Abstract

This work introduces a comprehensive dataset and framework for assessing the sustainability of high entropy alloys (HEAs) and other metallic alloys. The dataset includes nine crafted indicators—raw material price, supply risk, normalized vulnerability to supply restriction, embodied energy, water usage, rock-to-metal ratio, human health damage, human rights pressure, and labor rights pressure—for 18 elements: Al, Co, Cr, Cu, Fe, Hf, Mn, Mo, Nb, Ni, Re, Ru, Si, Ta, Ti, V, W, and Zr. This methodology evaluates economic viability, environmental impact, and societal implications using alloy compositions as input. The Python package, AlloySustainability, streamlines indicator computation and enables users to benchmark alloys against a database encompassing 340 HEAs and over 240 conventional steels and Ni-based superalloys. By integrating these tools with principles of responsible and informed design, this work promotes transparency and fosters innovative alloy development. The dataset and tools, freely available on GitHub, empower the scientific community to advance sustainable practices in metallurgy.

Similar content being viewed by others

Background & Summary

The development of alloys is increasingly shaped by societal needs and environmental regulations. For instance, the European Union’s Restriction of Hazardous Substances (RoHS) Directive, specifically Directive 2011/65/EU (also known as RoHS 2) issued by the European Parliament and Council on June 8, 2011, which limits the use of certain hazardous substances in electrical and electronic equipment, catalyzed the shift from Tin-Lead to Lead-free solders in electronic products, establishing Sn-Ag-Cu (SAC) alloys as the new industry standard. Similarly, the EU’s REACH regulations, formally known as Regulation (EC) No. 1907/2006 of the European Parliament and of the Council of December 18, 2006, have imposed strict controls on the use of hexavalent chromium. This has prompted the advancement and adoption of alternative surface treatments, such as zinc-nickel coatings and trivalent chromium anodizing processes. Concerns over nickel’s health impacts have led to the innovation of nickel-free stainless steels, utilizing manganese (Mn) or nitrogen (N) as substitutes. Additionally, recognizing the health risks posed by beryllium, the industry has seen a transition to beryllium-free copper alloys like Cu-Ni-Si. These shifts underline a critical insight: materials science is integral to an ecosystem where societal and environmental considerations are not merely constraints but catalysts for innovation. This continuous evolution in materials is propelled by the proactive integration of these considerations, reflecting a commitment to responsible development and the betterment of society.

With High Entropy Alloys (HEAs) at the forefront of research due to their unique properties and distinctive characteristics, it has become imperative to rigorously evaluate their societal impact since the concept was first proposed in 20041,2. Reflecting on this, Cann et al.3. highlighted that “Significant efforts are needed to select economically and environmentally viable alloy combinations that meet today’s technical demands.” This statement encapsulates the essence of our research and the critical need for a balanced approach to alloy design.

Recent studies have begun to explore the broader implications of HEAs beyond their technical performance. Fu et al.4 have examined resource efficiency, considering factors such as price, availability, and recyclability, while emphasizing the need to address economic and environmental aspects of HEA design early in the development process to ensure their technological viability. Similarly, Wang et al.5 have analyzed availability, prices, and chemical hazards, focusing specifically on refractory element-based HEAs. While these studies provide valuable initial insights, they remain limited in scope, addressing only a subset of potential impacts and alloy compositions. Our work seeks to expand these efforts by developing a comprehensive set of indicators that evaluate economic, environmental, and societal impacts. By examining these factors, we aim to provide a robust framework for guiding alloy design towards more sustainable and responsible practices. Drawing inspiration from other professions where ethical considerations are deeply integrated—such as ESG principles in investment, bioethics in medicine, and ethical AI—we have crafted a similar approach for alloy design. This method underscores the importance of making informed, conscientious choices in elemental composition. The indicators selected for this work were meticulously chosen to align with the three pillars of sustainable development: economic viability, environmental impact, and human well-being.

