 80%36. Zhang considered that 11S had a strong capability of forming heat-induced gels among soybean proteins37. Therefore, it is also of great importance to investigate the 7S and 11S of soy protein for the formation of tofu gel.

There existed no obvious differences in the number and location of the reduced electrophoretic bands for all samples (Fig. S3), suggesting that the extra wheat flour did not influence the subunits of soy protein. It indicated that there existed no covalent bonds between soy protein and flour, even by thermal and acid treatment. The color of basic subunits (20 kDa) and acid subunits (35–37 kDa) of soybean 11S protein weakened slightly with the increase of flour content, but not obviously. It was speculated that this may be part of the soy protein replaced by gluten protein. Due to the low flour content, the extracted gluten protein content is also extremely low, which cannot be displayed in the electrophoresis band. Gluten proteins, particularly gliadins and glutenins, can form intermolecular interactions with soy proteins through hydrogen bonding, hydrophobic interactions, and disulfide exchanges under certain conditions38. These interactions may not necessarily lead to distinct band shifts on SDS-PAGE but could influence the structural properties of the tofu gel network. Furthermore, previous studies have shown that gluten can interact with soy proteins to modulate gel elasticity and WHC, which may contribute to the textural modifications observed in wheat flour-supplemented tofu39. Nevertheless, the 7S protein band of soybean remained basically unchanged. In general, the addition of flour has no impact on the structure of soybean 7S and 11S protein, further indicating that flour does not cause structural changes in the process of soybean protein gel.

Correlation among texture characteristics, secondary structure, and intermolecular forces

With the aim of acquiring insight into the association among a variety of indicators, a visual correlation analysis chart was made, which can be found in Fig. 4. There existed a significantly positive association between yield and viscosity (p < 0.01), and they were also positively correlated with the water holding capacity of tofu (p < 0.05), because with the addition of wheat flour, more water-swelling starch granules were brought. Then, the starch granules could enhance the viscosity of the system and were filled in the protein network during the gelation process. The water absorbed by the starch is more difficult to come out. As the results, while the WHC and the yield increases.

Correlation between texture characteristics, secondary structure, and intermolecular forces shown in Fig. 4. Hardness, chewiness, and adhesiveness were positively correlated (p < 0.05). Specifically, it indicates the greater the hardness, the more chewable it is. In addition, the β-sheet was negatively correlated with ionic bond content (p < 0.05), but positively related to disulfide bond content (p < 0.05), revealing that the change of β-sheet structure also exposed more hydrophobic groups and sulfhydryl groups hidden inside the protein structure31. This also leads to enhanced disulfide bonds and hydrophobic associations between gel molecules. Moreover, the elasticity of the sample has a strong correlation with the hydrogen bond and ionic bond (p < 0.05). Pérez-Mateos considered that the formation of too many covalent bonds would generate the increase of gel hardness and the decrease of elasticity, whereas the high proportion of secondary bonds containing the ionic bond, hydrogen bond and hydrophobic interaction would contribute to the improvement of gel elasticity40.

Briefly, adding an appropriate amount of wheat flour (5–10%) can effectively increase the yield of tofu, also exerting a certain role in improving product quality. The addition of wheat flour generates no great impact on the color and flavor of Suanjiang tofu, and it is easily accepted by consumers. However, the interaction between various elements is complex and requires further exploration.

