Abstract

To address the challenge of high sodium in paocai, this study evaluated the partial substitution of NaCl with KCl during radish paocai fermentation, focusing on microbial kinetics and flavor. The methodology integrated microbial growth modeling with comprehensive flavor analysis (HS-SPME-GC-MS, HS-GC-IMS, E-tongue) and Random Forest (RF) machine learning. Substituting 30% NaCl with KCl (K30) significantly increased mannitol and glutamic acid, enhancing desirable fresh, sweet, and umami tastes. RF modeling identified erucin, 1-hexanol, 3-methylbutan-1-ol, and 2-methoxy-4-vinylphenol as potential key aroma compounds. The K30 treatment also improved the aroma profile by increasing volatile compounds associated with cabbage, fruit, and sweet notes. Conclusively, sensory analysis confirmed that K30 paocai exhibited superior sourness, sweetness, umami, and overall acceptability. These findings support that 30% NaCl substitution with KCl is a valuable strategy for producing low-sodium radish paocai with an enhanced flavor profile, offering a practical framework for sodium reduction across traditionally fermented foods.

Similar content being viewed by others

Introduction

Paocai, a traditional Chinese fermented vegetable primarily fermented by lactic acid bacteria (LAB), is appreciated for its desirable sensory attributes and various nutritional benefits1. Sodium chloride (NaCl) is a fundamental component in traditional paocai production, where its high concentration is crucial for maintaining color and texture, promoting flavor development, and ensuring extended shelf life2,3. However, excessive sodium consumption is linked to increased risk of numerous health complications, imposing a substantial economic strain on healthcare systems4.

NaCl plays a multifaceted role in paocai fermentation, impacting water activity, oxygen solubility, osmotic pressure, and nutrient availability, thereby influencing microbial activity and metabolite production5,6. While high salinity enhances safety and flavor, low salinity increases spoilage risks, underscoring the challenge of producing palatable, low-sodium paocai for a health-conscious market7. Partial substitution with potassium chloride (KCl) presents a promising sodium-reduction strategy4, owing to similar flavor and inhibitory effects on spoilage organisms8,9,10. Previous studies have successfully employed KCl as a partial replacement for NaCl in the production of wheat bread, table olives, and shalgam, showing that these products can meet consumer demand for lower sodium intake without sacrificing traditional sensory qualities10,11,12,13. Furthermore, Li et al.14 observed that KCl promoted LAB growth and lactic acid production in the fermentation of northeastern sauerkraut. These findings suggest that KCl may be the most suitable salt substitute for reducing dietary sodium, particularly in traditional fermented foods where such substitutions can be implemented without negatively affecting sensory attributes. However, a comprehensive understanding of fermentation kinetics and flavor variations resulting from KCl substitution in paocai remains necessary.

The flavor profile of food products is a key determinant of palatability and a major factor influencing consumer acceptance15. While unsupervised methods like principal component analysis (PCA) are commonly employed for dimensionality reduction and statistical analysis of flavor datasets, they may not fully capture nuanced flavor relationships15,16. Supervised learning algorithms, particularly Random Forest (RF) and support vector machine (SVM), offer enhanced capabilities for flavor prediction through classification and regression analyses based on user-defined hypotheses15. The RF model, known for its robustness and ability to handle high-dimensional data, has demonstrated accuracy in predicting sensory attributes of diverse compounds16, as exemplified by its use in tracing fishy off-flavors in milk powder17. Therefore, a supervised learning approach, particularly utilizing RF modeling, provides an innovative framework for predicting and tailoring flavor attributes, offering significant potential for optimizing potassium-substituted pickle products.

Based on our previous finding that Levilactobacillus brevis enhanced radish paocai fermentation and flavor18, this study quantified the impact of NaCl substitution with KCl on the flavor profile of L. brevis fermented paocai. A controlled fermentation study was conducted, employing KCl replacement levels of 0%, 10%, 30%, and 50% while maintaining a total salt content of 1.5%. Fermentation kinetics, physicochemical properties, and key flavor compounds were subsequently analyzed. Mathematical models were developed to assess the influence of KCl substitution on microbial growth. Finally, machine learning techniques were used to predict and optimize flavor profiles, enabling a multi-parameter optimization approach to predict the optimal KCl substitution level for maximizing sensory acceptability.

Results

Fermentation modeling

The initial LAB counts in radish paocai were about 7.40 log CFU/g (Fig. 1a). The LAB counts quickly increased to 8.31–8.47 log CFU/g on the first day of fermentation. On the fifth day of fermentation, the LAB counts reached the highest of 8.75–8.87 log CFU/g, and partial replacement of NaCl with KCl showed no significant impact on LAB growth dynamics. The growth model curves exhibited an inverted mirror J-shape (Fig. 1b–e). The R2 values, all near 1, and RMSE values, all below 1 (Table S1), indicated an excellent fit of the model to the growth data. Model predictions revealed that the highest ymax (2.2410 log CFU/mL) was achieved without KCl substitution (K00).

pH, TTA, and total sugar contents

The pH value and TTA are key parameters for monitoring paocai fermentation. The pH value of radish paocai decreased rapidly from the initial of 5.95 to 3.61 by day 5 before stabilizing. TTA increased from 0.06% to over 0.3% by day 5. During fermentation there were no significant differences in either pH or TTA levels among the different groups (Fig. 1a).

Initially, sugar dissolution exceeded utilization, leading to a peak in sugar content (10.04–12.24 g/L) by day 5. The K10 and K30 groups showed significantly lower sugar contents than other groups (Fig. 1a). As microbial activity persisted and sugar dissolution declined, sugar consumption exceeding dissolution, resulting in decreased sugar content in radish paocai by day 8 (5.25–7.23 g/L) with no significant group differences.

Texture

The textural properties of radish paocai during fermentation, including hardness, chewiness, cohesiveness, and springiness, were shown in Fig. 2. No significant differences were observed in the chewiness, cohesiveness, and springiness of radish paocai after fermentation. However, the hardness of radish paocai displayed a pattern of rising at first, followed by a decline as the fermentation continued. Among all the groups, K50 exhibited the highest hardness.

Profiling of non-VOCs

The levels of mannitol, sucrose, glucose, and fructose throughout fermentation were shown in Fig. S1. Before fermentation, radish paocai contained 1.49, 11.18, and 8.74 g/kg of sucrose, glucose, and fructose, respectively, while mannitol was undetectable. Sucrose was hydrolyzed into glucose and fructose after fermentation19, and was not detected after 5 days. Throughout the fermentation process, glucose was continually utilized, with no significant differences observed among the four groups. Fructose was consumed to form mannitol, contributing to the fresh, sweet taste for radish paocai20. The K30 group produced the highest level of mannitol by day 5, at 5.60 g/kg.

