Abstract

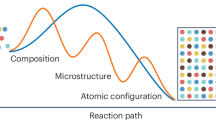

Entropy-related phase stabilization can allow compositionally complex solid solutions of multiple principal elements. The massive mixing approach was originally introduced for metals and has recently been extended to ionic, semiconductor, polymer and low-dimensional materials. Multielement mixing can leverage new types of random, weakly ordered clustering and precipitation states in bulk materials as well as at interfaces and dislocations. The many possible atomic configurations offer opportunities to discover and exploit new functionalities, as well as to create new local symmetry features, ordering phenomena and interstitial configurations. This opens up a huge chemical and structural space in which uncharted phase states, defect chemistries, mechanisms and properties, some previously thought to be mutually exclusive, can be reconciled in one material. Earlier research concentrated on mechanical properties such as strength, toughness, fatigue and ductility. This Review shifts the focus towards multifunctional property profiles, including electronic, electrochemical, mechanical, magnetic, catalytic, hydrogen-related, Invar and caloric characteristics. Disruptive design opportunities lie in combining several of these features, rendering high-entropy materials multifunctional without sacrificing their unique mechanical properties.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Yeh, J. W. et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6, 299–303 (2004).

Yeh, J.-W. in High-Entropy Alloys: Fundamentals and Applications (eds Gao, M. C. et al.) 1–19 (Springer, 2016).

Murty, B. S., Yeh, J. W., Ranganathan, S. & A brief history of alloys and the birth of high-entropy alloys. High Entropy Alloys https://doi.org/10.1016/b978-0-12-800251-3.00001-8 (2014).

Cantor, B. Multicomponent and high entropy alloys. Entropy 16, 4749–4768 (2014).

George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019).

Tsai, M. H. Physical properties of high entropy alloys. Entropy 15, 5338–5345 (2013).

Senkov, O. N., Wilks, G. B., Miracle, D. B., Chuang, C. P. & Liaw, P. K. Refractory high-entropy alloys. Intermetallics 18, 1758–1765 (2010).

Zhang, Y., Yang, X. & Liaw, P. K. Alloy design and properties optimization of high-entropy alloys. JOM 64, 830–838 (2012).

Li, Z., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 534, 227–30 (2016).

Zhang, Y. et al. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014).

Li, Z. & Raabe, D. Strong and ductile non-equiatomic high-entropy alloys: design, processing, microstructure, and mechanical properties. JOM 69, 2099–2106 (2017).

Li, Z. Interstitial equiatomic CoCrFeMnNi high-entropy alloys: carbon content, microstructure, and compositional homogeneity effects on deformation behavior. Acta Mater. 164, 400–412 (2019).

Gludovatz, B., George, E. P. & Ritchie, R. O. Processing, microstructure and mechanical properties of the CrMnFeCoNi high-entropy alloy. JOM 67, 2262–2270 (2015).

Lu, W. et al. Interfacial nanophases stabilize nanotwins in high-entropy alloys. Acta Mater. 185, 218–232 (2019).

Li, L. et al. Segregation-driven grain boundary spinodal decomposition as a pathway for phase nucleation in a high-entropy alloy. Acta Mater. 178, 1–9 (2019).

Donohue, M. D. & Aranovich, G. L. Classification of Gibbs adsorption isotherms. Adv. Colloid Interface Sci. 76–77, 137–152 (1998).

McLean, D. & Maradudin, A. Grain boundaries in metals. Phys. Today 11, 35–36 (1958).

Li, L., Kamachali, R. D., Li, Z. & Zhang, Z. Grain boundary energy effect on grain boundary segregation in an equiatomic high-entropy alloy. Phys. Rev. Mater. 4, 53603 (2020).

Korte-Kerzel, S. et al. Defect phases — thermodynamics and impact on material properties. Int. Mater. Rev. 67, 89–117 (2022).

Welk, B. A. et al. Nature of the interfaces between the constituent phases in the high entropy alloy CoCrCuFeNiAl. Ultramicroscopy 134, 193–199 (2013).

Ghigna, P. et al. Lithiation mechanism in high-entropy oxides as anode materials for Li-ion batteries: an operando XAS study. ACS Appl. Mater. Interfaces 12, 50344–50354 (2020).

Schneeweiss, O. et al. Magnetic properties of the CrMnFeCoNi high-entropy alloy. Phys. Rev. B 96, 014437 (2017).

Pickering, E. J. & Jones, N. G. High-entropy alloys: a critical assessment of their founding principles and future prospects. Int. Mater. Rev. 61, 183–202 (2016).

Mu, S., Pei, Z., Liu, X. & Stocks, G. M. Electronic transport and phonon properties of maximally disordered alloys: from binaries to high-entropy alloys. J. Mater. Res. 33, 2857–2880 (2018).

Rao, Z. et al. Unveiling the mechanism of abnormal magnetic behavior of FeNiCoMnCu high-entropy alloys through a joint experimental-theoretical study. Phys. Rev. Mater. 4, 14402 (2020).

Gao, M. C. et al. High-entropy functional materials. J. Mater. Res. 33, 3138–3155 (2018).

Yeh, J.-W., Chen, S. K., Shih, H. C., Zhang, Y. & Zuo, T. T. in High-Entropy Alloys: Fundamentals and Applications (eds Gao, M. C. et al.) 237–265 (Springer, 2016).

Duan, J. et al. A novel high-entropy alloy with an exceptional combination of soft magnetic properties and corrosion resistance. Sci. China Mater. 66, 772–779 (2023).

Mishra, R. K., Sahay, P. P. & Shahi, R. R. Alloying, magnetic and corrosion behavior of AlCrFeMnNiTi high entropy alloy. J. Mater. Sci. 54, 4433–4443 (2019).

Jin, X. et al. CoCrFeMnNi high-entropy alloy powder with excellent corrosion resistance and soft magnetic property prepared by gas atomization method. Materwiss. Werkstofftech. 50, 837–843 (2019).

Wang, W. et al. A corrosion-resistant soft-magnetic high entropy alloy. Mater. Lett. 304, 130571 (2021).

Zhang, H. et al. A novel FeCoNiCr0.2Si0.2 high entropy alloy with an excellent balance of mechanical and soft magnetic properties. J. Magn. Magn. Mater. 478, 116–121 (2019).

Chen, C. et al. A novel ultrafine-grained high entropy alloy with excellent combination of mechanical and soft magnetic properties. J. Magn. Magn. Mater. 502, 166513 (2020).