Microbiological composition

During the natural fermentation of tofu, the composition of microbial community changed greatly. Acetobacter was the dominant genus in all the samples and the result is shown in Fig. 5. The relative abundance of Acetobacter spp. was 54%, 96%, and 91% in the 0%, 5%, and 10% treatment groups, respectively, while the 15% treatment group had the highest relative abundance of Acetobacter (97%). At the genus level, a total of 152 genera were identified in all the samples, and we displayed their major dominant bacteria in Fig. 5 based on the percentage of content, with minor content genera categorized as others. Among the dominant genera in 15% were mainly Acetobacter (97%) and Blautia (1%), in 10% the dominant genera were Acetobacter (91%), Wolbachia (6%) and Bacteroides (1%), Acetobacter (96%), the dominance of Acetobacter in the microbial community may play a key role in Suanjiang tofu flavor formation. Acetobacter is well known for its ability to convert ethanol into acetic acid, which contributes to the characteristic sourness of fermented foods. Moreover, it may interact with other microbial species in the fermentation process, influencing the production of volatile flavor compounds such as esters, aldehydes, and ketones16. Ruminococcus (1%) were 5% dominant genera. However, the genera were most abundant in the no wheat flour added group. Among them, Fusobacterium affects host health, and Prevotella is an oral flora that causes periodontal disease and upper respiratory tract infections. The above data showed that the relative abundance of harmful genera during fermentation with the addition of wheat flour was significantly reduced (p < 0.05). The observed decline in bacterial diversity with increasing wheat flour content suggests a shift in the microbial ecosystem during fermentation. One possible explanation is that wheat flour provides a selective advantage to Acetobacter that efficiently utilize starch and other fermentable carbohydrates, leading to the dominance of a few species while suppressing others41. However, the relative abundance of Acetobacter increased to 97%, and the above results suggest that the Suanjiang tofu flavor formed with the addition of wheat flour was mainly due to Acetobacter.

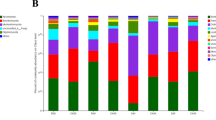

Microbial diversity analysis

Generally speaking, Chao was used to calculate the number of bacterial species, Shannon and Simpson indexes were used to estimate the diversity of microorganisms. Bacterial α-diversity (Fig. 6) revealed that sample 0% treatment group had the highest number of OTUs, Chao, Shannon and lowest Simpson index. It has been previously reported that the lower the Simpson index of a sample, the higher the microbial diversity. The lowest Simpson’s index obtained in 0% of the sample indicates that this sample is rich in diversity as compared to other samples. The highest Simpson index was obtained in sample 15% indicating lower species richness, evenness, and diversity in this sample. Compared with the 15% treatment group, although the 10% treatment group had higher Chao and Shannon index values, the occurrence rate of genus in this treatment group was very low. This is attributed to the fact that the addition of wheat flour contributes to the growth of dominant bacteria in suanjiang tofu and inhibits the growth of other microorganisms, leading to a decrease in microbial diversity.

Discussion

In conclusion, this study demonstrated that incorporating an appropriate amount of wheat flour (5–10%) enhances acid production, shortens the fermentation period, and increases the yield of Suanjiang tofu. Additionally, wheat flour influences the structural properties of tofu gel by modulating protein interactions, with hydrophobic interactions and disulfide bonds playing a crucial role in maintaining gel stability. These findings provide valuable insights for the industrial production of fermented tofu, particularly in optimizing ingredient composition to balance texture and yield. Moreover, the current research can also provide a certain theoretical basis for the industrialization of green tofu. Future research should focus on refining wheat flour concentrations, exploring alternative fermentation conditions, and investigating the molecular mechanisms underlying protein-starch interactions to further improve the quality and scalability of Suanjiang tofu production.

Methods

Soybeans and soy whey were provided by Guizhou Zhongyi Food Co., Ltd. (Guiyang, Guizhou, China). Wheat flour (68% starch, 12% protein, 1.8% lipid dry basis, and 5.5% fiber) was purchased from Wal-Mart store (Guiyang, Guizhou, China). The lactic acid bacteria were selected from the natural FSW provided by Guizhou Zhongyi Food Co. Ltd. (Guiyang, Guizhou, China). SDS-PAGE gel preparation kit and rainbow broad-spectrum protein markers were obtained from Beijing SuoLaibao Technology Co., Ltd. (Beijing, China). MRS agar was purchased from Qingdao Hope Bio-Technology Co,. Ltd. (Qingdao, Shandong, China). Moreover, the other chemical reagents were of analytical grade.

