Abstract

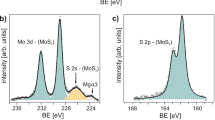

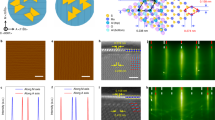

Batch production of single-crystal two-dimensional (2D) transition metal dichalcogenides is one prerequisite for the fabrication of next-generation integrated circuits. Contemporary strategies for the wafer-scale high-quality crystallinity of 2D materials centre on merging unidirectionally aligned, differently sized domains. However, an imperfectly merged area with a translational lattice brings about a high defect density and low device uniformity, which restricts the application of the 2D materials. Here we establish a liquid-to-solid crystallization in 2D space that can rapidly grow a centimetre-scale single-crystal MoS2 domain with no grain boundaries. The large MoS2 single crystal obtained shows superb uniformity and high quality with an ultra-low defect density. A statistical analysis of field effect transistors fabricated from the MoS2 reveals a high device yield and minimal variation in mobility, positioning this FET as an advanced standard monolayer MoS2 device. This 2D Czochralski method has implications for fabricating high-quality and scalable 2D semiconductor materials and devices.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are available in the main text or Supplementary Information. Source data are provided with this paper.

References

Zhang, T., Wang, J., Wu, P., Lu, A.-Y. & Kong, J. Vapour-phase deposition of two-dimensional layered chalcogenides. Nat. Rev. Mater. 8, 799–821 (2023).

Li, T. et al. Epitaxial growth of wafer-scale molybdenum disulfide semiconductor single crystals on sapphire. Nat. Nanotechnol. 16, 1201–1207 (2021).

Chhowalla, M., Jena, D. & Zhang, H. Two-dimensional semiconductors for transistors. Nat. Rev. Mater. 1, 16052 (2016).

Sheng, C. et al. Two‐dimensional semiconductors: from device processing to circuit integration. Adv. Func. Mater. 33, 2304778 (2023).

Wang, Q. et al. Wafer-scale highly oriented monolayer MoS2 with large domain sizes. Nano Lett. 20, 7193–7199 (2020).

Chubarov, M. et al. Wafer-scale epitaxial growth of unidirectional WS2 monolayers on sapphire. ACS Nano 15, 2532–2541 (2021).

Yang, P. et al. Epitaxial growth of centimeter-scale single-crystal MoS2 monolayer on Au (111). ACS Nano 14, 5036–5045 (2020).

O’Brien, K. P. et al. Process integration and future outlook of 2D transistors. Nat. Commun. 14, 6400 (2023).

Li, R. et al. Controlled lattice deformation for high-mobility two-dimensional MoTe2 growth. J. Materiomics 11, 100868 (2025).

Xu, X. et al. Growth of 2D materials at the wafer scale. Adv. Mater. 34, 2108258 (2022).

Gao, Y. et al. Ultrafast growth of high‐quality monolayer WSe2 on Au. Adv. Mater. 29, 1700990 (2017).

Chang, M.-C. et al. Fast growth of large-grain and continuous MoS2 films through a self-capping vapor-liquid-solid method. Nat. Commun. 11, 3682 (2020).

Chen, J. et al. Chemical vapor deposition of large-size monolayer MoSe2 crystals on molten glass. J. Am. Chem. Soc. 139, 1073–1076 (2017).

Wu, T. et al. Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu–Ni alloys. Nat. Mater. 15, 43–47 (2016).

Guo, W. et al. Oxidative‐etching‐assisted synthesis of centimeter‐sized single‐crystalline graphene. Adv. Mater. 28, 3152–3158 (2016).

Guo, Y., Hu, Y. & Yuan, Q. Synthesis of two‐dimensional materials: how computational studies can help? Wiley Interdiscip. Rev. Comput. Mol. Sci. 13, e1635 (2023).

Dong, J., Zhang, L., Dai, X. & Ding, F. The epitaxy of 2D materials growth. Nat. Commun. 11, 5862 (2020).

Teal, G. K., Sparks, M. & Buehler, E. Growth of germanium single crystals containing p−n junctions. Phys. Rev. 81, 637 (1951).

Suzuki, H. et al. Surface diffusion-limited growth of large and high-quality monolayer transition metal dichalcogenides in confined space of microreactor. ACS Nano 16, 11360–11373 (2022).

Zhang, P. et al. Flux-assisted growth of atomically thin materials. Nat. Synth. 1, 864–872 (2022).