Liu, X. & Vecchio, K. Simultaneously improving mechanical and magnetic properties through heterogeneous lamella structures in a superalloy-like, soft magnetic complex concentrated alloy. Mater. Res. Lett. 11, 749–756 (2023).

Fu, Z. et al. Exceptional combination of soft magnetic and mechanical properties in a heterostructured high-entropy composite. Appl. Mater. Today 15, 590–598 (2019).

Li, Z. et al. Strength, plasticity and coercivity tradeoff in soft magnetic high-entropy alloys by multiple coherent interfaces. Acta Mater. 254, 118970 (2023).

Han, L. et al. A mechanically strong and ductile soft magnet with extremely low coercivity. Nature 608, 310–316 (2022).

Han, L. et al. Ultrastrong and ductile soft magnetic high-entropy alloys via coherent ordered nanoprecipitates. Adv. Mater. 33, 2102139 (2021).

Han, L. et al. Strong and ductile high temperature soft magnets through Widmanstätten precipitates. Nat. Commun. 14, 8176 (2023).

Nemani, S. K., Torkamanzadeh, M., Wyatt, B. C., Presser, V. & Anasori, B. Functional two-dimensional high-entropy materials. Commun. Mater. 4, 16 (2023).

Löffler, T., Ludwig, A., Rossmeisl, J. & Schuhmann, W. What makes high-entropy alloys exceptional electrocatalysts? Angew. Chem. Int. Ed. 60, 26894–26903 (2021).

Tomboc, G. M., Kwon, T., Joo, J. & Lee, K. High entropy alloy electrocatalysts: a critical assessment of fabrication and performance. J. Mater. Chem. A Mater. 8, 14844–14862 (2020).

Banko, L. et al. Unravelling composition–activity–stability trends in high entropy alloy electrocatalysts by using a data-guided combinatorial synthesis strategy and computational modeling. Adv. Energy Mater. 12, 2103312 (2022).

Luo, H., Li, Z. & Raabe, D. Hydrogen enhances strength and ductility of an equiatomic high-entropy alloy. Sci. Rep. 7, 9892 (2017).

Luo, H., Li, Z., Mingers, A. M. & Raabe, D. Corrosion behavior of an equiatomic CoCrFeMnNi high-entropy alloy compared with 304 stainless steel in sulfuric acid solution. Corros. Sci. 134, 131–139 (2018).

Luo, H. et al. A strong and ductile medium-entropy alloy resists hydrogen embrittlement and corrosion. Nat. Commun. 11, 3081 (2020).

Körmann, F. et al. ‘Treasure maps’ for magnetic high-entropy-alloys from theory and experiment. Appl. Phys. Lett. 107, 142404 (2015).

Lucas, M. S. et al. Magnetic and vibrational properties of high-entropy alloys. J. Appl. Phys. 109, 10–13 (2011).

Liu, X., Zhang, J. & Pei, Z. Machine learning for high-entropy alloys: progress, challenges and opportunities. Prog. Mater. Sci. 131, 101018 (2023).

Rickman, J. M., Balasubramanian, G., Marvel, C. J., Chan, H. M. & Burton, M.-T. Machine learning strategies for high-entropy alloys. J. Appl. Phys. 128, 221101 (2020).

Raabe, D., Mianroodi, J. R. & Neugebauer, J. Accelerating the design of compositionally complex materials via physics-informed artificial intelligence. Nat. Comput. Sci. 3, 198–209 (2023).

Pei, Z., Yin, J., Hawk, J. A., Alman, D. E. & Gao, M. C. Machine-learning informed prediction of high-entropy solid solution formation: beyond the Hume–Rothery rules. NPJ Comput. Mater. 6, 50 (2020).

Qiao, L., Liu, Y. & Zhu, J. A focused review on machine learning aided high-throughput methods in high entropy alloy. J. Alloy. Compd. 877, 160295 (2021).

Ma, D., Grabowski, B., Körmann, F., Neugebauer, J. & Raabe, D. Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: importance of entropy contributions beyond the configurational one. Acta Mater. 100, 90–97 (2015).

Zhang, F. et al. An understanding of high entropy alloys from phase diagram calculations. CALPHAD 45, 1–10 (2014).

Curtarolo, S. et al. The high-throughput highway to computational materials design. Nat. Mater. 12, 191–201 (2013).

Holm, E. A. et al. Overview: computer vision and machine learning for microstructural characterization and analysis. Metall. Mater. Trans. A 51, 5985–5999 (2020).

Muhammad, W., Brahme, A. P., Ibragimova, O., Kang, J. & Inal, K. A machine learning framework to predict local strain distribution and the evolution of plastic anisotropy & fracture in additively manufactured alloys. Int. J. Plast. 136, 102867 (2021).

Yang, Z. et al. Establishing structure–property localization linkages for elastic deformation of three-dimensional high contrast composites using deep learning approaches. Acta Mater. 166, 335–345 (2019).

Raabe, D. et al. Current challenges and opportunities in microstructure-related properties of advanced high-strength steels. Metall. Mater. Trans. A 51, 5517–5586 (2020).

Halpren, E., Yao, X., Chen, Z. W. & Singh, C. V. Machine learning assisted design of BCC high entropy alloys for room temperature hydrogen storage. Acta Mater. 270, 119841 (2024).

Sasidhar, K. N. et al. Enhancing corrosion-resistant alloy design through natural language processing and deep learning. Sci. Adv. 9, 7992 (2023).

Pei, Z., Yin, J., Liaw, P. K. & Raabe, D. Toward the design of ultrahigh-entropy alloys via mining six million texts. Nat. Commun. 14, 54 (2023).

Sandlöbes, S. et al. A rare-earth free magnesium alloy with improved intrinsic ductility. Sci. Rep. 7, 10458 (2017).

Zhao, S. et al. Machine learning assisted design of high-entropy alloys with ultra-high microhardness and unexpected low density. Mater. Des. https://doi.org/10.1016/j.matdes.2024.112634 (2024).

Rao, Z. et al. Machine learning–enabled high-entropy alloy discovery. Science 378, 78–85 (2022).

Katiyar, N. K., Goel, G. & Goel, S. Emergence of machine learning in the development of high entropy alloy and their prospects in advanced engineering applications. Emergent Mater. 4, 1635–1648 (2021).