Preparation of Suanjiang tofu

Wheat flour was mixed with soy whey at concentrations of 0%, 5%, 10%, and 15% (w/w) and thoroughly homogenized. The mixture was then inoculated with Lactiplantibacillus plantarum L4 and Lacticaseibacillus casei L6 at a 1:1 ratio, with a total inoculation level of 3%. Fermentation was conducted at 37 °C for 48 h (relative humidity: 70%), yielding FSW. For Suanjiang tofu preparation, high-quality soybeans, free from black spots and with intact surfaces, were selected. The soybeans were soaked in water at a 1:3 ratio (w/v) for 10–12 h. After soaking, they were blended with water at a 1:10 ratio (w/v) to produce soybean slurry, followed by the removal of soybean residue. The resulting liquid was brought to a boil, maintained at 100 °C for 5 min, and then cooled to 80 °C to obtain soybean milk. FSW was gradually added to the soybean milk at a 3:20 (v/v) ratio with continuous stirring until uniform coagulation was achieved. The coagulated mixture was then transferred into a tofu mold and pressed under a weighted load for 20 min to remove excess moisture, yielding Suanjiang tofu, the preparation process of Suanjiang tofu shown in Fig. 7.

Determination of pH and lactic acid bacteria count

The pH values were measured using a pH meter (PHS-3E, Shanghai Instrument Science Co. Ltd., Shanghai, China). The pH of Suanjiang tofu was measured at fermentation time points of 0 h, 12 h, 24 h, 36 h, and 48 h. The numbers of lactic acid bacteria (LAB) were calculated by MRS agar. First, Suanjiang tofu samples (1 mL) were mixed with 9 mL of sterile physiological saline and homogenized using a vortex mixer (Kasvi, Curitiba, Brazil). The homogenized samples were then serially diluted and spread onto MRS agar supplemented with 50 mg/L nystatin to inhibit fungal growth42. The plates were incubated at 37 °C for 48 h, after which colony-forming units (CFU) were enumerated at 0, 12, 24, 36, and 48 h to monitor LAB population dynamics over time.

Determination of yield and WHC

Tofu yield calculation and analysis was performed by referring to the method of ref. 43. The weight of the new tofu gel made from 1000 mL of suspension was divided by 1000. Then, the obtained value indicated the yield. The tofu gel was prepared by the method described in 2.2 and kept at 4 °C for 12 h. Then, the tofu samples were cut into 5 × 5 × 5 mm cubes. Approximately 3 g of the sample was weighed, and placed in a 50 mL centrifuge tube (with absorbent cotton at the bottom). Subsequently, it was centrifuged at 6000 rpm for 15 min at 4 °C with the use of a high speed refrigerated centrifuge (GL-20G-II,Shanghai Anting Scientific Instrument Factory, Shanghai, China). Here, it is of note that water holding capacity (%) is defined as the percentage of water contained in the gel after centrifugation to the total water contained in the gel before centrifugation.

Determination of texture

The tofu sample was taken out of the refrigerator, which was equilibrated at room temperature for 30 min, cut into cubes of 1.5 cm × 1.5 cm × 1.5 cm, and explored with the physical property tester (CT3, Brookfield, America). Moreover, the measurement parameters include a trigger force of 3 g. A cylinder aluminum probe (50.8 mm diameter; TA25/1000) was applied in a texture profile analysis (TPA), at the initial speed of 1.0 mm/s, a test speed of 1.0 mm/s, a post-compression speed of 1.0 mm/s, and a compression ratio of 30%. Furthermore, hardness, elasticity, viscosity, adhesiveness, chewiness and other indicators were selected. The measurements were repeated triplicate for each sample. TPA results were processed with the software offered by the instrument.

Determination of scanning electronic microscopy (SEM)

The sample was cut into slices of about 2 mm, which were placed in Gluta fixative (special for electron microscopy, 2.5%) and fixed forover12 h. Then, the sample was washed three times with 0.1 mol/L phosphate buffer for 15 min each time. Dehydration was performed with the use of an ethanol gradient (50, 70, 80, 90, and 95%) for 15 min each time. It was dehydrated twice with 100% ethanol for 15 min each time. The dehydrated samples were replaced twice with tertiary butanol and freeze-dried with a freeze-dryer (1-4/LDC-1M, BMH Instrument Co. Ltd., Beijing, China). The pulverized freeze-dried raw samples were spread on a SEM stub with sticky double-side carbon tape and coated with a thin old layer based on a coater. However, the examination was taken by a secondary electron scanning electron microscope (SU8010, HITACHI, Japan), which was operated at 5.0 kV high voltage44.

