Abstract

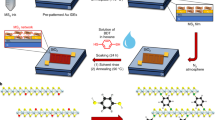

Sustainable manufacturing that prioritizes energy efficiency, minimal water use, scalability and the ability to generate diverse materials is essential to advance inorganic materials production while maintaining environmental consciousness. However, current manufacturing practices are not yet equipped to fully meet these requirements. Here we describe a flash-within-flash Joule heating (FWF) technique—a non-equilibrium, ultrafast heat conduction method—to prepare ten transition metal dichalcogenides, three group XIV dichalcogenides and nine non-transition metal dichalcogenide materials, each in under 5 s while in ambient conditions. FWF achieves enormous advantages in facile gram scalability and in sustainable manufacturing criteria when compared with other synthesis methods. Also, FWF allows the production of phase-selective and single-crystalline bulk powders, a phenomenon rarely observed by any other synthesis method. Furthermore, FWF MoSe2 outperformed commercially available MoSe2 in tribology, showcasing the quality of FWF materials. The capability for atom substitution and doping further highlights the versatility of FWF as a general bulk inorganic materials synthesis protocol.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its Supplementary Information files. Should any raw data files be needed in another format, they are available from the corresponding author upon reasonable request. All data used in this manuscript are also available in Zenodo at https://doi.org/10.5281/zenodo.12536975 (ref. 48). Source data are provided with this paper.

Code availability

The code used for DFT calculations can be found in Zenodo at https://doi.org/10.5281/zenodo.12536975 (ref. 48).

References

Raabe, D. The materials science behind sustainable metals and alloys. Chem. Rev. 123, 2436–2608 (2023).

Aykol, M., Montoya, J. H. & Hummelshøj, J. Rational solid-state synthesis routes for inorganic materials. J. Am. Chem. Soc. 143, 9244–9259 (2021).

Wang, C. et al. A general method to synthesize and sinter bulk ceramics in seconds. Science 368, 521–526 (2020).

Deng, B. et al. High-surface-area corundum nanoparticles by resistive hotspot-induced phase transformation. Nat. Commun. 13, 5027 (2022).

Zheng, X. et al. Hydrogen-substituted graphdiyne-assisted ultrafast sparking synthesis of metastable nanomaterials. Nat. Nanotechnol. 18, 153–159 (2023).

Chen, W. et al. Millisecond conversion of metastable 2D materials by flash Joule heating. ACS Nano 15, 1282–1290 (2021).

Luong, D. X. et al. Gram-scale bottom-up flash graphene synthesis. Nature 577, 647–651 (2020).

Deng, B. et al. Phase controlled synthesis of transition metal carbide nanocrystals by ultrafast flash Joule heating. Nat. Commun. 13, 262 (2022).

Wyss, K. M., Luong, D. X. & Tour, J. M. Large‐scale syntheses of 2D materials: flash Joule heating and other methods. Adv. Mater. 34, 2106970 (2022).

Wyss, K. M. et al. Synthesis of clean hydrogen gas from waste plastic at zero net cost. Adv. Mater. 35, 2306763 (2023).

Yao, Y. et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359, 1489–1494 (2018).

Chen, Y. et al. Ultra-fast self-assembly and stabilization of reactive nanoparticles in reduced graphene oxide films. Nat. Commun. 7, 12332 (2016).

Eddy, L. et al. Automated laboratory kilogram‐scale graphene production from coal. Small Methods 8, 2301144 (2024).

Dong, Q. et al. Programmable heating and quenching for efficient thermochemical synthesis. Nature 605, 470–476 (2022).

Li, L. et al. Kilogram-scale synthesis and functionalization of carbon dots for superior electrochemical potassium storage. ACS Nano 15, 6872–6885 (2021).

Upadhyay, S. & Pandey, O. P. Synthesis of layered 2H–MoSe2 nanosheets for the high-performance supercapacitor electrode material. J. Alloy. Compd 857, 157522 (2021).

Ubaldini, A. & Giannini, E. Improved chemical vapor transport growth of transition metal dichalcogenides. J. Cryst. Growth 401, 878–882 (2014).

Hellweg, S. & Canals, L. M. I. Emerging approaches, challenges and opportunities in life cycle assessment. Science 344, 1109–1113 (2014).

Joo, J., Chow, B. Y., Prakash, M., Boyden, E. S. & Jacobson, J. M. Face-selective electrostatic control of hydrothermal zinc oxide nanowire synthesis. Nat. Mater. 10, 596–601 (2011).

Du, Z. et al. Conversion of non-van der Waals solids to 2D transition-metal chalcogenides. Nature 577, 492–496 (2020).

Feng, Y. et al. Synthesis of noble metal chalcogenides via cation exchange reactions. Nat. Synth. 1, 626–634 (2022).

Chen, X., Liu, L., Yu, P. Y. & Mao, S. S. Increasing solar absorption for photocatalysis with black hydrogenated titanium dioxide nanocrystals. Science 331, 746–750 (2011).

