Abstract

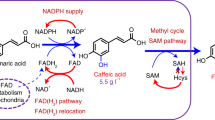

Porphyrins and their derivatives find extensive applications in medicine, food, energy and materials. In this study, we produced porphyrin compounds by combining Rhodobacter sphaeroides as an efficient cell factory with enzymatic catalysis. Genome-wide CRISPRi-based screening in R. sphaeroides identifies hemN as a target for improved coproporphyrin III (CPIII) production, and exploiting phosphorylation of PrrA further improves the production of bioactive CPIII to 16.5 g L−1 by fed-batch fermentation. Subsequent screening and engineering high-activity metal chelatases and coproheme decarboxylase results in the synthesis of various metalloporphyrins, including heme and the anti-tumor agent zincphyrin. After pilot-scale fermentation (200 L) and setting up the purification process for CPIII (purity >95%), we scaled up the production of heme and zincphyrin through enzymatic catalysis in a 5-L bioreactor, with CPIII achieving respective enzyme conversion rates of 63% and 98% and yielding 10.8 g L−1 and 21.3 g L−1, respectively. Our strategy offers a solution for high-yield bioproduction of heme and other valuable porphyrins with substantial industrial and medical applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the primary data supporting the findings of this study are accessible within the paper and its Supplementary Information files. Additional data can be obtained from the corresponding author upon reasonable request. Source data are provided with this paper.

Code availability

The developed code in this work is available at https://codeocean.com/capsule/8302979/tree/v1 or https://doi.org/10.24433/CO.8752603.v1.

Change history

02 July 2024

A Correction to this paper has been published: https://doi.org/10.1038/s41587-024-02317-w

References

Hiroto, S., Miyake, Y. & Shinokubo, H. Synthesis and functionalization of porphyrins through organometallic methodologies. Chem. Rev. 117, 2910–3043 (2017).

Barr, H. et al. Eradication of high-grade dysplasia in columnar-lined (Barrett’s) oesophagus by photodynamic therapy with endogenously generated protoporphyrin IX. Lancet 348, 584–585 (1996).

Surdel, M. C. et al. Antibacterial photosensitization through activation of coproporphyrinogen oxidase. Proc. Natl Acad. Sci. USA 114, E6652–E6659 (2017).

Drury, S. L. et al. Simultaneous exposure to intracellular and extracellular photosensitizers for the treatment of Staphylococcus aureus infections. Antimicrob. Agents Chemother. 65, e0091921 (2021).

Poulos, T. L. Heme enzyme structure and function. Chem. Rev. 114, 3919–3962 (2014).

Zhang, J. et al. Recent advances in microbial production of high-value compounds in the tetrapyrrole biosynthesis pathway. Biotechnol. Adv. 55, 107904 (2022).

Choi, K. R., Yu, H. E., Lee, H. & Lee, S. Y. Improved production of heme using metabolically engineered Escherichia coli. Biotechnol. Bioeng. 119, 3178–3193 (2022).

Zhang, W., Lai, W. & Cao, R. Energy-related small molecule activation reactions: oxygen reduction and hydrogen and oxygen evolution reactions catalyzed by porphyrin- and corrole-based systems. Chem. Rev. 117, 3717–3797 (2017).

Singh, S. et al. Glycosylated porphyrins, phthalocyanines, and other porphyrinoids for diagnostics and therapeutics. Chem. Rev. 115, 10261–10306 (2015).

Espinas, N. A., Kobayashi, K., Takahashi, S., Mochizuki, N. & Masuda, T. Evaluation of unbound free heme in plant cells by differential acetone extraction. Plant Cell Physiol. 53, 1344–1354 (2012).

In, M.-J., Kim, D. C., Chae, H. J. & Oh, N.-S. Effects of degree of hydrolysis and pH on the solubility of heme-iron enriched peptide in hemoglobin hydrolysate. Biosci. Biotechnol. Biochem. 67, 365–367 (2003).

Lichtenthaler, H. K. & Buschmann, C. Extraction of phtosynthetic tissues: chlorophylls and carotenoids. Curr. Protoc. Food Anal. Chem. 1, F4.2.1–F4.2.6 (2001).

Kwon Seok, J., de Boer Arjo, L., Petri, R. & Schmidt-Dannert, C. High-level production of porphyrins in metabolically engineered Escherichia coli: systematic extension of a pathway assembled from overexpressed genes involved in heme biosynthesis. Appl. Environ. Microbiol. 69, 4875–4883 (2003).