Bauer, S. et al. Roadmap on data-centric materials science. Model. Simul. Mater. Sci. Eng. 32, 063301 (2024).

Shi, L. et al. Connecting the composition, structure, and magnetic property in high-entropy metallic glasses. Acta Mater. 254, 118983 (2023).

Pedersen, J. K. et al. Bayesian optimization of high-entropy alloy compositions for electrocatalytic oxygen reduction. Angew. Chem. Int. Ed. 60, 24144–24152 (2021).

Khatamsaz, D. et al. Bayesian optimization with active learning of design constraints using an entropy-based approach. NPJ Comput. Mater. 9, 49 (2023).

Kim, M. et al. Exploring optimal water splitting bifunctional alloy catalyst by pareto active learning. Adv. Mater. 35, 2211497 (2023).

Sathiyamoorthi, P. & Kim, H. S. High-entropy alloys with heterogeneous microstructure: processing and mechanical properties. Prog. Mater. Sci. 123, 100709 (2022).

Chen, T. et al. Microstructure and properties of TiC/Fe24Ni24Co24Mn18 high-entropy composite with exceptionally low coercivity. Mater. Today Commun. 35, 106150 (2023).

Ferrari, A., Körmann, F., Asta, M. & Neugebauer, J. Simulating short-range order in compositionally complex materials. Nat. Comput. Sci. 3, 221–229 (2023).

Zhang, Y., Zuo, T., Cheng, Y. & Liaw, P. K. High-entropy alloys with high saturation magnetization, electrical resistivity, and malleability. Sci. Rep. 3, 1455 (2013).

Yan, X. & Zhang, Y. Functional properties and promising applications of high entropy alloys. Scr. Mater. 187, 188–193 (2020).

Chaudhary, V., Chaudhary, R., Banerjee, R. & Ramanujan, R. V. Accelerated and conventional development of magnetic high entropy alloys. Mater. Today 49, 231–252 (2021).

Xu, J., Zhao, Z. F. & Wang, Y. Effect of annealing treatment on the microstructure and magnetic properties of FeSiBAlNi (C, Ce) high entropy alloys. Mater. Sci. Forum 849, 52–57 (2016).

Morley, N. A., Lim, B., Xi, J., Quintana-Nedelcos, A. & Leong, Z. Magnetic properties of the complex concentrated alloy system CoFeNi0.5Cr0.5Alx. Sci. Rep. 10, 14506 (2020).

Cieslak, J., Tobola, J. & Reissner, M. The effect of bcc/fcc phase preference on magnetic properties of AlxCrFeCoNi high entropy alloys. Intermetallics 118, 106672 (2020).

Zhou, K. X. et al. FeCoNiAlSi high entropy alloys with exceptional fundamental and application-oriented magnetism. Intermetallics 122, 106801 (2020).

Sahu, P., Bagri, A. S., Anoop, M. D., Kumar, M. & Kumar, V. Impact of Si and Mg on microstructural and magnetic behavior of Fe–Co–Ni (Mg–Si)x (x = 0.00,0.1,0.2) multicomponent alloys. Silicon 12, 893–902 (2020).

Borkar, T. et al. A combinatorial approach for assessing the magnetic properties of high entropy alloys: role of Cr in AlCoxCr1–xFeNi. Adv. Eng. Mater. 19, 1700048 (2017).

Zhang, Q. et al. The effects of phase constitution on magnetic and mechanical properties of FeCoNi(CuAl)x (x = 0–1.2) high-entropy alloys. J. Alloy. Compd. 693, 1061–1067 (2017).

Mishra, R. K. & Shahi, R. R. Phase evolution and magnetic characteristics of TiFeNiCr and TiFeNiCrM (M = Mn, Co) high entropy alloys. J. Magn. Magn. Mater. 442, 218–223 (2017).

Huang, S., Vida, Á., Heczel, A., Holmström, E. & Vitos, L. Thermal expansion, elastic and magnetic properties of FeCoNiCu-based high-entropy alloys using first-principle theory. JOM 69, 2107–2112 (2017).

Zhang, X., Han, L., Dehm, G. & Liebscher, C. H. Microstructure and physical properties of dual-phase soft magnetic Fe–Co–Ti–Ge alloys. J. Alloy. Compd. 945, 169282 (2023).

Kurniawan, M., Perrin, A., Xu, P., Keylin, V. & McHenry, M. Curie temperature engineering in high entropy alloys for magnetocaloric applications. IEEE Magn. Lett. 7, 1–5 (2016).

Zhang, B. et al. Magnetic transformation of Mn from anti-ferromagnetism to ferromagnetism in FeCoNiZMnx (Z = Si, Al, Sn, Ge) high entropy alloys. J. Mater. Sci. Technol. 68, 124–131 (2021).

Zuo, T. et al. Tailoring magnetic behavior of CoFeMnNiX (X = Al, Cr, Ga, and Sn) high entropy alloys by metal doping. Acta Mater. 130, 10–18 (2017).

Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 26, 1397–1402 (1990).

Pavithra, C. L. P. et al. An advancement in the synthesis of unique soft magnetic CoCuFeNiZn high entropy alloy thin films. Sci. Rep. 11, 8836 (2021).

Zhang, Y., Zuo, T., Cheng, Y. & Liaw, P. K. High-entropy alloys with high saturation magnetization, electrical resistivity and malleability. Sci. Rep. 3, 1455 (2013).

Song, X., Liaw, P. K., Wei, Z., Liu, Z. & Zhang, Y. Evolution of the microstructures, magnetic and mechanical behaviors of Co47.5Fe28.5Ni19Si3.4Al1.6 high-entropy alloy fabricated by laser powder bed fusion. Addit. Manuf. 71, 103593 (2023).

Coey, J. M. D. Magnetism and Magnetic Materials (Cambridge Univ. Press, 2010).

Kuz’min, M. D., Skokov, K. P., Jian, H., Radulov, I. & Gutfleisch, O. Towards high-performance permanent magnets without rare earths. J. Phys. Condens. Matter 26, 064205 (2014).

Gao, Q., Opahle, I., Gutfleisch, O. & Zhang, H. Designing rare-earth free permanent magnets in Heusler alloys via interstitial doping. Acta Mater. 186, 355–362 (2020).

Na, S.-M., Lambert, P. K. & Jones, N. J. Hard magnetic properties of FeCoNiAlCuxTix based high entropy alloys. AIP Adv. 11, 015210 (2021).

