Abstract

To address the “gel weakening” of fish gelatin (FG) under acidic conditions,this study investigates the enhancement of gel performance in FG through the incorporation of locust bean gum (LBG) and explores its feasibility for application in acidic gel systems. Results show that the gel properties of FG were significantly improved through LBG modification. At pH 3−7, gel strength and melting temperature of LBG-modified FG (FG-LBG) surpassed those of unmodified FG (524.68 ± 1.54 g, 28.86 ± 0.03 °C). Specifically, at pH 3, after LBG modification, the gel strength and melting temperature of FG increased by 62.65% and 29.44%, respectively. LBG alters the conformation of FG via electrostatic and hydrogen bonding interactions, forming a denser polymer network. The acidic gel gummies prepared from the FG modified with LBG exhibit superior gel properties and texture characteristics. This study provides a basis for the modification of FG under acidic conditions.

Similar content being viewed by others

Introduction

Fish gelatin (FG) is a macromolecular polypeptide polymer derived from the hydrolysis of collagen, which has similar multifunctional properties to mammalian gelatin1. Compared with mammalian gelatin, FG could meet the needs of people with special religious and cultural beliefs while avoiding some of the zoonotic threats to human health. In addition, FG has a wide and abundant source of raw materials, as fish processing generated 30% of processing waste, such as fish skin, fish bones, and fish scales, which could be used to extract FG2,3. It could be used as a good substitute for mammalian gelatin. However, the low proline and hydroxyproline contents of FG result in lower rheological and gelling properties than mammalian gelatin4. Therefore, the use of different methods to improve the rheological and gelling properties of FG has been widely discussed by researchers. Common FG modification methods include the mechanical method (high pressure, ultrasonic, irradiation, etc.)5, the aldehyde method6,7, the enzyme method8, polysaccharide modification9,10, etc. Polysaccharide modification has shown greater advantages on account of its simplicity and low cost11. The gelling and rheological properties of FG-polysaccharide composite systems were improved by electrostatic and hydrogen bonding interactions between the polysaccharide molecules and the FG molecules12.

In addition, FG is also used in acidic food environments such as yogurt and acid gel gummies. Acidic conditions have a strong influence on the gelling properties of gelatin. When pH was low, gelling of gelatin was inhibited and led to a suboptimal value13. However, many modification methods were not effective under the condition of strong acid. For examples, γ-Polyglutamic acid (γ-PGA) could improve the gelling properties of FG but have no positive effect under strong acid conditions (pH ≤ 3)14. In addition, the hardness of FG modified by phosphorylation decreased under weak acidic conditions15. Therefore, a method to improve the performance of FG under acidic conditions is urgently needed.

Locust bean gum (LBG) is a type of plant galactomannan extracted from the endosperm of carob seeds. Its main structure is primarily composed of β-(1-4)-D-mannose, with a single α-D-mannose side chain randomly connected at the O-6 of the mannose residue16,17. LBG is used as a thickener, stabilizer, and emulsifier18. Owing to its unique creamy flavour, it is widely used in a variety of food products. LBG could form a highly viscous solution when cooled at a relatively low concentration. It has no gelling properties by itself, but can cooperate with other polysaccharides to improve the viscosity and gel strength of the system18. The interaction between FG and LBG under acidic conditions has not been previously documented.

In this study, tilapia protein gel and LBG were used as experimental materials. Non-covalent modification of FG was carried out by using LBG. The structural and gelling properties of the FG-LBG complexes were investigated at different pH values (2−7). The microstructure was observed using scanning electron microscopy (SEM) to further explore the relationship between properties and structure. This work further explored the intrinsic mechanisms by which LBG improved the gelling properties of FG in acidic environments. The FG-LBG was then applied to acid gel gummies to determine its gelling properties.

Results

Gel strength analysis

The gel strength of gelatin is a critical factor in determining its impact on product quality during application19. As shown in Fig. 1A, the gel strength of group F increased with rising pH, reaching a peak value of 524.68 ± 1.54 g in F7. The gel strength of F group significantly reduced (<400 g) in strong acidic environment (pH ≤ 3). This might be attributed to the inhibition of network structure formation when the FG deviated from the isoelectric point (6.5−9.0)20,21. At extremely acidic pH, the FG network experienced large repulsive forces that separated the FG molecules and prevented them from orientating into the desired network structure. As the pH approached the isoelectric point, intermolecular electrostatic gravitational forces dominated, orienting the FG chains into a more compact structure, which was similar as the report from Goudie, McCreath, Parkinson, Davidson, and Liggat (2023).

A The influence of pH value on the gel strength of the system. Different lowercase letters (a-j) indicated significant differences (P < 0.05). B The influence of pH value on the gelatin melting temperature of the system. Different lowercase letters (a-h) indicated significant differences (P < 0.05). C, D The influence of pH value on the thermal stability of the system.

The gel strength of group L increased and then decreased with the increase of pH. The maximum value of 713.48 ± 6.08 g was reached at L5. Gel strength of FG was significantly increased after modification by LBG. Under the same pH conditions, the gel strength of group L was visibly higher than that of group F (P < 0.05). The negative charge of LBG might interact with the positive charge of FG to promote the formation of gelatin network. With the increase of pH, the interaction weakened and the gel strength decreased. This was similar to the results of Hu et al.14. They found that at pH ≥ 5, FG (positively charged) and γ-PGA (negatively charged) could combine to form complex aggregates through electrostatic interactions. As the pH of the system increased, the positive charge on FG gradually decreased. The alteration in the charge states of FG and LBG results in a reduction in electrostatic attraction between them, which in turn causes a gradual decline in the proportional increase of FG gel strength. Interestingly, at pH 3-7, all gel strength values of group L were higher than the maximum in group F (pH 7). Under the same pH conditions, L3 exhibited the maximum increased ratio of gel strength with 62.65%. The increment in gel strength of group L decreased gradually with the gradual increase of pH. The results showed that LBG was suitable for acidic environments and was effective in improving the gelling properties of FG.

