Abstract

Enabling vertical-stack proximal cooperation between multirotor flying robots can facilitate the execution of complex aerial manipulation tasks. However, vertical-stack proximal flight is commonly regarded as a dangerous condition that should be avoided because of persistent and intense downwash interference generated between flying robots1,2. Here we propose a cooperative aerial manipulation system, called FlyingToolbox, that can work stably with sub-centimetre-level docking accuracy under vertical-stack flight conditions. The system consists of a toolbox micro-aerial vehicle (MAV) and a manipulator MAV. The robotic arm of the manipulator MAV can autonomously dock with a tool carried by the toolbox MAV, in which the docking accuracy reaches 0.80 ± 0.33 cm in the presence of downwash airflow of up to 13.18 m s−1. By enabling midair tool exchange in proximity, FlyingToolbox resolves the paradox between flight proximity and manipulation accuracy, suggesting a new model for heterogeneous and interactive flying robot cooperation in diverse applications3,4,5.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are presented in the paper or the extended data. Other source data related to the study are available from the corresponding author upon reasonable request. Source data are provided with this paper.

Code availability

The mechanical design and the code for disturbance estimation, visual sensing, trajectory generation and task planning are available at GitHub (https://github.com/WindyLab/FlyingToolbox).

References

Shi, G., Hönig, W., Shi, X., Yue, Y. & Chung, S. J. Neural-Swarm2: planning and control of heterogeneous multirotor swarms using learned interactions. IEEE Trans. Robot. 38, 1063–1079 (2021).

Zhang, R., Zhang, D. & Mueller, M. W. Proxfly: robust control for close proximity quadcopter flight via residual reinforcement learning. In Proc. 2025 IEEE International Conference on Robotics and Automation (ICRA), 13683–13689 (IEEE, 2025).

Ollero, A., Tognon, M., Suarez, A., Lee, D. & Franchi, A. Past, present, and future of aerial robotic manipulators. IEEE Trans. Robot. 38, 626–645 (2021).

Kim, S., Seo, H., Shin, J. & Kim, H. J. Cooperative aerial manipulation using multirotors with multi-DOF robotic arms. IEEE/ASME Trans. Mechatron. 23, 702–713 (2018).

Rossi, E. et al. Cooperative aerial load transportation via sampled communication. IEEE Control Syst. Lett. 4, 277–282 (2019).

Spieler, P. et al. Parsec: an aerial platform for autonomous deployment of self-anchoring payloads on natural vertical surfaces. In Proc. 2023 IEEE International Conference on Robotics and Automation (ICRA), 5331–5337 (IEEE, 2023).

Lee, J. et al. Introspective perception for long-term aerial telemanipulation with virtual reality. IEEE Trans Field Robot. 1, 360–393 (2024).

Yiğit, A., Cuvillon, L., Perozo, M. A., Durand, S. & Gangloff, J. Dynamic control of a macro–mini aerial manipulator with elastic suspension. IEEE Trans. Robot. 39, 4820–4836 (2023).

Guo, X. et al. Powerful UAV manipulation via bioinspired self-adaptive soft self-contained gripper. Sci. Adv. 10, eadn6642 (2024).

Luo, W., Chen, J., Ebel, H. & Eberhard, P. Time-optimal handover trajectory planning for aerial manipulators based on discrete mechanics and complementarity constraints. IEEE Trans. Robot. 39, 4332–4349 (2023).

Garimella, G. & Kobilarov, M. Towards model-predictive control for aerial pick-and-place. In Proc. 2015 IEEE International Conference on Robotics and Automation (ICRA), 4692–4697 (2015).

Ryll, M. et al. 6D interaction control with aerial robots: the flying end-effector paradigm. Int. J. Robot. Res. 38, 1045–1062 (2019).

Bodie, K. et al. Active interaction force control for contact-based inspection with a fully actuated aerial vehicle. IEEE Trans. Robot. 37, 709–722 (2020).

Alexis, K., Darivianakis, G., Burri, M. & Siegwart, R. Aerial robotic contact-based inspection: planning and control. Auton. Robot. 40, 631–655 (2016).