Our methodological approach to selecting these indicators has been informed by the field’s demand for transparent, ethical, and sustainable practices. Presented to the scientific community during the Thermec’2023 conference in Vienna, our initial findings have garnered significant interest, reinforcing the importance of sharing our comprehensive database. The set of nine indicators we introduce aims to guide alloy designers towards compositions that are more economically viable, environmentally conscious, and socially responsible. This initiative led to the creation of a database, presented in this article, consisting of nine indicators designed to efficiently evaluate the sustainability of alloy compositions containing any of the following elements: Al, Co, Cr, Cu, Fe, Hf, Mn, Mo, Nb, Ni, Re, Ru, Si, Ta, Ti, V, W, and Zr. This database, freely available at the open repository figshare6 and on GitHub (https://github.com/sgorsse/AlloySustainability), was used to assess the impacts of 340 newly proposed high entropy alloy compositions, as detailed in a recently published study7. Furthermore, we have developed an installable Python package indexed in PyPI (https://pypi.org/project/AlloySustainability/) that allows users to compute the nine indicators for alloys of their interest within the 18-compositional space defined above. Users can also compare the computed indicators of their alloys against the median values for FCC HEAs, BCC HEAs, steels, and Ni-based superalloys, providing a benchmark for understanding how their designs align with or differ from existing compositions. Additionally, we provide a single-use interactive web application, named the Alloy Societal Impact Calculator, hosted on the Model Warehouse of the AI Machine Learning Platform at the High Entropy Materials Center. This application is freely accessible with registration at: https://black-stone-0b1668410.3.azurestaticapps.net/#/materials_informatics.

Methods

Our methodology evaluates the sustainability of alloy compositions using nine specific indicators, each providing insights into a distinct category. Higher indicator values correspond to greater negative implications. A comprehensive explanation of these indicators and their application can be found in ref. 7.

Economic viability.

-

Raw Material Price (MP): Uses the price of pure alloying additions as a cost proxy.

-

Supply Risk (SR): Based on Graedel et al.‘s aggregated supply risk indicator8, this metric evaluates the potential for supply disruptions from geopolitical and natural events.

-

Normalized Vulnerability to Supply Restriction (NVSR): Adjusts the vulnerability to supply restriction (VSR)8 by the logarithmic production volume of the element, considering both scarcity and the potential for recycling.

Environmental impact.

-

Embodied Energy9 (EE): Reflects the total energy required for metal production, from extraction to transportation, correlating with greenhouse gas emissions. By assessing the energy required, we aimed to provide an indirect yet robust evaluation of the environmental burdens, including carbon footprint, associated with alloying addition production.

-

Water Usage9 (WU): Measures the total water consumption in alloying addition production.

-

Rock to Metal Ratio10 (RMR): Indicates land use intensity in mining operations, with higher ratios pointing to greater environmental disturbances.

Human well-being.

-

Human Health Damage (HHD): An aggregate indicator from Graedel et al.8 measuring metals’ direct impacts on human health.

-

Human Rights Pressure (HRP): Defined as a measure of potential human rights concerns associated with the sourcing of elements. It is derived from the Human Rights Index11 (HRI), which is defined at the country level and reflects the extent of respect for human rights within each country (c). Since higher values of the Human Rights Index (HRI) indicate broader respect for human rights, we inverted the scale to reflect pressure (higher values indicating greater concerns). The formula below ensures that HRP is normalized within the same range as HRI while maintaining interpretability, where higher HRP values correspond to greater human rights pressures.

$${{HRP}}_{c}={-{HRI}}_{c}+\min \left({{HRI}}_{c}\right)+\max \left({{HRI}}_{c}\right)$$ -

Labor Rights Pressure (LRP): Assesses labor rights concerns in extraction countries (\(c\)), derived from the Labor Rights Index12 (LRI). Using the same approach as HRP, we invert the LRI scale to reflect pressure, where higher LRP values indicate greater concerns. The formula ensures normalization within the same range as LRI while maintaining interpretability.

Evaluation of element indicators

Table 1 lists element indicators, their units, value ranges, source references, and calculation formulas where applicable. It offers a concise overview of metrics assessing element impacts.

Elemental Human Rights Pressure (\({{HRP}}_{i}\)) and Labor Rights Pressure (\({{LRP}}_{i}\)) are determined by the countries of origin for each element. These indicators can be calculated as a matrix product expressed as follows:

here \({\mathbb{G}}\) is the global supply matrix which gives the percentage of the production of raw materials of countries in the world13, and \({\mathbb{C}}\) the country indicator matrix.