Melting temperature analysis

The melting temperature is one of the important indexes to evaluate the gel properties of gelatin5. The impact of different pH levels combined with LBG modifications on the melting temperature of FG is illustrated in Fig. 1B. The melting temperature of group F increased with increasing pH and reached a maximum value of 28.86 ± 0.03 °C at F7. The melting temperature of FG was lower in strongly acidic environments (pH ≤ 3). However, the melting temperature didn’t change significantly when pH values were 5−7. At the isoelectric point, the positive and negative charges of the entire molecule were balanced, thus promoting helix formation. As the pH deviated from the isoelectric point, the spin decreased as the increase in repulsive charge inhibited the formation of intermolecular helices owing to the increase in repulsive charge22. Between pH 5 - 7, the charges throughout the gelatin network were more balanced. This resulted in a stronger, more compact network with a higher melt temperature.

The melting temperature of group L first increased and then decreased with increasing pH, reaching a maximum value of 34.80 ± 0.12 °C at L3. The melting temperature of FG modified by LBG was already higher than that of mammalian gelatin (28-31 °C)1. Particularly, L3 showed an increase of 7.98 °C over F3. Under the same pH condition, the melting temperature of group L was higher than that of group F (P <0.05). The viscosity of the system increased after modification by LBG, indicating that the interaction between protein molecules changed23. The existence of many -OH groups in the molecular structure of LBG might contribute to the structural strength of the colloidal network by interacting with FG to form hydrogen bonds. This was similar to that reported by Lu et al.24. They found that the LBG enhanced the hydrogen bonding interactions between the casein/κ-carrageenan gel molecules to form a more uniform and dense gel network structure. The thermal stability of casein/κ-carrageenan binary gels could be improved by the addition of appropriate amount of LBG. However, as the pH increased the interaction between the two weakened leading to a decrease in melting temperature. Interestingly, the melting temperature of L group was higher than the highest value of F group (pH 7) at pH values between 3 and 7, which was consistent with the change in gel strength. This suggested that the acidic environment of LBG was effective in improving the gelling properties of FG.

DSC analysis

DSC is capable of detecting changes in the heat flow of a sample during the temperature variation process and is widely employed to assess the thermal stability of the sample. In general, the thermal stability of a protein is defined as the energy required to disrupt its naturally ordered structure. This is attributed to the fact that protein molecules must absorb energy during expansion to overcome intramolecular forces, including disulfide bonds, hydrogen bonds, and hydrophobic interactions25. As shown in Fig. 1C, D, all samples exhibited endothermic peaks within the temperature range of 80-105 °C. When the temperature reaches a specific point, the rate of thermal denaturation of the sample reaches its maximum. At this temperature, denoted as Tp, the denaturation rate is the fastest26. As shown in Fig. 1C, the Tp-values for the F2-F7 samples were 83.32 °C, 89.94 °C, 91.23 °C, 91.06 °C, 92.99 °C, and 99.10 °C, respectively. With increasing pH of the solution, the thermal stability performance of the samples in group F showed an upward trend. Derkach et al.27 found that thermal stability was positively correlated with the content of triple helix structure and molecular weight. Under acidic conditions, the helical structure was disrupted, resulting in a significant decrease in thermal stability. As depicted in Fig. 1D, the Tp-values for the L2-L7 samples were 89.90 °C, 103.12 °C, 99.45 °C, 91.25 °C, 96.72 °C, and 96.65 °C, respectively. With increasing pH of the solution, the thermal stability performance of the samples in group L exhibited a trend of first increasing and then decreasing. Among these, the L3 sample demonstrated the highest thermal stability. This changing trend aligns with the variation trend of the gelation melting temperature observed previously. This phenomenon may be attributed to the presence of numerous hydroxyl groups in the LBG molecular structure, which potentially interact with FG to form hydrogen bonds, thereby enhancing the colloid network structure. Lu et al.24 had reported that LBG could significantly enhance the hydrogen bond interaction between casein/κ-carrageenan gel molecules, promote the formation of a more uniform and dense gel network structure, and improve the thermal stability of the binary casein /κ -carrageenan gel.

Apparent viscosity analysis

Apparent viscosity reflects the change of intermolecular forces of proteins. The greater the intermolecular forces, the higher the apparent viscosity of the protein. Viscosity can control the processing characteristics of gelatin products. It is mainly affected by shear rate, pH, shear pressure and time28. As shown in Fig. 2A–D, except for F7, the shear rate of group F was not significantly affected by pH. The viscosity value of gelatin at pH 2−6 was small thus there was no significant difference. In a strongly acidic environment, the degree of hydrolysis of FG increases, leading to an elevation in low-molecular-weight components and consequently a reduction in viscosity. When the pH gradually increased, the intermolecular electrostatic attraction played a dominant role in promoting the formation of the gel network structure leading to an increase in the viscosity of the solution22.

It was obvious that the apparent viscosity of group L samples gradually decreased (from 0.1 to 100 s) with the increase of shear rate. This shear thinning phenomenon indicates that all samples behave as pseudoplastic fluids. In other words, as the shear rate increased, the molecular entanglement of gelatin gradually decreased29. Deepa Agarwal23 also found that LBG could improve the viscosity of plant proteins. The viscosity of group L exhibited an overall trend of initially increasing and subsequently decreasing. It is worth noting that the viscosities of samples L3 and L4 were significantly higher than those of other samples. This might be related to electrostatic interactions between proteins and polysaccharides FG-LBG could form tighter structures at pH 3-4. The similar situation was reported by Feng30. This could also be one of the reasons for the high melting temperatures of the L3 and L4 samples, where the high viscosity prevented the bubbles from rising (Fig. 1B). In Fig. 2A and C, the change of shear pressure with shear rate was consistent with the change of viscosity, which could help explain the apparent viscosity change law of colloid under shear rate. When the shear rate was low, the shear pressure of the system was also low. The stable state of the solution could not be destroyed, the apparent viscosity value was high. As the shear rate increased, the hydrogen bonds in the protein were broken leading to disintegration of the network structure. Consequently, the apparent viscosity of the composite colloidal solution gradually decreased until it reached an equilibrium state31.