Li, S. et al. Vapour–liquid–solid growth of monolayer MoS2 nanoribbons. Nat. Mater. 17, 535–542 (2018).

Zhao, T. et al. Substrate engineering for wafer-scale two-dimensional material growth: strategies, mechanisms, and perspectives. Chem. Soc. Rev. 52, 1650–1671 (2023).

Chen, J. et al. Chemical vapor deposition of high‐quality large‐sized MoS2 crystals on silicon dioxide substrates. Adv. Sci. 3, 1500033 (2016).

Chen, W. et al. Oxygen-assisted chemical vapor deposition growth of large single-crystal and high-quality monolayer MoS2. J. Am. Chem. Soc. 137, 15632–15635 (2015).

Ji, Q. et al. Revealing the Brønsted-Evans-Polanyi relation in halide-activated fast MoS2 growth toward millimeter-sized 2D crystals. Sci. Adv. 7, eabj3274 (2021).

Kim, H., Ovchinnikov, D., Deiana, D., Unuchek, D. & Kis, A. Suppressing nucleation in metal–organic chemical vapor deposition of MoS2 monolayers by alkali metal halides. Nano Lett. 17, 5056–5063 (2017).

Park, J. H. et al. Synthesis of high-performance monolayer molybdenum disulfide at low temperature. Small Methods 5, 2000720 (2021).

Shi, R. et al. Oxide inhibitor-assisted growth of single-layer molybdenum dichalcogenides (MoX2, X = S, Se, Te) with controllable molybdenum release. ACS Nano 14, 7593–7601 (2020).

Yang, P. et al. Batch production of 6-inch uniform monolayer molybdenum disulfide catalyzed by sodium in glass. Nat. Commun. 9, 979 (2018).

Zhou, J. et al. A library of atomically thin metal chalcogenides. Nature 556, 355–359 (2018).

Hong, J. et al. Exploring atomic defects in molybdenum disulphide monolayers. Nat. Commun. 6, 6293 (2015).

Qiu, H. et al. Hopping transport through defect-induced localized states in molybdenum disulphide. Nat. Commun. 4, 2642 (2013).

Yu, Z. et al. Towards intrinsic charge transport in monolayer molybdenum disulfide by defect and interface engineering. Nat. Commun. 5, 5290 (2014).

Edwards, H. W. Interference in thin metallic films. Phys. Rev. 38, 166–173 (1931).

Zu, Y. et al. Study on the influence of the pulling rate on the axial and radial uniformity of gallium in Czochralski monocrystalline silicon crystal. Silicon 15, 6073–6084 (2023).

Li, F. et al. Rational kinetics control toward universal growth of 2D vertically stacked heterostructures. Adv. Mater. 31, 1901351 (2019).

Chen, Y. et al. Growing uniform graphene disks and films on molten glass for heating devices and cell culture. Adv. Mater. 27, 7839–7846 (2015).

Chen, Z. et al. Growth of 12-inch uniform monolayer graphene film on molten glass and its application in PbI2-based photodetector. Nano Res. 12, 1888–1893 (2019).

Das, S. et al. Transistors based on two-dimensional materials for future integrated circuits. Nat. Electron. 4, 786–799 (2021).

Zhang, X. et al. Van der Waals‐interface‐dominated all‐2D electronics. Adv. Mater. 35, 2207966 (2023).

Li, M.-Y. et al. Wafer-scale Bi-assisted semi-auto dry transfer and fabrication of high-performance monolayer CVD WS2 transistor. In 2022 IEEE Symposium on VLSI Technology and Circuits 290–291 (IEEE, 2022).

Fu, J.-H. et al. Oriented lateral growth of two-dimensional materials on c-plane sapphire. Nat. Nanotechnol. 18, 1289–1294 (2023).

Xia, Y. et al. 12-inch growth of uniform MoS2 monolayer for integrated circuit manufacture. Nat. Mater. 22, 1324–1331 (2023).

Gao, L. et al. Defect-engineered atomically thin MoS2 homogeneous electronics for logic inverters. Adv. Mater. 32, 1906646 (2020).

Li, H. et al. From bulk to monolayer MoS2: evolution of Raman scattering. Adv. Func. Mater. 22, 1385–1390 (2012).

Zhang, X. et al. Hidden vacancy benefit in monolayer 2D semiconductors. Adv. Mater. 33, 2007051 (2021).

Dai, Y., Zhang, Y., Li, Q. & Nan, C. Synthesis and optical properties of tetrapod-like zinc oxide nanorods. Chem. Phys. Lett. 358, 83–86 (2002).

