Abstract

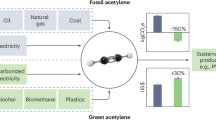

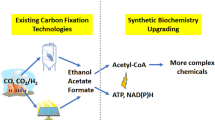

Many industrial chemicals that are produced from fossil resources could be manufactured more sustainably through fermentation. Here we describe the development of a carbon-negative fermentation route to producing the industrially important chemicals acetone and isopropanol from abundant, low-cost waste gas feedstocks, such as industrial emissions and syngas. Using a combinatorial pathway library approach, we first mined a historical industrial strain collection for superior enzymes that we used to engineer the autotrophic acetogen Clostridium autoethanogenum. Next, we used omics analysis, kinetic modeling and cell-free prototyping to optimize flux. Finally, we scaled-up our optimized strains for continuous production at rates of up to ~3 g/L/h and ~90% selectivity. Life cycle analysis confirmed a negative carbon footprint for the products. Unlike traditional production processes, which result in release of greenhouse gases, our process fixes carbon. These results show that engineered acetogens enable sustainable, high-efficiency, high-selectivity chemicals production. We expect that our approach can be readily adapted to a wide range of commodity chemicals.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data presented in this manuscript are available as supplementary data files. Supplementary Tables 1-10 are available on Zenodo: https://doi.org/10.5281/zenodo.5838304. All proteomics raw data are available at the ProteomeXchange Consortium via the MassIVE repository (ftp://massive.ucsd.edu/MSV000085940/) (MassIVE accession: MSV000085940; ProteomeXchange accession: PXD020853). All genome sequences are available through the Joint Genome Institute Integrated Microbial Genomes & Microbiomes system platform or the National Center of Biotechnology Information GenBank under accession numbers provided in Supplementary Table 7. Any additional data may be available from the authors upon reasonable request. Materials are available upon reasonable request and under a material transfer agreement, but strains may require a license.

References

Aguado-Deblas, L. et al. Acetone prospect as an additive to allow the use of castor and sunflower oils as drop-in biofuels in diesel/acetone/vegetable oil triple blends for application in diesel engines. Molecules 25, 2935 (2020).

Elfasakhany, A. Performance and emissions analysis on using acetone–gasoline fuel blends in spark-ignition engine. Eng. Sci. Technol. Int. J. 19, 1224–1232 (2016).

Anbarasan, P. et al. Integration of chemical catalysis with extractive fermentation to produce fuels. Nature 491, 235–239 (2012).

Ryan, C. F. et al. Synthesis of aviation fuel from bio-derived isophorone. Sustain. Energy Fuels 4, 1088–1092 (2020).

Kratzel, A. et al. Inactivation of severe acute respiratory syndrome coronavirus 2 by WHO-recommended hand rub formulations and alcohols. Emerg. Infect. Dis. 26, 1592–1595 (2020).

Wernet, G. et al. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230 (2016).

Jones, D. T. & Woods, D. R. Acetone–butanol fermentation revisited. Microbiol. Rev. 50, 484–524 (1986).

Ismaiel, A. A., Zhu, C. X., Colby, G. D. & Chen, J. S. Purification and characterization of a primary–secondary alcohol dehydrogenase from two strains of Clostridium beijerinckii. J. Bacteriol. 175, 5097–5105 (1993).

Hanai, T., Atsumi, S. & Liao, J. C. Engineered synthetic pathway for isopropanol production in Escherichia coli. Appl. Environ. Microbiol. 73, 7814–7818 (2007).

May, A. et al. A modified pathway for the production of acetone in Escherichia coli. Metab. Eng. 15, 218–225 (2013).

Liang, L. et al. CRISPR EnAbled Trackable genome Engineering for isopropanol production in Escherichia coli. Metab. Eng. 41, 1–10 (2017).

Soma, Y., Yamaji, T., Matsuda, F. & Hanai, T. Synthetic metabolic bypass for a metabolic toggle switch enhances acetyl-CoA supply for isopropanol production by Escherichia coli. J. Biosci. Bioeng. 123, 625–633 (2017).

Jojima, T., Inui, M. & Yukawa, H. Production of isopropanol by metabolically engineered Escherichia coli. Appl. Microbiol. Biotechnol. 77, 1219–1224 (2008).