Chermprayong, P., Zhang, K., Xiao, F. & Kovac, M. An integrated delta manipulator for aerial repair: a new aerial robotic system. IEEE Robot. Autom. Mag. 26, 54–66 (2019).

Zhang, K. et al. Aerial additive manufacturing with multiple autonomous robots. Nature 609, 709–717 (2022).

Hunt, G., Mitzalis, F., Alhinai, T., Hooper, P. A. & Kovac, M. 3D printing with flying robots. In Proc. 2014 IEEE International Conference on Robotics and Automation (ICRA), 4493–4499 (IEEE, 2014).

Wang, M. et al. Millimeter-level pick and peg-in-hole task achieved by aerial manipulator. IEEE Trans. Robot. 40, 1242–1260 (2024).

Orsag, M., Korpela, C., Bogdan, S. & Oh, P. Dexterous aerial robots–mobile manipulation using unmanned aerial systems. IEEE Trans. Robot. 33, 1453–1466 (2017).

Lee, D., Seo, H., Kim, D. & Kim, H. J. Aerial manipulation using model predictive control for opening a hinged door. In Proc. 2020 IEEE International Conference on Robotics and Automation (ICRA), 1237–1242 (IEEE, 2020).

Estrada, M. A., Mintchev, S., Christensen, D. L., Cutkosky, M. R. & Floreano, D. Forceful manipulation with micro air vehicles. Sci. Robot. 3, eaau6903 (2018).

Nguyen, H. & Alexis, K. Forceful aerial manipulation based on an aerial robotic chain: hybrid modeling and control. IEEE Robot. Autom. Lett. 6, 3711–3719 (2021).

Vásárhelyi, G. et al. Optimized flocking of autonomous drones in confined environments. Sci. Robot. 3, eaat3536 (2018).

Zhou, X. et al. Swarm of micro flying robots in the wild. Sci. Robot. 7, eabm5954 (2022).

Uzun, S., Üre, N. K. & Açıkmeıe, B. Decentralized state-dependent Markov chain synthesis with an application to swarm guidance. IEEE Trans. Autom. Control 69, 5759–5774 (2024).

Bandyopadhyay, S., Chung, S. J. & Hadaegh, F. Y. Probabilistic and distributed control of a large-scale swarm of autonomous agents. IEEE Trans. Robot. 33, 1103–1123 (2017).

Shi, G., et al. Neural lander: stable drone landing control using learned dynamics. In Proc. 2019 IEEE International Conference on Robotics and Automation (ICRA), 9784–9790 (IEEE, 2019).

Polvara, R. et al. Toward end-to-end control for UAV autonomous landing via deep reinforcement learning. In Proc. 2018 International Conference on Unmanned Aircraft Systems (ICUAS), 115–123 (IEEE, 2018).

Saripalli, S., Montgomery, J. F. & Sukhatme, G. S. Visually guided landing of an unmanned aerial vehicle. IEEE Trans. Robot. Autom. 19, 371–380 (2003).

Gonçalves, V. M., McLaughlin, R. & Pereira, G. A. Precise landing of autonomous aerial vehicles using vector fields. IEEE Robot. Autom. Lett. 5, 4337–4344 (2020).

Shankar, A., Woo, H. & Prorok, A. Docking multirotors in close proximity using learnt downwash models. In Proc. International Symposium on Experimental Robotics, 427–437 (Springer, 2023).

Gielis, J., Shankar, A., Kortvelesy, R. & Prorok, A. Modeling aggregate downwash forces for dense multirotor flight. In Proc. International Symposium on Experimental Robotics, 393–404 (Springer, 2023).

Smith, H., Shankar, A., Gielis, J., Blumenkamp, J. & Prorok, A. SO(2)-equivariant downwash models for close proximity flight. IEEE Robot. Autom. Lett. 9, 1174–1181 (2023).

