Abstract

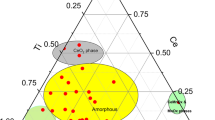

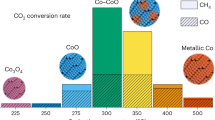

Ceria nanoparticles supported on alumina are widely used in various catalytic reactions, particularly in conjunction with platinum group metals (PGMs)1,2,3,4,5,6,7,8,9. Here we found that treating these catalysts at temperatures between 750 and about 1,000 °C in the presence of CO and NO in steam (reactive treatment under reducing atmosphere) leads to the dispersion of ceria nanoparticles into high-density 2D (roughly one atomic layer thin) CexOy domains, as confirmed by microscopy, X-ray photoelectron spectroscopy (XPS), X-ray absorption spectroscopy (XAS), infrared spectroscopy and density functional theory (DFT) calculations. These domains, which densely cover the alumina, exhibit substantially enhanced oxygen mobility and storage capacity, facilitating easier extraction of oxygen and the formation of Ce3+ sites and oxygen vacancies. As a result, these catalysts—whether with or without PGMs, such as Rh and Pt—show improved activity for several industrially important catalytic reactions, including NO and N2O reduction, as well as CO and NO oxidation, even after exposure to harsh ageing conditions. This study shows a catalyst architecture with superior redox properties under conditions that typically cause sintering, offering a pathway to more efficient metal–ceria catalysts for enhanced general catalysis.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data are available in the main text or the Supplementary Information and are also available from the corresponding authors on request. The structures from the DFT calculations are available at Zenodo: https://doi.org/10.5281/zenodo.14030546 (ref. 44). Source data are provided with this paper.

References

Summers, J. C. & Ausen, S. A. Interaction of cerium oxide with noble metals. J. Catal. 58, 131–143 (1979).

Trovarelli, A. Catalytic properties of ceria and CeO2-containing materials. Catal. Rev. Sci. Eng. 38, 439–520 (1996).

Montini, T., Melchionna, M., Monai, M. & Fornasiero, P. Fundamentals and catalytic applications of CeO2-based materials. Chem. Rev. 116, 5987–6041 (2016).

Gorte, R. J. Ceria in catalysis: from automotive applications to the water–gas shift reaction. AIChE J 56, 1126–1135 (2010).

Rodriguez, J. A., Grinter, D. C., Liu, Z., Palomino, R. M. & Senanayake, S. D. Ceria-based model catalysts: fundamental studies on the importance of the metal–ceria interface in CO oxidation, the water–gas shift, CO2 hydrogenation, and methane and alcohol reforming. Chem. Soc. Rev. 46, 1824–1841 (2017).

Farmer, J. A. & Campbell, C. T. Ceria maintains smaller metal catalyst particles by strong metal-support bonding. Science 329, 933–936 (2010).

Meunier, F. C. et al. Synergy between metallic and oxidized Pt sites unravelled during room temperature CO oxidation on Pt/ceria. Angew. Chem. Int. Ed. 60, 3799–3805 (2021).

Jones, J. et al. Thermally stable single-atom platinum-on-ceria catalysts via atom trapping. Science 353, 150–154 (2016).

Vayssilov, G. N. et al. Support nanostructure boosts oxygen transfer to catalytically active platinum nanoparticles. Nat. Mater. 10, 310–315 (2011).

Mudiyanselage, K. et al. Importance of the metal–oxide interface in catalysis: in situ studies of the water–gas shift reaction by ambient-pressure X-ray photoelectron spectroscopy. Angew. Chem. Int. Ed. 52, 5101–5105 (2013).

Daturi, M. et al. Evidence of a lacunar mechanism for deNOx activity in ceria-based catalysts. Phys. Chem. Chem. Phys. 3, 252–255 (2001).

Datye, A. & Wang, Y. Atom trapping: a novel approach to generate thermally stable and regenerable single-atom catalysts. Natl Sci. Rev. 5, 630–632 (2018).

Shyu, J. Z., Weber, W. H. & Gandhi, H. S. Surface characterization of alumina-supported ceria. J. Phys. Chem. 92, 4964–4970 (1988).

Shyu, J. Z. et al. Characterization of Pd/γ-alumina catalysts containing ceria. J. Catal. 114, 23–33 (1988).

Koleva, I. Z., Aleksandrov, H. A., Vayssilov, G. N., Duarte, R. & van Bokhoven, J. A. Relative stability and reducibility of CeO2 and Rh/CeO2 species on the surface and in the cavities of γ-Al2O3: a periodic DFT study. Phys. Chem. Chem. Phys. 17, 22389–22401 (2015).

