Abstract

Turbulence widely appears in natural and industrial environments, with its multi-scale structures posing significant challenges for accurate simulation and prediction. Nowadays, turbulence databases play a crucial role in advancing scientific research. However, existing turbulence databases primarily focus on fundamental turbulence problems and are predominantly limited to turbulent flows at low-to-moderate Reynolds number, making them insufficient to address high-Reynolds-number turbulence challenges in complex engineering applications. Under the support of National Natural Science Foundation of China, the research project “Integration research on construction of high Reynolds number turbulence databases and turbulence machine learning” has been conducted, leading to the establishment of the globally shared high-Reynolds-number turbulence database, AeroFlowData. This database is developed under the leadership of Northwestern Polytechnical University, in collaboration with eight research institutions in China. The project team employs numerical simulations, experimental measurements, and data assimilation methods to acquire turbulence data. AeroflowData currently includes nearly 40 models, covering hypersonic vehicles, civil aircrafts, and turbomachinery blades, with over 500 computational and experimental flow conditions and a total data of nearly 100TB.

Similar content being viewed by others

Background & Summary

Turbulence is widely prevalent in nature and engineering applications, such as in the atmosphere, oceans, aerospace, and gas turbines. Turbulence features extremely complex multiscale flow structures, making its accurate simulation and prediction a major challenge in fluid mechanics.

Turbulence research faces challenges such as difficulty in data acquisition, high acquisition costs, and large data storage requirements. Since the 1990s, with the continuous advancement of high-performance computing and rapid progress in experimental measurement techniques, extensive computational and experimental data have been accumulated. Numerous research institutions worldwide have successively established turbulence databases, providing data exchange and sharing in an open-access format via the internet, which has significantly promoted the progress and development of turbulence research.

Advisory Group for Aerospace Research and Development (AGARD) initiated efforts to validate computational fluid dynamics (CFD), leading to the establishment of the AGARD turbulence database (https://torroja.dmt.upm.es/turbdata/agard/). With the rapid development of large-scale computing over the past two decades, direct numerical simulation (DNS) was conducted on four fundamental turbulence problems, forming the turbulence database of the Technical University of Madrid (https://torroja.dmt.upm.es/turbdata/). In Europe, the European Research Community On Flow, Turbulence And Combustion (ERCOFTAC) organization collected extensive large eddy simulation (LES), DNS, and experimental data to create the flow database, which is publicly accessible online (http://cfd.mace.manchester.ac.uk/ercoftac). The turbulence database at Johns Hopkins University in the United States is one of the most well-known, currently consisting of DNS datasets for nine fundamental turbulence problems, with ongoing expansions1,2 (https://turbulence.idies.jhu.edu/). NASA’s Langley research center, in collaboration with multiple organizations, conducted numerical simulations and experimental studies focused on validating Reynolds-averaged Navier-Stokes (RANS) turbulence models, establishing an online RANS model validation database (https://turbmodels.larc.nasa.gov/). The turbulence and heat transfer laboratory at the University of Tokyo in Japan conducted DNS calculations and experimental studies on various fundamental turbulence problems, creating an online turbulence database that includes data on turbulence, heat transfer, and electromagnetic flows (https://thtlab.jp/). In China, National Space Science Data Center, in collaboration with China Aerodynamics Research and Development Center, launched the national numerical wind tunnel engineering CFD validation and verification database3 (https://www.nssdc.ac.cn/). This database includes experimental and numerical data for typical benchmark models, providing efficient support for the reliability assessment and testing of CFD software. Additionally, McConkey et al.4 (https://www.kaggle.com/datasets/ryleymcconkey/ml-turbulence-dataset) established a dataset for data-driven turbulence modeling, comprising DNS/LES and RANS data for five low-Reynolds-number flows.

These turbulence databases have played a significant role in advancing turbulence research. However, from the perspectives of engineering applications and machine learning, several limitations and deficiencies remain: (1) Most existing data focus on fundamental turbulence problems with simple boundaries, such as channel flows, pipe flows, isotropic turbulence, and flat-plate boundary layers. However, turbulence problems with complex boundaries that are more representative of aerospace engineering scenarios are rarely addressed. (2) The computational results in existing databases are primarily concentrated on turbulent flows at low-to-moderate Reynolds number. Experimental results, constrained by measurement technology, often lack the spatial and temporal resolution comparable to computational data.

