Abstract

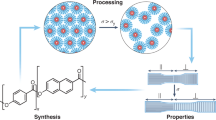

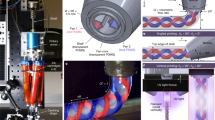

Printheads are the cornerstone of material extrusion 3D printing systems, now capable of processing virtually any material — organic or inorganic. Multimaterial capabilities have further expanded their versatility, enabling coextrusion, mixing and material switching. Advanced multifunctional printhead features allow for nozzle size and shape adjustments, printhead rotation and in situ property modulation. These improvements enable unprecedented design complexity, higher throughput and the fabrication of intricate material compositions across multiple length scales. Applications span from architected metamaterials with tunable properties to functional tissue from living cells and soft robotics with integrated sensing. This Review provides a comprehensive overview of this rapidly evolving field, introducing eight archetypal printhead categories and their hybrids. It explores their role in materials design, ability to overcome processing limitations and impact on emerging applications. Additionally, it identifies open challenges and offers an outlook on the future of multimaterial 3D printing.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Khan, N. & Riccio, A. A systematic review of design for additive manufacturing of aerospace lattice structures: current trends and future directions. Prog. Aerosp. Sci. 149, 101021 (2024).

Altıparmak, S. C. & Xiao, B. A market assessment of additive manufacturing potential for the aerospace industry. J. Manuf. Process. 68, 728–738 (2021).

Chaudhary, S., Avinashi, S. K., Rao, J. & Gautam, C. Recent advances in additive manufacturing, applications and challenges for dentistry: a review. ACS Biomater. Sci. Eng. 9, 3987–4019 (2023).

Zhu, C., Gemeda, H. B., Duoss, E. B. & Spadaccini, C. M. Toward multiscale, multimaterial 3D printing. Adv. Mater. 36, 2314204 (2024).

Gibson, I. et al. Additive Manufacturing Technologies Vol. 17 (Springer, 2021).

Subedi, S. et al. Multi-material vat photopolymerization 3D printing: a review of mechanisms and applications. NPJ Adv. Manuf. 1, 9 (2024).

Mehrpouya, M. et al. Multimaterial powder bed fusion techniques. Rapid Prototyp. J. 28, 1–19 (2022).

Wei, C. & Li, L. Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion. Virtual Phys. Prototyp. 16, 347–371 (2021).

Truby, R. L. & Lewis, J. A. Printing soft matter in three dimensions. Nature 540, 371–378 (2016).

Lewis, J. A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 16, 2193–2204 (2006).

Siqueira, G. et al. Cellulose nanocrystal inks for 3D printing of textured cellular architectures. Adv. Funct. Mater. 27, 1604619 (2017).

Kolesky, D. B. et al. 3D bioprinting of vascularized, heterogeneous cell-laden tissue constructs. Adv. Mater. 26, 3124–3130 (2014).

Kolesky, D. B., Homan, K. A., Skylar-Scott, M. A. & Lewis, J. A. Three-dimensional bioprinting of thick vascularized tissues. Proc. Natl Acad. Sci. USA 113, 3179–3184 (2016).

Schaffner, M., Rühs, P. A., Coulter, F., Kilcher, S. & Studart, A. R. 3D printing of bacteria into functional complex materials. Sci. Adv. 3, eaao6804 (2017).

Johnson, B. N. et al. 3D printed anatomical nerve regeneration pathways. Adv. Funct. Mater. 25, 6205–6217 (2015).

Joung, D. et al. 3D printed stem-cell derived neural progenitors generate spinal cord scaffolds. Adv. Funct. Mater. 28, 1801850 (2018).

Gantenbein, S. et al. Three-dimensional printing of mycelium hydrogels into living complex materials. Nat. Mater. 22, 128–134 (2023).

Studart, A. R. & Masania, K. Self-regenerating living material made of printed fungi. Nat. Mater. 22, 16–17 (2023).

Lewis, J. A. Colloidal processing of ceramics. J. Am. Ceram. Soc. 83, 2341–2359 (2000).

Minas, C., Carnelli, D., Tervoort, E. & Studart, A. R. 3D printing of emulsions and foams into hierarchical porous ceramics. Adv. Mater. 28, 9993–9999 (2016).

Moore, D. G., Barbera, L., Masania, K. & Studart, A. R. Three-dimensional printing of multicomponent glasses using phase-separating resins. Nat. Mater. 19, 212–217 (2020).

Hossain, S. S. & Lu, K. Recent progress of alumina ceramics by direct ink writing: ink design, printing and post-processing. Ceram. Int. 49, 10199–10212 (2023).

Huang, K., Elsayed, H., Franchin, G. & Colombo, P. Embedded direct ink writing of freeform ceramic components. Appl. Mater. Today 23, 101005 (2021).

Kleger, N., Cihova, M., Masania, K., Studart, A. R. & Löffler, J. F. 3D printing of salt as a template for magnesium with structured porosity. Adv. Mater. 31, 1903783 (2019).

Xu, C., Quinn, B., Lebel, L. L., Therriault, D. & L’Espérance, G. Multi-material direct ink writing (DIW) for complex 3D metallic structures with removable supports. ACS Appl. Mater. Interfaces 11, 8499–8506 (2019).

Muth, J. T. et al. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 26, 6307–6312 (2014).

Li, Y. & Li, B. Direct ink writing 3D printing of polydimethylsiloxane-based soft and composite materials: a mini review. Oxf. Open Mater. Sci. 2, itac008 (2022).

Compton, B. G. & Lewis, J. A. 3D-printing of lightweight cellular composites. Adv. Mater. 26, 5930–5935 (2014).

Kokkinis, D., Schaffner, M. & Studart, A. R. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 6, 8643 (2015).

Raney, J. R. et al. Rotational 3D printing of damage-tolerant composites with programmable mechanics. Proc. Natl Acad. Sci. USA 115, 1198–1203 (2018).