Six OAs were identified in radish paocai, including oxalic acid, tartaric acid, malic acid, lactic acid, acetic acid, and citric acid, with initial contents of 883.67, 52.23, 56.96, 13.27, 11.74, and 29.10 mg/100 g, respectively (Table 1). Oxalic acid was the main OA in radish paocai, and its content remained relatively constant throughout fermentation. The content of citric acid increased during fermentation, whereas the levels of tartaric acid and malic acid decreased. No significant differences were observed in the amounts of citric acid, tartaric acid, and malic acid among the various groups. The contents of lactic acid and acetic acid increased during fermentation. Compared to the other groups, lactic acid and acetic acid levels were significantly lower in the K10-14d and K30-14d groups. The K50 group exhibited the highest levels of lactic acid and acetic acid.

The composition of FAAs contributed to the unique taste profiles of radish paocai. Total 7 FAAs were detected, including those contributing to umami/sour (Asp and Glu), sweet (Ser, Gly, and Ala), and bitter (Val and Ile) tastes (Table S2). Glu and Asp were the main FAAs contributing to umami taste in the NF group. After 14 d of fermentation, the Asp content decreased significantly, and the TAVs values of Asp were less than 1 in all groups. In contrast, the Glu content increased significantly after fermentation. Consequently, Glu became the dominant FAA in radish paocai. The K30 group exhibited the highest TAV value of Glu of 1.40, followed by K10 of 1.34, K50 of 1.32, and K00 of 1.20. Substitution of NaCl with KCl may improve the umami taste, possibly due to the positive influence on proteolytic activity by interactions of salt ions (Na+, K+, Cl−)21. FAAs with sweet and bitter tastes were not major contributors to the overall taste due to their low TAV values18.

VOCs identified by HS-SPME-GC-MS

Total 50 VOCs were detected in radish paocai by HS-SPME-GC-MS, comprising 16 sulfides, 17 alcohols, 5 terpenes, 4 acids, 4 phenols, 2 aldehydes, 1 ketone, and 1 furan (Tables S3 and S4). As shown in Fig. 3a, 10 VOCs were common to all groups. Total 36 VOCs were identified in NF samples, and increased to 43-47 VOCs after fermentation. The contents and composition of VOCs in radish paocai changed significantly after fermentation, with decrease in sulfides and increase in alcohols and acids (Fig. 3b, c). Sulfides were the most abundant VOCs in NF samples (693.96 μg/kg), accounting for 95.06% of the total VOC content, followed by alcohols (2.74%) and terpenes (1.56%). The sulfides content in radish paocai decreased to 54.23–78.05 μg/kg by day 5, and further changed to 49.88–301.86 μg/kg by day 14. In NF samples, alcohols and acids were present at 20.00 μg/kg and 1.10 μg/kg, respectively, increasing to 207.37–593.30 μg/kg and 267.95–439.17 μg/kg after 14 days of fermentation, with significant differences observed among the groups.

The PCA in Fig. 3d revealed clear separation of samples based on fermentation time, while samples with varying KCl to NaCl ratios clustered together. The greater dispersion of samples at 14 days suggested that different contents of KCl replacement of NaCl had a more pronounced impact on the flavor profile of radish paocai in the later stage of fermentation.

KACs identified by HS-SPME-GC-MS

Based on OAV calculation, there were 18 VOCs identified as KACs responsible for the flavor profile of radish paocai, which included 7 sulfides, 6 alcohols, 2 acids, 2 phenols, and 1 aldehyde (Table 2 and Fig. 3e). The NF group exhibited a stronger odor of cabbage, garlic, and onion. At 5 d of fermentation, the odor profile of radish paocai comprised light notes of cabbage, garlic, onion, smoke, and spice. After 14 days of fermentation, the odor profile was dominated by mint, sweet, fruit, floral, herb, wood, mushroom, sour, pungent, smoke, and spice. Compared the total OAVs of KACs among the groups, K30 exhibited the highest total OAVs at both day 5 (126.14) and day 14 (107.59) of fermentation, indicating a more abundant flavor profile characterized by cabbage, mint, and sour notes.

As shown in Table 2, the total OAV of sulfides in NF group reached 11995.44, accounting for 99.87% of the total OAV. After fermentation, the levels of most sulfides decreased significantly except 3-methylthiopropyl isothiocyanate and erucin. On the 5 d of fermentation, dimethyl disulfide was undetectable in the K00 group. The OAVs of dimethyl disulfide remained high, reaching 52.39 in the K30 group, indicating its continued importance as a flavor compound with cabbage, garlic, onion, and meat odors. Additionally, allyl methyl disulfide was the main sulfides on the 5 d of fermentation, which showed the highest OAV in the K50 group (OAV = 68.21), mainly presenting garlic, onion, and leek flavor. After 14 d of fermentation, erucin was not detected in the K00 group, while its OAV significantly increased in radish paocai with KCl substitution, reaching the highest value of 68.96 in the K30 group. Among all groups, the total OAVs of sulfides in the K30 group on the 5-d fermentation were the highest, reaching 114.53.

Six alcohols were considered as the KACs (Table 2 and Fig. 3e). After fermentation, the levels of 1-hexanol, linalool, and α-terpineol increased. 1,8-Cineol was the predominant alcohol in NF group with OAV of 15.23. On the 5 d of fermentation, the OAV of 1,8-cineol decreased significantly to OAV < 1, but increased on the 14 d of fermentation, with the highest OAV of 17.07 in K30 group, contributing the mint, sweet, and camphor odors and enriching the overall fragrance of the K30 group.

Aldehydes and acids were not identified the KACs in NF samples. However, after 14 d of fermentation, the levels of decanal, acetic acid, and hexanoic acid increased, becoming KACs in radish paocai. The decanal content in K50 was notably greater than in other groups, with an OAV of 2.83, presenting fat and floral odors to the radish paocai. Based on the OAVs, acetic acid and hexanoic acid were identified as the KACs in radish paocai of 14 d fermentation. The OAV value of acetic acid in K50-14d (OAV = 1.84) was significantly higher than that in K10-14d (OAV = 1.10). Among all groups, the OAV of hexanoic acid in K10 was the lowest at 2.12, but showed no significant differences in other groups.