Strategy for imputing missing data

When encountering missing data, such as in 28% of the countries for the Labor Rights Pressure, we addressed the issue by leveraging correlations for data imputation. We compiled a dataset of 180 countries with 26 governance, social development, and sustainable competitiveness features7, which aided in imputing missing values for country-dependent indicators. Using a K-Nearest Neighbours (KNN) technique14, adapted from Python’s Scikit-Learn library15, we imputed missing data by finding the mean or median of the ‘k’ closest neighbors in our feature space. We standardized our imputation process with default Scikit-Learn settings, including using five neighbors to balance underfitting and overfitting risks. To normalize data and minimize outliers’ impact, we applied ‘RobustScaler’ and ‘MinMaxScaler’ from the Python framework, ensuring equal feature contribution to KNN distance calculations. This KNN methodology was similarly applied to missing element indicator values, supported by correlation analysis with additional elemental properties, ensuring a consistent and accurate treatment of missing data across the study.

Data Records

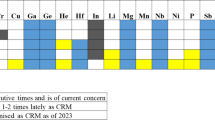

Our dataset of impacts, named ‘gen_18element_imputed_v202412’, is available in both CSV and JSON formats and has been deposited on GitHub and figshare6. In addition to the dataset, we have included detailed metadata in the machine-readable JSON format, and a README file providing documentation for the dataset and indicators. The dataset includes values for nine crafted indicators for a palette of eighteen elements commonly used in HEAs: Al, Co, Cr, Cu, Fe, Hf, Mn, Mo, Nb, Ni, Re, Ru, Si, Ta, Ti, V, W, and Zr. Figure 1 illustrates these indicators for the full palette of elements.

Tree plots - ‘footprints’ - across 9 indicators for our palette of 18 elements. Each indicator is represented by a block for 18 elements. The size and color of each sub-block represent the indicator value for each element. Darker red hues and larger block sizes denote higher impacts. MP-material price, SR-supply risk, NVSR-normalized vulnerability to supply restriction, EE-embodied energy, WU-water usage, RMR-rock-to-metal ratio, HHD-human health damage, HRP-human rights pressure, LRP-labor rights pressure.

Technical Validation

The data presented in this article were carefully collected, processed, and thoroughly verified for accuracy by a team of experienced materials scientists who deeply understand metallurgy, alloy design, high entropy alloys, and materials sustainability. The K-Nearest Neighbors14 (KNN) imputation method’s effectiveness was verified through self-validation. For this, part of our dataset was manipulated to create missing values, which were then estimated using KNN for country-dependent indicators. This approach suits the 180-country dataset well, ensuring accurate imputations. Countries naturally form clusters sharing similar characteristics (e.g., economic development, governance, or resource availability), which ensures that missing values are surrounded by relevant and similar neighbors, thereby enhancing the reliability of KNN imputations. For element indicators, with a smaller element dataset, we used Leave-One-Out Cross-Validation (LOOCV), ideal for its size, by validating each data point against the rest. The accuracy of our imputation was measured by comparing imputed values to actual ones, using Root Mean Square Error (RMSE) and Mean Absolute Percentage Error (MAPE) for quantification. This comparison, shown in Fig. 2, confirms the robustness of our KNN method for both datasets. For more detailed information, please refer to the following reference7.

Usage Notes

Evaluation of alloy indicators

This database, which evaluates the societal implications of HEAs and conventional alloys, provides data to support more sustainable and responsible alloy design practices that benefit both industry and society.

The price (MP), normalized vulnerability to supply restriction (NVSR), embodied energy (EE), water usage (WU), rock-to-metal ratio (RMR), human health damage (HHD), human rights pressure (HRP) and labor rights pressure (LRP) associated to an alloy composition are calculated as the weighted arithmetic average of its elemental constituents expressed in mass fraction. It was implemented in a Python code as the following matrix product:

\({{\bf{I}}}_{{\bf{alloy}}}\) is the vector of alloy indicators, \({\bf{W}}\) is the compositional vector storing the elemental compositions of alloys (in mass fraction), and \({\mathbb{E}}\) is the matrix of elemental constituents’ indicators (‘gen_18element_imputed_v202412’ deposited on GitHub).

Supply Risk (SR) was computed uniquely, acknowledging that an alloy’s likelihood of supply disruption escalates with the number of constituents. It’s defined as a disruption probability between 0 and 1, calculated by multiplying the probabilities of each constituent (k), as per the expression:

Installable Python package

To facilitate the calculation of sustainability indicators for alloys, we provide an installable Python package, AlloySustainability. This tool allows users to compute sustainability metrics for their alloys by simply inputting the chemical composition in terms of mass fractions for 18 elements (Table 2). The package automates the retrieval and processing of reference data, offering both numerical results and comparative visualizations against established alloy classes (Fig. 3). AlloySustainability is freely available on PyPI (https://pypi.org/project/AlloySustainability/) and can be installed using the command: pip install AlloySustainability.