Khivantsev, K. et al. Economizing on precious metals in three-way catalysts: thermally stable and highly active single-atom rhodium on ceria for NO abatement under dry and industrially relevant conditions. Angew. Chem. Int. Ed. 60, 391–398 (2021).

Bourges, P., Lunati, S. & Mabilon, G. N2O and NO2 formation during NO reduction on precious metal catalysts. Stud. Surf. Sci. Catal. 116, 213–222 (1998).

Getsoian, A. B., Theis, J. R., Paxton, W. A., Lance, M. J. & Lambert, C. K. Remarkable improvement in low temperature performance of model three-way catalysts through solution atomic layer deposition. Nat. Catal. 2, 614–622 (2019).

Henderson, M. A., Perkins, C. L., Engelhard, M., Thevuthasan, S. & Peden, C. H. F. Redox properties of water on the oxidized and reduced surfaces of CeO2(111). Surf. Sci. 526, 1–18 (2003).

Kuchibhatla, S. et al. Influence of aging and environment on nanoparticle chemistry – implication to confinement effects in nanoceria. J. Phys. Chem. C 116, 14108–14114 (2012).

Khivantsev, K., Jaegers, N. R., Kwak, J.-H., Szanyi, J. & Kovarik, L. Precise identification and characterization of catalytically active sites on the surface of γ-alumina. Angew. Chem. Int. Ed. 133, 17663–17671 (2021).

Kwak, J. H. et al. Coordinatively unsaturated Al3+ centers as binding sites for active catalyst phases of platinum on γ-Al2O3. Science 325, 1670–1673 (2009).

Mihaylov, M. Y. et al. FTIR and density functional study of NO interaction with reduced ceria: identification of \({{\rm{N}}}_{3}^{-}\) and NO2− as new intermediates in NO conversion. Appl. Catal. B: Environ. 176, 107–119 (2015).

Mihaylov, M. Y., Ivanova, E. Z., Vayssilov, G. N. & Hadjiivanov, K. I. Revisiting ceria-NOx interaction: FTIR studies. Catal. Today 357, 613–620 (2020).

Kašpar, J., de Leitenburg, C., Fornasiero, P., Trovarelli, A. & Graziani, M. NO reduction by CO over Rh/Al2O3. Effects of rhodium dispersion on the catalytic properties. J. Catal. 146, 136–143 (1994).

Malecka, M. & Kepinski, L. \({{\rm{Ce}}}_{0.4}^{{\rm{III}}}{{\rm{Ce}}}_{0.6}^{{\rm{IV}}}{{\rm{AlO}}}_{3.3}\) – an unexpected product of a solid state reaction in the CeO2–Al2O3 system. CrystEngComm 17, 8282–8288 (2015).

Skála, T., Tsud, N., Prince, K. C. & Matolín, V. Formation of alumina–ceria mixed oxide in model systems. Appl. Surf. Sci. 257, 3682–3687 (2011).

Song, I. et al. Understanding reactivity and stability of rhodium supported on different ceria facets in catalytic NO reduction and CO/hydrocarbon oxidation reactions. Preprint at https://doi.org/10.26434/chemrxiv-2023-9ldvr-v2 (2024).

Schmieg, S. J. & Belton, D. N. Effect of hydrothermal aging on oxygen storage/release and activity in a commercial automotive catalyst. Appl. Catal. B: Environ. 6, 127–144 (1995).

Sayle, D. C. et al. Aging mechanisms of nanoceria and pathways for preserving optimum morphology. Nano Today 51, 101916 (2023).

Fu, W. T. & Ijdo, D. J. W. The structure of CeAlO3 by Rietveld refinement of X-ray powder diffraction data. J. Solid State Chem. 177, 2973–2976 (2004).

Perdew, J. P. et al. Atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 46, 6671–6687 (1992).

Perdew, J. P. et al. Erratum: Atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 48, 4978 (1993).

Kresse, G. & Hafner, J. Ab initio molecular dynamics for liquid metals. Phys. Rev. B 47, 558–561 (1993).

Kresse, G. & Hafner, J. Ab initio molecular-dynamics simulation of the liquid-metal–amorphous-semiconductor transition in germanium. Phys. Rev. B 49, 14251–14269 (1994).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Migani, A., Vayssilov, G. N., Bromley, S. T., Illas, F. & Neyman, K. M. Dramatic reduction of the oxygen vacancy formation energy in ceria particles: a possible key to their remarkable reactivity at the nanoscale. J. Mater. Chem. 20, 10535–10546 (2010).

