Abstract

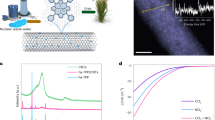

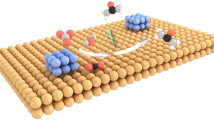

The electrosynthesis of pure urea via the co-reduction of CO2 and N2 remains challenging. Here we show that a proton-limited environment established in an electrolyser equipped with porous solid-state electrolyte, devoid of an aqueous electrolyte, can suppress the hydrogen evolution reaction and excessive hydrogenation of N2 to ammonia. This can instead be conducive to the C–N coupling of *CO2 with *NHNH (the intermediate from the semi-hydrogenation of N2), thereby facilitating the production of urea. By using nanosheets of an ultrathin two-dimensional metal–azolate framework with cyclic heterotrimetal clusters as catalyst, the Faradaic efficiency of urea production from pretreated flue gas (which contains mainly 85% N2 and 15% CO2) is as high as 65.5%, and no ammonia and other liquid products were generated. At a low cell voltage of 2.0 V, the current can reach 100 mA, and the urea production rate is as high as 5.07 g gcat−1 h−1 or 84.4 mmol gcat−1 h−1. Notably, it can continuously produce 6.2 wt% pure urea aqueous solution for at least 30 h, and about 1.24 g pure urea solid was obtained. The use of pretreated flue gas as a direct feedstock significantly reduces input costs, and the high reaction rate and selectivity contribute to a reduction in system scale and operational costs.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the finding of the study are available in the article and its Supplementary Information. Source data are provided with this paper.

References

Mao, Y. et al. Ambient electrocatalytic synthesis of urea by co-reduction of NO3− and CO2 over graphene-supported In2O3. Chin. Chem. Lett. 35, 108540 (2024).

Zhang, S. et al. High-efficiency electrosynthesis of urea over bacterial cellulose regulated Pd–Cu bimetallic catalyst. EES Catal. 1, 45–53 (2023).

Li, J., Zhang, Y., Kuruvinashetti, K. & Kornienko, N. Construction of C–N bonds from small-molecule precursors through heterogeneous electrocatalysis. Nat. Rev. Chem. 6, 303–319 (2022).

Zhu, X., Zhou, X., Jing, Y. & Li, Y. Electrochemical synthesis of urea on MBenes. Nat. Commun. 12, 4080 (2021).

Zhang, S. et al. Atomically dispersed bimetallic Fe–Co electrocatalysts for green production of ammonia. Nat. Sustain. 6, 169–179 (2022).

Yin, H.-Q. et al. Electrochemical urea synthesis by co-reduction of CO2 and nitrate with FeII-FeIIIOOH@BiVO4 heterostructures. J. Energy Chem. 84, 385–393 (2023).

Liu, X., Jiao, Y., Zheng, Y., Jaroniec, M. & Qiao, S.-Z. Mechanism of C–N bonds formation in electrocatalytic urea production revealed by ab initio molecular dynamics simulation. Nat. Commun. 13, 5471 (2022).

Zhao, Y. et al. Efficient urea electrosynthesis from carbon dioxide and nitrate via alternating Cu–W bimetallic C–N coupling sites. Nat. Commun. 14, 4491 (2023).

Xu, M. et al. Kinetically matched C–N coupling toward efficient urea electrosynthesis enabled on copper single-atom alloy. Nat. Commun. 14, 6994 (2023).

Chen, C. et al. Coupling N2 and CO2 in H2O to synthesize urea under ambient conditions. Nat. Chem. 12, 717–724 (2020).

Zhang, X. et al. Electrocatalytic urea synthesis with 63.5% Faradaic efficiency and 100% N‐selectivity via one‐step C–N coupling. Angew. Chem. Int. Ed. 62, e202305447 (2023).

Yuan, M. et al. Unveiling electrochemical urea synthesis by co‐activation of CO2 and N2 with Mott–Schottky heterostructure catalysts. Angew. Chem. Int. Ed. 133, 11005–11013 (2021).

Yuan, M. et al. Highly selective electroreduction of N2 and CO2 to urea over artificial frustrated Lewis pairs. Energy Environ. Sci. 14, 6605–6615 (2021).

Chen, X. et al. Efficient C–N coupling in the direct synthesis of urea from CO2 and N2 by amorphous SbxBi1−xOy clusters. Proc. Natl Acad. Sci. USA 120, e2306841120 (2023).

Paul, S., Sarkar, S., Adalder, A., Banerjee, A. & Ghorai, U. K. Dual metal site-mediated efficient C–N coupling toward electrochemical urea synthesis. J. Mater. Chem. A 11, 13249–13254 (2023).