Frequency sweep analysis

The frequency test of colloids can characterize the strength of the gelling properties of colloids32. As shown in Fig. 2 (E-H), the energy storage modulus of all colloids increased with the frequency, which was frequency dependent, indicating that the gel of the colloids was still in progress33. The sizes of m and n were analyzed by Power-law model (G’ (ω) = Aωm, G”(ω) = Bωn). The A (Pa) is the rigidity of FG gel, m means the frequency dependence. In addition, only the change of G’ in this experiment was suitable for the Power-law model, and the simulation degree was relatively high. In group F, pH 5-7 was FG showed higher G’, indicating a denser and more stable intermolecular network structure. It was evident from Table 1 that pH 5-7 had significantly higher A values than other pH. This was related to the content of triple helix. This was a similar result with the gel strength. However, the A-values were lower at pH 2-4. This might be due to the fact that FG undergoes hydrolysis of the high molecular weight material which reduce the content thus weakening the gel network structure22. The tanδ value increased with increasing frequency and this result suggested that the gel network might weaken at high frequencies.

In group L, L5 was exhibited the highest G’, indicating a denser gel network structure. Similar to group F pH 5-7 the A values were significantly higher than other pH. This was similar result with gel strength. It was noted that the A-value of group L was significantly higher than that of group F at the same pH. It was most obvious at pH 3. It might be that the structure of the gel network was enhanced by the electrostatic interaction between FG and polysaccharide molecules34. As shown in Table 1, the m-values of the L group were greater than those of the F group, indicating that the frequency dependence of the gel elasticity properties of the composite colloids was greater than that of the unmodified FG. Overall, the m-values were in the range of 0.0108-0.0249, indicating that there was agglomeration of the colloids, which contributed to the enhancement of their gelling properties35.

Zeta potential analysis

The stability of the composite system comprising FG and LBG at various pH levels, as well as the impact of electrostatic interaction on the system’s stability, can be elucidated through potential analysis. Electrostatic attraction serves as a primary driving force in the condensation process of composite systems36. As shown in Fig. 3A, the absolute value of group F potential decreased gradually with increasing pH. At pH 2, FG exhibited a positive charge and a high H+ concentration within the system, primarily resulting in electrostatic repulsion. As the pH value increased, the H+ concentration decreased while the OH- concentration gradually rose. Consequently, FG molecules were attracted to OH- resulting in a decrease in the potential value due to an increase in electrostatic attraction.

A The influence of pH value on the zeta potential of the system. Different lowercase letters (a-f) indicated significant differences within group F (P < 0.05), different uppercase letters (A-F) indicated significant differences within group L (P < 0.05), and different Roman letters (I - IV) indicated significant differences within group L0 (P < 0.05). B The proportion of gel strength loss of fish gelatin modified with locust bean gum at different pH values. Different lowercase letters indicated significant differences (P < 0.05). C Microstructure of the system at different pH values.

In the L0 group, the absolute value of the potential increased and then decreased with increasing pH. At pH 2, LBG was negatively charged. As the pH increased, the H+ concentration decreased the electrostatic attraction between both LBG molecules and H+ decreased, resulting in an increase in the absolute potential. The polysaccharide and gelatin molecules formed a dense gel network structure through electrostatic interactions37. Therefore, the formation of a complex between positively charged FG and negatively charged LBG through electrostatic interactions contributed to the enhancement of its gelling properties. It was noticed that the potential difference between FG and LBG reached a maximum at pH 3 and pH 4 (p > 0.05). Consequently, under this condition, the stronger electrostatic interaction between FG and LBG led to a significant increase in gel strength and melting temperature.

Gel strength loss analysis

To determine the amount of hydrogen bonding in gelatin samples modified by LBG, urea was added to the samples to evaluate the percentage of gelatin strength loss. It is evident from Fig.3B, the gel strength of all samples decreased significantly when mixed with urea, which illustrated the key role of hydrogen bonding in stabilizing gelatin gels. Hydrogen bonds had a significant effect on gel strength, and the change in hydrogen bonds reflected the change in gel strength1. As shown in Fig. 3B, the hydrogen bonding increased and then decreased with increasing pH, reaching a peak at pH 3. The presence of more H+ ions at pH 2 was more favorable for the formation of hydrogen bonds. At pH 3, hydroxyl groups on the side chains of LBG established hydrogen bonds with amino and carboxyl groups in gelatin, resulting in increased hydrogen bond content and a more stable network structure. Starting at pH 5, the degree of hydrolysis in gelatin decreased38, resulting in a significant decrease in the content of free amino and carboxyl hydrogen bonds. This resulted in less binding to LBG and lower hydrogen bonding content. This change was consistent with the trend of gel strength change in the previous period.

SEM analysis

The SEM results under different pH levels combined with LBG modification on FG are shown in Fig. 3C. Generally speaking, the ordered arrangement and association of protein gel molecules in the gel matrix directly contributed to the improvement in the gel strength of gelatin39. All samples showed a porous network structure. In a strongly acidic environment (pH≤3), group F exhibited a rough, loose and inhomogeneous network structure. In group F, the network structure gradually became dense with increasing pH and the pore size became smaller. This was due to the gradual decrease in electrostatic repulsion, forming an ordered network structure. Group L showed a better and dense network structure compared to group F. This was attributed to the fact that LBG polysaccharide molecules enhanced the network structure of FG through electrostatic and hydrogen bonding interactions. Lu showed that LBG enhanced the hydrogen bonding interactions between protein-carrageenan gel molecules to form a more homogeneous and dense gel network structure24. With the increase of pH, the gel network structure became denser, as well as the voids became smaller and aligned. When pH > 5, the electrostatic interactions between LBG and FG gradually weakened leading to inhomogeneous gels with deformation and protrusion of the surface structure. This was consistent with the previous results of gel strength.