Therefore, establishing a turbulence database for high-Reynolds-number complex flows in typical aerospace scenarios, systematically integrating experimental and computational data from relevant scientific research and engineering applications, holds significant practical value. This paper presents the first aerospace-oriented high-Reynolds-number turbulence database, AeroFlowData, facilitating efficient storage of massive heterogeneous turbulence data through a database sharing platform (https://aeroflowdata.nwpu.edu.cn/). AeroFlowData includes data from experiment, DNS, implicit LES (ILES), and detached eddy simulation (DES) for typical configurations such as hypersonic vehicles, civil aircrafts, and turbomachinery blades. Distinguishing from existing database, AeroFlowData offers a far richer variety of flow geometries— from canonical benchmark cases to realistic engineering configurations—enabling users to study turbulence over airfoils, bluff bodies and other complex shapes. Moreover, our dataset spans Reynolds numbers from the order of 104 up to 107, well beyond the typical 103–105 range of earlier databases, thereby providing data that bridge both fundamental turbulence studies and high-Reynolds-number engineering applications.

Methods

By employing CFD and experiment (EXP), a high-Reynolds-number turbulence database is developed. A summary of the datasets is provided in Table 1. The database includes numerical simulation and experimental data for typical configurations.

Supersonic/hypersonic turbulence

The supersonic/hypersonic turbulence dataset includes DNS and experimental data for representative configurations. Cases encompass flat plate, blunt cone, compression corner, incident shock wave and flat plate, and swept compression corner.

DNS data of supersonic/hypersonic turbulence

A summary of the cases is shown in Table 2. The inflow Mach number ranges from 2 to 8. The provided data content is shown in Table 12. Simulations is performed using the CPU-parallel computing program OpenCFD-SC and the CPU/GPU hybrid parallel computing program OpenCFD-SCU5. OpenCFD-SCU fully utilizes the floating-point computing advantages of GPUs, achieving speedups of over 100 times compared to OpenCFD-SC. These two CFD programs employ the finite difference method on structured grids. Convective terms are discretized using a 7th-order upwind scheme, viscous terms with a 6th-order central difference scheme, and time integration is performed using a 3rd-order Runge-Kutta scheme.

Ma is the Mach number, Re is the Reynolds number, L is the length of the wall, T∞ is the inflow temperature, Tw is the temperature of the wall, SR is the head radius of blunt cone, φ is the half cone angle of blunt cone, β is the turning angle of compression corner, α is the angle of attack, and γ is the swept angle for swept compression corner.

Flat plate

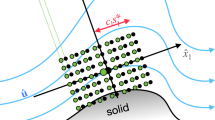

The boundary conditions are illustrated in Fig. 1. Profile of laminar flat plate boundary layer is applied at the inlet, non-reflective boundary conditions are used for the outlet and upper boundary, the wall is set as isothermal with no-slip conditions, and spanwise periodic boundary conditions are imposed. The computational parameters are listed in Table 2. Details of the calculations and results analysis can be found in the paper by Li et al.6,7,8,9 or on the AeroFlowData database website.

Flat plate boundary conditions9.

Figure 2 shows a schematic of the 2D cross-sectional grid for flat plate boundary layer at Ma = 2.25. The grid setup for the other three cases is similar, with differences in grid size and computational domain, as shown in Table 3.

Blunt cone

Blunt cones are typical configurations of supersonic and hypersonic vehicles. Investigating the boundary layer flow over their surfaces is a critical aspect of aerospace engineering. The boundary condition and grid are shown in Fig. 3. Profile of laminar blunt-cone boundary layer is applied at the inlet, non-reflecting boundary conditions are applied at the outlet and upper boundary, the wall is treated with an isothermal no-slip condition, and periodic boundary conditions are used in the circumferential direction. The computational parameters are listed in Table 2, and the grid specifications are provided in Table 4. Details of the calculations and results analysis can be found in the paper by Li et al.10 or on the AeroFlowData database website.

Grid configuration for blunt cone10.