Jones, S. W. et al. CO2 fixation by anaerobic non-photosynthetic mixotrophy for improved carbon conversion. Nat. Commun. 7, 12800 (2016).

Simpson, S. D. & Köpke, M. Pollution to products: recycling of ‘above ground’ carbon by gas fermentation. Curr. Opin. Biotechnol. 65, 180–189 (2020).

Marcellin, E. et al. Low carbon fuels and commodity chemicals from waste gases—systematic approach to understand energy metabolism in a model acetogen. Green Chem. 18, 3020 (2016).

Kato, J. et al. Metabolic engineering of Moorella thermoacetica for thermophilic bioconversion of gaseous substrates to a volatile chemical. AMB Express 11, 59 (2021).

Hoffmeister, S. et al. Acetone production with metabolically engineered strains of Acetobacterium woodii. Metab. Eng. 36, 37–47 (2016).

Banerjee, A., Leang, C., Ueki, T., Nevin, K. P. & Lovley, D. R. A lactose-inducible system for metabolic engineering of Clostridium ljungdahlii. Appl. Environ. Microbiol. 80, 2410–2416 (2014).

Garrigues, L., Maignien, L., Lombard, E., Singh, J. & Guillouet, S. E. Isopropanol production from carbon dioxide in Cupriavidus necator in a pressurized bioreactor. N. Biotechnol. 56, 16–20 (2020).

Lee, H. J., Son, J., Sim, S. J. & Woo, H. M. Metabolic rewiring of synthetic pyruvate dehydrogenase bypasses for acetone production in cyanobacteria. Plant Biotechnol. J. 18, 1860–1868 (2020).

Torella, J. P. et al. Efficient solar-to-fuels production from a hybrid microbial-water-splitting catalyst system. Proc. Natl Acad. Sci. USA 112, 2337–2342 (2015).

Hirokawa, Y., Dempo, Y., Fukusaki, E. & Hanai, T. Metabolic engineering for isopropanol production by an engineered cyanobacterium, Synechococcus elongatus PCC 7942, under photosynthetic conditions. J. Biosci. Bioeng. 123, 39–45 (2016).

Zhou, J., Zhang, H., Zhang, Y., Li, Y. & Ma, Y. Designing and creating a modularized synthetic pathway in cyanobacterium Synechocystis enables production of acetone from carbon dioxide. Metab. Eng. 14, 394–400 (2012).

Claassens, N. J., Cotton, C. A. R., Kopljar, D. & Bar-Even, A. Making quantitative sense of electromicrobial production. Nat. Catal. 2, 437–447 (2019).

Fast, A. G. & Papoutsakis, E. T. Stoichiometric and energetic analyses of non-photosynthetic CO2-fixation pathways to support synthetic biology strategies for production of fuels and chemicals. Curr. Opin. Chem. Eng. 1, 380–395 (2012).

Bar-Even, A., Noor, E. & Milo, R. A survey of carbon fixation pathways through a quantitative lens. J. Exp. Bot. 63, 2325–2342 (2012).

Köpke, M. et al. Clostridium ljungdahlii represents a microbial production platform based on syngas. Proc. Natl Acad. Sci. USA 107, 13087–13092 (2010).

Fackler, N. et al. Stepping on the gas to a circular economy: accelerating development of carbon-negative chemical production from gas fermentation. Ann. Rev. Chem. Biomol. Eng. 12, 439–470 (2021).

Jin, S. et al. Synthetic biology on acetogenic bacteria for highly efficient conversion of C1 gases to biochemicals. Int. J. Mol. Sci. 21, 7639 (2020).

Takors, R. et al. Using gas mixtures of CO, CO2 and H2 as microbial substrates: the do’s and don’ts of successful technology transfer from laboratory to production scale. Microb. Biotechnol. 11, 606–625 (2018).

Jones, D. T. Applied acetone–butonal fermentation. In: Clostridia: Biotechnology and Medical Applications (eds Dürre, P. & Bahl, H.) 125–168 (Wiley, 2001).

Jones, D. T. & Keis, S. Origins and relationships of industrial solvent-producing clostridial strains. FEMS Microbiol. Rev. 17, 223–232 (1995).