Violin plots of indicators for HEAs and conventional alloys generated by the installable Python package AlloySustainability proposed in the present study, showcasing the distribution of sustainability metrics across material groups and highlighting the calculated impacts for a specified alloy composition. The plots are divided into four groups: Steels, Ni-based superalloys, FCC HEAs, and BCC HEAs (mainly refractory HEAs). Each violin represents the distribution of a specific indicator, with median values marked. The calculated impact values for a new alloy, based on its specified composition, are highlighted as a black dot, with each value prominently displayed in the title of the corresponding plot.

Case study

The dataset serves as a valuable tool for identifying promising compositional spaces while highlighting those with high societal impacts to avoid. In a recent study7, it was used to evaluate HEAs against high-temperature Ni-based superalloys and steels for their room-temperature strength-ductility trade-offs. Building on data from three prior studies16,17,18, we analyzed 340 HEA compositions and grouped them based on their potential applications. The first group consists of 225 grades for high-temperature applications. This includes BCC-type HEAs inspired by Refractory HEAs (RHEAs) introduced by Senkov and Miracle19 composed of refractory metals such as MoNbTaVW. It also encompasses BCC/B2 refractory superalloys (RSAs)20, and FCC/L12 high entropy superalloys (HESAs)21,22. The second group includes 115 FCC-type HEAs with a Face-Centered Cubic structure, inspired by the Cantor alloy (CoCrFeMnNi). These alloys, known for their strength and ductility at room temperature, were compared to commonly used steels for load-bearing and damage-tolerant applications. Figure 4 visualizes a set of 3 indicators among the 9 provided for a subset of 225 high entropy alloy (HEA) compositions that have appeared in the literature and 29 leading commercial Ni-based superalloys used in turbine blades since 1946.

Assessment of HEAs for potential high-temperature applications (BCC-type HEAs, RHEAs, BCC/B2 RSAs, and FCC/L12 HESAs vs Ni-based superalloys). The x-axis provides the maximum operating temperature, with the HEA data randomly placed around an arbitrary high ‘ambition’ temperature that reflects the goals pursued in RHEA research. Yeh’s HESAs are outlined in yellow, Senkov’s RHEAs in green. Higher indicator values are undesirable. Embodied Energy is given on the y-axis. Symbol size shows Human Health Damage (HHD) and color gives the Supply Risk (SR).

Code availability

Data processing, validation, and plotting were performed using Excel and Jupyter notebooks23 in a Python 3 environment using common scientific libraries. The Python package AlloySustainability, used for computing and visualizing alloy sustainability indicators, is openly available on PyPI at https://pypi.org/project/AlloySustainability/. Furthermore, the Alloy Social Impact Calculator is located at the Model Warehouse of the AI Machine Learning Platform of the High Entropy Materials Center (https://black-stone-0b1668410.3.azurestaticapps.net/#/materials_informatics); it can be accessed freely with registration.

References

Yeh, J. W. et al. Nanostructured High‐Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Advanced Engineering Materials 6, 299–303, https://doi.org/10.1002/adem.200300567 (2004).

Cantor, B., Chang, I. T. H., Knight, P. & Vincent, A. J. B. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A 375-377, 213–218, https://doi.org/10.1016/j.msea.2003.10.257 (2004).

Cann, J. L. et al. Sustainability through alloy design: Challenges and opportunities. Progress in Materials Science 117 https://doi.org/10.1016/j.pmatsci.2020.100722 (2021).

Fu, X., Schuh, C. A. & Olivetti, E. A. Materials selection considerations for high entropy alloys. Scripta Materialia 138, 145–150, https://doi.org/10.1016/j.scriptamat.2017.03.014 (2017).

Wang, X., Kramer, A., Glaubensklee, C., He, H., Schoenung, J.M. Sustainability-Based Selection of Materials for Refractory High Entropy Alloys. The Minerals, Metals & Materials Series https://doi.org/10.1007/978-3-030-92563-5_38 (2022).

Gorsse, S., Langlois, T. & Barnett, M. R. Sustainability indicators in high entropy alloy design: an economic, environmental, and societal database. figshare https://doi.org/10.6084/m9.figshare.28235162 (2025).

Gorsse, S., Langlois, T. & Barnett, M. R. Considering sustainability when searching for new high entropy alloys. Sustainable Materials and Technologies 40, e00938, https://doi.org/10.1016/j.susmat.2024.e00938 (2024).