Franchin, G., Wahl, L. & Colombo, P. Direct ink writing of ceramic matrix composite structures. J. Am. Ceram. Soc. 100, 4397–4401 (2017).

Farahani, R. D., Dubé, M. & Therriault, D. Three-dimensional printing of multifunctional nanocomposites: manufacturing techniques and applications. Adv. Mater. 28, 5794–5821 (2016).

Smay, J. E., Cesarano, J. & Lewis, J. A. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 18, 5429–5437 (2002).

Saadi, M. et al. Direct ink writing: a 3D printing technology for diverse materials. Adv. Mater. 34, 2108855 (2022).

del Mazo-Barbara, L. & Ginebra, M.-P. Rheological characterisation of ceramic inks for 3D direct ink writing: a review. J. Eur. Ceram. Soc. 41, 18–33 (2021).

Buswell, R. A., De Silva, W. L., Jones, S. Z. & Dirrenberger, J. 3D printing using concrete extrusion: a roadmap for research. Cem. Concr. Res. 112, 37–49 (2018).

Ahn, B. Y. et al. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323, 1590–1593 (2009).

Skylar-Scott, M. A., Mueller, J., Visser, C. W. & Lewis, J. A. Voxelated soft matter via multimaterial multinozzle 3D printing. Nature 575, 330–335 (2019).

Ladd, C. et al. 3D printing of free standing liquid metal microstructures. Adv. Mater. 25, 5081–5085 (2013).

Kokkinis, D., Bouville, F. & Studart, A. R. 3D printing of materials with tunable failure via bioinspired mechanical gradients. Adv. Mater. 30, 1705808 (2018).

Mueller, J., Raney, J. R., Shea, K. & Lewis, J. A. Architected lattices with high stiffness and toughness via multicore–shell 3D printing. Adv. Mater. 30, 1705001 (2018).

Larson, N. M. et al. Rotational multimaterial printing of filaments with subvoxel control. Nature 613, 682–688 (2023).

Kim, Y., Yuk, H., Zhao, R., Chester, S. A. & Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 558, 274–279 (2018).

Mostafaei, A. et al. Additive manufacturing of nickel-based superalloys: a state-of-the-art review on process–structure–defect–property relationship. Prog. Mater. Sci. 136, 101108 (2023).

Dutta, B. & Froes, F. S. The additive manufacturing (AM) of titanium alloys. Met. Powder Rep. 72, 96–106 (2017).

Galante, R., Figueiredo-Pina, C. G. & Serro, A. P. Additive manufacturing of ceramics for dental applications: a review. Dent. Mater. 35, 825–846 (2019).

Dawood, A., Marti, B. M., Sauret-Jackson, V. & Darwood, A. 3D printing in dentistry. Br. Dent. J. 219, 521–529 (2015).

Tumbleston, J. R. et al. Continuous liquid interface production of 3D objects. Science 347, 1349–1352 (2015).

Janusziewicz, R., Tumbleston, J. R., Quintanilla, A. L., Mecham, S. J. & DeSimone, J. M. Layerless fabrication with continuous liquid interface production. Proc. Natl. Acad. Sci. USA 113, 11703–11708 (2016).

Oropallo, W. & Piegl, L. A. Ten challenges in 3D printing. Eng. Comput. 32, 135–148 (2016).

Rafiee, M., Farahani, R. D. & Therriault, D. Multi-material 3D and 4D printing: a survey. Adv. Sci. 7, 1902307 (2020).

Frazier, W. E. Metal additive manufacturing: a review. J. Mater. Eng. Perform. 23, 1917–1928 (2014).

Wang, Z., Wang, L., Tang, F. & Chen, J. Multi-material additive manufacturing via fused deposition modeling 3D printing: a systematic review on the material feeding mechanism. In Proc. Inst. Mech. Eng. E (Sage Publications, 2024).

Lewandowski, J. J. & Seifi, M. Metal additive manufacturing: a review of mechanical properties. Annu. Rev. Mater. Res. 46, 151–186 (2016).

Ngo, T. D., Kashani, A., Imbalzano, G., Nguyen, K. T. & Hui, D. Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. B Eng. 143, 172–196 (2018).

Nazir, A. et al. Multi-material additive manufacturing: a systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Mater. Des. 226, 111661 (2023).

Zhang, Y. S. et al. 3D extrusion bioprinting. Nat. Rev. Methods Primers 1, 75 (2021).

Rocha, V. G., Saiz, E., Tirichenko, I. S. & García-Tuñón, E. Direct ink writing advances in multi-material structures for a sustainable future. J. Mater. Chem. A 8, 15646–15657 (2020).

Wan, X., Luo, L., Liu, Y. & Leng, J. Direct ink writing based 4D printing of materials and their applications. Adv. Sci. 7, 2001000 (2020).

Zhang, Y. et al. Recent progress of direct ink writing of electronic components for advanced wearable devices. ACS Appl. Electron. Mater. 1, 1718–1734 (2019).

Han, D. & Lee, H. Recent advances in multi-material additive manufacturing: methods and applications. Curr. Opin. Chem. Eng. 28, 158–166 (2020).

Rau, D. A., Williams, C. B. & Bortner, M. J. Rheology and printability: a survey of critical relationships for direct ink write materials design. Prog. Mater. Sci. 140, 101188 (2023).

Herschel, W. H. & Bulkley, R. Konsistenzmessungen von gummi-benzollösungen. Kolloid Z. 39, 291–300 (1926).

Wilt, J. K., Gilmer, D., Kim, S., Compton, B. G. & Saito, T. Direct ink writing techniques for in situ gelation and solidification. MRS Commun. 11, 106–121 (2021).

Yuk, H. & Zhao, X. A new 3D printing strategy by harnessing deformation, instability, and fracture of viscoelastic inks. Adv. Mater. 30, 1704028 (2018).