Karim, A. S. et al. In vitro prototyping and rapid optimization of biosynthetic enzymes for cellular design. Nat. Chem. Biol. 16, 912–919 (2020).

Krüger, A. et al. Development of a clostridia-based cell-free system for prototyping genetic parts and metabolic pathways. Metab. Eng. 62, 95–105 (2020).

Heap, J. T., Pennington, O. J., Cartman, S. T. & Minton, N. P. A modular system for Clostridium shuttle plasmids. J. Microbiol. Methods 78, 79–85 (2009).

Maddock, D. J., Patrick, W. M. & Gerth, M. L. Substitutions at the cofactor phosphate-binding site of a clostridial alcohol dehydrogenase lead to unexpected changes in substrate specificity. Protein Eng. Des. Sel. 28, 251–258 (2015).

Köpke, M. et al. Reconstruction of an acetogenic 2,3-butanediol pathway involving a novel NADPH-dependent primary–secondary alcohol dehydrogenase. Appl. Environ. Microbiol. 80, 3394–3403 (2014).

Valgepea, K. et al. H2 drives metabolic rearrangements in gas-fermenting Clostridium autoethanogenum. Biotechnol. Biofuels 11, 55 (2018).

de Souza Pinto Lemgruber, R. et al. Systems-level engineering and characterisation of Clostridium autoethanogenum through heterologous production of poly-3-hydroxybutyrate (PHB). Metab. Eng. 53, 14–23 (2019).

Maia, P., Rocha, I. & Rocha, M. Identification of robust strain designs via tandem pFBA/LMOMA phenotype prediction. In: GECCO 2017: Proceedings of the Genetic and Evolutionary Computation Conference Companion 1661–1668 (Association for Computing Machinery, 2017).

Zitzler, E., Laumanns, M. & Thiele, L. SPEA2: improving the Strength Pareto Evolutionary Algorithm. In: Proceedings of the Fifth Conference on Evolutionary Methods for Design 95–100 (Association for Computing Machinery, 2001).

Takanashi, M. & Saito, T. Characterization of two 3-hydroxybutyrate dehydrogenases in poly(3-hydroxybutyrate)-degradable bacterium, Ralstonia pickettii T1. J. Biosci. Bioeng. 101, 501–507 (2006).

Segawa, M., Wen, C., Orita, I., Nakamura, S. & Fukui, T. Two NADH-dependent (S)-3-hydroxyacyl-CoA dehydrogenases from polyhydroxyalkanoate-producing Ralstonia eutropha. J. Biosci. Bioeng. 127, 294–300 (2019).

Tan, Y., Liu, Z.-Y., Liu, Z. & Li, F.-L. Characterization of an acetoin reductase/2,3-butanediol dehydrogenase from Clostridium ljungdahlii DSM 13528. Enzyme Microb. Technol. 79–80, 1–7 (2015).

Kim, J., Chang, J. H., Kim, E. J. & Kim, K. J. Crystal structure of (R)-3-hydroxybutyryl-CoA dehydrogenase PhaB from Ralstonia eutropha. Biochem. Biophys. Res. Commun. 443, 783–788 (2014).

Boynton, Z. L., Bennet, G. N. & Rudolph, F. B. Cloning, sequencing, and expression of clustered genes encoding beta-hydroxybutyryl-coenzyme A (CoA) dehydrogenase, crotonase, and butyryl-CoA dehydrogenase from Clostridium acetobutylicum ATCC 824. J. Bacteriol. 178, 3015–3024 (1996).

Vick, J. E. et al. Escherichia coli enoyl-acyl carrier protein reductase (FabI) supports efficient operation of a functional reversal of the β-oxidation cycle. Appl. Environ. Microbiol. 81, 1406–1416 (2015).

Liew, F. et al. Metabolic engineering of Clostridium autoethanogenum for selective alcohol production. Metab. Eng. 40, 104–114 (2017).

Mahamkali, V. et al. Redox controls metabolic robustness in the gas-fermenting acetogen Clostridium autoethanogenum. Proc. Natl Acad. Sci. USA 117, 13168–13175 (2020).