Jiao, D. et al. Boosting the efficiency of urea synthesis via cooperative electroreduction of N2 and CO2 on MoP. J. Mater. Chem. A 11, 232–240 (2023).

Yuan, M. et al. Electrochemical C–N coupling with perovskite hybrids toward efficient urea synthesis. Chem. Sci. 12, 6048–6058 (2021).

Yuan, M. et al. Artificial frustrated Lewis pairs facilitating the electrochemical N2 and CO2 conversion to urea. Chem. Catal. 2, 309–320 (2022).

Mukherjee, J. et al. Understanding the site‐selective electrocatalytic co‐reduction mechanism for green urea synthesis using copper phthalocyanine nanotubes. Adv. Funct. Mater. 32, 2200882 (2022).

Yuan, M. et al. Engineering surface atomic architecture of NiTe nanocrystals toward efficient electrochemical N2 fixation. Adv. Funct. Mater. 30, 2004208 (2020).

Yuan, M. et al. Host–guest molecular interaction promoted urea electrosynthesis over a precisely designed conductive metal–organic framework. Energy Environ. Sci. 15, 2084–2095 (2022).

Zhu, P. et al. Continuous carbon capture in an electrochemical solid-electrolyte reactor. Nature 618, 959–966 (2023).

Xia, C., Xia, Y., Zhu, P., Fan, L. & Wang, H. Direct electrosynthesis of pure aqueous H2O2 solutions up to 20% by weight using a solid electrolyte. Science 366, 226–231 (2019).

Kim, J. Y. ‘T.’, Sellers, C., Hao, S., Senftle, T. P. & Wang, H. Different distributions of multi-carbon products in CO2 and CO electroreduction under practical reaction conditions. Nat. Catal. 6, 1115–1124 (2023).

Zhu, P. & Wang, H. High-purity and high-concentration liquid fuels through CO2 electroreduction. Nat. Catal. 4, 943–951 (2021).

Romiluyi, O., Danilovic, N., Bell, A. T. & Weber, A. Z. Membrane‐electrode assembly design parameters for optimal CO2 reduction. Electrochem. Sci. Adv. 3, e2100186 (2023).

Fu, X. et al. Continuous-flow electrosynthesis of ammonia by nitrogen reduction and hydrogen oxidation. Science 379, 707–712 (2023).

Song, X. et al. One-step formation of urea from carbon dioxide and nitrogen using water microdroplets. J. Am. Chem. Soc. 145, 25910–25916 (2023).

Bell, A. T. A novel strategy for ionomer coating of Ag nanoparticles used for the electrochemical reduction of CO2 to CO in a membrane electrode assembly. Natl Sci. Rev. 11, nwad232 (2024).

Xia, C. et al. Continuous production of pure liquid fuel solutions via electrocatalytic CO2 reduction using solid-electrolyte devices. Nat. Energy 4, 776–785 (2019).

Fan, L., Xia, C., Zhu, P., Lu, Y. & Wang, H. Electrochemical CO2 reduction to high-concentration pure formic acid solutions in an all-solid-state reactor. Nat. Commun. 11, 3633 (2020).

Zhu, H.-L. et al. Continuously producing highly concentrated and pure acetic acid aqueous solution via direct electroreduction of CO2. J. Am. Chem. Soc. 146, 1144–1152 (2024).

Abdul-Baki, A. A., Teasdale, J. R., Korcak, R., Chitwood, D. J. & Huettel, R. N. Fresh-market tomato production in a low-input alternative system using cover-crop mulch. HortScience 31, 65–69 (1996).

Kumar, V., Mills, D. J., Anderson, J. D. & Mattoo, A. K. An alternative agriculture system is defined by a distinct expression profile of select gene transcripts and proteins. Proc. Natl Acad. Sci. USA 101, 10535–10540 (2004).

Zhu, P. et al. Direct and continuous generation of pure acetic acid solutions via electrocatalytic carbon monoxide reduction. Proc. Natl Acad. Sci. USA 118, e2010868118 (2021).

Kim, E. J. et al. Cooperative carbon capture and steam regeneration with tetraamine-appended metal–organic frameworks. Science 369, 392–396 (2020).

Schmitt, T. et al. Cost and Performance Baseline for Fossil Energy Plants Volume 1: Bituminous Coal and Natural Gas to Electricity (US Department of Energy, 2022); https://www.osti.gov/biblio/1893822; https://doi.org/10.2172/1893822

Skúlason, E. et al. A theoretical evaluation of possible transition metal electro-catalysts for N2 reduction. Phys. Chem. Chem. Phys. 14, 1235–1245 (2012).