Fourier transform infrared determination (FTIR)

FTIR spectroscopy serves as a critical analytical tool for elucidating the secondary structure of proteins40. In this study, the secondary structure of LBG-modified FG samples at various pH values was characterized by analyzing their FTIR spectra, with the results presented in Fig. 4A, B. Within the wavenumber range of 500−4000 cm-1, the absorption spectra of all samples exhibited similar profiles, featuring four characteristic absorption bands: the Amide A band (Amide-A, 3200-3600 cm-1, corresponding to the stretching vibrations of N-H and O-H), the Amide I band (Amide-I, 1600-1700 cm-1, representing the stretching vibration of C = O and the bending vibration of N-H), the Amide II band (Amide-II, 1500-1550 cm-1, associated with the bending vibration within the N-H plane and the stretching vibration of C-N), and the Amide III band (Amide-III, 1200-1300 cm-1, encompassing the stretching vibration of C-N, the bending vibration of N-H, the stretching vibration of C-C, and the bending vibration of C-H)41,42,43. The amide A absorption peak shifts to lower wavenumbers, and the stronger the hydrogen bond, the more pronounced this peak shift becomes44. As shown in Fig. 4A, F2 - F7 sample amide A absorption peaks were 3409.00, 3377.68, 3342.18, 3335.91, 3325.47, 3317.12 cm - 1. Under acidic conditions, as pH increases, the F-histamine A band shifts towards a lower wavenumbrate direction, indicating an enhanced hydrogen bonding of the amino group. As the pH value of the solution increases, the ability of free amino groups (-NH2) to form hydrogen bonds with water molecules, carboxyl groups or other amino groups significantly enhances, resulting in the amide A band moving towards low frequencies and the gradual formation of intermolecular hydrogen bonds. Enhanced hydrogen bonding is beneficial to improving the gel properties of FG45. This changing trend is consistent with the previous changes in gel properties. As shown in Fig. 4B, the absorption peaks of the amide A band in samples L2-L7 were 3350.53, 3333.83, 3348.44, 3371.42, 3373.58, and 3409.00 cm-1, respectively. In Group L, the absorption peak of the amide A band first shifted towards a lower wavenumber and then towards a higher wavenumber. This indicates that the hydrogen bonds between LBG and FG strengthen and then weaken to each other. Under strongly acidic conditions (pH≤3), the hydrogen bond interaction between FG and LBG was relatively strong. This was consistent with the result of the proportion of gel strength loss. Among all samples, L3 demonstrated the lowest wave number for the Amide A absorption peak, indicating the strongest hydrogen bonding effect within the system at this condition. This result further confirmed that LBG and FG form hydrogen bonds through interaction, thereby improving the gelling properties of FG.

Schematic model

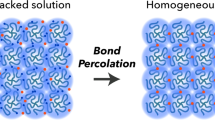

Based on the results of Sections 3.1–3.7, a schematic model was proposed to illustrate the progressive modification of FG by LBG under different pH conditions (Fig. 5). The structure of FG was severely damaged in a strongly acidic environment (pH ≤ 3), and the hydrolysis of the peptide chain pair led to a significant decrease in gelling properties21. It showed a loose gel network structure and a significant decrease in gel strength and melting temperature. The degree of hydrolysis of FG decreased as the solution pH increased. LBG modification could effectively improve the gelling properties of FG under strong acidity. Positively charged FG (Fig. 5A) and negatively charged LBG (Fig. 5B) formed a complex coacervates through electrostatic interactions (Fig. 5C). Hydrogen bonding was formed between the -OH group in the side chain of LBG and the free amino and carboxyl groups in FG, which was favorable for the formation of gel network structure. LBG could significantly improve the viscosity of FG and provide the product with better processing characteristics. The FG modified by LBG had higher gel strength and melting temperature, and the SEM results shown that the L group exhibited a better and denser network structure. When LBG and FG were mixed (Fig. 5D), there was a small enhancement of their gelling properties at pH 2 owing to the severe disruption of the structure of FG. At pH ≥ 3, FG and LBG formed a dense cohesive layer through electrostatic interactions. The electrostatic interaction between FG and LBG was the strongest at pH 3, and the gel strength and melting temperature were enhanced by the largest proportion. As a result, the gel strength and melting temperature were maximized proportionally. With the increase of pH, the interaction between the two weakened the proportion of enhancement gradually decreased. Similar results were reported by Hu et al.14.

Textural properties of FG gel gummies

Gummies are the popular type of confection and an emerging form of pharmaceutical vehicle. Gummies are made from gelatin, sweetener solids (sucrose and glucose syrup) and dietary acids. The addition of acids to gummies could lead to the hydrolysis of gelatin, thereby reducing the gelling properties of gelatin and weakening the texture46. Texture testing could simulate the change in the quality of colloids during chewing in the human mouth and teeth47. The effects of different pH values combined with LBG modification on the texture properties of FG acid gel gummies are shown in Table 2. Regardless of whether LBG was added, the hardness of FG gel gummies increased with the increase in pH value of the system. However, FG acid gel gummies unmodified by LBG had a lower hardness. It was noteworthy that the addition of LBG could greatly increase its hardness. When the pH of the gummies was 3-4, the negative electricity of the LBG interacted with the positively charged FG, which enhanced the gel network structure of the FG and increased the hardness of the FG gel. Springiness could be used to characterize the rubber-like elasticity of colloids in the mouth and the influence of initial shape variables on colloidal structure. As shown in Table 2, LBG maintained its springiness well while enhancing its hardness. Chewiness could describe the taste of colloids when they are chewed by the human mouth39. The gumminess of colloid was consistent with the change trend of its chewability and hardness. This was consistent with what Kaewruang reported48.