Bali, S. et al. Molecular hijacking of siroheme for the synthesis of heme and d1 heme. Proc. Natl Acad. Sci. USA 108, 18260–18265 (2011).

Dailey Harry, A. et al. Prokaryotic heme biosynthesis: multiple pathways to a common essential product. Microbiol. Mol. Biol. Rev. 81, e00048-16 (2017).

Dailey, H. A., Gerdes, S., Dailey, T. A., Burch, J. S. & Phillips, J. D. Noncanonical coproporphyrin-dependent bacterial heme biosynthesis pathway that does not use protoporphyrin. Proc. Natl Acad. Sci. USA 112, 2210–2215 (2015).

Fang, H. et al. Metabolic engineering of Escherichia coli for de novo biosynthesis of vitamin B12. Nat. Commun. 9, 4917 (2018).

Chen, G. E. et al. Complete enzyme set for chlorophyll biosynthesis in Escherichia coli. Sci. Adv. 4, eaaq1407 (2018).

Nielsen, M. T. et al. Assembly of highly standardized gene fragments for high-level production of porphyrins in E. coli. ACS Synth. Biol. 4, 274–282 (2015).

Zhang, J. et al. Heme biosensor-guided in vivo pathway optimization and directed evolution for efficient biosynthesis of heme. Biotechnol. Biofuels Bioprod. 16, 33 (2023).

Dai, J. et al. Differential gene content and gene expression for bacterial evolution and speciation of Shewanella in terms of biosynthesis of heme and heme-requiring proteins. BMC Microbiol. 19, 173 (2019).

Ouchane, S., Picaud, M., Therizols, P., Reiss-Husson, F. & Astier, C. Global regulation of photosynthesis and respiration by FnrL: the first two targets in the tetrapyrrole pathway. J. Biol. Chem. 282, 7690–7699 (2007).

Toriya, M. et al. Zincphyrin, a novel coproporphyrin III with zinc from Streptomyces sp. J. Antibiot. (Tokyo) 46, 196–200 (1993).

Nguyen, H. T. et al. Exploration of cryptic organic photosensitive compound as Zincphyrin IV in Streptomyces venezuelae ATCC 15439. Appl. Microbiol. Biotechnol. 104, 713–724 (2020).

Cleary, J. L., Kolachina, S., Wolfe, B. E. & Sanchez, L. M. Coproporphyrin III produced by the bacterium Glutamicibacter arilaitensis binds zinc and is upregulated by fungi in cheese rinds. mSystems. 3, e00036-18 (2018).

Zhao, X. R., Choi, K. R. & Lee, S. Y. Metabolic engineering of Escherichia coli for secretory production of free haem. Nat. Catal. 1, 720–728 (2018).

Ko, Y. J. et al. Animal-free heme production for artificial meat in Corynebacterium glutamicum via systems metabolic and membrane engineering. Metab. Eng. 66, 217–228 (2021).

Ishchuk, O. P. et al. Genome-scale modeling drives 70-fold improvement of intracellular heme production in Saccharomyces cerevisiae. Proc. Natl Acad. Sci. USA 119, e2108245119 (2022).

Choi, K. R., Yu, H. E. & Lee, S. Y. Production of zinc protoporphyrin IX by metabolically engineered Escherichia coli. Biotechnol. Bioeng. 119, 3319–3325 (2022).

Nelson, N. Metal ion transporters and homeostasis. EMBO J. 18, 4361–4371 (1999).

Frunzke, J., Gätgens, C., Brocker, M. & Bott, M. Control of heme homeostasis in Corynebacterium glutamicum by the two-component system HrrSA. J. Bacteriol. 193, 1212–1221 (2011).

Koripella, R. K. et al. Mechanism of elongation factor-G-mediated fusidic acid resistance and fitness compensation in Staphylococcus aureus. J. Biol. Chem. 287, 30257–30267 (2012).

Kojima, I., Maruhashi, K., Sato, H. & Fujiwara, Y. A highly active producer of coproporphyrin III and uroporphyrin III. J. Ferment. Bioeng. 76, 527–529 (1993).

Zhang, L. et al. Phosphate limitation increases coenzyme Q10 production in industrial Rhodobacter sphaeroides HY01. Synth. Syst. Biotechnol. 4, 212–219 (2019).