4-Ethylphenol and 2-methoxy-4-vinylphenol, absent in NF samples, became KACs after fermentation (Table 2 and Fig. 3e). The levels of 4-ethylphenol in the K00 and K10 groups were significantly higher compared to the K30 and K50 groups. The OAV of 2-methoxy-4-vinylphenol in the K00 group was significantly higher than in other groups, reaching 10.41 and 51.78 at 5 and 14 d of fermentation, respectively.

Key differential aroma compounds identified by HS-SPME-GC-MS

The distribution of VOCs in 14 d fermented radish paocai samples was analyzed using PLS-DA to assess flavor differences among the treatment groups (Fig. S2a). The model demonstrated robustness and high discriminative/predictive capability, with R2X, R2Y, and Q2 parameters of 0.936, 0.984, and 0.906, respectively. Sample distribution revealed clear distinctions, with raw material samples segregating from others, reflected by high negative loadings along the second component. This emphasized the pronounced differences in VOCs profiles between raw and fermented samples. Moreover, the distinct separations among paocai groups with different KCl substitution confirm the significant impact of treatment on VOCs profiles. This observation suggested that partial substitution with KCl significantly altered VOC profiles.

VOCs contributing to sample separations were identified using the VIP parameter, with 23 VOCs exhibiting significant VIP > 1 (Fig. S2b). Among these, erucin, 2-methoxy-4-vinylphenol, 3-methylbutan-1-ol, 1-hexanol, and 1-octen-3-ol also showed OAV > 1 and p < 0.05, and were thus identified as key differential aroma compounds, resulting in the variety of smoke, spice, cabbage, herb, wood, mushroom, fruit, and floral aromas in radish paocai prepared with different KCl substitution (Fig. 4).

Key aroma contributors by RF modeling

Volatile compounds with OAV > 0.1 were selected for analysis due to their significant contribution to flavor through synergistic effects, and their potential to identify key odorants in radish paocai22.To identify key aroma contributors, a RF classifier model was developed and trained using VOCs with OAV > 0.1 (Table S5). Data augmentation techniques were employed to improve model performance and reduce the risk of overfitting and gradient disappearance. The augmented data demonstrated a high degree of overlap with the original data in principal component space (Fig. S2c), confirming that the augmentation process effectively expanded the dataset without introducing significant bias. The RF model demonstrated strong predictive performance, with a cross-validation accuracy of 0.9772 ± 0.0186. Based on feature importance, as determined by the mean decrease in impurity, the analysis identified five key volatile compounds: erucin, 3-nonanol, 1-hexanol, 3-methylbutan-1-ol, and 2-methoxy-4-vinylphenol (Fig. S2d).

VOCs identified by HS-GC-IMS

Using HS-GC-IMS, we further investigated the VOCs of radish paocai fermented for 14 days (Table S6). A total of 26 VOCs were determined, including 7 sulfides, 5 alcohols, 2 aldehydes, 1 ketone, 2 acids, 1 phenol, 7 esters, and 1 pyrazine. Volatile fingerprints of radish paocai were constructed by analyzing the retention and drift times of these identified VOCs (Fig. 5). In the resulting fingerprint visualization, each column corresponds to a distinct volatile compound across various samples, while each row signifies the signal peak for an individual sample. The intensity of the coloration corresponds to the content of the volatile components, with brighter colors indicating higher contents. To facilitate more accurate comparisons of flavor properties among groups, the fingerprint changes were presented in separate frames in Fig. 5, divided into three regions labeled A, B, and C.

As shown in Figs. 5 and S3, six VOCs in region A containing 5-methylfurfural, furfural, acetic acid, ethyl butyrate, γ-butyrolactone, and methyl thiocyanate were considered as the characteristic VOCs of K00, accounting for 21.26% of the total VOCs in K00. Compared to other groups, the proportion of aldehydes in K00 was the highest of 14.04%. Fifteen VOCs were identified in region B. Among these, (E)-2-hexen-1-ol, methyl propyl disulfide, phenylethyl acetate, hexanoic acid, 2-ethyl-3,5-dimethylpyrazine, diallyl disulfide, dimethyl disulfide, 3-hydroxybutan-2-one, amyl acetate, and benzyl acetate level in the K30 group were significantly elevated compared to the other groups. The observed increase of sulfides such as diallyl disulfide and dimethyl disulfide in K30 might be attributed to the addition of K+, which stimulated cystathionine (beta)-lyase enzyme activity23,24. The formation of esters was usually caused by the esterification action involving acids and alcohols25. The VOCs of 4-ethylphenol, dimethyl trisulfide, butyl acetate, 3-methylbutan-1-ol, and 2-methylbutan-1-ol in region C exhibited higher contents in K50 and accounted for 2.56% of the total content (Fig. S3). These VOCs were mainly alcohols and could be considered as characteristic VOCs of K50. The accumulation of alcohols might be caused by the reduction of aldehydes, or by the production of LAB via the pyruvate metabolic pathway26. In the K50 group, the contents of 4-ethylphenol, dimethyl trisulfide, and butyl acetate were significantly greater than in the other groups, which contributed to the cocoa, malt, fruit, and cabbage odors for the radish paocai.

Taste characteristics by E-tongue

The E-tongue analysis was used to evaluate the taste characteristics of radish paocai fermented for 14 days, as shown in Fig. 6a. The tasteless was the output of the reference solution. Sourness, umami, saltiness, and sweetness were the main differences taste indexes of radish paocai, with the sweetness lower than the tasteless point. From K00 to K50, the sourness and saltiness of radish paocai decreased, while the sweetness and umami increased, and the changes mainly occurred between K10 and K30. Richness refers to the aftertaste of umami, emphasizing the enduring quality of umami, also refers to as umami persistence. The richness of radish paocai showed no significant differences among the groups. The astringency of K00-K50 ranged from 3.24 to 3.36, and the bitterness ranged from 6.02 to 5.88. The differences of astringency and bitterness among groups were too small and impossible to distinguish for people. Due to the high sensitivity of the E-tongue, the differences could be reflected. Aftertaste-B and aftertaste-A reflected the residual levels of bitterness and astringency, respectively, indicating no significant difference among the groups. Overall, NaCl replacement with KCl could reduce the sourness and saltiness of radish paocai, enhance the sweetness and umami, indicating that it was beneficial for improving the flavor of radish paocai.