Chen, H., Gou, J., Jia, W., Song, X. & Ma, T. Origin of hard magnetism in Fe–Co–Ni–Al–Ti–Cu high-entropy alloy: chemical shape anisotropy. Acta Mater. 246, 118702 (2023).

Lan, Q. et al. Highly complex magnetic behavior resulting from hierarchical phase separation in AlCo(Cr)FeNi high-entropy alloys. iScience 25, 104047 (2022).

Dasari, S. et al. Highly tunable magnetic and mechanical properties in an Al0.3CoFeNi complex concentrated alloy. Materialia 12, 100755 (2020).

Kovács, A. et al. Role of heterophase interfaces on local coercivity mechanisms in the magnetic Al0.3CoFeNi complex concentrated alloy. Acta Mater. 246, 118672 (2023).

Vishina, A. et al. High-throughput and data-mining approach to predict new rare-earth free permanent magnets. Phys. Rev. B 101, 94407 (2020).

Xia, W. et al. Accelerating the discovery of novel magnetic materials using machine learning–guided adaptive feedback. Proc. Natl Acad. Sci. USA 119, e2204485119 (2022).

Hirayama, Y., Takahashi, Y. K., Hirosawa, S. & Hono, K. Intrinsic hard magnetic properties of Sm(Fe1−xCox)12 compound with the ThMn12 structure. Scr. Mater. 138, 62–65 (2017).

Tozman, P., Sepehri-Amin, H., Takahashi, Y. K., Hirosawa, S. & Hono, K. Intrinsic magnetic properties of Sm(Fe1−xCox)11Ti and Zr-substituted Sm1−yZry(Fe0.8Co0.2)11.5Ti0.5 compounds with ThMn12 structure toward the development of permanent magnets. Acta Mater. 153, 354–363 (2018).

Tozman, P., Sepehri-Amin, H. & Hono, K. Prospects for the development of SmFe12-based permanent magnets with a ThMn12-type phase. Scr. Mater. 194, 113686 (2021).

Nguyen, D.-N., Kino, H., Miyake, T. & Dam, H.-C. Explainable active learning in investigating structure–stability of SmFe12−α−βXαYβ structures X, Y {Mo, Zn, Co, Cu, Ti, Al, Ga}. MRS Bull. 48, 31–44 (2023).

Fukazawa, T., Harashima, Y., Hou, Z. & Miyake, T. Bayesian optimization of chemical composition: a comprehensive framework and its application to R Fe12-type magnet compounds. Phys. Rev. Mater. 3, 053807 (2019).

Gutfleisch, O. et al. Mastering hysteresis in magnetocaloric materials. Phil. Trans. R. Soc. A 374, 20150308 (2016).

Scheibel, F. et al. Hysteresis design of magnetocaloric materials — from basic mechanisms to applications. Energy Technol. 6, 1397–1428 (2018).

Gottschall, T. et al. Making a cool choice: the materials library of magnetic refrigeration. Adv. Energy Mater. 9, 1901322 (2019).

Tegus, O., Brück, E., Buschow, K. H. J. & de Boer, F. R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 415, 150–152 (2002).

Fries, M. et al. Microstructural and magnetic properties of Mn–Fe–P–Si (Fe2 P-type) magnetocaloric compounds. Acta Mater. 132, 222–229 (2017).

Lu, S. F. et al. Effect of configuration entropy on magnetocaloric effect of rare earth high-entropy alloy. J. Alloy. Compd. 874, 159918 (2021).

Lu, S. F. et al. Magnetocaloric effect of high-entropy rare-earth alloy GdTbHoErY. J. Mater. Sci. Mater. Electron. 32, 10919–10926 (2021).

Yuan, Y. et al. Rare-earth high-entropy alloys with giant magnetocaloric effect. Acta Mater. 125, 481–489 (2017).

Guo, D., Moreno-Ramírez, L. M., Law, J.-Y., Zhang, Y. & Franco, V. Excellent cryogenic magnetocaloric properties in heavy rare-earth based HRENiGa2 (HRE = Dy, Ho, or Er) compounds. Sci. China Mater. 66, 249–256 (2023).

Dong, Z. et al. MnxCr0.3Fe0.5Co0.2Ni0.5Al0.3 high entropy alloys for magnetocaloric refrigeration near room temperature. J. Mater. Sci. Technol. 79, 15–20 (2021).

Dong, Z., Wang, Z. & Yin, S. Magnetic properties and large cryogenic magneto-caloric effect of Er0.2Tm0.2Ho0.2Cu0.2Co0.2 amorphous ribbon. Intermetallics 124, 106879 (2020).

Zhang, Y. et al. Tunable magnetic phase transition and magnetocaloric effect in the rare-earth-free Al–Mn–Fe–Co–Cr high-entropy alloys. Mater. Des. 229, 111894 (2023).

Zhang, Y. et al. The emergence of considerable room temperature magnetocaloric performances in the transition metal high-entropy alloys. Mater. Today Phys. 32, 101031 (2023).

Zhang, F. et al. Impact of fast-solidification on all-d-metal NiCoMnTi based giant magnetocaloric Heusler compounds. Acta Mater. 265, 119595 (2024).

Law, J. Y. & Franco, V. Review on magnetocaloric high-entropy alloys: design and analysis methods. J. Mater. Res. 38, 37–51 (2023).

Law, J. Y., Díaz-García, Á., Moreno-Ramírez, L. M. & Franco, V. Increased magnetocaloric response of FeMnNiGeSi high-entropy alloys. Acta Mater. 212, 116931 (2021).

Taubel, A. et al. Tailoring magnetocaloric effect in all-d-metal Ni-Co-Mn-Ti Heusler alloys: a combined experimental and theoretical study. Acta Mater. 201, 425–434 (2020).

Beckmann, B. et al. Dissipation losses limiting first-order phase transition materials in cryogenic caloric cooling: a case study on all-d-metal Ni(–Co)–Mn–Ti Heusler alloys. Acta Mater. 246, 118695 (2023).

Khan, A. N., Díaz-García, Á., Moreno-Ramírez, L. M., Law, J. Y. & Franco, V. Tunable magnetocaloric effect towards cryogenic range by varying Mn:Ni ratio in all-d-metal Ni(Co)–Mn–Ti Heusler alloys. J. Alloy. Compd. 973, 172938 (2024).