Wu, Z. et al. \({\mathcal{L}}1\) quad: \({\mathcal{L}}1\) adaptive augmentation of geometric control for agile quadrotors with performance guarantees. IEEE Trans. Control Syst. Technol. 33, 597–612 (2025).

Ebel, H., Luo, W., Yu, F., Tang, Q. & Eberhard, P. Design and experimental validation of a distributed cooperative transportation scheme. IEEE Trans. Autom. Sci. Eng. 18, 1157–1169 (2021).

Loianno, G. & Kumar, V. Cooperative transportation using small quadrotors using monocular vision and inertial sensing. IEEE Robot. Autom. Lett. 3, 680–687 (2018).

Lee, H., Kim, H. & Kim, H. J. Planning and control for collision-free cooperative aerial transportation. IEEE Trans. Autom. Sci. Eng. 15, 189–201 (2018).

Sanalitro, D., Savino, H. J., Tognon, M., Cortés, J. & Franchi, A. Full-pose manipulation control of a cable-suspended load with multiple UAVs under uncertainties. IEEE Robot. Autom. Lett. 5, 2185–2191 (2020).

Li, G., Ge, R. & Loianno, G. Cooperative transportation of cable suspended payloads with MAVs using monocular vision and inertial sensing. IEEE Robot. Autom. Lett. 6, 5316–5323 (2021).

Palunko, I., Cruz, P. & Fierro, R. Agile load transportation: safe and efficient load manipulation with aerial robots. IEEE Robot. Autom. Mag. 19, 69–79 (2012).

Gawel, A. et al. Aerial picking and delivery of magnetic objects with MAVs. In Proc. 2017 IEEE International Conference on Robotics and Automation (ICRA), 5746–5752 (IEEE, 2017).

Saunders, J., Saeedi, S. & Li, W. Autonomous aerial robotics for package delivery: a technical review. J. Field Robot. 41, 3–49 (2024).

Kornatowski, P. M., Feroskhan, M., Stewart, W. J. & Floreano, D. Downside up: rethinking parcel position for aerial delivery. IEEE Robot. Autom. Lett. 5, 4297–4304 (2020).

Lindsey, Q., Mellinger, D. & Kumar, V. Construction with quadrotor teams. Auton. Robot. 33, 323–336 (2012).

Augugliaro, F. et al. The flight assembled architecture installation: cooperative construction with flying machines. IEEE Control Syst. Mag. 34, 46–64 (2014).

Jimenez-Cano, A. E., Martin, J., Heredia, G., Ollero, A. & Cano, R. Control of an aerial robot with multi-link arm for assembly tasks. In Proc. 2013 IEEE International Conference on Robotics and Automation (ICRA), 4916–4921 (IEEE, 2013).

Zhang, X., Zhang, Y., Liu, P. & Zhao, S. Robust localization of occluded targets in aerial manipulation via range-only mapping. IEEE Robotics and Automation Letters 7, 2921–2928 (2022).

Scaramuzza, D. et al. Vision-controlled micro flying robots: from system design to autonomous navigation and mapping in GPS-denied environments. IEEE Robot. Autom. Mag. 21, 26–40 (2014).

Lee, J. et al. Visual-inertial telepresence for aerial manipulation. In Proc. 2020 IEEE International Conference on Robotics and Automation (ICRA), 1222–1229 (IEEE, 2020).

Jain, K. P., Fortmuller, T., Byun, J., Mäkiharju, S. A. & Mueller, M. W. Modeling of aerodynamic disturbances for proximity flight of multirotors. In Proc. 2019 International Conference on Unmanned Aircraft Systems (ICUAS), 1261–1269 (IEEE, 2019).

Khan, W., Nahon, M. & Caverly, R. Propeller slipstream model for small unmanned aerial vehicles. In Proc. AIAA Modeling and Simulation Technologies Conference (MST), 4907 (AIAA, 2013).

Davoudi, B., Taheri, E., Duraisamy, K., Jayaraman, B. & Kolmanovsky, I. Quad-rotor flight simulation in realistic atmospheric conditions. AIAA J. 58, 1992–2004 (2020).