Choi, C. H. et al. Polymeric carbon nitride with localized aluminum coordination sites as a durable and efficient photocatalyst for visible light utilization. ACS Catal. 8, 4241–4256 (2018).

Shi, W. et al. Reversible writing of high-mobility and high-carrier-density doping patterns in two-dimensional van der Waals heterostructures. Nat. Electron. 3, 99–105 (2020).

Dou, Y. et al. Approaching the activity limit of CoSe2 for oxygen evolution via Fe doping and Co vacancy. Nat. Commun. 11, 1664 (2020).

Zhu, L.-F. et al. Heterovalent-doping-enabled atom-displacement fluctuation leads to ultrahigh energy-storage density in AgNbO3-based multilayer capacitors. Nat. Commun. 14, 1166 (2023).

Zhu, W. et al. Ultrafast non‐equilibrium synthesis of cathode materials for Li‐ion batteries. Adv. Mater. 35, 2208974 (2023).

Förg, M. et al. Moiré excitons in MoSe2–WSe2 heterobilayers and heterotrilayers. Nat. Commun. 12, 1656 (2021).

Han, W. et al. Phase-controllable large-area two-dimensional In2Se3 and ferroelectric heterophase junction. Nat. Nanotechnol. 18, 55–63 (2023).

Jung, C. et al. Highly crystalline CVD-grown multilayer MoSe2 thin film transistor for fast photodetector. Sci. Rep. 5, 15313 (2015).

Kim, K. S. et al. Non-epitaxial single-crystal 2D material growth by geometric confinement. Nature 614, 88–94 (2023).

Si, M. et al. A ferroelectric semiconductor field-effect transistor. Nat. Electron. 2, 580–586 (2019).

Liu, Y. et al. Interlayer friction and superlubricity in single-crystalline contact enabled by two-dimensional flake-wrapped atomic force microscope tips. ACS Nano 12, 7638–7646 (2018).

Lee, C. et al. Frictional characteristics of atomically thin sheets. Science 328, 76–80 (2010).

Huang, Y. et al. Single-crystalline 2D erucamide with low friction and enhanced thermal conductivity. Colloids Surf. A 540, 29–35 (2018).

Zhang, X. R., Kong, G. Q., Wang, L. H. & Xu, X. L. Measurement and prediction on thermal conductivity of fused quartz. Sci. Rep. 10, 6559 (2020).

Ogugua, C. J. et al. Energy analysis of autoclave CFRP manufacturing using thermodynamics based models. Compos. Part A 166, 107365 (2023).

Couteau, E. et al. CVD synthesis of high-purity multiwalled carbon nanotubes using CaCO3 catalyst support for large-scale production. Chem. Phys. Lett. 378, 9–17 (2003).

Chinwego, C., Wagner, H., Giancola, E., Jironvil, J. & Powell, A. Technoeconomic analysis of rare-earth metal recycling using efficient metal distillation. JOM 74, 1296–1305 (2022).

Chaudhary, K. T., Rizvi, Z. H., Bhatti, K. A., Ali, J. & Yupapin, P. P. Multiwalled carbon nanotube synthesis using arc discharge with hydrocarbon as feedstock. J. Nanomater. 2013, 1–13 (2013).

Dudarev, S. L., Botton, G. A., Savrasov, S. Y., Humphreys, C. J. & Sutton, A. P. Electron-energy-loss spectra and the structural stability of nickel oxide: an LSDA+U study. Phys. Rev. B 57, 1505–1509 (1998).

Reuter, K. & Scheffler, M. Composition, structure, and stability of RuO2(110) as a function of oxygen pressure. Phys. Rev. B 65, 035406 (2001).

Chase, M. W., Curnutt, J. L., Prophet, H., McDonald, R. A. & Syverud, A. N. JANAF thermochemical tables, 1975 supplement. J. Phys. Chem. Ref. Data 4, 1–176 (1975).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Choi, C. H., James, D. & Tour, J. Flash-within-flash synthesis of gram-scale solid-state materials. Zenodo https://doi.org/10.5281/zenodo.13124514 (2024).

Acknowledgements

J.M.T. thanks the Air Force Office of Scientific Research (FA9550-22-1-0526) and the US Army Corp of Engineers, ERDC (W912HZ-21-2-0050) for financial support. Y.H. acknowledges support from the Welch Foundation (C-2065-20210327). Supercomputing time is provided by the National Energy Research Scientific Computing Center (NERSC); the authors extend their sincere gratitude to B. Yakobson for providing the computational resources necessary for this research. The authors also thank the Rice Microscopy Center, Shared Equipment Authority (SEA) at Rice University and all staff members for their contribution in sample preparation, nanofabrication and microscopy measurement.