Greene, J., Daniell, J., Köpke, M., Broadbelt, L. & Tyo, K. E. J. Kinetic ensemble model of gas fermenting Clostridium autoethanogenum for improved ethanol production. Biochem. Eng. J. 148, 46–56 (2019).

Wehrs, M. et al. Engineering robust production microbes for large-scale cultivation. Trends Microbiol. 27, 524–537 (2019).

Hoff, B. et al. Unlocking nature’s biosynthetic power—metabolic engineering for the fermentative production of chemicals. Angew. Chem. Int. Ed. Engl. 60, 2258–2278 (2021).

Nielsen, J. & Keasling, J. D. Engineering cellular metabolism. Cell 164, 1185–1197 (2016).

Crater, J. S. & Lievense, J. C. Scale-up of industrial microbial processes. FEMS Microbiol. Lett. 365, 138 (2018).

Bertsch, J. & Müller, V. Bioenergetic constraints for conversion of syngas to biofuels in acetogenic bacteria. Biotechnol. Bioeng. 8, 210 (2015).

Schuchmann, K. & Müller, V. Autotrophy at the thermodynamic limit of life: a model for energy conservation in acetogenic bacteria. Nat. Rev. Microbiol. 12, 809–821 (2014).

Erb, T. J. Back to the future: why we need enzymology to build a synthetic metabolism of the future. Beilstein J. Org. Chem. 15, 551–557 (2019).

Diether, M., Nikolaev, Y., Allain, F. H. & Sauer, U. Systematic mapping of protein-metabolite interactions in central metabolism of Escherichia coli. Mol. Syst. Biol. 15, e9008 (2019).

Kim, H. M., Chae, T. U., Choi, S. Y., Kim, W. J. & Lee, S. Y. Engineering of an oleaginous bacterium for the production of fatty acids and fuels. Nat. Chem. Biol. 15, 721–729 (2019).

Amin, S. A., Chavez, E., Porokhin, V., Nair, N. U. & Hassoun, S. Towards creating an extended metabolic model (EMM) for E. coli using enzyme promiscuity prediction and metabolomics data. Microb. Cell Fact. 18, 109 (2019).

Vögeli, B. et al. Archaeal acetoacetyl-CoA thiolase/HMG-CoA synthase complex channels the intermediate via a fused CoA-binding site. Proc. Natl Acad. Sci. USA 115, 3380–3385 (2018).

Chen, I. M. A. et al. The IMG/M data management and analysis system v.6.0: new tools and advanced capabilities. Nucleic Acids Res. 49, D751–D763 (2021).

Larkin, M. A. et al. Clustal W and Clustal X version 2.0. Bioinformatics 23, 2947–2948 (2007).

Nguyen, L., Schmidt, H. A., Von Haeseler, A. & Minh, B. Q. IQ-TREE: a fast and effective stochastic algorithm for estimating maximum-likelihood phylogenies. Mol. Biol. Evol. 32, 268–274 (2014).

Kalyaanamoorthy, S., Minh, B. Q., Wong, T. K. F., von Haeseler, A. & Jermiin, L. S. ModelFinder: fast model selection for accurate phylogenetic estimates. Nat. Methods 14, 587–589 (2017).

Letunic, I. & Bork, P. Interactive Tree Of Life (iTOL) v4: recent updates and new developments. Nucleic Acids Res. 47, 256–259 (2019).

Fero, M. J., Craft, J. K., Trang, V. & Hillson, N. J. Combinatorial-hierarchical DNA library design using the TeselaGen DESIGN Module with j5. Methods Mol. Biol. 2205, 19–47 (2020).

Liew, F. M. et al. Gas fermentation—a flexible platform for commercial scale production of low-carbon-fuels and chemicals from waste and renewable feedstocks. Front. Microbiol. 7, 694 (2016).

Valgepea, K. et al. Arginine deiminase pathway provides ATP and boosts growth of the gas-fermenting acetogen Clostridium autoethanogenum. Metab. Eng. 41, 202–211 (2017).

Ebrahim, A., Lerman, J. A., Palsson, B. O. & Hyduke, D. R. COBRApy: COnstraints-Based Reconstruction and Analysis for Python. BMC Syst. Biol. 7, 74 (2013).