Sensory properties

No substantial differences in color were observed among the four groups (Fig. 6b). The crispness of the radish paocai in the KCl replacement groups was enhanced, indicating improved texture. This may be attributed to K+ ions acting as compatible solutes, enabling their uptake and accumulation within cells. This intracellular accumulation counteracts cell swelling caused by increased external osmotic pressure, thereby better preserving the radish texture27. The K30 and K50 groups exhibited higher carbonate sensations. This carbonation is due to CO2 production during fermentation, which imparts a refreshing taste to fermented vegetables28. Bitterness was not a dominant taste attribute in the radish paocai, however, the K50 group exhibited the highest bitterness intensity among the four groups. At low levels, bitterness can contribute to the overall complexity and richness of the flavor profile. The K30 group exhibited higher sourness, sweetness, umami, and overall acceptability than other groups, indicating that replacing 30% NaCl with KCl could enhance the sensory quality of radish paocai.

Discussion

This study comprehensively investigated the effects of partial NaCl replacement (0%, 10%, 30%, and 50%) with KCl on the fermentation kinetics, flavor profiles, and sensory quality of radish paocai, employing growth modeling, flavor omics, data augmentation, and machine learning approaches.

Fermentation modeling illustrated the fitting results of the modified Weibull growth model to experimental data for LAB growth in radish paocai treated with varying levels of KCl substitution for NaCl. Model predictions revealed that the highest ymax was achieved without KCl substitution (K00), suggesting that partial replacement of NaCl with KCl may have inhibited the maximum potential growth increment of LAB. This inhibitory effect could be attributed to the antimicrobial properties of chloride salts such as KCl and MgCl2 on each growth phase of LAB, in addition to NaCl29. However, some studies have reported that KCl stimulates the maximum specific growth rate of LAB30, potentially explaining the rapid early-stage growth observed in K50 (k = 0.4918).

The observed pH decrease and TTA increase resulted from LAB metabolism and OAs production31. Crucially, TTA showed no significant variation, suggesting that KCl substitution for NaCl did not significantly influence radish paocai maturation. The texture softening observed in the later stage might be due to the buildup of soluble pectin32. This enhancement in hardness might due to the negative impact of potassium chloride on the production of pectinase, which is crucial for the breakdown of pectin33.

Vegetable sugars served as the primary carbon source during paocai fermentation, with sugar levels determined by dissolution from vegetables and microbial consumption34,35. Throughout the fermentation process, glucose was continually utilized, with no significant differences observed among the four groups. Fructose was consumed to form mannitol, contributing to the fresh, sweet taste for radish paocai20. Replacing NaCl with KCl in radish paocai significantly increased mannitol yield, indicating a positive influence of KCl on mannitol production.

OAs were essential flavor compounds in fermented vegetables and played a crucial role in inhibiting harmful microorganisms36. The changes in citric acid, tartaric acid, and malic acid contents during radish paocai fermentation aligned with previous studies indicating that L. brevis can metabolize tartaric acid into malic acid and succinic acid. Malic acid can be further metabolized via the malolactic fermentation pathway, resulting in reduced malic acid and increased lactic acid37,38. Lactic acid and acetic acid were the primary metabolites produced by heterofermentative LAB18. Based on the TAVs of OAs and the water dilution effect, lactic acid was identified as the primary contributors to the sour taste for radish paocai. Compared to the other groups, lactic acid and acetic acid levels were significantly lower in the K10-14d and K30-14d groups, possibly due to the influence of KCl on the malolactic pathway and pyruvate metabolism in L. brevis, given that malate dehydrogenase and pyruvate dehydrogenase were K⁺-dependent39. The K50 group exhibited the highest levels of lactic acid and acetic acid, suggesting that replacing 50% of NaCl with KCl could notably enhance the production of these acids and increase the sour taste of radish paocai.

Comparing HS-SPME-GC-MS and HS-GC-IMS, HS-SPME-GC-MS identified a total of 50 VOCs in radish paocai, which was significantly more than the 26 VOCs identified by HS-GC-IMS. Moreover, HS-SPME-GC-MS identified more sulfides and alcohols in paocai, while HS-GC-IMS detected more esters, as it was more effective in detecting VOCs with low molecular weight40. Additionally, HS-GC-IMS provided several benefits, such as enhanced analytical efficiency, the ability to visualize flavor compounds, and a lower cost41. However, as an emerging technology, the database of HS-GC-IMS is incomplete42. Therefore, using HS-GC-IMS as an additional technique alongside HS-SPME-GC-MS could facilitate a more thorough description of the flavor quality of paocai.

Sulfides are characteristic olfactory compounds in fermented vegetables, providing paocai cabbage, onion, and pungent flavors43. In NF group, the sulfides mainly including dimethyl trisulfide, dimethyl disulfide, and allyl methyl disulfide contributed cabbage, garlic, and onion odors, which were the primary flavor components of unfermented radish paocai. In radish paocai with potassium chloride replacing sodium chloride, the OAVs of dimethyl disulfide remained high, indicating its continued importance as a flavor compound with cabbage, garlic, onion, and meat odors. Sulfides exhibited unique olfactory characteristics due to their low odor thresholds and were described as sulfurous and spicy44. Most of these sulfides can be attributed to plant flavor components and their degradation products, or they result from the degradation of sulfur-containing FAAs (e.g., cystine, cysteine, and methionine), which is expected given the purpose flavor in paocai production (Fig. 7)45,46. Potassium ions may increase the activity of enzymes involved in sulfide generation or reduce the activity of enzymes involved in sulfide degradation, thereby increasing the sulfides contents47. The formation of aldehydes might be related to the hydrolysis of hemicellulose48. KCl might affect the hydrolysis reactions during the fermentation process of radish paocai, and increase the production of aldehydes such as furfural, contributing caramel-flavored for radish paocai49. Replacing NaCl with KCl effectively enhanced the caramel-like flavor caused by furfural and alleviated the pungent taste from methyl thiocyanate in radish paocai. Ketone, terpenes, and furans were present in relatively low contents and generally had high odor thresholds, therefore, their OAVs were less than 1, indicating that they were not the KACs in radish paocai. Among the groups, the K30 group exhibited the most abundant flavor compounds, which enhanced cabbage and fruit aroma to radish paocai. It was concluded that KCl substitution effectively enhanced mushroom, cabbage, spice, and caramel aromas, while reducing pungent odors in radish paocai.