Gel strength of FG gel gummies

Acids are important ingredients commonly used in food that can improve its flavor and extend its shelf life. The addition of these substances has a significant effect on the gelling properties of FG. As shown in Fig. 6A, the gel strength of FG acid gel adhesive exhibited a consistent increase with rising pH values, irrespective of the addition of LBG. The gel strength of acidic gel gummies modified by LBG was significantly improved, reaching 798.1 g at pH 4. Compared with the unmodified acid gel gummies at pH 4, the gel strength after modification was increased by 35.35%. Under acidic conditions, the pH value of gelatin deviated from the isoelectric point, and the charge of the peptide chain was the same, resulting in electrostatic repulsion. However, breaking the balance of the gel system and hindering the formation of the mesh structure led to the decrease of gel strength13. The addition of LBG could improve this situation and significantly improve the gel strength of FG acid gel gummies. The charged LBG was introduced into the gelatin molecules by electrostatic interaction between FG and LBG, which enhanced the gel network structure of the system. Bulent et al.49 also found that adding LBG could significantly improve the strength of soy protein hydrogels. Interestingly, the gel strength of acid gel gummies at the same pH was higher than that measured in previous experiments because xylitol added to acid gel gummies could enhance the gel strength of FG50.

A The influence of pH on the gel strength of acidic gel gummies. Different lowercase letters indicate significant differences (P < 0.05). B The influence of pH value on the gelatin melting temperature of acidic gel gummies. Different lowercase letters indicate significant differences (P < 0.05). C The influence of pH value on the apparent viscosity. D The influence of pH value on shear pressure.

Melting temperature of FG gel gummies

As shown in Fig. 6B, the melting temperature increased with the pH of the system, regardless of whether FG was modified or not. The melting temperature increased dramatically with the addition of LBG. This was consistent with the results of the previous experiments. This was owing to the enhancement of the gel network structure of the system through electrostatic interactions between FG and LBG23. The melting temperature of the FG acid gel gummies modified by LBG were all higher than the maximum of the original system. Especially at pH 3.5, the melting temperature of the FG acid gel gummies modified by LBG increased from 29.29 °C to 37.10 °C. The melting temperature of FG modified by LBG was already higher than that of mammalian gelatin (28−31 °C)1. The addition of LBG improved the thermal stability of acid gel gummies facilitating its production and storage. Interestingly, under the same pH condition, the melting temperature of the acid gel gummies was higher than that measured in previous experiments in this work. Because the xylitol added to the acid gel gummies could enhance the network structure of the FG and increase the melting temperature50.

Apparent viscosity of FG gel gummies

Rheological parameters are of great significance in industrial applications. Additionally, the viscosity of food also influences people’s sensory evaluation and acceptance of it51,52,53. As shown in Fig. 6C, D, the viscosity of FG acid gelatin was low and did not change significantly with increasing pH. The addition of LBG greatly improved the apparent viscosity of the acid gel gummies23. Viscosity was strongly positively correlated with hardness, i.e., harder products were the more tacker at the same time54. This was one of the reasons why LBG could enhance the hardness. FG has a small apparent viscosity and is not suitable for room temperature gel molding. The addition of LBG made the acid gel gummies liquid cure quickly in the low temperature zone. The cured acid gel gummies was solid, elastic and had good chewing resistance.

Discussion

In this work, the effect of LBG on improving the gelling properties and structure of FG under acidic conditions was investigated and applied to acidic gel gummies. The results showed that the weak gelation of FG was caused by pH deviation from the isoelectric point of gelatin under acid condition. 0.3% LBG changed the conformation of FG through electrostatic and hydrogen bond interactions to form a denser polymer. The modification of LBG increased the gel strength and melting temperature of FG, and improved the gelling performance of FG under acidic conditions. Interestingly, the gel strength and melting temperature of FG modified with LBG at pH 3−7 were both higher than the maximum values (pH 7) of unmodified FG. Especially at pH 3, the maximum increase ratio of gel strength and melting temperature of FG was 62.65% and 29.44%, respectively. At this moment, the electrostatic and hydrogen bond interactions were the strongest. In addition, LBG had promoting effects on the gelation of acid gel gummies. The acidic gel gummies modified by LBG had higher gel strength, higher melting temperature and better structural properties. In a word, LBG could effectively improve the gelling properties of FG under acidic conditions, which provided a theoretical basis for the further development of acid gel gummies and broadened its potential application in the food industry.

Methods

Reagents

Tilapia FG (240 Bloom) was supplied by Jiliding Marine Biotechnology Co., Ltd (Suzhou, China). LBG was provided by Shanghai Aladdin Biochemical Technology Co., Ltd (Shanghai, China). Sodium hydroxide and hydrochloric acid were analytically pure. Sweet orange compound fruit drink concentrate, xylitol and isomaltitol were food reagents.

Preparation and modification of FG solution

The final concentration of LBG was selected as 0.3% according to the preliminary experimental results. A 6.67% (w/v) FG solution was prepared at 60 °C. The LBG was added to the FG solution at a final concentration of 0.3% (w/v), and the mixture was stored in a water bath at 60 °C for 1 h. Then, adjusted the pH of the FG-LBG complex solution to 2, 3, 4, 5, 6, and 7 using 1 M HCl and NaOH solutions. Finally, all the samples were adjusted to the same volume. The FG without the addition of LBG modification was named F2–F7, collectively referred to as group F. The FG modified by LBG was named L2-L7 respectively, collectively referred to as group L. Individually dissolved LBG named L02- L07 collectively referred to as the group L0.

Determination of gel strength

The gel strength of each sample was measured according to the method of Hu et al.14 with some modifications. Approximately 15 g of solution was added to 25 mL glass beakers (36 mm × 50 mm) and incubated at 4 °C for 17 h. The gel strength of each sample was determined by the TA.XT plus texture analyzer of Stable Micro System Company in the UK. The gel strength of the colloid was evaluated by pressing 4 mm with a P 0.5 R probe with a diameter of 1.27 cm at a test speed of 1 mm/s.

Determination of melting temperature

The melting temperature of each sample was measured according to the method of Tu et al.5 with some modifications. The melting temperature was determined using the CXDC-0510 constant temperature water bath of Nanjing Shunma Instrument & Equipment Co., LTD. The each sample solution was poured into a 100×10 mm (length × diameter) glass tube with a spiral cap, leaving 1 cm headspace at the top. The tubes were placed at 4 °C for 17 h. The tubes were placed in a thermostatic water bath at 10 °C for 15 min, and the temperature of the water bath was gradually increased at a rate of 0.5 °C/min until the movement of bubbles at the bottom of the tubes indicated melting, which was recorded as the melting temperature.