Graedel, T. E., Harper, E. M., Nassar, N. T., Nuss, P. & Reck, B. K. Criticality of metals and metalloids. Proc Natl Acad Sci USA 112, 4257–4262, https://doi.org/10.1073/pnas.1500415112 (2015).

Ashby, M. F. Materials and the Environment. (2021).

Nassar, N. T., Lederer, G. W., Brainard, J. L., Padilla, A. J. & Lessard, J. D. Rock-to-Metal Ratio: A Foundational Metric for Understanding Mine Wastes. Environ Sci Technol 56, 6710–6721, https://doi.org/10.1021/acs.est.1c07875 (2022).

Herre, B. The ‘Varieties of Democraty’ Data: How Researchers Measure Human Rights?, https://ourworldindata.org/vdem-human-rights-data (2022).

Foundation, W. The Labour Rights Index Database, https://labourrightsindex.org/ (2022).

Ansys GRANTA EduPack software (ANSYS, Inc., Cambridge, UK, 2021).

Zhang, Z. Introduction to machine learning: k-nearest neighbors. Ann Transl Med 4, 218, https://doi.org/10.21037/atm.2016.03.37 (2016).

Pedregosa, F. et al. Scikit-learn: Machine Learning in Python. Journal of Machine Learning Research 12, 2825–2830 (2011).

Gorsse, S., Miracle, D. B. & Senkov, O. N. Mapping the world of complex concentrated alloys. Acta Materialia 135, 177–187, https://doi.org/10.1016/j.actamat.2017.06.027 (2017).

Gorsse, S., Nguyen, M. H., Senkov, O. N. & Miracle, D. B. Database on the mechanical properties of high entropy alloys and complex concentrated alloys. Data Brief 21, 2664–2678, https://doi.org/10.1016/j.dib.2018.11.111 (2018).

Borg, C. K. H. et al. Expanded dataset of mechanical properties and observed phases of multi-principal element alloys. Sci Data 7, 430, https://doi.org/10.1038/s41597-020-00768-9 (2020).

Senkov, O. N., Wilks, G. B., Miracle, D. B., Chuang, C. P. & Liaw, P. K. Refractory high-entropy alloys. Intermetallics 18, 1758–1765, https://doi.org/10.1016/j.intermet.2010.05.014 (2010).

Senkov, O., Isheim, D., Seidman, D. & Pilchak, A. Development of a Refractory High Entropy Superalloy. Entropy 18, https://doi.org/10.3390/e18030102 (2016).

Yeh, A. C. et al. Developing New Type of High Temperature Alloys–High Entropy Superalloys. International Journal of Metallurgical & Materials Engineering 1 https://doi.org/10.15344/2455-2372/2015/107 (2015).

Chen, Y.-T., Chang, Y.-J., Murakami, H., Gorsse, S. & Yeh, A.-C. Designing high entropy superalloys for elevated temperature application. Scripta Materialia 187, 177–182, https://doi.org/10.1016/j.scriptamat.2020.06.002 (2020).

Kluyver, T. et al. in 20th International Conference on Electronic Publishing. (ed and Loizides F. Schmidt B.).

Acknowledgements

This work has benefited from a government grant managed by the Agence Nationale de la Recherche under the France 2030 program; reference ANR-22-PEXD-0003. SG and MRB gratefully acknowledge the support of the CNRS through the IRP MALCOM initiative. The AI Machining Learning Platform website for the Social Impact Calculator is supported by the “High Entropy Materials Center” from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan.

Author information

Authors and Affiliations

Contributions

Stéphane Gorsse: Conceptualization; Methodology; Software; Validation; Formal analysis; Investigation; Data curation; Writing - original draft; Visualization; Supervision. Matthew Barnett: Conceptualization; Methodology; Validation; Formal analysis; Writing - review & editing; Supervision. Théo Langlois: Formal analysis; Investigation; Data curation; Writing - review & editing. An-Chou Yeh: Validation; Writing - review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Gorsse, S., Langlois, T., Yeh, AC. et al. Sustainability indicators in high entropy alloy design: an economic, environmental, and societal database. Sci Data 12, 288 (2025). https://doi.org/10.1038/s41597-025-04568-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-025-04568-x

This article is cited by

-

Sustainability of High Entropy Alloys and Do They Have a Place in a Circular Economy?

Metallurgical and Materials Transactions A (2025)