Colon, A. R., Kazmer, D. O., Peterson, A. M. & Seppala, J. E. Characterization of die-swell in thermoplastic material extrusion. Addit. Manuf. 73, 103700 (2023).

Wei, P. et al. Go with the flow: rheological requirements for direct ink write printability. J. Appl. Phys. 134, 100701 (2023).

Corker, A., Ng, H. C.-H., Poole, R. J. & García-Tuñón, E. 3D printing with 2D colloids: designing rheology protocols to predict ‘printability’ of soft-materials. Soft Matter 15, 1444–1456 (2019).

Tagliaferri, S., Panagiotopoulos, A. & Mattevi, C. Direct ink writing of energy materials. Mater. Adv. 2, 540–563 (2021).

M’barki, A., Bocquet, L. & Stevenson, A. Linking rheology and printability for dense and strong ceramics by direct ink writing. Sci. Rep. 7, 6017 (2017).

Chaisong, K., Phuruangrat, A., Kanesom, T., Soongprasit, K. & Lertwittayanon, K. Direct ink writing of tubular Al2O3 membrane support using agar-based ink in 3D-printing. Mat. Sci. Forum 1090, 67–73 (2023).

Valentine, A. D. et al. Hybrid 3D printing of soft electronics. Adv. Mater. 29, 1703817 (2017).

Nie, J., Li, M., Liu, W., Li, W. & Xing, Z. The role of plasticizer in optimizing the rheological behavior of ceramic pastes intended for stereolithography-based additive manufacturing. J. Eur. Ceram. Soc. 41, 646–654 (2021).

Shahzad, A. & Lazoglu, I. Direct ink writing (DIW) of structural and functional ceramics: recent achievements and future challenges. Compos. B Eng. 225, 109249 (2021).

Muth, J. T., Dixon, P. G., Woish, L., Gibson, L. J. & Lewis, J. A. Architected cellular ceramics with tailored stiffness via direct foam writing. Proc. Natl Acad. Sci. USA 114, 1832–1837 (2017).

Boley, J. W. et al. High-operating-temperature direct ink writing of mesoscale eutectic architectures. Adv. Mater. 29, 1604778 (2017).

Khondoker, M. A., Ostashek, A. & Sameoto, D. Direct 3D printing of stretchable circuits via liquid metal co-extrusion within thermoplastic filaments. Adv. Eng. Mater. 21, 1900060 (2019).

Garciamendez-Mijares, C. E. et al. Development of an affordable extrusion 3D bioprinter equipped with a temperature-controlled printhead. Int. J. Bioprint. 9, 0244 (2023).

Kokol, V., Pottathara, Y. B., Mihelčič, M. & Perše, L. S. Rheological properties of gelatine hydrogels affected by flow- and horizontally-induced cooling rates during 3D cryo-printing. Colloids Surf. A Physicochem. Eng. 616, 126356 (2021).

Skylar-Scott, M. A., Gunasekaran, S. & Lewis, J. A. Laser-assisted direct ink writing of planar and 3D metal architectures. Proc. Natl Acad. Sci. USA 113, 6137–6142 (2016).

Visser, C. W., Amato, D. N., Mueller, J. & Lewis, J. A. Architected polymer foams via direct bubble writing. Adv. Mater. 31, 1904668 (2019).

Ji, Z., Jiang, D., Zhang, X., Guo, Y. & Wang, X. Facile photo and thermal two-stage curing for high-performance 3D printing of poly (dimethylsiloxane). Macromol. Rapid Commun. 41, 2000064 (2020).

Jackson, S., Zaragoza, L., Kumar, B. K. & Dickens, T. Tuning of ultraviolet-curable ink printability via in situ ultraviolet irradiation during direct ink write applications. J. Appl. Polym. Sci. 141, e55360 (2024).

Wu, T. et al. Additively manufacturing high-performance bismaleimide architectures with ultraviolet-assisted direct ink writing. Mater. Des. 180, 107947 (2019).

Rau, D. A., Herzberger, J., Long, T. E. & Williams, C. B. Ultraviolet-assisted direct ink write to additively manufacture all-aromatic polyimides. ACS Appl. Mater. Interfaces 10, 34828–34833 (2018).

Li, Q. et al. Advances in frontal polymerization strategy: from fundamentals to applications. Prog. Polym. Sci. 127, 101514 (2022).

Aw, J. E. et al. Self-regulative direct ink writing of frontally polymerizing thermoset polymers. Adv. Mater. Technol. 7, 2200230 (2022).

Robertson, I. D. et al. Rapid energy-efficient manufacturing of polymers and composites via frontal polymerization. Nature 557, 223–227 (2018).

Ziaee, M., Johnson, J. W. & Yourdkhani, M. 3D printing of short-carbon-fiber-reinforced thermoset polymer composites via frontal polymerization. ACS Appl. Mater. Interfaces 14, 16694–16702 (2022).

Zhang, Z. et al. Frontal polymerization-assisted 3D printing of short carbon fibers/dicyclopentadiene composites. J. Manuf. Process. 71, 753–762 (2021).

Guo, S.-Z. et al. Solvent-cast three-dimensional printing of multifunctional microsystems. Small 9, 4118–4122 (2013).

Wu, W., DeConinck, A. & Lewis, J. A. Omnidirectional printing of 3D microvascular networks. Adv. Mater. 23, H178–H183 (2011).

Wu, W. et al. Direct-write assembly of biomimetic microvascular networks for efficient fluid transport. Soft Matter 6, 739–742 (2010).

Hajash, K., Sparrman, B., Guberan, C., Laucks, J. & Tibbits, S. Large-scale rapid liquid printing. 3D Print. Addit. Manuf. 4, 123–132 (2017).

Grosskopf, A. K. et al. Viscoplastic matrix materials for embedded 3D printing. ACS Appl. Mater. Interfaces 10, 23353–23361 (2018).