Taubel, A. et al. Influence of magnetic field, chemical pressure and hydrostatic pressure on the structural and magnetocaloric properties of the Mn–Ni–Ge system. J. Phys. D 50, 464005 (2017).

Fortunato, N. M. et al. High-throughput design of magnetocaloric materials for energy applications: MM′X alloys. Adv. Sci. 10, 2206772 (2023).

Rowe, D. M. CRC Handbook of Thermoelectrics (CRC Press, 2018).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Liu, D., Qin, B. & Zhao, L.-D. SnSe/SnS: multifunctions beyond thermoelectricity. Mater. Lab. 1, 220006 (2022).

He, R. et al. Studies on mechanical properties of thermoelectric materials by nanoindentation. Phys. Status Solidi 212, 2191–2195 (2015).

Rogl, G. et al. Mechanical properties of half-Heusler alloys. Acta Mater. 107, 178–195 (2016).

Liu, Z. et al. Mechanical properties of nanostructured thermoelectric materials α-MgAgSb. Scr. Mater. 127, 72–75 (2017).

Xia, X. et al. High-temperature oxidation behavior of filled skutterudites YbyCo4Sb12. J. Electron. Mater. 41, 2225–2231 (2012).

Li, F., Wei, T. R., Kang, F. & Li, J. F. Thermal stability and oxidation resistance of BiCuSeO based thermoelectric ceramics. J. Alloy. Compd. 614, 394–400 (2014).

Zhu, Y.-K. et al. Mediating point defects endows n-type Bi2Te3 with high thermoelectric performance and superior mechanical robustness for power generation application. Small 18, 2201352 (2022).

Ge, Z.-H. et al. Low-cost, abundant binary sulfides as promising thermoelectric materials. Mater. Today 19, 227–239 (2016).

Zhang, J. et al. Discovery of high-performance low-cost n-type Mg3Sb2-based thermoelectric materials with multi-valley conduction bands. Nat. Commun. 8, 13901 (2017).

Perumal, S., Roychowdhury, S., Negi, D. S., Datta, R. & Biswas, K. High thermoelectric performance and enhanced mechanical stability of p-type Ge1–xSbxTe. Chem. Mater. 27, 7171–7178 (2015).

Hatzikraniotis, E., Zorbas, K. T., Samaras, I., Kyratsi, T. & Paraskevopoulos, K. M. Efficiency study of a commercial thermoelectric power generator (TEG) under thermal cycling. J. Electron. Mater. 39, 2112–2116 (2010).

Al-Merbati, A. S., Yilbas, B. S. & Sahin, A. Z. A model study for cyclic thermal loading and thermal performance of a thermoelectric generator. Int. J. Energy Res. 38, 1351–1360 (2014).

Dong, J., Gao, J. & Yan, Q. High entropy strategy on thermoelectric materials. Mater. Lab. 2, 230001 (2023).

Jiang, B. et al. High figure-of-merit and power generation in high-entropy GeTe-based thermoelectrics. Science 377, 208–213 (2022).

Jiang, F. et al. Structure, magnetic and thermoelectric properties of high entropy selenides Bi0.6Sb0.6In0.4Cr0.4Se3. Mater. Lab. 1, 220045 (2022).

Ma, Z. et al. High thermoelectric performance and low lattice thermal conductivity in lattice-distorted high-entropy semiconductors AgMnSn1–xPbxSbTe4. Chem. Mater. 34, 8959–8967 (2022).

Kumar, A., Dragoe, D., Berardan, D. & Dragoe, N. Thermoelectric properties of high-entropy rare-earth cobaltates. J. Materiomics 9, 191–196 (2023).

Zhang, P. et al. High-entropy (Ca0.2Sr0.2Ba0.2La0.2Pb0.2)TiO3 perovskite ceramics with A-site short-range disorder for thermoelectric applications. J. Mater. Sci. Technol. 97, 182–189 (2022).

Lou, Z. et al. A novel high-entropy perovskite ceramics Sr0.9La0.1(Zr0.25Sn0.25Ti0.25Hf0.25)O3 with low thermal conductivity and high Seebeck coefficient. J. Eur. Ceram. Soc. 42, 3480–3488 (2022).

Zhang, Z. et al. Entropy engineering induced exceptional thermoelectric and mechanical performances in Cu2−yAgyTe1−2xSxSex. Acta Mater. 224, 117512 (2022).

Chen, R. et al. Entropy-driven multiscale defects enhance the thermoelectric properties of ZrCoSb-based half-Heusler alloys. Chem. Eng. J. 455, 140676 (2023).

Jiang, B. et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science 371, 830–834 (2021).

Shafeie, S. et al. High-entropy alloys as high-temperature thermoelectric materials. J. Appl. Phys. 118, 184905 (2015).

Pei, Y. et al. Convergence of electronic bands for high performance bulk thermoelectrics. Nature 473, 66–69 (2011).

Wang, X. et al. Enhanced thermoelectric performance in high entropy alloys Sn0.25Pb0.25Mn0.25Ge0.25Te. ACS Appl. Mater. Interfaces 13, 18638–18647 (2021).

Liu, R. et al. Entropy as a gene-like performance indicator promoting thermoelectric materials. Adv. Mater. 29, 1702712 (2017).

Roychowdhury, S. et al. Enhanced atomic ordering leads to high thermoelectric performance in AgSbTe2. Science 371, 722–727 (2021).

Campbell, F. C. Elements of Metallurgy and Engineering Alloys (ASM International, 2008).

Wassermann, E. F. & Acet, M. in Magnetism and Structure in Functional Materials (eds Planes, A. et al.) 177–197 (Springer, 2005).

Rao, Z. et al. 3d transition-metal high-entropy Invar alloy developed by adjusting the valence-electron concentration. Phys. Rev. Mater. 5, 044406 (2021).

Rao, Z., Springer, H., Ponge, D. & Li, Z. Combinatorial development of multicomponent Invar alloys via rapid alloy prototyping. Materialia 21, 101326 (2022).

Acet, M. Inducing strong magnetism in Cr20Mn20Fe20Co20Ni20 high-entropy alloys by exploiting its anti-Invar property. AIP Adv. 9, 095037 (2019).

Masumoto, H. On the thermal expansion of alloys of cobalt iron and chromium and a new alloy ‘stainless invar’. Sci. Report. Tohoku. Imp. Univ. 23, 265–275 (1934).

