Abstract

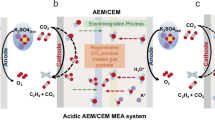

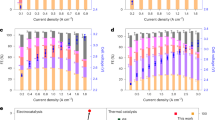

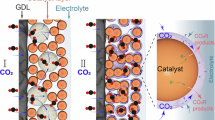

The electrochemical CO2 reduction reaction towards value-added fuel and feedstocks often relies on metal-based catalysts. Organic molecular catalysts, which are more acutely tunable than metal catalysts, are still unable to catalyse CO2 to hydrocarbons under industrially relevant current densities for long-term operation, and the catalytic mechanism is still elusive. Here we report 3,5-diamino-1,2,4-triazole-based membrane electrode assemblies for CO2-to-CH4 conversion with Faradaic efficiency of (52 ± 4)% and turnover frequency of 23,060 h−1 at 250 mA cm−2. Our mechanistic studies suggest that the CO2 reduction at the 3,5-diamino-1,2,4-triazole electrode proceeds through the intermediary *CO2–*COOH–*C(OH)2–*COH to produce CH4 due to the spatially distributed active sites and the suitable energy level of the molecular orbitals. A pilot system operated under a total current of 10 A (current density = 123 mA cm−2) for 10 h is able to produce CH4 at a rate of 23.0 mmol h−1.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that all data supporting the findings of this study are available within the paper, Supplementary Information and Source Data files. Source data are provided with this paper.

References

Peterson, A. A., Abild-Pedersen, F., Studt, F., Rossmeisl, J. & Nørskov, J. K. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 3, 1311–1315 (2010).

Ross, M. B. et al. Designing materials for electrochemical carbon dioxide recycling. Nat. Catal. 2, 648–658 (2019).

Nitopi, S. et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte. Chem. Rev. 119, 7610–7672 (2019).

Greenblatt, J. B., Miller, D. J., Ager, J. W., Houle, F. A. & Sharp, I. D. The technical and energetic challenges of separating (photo)electrochemical carbon dioxide reduction products. Joule 2, 381–420 (2018).

Shin, H., Hansen, K. U. & Jiao, F. Techno-economic assessment of low-temperature carbon dioxide electrolysis. Nat. Sustain. 4, 911–919 (2021).

Masel, R. I. et al. An industrial perspective on catalysts for low-temperature CO2 electrolysis. Nat. Nanotechnol. 16, 118–128 (2021).

Hori, Y., Kikuchi, K., Murata, A. & Suzuki, S. Production of methane and ethylene in electrochemical reduction of carbon dioxide at copper electrode in aqueous hydrogencarbonate solution. Chem. Lett. 15, 897–898 (1986).

Kuhl, K. P., Cave, E. R., Abram, D. N. & Jaramillo, T. F. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 5, 7050–7059 (2012).

Buonsanti, R. Copper, my precious! Nat. Catal. 4, 736–737 (2021).

Garza, A. J., Bell, A. T. & Head-Gordon, M. Mechanism of CO2 reduction at copper surfaces: pathways to C2 products. ACS Catal. 8, 1490–1499 (2018).

Luo, W., Nie, X., Janik, M. J. & Asthagiri, A. Facet dependence of CO2 reduction paths on Cu electrodes. ACS Catal. 6, 219–229 (2016).

Li, Y. C. et al. Binding site diversity promotes CO2 electroreduction to ethanol. J. Am. Chem. Soc. 141, 8584–8591 (2019).

Nam, D.-H. et al. Molecular enhancement of heterogeneous CO2 reduction. Nat. Mater. 19, 266–276 (2020).

Li, F. et al. Molecular tuning of CO2-to-ethylene conversion. Nature 577, 509–513 (2020).

Schmitt, K. G. & Gewirth, A. A. Situ surface-enhanced Raman spectroscopy of the electrochemical reduction of carbon dioxide on silver with 3,5-diamino-1,2,4-triazole. J. Phys. Chem. C 118, 17567–17576 (2014).

