Abstract

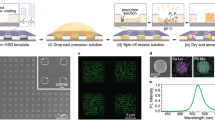

The extension of optoelectronic devices from planar to non-developable structures has led to remarkable success in bionics, optical imaging and soft electronics. However, non-developable optoelectronic devices are achieved mainly via physical deformations and limited to a few geometries. Here we report a self-assembly perovskite strategy for integrating optoelectronic arrays with arbitrary non-developable structures. The perovskite films are grown from a rapid nucleation-dominated crystallization driven by the low energy fluctuation of lead iodide solution, where the fluid precursor can be evenly dispersed along non-developable substrates by surface tension and then self-assembles into compact films through gaseous manipulation. The strategy covers arbitrarily shaped substrates with three-dimensional length scales over 106 orders of magnitude and enables the unique structural manipulations of photodiode arrays with micrometre precision. As a proof of concept, the theoretical focal surface of a single-lens image system is realized into a non-developable sensor, effectively correcting the off-axis coma aberrations compared with its planar or hemispherical counterpart.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data in this study are present within the article and its Supplementary Information. Further data are available from the corresponding author upon request. Source data are provided with this paper.

References

Ko, H. C. et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 454, 748–753 (2008).

Gu, L. et al. A biomimetic eye with a hemispherical perovskite nanowire array retina. Nature 581, 278–282 (2020).

Lee, W. et al. Two-dimensional materials in functional three-dimensional architectures with applications in photodetection and imaging. Nat. Commun. 9, 1417 (2018).

Song, Y. M. et al. Digital cameras with designs inspired by the arthropod eye. Nature 497, 95–99 (2013).

Jang, J. et al. 3D heterogeneous device arrays for multiplexed sensing platforms using transfer of perovskites. Adv. Mater. 33, 2101093 (2021).

Song, J. K. et al. Stretchable colour-sensitive quantum dot nanocomposites for shape-tunable multiplexed phototransistor arrays. Nat. Nanotechnol. 17, 849–856 (2022).

Zhang, D. et al. Large-scale planar and spherical light-emitting diodes based on arrays of perovskite quantum wires. Nat. Photon. 16, 284–290 (2022).

Rich, S. I., Jiang, Z., Fukuda, K. & Someya, T. Well-rounded devices: the fabrication of electronics on curved surfaces—a review. Mater. Horiz. 8, 1926–1958 (2021).

Rao, Z. et al. Curvy, shape-adaptive imagers based on printed optoelectronic pixels with a kirigami design. Nat. Electron. 4, 513–521 (2021).

Zhang, K. et al. Origami silicon optoelectronics for hemispherical electronic eye systems. Nat. Commun. 8, 1782 (2017).

Kim, M. et al. An aquatic-vision-inspired camera based on a monocentric lens and a silicon nanorod photodiode array. Nat. Electron. 3, 546–553 (2020).

Choi, C. et al. Human eye-inspired soft optoelectronic device using high-density MoS2-graphene curved image sensor array. Nat. Commun. 8, 1664 (2017).

Huang, Y. et al. Assembly and applications of 3D conformal electronics on curvilinear surfaces. Mater. Horiz. 6, 642–683 (2019).

Gao, W., Xu, Z., Han, X. & Pan, C. Recent advances in curved image sensor arrays for bioinspired vision system. Nano Today 42, 101366 (2022).

Wessely, M. et al. Sprayable user interfaces: prototyping large-scale interactive surfaces with sensors and displays. In Proc. 2020 CHI Conference on Human Factors in Computing Systems (eds CHI Conference Editorial Board) 1–12 (Association for Computing Machinery, 2020).

Toriz-Garcia, J. J. et al. Fabrication of a 3D electrically small antenna using holographic photolithography. J. Micromech. Microeng. 23, 055010 (2013).

Carey, T., Jones, C., Le Moal, F., Deganello, D. & Torrisi, F. Spray-coating thin films on three-dimensional surfaces for a semitransparent capacitive-touch device. ACS Appl. Mater. Interfaces 10, 19948–19956 (2018).

Lee, J.-G. et al. Highly flexible, stretchable, wearable, patternable and transparent heaters on complex 3D surfaces formed from supersonically sprayed silver nanowires. J. Mater. Chem. A 5, 6677–6685 (2017).

Zhang, Y. et al. Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nat. Rev. Mater. 2, 17019 (2017).

Li, S. X. et al. Curved photodetectors based on perovskite microwire arrays via in situ conformal nanoimprinting. Adv. Funct. Mater. 32, 2202277 (2022).

Feng, X. et al. Differential perovskite hemispherical photodetector for intelligent imaging and location tracking. Nat. Commun. 15, 577 (2024).

Feng, X. et al. Spray-coated perovskite hemispherical photodetector featuring narrow-band and wide-angle imaging. Nat. Commun. 13, 6106 (2022).

Kim, H., Moon, J., Lee, K. & Kanicki, J. 3D printed masks and transfer stamping process to enable the fabrication of the hemispherical organic photodiodes. Adv. Mater. Technol. 2, 1700090 (2017).

Kelso, M. V. et al. Spin coating epitaxial films. Science 364, 166–169 (2019).

Shi, G. et al. Manipulating solvent fluidic dynamics for large-area perovskite film-formation and white light-emitting diodes. Nat. Commun. 15, 1066 (2024).

Raga, S. R., Ono, L. K. & Qi, Y. Rapid perovskite formation by CH3NH2 gas-induced intercalation and reaction of PbI2. J. Mater. Chem. A 4, 2494–2500 (2016).

Singh, A. et al. Methylamine gas treatment affords improving semitransparency, efficiency, and stability of CH3NH3PbBr3‐based perovskite solar cells. Sol. RRL 5, 2100277 (2021).