Zhang, Y. et al. Coaxially printed magnetic mechanical electrical hybrid structures with actuation and sensing functionalities. Nat. Commun. 14, 4428 (2023).

Gao, J. et al. Foaming photothermal inks for direct-ink writing: hierarchical design and enhanced solar-powered interfacial evaporation. J. Mater. Chem. A 12, 6592–6609 (2024).

Zheng, S., Zlatin, M., Selvaganapathy, P. R. & Brook, M. A. Multiple modulus silicone elastomers using 3D extrusion printing of low viscosity inks. Addit. Manuf. 24, 86–92 (2018).

Larson, N. M. Opportunities at the frontier of multimaterial additive manufacturing with subvoxel control. MRS Bull. 49, 1217–1225 (2024).

Rao, R. B., Krafcik, K. L., Morales, A. M. & Lewis, J. A. Microfabricated deposition nozzles for direct-write assembly of three-dimensional periodic structures. Adv. Mater. 17, 289–293 (2005).

Yang, L., Sepasgozar, S. M., Shirowzhan, S., Kashani, A. & Edwards, D.Nozzle criteria for enhancing extrudability, buildability and interlayer bonding in 3D printing concrete. Autom. Constr. 146, 104671 (2023).

Kim, T., Trangkanukulkij, R. & Kim, W. S. Nozzle shape guided filler orientation in 3D printed photo-curable nanocomposites. Sci. Rep. 8, 3805 (2018).

Dreier, L. et al. Liquid lace: regular pattern formation by under-extrusion. Phys. Rev. Fluids 9, 110512 (2024).

Kuipers, T., Doubrovski, E. L., Wu, J. & Wang, C. C. A framework for adaptive width control of dense contour-parallel toolpaths in fused deposition modeling. Comput. Aided Des. 128, 102907 (2020).

Qu, H. et al. Gradient matters via filament diameter-adjustable 3D printing. Nat. Commun. 15, 2930 (2024).

Houriet, C. et al. 3D printing of flow-inspired anisotropic patterns with liquid crystalline polymers. Adv. Mater. 36, 2307444 (2024).

Zhan, Q., Wu, H., Zhang, L., Yuan, P. F. & Gao, T. 3D concrete printing with variable width filament. In Proc. Int. Conf. Educ. Res. Comput. Aided Archit. Des. Eur. Vol. 2 (eds Stojakovic, V. & Tepavcevic, B.) 153–160 (Univ. Novi Sad, 2021).

Moetazedian, A., Budisuharto, A. S., Silberschmidt, V. V. & Gleadall, A. Convex (continuously varied extrusion): a new scale of design for additive manufacturing. Addit. Manuf. 37, 101576 (2021).

Parilusyan, B. et al. Local layer splitting: an additive manufacturing method to define the mechanical properties of soft pneumatic actuators during fabrication. In 2023 IEEE Int. Conf. Robot. Autom. 12331–12337 (IEEE, 2023).

Li, M., Tian, X., Schreyer, D. J. & Chen, X. Effect of needle geometry on flow rate and cell damage in the dispensing-based biofabrication process. Biotechnol. Prog. 27, 1777–1784 (2011).

Martanto, W., Baisch, S. M., Costner, E. A., Prausnitz, M. R. & Smith, M. K. Fluid dynamics in conically tapered microneedles. AIChE J. 51, 1599–1607 (2005).

James, D. F. & Roos, C. A. Pressure drop of a Boger fluid in a converging channel. J. Nonnewton. Fluid Mech. 293, 104557 (2021).

Schuller, T., Jalaal, M., Fanzio, P. & Galindo-Rosales, F. J. Optimal shape design of printing nozzles for extrusion-based additive manufacturing. Addit. Manuf. 84, 104130 (2024).

Sydney Gladman, A., Matsumoto, E. A., Nuzzo, R. G., Mahadevan, L. & Lewis, J. A. Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016).

Fergerson, A. S., Gorse, B. H., Maguire, S. M., Ostermann, E. C. & Davidson, E. C. Reprocessable and mechanically tailored soft architectures through 3D printing of elastomeric block copolymers. Adv. Funct. Mater. 34, 2411812 (2024).

Gantenbein, S. et al. Three-dimensional printing of hierarchical liquid-crystal-polymer structures. Nature 561, 226–230 (2018).

Vassilakos, A., Giannatsis, J. & Dedoussis, V. Fabrication of parts with heterogeneous structure using material extrusion additive manufacturing. Virtual Phys. Prototyp. 16, 267–290 (2021).

Sow, M. et al. Influence of beam diameter on laser powder bed fusion (L-PBF) process. Addit. Manuf. 36, 101532 (2020).

Yadroitsev, I., Yadroitsava, I. & Du Plessis, A. in Fundamentals of Laser Powder Bed Fusion of Metals (eds Yadroitsev, I. et al.) 15–38 (Elsevier, 2021).

Paral, S. K., Lin, D.-Z., Cheng, Y.-L., Lin, S.-C. & Jeng, J.-Y. A review of critical issues in high-speed vat photopolymerization. Polymers 15, 2716 (2023).

Tezel, T. & Kovan, V. Determination of optimum production parameters for 3D printers based on nozzle diameter. Rapid Prototyp. J. 28, 185–194 (2022).

Pan, Y., Zhao, X., Zhou, C. & Chen, Y. Smooth surface fabrication in mask projection based stereolithography. J. Manuf. Process. 14, 460–470 (2012).

Lettori, J., Raffaeli, R., Bilancia, P., Peruzzini, M. & Pellicciari, M. A review of geometry representation and processing methods for Cartesian and multiaxial robot-based additive manufacturing. Int. J. Adv. Manuf. Technol. 123, 3767–3794 (2022).

Chesser, P. et al. Extrusion control for high quality printing on big area additive manufacturing (BAAM) systems. Addit. Manuf. 28, 445–455 (2019).