Vayssilov, G. N., Mihaylov, M., St. Petkov, P., Hadjiivanov, K. I. & Neyman, K. M. Reassignment of the vibrational spectra of carbonates, formates, and related surface species on ceria: a combined density functional and infrared spectroscopy investigation. J. Phys. Chem. C 115, 23435–23454 (2011).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Digne, M., Sautet, P., Raybaud, P., Euzen, P. & Toulhoat, H. Use of DFT to achieve a rational understanding of acid–basic properties of γ-alumina surfaces. J. Catal. 226, 54–68 (2004).

Pueyo Bellafont, N., Viñes, F., Hieringer, W. & Illas, F. Predicting core level binding energies shifts: suitability of the projector augmented wave approach as implemented in VASP. J. Comput. Chem. 38, 518–522 (2017).

Aleksandrov, H. Dataset for the article “Transforming ceria into 2-dimensional clusters enhances catalytic activity”. Zenodo https://doi.org/10.5281/zenodo.14030546 (2024).

Acknowledgements

Y.W., A.D., and H.P. acknowledge the financial support by the U.S. Department of Energy’s Basic Energy Sciences (DOE/BES) Catalysis Science programme, grant DE-FG02-05ER15712. K.K., J.S., L.K., M.B., D.J., and W.H. were supported by the U.S. Department of Energy’s Basic Energy Sciences (DOE/BES), Division of Chemical Sciences, Geosciences, and Biosciences within the Catalysis Science programme (DE-AC05-RL01830, FWP-47319). K.K., M.H.E., X.S.L, J.T., and I.S. acknowledge the financial support by the U.S. Department of Energy, Energy Efficiency and Renewable Energy, Vehicle Technology Office. PNNL is a multi-programme national laboratory operated for the DOE by Battelle Memorial Institute under contract DE-AC06-76RL01830. The 14.1-T NMR spectrometer was acquired with support from the BES Chemical Sciences, Geosciences, & Biosciences (CSGB) Division. D.P.D., C.J.B. and J.T.M. were supported in part by the National Science Foundation under Cooperative Agreement No. EEC-1647722. Use of the Advanced Photon Source was supported by the U.S. Department of Energy Office of Basic Energy Sciences under contract no. DE-AC02-06CH11357. MRCAT operations, beamlines 10-BM and 10-ID, are supported by the Department of Energy and the MRCAT member institutions. H.A.A. and I.Z.K. are grateful to the European Union’s NextGenerationEU, through the National Recovery and Resilience Plan of the Republic of Bulgaria, project no. BG-RRP-2.004-0008, for the financial support. Computational resources at the Nestum computational facility of Sofia Tech Park (Bulgaria) have been used. The authors thank COST Action CA18234 for stimulating this study.

Author information

Authors and Affiliations

Contributions

K.K. designed the research and carried out most of the catalytic tests, syntheses, infrared characterization measurements, data analysis and drafted the manuscript; K.K., H.A.A., J.S., A.D. and Y.W. supervised the project; K.K., H.A.A., J.S., A.D. and Y.W. revised the manuscript; Y.S., P.T. and X.W. supplied the commercial supports; L.K., H.P. and A.D. performed microscopy measurements; M.H.E. performed XPS; T.R.G. performed NMR spectroscopy; I.Z.K., G.N.V. and H.A.A. performed the DFT calculations; M.B. performed XRD measurements and Rietveld refinement; D.P.D., C.J.B. and J.T.M. performed XAS and analysed the XAS data; K.K., Y.W., D.J., J.S. and A.D. discussed the H2 treatment experiments; I.S., J.T. and W.H. contributed to synthesis efforts; X.S.L. performed BET surface-area measurements; all of the authors contributed to the discussion of the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Frédéric Meunier, Martin Votsmeier and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

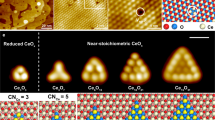

Extended Data Fig. 1 HAADF-STEM microscopy.

a–f, HAADF-STEM images of 0.1 wt% Rh/CeAl08 sample (imaged after last reactive treatment 8 as specified in Fig. 4a). The images corroborate the formation of approximately one-monolayer-thin CexOy patches on the surface of alumina. Scale bars, 5 nm.

Extended Data Fig. 2 HAADF-STEM microscopy.

a–d, High-magnification HAADF-STEM image of ceria–zirconia/alumina sample after 1,000 °C reactive treatment 4 in Supplementary Fig. 6. The alumina surfaces are covered with a dense layer of ultrasmall ceria–zirconia clusters (they are ceria–zirconia clusters as evidenced by EDS maps) after reactive treatment.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khivantsev, K., Pham, H., Engelhard, M.H. et al. Transforming ceria into 2D clusters enhances catalytic activity. Nature 640, 947–953 (2025). https://doi.org/10.1038/s41586-025-08684-x

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41586-025-08684-x