Resasco, J. & Bell, A. T. Electrocatalytic CO2 reduction to fuels: progress and opportunities. Trends Chem. 2, 825–836 (2020).

Tăbăcaru, A. et al. Nickel(ii) and copper(i, ii)-based metal–organic frameworks incorporating an extended tris-pyrazolate linker. CrystEngComm 17, 4992–5001 (2015).

Lv, C. et al. Selective electrocatalytic synthesis of urea with nitrate and carbon dioxide. Nat. Sustain. 4, 868–876 (2021).

Huang, J. et al. Single‐product faradaic efficiency for electrocatalytic of CO2 to CO at current density larger than 1.2 A cm−2 in neutral aqueous solution by a single‐atom nanozyme. Angew. Chem. Int. Ed. 61, e202210985 (2022).

Kar, T., Scheiner, S., Roy, A. K. & Bettinger, H. F. Unusual low-vibrational C=O mode of COOH can distinguish between carboxylated zigzag and armchair single-wall carbon nanotubes. J. Phys. Chem. C 116, 26072–26083 (2012).

Giubertoni, G., Sofronov, O. O. & Bakker, H. J. Observation of distinct carboxylic acid conformers in aqueous solution. J. Phys. Chem. Lett. 10, 3217–3222 (2019).

Zhan, P. et al. Efficient electrosynthesis of urea over single‐atom alloy with electronic metal support interaction. Angew. Chem. Int. Ed. 63, e202409019 (2024).

Qiu, W. et al. Overcoming electrostatic interaction via pulsed electroreduction for boosting the electrocatalytic urea synthesis. Angew. Chem. Int. Ed. 63, e202402684 (2024).

Ramadhany, P. et al. Triggering C‒N coupling on metal oxide nanocomposite for the electrochemical reduction of CO2 and NOx− to formamide. Adv. Energy Mater. 14, 2401786 (2024).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Hutter, J., Iannuzzi, M., Schiffmann, F. & VandeVondele, J. cp2k: atomistic simulations of condensed matter systems. WIREs Comput. Mol. Sci. 4, 15–25 (2014).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Grimme, S. Semiempirical GGA‐type density functional constructed with a long‐range dispersion correction. J. Comput. Chem. 27, 1787–1799 (2006).

Goedecker, S., Teter, M. & Hutter, J. Separable dual-space Gaussian pseudopotentials. Phys. Rev. B 54, 1703–1710 (1996).

VandeVondele, J. & Hutter, J. Gaussian basis sets for accurate calculations on molecular systems in gas and condensed phases. J. Chem. Phys. 127, 114105 (2007).

Acknowledgements

This work was supported by the National Key R&D Program of China (grant no. 2024YFF0506100 to P.-Q.L.), NSFC (grant nos. 22090061 and 22488101 to X.-M.C., grant no. 22371304 to P.-Q.L.), the Special Fund Project for Science and Technology Innovation Strategy of Guangdong Province (grant no. STKJ2023078 to X.-M.C. and P.-Q.L.), Fundamental Research Funds for the Central Universities, Sun Yat-Sen University (grant no. 24lgzy006 to P.-Q.L.), and the Guangzhou Science and Technology Program (grant no. SL2023A04J01767 to P.-Q.L.).

Author information

Authors and Affiliations

Contributions

P.-Q.L. designed the research. Y.-C.L. performed the syntheses and measurements. H.-L.Z. and X.-F.Q. assisted with the measurements. J.-R.H. performed the PDFT calculations. C.Y. performed the X-ray absorption spectroscopy measurements. Y.-C.L., J.-R.H., P.-Q.L. and X.-M.C. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Nanotechnology thanks Lin Guo, Shuangyin Wang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–51, discussion and Tables 1–5.

Source data

Source Data Fig. 1

Source data.

Source Data Fig. 2

Source data.

Source Data Fig. 3

Source data.

Source Data Fig. 4

Source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, YC., Huang, JR., Zhu, HL. et al. Electrosynthesis of pure urea from pretreated flue gas in a proton-limited environment established in a porous solid-state electrolyte electrolyser. Nat. Nanotechnol. 20, 907–913 (2025). https://doi.org/10.1038/s41565-025-01914-3

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41565-025-01914-3

This article is cited by

-

Optimizing oxygen and water affinity in aliphatic acylhydrazone covalent organic frameworks for efficient H2O2 photosynthesis from water and air

Science China Materials (2026)

-

Nutrient diffusion-inspired catalysts with self-reinforced concentration gradient for sustainable electroreduction of dilute CO2

Nature Communications (2025)