Lao, W., Li, M. & Tjahjowidodo, T. Variable-geometry nozzle for surface quality enhancement in 3D concrete printing. Addit. Manuf. 37, 101638 (2021).

Xu, J. et al. Volume-forming 3D concrete printing using a variable-size square nozzle. Autom. Constr. 104, 95–106 (2019).

Armstrong, C. D., Todd, N., Alsharhan, A. T., Bigio, D. I. & Sochol, R. D. A 3D printed morphing nozzle to control fiber orientation during composite additive manufacturing. Adv. Mater. Technol. 6, 2000829 (2021).

Kang, S. W. & Mueller, J. Multiscale 3D printing via active nozzle size and shape control. Sci. Adv. 10, eadn7772 (2024).

Liu, Z. et al. Modelling and parameter optimization for filament deformation in 3D cementitious material printing using support vector machine. Compos. B Eng. 193, 108018 (2020).

Dhakal, N., Wang, X., Espejo, C., Morina, A. & Emami, N. Impact of processing defects on microstructure, surface quality, and tribological performance in 3D printed polymers. J. Mater. Res. Technol. 23, 1252–1272 (2023).

Gharehpapagh, B., Dilberoglu, U. M., Yaman, U. & Dolen, M. Adaptive toolpath generation for material extrusion additive manufacturing using a nozzle with rectangular orifice. Addit. Manuf. 78, 103873 (2023).

Gao, Z. et al. Simultaneous multi-material embedded printing for 3D heterogeneous structures. Int. J. Extreme Manuf. 5, 035001 (2023).

Cheng, P. et al. A novel dual-nozzle 3D printing method for continuous fiber reinforced composite cellular structures. Compos. Commun. 37, 101448 (2023).

Hansen, C. J. et al. High-throughput printing via microvascular multinozzle arrays. Adv. Mater. 25, 96–102 (2013).

Lewis, J. A., Skylar-Scott, M. A., Mueller, J. & Kolesky, D. Systems and methods for automated nozzle design and 3D printing. US patent 10,946,588 (2021).

Uzel, S. G., Weeks, R. D., Eriksson, M., Kokkinis, D. & Lewis, J. A. Multimaterial multinozzle adaptive 3D printing of soft materials. Adv. Mater. Technol. 7, 2101710 (2022).

Wilt, J. K., Hmeidat, N. S., Bohling, J. W. & Compton, B. G. High through-thickness thermal conductivity of 3D-printed composites via rotational direct ink writing. Addit. Manuf. Lett. 7, 100167 (2023).

Ren, L. et al. Rotational co-extrusion 4D printing of heterogeneous filaments to enable sophisticated shape morphing. Addit. Manuf. 73, 103661 (2023).

Gunduz, I. et al. 3D printing of extremely viscous materials using ultrasonic vibrations. Addit. Manuf. 22, 98–103 (2018).

Tofangchi, A., Han, P., Izquierdo, J., Iyengar, A. & Hsu, K. Effect of ultrasonic vibration on interlayer adhesion in fused filament fabrication 3D printed abs. Polymers 11, 315 (2019).

Nawafleh, N., Wright, W., Dariavach, N. & Celik, E. 3D-printed thermoset syntactic foams with tailorable mechanical performance. J. Mater. Sci. 55, 16048–16057 (2020).

Lin, S., Zhang, L. & Cong, L. A micro-vibration-driven direct ink write printing method of gallium–indium alloys. Sci. Rep. 13, 3914 (2023).

Friedrich, L. & Begley, M. Printing direction dependent microstructures in direct ink writing. Addit. Manuf. 34, 101192 (2020).

Wu, S. et al. Evolutionary algorithm-guided voxel-encoding printing of functional hard-magnetic soft active materials. Adv. Intell. Syst. 2, 2000060 (2020).

Yuran, A. F. & Yavuz, I. Effect of heat break geometry on the thermal performance of a 3D printer extruder. IJSTR 6, 41–50 (2020).

Zhang, P., Gao, Q., Yu, K., Yao, Y. & Lu, L. Investigation on the temperature control accuracy of a print head for extrusion 3D printing and its improved design. Biomedicines 10, 1233 (2022).

Khan, Z., Koltay, P., Zengerle, R., Kartmann, S. & Shu, Z. One-stop hybrid printing of bulk metal and polymer for 3D electronics. Adv. Eng. Mater. 26, 2300922 (2024).

Wang, L. et al. Development of high-frequency and high-viscosity piezoelectric DOD print head and its jet performance. Sensor Actuat. A Phys. 337, 113409 (2022).

Sanz-Garcia, A., Sodupe-Ortega, E., Pernía-Espinoza, A., Shimizu, T. & Escobedo-Lucea, C. A versatile open-source printhead for low-cost 3D microextrusion-based bioprinting. Polymers 12, 2346 (2020).

Kotikian, A., Truby, R. L., Boley, J. W., White, T. J. & Lewis, J. A. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 30, 1706164 (2018).

Kotikian, A. et al. Innervated, self-sensing liquid crystal elastomer actuators with closed loop control. Adv. Mater. 33, 2101814 (2021).

Sun, Y. et al. 3D printing of thermosets with diverse rheological and functional applicabilities. Nat. Commun. 14, 245 (2023).

Shang, E. et al. Laser-assisted direct ink writing for high-fidelity fabrication of elastomeric complex structures. Adv. Mater. Interfaces 10, 2300300 (2023).

Peng, X. et al. 4D printing of freestanding liquid crystal elastomers via hybrid additive manufacturing. Adv. Mater. 34, 2204890 (2022).

Lenshof, A. & Laurell, T. in Encyclopedia of Nanotechnology (ed. Bhushan, B.) 45–50 (Springer, 2012).

Friedrich, L., Collino, R., Ray, T. & Begley, M. Acoustic control of microstructures during direct ink writing of two-phase materials. Sensor Actuat. A Phys. 268, 213–221 (2017).