He, X. & Leang, K. K. Quasi-steady in-ground-effect model for single and multirotor aerial vehicles. AIAA J. 58, 5318–5331 (2020).

Mahony, R., Kumar, V. & Corke, P. Multirotor aerial vehicles: modeling, estimation, and control of quadrotor. IEEE Robot. Autom. Mag. 19, 20–32 (2012).

McKinnon, C. D. & Schoellig, A. P. Unscented external force and torque estimation for quadrotors. In Proc. 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 5651–5657 (IEEE, 2016).

Cao, H., Li, Y., Liu, C. & Zhao, S. ESO-based robust and high-precision tracking control for aerial manipulation. IEEE Trans. Autom. Sci. Eng. 21, 2139–2155 (2023).

Bauersfeld, L., Muller, K., Ziegler, D., Coletti, F. & Scaramuzza, D. Robotics meets fluid dynamics: a characterization of the induced airflow below a quadrotor as a turbulent jet. IEEE Robot. Autom. Lett. 10, 1241–1248 (2025).

Waslander, S. & Wang, C. Wind disturbance estimation and rejection for quadrotor position control. In Proc. AIAA Infotech@Aerospace Conference, 1983–1995 (AIAA, 2009).

Cao, H., Shen, J., Liu, C., Zhu, B. & Zhao, S. Motion planning for aerial pick-and-place with geometric feasibility constraints. IEEE Trans. Autom. Sci. Eng. 22, 2577–2594 (2024).

Yu, J. & LaValle, S. M. Optimal multirobot path planning on graphs: complete algorithms and effective heuristics. IEEE Trans. Robot. 32, 1163–1177 (2016).

Acknowledgements

This work was supported by the STI 2030-Major Projects (grant no. 2022ZD0208804) and the Research Center for Industries of the Future at Westlake University (grant no. WU2022C027). We thank Y. Li, S. Guo, C. Zheng, Z. Ma and H. Chen for assistance with software and circuit development, and K. Li for assistance with the onboard vision system development. We also thank B. Zhu, R. Wang, H. Jiang, Y. Sun, and C. Ma for supporting this study.

Author information

Authors and Affiliations

Contributions

S.Z., H.C., C.L. and S.S. designed the research; H.C., J.S., Y.Z. and Z.F. performed the research; H.C., S.Z., C.L. and S.S. analysed the data; and S.Z., H.C., C.L. and S.S. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Vladlen Koltun, Seungjae Lee and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

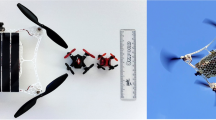

Extended Data Fig. 1 Hardware components of FlyingToolbox.

a. The motor-to-motor distances of the manipulator MAV and the toolbox MAV are 65 cm and 102 cm, respectively. The toolbox MAV is designed to be larger than the manipulator MAV to ensure sufficient payload capacity to support the toolbox and counteract disturbances caused by the manipulator MAV. The weight of the manipulator MAV including all payloads such as the robotic arm and batteries is 5.08 kg. The weight of the toolbox MAV including all payloads but tools is 6.32 kg. The six tools weigh between 0.20 kg and 0.34 kg. The dimensions of the Delta arm are shown in the figure. The reason to choose a Delta arm is that since the heavier components of the Delta arm, such as joint servos, are fixed to the MAV’s body, the moving parts are lighter in mass, resulting in smaller disturbances and faster end-effector response speed. The Delta arm’s end-effector can achieve a maximum linear velocity of 1.2 m/s, with a workspace of around 16 × 16 × 20 cm. When the base is fixed, its end-effector control accuracy reaches 0.2 cm. The manipulator MAV is equipped with a NUC12WSHi5 onboard computer with a hybrid Core i5 processor, while the toolbox MAV is equipped with an NVIDIA Jetson Xavier NX onboard computer incorporating a 6-core NVIDIA Carmel ARMv8.2 64-bit CPU cluster. b. At the bottom of the manipulator MAV’s robotic arm is a conical recess containing an iron plate. The dimensions in the figure are in millimeters, and the same applies to the following two figures. c. Each tool features a conical protrusion with an electromagnet on top. The electromagnet can be activated or deactivated wirelessly. d. The top surface of the toolbox has four circular holes, each with a radius of 60 mm.