Masumoto, H. On the thermal expansion of the alloys of iron, nickel, and cobalt and the cause of the small expansibility of alloys of the Invar type. Sci. Rep. Tohoku Imp. Univ. 20, 101–123 (1931).

Orbay, Y. et al. Magnetic properties of the FCC and BCC phases of (MnFeCoNi)80Cu20−xZx (Z: Al, Ga) high-entropy alloys. Acta Mater. 259, 119240 (2023).

Lin, C. L. et al. Investigation on the thermal expansion behavior of FeCoNi and Fe30Co30Ni30Cr10−xMnx high entropy alloys. Mater. Chem. Phys. 271, 124907 (2021).

Tanimoto, H., Hozumi, R. & Kawamura, M. Electrical resistivity and short-range order in rapid-quenched CrMnFeCoNi high-entropy alloy. J. Alloy. Compd. 896, 163059 (2022).

Pal, S., Nair, R. B. & McDonald, A. Toward understanding the microstructure and electrical resistivity of thermal-sprayed high-entropy alloy coatings. J. Mater. Sci. 57, 20928–20944 (2022).

Kitagawa, J. Magnetic properties, electrical resistivity, and hardness of high-entropy alloys FeCoNiPd and FeCoNiPt. J. Magn. Magn. Mater. 563, 170024 (2022).

Zhu, S. et al. A strong ferritic high‐resistivity multicomponent alloy with tunable ordered coherent multicomponent nanoprecipitates. Acta Mater. 238, 118209 (2022).

Kao, Y. F. et al. Electrical, magnetic, and Hall properties of AlxCoCrFeNi high-entropy alloys. J. Alloy. Compd. 509, 1607–1614 (2011).

Chou, H. P., Chang, Y. S., Chen, S. K. & Yeh, J. W. Microstructure, thermophysical and electrical properties in AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. Mater. Sci. Eng. B 163, 184–189 (2009).

Li, P., Wang, A. & Liu, C. T. Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl)x high entropy alloys. Intermetallics 87, 21–26 (2017).

Chen, S.-K. & Kao, Y.-F. Near-constant resistivity in 4.2–360 K in a B2 Al2.08CoCrFeNi. AIP Adv. 2, 012111 (2012).

Bardeen, J., Cooper, L. N. & Schrieffer, J. R. Theory of superconductivity. Phys. Rev. 108, 1175–1204 (1957).

Mizuguchi, Y., Kasem, M. R. & Matsuda, T. D. Superconductivity in CuAl2-type Co0.2Ni0.1Cu0.1Rh0.3Ir0.3Zr2 with a high-entropy-alloy transition metal site. Mater. Res. Lett. 9, 141–147 (2021).

Marik, S. et al. Superconductivity in a new hexagonal high-entropy alloy. Phys. Rev. Mater. 3, 060602 (2019).

Liu, B. et al. Superconductivity and paramagnetism in Cr-containing tetragonal high-entropy alloys. J. Alloy. Compd. 869, 159293 (2021).

Uporov, S. A. et al. Pressure effects on electronic structure and electrical conductivity of TiZrHfNb high-entropy alloy. Intermetallics 140, 107394 (2022).

El-Atwani, O. et al. Outstanding radiation resistance of tungsten-based high-entropy alloys. Sci. Adv. 5, eaav2002 (2024).

Orhan, O. K., Hendy, M. & Ponga, M. Electronic effects on the radiation damage in high-entropy alloys. Acta Mater. 244, 118511 (2023).

Cusentino, M. A., Wood, M. A. & Dingreville, R. Compositional and structural origins of radiation damage mitigation in high-entropy alloys. J. Appl. Phys. 128, 125904 (2020).

Levenets, A. V, Tikhonovsky, M. A., Voyevodin, V. N., Shepelev, A. G. & Nemashkalo, O. V. High-entropy alloys as a prospective class of new radiation-tolerant materials research development analysis based on the information databases. Voprosy Atomnoj Nauki Tekhniki https://doi.org/10.46813/2021-132-003 (2021).

Zhang, H. et al. Effects of nitrogen doping on microstructures and irradiation resistance of Ti–Zr–Nb–V–Mo refractory high-entropy alloy. Acta Metall. Sin. https://doi.org/10.1007/s40195-024-01686-0 (2024).

Kombaiah, B. et al. Nanoprecipitates to enhance radiation tolerance in high-entropy alloys. ACS Appl. Mater. Interfaces 15, 3912–3924 (2023).

Deluigi, O. R. et al. Simulations of primary damage in a high entropy alloy: probing enhanced radiation resistance. Acta Mater. 213, 116951 (2021).

Lin, Y. et al. Enhanced radiation tolerance of the Ni-Co-Cr-Fe high-entropy alloy as revealed from primary damage. Acta Mater. 196, 133–143 (2020).

Tunes, M. A. et al. From high-entropy alloys to high-entropy ceramics: the radiation-resistant highly concentrated refractory carbide (CrNbTaTiW)C. Acta Mater. 250, 118856 (2023).

Mañosa, L. & Planes, A. Elastocaloric effect in shape-memory alloys. Shape Mem. Superelast. https://doi.org/10.1007/s40830-024-00477-x (2024).

Zarnetta, R. et al. Identification of quaternary shape memory alloys with near-zero thermal hysteresis and unprecedented functional stability. Adv. Funct. Mater. 20, 1917–1923 (2010).

Chen, H. et al. Unprecedented non-hysteretic superelasticity of [001]-oriented NiCoFeGa single crystals. Nat. Mater. 19, 712–718 (2020).

Tanaka, Y. et al. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 327, 1488–1490 (2010).

Omori, T. et al. Superelastic effect in polycrystalline ferrous alloys. Science 333, 68–71 (2011).

Firstov, G. S., Kosorukova, T. A., Koval, Y. N. & Odnosum, V. V. High entropy shape memory alloys. Mater. Today Proc. 2, S499–S503 (2015).

Firstov, G. S., Kosorukova, T. A., Koval, Y. N. & Verhovlyuk, P. A. Directions for high-temperature shape memory alloys’ improvement: straight way to high-entropy materials? Shape Mem. Superelast. 1, 400–407 (2015).

Piorunek, D. et al. Effect of off-stoichiometric compositions on microstructures and phase transformation behavior in Ni–Cu–Pd–Ti–Zr–Hf high entropy shape memory alloys. J. Alloy. Compd. 857, 157467 (2021).