Shi, T. et al. Screening and engineering of high-activity promoter elements through transcriptomics and red fluorescent protein visualization in Rhodobacter sphaeroides. Synth. Syst. Biotechnol. 6, 335–342 (2021).

Lee, S. Q. E., Tan, T. S., Kawamukai, M. & Chen, E. S. Cellular factories for coenzyme Q10 production. Microb. Cell. Fact. 16, 39 (2017).

Lu, W. et al. Identification and elimination of metabolic bottlenecks in the quinone modification pathway for enhanced coenzyme Q10 production in Rhodobacter sphaeroides. Metab. Eng. 29, 208–216 (2015).

Wang, Z.-J. et al. Oxygen uptake rate controlling strategy balanced with oxygen supply for improving coenzyme Q10 production by Rhodobacter sphaeroides. Biotechnol. Bioprocess Eng. 25, 459–469 (2020).

Klaus, O. et al. Engineering phototrophic bacteria for the production of terpenoids. Curr. Opin. Biotechnol. 77, 102764 (2022).

Qiang, S. et al. Elevated β-carotene synthesis by the engineered rhodobacter sphaeroides with enhanced CrtY expression. J. Agric. Food Chem. 67, 9560–9568 (2019).

Orsi, E. et al. Growth-uncoupled isoprenoid synthesis in Rhodobacter sphaeroides. Biotechnol. Biofuels 13, 123 (2020).

Hu, J., Yang, H., Wang, X., Cao, W. & Guo, L. Strong pH dependence of hydrogen production from glucose by Rhodobacter sphaeroides.Int. J. Hydrog. Energy 45, 9451–9458 (2020).

Li, S. et al. Photoautotrophic hydrogen production of Rhodobacter sphaeroides in a microbial electrosynthesis cell. Bioresour. Technol. 320, 124333 (2021).

Orsi, E., Beekwilder, J., Eggink, G., Kengen, S. W. M. & Weusthuis, R. A. The transition of Rhodobacter sphaeroides into a microbial cell factory. Biotechnol. Bioeng. 118, 531–541 (2021).

Oh, J.-I. & Kaplan, S. Generalized approach to the regulation and integration of gene expression. Mol. Microbiol. 39, 1116–1123 (2001).

Imam, S., Noguera, D. R. & Donohue, T. J. Global analysis of photosynthesis transcriptional regulatory networks. PLoS Genet. 10, e1004837 (2014).

Kang, Z. et al. Recent advances in microbial production of δ-aminolevulinic acid and vitamin B12. Biotechnol. Adv. 30, 1533–1542 (2012).

Nishikawa, S. et al. Rhodobacter sphaeroides mutants which accumulate 5-aminolevulinic acid under aerobic and dark conditions. J. Biosci. Bioeng. 87, 798–804 (1999).

Urakami, T. & Yoshida, T. Production of ubiquinone and bacteriochlorophyll a by Rhodobacter sphaeroides and Rhodobacter sulfidophilus. J. Ferment. Bioeng. 76, 191–194 (1993).

Zeilstra-Ryalls, J. H. & Kaplan, S. Aerobic and anaerobic regulation in Rhodobacter sphaeroides 2.4.1: the role of the fnrL gene. J. Bacteriol. 177, 6422–6431 (1995).

Wei, W. et al. Lysine acetylation regulates the function of the global anaerobic transcription factor FnrL in Rhodobacter sphaeroides. Mol. Microbiol. 104, 278–293 (2017).

Tao, Y. et al. Characteristics of a new photosynthetic bacterial strain for hydrogen production and its application in wastewater treatment. Int. J. Hydrog. Energy 33, 963–973 (2008).

Qu, Y., Su, A., Li, Y., Meng, Y. & Chen, Z. Manipulation of the regulatory genes ppsR and prrA in Rhodobacter sphaeroides enhances lycopene production. J. Agric. Food Chem. 69, 4134–4143 (2021).

Rowan-Nash Aislinn, D., Korry Benjamin, J., Mylonakis, E. & Belenky, P. Cross-domain and viral interactions in the microbiome. Microbiol. Mol. Biol. Rev. 83, e00044-00018 (2019).

Dailey, T. A. et al. Discovery and characterization of HemQ: an essential heme biosynthetic pathway component. J. Biol. Chem. 285, 25978–25986 (2010).

Toriya, M., Yamamoto, M., Saeki, K., Fujii, Y. & Matsumoto, K. Antitumor effect of photodynamic therapy with zincphyrin, zinc-coproporphyrin III, in mice. Biosci. Biotechnol. Biochem. 65, 363–370 (2001).