Extended Data Fig. 2 Onboard vision system of FlyingToolbox.

a. The design of the onboard vision system involves six steps: three offline steps (QR code array design, camera calibration, and hand-eye calibration) and three online steps (QR code detection, 6D pose estimation, and filtering at 50 Hz). b. Offline hand-eye calibration was performed using a motion capture system to determine the transformation between the camera frame and the manipulator MAV base frame. The two manipulator MAVs are equipped with an Intel RealSense L515 camera and a D435i camera, respectively, both operating at 640 × 480 pixel resolution. c. The onboard camera can detect a subset of the QR codes during aerial docking. d. The vision system achieves an average positioning error of 0.48 cm with a standard deviation of 0.12 cm when the vertical distance between the manipulator MAV and the toolbox MAV is 0.6 m.

Extended Data Fig. 3 Performance evaluation of the controller of the toolbox MAV.

a. Experimental setup. The toolbox MAV remains stationary while the manipulator MAV gradually approaches from above until the bottom of the robotic arm is 6 cm above the toolbox. This creates three phases of influence on the toolbox MAV: approach, above, and leave. Here, “above” refers to the phase when at least one of the manipulator MAV’s rotors enters the vertical projection area determined by the rotors of the toolbox MAV. b. Ablation study of force compensation. The proposed controller is compared to two baseline controllers, a PX4 open-source flight controller (baseline 1) and the proposed controller without force compensation (baseline 2). As can be seen, the proposed controller outperforms the baselines in terms of both control accuracy and settling time. The settling time is defined as the time at which the toolbox MAV’s height first enters the ± 1 cm error band. The statistical results were based on 5, 8, and 13 trials of experiments using baseline 1, baseline 2, and the proposed controller, respectively. c. Ablation study of torque compensation. As can be seen, torque compensation can improve control accuracy especially when the downwash of the manipulator MAV starts or ends impacting the toolbox MAV. For instance, the maximum error in the y-direction can be reduced from 11.9 cm to 4.8 cm with torque compensation.

Extended Data Fig. 4 A more complex multi-task demonstration that involves three MAVs.

Two manipulator MAVs (denoted as M1 and M2) collaborate with a toolbox MAV to perform multiple manipulation tasks fully autonomously. a. The complete procedure. An iron plate and a ball were initially placed on top of the right and left pillars, respectively. The goal is to move the iron plate and the ball to the top of the middle pillar so that the ball is placed right on the iron plate. M1 first docked with an electromagnet tool, picked up the iron plate from the right pillar, and placed it on the middle pillar. M2 first docked with a soft gripper tool, picked up the ball from the left pillar, and eventually stacked the ball on the iron plate that had been placed on the middle pillar. b. Snapshots of object manipulation during the task. c. Snapshots of the FlyingToobox system during the task.

Extended Data Fig. 5 Aerial docking in motion.

a. The manipulator MAV docked with the toolbox MAV, which moves at a speed of 0.16 m/s. The manipulator MAV successfully retrieved a gripper tool from the toolbox. b. The reference (gray dotted curve) and the actual value (blue curve) of the position of the bottom of the robotic arm of the manipulator MAV before docking. c. The reference (gray dotted curve) and the actual value (green curve) of the position of the toolbox MAV before docking. The transition of the toolbox MAV from a hovering state to a moving state transforms the control problem from setpoint control to tracking control. The proposed control method demonstrates the capability to handle time-varying references. To obtain the time-varying position and velocity of the toolbox MAV, this experiment relies on a high-accuracy indoor positioning system rather than the onboard vision system. All other elements, such as disturbance estimation, remain consistent with the hovering case.