Author information

Authors and Affiliations

Contributions

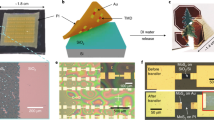

C.H.C. conceived the idea with L.E., achieved the first demonstration of FWF, conducted the synthesis of 22 materials, gram scalability, Raman, XRD, STEM, selected area electron diffraction and EDX characterization, and manuscript writing under the guidance of J.M.T. and Y.H.; J.S. performed the device fabrications and electrical measurements for MoSe2, WSe2 and α-In2Se3 materials and aided the synthesis of α-In2Se3; L.E. managed the FJH system and aided C.H.C. with the synthesis; V.G. performed the tribological experiments to analyse the COF. K.M.W. performed LCA analysis; B.D. acquired and analysed the XPS data; H.G. performed FIB for cross-section STEM sample preparation. G.G. aided C.H.C. in initial STEM characterization. Y.Z. contributed to the discussion of ultrafast thermal conduction pathway, calculation of internal tube temperature, and oxygen outgassing modelling. C.F.H.III supervised V.G. in performing and analysing tribological data. Y.H. supervised C.H.C. in microscopy analysis and guided C.H.C. in manuscript writing and figures. J.M.T. supervised C.H.C. in material synthesis, guided C.H.C. in manuscript writing and oversaw the entire project.

Corresponding authors

Ethics declarations

Competing interests

A provisional patent application directed to this technology (63/520,553) has been filed by Rice University, but it is currently unlicensed. The inventors listed are Chi Hun ‘William’ Choi, Lucas Eddy and James M. Tour. The other authors declare no competing interests.

Peer review

Peer review information

Nature Chemistry thanks Il-Doo Kim and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Internal tube temperature measurement.

a. A schematic description of the temperature measurement for a normal FWF reaction. b. A schematic description of the temperature measurement of skewed internal tube to decipher internal temperature during the reaction. For both temperature measurements, the laser-assisted thermometer is located 10 cm above the sample. The current flow could be different between the two configurations as the resistance might differ by packing of the metallurgical coke for the right configuration when compared to the left configuration. Yet, the total energy input remains constant. c. The infrared thermometer with an alignment laser was focused onto the sample area to read the time-dependent temperature change during the FWF reaction. d. The reaction dynamics during the FWF reaction.

Extended Data Fig. 2 XRD and Raman spectra for doping capability in Sn-based TMDs.

a. XRD spectrum of SnS2, Se-doped SnS2 (denoted as SnSxSey), and SnSe2. b. Raman spectrum of SnS2, Se-doped SnS2 (denoted as SnSxSey), and SnSe2 with pictures of corresponding powders as subsets. For SnSe2, a small amount of SnO2 (denoted in purple) is formed on the surface (confirmed by EDX mapping, see Fig. 3g).

Extended Data Fig. 3 Selected area electron diffraction (SAED) patterns of SnS2, α-In2Se3, MoSe2, and WSe2 flakes.

a. SAED of SnS2. b. SAED of α-In2Se3. c. SAED of MoSe2. d. SAED of WSe2. All the materials showed a single-crystalline nature in each flake.

Extended Data Fig. 4 S/TEM images and SAED patterns for commercial MoSe2 (a–c) and FWF MoSe2 (d–f).

a. TEM image of commercial MoSe2 with ~20 nm of amorphous layer at the edge of the flake. b. TEM image of another area of commercial MoSe2 with ~10 nm amorphous layer at the edge of the flake. c. SAED pattern of commercial MoSe2 indicating polycrystallinity and amorphous constituents. d. TEM image of FWF MoSe2 with little to no amorphous layer at the edge of the flake. e. ADF-STEM atomic resolution image of MoSe2 indicating sharp, well-defined crystalline structure at the edge of the flake. f. SAED pattern of FWF MoSe2 showing single crystallinity with no amorphous constituents.

Supplementary information

Supplementary Information

Supplementary methods (sample preparation), discussion (further discussion of the LCA), Figs. 1–40, Tables 1–9 and references.

Supplementary Video 1

Visualization of the tribological experiment procedure to obtain the COF.

Source data

Source Data Fig. 2

Source data for Fig. 2e–h.

Source Data Fig. 5

Source data for Fig. 5a.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Choi, C.H.‘., Shin, J., Eddy, L. et al. Flash-within-flash synthesis of gram-scale solid-state materials. Nat. Chem. 16, 1831–1837 (2024). https://doi.org/10.1038/s41557-024-01598-7

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41557-024-01598-7

This article is cited by

-

Flash Joule heating for synthesis, upcycling and remediation

Nature Reviews Clean Technology (2025)

-

A universal protocol for ultrafast direct regeneration and upcycling of spent lithium-ion battery cathode materials

Nature Protocols (2025)

-

Joule Heating-Driven sp2-C Domains Modulation in Biomass Carbon for High-Performance Bifunctional Oxygen Electrocatalysis

Nano-Micro Letters (2025)