Yamamoto, M. et al. Production of singlet oxygen on irradiation of a photodynamic therapy agent, zinc-coproporphyrin III, with low host toxicity. Biometals 16, 591–597 (2003).

Voigt, C. A. Synthetic biology 2020–2030: six commercially-available products that are changing our world. Nat. Commun. 11, 6379 (2020).

Lechardeur, D. et al. Discovery of intracellular heme-binding protein HrtR, which controls heme efflux by the conserved HrtB-HrtA transporter in Lactococcus lactis. J. Biol. Chem. 287, 4752–4758 (2012).

Zou, Z.-P., Du, Y., Fang, T.-T., Zhou, Y. & Ye, B.-C. Biomarker-responsive engineered probiotic diagnoses, records, and ameliorates inflammatory bowel disease in mice. Cell Host Microbe 31, 199–212 (2023).

Weber, P. C., Ohlendorf, D. H., Wendoloski, J. J. & Salemme, F. R. Structural origins of high-affinity biotin binding to streptavidin. Science 243, 85–88 (1989).

Chen, J. S. et al. CRISPR–Cas12a target binding unleashes indiscriminate single-stranded DNase activity. Science 360, 436–439 (2018).

Celis, A. I. et al. Structure-based mechanism for oxidative decarboxylation reactions mediated by amino acids and heme propionates in coproheme decarboxylase (HemQ). J. Am. Chem. Soc. 139, 1900–1911 (2017).

Griffiths, M. & Stanier, R. Y. Some mutational changes in the photosynthetic pigment system of Rhodopseudomonas spheroides. Microbiology 14, 698–715 (1956).

Skotnicová, P. et al. The cyanobacterial protoporphyrinogen oxidase HemJ is a new b-type heme protein functionally coupled with coproporphyrinogen III oxidase. J. Biol. Chem. 293, 12394–12404 (2018).

Kanazireva, E. & Biel, A. J. Cloning and overexpression of the Rhodobacter capsulatus hemH gene. J. Bacteriol. 177, 6693–6694 (1995).

Yoshida, H., Kotani, Y., Ochiai, K. & Araki, K. Production of ubiquinone-10 using bacteria. J. Gen. Appl. Microbiol. 44, 19–26 (1998).

Gibson, L. C. D., McGlynn, P., Chaudhri, M. & Hunter, C. N. A putative anaerobic coproporphyrinogen III oxidase in Rhodobacter sphaeroides. II. Analysis of a region of the genome encoding hemF and the puc operon. Mol. Microbiol. 6, 3171–3186 (1992).

Oh, J.-I., Eraso Jesus, M. & Kaplan, S. Interacting regulatory circuits involved in orderly control of photosynthesis gene expression in Rhodobacter sphaeroides 2.4.1. J. Bacteriol. 182, 3081–3087 (2000).

Eraso, J. M. & Kaplan, S. prrA, a putative response regulator involved in oxygen regulation of photosynthesis gene expression in Rhodobacter sphaeroides. J. Bacteriol. 176, 32–43 (1994).

Oh, J.-I., Ko, I.-J. & Kaplan, S. The default state of the membrane-localized histidine kinase Prrb of Rhodobacter sphaeroides 2.4.1 is in the kinase-positive mode. J. Bacteriol. 183, 6807–6814 (2001).

Hornbeck, P. V. Enzyme-linked immunosorbent assays. Curr. Opin. Immunol. 110, 2.1.1–2.1.23 (2015).

Liang, M. et al. A CRISPR–Cas12a-derived biosensing platform for the highly sensitive detection of diverse small molecules. Nat. Commun. 10, 3672 (2019).

Zeng, X. et al. An in vitro CRISPR–Cas12a-mediated protocol for direct cloning of large DNA fragments. STAR Protoc. 4, 102435 (2023).