The metabolic pathways were retrieved from the KEGG pathway database (https://www.genome.jp/kegg/pathway.html) and heatmaps reflecting the changes of some important flavor compounds.

This study highlighted the effectiveness of the RF model in identifying key aroma contributors in radish paocai, particularly when combined with data augmentation techniques. Notably, erucin, 1-hexanol, 3-methylbutan-1-ol, and 2-methoxy-4-vinylphenol also met the screening criteria of OAV > 1, VIP > 1, and p < 0.05 (Fig. 4), suggesting their crucial role in the flavor differences of radish paocai prepared with KCl substitution for NaCl. Erucin is a characteristic flavor compound in cruciferous vegetables, including radish, and their processed product2,18. 2-Methoxy-4-vinylphenol is one of the skeleton aroma-active compounds in radish paocai50. The congruence between the findings of this study and previous studies reinforced the pivotal role of these VOCs in shaping the characteristic aroma profile of radish paocai.

In conclusion, replacing 30% of NaCl with KCl presents a highly effective and practical strategy for producing low-sodium radish paocai that not only meets consumer health demands but also exhibits an enhanced sensory profile. These findings have significant practical implications for the fermented food industry, offering a viable, data-driven approach to sodium reduction without compromising the authentic flavor crucial for consumer acceptance. The identification of key molecular markers like erucin and 1-hexanol provides a quantitative tool for quality control and targeted flavor optimization in industrial production. Despite these promising results, this study has limitations that open avenues for future research. Our work focused on the final flavor profile but did not elucidate the underlying molecular mechanisms, particularly how KCl substitution affects the enzymatic activity and metabolic regulation of the fermenting microbiota, such as Levilactobacillus brevis. Future studies should, therefore, incorporate proteomic and transcriptomic analyses to map the metabolic pathways and gene regulatory networks influenced by KCl. Such insights would bridge the gap between salt substitution and microbial response, enabling the rational design of healthier, low-sodium fermented vegetables with precisely engineered sensory attributes.

Methods

Materials

Radish (Raphanus sativus L.) and other paocai ingredients were purchased from Yantai, China. MRS broth was obtained from Aobox (Beijing, China). Organic acids (OAs), free sugars, mannitol, amino acid standards, 3-octanol, n-alkanes standard (C7-C30), and n-ketones standard (C4-C9) were obtained from the Sigma Chemical Co. (St. Louis, USA).

Starter culture

The LAB strain L. brevis PL6-1 (CGMCC 19868) was incubated in MRS broth as the method described by Zhang et al.18.

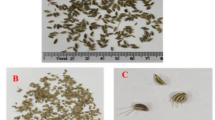

Paocai making and sampling

The preparation of radish paocai followed the modified method proposed by Zhang et al.18. Salt content was 1.5%, and four treatments were designed based on the following salt compositions: [K00] with 100% NaCl, [K10] with 90% NaCl and 10% KCl, [K30] with 70% NaCl and 30% KCl, and [K50] with 50% NaCl and 50% KCl. The starter was inoculated at the initial count of 7.00–7.50 log CFU/g for paocai fermentation. The fermentation of paocai was conducted at 15 °C for 14 d.

The fermented radish and brine were sampled with 1:1 (w/w) on 0, 1, 3, 5, 8, 11, and 14 d, then homogenized to prepare for subsequent analyses.

LAB counts and fermentation modeling

The LAB counts were determined using plate counting method with MRS agar and expressed in log CFU/g. The growth kinetics of LAB in radish paocai subjected to varying levels of KCl substitution for NaCl were described using a modified Weibull model51. Specifically, an exponential decay term e-μt was incorporated to account for the observed post-growth decline. A new parameter, N0 (initial value), was introduced to ensure the model starts from a non-zero baseline. Prior to model fitting, the microbial growth data, expressed as log CFU/g, underwent rigorous preprocessing, including outlier identification and removal, and imputation of any remaining missing values. For fitting the sigmoidal-shaped curve to the growth data, the following Eq. (1) was used:

Note: N(t) represents the growth quantity at time t, N0 is the initial growth quantity (baseline value), ymax denotes the maximum possible growth increment, λ is the scale parameter (controlling the timescale of growth rate), k is the shape parameter (governing the curve’s shape, k > 0), and μ is the decay rate parameter (regulating the rate of late-phase decline, μ ≥ 0).

Model performance was assessed using the coefficient of determination (R2) and the root mean square error (RMSE). Higher R2 values and lower RMSE values indicate superior model fit, reflecting improved predictive accuracy. The equations for calculating R2 and RMSE were given as follows52:

Note: yi denotes the i-th observed value (actual measured value), ŷi is the i-th predicted value (model fitted value), and ȳ represents the mean of all observed values, and n is the sample size.

Physicochemical properties and texture analysis

The pH value, total titratable acidity (TTA), total sugar content, and texture of radish paocai were determined following established methodologies18.

Non-VOCs analysis

Non-VOCs including OAs, mannitol, free sugars, and FAAs were determined as described in our previous work18. The taste activity values (TAVs) of OAs and FAAs were calculated based on their respective taste thresholds (TTs). The compounds with TAV > 1 were considered significant contributors to the overall flavor profile.

VOCs analysis

The VOCs of radish paocai were analyzed using two complementary techniques: Headspace solid phase microextraction-gas chromatography (HS-SPME-GC-MS) and headspace-gas chromatography-ion mobility spectrometry (HS-GC-IMS). The HS-SPME-GC-MS methodology was based on the method described by Zhang et al.18.

The HS-GC-IMS analysis was performed using the main system (FlavorSpec, G.A.S. mbH, Dortmund, Germany) equipped with a MXT-5 column (30 m × 0.53 mm i.d., 0.1 µm film thickness, RESTEK) and an autosampler headspace unit (CTC Analytics AG, Zwingen, Switzerland). The homogenized sample (3 g) was transferred to a 20 mL headspace glass vial. Following incubation at 60 °C for 15 min, 100 μL of headspace gas was injected at 65 °C in splitless mode. The chromatography parameters were as follows: Drift gas flow rate (E1): 150 mL/min, carrier gas flow rate (E2): 2 mL/min for 2 min, increased to 100 mL/min, and maintained at 100 mL/min for 18 min. VOCs were identified by comparing RI and drift time with the HS-GC-IMS library.

Identification of key differential aroma compounds

The odor activity value (OAV) was determined using the formula OAV = C/OT, where C denotes the content of VOC (μg/kg), and OT (μg/kg) represents the odor threshold of the VOC in water46. The VOC with OAV > 1 was defined as the key aroma-active compounds (KACs) to the overall flavor profile.