Smithe, K. K., Suryavanshi, S. V., Muñoz Rojo, M., Tedjarati, A. D. & Pop, E. Low variability in synthetic monolayer MoS2 devices. ACS Nano 11, 8456–8463 (2017).

Kim, K. S. et al. Non-epitaxial single-crystal 2D material growth by geometric confinement. Nature 614, 88–94 (2023).

Wei, X. et al. Homojunction-loaded inverters based on self-biased molybdenum disulfide transistors for sub-picowatt computing. Nat. Electron. 7, 138–146 (2024).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant numbers 52225206, 51991340, 92163205, 52188101, 62322402, 52350301, 62204012, 51991342, 52250398, 52303362 and 62304019), the National Key Research and Development Program of China (grant numbers 2022YFA1203800 and 2022YFA1203803), the Beijing Nova Program (grant numbers 20220484145 and 20230484478), the Fundamental Research Funds for the Central Universities (grant numbers FRF-TP-22-004C2, FRF-06500207, FRF-TP-22-004A1, FRF-IDRY-22-016 and FRF-IDRY-23-038), the State Key Lab for Advanced Metals and Materials (number 2023-Z05) and special support from the Postdoctoral Science Foundation (number 8206400173).

We are grateful for the help with STEM provided by Q. Zhang of the Institute of Physics, Chinese Academy of Sciences and B. Han of Peking University. We are grateful to H. Guo and G. Li at the Institute of Physics, Chinese Academy of Sciences for the help with LEED. We thank X. Liu and Y. Tian at the National Center for Nanoscience and Technology for the low-temperature PL characteristics. We are grateful to G. Zhang and Y. Xiong of the Institute of Physics, Chinese Academy of Sciences for STM characteristics. We are grateful to J. Shang, H. Zhao, Y. Geng and C. Chen of the University of Science and Technology Beijing for the preparation of FETs. We are grateful to Y. Yu at the Southern University of Science and Technology for constructive discussions. We are grateful to Y. Wang and H. He of the Institute of Process Engineering, Chinese Academy of Sciences for constructive discussions.

Author information

Authors and Affiliations

Contributions

H.J., Z.Z. and Y.Z. initiated and supervised the project. H.J. and X.Z. created the MoS2 monolayers using the 2DCZ method. K.C., X.H. and Y.W. performed device fabrication, data collection and analysis. Y.L., H.Y., L.G. and M.H. assisted in carrying out the mechanism. L.G. performed part of the Raman, PL, LEED and characterization analyses. H.Y. performed the AFM analysis and nano-scratch test. H.J., K.C., X.H., Z.Z., X.Z. and Y.Z. cowrote the paper. All authors discussed the results and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Jong-Hyun Ahn, Lain-Jong Li and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–16, Table 1 and references.

Supplementary Video 1

In situ imaging of 2DCZ.

Supplementary Video 2

The spreading process of the 2D liquid precursor.

Supplementary Video 3

The water-assisted transfer process (×20).

Supplementary Video 4

The fully spontaneous transfer process.

Supplementary Table 1

Comparison of growth and performance of large-area MoS2 materials with reported works.

Source data

Source Data Fig. 1

Benchmark comparison and comparison of defect density.

Source Data Fig. 4

Statistical distribution of the Raman peak difference; Raman line scan contour map covering a centimetre length range; and statistical bar graph showing defect density observed in HAADF-STEM images.

Source Data Fig. 5

Transfer characteristics of FET array; statistical distribution of SS, mobility and Vth; output characteristics; and transfer characteristics of the short-channel FET.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, H., Zhang, X., Chen, K. et al. Two-dimensional Czochralski growth of single-crystal MoS2. Nat. Mater. 24, 188–196 (2025). https://doi.org/10.1038/s41563-024-02069-7

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41563-024-02069-7

This article is cited by

-

Biomimetic Synapses Based on Halide Perovskites for Neuromorphic Vision Computing: Materials, Devices, and Applications

Nano-Micro Letters (2026)

-

InvDesFlow-AL: active learning-based workflow for inverse design of functional materials

npj Computational Materials (2025)

-

Large-scale single MoS2 crystals unlocked

Nature Reviews Materials (2025)

-

Angle-resolved scatterometry combined with deep learning assisted in-situ monitoring of nanowire doping in molecular beam epitaxy process

Microsystems & Nanoengineering (2025)

-

Room-temperature solution processing of high-mobility MoS2 thin films

Nature Communications (2025)