Extended Data Fig. 6 Comparison of three disturbance estimation methods: unscented Kalman filter (UKF)55, extended state observer (ESO)56, and our proposed method.

a. Experimental setup. The manipulator MAV moves along a straight line from one side of the toolbox MAV to the other side, creating three phases of influence on the toolbox MAV: before, above, and after. Here, “above” refers to the phase when at least one of the manipulator MAV’s rotors enters the vertical projection area determined by the rotors of the toolbox MAV. Three methods were respectively used to estimate the vertical disturbance force, while the other system components remained the same. b. Maximum height error. For each estimation method, 18 experimental trials were conducted. Across the 18 trials, the proposed method’s average maximum error was 2.1 cm, representing at least 61.1% reduction compared to 5.4 cm and 5.9 cm of the UKF and ESO methods. c,d, and e show the height variations of the toolbox MAV for the three estimation methods. Each gray curve represents a single trial. Each thick curve indicates the average over 18 trials, while the shaded area depicts the standard deviation. As can be seen, the height fluctuation by the proposed learning-based method was considerably smaller than that of the reactive methods. Notably, when the disturbance appeared, the learning-based method resulted in a slight height increase rather than a decrease in the reactive case, demonstrating its predictive characteristics.

Extended Data Fig. 7 Motion planning of the FlyingToolbox system.

a. Path planning for each MAV is performed by a specially designed user interface. b. Motion trajectories for both the manipulator MAV and toolbox MAV are generated using a Bezier curve-based method, which incorporates flight corridor and trajectory generation. Safe flight corridors are established by considering only static obstacles, ensuring that MAVs do not enter the same area simultaneously to avoid collisions. c & d. The toolbox MAV and manipulator MAV follow state machines that define the actions to be performed after completing their respective trajectories. These actions enable the MAVs to execute the corresponding manipulation tasks.

Supplementary information

Supplementary Video 1

Multi-task cooperative aerial manipulation: 1 manipulator MAV + 1 toolbox MAV. This video shows the complete procedure of a cooperative manipulation task, in which one manipulator MAV conducts multi-stage manipulation tasks with the support of a toolbox MAV fully autonomously. In this task, the manipulator MAV first mounted a scissors tool and cut a string using the scissors. Subsequently, it released the scissors tool and switched to a gripper tool, which was then used to pick up and place an object from one location to another.

Supplementary Video 2

More complex cooperative aerial manipulation: 2 manipulator MAVs + 1 toolbox MAV. This video shows two manipulator MAVs (denoted as M1 and M2) collaborating with one toolbox MAV to perform multi-stage manipulation tasks fully autonomously. M1 first docked with an electromagnet tool, picked up the iron plate from the right pillar and placed it on the middle pillar. M2 first docked with a soft gripper tool, picked up the ball from the left pillar and eventually stacked the ball on the iron plate that had been placed on the middle pillar. As the experimental space was confined, the three flying MAVs generated highly dynamic airflow in the field, as evidenced by the movement of the window curtains and red ribbons in the videos.

Supplementary Video 3

Consecutive aerial docking 20 times. This video shows 20 consecutive docking operations, which comprised 10 pick-ups and 10 returns. A toolbox MAV flies to a designated location and maintains a hovering state. A manipulator MAV continuously performs continuous aerial docking with the toolbox MAV to retrieve and return tools, repeating the process 20 times. The average error of the 20 docking trials is 0.80 cm, with a standard deviation of 0.33 cm.

Supplementary Video 4

Aerial docking in motion. This video shows a more complex aerial-docking-in-motion task, in which a toolbox MAV was in motion and a manipulator MAV successfully performed aerial docking to retrieve a tool. In the task, the toolbox MAV flies at a constant speed of 0.16 m s−1. The manipulator MAV tracks the toolbox MAV and performs aerial docking to retrieve a gripper tool. This demonstration showcases the potential of the proposed system in more demanding scenarios, expanding the boundaries of its abilities.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, H., Shen, J., Zhang, Y. et al. Proximal cooperative aerial manipulation with vertically stacked drones. Nature 646, 576–583 (2025). https://doi.org/10.1038/s41586-025-09575-x

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41586-025-09575-x