Foresti, D. et al. Acoustophoretic printing. Sci. Adv. 4, eaat1659 (2018).

Wadsworth, P., Nelson, I., Porter, D. L., Raeymaekers, B. & Naleway, S. E. Manufacturing bioinspired flexible materials using ultrasound directed self-assembly and 3D printing. Mater. Des. 185, 108243 (2020).

Ma, C. et al. Magnetic multimaterial printing for multimodal shape transformation with tunable properties and shiftable mechanical behaviors. ACS Appl. Mater. Interfaces 13, 12639–12648 (2020).

Lebel, L. L., Aissa, B., Khakani, M. A. E. & Therriault, D. Ultraviolet-assisted direct-write fabrication of carbon nanotube/polymer nanocomposite microcoils. Adv. Mater. 22, 592–596 (2010).

Huang, K., De Marzi, A., Franchin, G. & Colombo, P. UV-assisted robotic arm freeforming of SiOC ceramics from a preceramic polymer. Addit. Manuf. 83, 104051 (2024).

Lipkowitz, G. et al. Growing three-dimensional objects with light. Proc. Natl Acad. Sci. USA 121, e2303648121 (2024).

Hausladen, M. M., Gorbea, G. D., Francis, L. F. & Ellison, C. J. UV-assisted direct ink writing of dual-cure polyurethanes. ACS Appl. Polym. Mater. 6, 2253–2265 (2024).

Brown, T. D., Dalton, P. D. & Hutmacher, D. W. Melt electrospinning today: an opportune time for an emerging polymer process. Prog. Polym. Sci. 56, 116–166 (2016).

Dalton, P. D. Melt electrowriting with additive manufacturing principles. Curr. Opin. Biomed. Eng. 2, 49–57 (2017).

Zhong, H., Huang, J., Wu, J. & Du, J. Electrospinning nanofibers to 1D, 2D, and 3D scaffolds and their biomedical applications. Nano Res. 15, 787–804 (2022).

Wang, X., Kim, Y. I., Yarin, A. L. & Pan, Y. Electric field-assisted micro-scale direct ink writing for electronic textiles. Manuf. Lett. 41, 841–849 (2024).

Plog, J., Wang, X., Lichade, K. M., Pan, Y. & Yarin, A. L. Extremely-fast electrostatically-assisted direct ink writing of 2D, 2.5D and 3D functional traces of conducting polymer Poly (3,4-ethylenedioxythiophene) polystyrene sulfonate-polyethylene oxide (PEDOT: PSS-PEO). J. Colloid Interface Sci. 651, 1043–1053 (2023).

Hardin, J. O., Ober, T. J., Valentine, A. D. & Lewis, J. A. Microfluidic printheads for multimaterial 3D printing of viscoelastic inks. Adv. Mater. 27, 3279–3284 (2015).

Hassan, I. & Selvaganapathy, P. R. Microfluidic printheads for highly switchable multimaterial 3D printing of soft materials. Adv. Mater. Technol. 7, 2101709 (2022).

Habib, A., Quigley, C., Sarah, R., Hurd, W. & Clark, S. Design and fabrication of in-house nozzle system to extrude multi-hydrogels for 3D bioprinting process. J. Manuf. Sci. Eng. 146, 021003 (2024).

Ober, T. J., Foresti, D. & Lewis, J. A. Active mixing of complex fluids at the microscale. Proc. Natl Acad. Sci. USA 112, 12293–12298 (2015).

Rahman, T. T., Wood, N., Rahman, A. M., Pei, Z. & Qin, H. Applying in situ ionic crosslinking in bioprinting using algae cells. J. Manuf. Sci. Eng. 146, 034501 (2024).

Therriault, D., White, S. R. & Lewis, J. A. Chaotic mixing in three-dimensional microvascular networks fabricated by direct-write assembly. Nat. Mater. 2, 265–271 (2003).

Meijer, H. E., Singh, M. K. & Anderson, P. D. On the performance of static mixers: a quantitative comparison. Prog. Polym. Sci. 37, 1333–1349 (2012).

Hessel, V., Löwe, H. & Schönfeld, F. Micromixers — a review on passive and active mixing principles. Chem. Eng. Sci. 60, 2479–2501 (2005).

Liu, Y. et al. On the selection of rheological tests for the prediction of 3D printability. J. Rheol. 67, 791 (2023).

Zeng, M. et al. High-throughput printing of combinatorial materials from aerosols. Nature 617, 292–298 (2023).

Khatri, N. R. et al. Integrating helicoid channels for passive control of fiber alignment in direct-write 3D printing. Addit. Manuf. 48, 102419 (2021).

Wang, P. et al. Novel stirring-rod-inspired mixer-integrated printhead for fabricating gradient tissue structures. Mater. Des. 229, 111866 (2023).

Bolívar-Monsalve, E. J. et al. Continuous chaotic bioprinting of skeletal muscle-like constructs. Bioprinting 21, e00125 (2021).

Bolívar-Monsalve, E. J. et al. One-step bioprinting of multi-channel hydrogel filaments using chaotic advection: fabrication of pre-vascularized muscle-like tissues. Adv. Healthc. Mater. 11, 2200448 (2022).

Guo, W. et al. 3D printing of multifunctional gradient bone scaffolds with programmable component distribution and hierarchical pore structure. Compos. Part A Appl. Sci. Manuf. 166, 107361 (2023).

Ceballos-González, C. F. et al. High-throughput and continuous chaotic bioprinting of spatially controlled bacterial microcosms. ACS Biomater. Sci. Eng. 7, 2408–2419 (2021).

Ceballos-González, C. F. et al. Plug-and-play multimaterial chaotic printing/bioprinting to produce radial and axial micropatterns in hydrogel filaments. Adv. Mater. Technol. 8, 2202208 (2023).