Differential scanning calorimetry (DSC)

The DSC test referred to the method of Ma et al.55, and made appropriate modifications. The thermal properties of the samples were analyzed by DSC test using the DSC2500 instrument from TA Company in the United States. Place approximately 2 mg of the sample in an aluminum crucible, record the weight of the sample (accurate to 0.01 mg), and calculate the peak temperature (Tp) of the sample through the DSC curve (20−180 °C, 10 °C/min).

Rheological behavior analysis

The rheological test of modified FG was measured according to the method of Hu et al.14 Each sample was measured with the Anton Paar MCR 302 rheometer to apparent viscosity and frequency scanning. The prepared sample (about 19 mL) was poured into PP50 cylinder. The apparent viscosity test sample was held at 25 °C for 30 min. The following apparent tests were performed: FG solution shear the rate was 0.1−100 1/s.

Frequency scanning: each sample at 5 °C for 25 min and at a 0.5 strain. The frequency of FG solution was 0.1−100 Hz.

Zeta potential measurement

The zeta potential of each samples were measured according to the method of Wu et al.56 Dilute the solution 10 times and adjust the pH from 2 to 7. The zeta potential was determined using the Zetasizer nano-zsp nanoparticle size potential analyzer from Malvern Panalytical. All tests were performed at 25 °C.

Gel strength loss measurement

The hydrogen bonds of each sample were determined according to the method of Xu et al.57 1 M of urea was mixed with the sample solution as the dissociation reagent, and then the mixed sample solution was placed in a 25 mL small beaker and incubated at 10 °C for 17 h. The change of gel strength was determined by P 0.5 R probe to determine the hydrogen bond of each sample.

Microstructure

The microstructure was measured according to the method of Wang et al.58 The microstructure was measured using the S-3400N scanning electron microscope of Hitachi Company in Japan. Each sample was cut into small colloidal chunks, 2-3 mm thick, and placed in a phosphate buffer containing 2.5% glutaraldehyde (0.2 M, pH 7.0). It was then fixed at 4 °C for 14 h. The sample was rinsed three times with distilled water. The microstructure of the sample was observed after freeze-drying.

FTIR

The FTIR test was appropriately modified according to the method of Zhang et al.59 The experiment was carried out using the Nicolet 6700 Fourier Transform Infrared Spectrometer manufactured by Thermo Fisher Scientific in the United States. Freeze-dried samples were accurately weighed and mixed with KBr at a ratio of 1:100 in an agate mortar. After thorough mixing, the mixture was ground into a fine powder, followed by tablet pressing under specified conditions. Subsequently, full-band scanning was performed within the wavenumber range of 500−4000 cm−1, with a spectral resolution of 4.0 cm−1 and 32 scans per sample. The absorbance values of the samples were subsequently determined.

Preparation of acid gel gummies

Modifications were made according to the reported method of Yan60. In the control group, 6.67 g of FG, 7 g of xylitol, 3 g of isomaltitol, 16 g of juice (concentrated orange juice), and water were added to 100 g. In addition to the above substances, 0.3 g LBG was added to the experimental group. The two groups were heated and stirred at 60 °C for 60 min, respectively. After cooling to room temperature, the pH was adjusted to 3, 3.5, and 4 with 0.1 mol/L citric acid.

Analysis of gelling properties of acid gummies

According to the reported method of Sow et al.47, texture profile analysis of FG gel gummies was measured. The measurement was carried out using the TA.XT plus texture analyzer from Stable Micro System in the UK. Pour the prepared solution into the mold and incubate at 25 °C for 17 h. The colloid was removed and cut into 2.2 cm × 1.5 cm (diameter × height) small cylindrical colloid. The texture detection was carried out by a texture analyzer. The probe was P 36 R and the row variable was 40%.

Determination of gel strength of acid gummies

The gel strength of each sample was measured according to the method of Hu et al.14 with some modifications. Approximately 15 g of solution was added to 25 mL glass beakers (36 mm × 50 mm) and incubated at 4 °C for 17 h. The gel strength of each sample was determined by the TA.XT plus texture analyzer of Stable Micro System Company in the UK. The gel strength of the colloid was evaluated by pressing 4 mm with a P 0.5 R probe with a diameter of 1.27 cm at a test speed of 1 mm/s.

Determination of melting temperature of acid gel gummies

The melting temperature of each sample was measured according to the method of Tu et al.5 with some modifications. The melting temperature was determined using the CXDC-0510 constant temperature water bath of Nanjing Shunma Instrument & Equipment Co., LTD. Each sample solution was poured into a 100 × 10 mm (length × diameter) glass tube with a spiral cap, leaving 1 cm headspace at the top. The tubes were placed at 4 °C for 17 h. The tubes were placed in a thermostatic water bath at 10 °C for 15 min, and the temperature of the water bath was gradually increased at a rate of 0.5 °C/min until the movement of bubbles at the bottom of the tubes indicated melting, which was recorded as the melting temperature.

Apparent viscosity analysis of acid gel gummies

The rheological test of modified FG was measured according to the method of Hu et al.14 Each sample was measured with the Anton Paar MCR 302 rheometer to apparent viscosity and frequency scanning. The prepared sample (about 19 mL) was poured into PP50 cylinder. The apparent viscosity test sample was held at 25 °C for 30 min. The shear rate of FG acid gel gummies was 0.01−100 1/s.

Data analysis

All the experiments were repeated three times, and the results were reported as the mean ± standard deviations. SPSS 27.0 (SPSS Inc., Chicago, IL, USA) software was used for a one-way analysis of variance. P-values less than 0.05 were considered statistically significant.

Data Availability

Data available upon request

References

Karim, A. A. & Bhat, R. Fish gelatin: properties, challenges, and prospects as an alternative to mammalian gelatins. Food Hydrocoll. 23, 563–576 (2009).