He, S. et al. Interpretable machine learning workflow for evaluation of the transformation temperatures of TiZrHfNiCoCu high entropy shape memory alloys. Mater. Des. 225, 111513 (2023).

Thiercelin, L., Peltier, L. & Meraghni, F. Physics-informed machine learning prediction of the martensitic transformation temperature for the design of ‘NiTi-like’ high entropy shape memory alloys. Comput. Mater. Sci. 231, 112578 (2024).

Akrami, S. et al. Defective high-entropy oxide photocatalyst with high activity for CO2 conversion. Appl. Catal. B 303, 1–24 (2022).

Xin, Y. et al. High-entropy alloys as a platform for catalysis: progress, challenges, and opportunities. ACS Catal. 10, 11280–11306 (2020).

Löffler, T. et al. Discovery of a multinary noble metal–free oxygen reduction catalyst. Adv. Energy Mater. 8, 1802269 (2018).

Yao, Y. et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359, 1489–1494 (2018).

Batchelor, T. A. A. et al. High-entropy alloys as a discovery platform for electrocatalysis. Joule 3, 834–845 (2019).

Yao, Y. et al. High-entropy nanoparticles: synthesis–structure–property relationships and data-driven discovery. Science 376, eabn3103 (2023).

Zhang, Y., Wang, D. & Wang, S. High-entropy alloys for electrocatalysis: design, characterization, and applications. Small 18, 2104339 (2022).

Ren, J.-T., Chen, L., Wang, H.-Y. & Yuan, Z.-Y. High-entropy alloys in electrocatalysis: from fundamentals to applications. Chem. Soc. Rev. 52, 8319–8373 (2023).

Schweidler, S. et al. High-entropy materials for energy and electronic applications. Nat. Rev. Mater. 9, 266–281 (2024).

Sun, Y. & Dai, S. High-entropy materials for catalysis: a new frontier. Sci. Adv. 7, eabg1600 (2024).

Wang, X., Guo, W. & Fu, Y. High-entropy alloys: emerging materials for advanced functional applications. J. Mater. Chem. A Mater. 9, 663–701 (2021).

Mints, V. A., Svane, K. L., Rossmeisl, J. & Arenz, M. Exploring the high-entropy oxide composition space: insights through comparing experimental with theoretical models for the oxygen evolution reaction. ACS Catal. 14, 6936–6944 (2024).

Batchelor, T. A. A. et al. Complex-solid-solution electrocatalyst discovery by computational prediction and high-throughput experimentation. Angew. Chem. Int. Ed. 60, 6932–6937 (2021).

Clausen, C. M., Nielsen, M. L. S., Pedersen, J. K. & Rossmeisl, J. Ab initio to activity: machine learning-assisted optimization of high-entropy alloy catalytic activity. High Entropy Alloy. Mater. https://doi.org/10.1007/s44210-022-00006-4 (2022).

Yao, Y. et al. Extreme mixing in nanoscale transition metal alloys. Matter 4, 2340–2353 (2021).

Li, T. et al. Denary oxide nanoparticles as highly stable catalysts for methane combustion. Nat. Catal. 4, 62–70 (2021).

Priamushko, T., Kormányos, A. & Cherevko, S. What do we know about the electrochemical stability of high-entropy alloys? Curr. Opin. Chem. Eng. 44, 101020 (2024).

Kormányos, A. et al. Stability of high-entropy alloys under electrocatalytic conditions. iScience 26, 107775 (2023).

De Vrieze, J. E., Gunasooriya, G. K. K., Thybaut, J. W. & Saeys, M. Operando computational catalysis: shape, structure, and coverage under reaction conditions. Curr. Opin. Chem. Eng. 23, 85–91 (2019).

Gao, S. et al. Synthesis of high-entropy alloy nanoparticles on supports by the fast moving bed pyrolysis. Nat. Commun. 11, 2016 (2020).

Tao, L. et al. A general synthetic method for high-entropy alloy subnanometer ribbons. J. Am. Chem. Soc. 144, 10582–10590 (2022).

Wei, J. et al. Deep eutectic solvent assisted facile synthesis of low-dimensional hierarchical porous high-entropy oxides. Nano Res. 15, 2756–2763 (2022).

Dangwal, S. & Edalati, K. High-entropy alloy TiV2ZrCrMnFeNi for hydrogen storage at room temperature with full reversibility and good activation. Scr. Mater. 238, 115774 (2024).

Ma, X. et al. Study on microstructure and the hydrogen storage behavior of a TiVZrNbFe high-entropy alloy. Intermetallics 157, 107885 (2023).

Shahi, R. R., Gupta, A. K. & Kumari, P. Perspectives of high entropy alloys as hydrogen storage materials. Int. J. Hydrog. Energy 48, 21412–21428 (2023).

Mohammadi, A. et al. High-entropy hydrides for fast and reversible hydrogen storage at room temperature: binding-energy engineering via first-principles calculations and experiments. Acta Mater. 236, 118117 (2022).

Moore, C. M. et al. Hydrogen accommodation in the TiZrNbHfTa high entropy alloy. Acta Mater. 229, 117832 (2022).

Sahlberg, M., Karlsson, D., Zlotea, C. & Jansson, U. Superior hydrogen storage in high entropy alloys. Sci. Rep. 6, 36770 (2016).

Chen, S. K., Lee, P. H., Lee, H. & Su, H. T. Hydrogen storage of C14-CruFevMnwTixVyZrz alloys. Mater. Chem. Phys. 210, 336–347 (2018).

Edalati, P. et al. Reversible room temperature hydrogen storage in high-entropy alloy TiZrCrMnFeNi. Scr. Mater. 178, 387–390 (2020).

Andrade, G. et al. Crystal structure and hydrogen storage properties of AB-type TiZrNbCrFeNi high-entropy alloy. Int. J. Hydrog. Energy 48, 13555–13565 (2023).

Edalati, K. et al. Design and synthesis of a magnesium alloy for room temperature hydrogen storage. Acta Mater. 149, 88–96 (2018).

Shang, Y. et al. Ultra-lightweight compositionally complex alloys with large ambient-temperature hydrogen storage capacity. Mater. Today 67, 113–126 (2023).

Marques, F., Balcerzak, M., Winkelmann, F., Zepon, G. & Felderhoff, M. Review and outlook on high-entropy alloys for hydrogen storage. Energy Env. Sci. 14, 5191–5227 (2021).