To identify the KACs responsible for aroma variations, differential VOCs with OAV > 1, VIP (variable importance in projection) > 1, and p < 0.05 were further screened as the key differential aroma compounds that might lead to aroma differences of radish paocai with partial replacement of NaCl by KCl.

Machine learning methodology for flavor profiling

Volatile compounds with OAV > 0.1 were subjected for data augmentation based on the method of Chang et al.53 with some modifications. The data augmentation procedure, implemented in a Python 3.11.7 environment, utilized a custom-developed smart_augmentation() function. Prior to augmentation, raw data were loaded and preprocessed using the pandas and numpy libraries. Global statistical measures, including the mean and standard deviation, were calculated according to Eqs. (4) and (5), respectively. Special attention was given to verifying the integrity of the group variable in the final column and to ensuring that computed standard deviations met a minimum threshold of 0.1 to prevent numerical instability.

Note: μj denotes the global mean of feature j, N indicates the total number of samples, xij represents the value of the j-th feature in the i-th sample, and σj is the global standard deviation of feature j (with a lower bound set at 0.1).

For noise generation, a quasi-Monte Carlo sampling approach was employed through scipy.stats.qmc.LatinHypercube(), with subsequent scaling of the noise distribution to appropriate intervals using qmc.scale() as specified in Eq. (6).

Note: \({\epsilon }_{j}^{{\prime} }\) denotes the scaled noise, constrained to the range \([-2\times \lambda \times {\sigma }_{j},2\times \lambda \times {\sigma }_{j}]\), \({\epsilon }_{j}\) represents the standardized noise generated through data enhancement method based on Latin hypercube sampling (bounded within [0,1]), \({\sigma }_{j}\) indicates the global standard deviation of the j-th feature, and λ functions as the noise intensity parameter.

Following initial noise injection (Eq. 7), an exponential correction (Eq. 8) was applied to eliminate physiologically implausible negative values and maintain the biological validity of augmented samples.

Note: \({x}_{{ij}}^{{new}}\) corresponds to the noise-augmented feature value, λ parameterizes the noise intensity, \({\epsilon }_{j}^{{\prime} }\) constitutes the scaled noise component, \({\sigma }_{j}\) is defined as the standard deviation for feature j, and 1e-6 provides numerical stabilization by preventing division-by-zero exceptions.

PCA was conducted on both the original and augmented datasets. The augmented data were considered acceptable for machine learning model training if they maintain a similar structural distribution to the corresponding original data in the PCA space, thus preserving group integrity.

A predictive model was constructed using the RF classifier algorithm (scikit-learn, Python). Prior to model training, concentration data for compounds with OAV > 0.1 were preprocessed using the pandas and numpy libraries. Outliers and missing values were addressed using the 3σ principle, as defined in Eq. (9).

Note: x represents the data retention range, μ denotes the mean, and σ stands for the standard deviation.

The data was split into training and testing sets in a 7:3 ratio using the train_test_split() function, with the stratify parameter set to maintain class proportions and random_state of 42 for reproducibility. A 5-fold cross-validation was performed (using the cross_val_score() function), and the mean cross-validation accuracy and its standard deviation were computed using Eq. (10) and Eq. (11), respectively.

Note: Acc represents the mean cross-validation accuracy, k denotes the total number of folds (k = 5), TP/TN indicates the true positives/negatives for the i-th fold, FP/FN refers to the false positives/negatives for the i-th fold, \(\sigma\) denotes the standard deviation of cross-validation accuracy, \({{Acc}}_{i}\) indicates the accuracy of the i-th validation fold, and \({\mu }_{{Acc}}\) is the mean accuracy across all k folds.

Feature importance was calculated based on Random Forest’s built-in impurity reduction algorithm. The relative contribution of each feature to model predictions was directly obtained through the feature_importances_attribute, and finally, the feature ranking result was output by pandas. DataFrame().

E-tongue analysis

The E-tongue analysis was performed base on a previous study18. The taste profile of radish paocai was conducted by a TS-5000Z E-tongue system (Insent Inc., Japan) and evaluate 9 basic taste attributes including sourness, bitterness, astringency, aftertaste-bitterness, aftertaste-astringent, umami, richness, saltiness, and sweetness.

Sensory evaluation

The sensory evaluation was conducted in accordance with protocols approved by the Institutional Review Board of Ludong University (U-IRB202407002). Eleven trained assessors (5 males and 6 females, aged 20–45 years) were recruited according to ISO 4121:2003 and GB/T 29604-2013 guidelines. Quantitative descriptive analysis (QDA) was employed to evaluate sensory properties, including appearance (whiteness, glossiness), texture/mouthfeel (crispness, carbonation), flavor (sourness, saltiness, sweetness, bitterness, and umami), and overall acceptability. The samples, prepared with radish and brine in a 1:1 ratio, were coded with random three-digit numbers. Assessors evaluated each sample using a 9-point intensity scoring scale, where 1–2 denoted very weak, 3–4 represented ordinary, 5–6 indicated moderate, 7–8 reflected strong, and 9 signified very strong.

Data analysis

The data were presented as means ± standard deviation. Statistical comparisons were performed using one-way ANOVA (p < 0.05) with SPSS statistics version 22 (IBM, Armonk, NY, USA). A clustered heatmap was generated using the Hiplot platform (https://hiplot.cn/). Unsupervised principal component analysis (PCA) and partial least squares discriminant analysis (PLS-DA) were conducted with Simca 14.1 (Umetrics, Umea, Sweden) for comprehensive statistical evaluations.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Lu, Y. et al. Fermented vegetables in China: overview, novel processes, influencing factors, lactic acid bacteria and industrialisation status. Int. J. Food Sci. Technol. 59, 4420–4436 (2024).

Mi, T. et al. Effects of salt concentration on the quality and microbial diversity of spontaneously fermented radish paocai. Food Res. Int. 160, 111622 (2022).

Zhang, Q. et al. Microbial safety and sensory quality of instant low-salt Chinese paocai. Food Control 59, 575–580 (2016).

Lin, X. et al. Sodium reduction in traditional fermented foods: challenges, strategies, and perspectives. J. Agric. Food Chem. 69, 8065–8080 (2021).

Panagou, E., Hondrodimou, O., Mallouchos, A. & Nychas, G.-J. A study on the implications of NaCl reduction in the fermentation profile of Conservolea natural black olives. Food Microbiol. 28, 1301–1307 (2011).