Determination of rheological behavior

The rheological behavior of tofu gel was modified using the method of Wang et al.31. Dynamic rheological evaluations were carried out with the use of an advanced rheometer (ARES-G2, TA instruments, DE, USA). Parallel-plate geometry (40 mm diameter, 1 mm gap) was adopted for measuring the dynamic viscoelastic parameters as the function of temperature (T). In order to avert moisture loss, edges of the samples were coated with silicone oil. Dynamic temperature sweep measurements were performed at the frequency of 1 Hz and a deformation of 1.0%%, whereas the temperature of the plate was programmed to elevate from 25 to 90 °C at a heating rate of 2.0 °C/min. Frequency sweep tests were conductedfrom0.1 to 100 rad/s at 25 °C. The storage modulus (G’), loss modulus (G”), and initial phase angle (tan δ) data were collected. The measurements were repeated triplicate for each sample.

Determination of Fourier transform infrared spectroscopy (FT-IR)

A PerkinElmer FT-IR spectrometer (Frontier, PerkinElmer, Boston, MA, USA) was used to determine FT-IR spectra of the freeze-dried tofu gels. The gel sample (3 mg) was weighed and mixed with dry potassium bromide in the ratio of 1:100 (w/ w), followed by placing it in a mortar and grinding again. Afterwards, it was compressed using a tableting machine. The samples were scanned using the PerkinElmer FTIR spectrometer (Frontier, Perkin Elmer, Boston, MA, USA) with the resolution of 4 cm−1, a scanning and of 4000–400 cm−1 and a scan count of ref. 31, whereas OMNIC 6.0 data processing software was used to process the original spectrum. The band of the amide I region (1600–1700) cm−1 was intercepted. Peakfit V4.12 was adopted for baseline correction, deconvolution and second derivative fitting. In addition, the number of sub-peaks was between 12 and 13. The peak location was identified and the peak area data were derived. Then, the relative percentage content of each sub-peak area was calculated.

Determination of intermolecular forces in the gel

Intermolecular force in the gel was determined as described by Xiao et al. method with some modifications45. Tofu samples were solubilized in varying elective solutions with the aim of cleaving the specific interactions: 0.1 M NaCl, 0.6 M NaCl, 0.6 M NaCl + 1.5 M urea, and 0.6 M NaCl + 8 M urea on the basis of 0.05 M phosphate buffer (pH 7.0). Besides, it (200 mg) was stirred with each reagent (20 mL) at 25 °C for 1 h, and then it was centrifuged (8000 rpm, 4 °C, 20 min). Furthermore, the protein concentration in the supernatant was confirmed with the use of coomassie brilliant blue, while bovine serum albumin was adopted to be the standard.

Determination of sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE)

By adopting Balang method46, 3 g minced gel sample was homogenized with 27 mL 5% SDS solution, and the protein was fully dissolved in 85 °C water bath for 1 h. Additionally, using a high speed centrifuge (GL-20G-II, Shanghai Anting Scientific Instrument Factory, Shanghai, China), the insoluble material was removed after centrifugation at 4 °C and 12,000 rpm for 20 min. The protein content in the supernatant was identified by total protein quantitative assay kit (purchased from Nanjing Jiancheng Institute of Biological Engineering). In addition, the sample was adjusted to 2 mg/mL before use. The 10 μL sample buffer was added to 30 μL electrophoretic protein samples and mixed in a 1.5 mL centrifuge tube. Boiling water was heated for 5–10 min, which was cooled and centrifuged for use. SDS–PAGE analysis was performed by adopting an SDS–Tris–glycine buffer system with 5% stacking gels and 12% separating gels, when the starting voltage of electrophoresis was 80 V and was changed to 120 V after all samples were moved to the separation gels. After the completion of electrophoresis, Stain for 30 min with the stain solution by 0.12% (w/v) Coomassie Brilliant Blue R-250 followed by detained in 50% (v/v) methanol in the presence of 10% (v/v) acetic acid to decolorize, and the background was colorless. Moreover, on the basis of a Gel Doc EZ imager (Bio-Rad Laboratories, Shanghai, China) gel imaging system, the protein bands in the gels were scanned.