Han, Z., Kortlever, R., Chen, H.-Y., Peters, J. C. & Agapie, T. CO2 reduction selective for C ≥ 2 products on polycrystalline copper with N-substituted pyridinium additives. ACS Cent. Sci. 3, 853–859 (2017).

Hoang, T. T. H., Ma, S., Gold, J. I., Kenis, P. J. A. & Gewirth, A. A. Nanoporous copper films by additive-controlled electrodeposition: CO2 reduction catalysis. ACS Catal. 7, 3313–3321 (2017).

Tornow, C. E., Thorson, M. R., Ma, S., Gewirth, A. A. & Kenis, P. J. A. Nitrogen-based catalysts for the electrochemical reduction of CO2 to CO. J. Am. Chem. Soc. 134, 19520–19523 (2012).

Hoang, T. T. H. et al. Nanoporous copper–silver alloys by additive-controlled electrodeposition for the selective electroreduction of CO2 to ethylene and ethanol. J. Am. Chem. Soc. 140, 5791–5797 (2018).

Matsushima, H., Taranovskyy, A., Haak, C., Gründer, Y. & Magnussen, O. M. Reconstruction of Cu(100) electrode surfaces during hydrogen evolution. J. Am. Chem. Soc. 131, 10362–10363 (2009).

Liu, X. et al. Understanding trends in electrochemical carbon dioxide reduction rates. Nat. Commun. 8, 15438 (2017).

Ren, S. et al. Molecular electrocatalysts can mediate fast, selective CO2 reduction in a flow cell. Science 365, 367–369 (2019).

Sun, L., Reddu, V., Fisher, A. C. & Wang, X. Electrocatalytic reduction of carbon dioxide: opportunities with heterogeneous molecular catalysts. Energy Environ. Sci. 13, 374–403 (2020).

Sung, S., Kumar, D., Gil-Sepulcre, M. & Nippe, M. Electrocatalytic CO2 reduction by imidazolium-functionalized molecular catalysts. J. Am. Chem. Soc. 139, 13993–13996 (2017).

Baxter, R. J. & Hu, P. Insight into why the Langmuir-Hinshelwood mechanism is generally preferred. J. Chem. Phys. 116, 4379–4381 (2002).

Schreier, M., Yoon, Y., Jackson, M. N. & Surendranath, Y. Competition between H and CO for active sites governs copper-mediated electrosynthesis of hydrocarbon fuels. Angew. Chem. Int. Ed. 57, 10221–10225 (2018).

Seshadri, G., Lin, C. & Bocarsly, A. B. A new homogeneous electrocatalyst for the reduction of carbon dioxide to methanol at low overpotential. J. Electroanal. Chem. 372, 145–150 (1994).

Barton Cole, E. et al. Using a one-electron shuttle for the multielectron reduction of CO2 to methanol: kinetic, mechanistic, and structural insights. J. Am. Chem. Soc. 132, 11539–11551 (2010).

Xiang, D., Magana, D. & Dyer, R. B. CO2 reduction catalyzed by mercaptopteridine on glassy carbon. J. Am. Chem. Soc. 136, 14007–14010 (2014).

Costentin, C., Savéant, J.-M. & Tard, C. Catalysis of CO2 electrochemical reduction by protonated pyridine and similar molecules. Useful lessons from a methodological misadventure. ACS Energy Lett. 3, 695–703 (2018).

Saveant, J.-M. & Tard, C. Attempts To catalyze the electrochemical CO2-to-methanol conversion by biomimetic 2e– + 2H+ transferring molecules. J. Am. Chem. Soc. 138, 1017–1021 (2016).

Wu, Y., Liang, Y. & Wang, H. Heterogeneous molecular catalysts of metal phthalocyanines for electrochemical CO2 reduction reactions. Acc. Chem. Res. 54, 3149–3159 (2021).

Ogura, K., Endo, N. & Nakayama, M. Mechanistic studies of CO2 reduction on a mediated electrode with conducting polymer and inorganic conductor films. J. Electrochem. Soc. 145, 3801 (1998).