Acknowledgements

We thank Q. Chen (School of Biotechnology, East China University of Science and Technology), L. Zhang (School of Chemistry and Molecular Engineering, East China Normal University) and W. Zhang (State Key Laboratory of Microbial Technology, Shandong University) for their technical support in enzyme mining, engineering and characterization. We are also deeply grateful to Z. Zhou (Institute of Plant Physiology and Ecology, Chinese Academy of Sciences) for her generous gift of the ZX-5 strain and to Inner Mongolia Kingdomway Pharmaceutical Co., Ltd. for providing the HY01 strain. We would like to extend our gratitude to D.-Q. Lin from the College of Chemical and Biological Engineering at Zhejiang University for his invaluable guidance in conducting the techno-economic analysis and for providing assistance in using the SuperPro Designer simulation software. During the manuscript preparation, we also greatly appreciate the constructive insights provided by J.-J. Zhong, L. Bai and T. Liu from the School of Life Sciences and Biotechnology, Shanghai Jiao Tong University. This work was financially supported, in part, by grants from the National Key Research and Development Program of China (2020YFA0907800 to Z.L. and 2020YFA0907304 to T.G.-Y.); the National Natural Science Foundation of China (32121005 to Z.L. and 32370064 and 31870040 to T.G.-Y.); 2023 Double World-Class Project-Key Program-Intelligent Biomanufacturing to Z.L.; and the Open Funding Project of the State Key Laboratory of Microbial Metabolism (MMLKF22-03 to T.G.-Y.).

Author information

Authors and Affiliations

Contributions

G.-Y.T. and Lixin Zhang supervised the project. G.-Y.T., Lixin Zhang and W.W. designed the experiments. Lu Zhang, T.S., X.H., M.Y., W.J. and D.L. engineered and optimized R. sphaeroides. Z.W. and H.C. designed the crRNA library and screened the strains. T.C., X.C., H.C., Z.W., X.W. and B.G. mined the enzyme and performed enzymatic catalysis. Y.W., X.C. and M.L. developed the heme detection method and conducted high-throughput screening work. H.W., H.C., G.Z., X.L., J.Z., H.L., X.X. and Y.X. isolated, prepared and identified chemical compounds. H.C., Z.W., L.O., Y.L., J.Y. and Z.L. conducted the fed-batch work in bioreactor. H.C., Z.W. and Z.L. developed the pilot-scale fermentation process and the method for isolating and purifying CPIII. Z.W. and H.C. conducted the techno-economic analysis. G.-Y.T. wrote the manuscript. Lixin Zhang, G.-Y.T. and Y.T. edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

G.-Y.T, Lixin Zhang, W.W., Lu Zhang, Y.W., T.C. and H.C. filed eight Chinese patent applications (201910999107.4, 202211452809.9, 202211487904.2, 202310737429.8, 202310738915.1, 202310750263.3, 202310754364.8 and 2023118130742) based on this work. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Biotechnology thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Porphyrin pathway-derived products or intermediates and the verification of CPIII production in fermentation broth.

a, The chemical structures of key products or intermediates in porphyrin biosynthetic pathway. 5-ALA, 5-Aminolevulinate; UPENIII, Uroporphyrinogen III; CPENIII, Coproporphyrinogen III; CPIII, Coproporphyrin III; Fe-CPIII, Fe-coproporphyrin III; VB12, Vitamin B12; PPIX, Protoporphyrin IX; Bchl, Bacteriochlorophyll. b, Structure verification of CPIII in fermentation broth sample. i) HPLC profile of sample and standard CPIII; ii) MS/MS spectra with 50-eV collision energy for purified and standard CPIII.

Extended Data Fig. 2 Construction and PCR verification of various mutants and stepwise enhancement of CPIII production in R. sphaeroides.

a, Construction and PCR verification 2.4.1-ΔfnrL. b, Construction and PCR verification of ZX-5-ΔfnrL. F1 and F2 are the PCR products that were amplified using ZX-5-ΔfnrL-up-ck-F/R and ZX-5-ΔfnrL-dn-ck-F/R, respectively. c. Construction and PCR verification of HY01-ΔfnrL. d. Construction and PCR verification of HY01-ΔhemN. F3 and F4 are the PCR products that were amplified using HY01-ΔhemN-up-ck-F/R and HY01-ΔhemN-dn-ck-F/R. e. Construction and PCR verification of HY01-ΔhemN-prrABpLB2. F5 and F6 are the PCR products that were amplified using ΔhemN-prrAB-up-ck-F/R and ΔhemN-prrAB-dn-ck-F/R. The PCR verifications in b-c were performed three times each (n = 3; replicates are shown in Source Data files; in each replicate, at least two double crossover conjugants were selected). f. Heat map depicts the differentially expressed PrrA target operons (selected) during fermentation in bioreactor at 16, 24, 40 and 60 h. This result indicated that three genes associated with the porphyrin metabolism pathway, namely hemA, hemC, and hemE, which are regulated by prrA, exhibited a substantial upregulation in transcription levels at the 40 h of fermentation compared to the 24 h. FPKM (fragments per kilobase of transcript per million fragments mapped) values were taken as generation of the heat map by origin 2022 software. g. Stepwise enhancement of CPIII production in R. sphaeroides (n = biologically independent replicates). *: Fed-batch fermentation in 5-L bioreactor; #: IPTG addition. Bar graph with error bars represents mean ± s. d.