Determination of microbiological components

High-throughput sequencing was used to characterize the microbial community composition in the tofu samples. Whole genomic DNA was directly extracted from each sample using a DNA extraction kit (Axygen, USA) according to the manufacturer method. 16S rRNA V4 region F: 5′-AYTGGGGYDTAAAGNG -3′ and R: 5′-TACNVGGGGTATCTAATCC -3′ were used as universal primers (provided by Personalbro). Reactions were performed in a final volume of 25 μL containing 5 μL of 5 × reaction buffer, 5 μL of 5 × GC buffer, 2 μL of dNTP (2.5 mM), 1 μL of forward primer (10 μM), 1 μL of reverse primer (10 μM), 2 μL of DNA template, 8.75 μL of ddH2O, and 0.25 μL of Q5 DNA polymerase (when some samples are difficult to amplify, the actual amplification system will be partially fine-tuned). Reaction conditions: initial denaturation at 98 °C for 2 min, followed by 30 cycles of denaturation at 98 °C for 15 s, annealing at 55 °C for 30 s, extension at 72 °C for 30 s, and final extension at 72 °C for 5 min. PCR products were extracted on a 2.0% agarose gel. The DNA bands were purified to the correct size (480 bp for 16S rDNA and 300 bp for ITS1 rDNA). After purification, both libraries were sequenced by the Illumina Miseq PE300 platform (Illumuina, San Diego, USA) of Majorbio BioPharma Technology Co.

Statistical analysis

We repeated all measurements for three times with the findings being denoted to be the mean values ± standard deviation. Nevertheless, data analysis was performed by adopting the SPSS (version 20, Chicago, USA) software in order to perform one-way analysis of variance (ANOVA) followed by Duncan’s multiple comparison test, with p < 0.05 showing the significance. For the drawings Origin Pro 2016 64-bit software (Origin Lab Corp., Northampton, MA, USA), we adopted the correlation calculations.

Data availability

All relevant data supporting this study is included within the manuscript and supplementary data. Additional raw data will be made available from the corresponding author upon reasonable request.

References

Li, X., Toyoda, K. & Ihara, I. Coagulation process of soymilk characterized by electrical impedance spectroscopy. J. Food Eng. 105, 563–568 (2011).

Huang, Z., He, W., Zhao, L., Liu, H. & Zhou, X. Processing technology optimization for tofu curded by fermented yellow whey using response surface methodology. Food Sci. Nutr. 9, 1–11 (2021).

Fei, Y., Li, L., Chen, L., Zheng, Y. & Yu, B. High-throughput sequencing and culture-based approaches to analyze microbial diversity associated with chemical changes in naturally fermented tofu whey, a traditional Chinese tofu-coagulant. Food Microbiol. 76, 69–77 (2018).

Xu, Y. et al. Naturally fermented acid slurry of soy whey: High-throughput sequencing-based characterization of microbial flora and mechanism of tofu coagulation. Front. Microbiol. 10, 1–12 (2019).

Chu, L., Yang, L., Li, J., Lin, L. & Zheng, G. Effect of Smilax china L. starch on the gel properties and interactions of calcium sulfate-induced soy protein isolate gel. Int. J. Biol. Macromol. 135, 127–132 (2019).

Yan, S., Liu, H., Zhang, J. & Tong, Q. Lactobacillus delbrueckii is the key functional microorganism of natural fermented tofu sour water involved in the traditional coagulation of Chinese Huizhou Mao-tofu. LWT Food Sci. Technol.131, 109706 (2020).

Primadi Gayuh Laksono Putro, H. & Hadiyanto, A. Water quality parameters of tofu wastewater: a review. IOP Conf. Ser. Mater. Sci. Eng. 1156, 012018 (2021).

Li, C. et al. Production of tofu by lactic acid bacteria isolated from naturally fermented soy whey and evaluation of its quality. LWT Food Sci. Technol. 82, 227–234 (2017).

Xing, G. et al. Gelling behavior of bio-tofu coagulated by microbial transglutaminase combined with lactic acid bacteria. Food Res. Int. 134, 109200 (2020).