Aydin, R. & Köleli, F. Electrocatalytic conversion of CO2 on a polypyrrole electrode under high pressure in methanol. Synth. Met. 144, 75–80 (2004).

Torbensen, K. et al. Molecular catalysts boost the rate of electrolytic CO2 reduction. ACS Energy Lett. 5, 1512–1518 (2020).

Mao, Y., Head-Gordon, M. & Shao, Y. Unraveling substituent effects on frontier orbitals of conjugated molecules using an absolutely localized molecular orbital based analysis. Chem. Sci. 9, 8598–8607 (2018).

Lee, G. et al. Electrochemical upgrade of CO2 from amine capture solution. Nat. Energy 6, 46–53 (2021).

Jakobsen, J. B., Rønne, M. H., Daasbjerg, K. & Skrydstrup, T. Are amines the holy grail for facilitating CO2 reduction? Angew. Chem. Int. Ed. 60, 9174–9179 (2021).

Lin-Vien, D., Colthup, N. B., Fateley, W. G. & Grasselli, J. G. in The Handbook of Infrared and Raman Characteristic Frequencies of Organic Molecules 477–490 (Academic Press, 1991).

Pérez-Gallent, E., Figueiredo, M. C., Calle-Vallejo, F. & Koper, M. T. M. Spectroscopic observation of a hydrogenated CO dimer intermediate during CO reduction on Cu(100) electrodes. Angew. Chem. Int. Ed. 56, 3621–3624 (2017).

Zhao, Y. et al. Elucidating electrochemical CO2 reduction reaction processes on Cu(hkl) single-crystal surfaces by in situ Raman spectroscopy. Energy Environ. Sci. 15, 3968–3977 (2022).

Shan, W. et al. In situ surface-enhanced Raman spectroscopic evidence on the origin of selectivity in CO2 electrocatalytic reduction. ACS Nano 14, 11363–11372 (2020).

Xiao, H., Cheng, T., Goddard, W. A. III & Sundararaman, R. Mechanistic explanation of the pH dependence and onset potentials for hydrocarbon products from electrochemical reduction of CO on Cu (111). J. Am. Chem. Soc. 138, 483–486 (2016).

Bagger, A., Ju, W., Varela, A. S., Strasser, P. & Rossmeisl, J. Electrochemical CO2 reduction: a classification problem. ChemPhysChem 18, 3266–3273 (2017).

Sprung, M. A. A summary of the reactions of aldehydes with amines. Chem. Rev. 26, 297–338 (1940).

Yasuda, T., Namekawa, K., Iijima, T. & Yamamoto, T. New luminescent 1,2,4-triazole/thiophene alternating copolymers: synthesis, characterization, and optical properties. Polymer 48, 4375–4384 (2007).

Kim, J. & Swager, T. M. Control of conformational and interpolymer effects in conjugated polymers. Nature 411, 1030–1034 (2001).

Xiao, H., Goddard, W. A., Cheng, T. & Liu, Y. Cu metal embedded in oxidized matrix catalyst to promote CO2 activation and CO dimerization for electrochemical reduction of CO2. Proc. Natl Acad. Sci. USA 114, 6685–6688 (2017).

Razzaq, R., Li, C. & Zhang, S. Coke oven gas: availability, properties, purification, and utilization in China. Fuel 113, 287–299 (2013).

Li, J. et al. A holistic life cycle evaluation of coking production covering coke oven gas purification process based on the subdivision method. J. Cleaner Prod. 248, 119183 (2020).

de Oliveira Carneiro, L., de Vasconcelos, S. F., de Farias Neto, G. W., Brito, R. P. & Brito, K. D. Improving H2S removal in the coke oven gas purification process. Sep. Purif. Technol. 257, 117862 (2021).