Idaszek, J. et al. 3D bioprinting of hydrogel constructs with cell and material gradients for the regeneration of full-thickness chondral defect using a microfluidic printing head. Biofabrication 11, 044101 (2019).

Khondoker, M. A. H., Asad, A. & Sameoto, D. Printing with mechanically interlocked extrudates using a custom bi-extruder for fused deposition modelling. Rapid Prototyp. J. 24, 921–934 (2018).

Ortega, J. M. et al. Active mixing of disparate inks for multimaterial 3D printing. Adv. Mater. Technol. 4, 1800717 (2019).

Golobic, A. M. et al. Active mixing of reactive materials for 3D printing. Adv. Eng. Mater. 21, 1900147 (2019).

Zhang, N. & Sanjayan, J. Extrusion nozzle design and print parameter selections for 3D concrete printing. Cem. Concr. Compos. 137, 104939 (2023).

Ramakrishnan, S., Kanagasuntharam, S. & Sanjayan, J. In-line activation of cementitious materials for 3D concrete printing. Cem. Concr. Compos. 131, 104598 (2022).

Wangler, T., Pileggi, R., Gürel, S. & Flatt, R. J. A chemical process engineering look at digital concrete processes: critical step design, inline mixing, and scaleup. Cem. Concr. Res. 155, 106782 (2022).

Diañez, I. et al. Implementation of a novel continuous solid/liquid mixing accessory for 3D printing of dysphagia-oriented thickened fluids. Food Hydrocoll. 120, 106900 (2021).

Kennedy, Z. C. & Christ, J. F. Printing polymer blends through in situ active mixing during fused filament fabrication. Addit. Manuf. 36, 101233 (2020).

Justino Netto, J. M. & Silveira, Zd. C. Design of an innovative three-dimensional print head based on twin-screw extrusion. J. Mech. Des. 140, 125002 (2018).

Hassan, I. & Selvaganapathy, P. R. A microfluidic printhead with integrated hybrid mixing by sequential injection for multimaterial 3D printing. Addit. Manuf. 50, 102559 (2022).

Teves, S. et al. Active-mixing printhead for on-the-fly composition adjustment of multi component materials in direct ink writing. Add. Manuf. Lett. 10, 100217 (2024).

Gratson, G. M. et al. Direct-write assembly of three-dimensional photonic crystals: conversion of polymer scaffolds to silicon hollow-woodpile structures. Adv. Mater. 18, 461–465 (2006).

Cornock, R., Beirne, S. & Wallace, G. G. Development of a coaxial melt extrusion printing process for specialised composite bioscaffold fabrication. In IEEE/ASME Int. Conf. Adv. Intell. Mechatron. 973–978 (IEEE, 2013).

Frutiger, A. et al. Capacitive soft strain sensors via multicore–shell fiber printing. Adv. Mater. 27, 2440–2446 (2015).

Ritchie, R. O. The conflicts between strength and toughness. Nat. Mater. 10, 817–822 (2011).

Mueller, J. & Shea, K. Stepwise graded struts for maximizing energy absorption in lattices. Extreme Mech. Lett. 25, 7–15 (2018).

Mueller, J., Raney, J. R., Kochmann, D. M. & Shea, K. Stiffness-independent toughening of beams through coaxial interfaces. Adv. Sci. 5, 1800728 (2018).

Xia, Y. et al. Microstructure and mechanical property of Cf/SiC core/shell composite fabricated by direct ink writing. Scr. Mater. 165, 84–88 (2019).

Abdullah, A. M., Ding, Y., He, X., Dunn, M. & Yu, K. Direct-write 3D printing of UV-curable composites with continuous carbon fiber. J. Compos. Mater. 57, 851–863 (2023).

Sweeney, C. B. et al. Welding of 3D-printed carbon nanotube–polymer composites by locally induced microwave heating. Sci. Adv. 3, e1700262 (2017).

Liu, D. et al. Customizable and stretchable fibre-shaped electroluminescent devices via multicore-shell direct ink writing. J. Mater. Chem. C 8, 15092–15098 (2020).

Ji, D., Zheng, H., Zhang, H., Liu, W. & Ding, J. Coaxial 3D-printing constructing all-in-one fibrous lithium-, sodium-, and zinc-ion batteries. Chem. Eng. J. 433, 133815 (2022).

Chortos, A. et al. Printing reconfigurable bundles of dielectric elastomer fibers. Adv. Funct. Mater. 31, 2010643 (2021).

Li, S. et al. Direct ink writing of cephalopod skin-like core–shell fibers from cholesteric liquid crystal elastomers and dyed solutions. Adv. Funct. Mater. 35, 2413965 (2024).

Zhao, J. et al. Direct coherent multi-ink printing of fabric supercapacitors. Sci. Adv. 7, eabd6978 (2021).

Yu, Y., Zhang, Y., Martin, J. A. & Ozbolat, I. T. Evaluation of cell viability and functionality in vessel-like bioprintable cell-laden tubular channels. J. Biomech. Eng. 135, 091011 (2013).

Gao, Q., He, Y., Fu, J.-z, Liu, A. & Ma, L. Coaxial nozzle-assisted 3D bioprinting with built-in microchannels for nutrients delivery. Biomaterials 61, 203–215 (2015).

Akkineni, A. R., Ahlfeld, T., Lode, A. & Gelinsky, M. A versatile method for combining different biopolymers in a core/shell fashion by 3D plotting to achieve mechanically robust constructs. Biofabrication 8, 045001 (2016).

Cui, H. et al. In vitro and in vivo evaluation of 3D bioprinted small-diameter vasculature with smooth muscle and endothelium. Biofabrication 12, 015004 (2019).

Shao, L. et al. Directly coaxial 3D bioprinting of large-scale vascularized tissue constructs. Biofabrication 12, 035014 (2020).

Peng, F., Zhao, Z., Xia, X., Cakmak, M. & Vogt, B. D. Enhanced impact resistance of three-dimensional-printed parts with structured filaments. ACS Appl. Mater. Interfaces 10, 16087–16094 (2018).