Chua, J.-Y. & Liu, S.-Q. Soy whey: More than just wastewater from tofu and soy protein isolate industry. Trends Food Sci. Technol. 91, 24–32 (2019).

Mi, H. et al. The effect of modified starches on the gel properties and protein conformation of Nemipterus virgatus surimi. J. Texture Stud. 50, 571–581 (2019).

Luo, Z. & Wang, Z. The role of starch granule-associated proteins in enhancing the strength of indica rice starch gels. Food Hydrocoll. 131, 107826 (2022).

Fu, B. X., Wang, K. & Dupuis, B. Predicting water absorption of wheat flour using high shear-based GlutoPeak test. J. Cereal Sci. 76, 116–121 (2017).

Qiao, Z. et al. Microbiological and chemical changes during the production of acidic whey, a traditional chinese tofu-coagulant. Int. J. Food Prop. 13, 90–104 (2010).

Cao, F.-H. et al. Effects of organic acid coagulants on the physical properties of and chemical interactions in tofu. LWT Food Sci. Technol. 85, 58–65 (2017).

Liu, X., Zhang, X., Wang, Y. & Zhao, L. Microbial interactions and volatile compound production in traditional fermented foods: a review. Food Microbiol. 102, 103925 (2022).

Kao, F.-J., Su, N.-W. & Lee, M.-H. Effect of calcium sulfate concentration in soymilk on the microstructure of firm tofu and the protein constitutions in tofu whey. J. Agric. Food Chem. 51, 6211–6216 (2003).

Gao, J. et al. Dose-effect relationship and molecular mechanism of cellulose nanocrystals improving the gel properties of pea protein isolate. Food Hydrocoll. 151, 109750 (2024).

Zhang, H., Lv, S., Jin, C., Ren, F. & Wang, J. Wheat gluten amyloid fibrils: Conditions, mechanism, characterization, application, and future perspectives. Int. J. Biol. Macromol. 253, 26435 (2023).

Liu, X., Chao, C., Yu, J., Copeland, L. & Wang, S. Mechanistic studies of starch retrogradation and its effects on starch gel properties. Food Hydrocoll. 120, 106914 (2021).

Zhang, L., Wang, Y. & Liu, X. Fermentation-induced textural and structural modifications in tofu: a review. Food Hydrocoll. 102, 105621 (2020).

Wang, R., Li, J. & Sun, X. Influence of microbial fermentation on tofu texture and sensory attributes. Int. J. Food Sci. Technol. 53, 1789–1798 (2018).

Fevzioglu, M., Ozturk, O. K., Hamaker, B. R. & Campanella, O. H. Quantitative approach to study secondary structure of proteins by FT-IR spectroscopy, using a model wheat gluten system. Int. J. Biol. Macromol. 164, 2753–2760 (2020).

Taktak, W. et al. Physicochemical, textural, rheological and microstructural properties of protein isolate gels produced from European eel (Anguilla anguilla) by heat-induced gelation process. Food Hydrocoll. 82, 278–287 (2018).

Nakamura, S., Arai, T. & Yamada, Y. Structural changes in soy protein gels: the role of β-sheets in gel network formation. Food Hydrocoll. 113, 106512 (2021).

Tang, C. H. & Liu, R. Relationship between secondary structure and gel properties of plant proteins: a review. Trends Food Sci. Technol. 134, 45–58 (2023).

Sun, X. & Hayakawa, F. Influence of β-sheet structures on the water retention and mechanical properties of soybean protein gels. J. Food Sci. 85, 678–687 (2020).

Zhang, Y., Wang, Y. & Li, J. Effect of protein conformation on the gelation properties of soybean protein isolates. Int. J. Food Sci. Technol. 54, 1532–1540 (2019).

Sun, J. et al. Investigation the influences of water-extractable and water-unextractable arabinoxylan on the quality of whole wheat you-tiao and its mechanism. Food Chem. 386, 132809 (2022).

Moreno, H. M. et al. Evaluation of gels made with different commercial pea protein isolate: Rheological, structural and functional properties. Food Hydrocoll. 99, 105375 (2020).