Gabardo, C. M. et al. Continuous carbon dioxide electroreduction to concentrated multi-carbon products using a membrane electrode assembly. Joule 3, 2777–2791 (2019).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Hafner, J. Ab initio molecular-dynamics simulation of the liquid–metal–amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Sullivan, I. et al. Coupling electrochemical CO2 conversion with CO2 capture. Nat. Catal. 4, 952–958 (2021).

Mathew, K., Kolluru, V. S. C., Mula, S., Steinmann, S. N. & Hennig, R. G. Implicit self-consistent electrolyte model in plane-wave density-functional theory. J. Chem. Phys. 151, 234101 (2019).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Alavi, A., Hu, P., Deutsch, T., Silvestrelli, P. L. & Hutter, J. CO oxidation on Pt(111): an ab initio density functional theory study. Phys. Rev. Lett. 80, 3650–3653 (1998).

Liu, Z.-P. & Hu, P. General rules for predicting where a catalytic reaction should occur on metal surfaces: a density functional theory study of C–H and C–O bond breaking/making on flat, stepped, and kinked metal surfaces. J. Am. Chem. Soc. 125, 1958–1967 (2003).

Acknowledgements

Y.W., Z.X., W.W. and Q.L. acknowledge the financial support from the Excellent Young Scientist Fund (Hong Kong and Macau) from the National Natural Science Foundation of China (project number 22222208) and the Research Grants Council of the Hong Kong Special Administrative Region (project number 14307322). The computational study is supported by the Marsden Fund Council from Government funding (21-UOA-237) and Catalyst: Seeding General Grant (22-UOA-031-CGS), managed by Royal Society Te Apārangi. Z.W. and R.L. wish to acknowledge the use of New Zealand eScience Infrastructure (NeSI) high-performance computing facilities, consulting support and/or training services as part of this research. S.-F.H., Z.-Y.L. and H.-J.T. gratefully acknowledge the support from the National Science and Technology Council, Taiwan (contract number NSTC 112-2628-M-A49-001) and the support from the Yushan Young Scholar Program and the Center for Emergent Functional Matter Science of National Yang Ming Chiao Tung University, Ministry of Education, Taiwan.

Author information

Authors and Affiliations

Contributions

Y.W., Z.W. and S.-F.H. designed and supervised the project. Z.X. carried out the electrochemical measurements, NMR, Fourier transform infrared, X-ray photoelectron spectroscopy (XPS), inductively coupled plasma mass spectrometry (ICP-MS), X-ray fluorescence (XRF) and scanning electron microscopy (SEM) measurements and analysed the data. R.L. carried out DFT calculations and analysed the data. Z.-Y.L. and H.-J.T. performed in situ Raman analysis. Z.X., R.L., W.W., Q.L., Y.C.L., C.S., J.C.Y., S.-F.H., Z.W. and Y.W. co-wrote the paper. All authors discussed the results and contributed to the preparation of the paper.

Corresponding authors

Ethics declarations

Competing interests

Y.W. and Z.X. declare that a US provisional patent titled ‘Small Molecules Based Electrode for Green Methane and Town Gas Production from Carbon Dioxide at High Rates’ has been granted (application number 63/587,837), and a Patent Cooperation Treaty (PCT) application is filed (application number PCT/CN2024/103140). The other authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Mei Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods 1 and 2, Notes 1–4, Figs. 1–35 and Tables 1–12.

Supplementary Data 1

Source data for supplementary figures.

Supplementary Data 2

The atomic coordinates of the optimized models.

Source data

Source Data Fig. 2

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, Z., Lu, R., Lin, ZY. et al. Electroreduction of CO2 to methane with triazole molecular catalysts. Nat Energy 9, 1397–1406 (2024). https://doi.org/10.1038/s41560-024-01645-0

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41560-024-01645-0

This article is cited by

-

Membrane-free CO2 hydrogenation electrolyzer for salt precipitation management in acidic electrochemical CO2 reduction

Nature Communications (2026)

-

Boosting electrochemical CO2 methanation via electronic metal-support interactions in CuO/MgO heterostructures

Science China Chemistry (2026)

-

Producing methane through organocatalysis

Nature Energy (2024)