Felderhoff, M., Weidenthaler, C., von Helmolt, R. & Eberle, U. Hydrogen storage: the remaining scientific and technological challenges. Phys. Chem. Chem. Phys. 9, 2643–2653 (2007).

Weidenthaler, C. & Felderhoff, M. Solid-state hydrogen storage for mobile applications: quo vadis? Energy Env. Sci. 4, 2495–2502 (2011).

Kumbhakar, M. et al. High-throughput screening of high-entropy fluorite-type oxides as potential candidates for photovoltaic applications. Adv. Energy Mater. https://doi.org/10.1002/aenm.202204337 (2023).

Suhr, E. et al. High-throughput exploration of structural and electrochemical properties of the high-entropy nitride system (Ti–Co–Mo–Ta–W)N. Adv. Eng. Mater. 25, 2300550 (2023).

He, C. Y. et al. Scalable and highly efficient high temperature solar absorber coatings based on high entropy alloy nitride AlCrTaTiZrN with different antireflection layers. J. Mater. Chem. A 9, 6413–6422 (2021).

Khan, M., Rahaman, M. Z. & Ali, M. L. Pressure-induced band gap engineering of nontoxic lead-free halide perovskite CsMgI3 for optoelectronic applications. ACS Omega 8, 24942–24951 (2023).

Wang, S.-P. & Xu, J. TiZrNbTaMo high-entropy alloy designed for orthopedic implants: as-cast microstructure and mechanical properties. Mater. Sci. Eng. C 73, 80–89 (2017).

Castro, D., Jaeger, P., Baptista, A. C. & Oliveira, J. P. An overview of high-entropy alloys as biomaterials. Metals 11, 648 (2021).

de Oliveira, T. G., Fagundes, D. V., Capellato, P., Sachs, D. & da Silva, A. A. A. P. A review of biomaterials based on high-entropy alloys. Metals 12, 1940 (2022).

Shi, Z., Fang, Q., Liaw, P. K. & Li, J. Corrosion-resistant biomedical high-entropy alloys: a review. Adv. Eng. Mater. 25, 2300968 (2023).

Rashidy Ahmady, A. et al. High entropy alloy coatings for biomedical applications: a review. Smart Mater. Manuf. 1, 100009 (2023).

Feng, J. et al. Preparation of TiNbTaZrMo high-entropy alloy with tunable Young’s modulus by selective laser melting. J. Manuf. Process. 85, 160–165 (2023).

Yang, W. et al. Design and properties of novel Ti–Zr–Hf–Nb–Ta high-entropy alloys for biomedical applications. Intermetallics 141, 107421 (2022).

Popescu, G. et al. New TiZrNbTaFe high entropy alloy used for medical applications. IOP Conf. Ser. Mater. Sci. Eng. 400, 022049 (2018).

Shittu, J. et al. Biocompatible high entropy alloys with excellent degradation resistance in a simulated physiological environment. ACS Appl. Bio Mater. 3, 8890–8900 (2020).

Motallebzadeh, A. et al. Microstructural, mechanical and electrochemical characterization of TiZrTaHfNb and Ti1.5ZrTa0.5Hf0.5Nb0.5 refractory high-entropy alloys for biomedical applications. Intermetallics 113, 106572 (2019).

Hori, T., Nagase, T., Todai, M., Matsugaki, A. & Nakano, T. Development of non-equiatomic Ti–Nb–Ta–Zr–Mo high-entropy alloys for metallic biomaterials. Scr. Mater. 172, 83–87 (2019).

Takahashi, M., Sato, K., Togawa, G. & Takada, Y. Mechanical properties of Ti–Nb–Cu alloys for dental machining applications. J. Funct. Biomater. 13, 263 (2022).

Zhou, E. et al. A novel Cu-bearing high-entropy alloy with significant antibacterial behavior against corrosive marine biofilms. J. Mater. Sci. Technol. 46, 201–210 (2020).

Raabe, D., Tasan, C. C. & Olivetti, E. A. Strategies for improving the sustainability of structural metals. Nature 575, 64–74 (2019).

Raabe, D. The materials science behind sustainable metals and alloys. Chem. Rev. 123, 2436–2608 (2023).

Zhang, Z., Tang, H. & Xu, Z. Fatigue database of complex metallic alloys. Sci. Data 10, 447 (2023).

Wang, W. et al. Automated pipeline for superalloy data by text mining. NPJ Comput. Mater. 8, 9 (2022).

Zhou, Z. et al. Machine learning guided appraisal and exploration of phase design for high entropy alloys. NPJ Comput. Mater. 5, 128 (2019).

Gutfleisch, O. et al. Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient. Adv. Mater. 23, 821–842 (2011).

Torrubia, J., Valero, A. & Valero, A. Energy and carbon footprint of metals through physical allocation. Implications for energy transition. Resour. Conserv. Recycl. 199, 107281 (2023).

Acknowledgements

The support of T. You, S. Zhang, C. Jung and K. Jang from the Max Planck Institute for Sustainable Materials, M. Dai from TU Darmstadt, and J. Frenzel from the Ruhr-Universität Bochum is gratefully acknowledged. D.R. acknowledges financial support through the special focus programme SPP 2006 on Compositionally Complex Alloys–High Entropy Alloys (CCA-HEA), funded by the Deutsche Forschungsgemeinschaft (DFG) under project no. 313773923. Z.L. acknowledges financial support from the Science and Technology Innovation Program of Hunan Province in China (grant no. 2023RC1013). O.G., D.R., Z.R., H.Z. and L.H. acknowledge funding from the European Innovation Council and SMEs Executive Agency (EISMEA) under grant agreement no. 101099736 (Pathfinder Open CoCoMag project) and support by the DFG, project ID no. 405553726, Collaborative Research Centre Transregio CRC-TRR 270. H.H. acknowledges financial support through the DFG via the projects HA 1344/45-1 and HA 1344/43-1/-2. A.L., C.S. and D.R. acknowledge funding by the DFG — SFB 1625, project no. 506711657.

Author information

Authors and Affiliations

Contributions

L.H., Z.L., A.L., O.G. and D.R. developed the ideas for the paper. All authors contributed equally to the concept, discussion of the results and manuscript writing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Materials thanks Qihong Fang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, L., Zhu, S., Rao, Z. et al. Multifunctional high-entropy materials. Nat Rev Mater 9, 846–865 (2024). https://doi.org/10.1038/s41578-024-00720-y

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41578-024-00720-y