Extended Data Fig. 3 Verification of metalloporphyrin production by HRMS and biocatalytic synthesis of Zincphyrin.

a-d, Identification of Co-CPIII, Ni-CPIII, Cu-CPIII, and Mn-CPIII by high-resolution mass spectrometry (HRMS). All the accurate mass measurements for impurities were within < 5 ppm of the theoretical m/z value. e, HPLC profile of the enzymatic catalysis of CPIII for the in vitro synthesis of Zincphyrin using HemHSa and zinc sulfate. The reaction is conducted in Tris-HCl buffer (pH 8.0) at 37 °C under the following conditions: i) In the reaction system, only 50 μM CPIII is present. ii) In condition i, 50 μM ZnSO4 and 1 μM HemHSa were added.

Extended Data Fig. 4 Methodological characterization and analysis of CRISPR-Cas12a-based heme detection.

a. Fluorescence intensity of detection system in the presence of heme and its structural analogues (n = 3 biological independent detection of fluorescence intensity per condition). Fluorescence intensity was measured in the presence of heme, coproporphyrin I, coproporphyrin III, Fe-coproheme III, and protoporphyrin, with a concentration of 200 nM for heme and 2000 nM for each of the remaining porphyrin compounds. b. The linear relationship between the concentration of heme and the cleavage rate. The concentration range in which the calibration curve was linear was 10–200 nM (n = 3 biological independent replicates; R2 > 0.993). Bar graphs with error bars in a and b represent mean ± s. d. c. Analysis of the reproducibility and accuracy of heme detection method. Three different concentrations of heme samples (sample 1, 2, 3) were independently tested in six times (n = 6) using a 96-well plate. The coefficient of variation (c.v.) and sample recovery (Rec.) rate were calculated for the detection results.

Extended Data Fig. 5 Mining HemQ homologs and comparing crude enzyme activities.

a. Mining of hemQ homologous (NCBI blast 2.11.0+) by using maximum likelihood method. The evolutionary history was inferred by using the Maximum Likelihood method and JTT matrix-based model. The tree with the highest log likelihood (−1234833.12) is shown. Initial tree(s) for the heuristic search were obtained automatically by applying Neighbor-Join and BioNJ algorithms to a matrix of pairwise distances estimated using the JTT model, and then selecting the topology with superior log likelihood value. The tree is drawn to scale, with branch lengths measured in the number of substitutions per site. This analysis involved 1000 amino acid sequences. There were a total of 1761 positions in the final dataset. Evolutionary analyses were conducted in MEGA X (version: 10.2.6). Utilizing hemQ from Bacillus subtilis (P39645) as a probe sequence, a total of 30 candidate genes were selected. The codon optimization and complete gene synthesis for the selected candidates were conducted by GenScript Inc (Nanjing, China). E. coli was employed for recombinant protein expression and subsequent activity assessment. b. The crude enzyme activity of HemQ28 compared to different previously reported HemQ homologous proteins. HemQBs, HemQCg, HemQSa, and HemQMt are derived from Bacillus subtilis, Corynebacterium glutamicum, Staphylococcus aureus, and Mycobacterium tuberculosis, respectively. All these proteins were recombinantly expressed in E. coli and prepared as corresponding crude enzyme solutions. The enzyme activity unit (U) was defined as the amount of enzyme required to catalyze the conversion of 1 μM substrate or generate 1 μM product within one minute under optimal temperature (37 °C) and pH conditions. This study used bovine serum albumin (BSA) at a known concentration as a reference and obtained bands of the target protein through SDS-PAGE. Subsequently, the concentration of the target protein was estimated by comparing its band intensities with those of BSA using BioRad Image Lab software (version: 6.0.0 build 25). Three biologically independent replicates (n = 3) were conducted for enzymatic activity detection of each HemQ homologue. Bar graph with error bars represent mean ± s. d. *P < 0.05.

Extended Data Fig. 6 Error-prone mutagenesis and screening of HemQ28 variant.