Gonçalves, E., Pereira, R., Rocha, I. & Rocha, M. Optimization approaches for the in silico discovery of optimal targets for gene over/underexpression. J. Comput. Biol. 19, 102–114 (2012).

Kwon, Y. C. & Jewett, M. C. High-throughput preparation methods of crude extract for robust cell-free protein synthesis. Sci. Rep. 5, 8663 (2015).

Jewett, M. C. & Swartz, J. R. Mimicking the Escherichia coli cytoplasmic environment activates long-lived and efficient cell-free protein synthesis. Biotechnol. Bioeng. 86, 19–26 (2004).

Jewett, M. C., Calhoun, K. A., Voloshin, A., Wuu, J. J. & Swartz, J. R. An integrated cell-free metabolic platform for protein production and synthetic biology. Mol. Syst. Biol. 4, 220 (2008).

Karim, A. S., Rasor, B. J. & Jewett, M. C. Enhancing control of cell-free metabolism through pH modulation. Synth. Biol. 5, ysz027 (2020).

Batth, T. S. et al. Protein aggregation capture on microparticles enables multipurpose proteomics sample preparation. Mol. Cell. Proteomics 18, 1027–1035 (2019).

Walker, C., Ryu, S., Giannone, R. J., Garcia, S. & Trinh, C. T. Understanding and eliminating the detrimental effect of thiamine deficiency on the oleaginous yeast Yarrowia lipolytica. Appl. Environ. Microbiol 86, e02299–19 (2020).

Taverner, T. et al. DanteR: an extensible R-based tool for quantitative analysis of -omics data. Bioinformatics 28, 2404–2406 (2012).

Tyanova, S. et al. The Perseus computational platform for comprehensive analysis of (prote)omics data. Nat. Methods 13, 731–740 (2016).

Acknowledgements

We would like to thank members of LanzaTech’s Synthetic Biology, Strain Development, Process Integration, Analytics, Engineering Design & Development, AI & Modeling, Computational Biology and Freedom Pines teams for their support and conversations about this work, in particular A. Juminaga, A. Quattlebaum, A. Shah, J. Winkler, J. Cogan, L. Fantroy, M. Maas, M. Martin, N. Gayner, N. Fackler, R. C. Tappel, S. Nagaraju, S. Chong, V. Reynoso, W. P. Mitchell and W. Allen, and R. Kalvakaalva for his work on the Addendum, which provides additional information on the life-cycle analysis. We would also like to thank the Joint Genome Institute DNA synthesis team for their support and conversations on this work, in particular J.-F. Chen, M. Harmon-Smith, R. Evans and Y. Yoshikuni. Funding: Acetone strain and process development, genome-scale modeling, LCA work and initial pilot runs were supported by the U.S. Department of Energy Bioenergy Technologies Office under contract nos. DE-EE0007566 and CRADA/NFE-16-06364 between LanzaTech and the Oak Ridge National Laboratory (F.L., R.N., T.A., C.C., R.O.J., L.W., J.S., P.C., S.D.T., Z.R., A.G., L.T., N.L.E., J.C.B., J.D., R.C., T.J.T., R.J.G., R.L.H., S.D.S., S.D.B., C.L. and M.K.). Cell-free prototyping work was funded by the U.S. Department of Energy Office of Science, Biological and Environmental Research Division, Genomic Science Program, under contract nos. DE-SC0018249 and FWP ERKP903 (F.L., B.J.R., R.O.J., N.L.E., T.J.T., R.J.G., R.L.H., A.S.K., S.D.S., S.D.B., M.C.J. and M.K.). This manuscript was co-authored by UT-Battelle under contract no. DE-AC05-00OR22725 with the U.S. Department of Energy (T.J.T., N.L.E., R.J.G. and R.L.H.). DNA synthesis for the gene libraries was supported by the Joint Genome Institute Community Science Program under award no. CSP-503280; https://doi.org/10.46936/10.25585/60001121 (M.C.J. and M.K.). The work conducted by the U.S. Department of Energy Joint Genome Institute (https://ror.org/04xm1d337), a DOE Office of Science User Facility, is supported by the Office of Science of the U.S. Department of Energy operated under contract no. DE-AC02-05CH11231. B.J.R. is supported by a National Defense Science and Engineering Graduate Fellowship (award ND-CEN-017-095). We also thank the following investors in LanzaTech’s technology: BASF, CICC Growth Capital Fund I, CITIC Capital, Indian Oil Company, K1W1, Khosla Ventures, the Malaysian Life Sciences Capital Fund, L. P., Mitsui, the New Zealand Superannuation Fund, Novo Holdings A/S, Petronas Technology Ventures, Primetals, Qiming Venture Partners, Softbank China and Suncor.