Coppola, D. et al. Fish waste: from problem to valuable resource. Mar. Drugs 19, 116 (2021).

Rather, J. A. et al. A comprehensive review on gelatin: Understanding impact of the sources, extraction methods, and modifications on potential packaging applications. Food Packaging Shelf Life 34, 100945 (2022).

Sha, X. M. et al. Effect of ammonium sulfate fractional precipitation on gel strength and characteristics of gelatin from bighead carp (Hypophthalmichthys nobilis) scale. Food Hydrocoll. 36, 173–180 (2014).

Tu, Z. C. et al. Physico-chemical properties of gelatin from bighead carp (Hypophthalmichthys nobilis) scales by ultrasound-assisted extraction. J. Food Sci. Technol. Mysore 52, 2166–2174 (2015).

Biscarat, J. et al. Effect of chemical cross-linking on gelatin membrane solubility with a non-toxic and non-volatile agent: terephthalaldehyde. Int. J. Biol. Macromol. 74, 5–11 (2015).

Tian, Z., Liu, W. & Li, G. The microstructure and stability of collagen hydrogel cross-linked by glutaraldehyde. Polym. Degrad. Stab. 130, 264–270 (2016).

Gaspar, A. L. & de Góes-Favoni, S. P. Action of microbial transglutaminase (MTGase) in the modification of food proteins: a review. Food Chem. 171, 315–322 (2015).

Cheng, L. H. et al. Using fish gelatin and pectin to make a low-fat spread. Food Hydrocoll. 22, 1637–1640 (2008).

Van Nieuwenhove, I. et al. Gelatin- and starch-based hydrogels. Part A: hydrogel development, characterization and coating. Carbohydr. Polym. 152, 129–139 (2016).

Huang, T. et al. Fish gelatin modifications: a comprehensive review. Trends Food Sci. Technol. 86, 260–269 (2019).

Sow, L. C. et al. Nanostructural analysis and textural modification of tilapia fish gelatin affected by gellan and calcium chloride addition. LWT Food Sci. Technol. 85, 137–145 (2017).

Pang, Z. et al. Rheology, texture and microstructure of gelatin gels with and without milk proteins. Food Hydrocoll. 35, 484–493 (2014).

Hu, Z. Z. et al. Gelling properties and structure modification of tilapia skin gelatin by the addition of γ-polyglutamic acid at different pH levels. Int. J. Food Sci. Technol. 56, 5812–5823 (2021).

Hu, B. et al. Effects of different phosphorylation times and pH on fish gelatin: functional properties, structural and mechanism analysis. Food Hydrocoll. 152, Article 109876 (2024).

Cerqueira, M. A. et al. Structural and thermal characterization of galactomannans from non-conventional sources. Carbohydr. Polym. 83, 179–185 (2011).

Zhang, H. et al. Behavior of bovine serum albumin in the presence of locust bean gum. Int. J. Biol. Macromol. 111, 1–10 (2018).

Mumtaz Hamdani, A. & Ahmed Wani, I. Guar and locust bean gum: composition, total phenolic content, antioxidant and antinutritional characterisation. Bioact. Carbohydr. Diet. Fibre 11, 53–59 (2017).

Kuan, Y. H. et al. Effects of sugars on the gelation kinetics and texture of duck feet gelatin. Food Hydrocoll. 58, 267–275 (2016).

Ahmad, T. et al. Recent advances on the role of process variables affecting gelatin yield and characteristics with special reference to enzymatic extraction: a review. Food Hydrocoll. 63, 85–96 (2017).

Ge, S. et al. Enhanced mechanical properties and gelling ability of gelatin hydrogels reinforced with chitin whiskers. Food Hydrocoll. 75, 1–12 (2018).

Goudie, K. J. et al. Investigation of the influence of pH on the properties and morphology of gelatin hydrogels. J. Polym. Sci. 61, 2316–2332 (2023).

Agarwal, D. et al. Microstructure, rheological and water mobility behaviour of plant-based protein isolates (pea and quinoa) and locust bean gum mixtures. Food Res. Int. 164, Article 112311 (2023).

Lu, Z. et al. Improvement of casein/κ-carrageenan composite gel properties: role of locust bean gum concentration. Food Hydrocoll. 158, 110547 (2025).

Jongjareonrak, A. et al. Characterization of edible films from skin gelatin of brownstripe red snapper and bigeye snapper. Food Hydrocoll. 20, 492–501 (2006).

Zhang, S. et al. Effect of steam explosion treatments on the functional properties and structure of camellia (Camellia oleifera Abel.) seed cake protein. Food Hydrocoll. 93, 189–197 (2019).

Derkach, S. R. et al. tailoring cod gelatin structure and physical properties with acid and alkaline extraction. Polymers 11, 1724 (2019).

Marcotte, M., Hoshahili, A. R. T. & Ramaswamy, H. S. Rheological properties of selected hydrocolloids as a function of concentration and temperature. Food Res. Int. 34, 695–703 (2001).

Ji, S. et al. Incorporating acetylated starch regulates the structure and sol-gel performance of wheat starch-based binary system. Food Hydrocoll 140, 108635 (2023).

Feng, J. et al. Interaction between fish gelatin and tremella polysaccharides from aqueous solutions to complex coacervates: structure and rheological properties. Food Hydrocoll 138, 108439 (2023).

Chiou, B. S. et al. Rheological and mechanical properties of cross-linked fish gelatins. Polymer 47, 6379–6386 (2006).

Fonkwe, L. G., Narsimhan, G. & Cha, A. S. Characterization of gelation time and texture of gelatin and gelatin-polysaccharide mixed gels. Food Hydrocoll. 17, 871–883 (2003).

Huang, T. et al. Comparison of rheological behaviors and nanostructure of bighead carp scales gelatin modified by different modification methods. J. Food Sci. Technol. Mysore 54, 1256–1265 (2017).

Shi, X. D. et al. Fabrication, interaction mechanism, functional properties, and applications of fish gelatin-polysaccharide composites: a review. Food Hydrocoll. 122, 107106 (2022).