Wang, K.-Q. et al. Changes in chemical interactions and protein conformation during heat-induced wheat gluten gel formation. Food Chem. 214, 393–399 (2017).

Lin, D. et al. Effect of plant protein mixtures on the microstructure and rheological properties of myofibrillar protein gel derived from red sea bream (Pagrosomus major). Food Hydrocoll. 96, 537–545 (2019).

Chen, Y., Tang, C. H. & Li, B. Influence of wheat starch on soy protein gelation: Impact on intermolecular interactions and gel properties. J. Food Sci. 84, 1574–1582 (2019).

Zhang, H., Wang, Q. & Guo, X. Hydrogen bonding and protein network formation in wheat-soy composite gels. Food Hydrocoll. 103, 105730 (2020).

Liu, R., Zhao, S. & Tang, Y. The role of electrostatic interactions in mixed protein networks: Implications for food gel properties. Food Chem. 345, 128748 (2020).

Huang, Z. et al. Recent advances in soybean protein processing technologies: a review of preparation, alterations in the conformational and functional properties. Int. J. Biol. Macromol. 248, 125862 (2023).

Zhang, B., Wu, H.-X., Yang, H.-C., Xiang, X.-W., Li, H.-B. & Deng, S.-G. Cryoprotective roles of trehalose and alginate oligosaccharides during frozen storage of peeled shrimp (Litopenaeus vannamei). Food Chem. 228, 257–264 (2017).

Zhang, H., Liu, R. & Tang, C. Interactions between gluten and plant proteins: implications for dough rheology and food structure. Food Hydrocoll. 101, 105485 (2020).

Wang, X., Zhao, S. & Sun, L. Influence of gluten on the gelation and texture properties of mixed protein gels. J. Agric. Food Chem. 67, 5121–5129 (2019).

Pérez-Mateos, M., Lourenço, H., Montero, P. & Borderías, A. J. Rheological and biochemical characteristics of high-pressure- and heat-induced gels from blue whiting (Micromesistius poutassou) muscle proteins. J. Agric. Food Chem. 45, 44–49 (1997).

Kim, S. A. et al. Microbial composition of turbid rice wine (Makgeolli) at different stages of production in a real processing line. Food Control 53, 1–8 (2015).

Freire, A. L., Ramos, C. L., da Costa Souza, P. N., Cardoso, M. G. B. & Schwan, R. F. Nondairy beverage produced by controlled fermentation with potential probiotic starter cultures of lactic acid bacteria and yeast. Int. J. Food Microbiol. 248, 39–46 (2017).

Khoder, R. M. et al. Effects of nano fish bone on gelling properties of tofu gel coagulated by citric acid. Food Chem. 332, 127401 (2020).

Tang, Z. et al. Insights into the structural characteristics and in vitro starch digestibility on steamed rice bread as affected by the addition of okara. Food Hydrocoll. 113, 106533 (2021).

Si, X. et al. Interactions between gluten and water-unextractable arabinoxylan during the thermal treatment. Food Chem. 345, 128785 (2021).

Balange, A. & Benjakul, S. Enhancement of gel strength of bigeye snapper (Priacanthus tayenus) surimi using oxidised phenolic compounds. Food Chem. 113, 61–70 (2009).

Acknowledgements

The author gratefully thanks the Key Project in Agricultural of Guizhou Province in [2019] 2379.

Author information

Authors and Affiliations

Contributions

Shan Yu: Conceptualization, Methodology, Formal analysis, Data Curation, Writing—original draft, Data visualization; Jiangli Wu: Conceptualization, Methodology, Writing—original draft, Resources; Fuyi Hui: Formal analysis, Investigation, Resources; Jin Fan: Conceptualization, Methodology; Wei Zhang: Formal analysis, Investigation, Resources; Zhengbin Yang: Methodology; Ziru Dai: Resources, Writing—review & editing; Xuefeng Zeng: Writing—review & editing, Project administration, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, S., Wu, J., Hui, F. et al. Investigation the microbial community and quality of Suanjiang tofu with the addition of wheat flour. npj Sci Food 9, 86 (2025). https://doi.org/10.1038/s41538-025-00454-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41538-025-00454-3