Author information

Authors and Affiliations

Contributions

T.J.T., A.S.K., S.D.S., S.D.B., C.L., M.C.J. and M.K. designed the study. R.O.J. and F.L. performed the sequence mining. F.L. developed the combinatorial library framework. F.L., R.N., R.O.J., L.W., C.L. and M.K. performed all strain engineering. A.P.M. and M.K. performed in silico analysis. J.S. and J.D. performed modeling. B.J.R. and A.S.K. performed all cell-free experiments. T.A., Z.R., L.T., J.C.B. and S.D.B. performed all fermentation experiments. C.C., A.G. and R.C. performed LCA. P.C., N.L.E., R.J.G. and R.L.H. performed all omics experiments. E.L., R.N., T.A., B.J.R., A.S.K., C.L. and M.K. performed data analysis and visualization. E.L., R.N., T.A., C.L., B.J.R., A.S.K, M.C.J. and M.K. wrote the manuscript. All authors edited and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

F.L., R.N., T.A., C.C., R.O.J., L.W., J.S., S.T., A.P.M., A.G., L.T., J.C.B., J.D., R.C., S.D.S., S.D.B., C.L. and M.K. are current or former employees of LanzaTech, a for-profit company pursuing commercialization of the acetone and isopropanol gas fermentation process discussed here. M.C.J. consults for and has joint funding with LanzaTech. F.L. and M.K. are co-inventors on granted US patent 9,365,868 (assigned to LanzaTech) related to the production of acetone and isopropanol by fermentation of a gaseous substrate comprising CO that incorporates discoveries incorporated in this manuscript. M.K. is co-inventor on granted US patent 9,550,979 (assigned to LanzaTech) related to alcohol dehydrogenases with engineered metabolic activity that incorporates discoveries incorporated in this manuscript. R.O.J., A.P.M. and M.K. are co-inventors on US patent application 2015/0152445 (assigned to LanzaTech) related to inactivation of secondary alcohol dehydrogenases that incorporates discoveries incorporated in this manuscript. C.L. is an inventor on provisional US patent application 63/035,739 (assigned to LanzaTech) related to integration of acetone and isopropanol biosynthesis gene variants that incorporates discoveries incorporated in this manuscript. R.N. is an inventor on provisional US patent application 63/083,257 (assigned to LanzaTech) related to expressing multiple copies of acetone and isopropanol biosynthesis gene variants that incorporates discoveries incorporated in this manuscript. M.C.J. and A.S.K. are co-inventors on a US provisional patent application that incorporates discoveries described in this manuscript. Their interests are reviewed and managed by Northwestern University in accordance with their conflict of interest policies. All other authors declare no competing interests.

Peer review

Peer review information

Nature Biotechnology thanks Corinne Scown, Shang-Tian Yang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Text, Supplementary Figs. 1–12 and Material Transfer Agreement

Supplementary Data

Supplementary Tables 1–10

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liew, F.E., Nogle, R., Abdalla, T. et al. Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nat Biotechnol 40, 335–344 (2022). https://doi.org/10.1038/s41587-021-01195-w

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41587-021-01195-w

This article is cited by

-

Bioenergy carbon capture storage and utilization: a critical review of market dynamics and policy implications

Biotechnology for Biofuels and Bioproducts (2026)

-

Bioadaptive Ni single atoms unlock high rate microbial electrosynthesis of isopropanol from CO2

Nature Communications (2026)

-

Optimizing Lactiplantibacillus plantarum JCM 1149 growth conditions for improvement of the gelation and nutritional qualities of fermented soy milk

Biotechnology Letters (2026)

-

Method for automated high performance closed batch cultivation of gas-utilizing methanogens

AMB Express (2025)

-

MACAW: a method for semi-automatic detection of errors in genome-scale metabolic models

Genome Biology (2025)