The process of mutation and screening includes: error-prone PCR, DNA assembly, plasmid transformation, cell culture and preservation, protein expression, enzymatic reaction and heme extraction, biosensing of heme, and detection and analysis.

Extended Data Fig. 7 Biocatalysis of heme by CPIII and the stability assessment of HemQ28-M.

a, b, Quantitative analysis of heme and other chemicals after enzymatic catalysis (n = 3 biologically independent replicates). c, d, Effects of temperature and pH on the enzymatic activity of HemQSa and HemQ28-M. Three biologically independent replicates (n = 3) were conducted for each condition in c and d. e, One-time addition of crude enzyme catalyzed the conversion CPIII to heme in 5-L bioreactor. At the beginning of the reaction, 2 L of CPIII with a concentration of 18 g/L was added all at once. The crude enzyme supernatant obtained by crushing 180 g of wet recombinant E. coli cells was added to the reaction system at the beginning of the reaction (that is, 0 h). The reaction was performed at 37 °C and pH 7.0 with agitation at 100 rpm. f, Heme production rate after fed-batch addition of crude enzyme solution (CES) in 5-L bioreactor. After the enzymatic reaction commenced, the CES obtained by crushing wet recombinant E. coli cells was fed-batch added to the 5-L bioreactor at 1, 3, 5, and 7 h. This study measured the heme production rate within two hours after the addition of CES at 1, 3, and 5 h. The concentration of the target fusion protein in the CES was determined by comparing its band’s grayscale intensity with that of a BSA standard following SDS-PAGE electrophoresis, using a concentration of 0.5 g/L BSA as a reference for quantification. Each addition of CES contains 722 ± 140 mg of target fusion protein (derived from approximately 36 g of wet E. coli cells). After each addition of CES, heme concentration increases were measured at five intervals (specifically, 0–5 min, 5–10 min, 25–30 min, 55–60 min, and 115–120 min) within the subsequent two hours to calculate the heme production rate for each corresponding time interval. Bar graphs with error bars represent mean ± s. d. *P < 0.05.

Extended Data Fig. 8 Purification and preparation of CPIII from fermentation broth through crystallization.

a, Proposed workflow for the purification and preparation of CPIII through crystallization. b, Effects of precipitation pretreatment on crystallization efficiency (three independent replicates were conducted under each condition). Control: direct crystallization using fermentation broth supernatant; NaOH: crystallization after alkaline precipitation (pH 8.5) using NaOH; IPA: addition of 20% isopropanol to the fermentation broth supernatant for alcohol precipitation followed by crystallization; NaOH-IPA: crystallization after combined alkaline and isopropanol precipitation. c, Effects of precipitation pretreatment and acidic acetone extraction on crystallization efficiency (three independent replicates were conducted under each condition). After combined alkaline precipitation and isopropanol precipitation (NaOH-IPA), the obtained supernatant undergoes crystallization following treatment with 30% acidic acetone. CPIII purity and recovery rates were calculated separately according to the Method section. d–g, Effect of pH, CPIII concentration, temperature, and crystallization time on the purity or recovery rate of CPIII. The CPIII fermentation broth supernatant was applied to optimized crystallization conditions. Purity and recovery rates were calculated separately following the procedures outlined in the Method section. h, Effects of recrystallisation time on the purity or recovery rate of CPIII. i, Effect of primary crystallization and recrystallization on the purity and recovery rate of CPIII (three independent replicates were conducted under each condition). CPIII purity and recovery rates were calculated separately according to the Method section. j, The HPLC quantitative standard curve for CPIII. CPIII standard (#C882263; Macklin3 Inc, Shanghai, China) of 1 mg was dissolved in 1 mL of DMSO to prepare a stock solution with a concentration of 1000 mg/L. Under subdued light conditions, the CPIII stock solution was further diluted in a series of concentrations using DMSO, resulting in solutions with concentrations of 125 mg/L, 62.5 mg/L, 31.25 mg/L, 15.625 mg/L, and 7.8125 mg/L. Each concentration was prepared in triplicate. The peak areas of CPIII at 390 nm were determined using HPLC. The peak area values were obtained for each concentration, and the data represent mean ± s. d. of three replication. k, The HPLC profiles of purified CPIII sample and the CPIII standard. Based on the CPIII standard curve calculation, the purity of CPIII samples was determined to be 95.2%.

Extended Data Fig. 9 Simulation of large-scale CPIIII and heme bioproduction processes for techno-economic analysis.