Lee, M., Song, J. H., Jung, M. Y., Lee, S. H. & Chang, J. Y. Large-scale targeted metagenomics analysis of bacterial ecological changes in 88 kimchi samples during fermentation. Food Microbiol. 66, 173–183 (2017).

Bordin, M. S. P. et al. Mathematical modeling of multicomponent NaCl and KCl diffusion process during the salting of pre-cooked champignon mushrooms. Food Chem. 273, 99–105 (2019).

Bidlas, E. & Lambert, R. J. W. Comparing the antimicrobial effectiveness of NaCl and KCl with a view to salt/sodium replacement. Int. J. Food Microbiol. 124, 98–102 (2008).

Cepanec, K., Vugrinec, S., Cvetković, T. & Ranilović, J. Potassium chloride-based salt substitutes: A critical review with a focus on the patent literature. Compr. Rev. Food Sci. F. 16, 881–894 (2017).

Tzamourani, A. et al. Inoculated fermentation of cv. Conservolea natural black olives with multifunctional starter cultures in reduced‐sodium brines. Int. J. Food Sci. Technol. 59, 4093–4108 (2024).

Reißner, A.-M., Wendt, J., Zahn, S. & Rohm, H. Sodium-chloride reduction by substitution with potassium, calcium and magnesium salts in wheat bread. LWT 108, 153–159 (2019).

Pino, A. et al. Fermentation of Nocellara Etnea table olives by functional starter cultures at different low salt concentrations. Front. Microbiol. 9, 1125 (2018).

Agirman, B. & Erten, H. The influence of various chloride salts to reduce sodium content on the quality parameters of şalgam (Shalgam): a traditional Turkish beverage based on black carrot. J. Food Qual. 2018, 3292185 (2018).

Li, Z. et al. Effect of KCl replacement of NaCl on fermentation kinetics, organic acids and sensory quality of sauerkraut from Northeast China. J. Food Process. Preserv. 46, e16622 (2022).

Zeng, X. et al. Food flavor analysis 4.0: a cross-domain application of machine learning. Trends Food Sci. Technol. 138, 116–125 (2023).

Cai, D., Li, X., Liu, H., Wen, L. & Qu, D. Machine learning and flavoromics-based research strategies for determining the characteristic flavor of food: a review. Trends Food Sci. Technol. 154, 104794 (2024).

Chen, C., Husny, J. & Rabe, S. Predicting fishiness off-flavour and identifying compounds of lipid oxidation in dairy powders by SPME-GC/MS and machine learning. Int. Dairy J. 77, 19–28 (2018).

Zhang, X. et al. Effect of Levilactobacillus brevis as a starter on the flavor quality of radish paocai. Food Res. Int. 168, 112780 (2023).

Choi, Y.-J. et al. Changes in volatile and non-volatile compounds of model kimchi through fermentation by lactic acid bacteria. LWT 105, 118–126 (2019).

Seo, H. et al. Suitability analysis of 17 probiotic type strains of lactic acid bacteria as starter for kimchi fermentation. Foods 10, 1435 (2021).

Gan, X. et al. Does protein oxidation affect proteolysis in low sodium Chinese traditional bacon processing? Meat Sci. 150, 14–22 (2019).

Li, Y. et al. Identification, quantitation and sensorial contribution of lactones in brandies between China and France. Food Chem. 357, 129761 (2021).

Wang, Z. et al. Identification and functional characterization of a cystathionine β-lyase (CBL) enzyme for H2S production in Arabidopsis thaliana. Plant Physiol. Biochem. 182, 76–89 (2022).

María Fernández et al. Molecular and functional analyses of the metC gene of Lactococcus lactis, encoding cystathionine beta-lyase. Appl. Environ. Microbiol. 66, 42–48 (2000).

Zhao, Y., Wu, Z., Miyao, S. & Zhang, W. Unraveling the flavor profile and microbial roles during industrial Sichuan radish paocai fermentation by molecular sensory science and metatranscriptomics. Food Biosci. 48, 101815 (2022).

Qi, J. et al. Insights into the improvement of bioactive phytochemicals, antioxidant activities and flavor profiles in Chinese wolfberry juice by select lactic acid bacteria. Food Biosci. 43, 101264 (2021).

Ruan, J. et al. Effect of partial replacement of NaCl by KCl and calcium ascorbate on the dynamics of bacterial community during storage of bacon based on 16S rRNA gene amplicon sequencing. LWT 184, 115013 (2023).

Kang, S.-M., Yang, W.-S., Kim, Y.-C., Joung, E.-Y. & Han, Y.-G. Strain improvement of Leuconostoc mesenteroides for kimchi fermentation and effect of starter. Microbiol. Biotechnol. Lett. 23, 461–471 (1995).

Bautista-Gallego, J., Arroyo-López, F. N., Durán-Quintana, M. C., & Garrido-Fernández, A. Individual effects of sodium, potassium, calcium, and magnesium chloride salts on Lactobacillus pentosus and Saccharomyces cerevisiae growth. J. Food Prot. 71, 1412–1421 (2008).

Arroyo-López, F. N., Bautista-Gallego, J., Chiesa, A., Durán-Quintana, M. C. & Garrido-Fernández, A. Use of a D-optimal mixture design to estimate the effects of diverse chloride salts on the growth parameters of Lactobacillus pentosus. Food Microbiol. 26, 396–403 (2009).

Zhao, N. et al. Assessment of biogenic amine and nitrite production in low-salt Paocai during fermentation as affected by reused brine and fresh brine. Food Biosci. 41, 100958 (2021).

Kim, J. Y., Kim, B. S., Kim, J. H., Oh, S. I. & Koo, J. Development of dynamic model for real-time monitoring of ripening changes of kimchi during distribution. Foods 9, 1075 (2020).

Mohandas, A. et al. Production of pectinase from Bacillus sonorensis MPTD1. Food Technol. Biotechnol. 56, 110–116 (2018).

Jeong, S. H., Jung, J. Y., Lee, S. H., Jin, H. M. & Jeon, C. O. Microbial succession and metabolite changes during fermentation of dongchimi, traditional Korean watery kimchi. Int. J. Food Microbiol. 164, 46–53 (2013).

Zhao, N. et al. Illumination and reconstruction of keystone microbiota for reproduction of key flavor-active volatile compounds during paocai (a traditional fermented vegetable) fermentation. Food Biosci. 56, 103148 (2023).