Naqi, A., Swain, Z. & Mackay, M. E. Dual material fused filament fabrication via core–shell die design. ACS Appl. Polym. Mater. 5, 2481–2489 (2023).

Leschok, M., Reiter, L. & Dillenburger, B. Large-scale hollow-core 3D printing (HC3DP): a polymer 3D printing technology for large-scale ultralightweight components. Addit. Manuf. 78, 103874 (2023).

Ames, D., Lazarus, N. & Mueller, J. Liquid metal core–shell 3D printing. Adv. Eng. Mater. https://doi.org/10.1002/adem.202402959 (2025).

Ren, J. et al. Multicore–shell direct ink writing of coaxial transmission lines. ACS Appl. Eng. Mater. 2, 67–75 (2024).

Ames, D. C., Propst, S., Shah, A. & Mueller, J. Voxel interface control in multimaterial extrusion 3D printing. Adv. Mater. 36, 2407599 (2024).

Hassan, S. et al. Tunable and compartmentalized multimaterial bioprinting for complex living tissue constructs. ACS Appl. Mater. Interfaces 14, 51602–51618 (2022).

Liu, W. et al. Rapid continuous multimaterial extrusion bioprinting. Adv. Mater. 29, 1604630 (2017).

Biedermann, M. & Meboldt, M. Computational design synthesis of additive manufactured multi-flow nozzles. Addit. Manuf. 35, 101231 (2020).

Ravichandran, D. et al. Multiphase direct ink writing (MDIW) for multilayered polymer/nanoparticle composites. Addit. Manuf. 47, 102322 (2021).

Bayles, A. V. et al. Structuring hydrogel cross-link density using hierarchical filament 3D printing. ACS Appl. Mater. Interfaces 14, 15667–15677 (2022).

Ravichandran, D. et al. Multi-material 3D printing-enabled multilayers for smart actuation via magnetic and thermal stimuli. J. Mater. Chem. C 10, 13762–13770 (2022).

Pleij, T., Bayles, A. V. & Vermant, J. Advective assembler-enhanced support bath rotational direct ink writing. Adv. Mater. Technol. 9, 2400005 (2024).

Bayles, A. V. & Vermant, J. Divide, conquer, and stabilize: engineering strong fluid–fluid interfaces. Langmuir 38, 6499–6505 (2022).

Bai, Z. et al. Subvoxel-controlled microfluidic printing of dual-material and multi-structural filaments. Adv. Mater. Technol. 9, 2301150 (2024).

O’Neill, K. L. & Dalton, P. D. A decade of melt electrowriting. Small Methods 7, 2201589 (2023).

Zheng, X. et al. Ultralight, ultrastiff mechanical metamaterials. Science 344, 1373–1377 (2014).

Weiss, J. D. et al. A low-cost, open-source 3D printer for multimaterial and high-throughput direct ink writing of soft and living materials. Adv. Mater. 37, 2414971 (2025).

Jeon, S. et al. Direct-ink-write cross-linkable bottlebrush block copolymers for on-the-fly control of structural color. Proc. Natl Acad. Sci. USA 121, e2313617121 (2024).

Li, M., Pal, A., Aghakhani, A., Pena-Francesch, A. & Sitti, M. Soft actuators for real-world applications. Nat. Rev. Mater. 7, 235–249 (2022).

Zhou, C. et al. Ferromagnetic soft catheter robots for minimally invasive bioprinting. Nat. Commun. 12, 5072 (2021).

Du Pasquier, C. & Shea, K. A nonlinear optimization method for large shape morphing in 3D printed pneumatic lattice structures. Smart Mater. Struct. 31, 065016 (2022).

Sparrman, B. et al. Printed silicone pneumatic actuators for soft robotics. Addit. Manuf. 40, 101860 (2021).

Brown, N. & Mueller, J. Hybrid formative-additive manufacturing. Adv. Mater. https://doi.org/10.1002/adma.202417609 (2025).

Wehner, M. et al. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 536, 451–455 (2016).

Tibbits, S. 4D printing: multi-material shape change. Arch. Des. 84, 116–121 (2014).

Boley, J. W. et al. Shape-shifting structured lattices via multimaterial 4D printing. Proc. Natl Acad. Sci. USA 116, 20856–20862 (2019).

Lu, X. et al. 4D-printing of photoswitchable actuators. Angew. Chem. Int. Ed. 60, 5536–5543 (2021).

Stankey, P. P. et al. Embedding biomimetic vascular networks via coaxial sacrificial writing into functional tissue. Adv. Mater. 36, 2401528 (2024).

Gleadall, A. FullControl GCode Designer: Open-source software for unconstrained design in additive manufacturing. Addit. Manuf. 46, 102109 (2021).

Propst, S. & Mueller, J. Time code for multifunctional 3D printhead controls. Nat. Commun. 16, 1035 (2025).

Weeks, R. D., Truby, R. L., Uzel, S. G. & Lewis, J. A. Embedded 3D printing of multimaterial polymer lattices via graph-based print path planning. Adv. Mater. 35, 2206958 (2023).

Kajtez, J. et al. Embedded 3D printing in self-healing annealable composites for precise patterning of functionally mature human neural constructs. Adv. Sci. 9, 2201392 (2022).

Acknowledgements

J.M. discloses support for this work from the Jean-Jacques and Felicia Lopez-Loreta Foundation for Academic Excellence through the 2020 Prize.

Author information

Authors and Affiliations

Contributions

The authors contributed equally to all aspects of the article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Materials thanks Fergal Coulter, Michael Dickey, Qi Ge and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Brown, N.C., Ames, D.C. & Mueller, J. Multimaterial extrusion 3D printing printheads. Nat Rev Mater 10, 807–825 (2025). https://doi.org/10.1038/s41578-025-00809-y

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41578-025-00809-y