Razi, S. M. et al. The effect of basil seed gum (BSG) on the rheological and physicochemical properties of heat-induced egg albumin gels. Food Hydrocoll. 82, 268–277 (2018).

Muhoza, B. et al. Gelatin and pectin complex coacervates as carriers for cinnamaldehyde: effect of pectin esterification degree on coacervate formation, and enhanced thermal stability. Food Hydrocoll. 87, 712–722 (2019).

Alcântara, M. G. et al. Electrostatic hydrogels formed by gelatin and carrageenan induced by acidification: Rheological and structural characterization. Food Struct. 24, 100137 (2020).

Gomez, G. et al. Fish gelatin: a renewable material for developing active biodegradable films. Trends Food Sci. Technol. 20, 3–16 (2009).

Kaewruang, P., Benjakul, S. & Prodpran, T. Effect of phosphorylation on gel properties of gelatin from the skin of unicorn leatherjacket. Food Hydrocoll. 35, 694–699 (2014).

Stanca, M. et al. Physico-chemical changes induced by gamma irradiation on some structural protein extracts. Biomolecules 13, 774 (2023).

Cebi, N. et al. An evaluation of fourier transforms infrared spectroscopy method for the classification and discrimination of bovine, porcine and fish gelatins. Food Chem. 190, 1109–1115 (2016).

Nikoo, M. et al. Physical and chemical properties of gelatin from the skin of cultured amur sturgeon (acipenser schrenckii). J. Appl. Ichthyol. 29, 943–950 (2013).

Su, Y. R. et al. Effect of grape seed proanthocyanidin-gelatin colloidal complexes on stability and in vitro digestion of fish oil emulsions. J. Agric. Food Chem. 63, 10200–10208 (2015).

Duhoranimana, E. et al. Effect of sodium carboxymethyl cellulose on complex coacervates formation with gelatin: coacervates characterization, stabilization and formation mechanism. Food Hydrocoll. 69, 111–120 (2017).

Chen, R. et al. Frabrication of carboxymethylchitin nanofibers and fish gelatin hybrid gels with robust gel performance. Food Hydrocoll. 160, 110733 (2025).

Wang, R. & Hartel, R. W. Citric acid and heating on gelatin hydrolysis and gelation in confectionery gels. Food Hydrocoll. 129, 107642 (2022).

Sow, L. C. & Yang, H. Effects of salt and sugar addition on the physicochemical properties and nanostructure of fish gelatin. Food Hydrocoll. 45, 72–82 (2015).

Kaewruang, P. et al. Impact of divalent salts and bovine gelatin on gel properties of phosphorylated gelatin from the skin of unicorn leatherjacket. Lwt Food Sci. Technol. 55, 477–482 (2014).

Basyigit, B. et al. Locust bean gum provides excellent mechanical and release attributes to soy protein-based natural hydrogels. Int. J. Biol. Macromol. 231, Article 123352 (2023).

Cai, L. et al. Confectionery gels: Effects of low calorie sweeteners on the rheological properties and microstructure of fish gelatin. Food Hydrocoll. 67, 157–165 (2017).

Gerschenson, L. N., Rojas, A. M. & Marangoni, A. G. Effects of processing on kiwi fruit dynamic rheologicalbehaviour and tissue structure. Food Res. Int. 34, 1–6 (2001).

Maceiras, R., Álvarez, E. & Cancela, M. A. Rheological properties of fruit purees: effect of cooking. J. Food Eng. 80, 763–769 (2007).

Molina-Rubio, M. P., Casas-Alencáster, N. B. & Martínez-Padilla, L. P. Effect of formulation and processing conditions on the rheological and textural properties of a semi-liquid syrup model. Food Res. Int. 43, 678–682 (2010).

Wang, R. & Hartel, R. W. Confectionery gels: gelling behavior and gel properties of gelatin in concentrated sugar solutions. Food Hydrocoll. 124, 107132 (2022).

Ma, Y. et al. Glycosylation of egg white protein with maltodextrin in the dry state: changes in structural and gel properties. Food Chem. 401, 134113 (2023).

Wu, B. C. & McClements, D. J. Microgels formed by electrostatic complexation of gelatin and OSA starch: potential fat or starch mimetics. Food Hydrocoll. 47, 87–93 (2015).

Xu, L. et al. Influence of konjac glucomannan on the emulsion-filled/non-filled chicken gel: study on intermolecular forces, microstructure and gelling properties. Food Hydrocoll. 124, 107269 (2022).

Wangtueai, S., Noomhorm, A. & Regenstein, J. M. Effect of microbial transglutaminase on gel properties and film characteristics of gelatin from lizardfish (Saurida spp.) scales. J. Food Sci. 75, C731–C739 (2010).

Zhang, Y. et al. Effect of carbon numbers and structures of monosaccharides on the glycosylation and emulsion stabilization ability of gelatin. Food Chem. 389, 133128 (2022).

Yan, B. et al. Improvement of vitamin C stability in vitamin gummies by encapsulation in casein gel. Food Hydrocoll. 113, 106414 (2021).

Acknowledgements

This study was supported by the National Key R&D Program of China (No. 2022YFD2100905), the National Natural Science Foundation of China (No. 32160576) and the earmarked fund for CARS (CARS-45).

Author information

Authors and Affiliations

Contributions

Fen-Fen Wu: Conceptualization, Methodology, Writing-Original Draft, Formal analysis. Zong-Cai Tu: Investigation, Formal analysis, Date Curation. Jie Cheng: Formal analysis. Hui Wang: Software, Investigation. Zi-Zi Hu: Conceptualization, Resources, Supervision. Xiao-Mei Sha: Investigation, Data curation, Visualization, Project administration, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, FF., Tu, ZC., Cheng, J. et al. Locust bean gum improved the gelling properties of fish gelatin in acidic environments and its application in acid gel gummies. npj Sci Food 9, 179 (2025). https://doi.org/10.1038/s41538-025-00550-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41538-025-00550-4