Wang, J. et al. SPME/GC-MS characterization of volatile compounds of Chinese traditional-chopped pepper during fermentation. Int. J. Food Prop. 22, 1863–1872 (2019).

Kaneuchi, C., Seki, M. & Komagata, K. Production of succinic acid from citric acid and related acids by Lactobacillus strains. Appl. Environ. Microbiol. 54, 3053–3056 (1988).

Luo, Y. et al. Sichuan paocai fermented by mixed-starter culture of lactic acid bacteria. Food Sci. Nutr. 8, 5402–5409 (2020).

Perkins, J. & Gadd, G. M. Interactions of Cs+ and other monovalent cations (Li+, Na+, K+, Rb+, NH4+) with K+-dependent pyruvate kinase and malate dehydrogenase from the yeasts Rhodotorula rubra and Saccharomyces cerevisiae. Mycol. Res. 100, 449–454 (1996).

Chen, K. et al. Feasibility of using gas chromatography-ion mobility spectrometry to identify characteristic volatile compounds related to brandy aging. J. Food Compos. Anal. 98, 103812 (2021).

Fan, X., Zhong, M., Feng, L., Huo, Y. & Pan, L. Evaluation of flavor characteristics in tartary buckwheat (Fagopyrum tataricum) by E-nose, GC-IMS, and HS-SPME-GC-MS: influence of different roasting temperatures. LWT 191, 115672 (2024).

Yao, W. et al. Flavor profile analysis of grilled lamb seasoned with classic salt, chili pepper, and cumin (Cuminum cyminum) through HS-SPME-GC-MS, HS-GC-IMS, E-nose techniques, and sensory evaluation on Sonit sheep. Food Chem. 454, 139514 (2024).

Zhao, N. et al. Multiple roles of lactic acid bacteria microflora in the formation of marker flavour compounds in traditional Chinese paocai. RSC Adv. 6, 89671–89678 (2016).

Li, H. et al. The impact of different cooking methods on the flavor profile of fermented Chinese spicy cabbage. Molecules 28, 6539 (2023).

Zhou, Q. et al. Unraveling the core bacterial community responsible for quality and flavor improvement of the radish paocai during spontaneous fermentation. Food Biosci. 55, 102956 (2023).

Xiao, M. et al. Exploring the typical flavours formation by combined with metatranscriptomics and metabolomics during Chinese Sichuan paocai fermentation. LWT 153, 112474 (2022).

Bones, A. M. & Rossiter, J. T. The enzymic and chemically induced decomposition of glucosinolates. Phytochemistry 67, 1053–1067 (2006).

Boguta, A. M., Bringel, F., Martinussen, J. & Jensen, P. R. Screening of lactic acid bacteria for their potential as microbial cell factories for bioconversion of lignocellulosic feedstocks. Microb. Cell Fact. 13, 97 (2014).

Liu, L. et al. Corn stover pretreatment by inorganic salts and its effects on hemicellulose and cellulose degradation. Bioresour. Technol. 100, 5865–5871 (2009).

Zhao, Y. et al. Characterization of aroma and bacteria profiles of Sichuan industrial paocai by HS-SPME-GC-O-MS and 16S rRNA amplicon sequencing. Food Res. Int. 149, 110667 (2021).

Yin, X., Goudriaan, J., Lantinga, E. A., Vos, J. & Spiertz, H. J. A flexible sigmoid function of determinate growth. Ann. Bot. 91, 361–371 (2003).

Zhu, M. et al. Machine learning-assisted aroma profile prediction in Jiang-flavor baijiu. Food Chem. 478, 143661 (2025).

Chang, H., Sun, Y., Lu, S. & Lin, D. A multistrategy differential evolution algorithm combined with Latin hypercube sampling applied to a brain-computer interface to improve the effect of node displacement. Sci. Rep. 14, 20420 (2024).

Li, D. et al. Physiochemical, microbiological and flavor characteristics of traditional Chinese fermented food Kaili Red Sour Soup. LWT 142, 110933 (2021).

Han, D. et al. Characterization and comparison of flavor compounds in stewed pork with different processing methods. LWT 144, 111229 (2021).

Abe, K., Hori, Y. & Myoda, T. Characterization of key aroma compounds in aged garlic extract. Food Chem. 312, 126081 (2020).

Flavor & Extract Manufacturers Association, https://www.vcf-online.nl/VcfHome.cfm (2025).

Guo, X., Ho, C.-T., Schwab, W. & Wan, X. Effect of the roasting degree on flavor quality of large-leaf yellow tea. Food Chem. 347, 129016 (2021).

Guo, X., Schwab, W., Ho, C.-T., Song, C. & Wan, X. Characterization of the aroma profiles of oolong tea made from three tea cultivars by both GC-MS and GC-IMS. Food Chem. 376, 131933 (2022).

Yao, L. et al. Characterization of key aroma compounds in Xinjiang dried figs (Ficus carica L.) by GC-MS, GC-olfactometry, odor activity values, and sensory analyses. LWT 150, 111982 (2021).

Yang, F., Liu, Y., Wang, B., Song, H. & Zou, T. Screening of the volatile compounds in fresh and thermally treated watermelon juice via headspace-gas chromatography-ion mobility spectrometry and comprehensive two-dimensional gas chromatography-olfactory-mass spectrometry analysis. LWT 137, 110478 (2021).

Acknowledgements

This work was supported by Research Projects of Science & Technology Innovation and development Plan in Yantai City (2024XDRH116, 2023ZDCX028), Innovation Project for Graduate Students of Ludong University (IPGS2024-092). The funder played no role in study design, data collection, analysis and interpretation of data, or the writing of this manuscript.

Author information

Authors and Affiliations

Contributions

Yaxin Li: Data curation, Investigation, Writing—original draft; Yunjing Gu: Investigation; Weiye Cheng: Software; Zifan Li: Data curation; Xiru Zhang: Data curation, Writing—original draft; Yaran Zhao: Investigation; Kanghee Ko: Methodology; Wenli Liu: Methodology, Writing—review and editing; Xiaoping Liu: Methodology, Supervision; Huamin Li: Funding acquisition, Methodology, Writing—review and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Y., Gu, Y., Cheng, W. et al. Fermentation modeling and machine learning for flavor prediction in low-sodium radish paocai with potassium chloride substitution. npj Sci Food 9, 156 (2025). https://doi.org/10.1038/s41538-025-00528-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41538-025-00528-2