Mao, J. et al. Novel direct nanopatterning approach to fabricate periodically nanostructured perovskite for optoelectronic applications. Adv. Funct. Mater. 27, 1606525 (2017).

Jeong, B. et al. Solvent-assisted gel printing for micropatterning thin organic-inorganic hybrid perovskite films. ACS Nano 10, 9026–9035 (2016).

Lee, L. et al. Wafer-scale single-crystal perovskite patterned thin films based on geometrically-confined lateral crystal growth. Nat. Commun. 8, 15882 (2017).

Zhou, Z. et al. Methylamine-gas-induced defect-healing behavior of CH3NH3PbI3 thin films for perovskite solar cells. Angew. Chem. Int. Ed. 54, 9705–9709 (2015).

Fan, H. et al. Methylamine-assisted growth of uniaxial-oriented perovskite thin films with millimeter-sized grains. Nat. Commun. 11, 5402 (2020).

Zhou, Y. et al. Self-powered perovskite photon-counting detectors. Nature 616, 712–718 (2023).

Feng, X., Tan, M., Li, M., Wei, H. & Yang, B. Polyhydroxy ester stabilized perovskite for low noise and large linear dynamic range of self-powered photodetectors. Nano Lett. 21, 1500–1507 (2021).

Wang, M., Gao, W., Cao, F. & Li, L. Ethylamine iodide additive enables solid-to-solid transformed highly oriented perovskite for excellent photodetectors. Adv. Mater. 34, e2108569 (2022).

Kim, J. H. et al. Thickness-insensitive properties of α-MoO3 nanosheets by weak interlayer coupling. Nano Lett. 19, 8868–8876 (2019).

Liu, D. et al. Impact of ultrathin C60 on perovskite photovoltaic devices. ACS Nano 12, 876–883 (2018).

Liu, C. et al. Ultra-thin MoOx as cathode buffer layer for the improvement of all-inorganic CsPbIBr2 perovskite solar cells. Nano Energy 41, 75–83 (2017).

He, Z. et al. Perovskite retinomorphic image sensor for embodied intelligent vision. Sci. Adv. 11, eads2834 (2025).

Park, J. et al. Avian eye–inspired perovskite artificial vision system for foveated and multispectral imaging. Sci. Robot. 9, eadk6903 (2024).

Wang, C. et al. Strain-insensitive viscoelastic perovskite film for intrinsically stretchable neuromorphic vision-adaptive transistors. Nat. Commun. 15, 3123 (2024).

Acknowledgements

We acknowledge support from the National Natural Science Foundation of China (52025028, 52450138, 52332008, 52302191, 52372214 and U22A20137) and China Postdoctoral Science Foundation (2022M722309 and 2022TQ0228), funded by the Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Contributions

L.L. managed the whole project. L.L. and Meng Wang conceived and designed the experiments. L.L. and Meng Wang analysed the data. Meng Wang performed the experiments and wrote the paper. F.C., L.M., Min Wang and L.L. reviewed the paper. All authors discussed the results and provided comments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Zhiyong Fan, Kenjiro Fukuda and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Retardation effect caused by spatial variations and optimization using air flows.

a, Schematic illustration of the retardation effect caused by the residual evaporating gas. b–d, Demonstrations of the retardation effect by simulating different exposure rooms for the crystallization of the PbI2 solutions in (b) an open environment, (c) a limited large room and (d) a limited small room. e, f, Morphologies of the film crystallizing at the outer and inner surfaces of a hollow hemisphere under (e) natural conditions and (f) continuous air flow.

Extended Data Fig. 2 Demonstration of an actual operation to deposit an MPI layer on a glass sphere.

For a better demonstration, some processes are simplified. For example, the drying oven is replaced by a blower to provide air flow.

Extended Data Fig. 3 Modification effect of the liquefication process on the film morphology.

a, Time-resolved optical microscope images of a cluster of PbI2 powder in an MA environment. b, Schematic illustration of the healing effect of the liquefaction process on the micro-pinholes. c, d, Demonstration of the healing process observed under an optical microscope in (c) and magnified morphology observed under a scanning electron microscope in (d).

Extended Data Fig. 4 Characterizations of an individual pixel of the rippled-shaped array.

a, SEM image of the vertical section of a single pixel. b–c, Energy band alignment of the vertical photodiode and its working mechanism under self-powered mode; here, light-generated holes and electrons are transported to the corresponding electrodes through built-in electric fields. d, Time-dependent current curve under periodic on/off light and corresponding rise/decay times. e, Dependence of the current and R on the intensity of the incident light (532 nm).

Extended Data Fig. 5 Integration process and characterization system.

a, Shadow masks and the geometry of the crossbar array. b, Real pictures of the focal substrate and shadow mask. c, Schematic illustrations of the device integration process. d, Pictures of the constructed sensor array on the focal substrate. Inset i shows the coverage by the shadow mask, ii shows the magnified image of the white square frame, and iii highlights the contrast ratio to show the transparent top ITO channel. e–g, Image characterization system. The sensor array is integrated with (e) an optical lens fixed in a front shell and further linked with (f) a print broad circuit through epitaxial circuits. The output signals are collected by the multichannel matrix system in (g).

Supplementary information

Supplementary Information

Supplementary Notes 1–11, Figs. 1–34, Table 1 and references.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Extended Data Fig. 4

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, M., Cao, F., Meng, L. et al. Direct integration of optoelectronic arrays with arbitrary non-developable structures. Nat. Mater. 24, 1778–1784 (2025). https://doi.org/10.1038/s41563-025-02322-7

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41563-025-02322-7

This article is cited by

-

The development of customized perovskite photodetectors

Nature Electronics (2025)