This model is designed to simulate the large-scale production of CPIII crystals (with a CPIII content of at least 95%, w/w) and heme crystals (with a heme content of at least 93%, w/w). The process for CPIII production consists of two sections: CPIII fermentation for obtaining CPIII fermentation broth, and CPIII preparation for obtaining CPIII crystal product via purification and crystallization. The annual production rate is 20 tons of CPIII. According to the model, the installation is planned to operate 24 hours a day, for a total of 329 days per year (the remaining days were allocated for maintenance and conservation tasks). The annual batch throughput for producing heme is 69 batches, with each batch time and cycle time is 127 and 114 h, respectively. The process for heme production comprises five sections: CPIII fermentation to obtain CPIII fermentation broth (shared with CPIII production), CPIII preparation to obtain CPIII crystal products through purification and crystallization (shared with CPIII production), E. coli culture to cultivate E. coli cells expressing recombinant fusion proteins in fermenters, CES preparation involves cell storage and disruption to obtain cell lysate supernatant containing recombinant fusion proteins, and the Heme preparation section to catalyze the conversion of CPIII into heme using CES and subsequently purify and crystallize to obtain the final heme product (crystallization and purification equipment and lines are shared with CPIII production). The annual production rate is 16 tons of heme. According to the model, the installation is planned to operate 24 hours a day, for a total of 330 days per year (the remaining days were allocated for maintenance and conservation tasks). The annual batch throughput for producing heme is 69 batches, with each batch time and cycle time is 148 and 114 h, respectively. The modeling process utilizes parameters or data from both the built-in database of SuperPro® Designer simulation software and project-specific data from both the experimental results of this study and the Supplementary Table. 4.

Extended Data Fig. 10 Techno-economic analysis of large-scale CPIII and heme bioproduction.

a, Breakdown of annual operating cost for CPIII and heme production. i, Annual cost breakdown by section (%) for CPIII production. ii, Annual operating cost breakdown (%) for CPIII production. iii, Annual cost breakdown by section (%) for heme production. iv, Annual operating cost breakdown (%) for heme production. In this model, the total annual operating costs for CPIII and heme are $935,000 and $2,512,000, respectively (Supplementary Table. 5). The data in panels i and iii are derived from Itemized Cost analyses conducted within this model, while the data in panels ii and iv stem from the Economic Evaluation analysis. The facility-dependent cost encompasses expenses for maintenance, depreciation, and miscellaneous costs. Labor-Dependent Cost: comprises all labor-dependent operating expenses excluding those for laboratory analyses, quality control, and quality analyses. Laboratory/QC/QA Cost: covers laboratory analyses, quality control, and quality analyses. Consumables Cost: certain equipment necessitates the use of consumables; this cost category includes expenses for periodically replaced materials. Utilities: Heating Agents, Cooling Agents, and Power Types. The modeling process utilizes parameters or data from both the built-in database of SuperPro® Designer simulation software and project-specific data from both the experimental results of this study and the Supplementary Table. 4. b. The annual average price and gross margin of heme in the international trading market over the last six years (2018–2023). The information related to the price and gross margin of heme in the international trading market is based on the 2023 Heme Market Research Report, a commercially available market research report provided by MARKET MONITOR Co., Ltd, Changsha, China. The Market Research Report was published on July 15, 2023, with the report code GMM2292280. For more details, please visit the webpage: https://www.globalmarketmonitor.com.cn/reports/2292280-hemoglobin-market-report.html.

Supplementary information

Supplementary Information

Supplementary Tables 1–10 and Supplementary Notes 1, 3 and 4.

Supplementary Data

Supplementary Note 2. The sequence of all the oligonucleotides encoding crRNA.

Source data

Source Data Figs. 1, 2 and 4–6 and Extended Data Figs. 2, 4, 5, 7 and 8

Statistical Source Data

Source Data Figs. 5 and 6 and Extended Data Fig. 2

Unprocessed gels.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, H., Wang, Y., Wang, W. et al. High-yield porphyrin production through metabolic engineering and biocatalysis. Nat Biotechnol (2024). https://doi.org/10.1038/s41587-024-02267-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41587-024-02267-3

This article is cited by

-

Scalable secondary metabolite production in Streptomyces using a plug-and-play system

Nature Biotechnology (2025)

-

Photocatalytic technology in lignin: from traditional depolymerization to actively light-driven conversion

Advanced Composites and Hybrid Materials (2025)