Compression corner

Shock wave boundary layer interaction (SWBLI) is a common flow phenomenon in supersonic and hypersonic flight. The compression corner is one of the typical configurations used to study SWBLI. Profile of laminar flat plate boundary layer is applied at the inlet, non-reflecting boundary conditions are applied at the outlet and upper boundary, the wall is treated with isothermal no-slip boundary conditions, and periodic boundary conditions are applied in the spanwise direction. The computational parameters are provided in Table 2. Figure 4 illustrates the grid distribution for 24° compression corner case5,11. Table 5 provides the grid numbers and computational domains.

Incident shock wave and flat plate

Incident shock wave and flat-plate turbulent boundary layer interaction is a typical configuration for SWBLI, frequently observed within aircraft engines. The geometry and boundary conditions are illustrated in Fig. 5. Profile of laminar flat plate boundary layer is applied at the inlet, and non-reflecting boundary conditions are applied at the outlet boundary. The wall is treated with isothermal no-slip boundary conditions, while periodic boundary conditions are applied in the spanwise direction. At xs, a shock with an angle of 33.2° is introduced at the upper boundary, and the remaining sections apply non-reflecting boundary conditions. Computational parameters are provided in Table 2. The grid layout is illustrated in Fig. 5, with grid dimensions Nx × Ny × Nz = 3700 × 300 × 250, and computational domain Lx × Ly × Lz = 5.34 × 0.492 × 0.175 (inch).

Grid of incident shock wave and flat plate (grid points are displayed with intervals of 10 in x-direction and 4 in y-direction)35.

Swept compression corner

The swept compression corner is a typical configuration for studying three-dimensional SWBLI. At large sweep angles, the SWBLI of a swept compression corner exhibits “quasi-conical symmetry” characteristics12,13. This case is shown in Fig. 6, illustrating the symmetric swept compression corner configuration at Ma = 6, with a corner angle of 34° and a sweep angle of 45°. This symmetric configuration facilitates the application of spanwise boundary conditions. Profile of laminar flat plate boundary layer is applied at the inlet, non-reflecting boundary conditions are applied at the outlet and upper boundary, the wall is treated with isothermal no-slip boundary conditions, and periodic boundary conditions are applied in the spanwise direction. The computational parameters are listed in Table 2.

Symmetric swept compression ramp configuration36.

Figures 6, 7 illustrates the computational domain and grid distribution. The computational domain is divided into a core region and a buffer region. The grid in the core region is uniformly distributed along the spanwise direction and relatively dense, as this region is the primary focus during the simulations. The total grid resolution is Nx × Ny × Nz = 3800 × 320 × 1690. The computational domain dimensions for the core region are Lx × Ly × Lz = 499.7 × 55 × 70 (mm).

Mesh distribution at z = 30 mm cross-section of symmetric swept compression ramp (every 20 grid points)36.

Experimental data of hypersonic turbulence

Hypersonic experiments are conducted in a conventional hypersonic blowdown wind tunnel in China Academy of Aerospace Aerodynamics. The air is used as the working medium of wind tunnel. Before the experiment, the model surface is at room temperature. During the test, an infrared thermal imager begins data acquisition as the wind tunnel flow field is established and stabilized. The model is then quickly inserted into the center of the flow field, where it remains stable for approximately 5 seconds before being removed, marking the end of the experiment. The experimental models and main parameters are summarized in Table 6.

Flat plate

The flat plate model measures 480 mm in length and 300 mm in width, with a nominal sharp leading edge and a leading-edge wedge angle of 20°. The model consists of two sections: the leading edge and base are made of steel to ensure structural strength and rigidity, while the rear section is fabricated from polyether ether ketone (PEEK). This non-metallic material, commonly used in infrared thermal imaging experiments, features high emissivity and low thermal conductivity.

An infrared thermal imager is used to capture the surface temperature evolution of the model, identifying the surface heat flux distribution. The transition location and characteristics of the boundary layer are determined from the heat flux distribution. By adjusting the total pressure of the freestream, the unit Reynolds number is varied to obtain boundary layer transition data under different freestream conditions. Specific freestream conditions are listed in Table 6.

Blunt cone

The blunt cone has a half-cone angle of 7° and a total length of 476 mm (measured from the center of the spherical nose tip to the tail). The forward section of the model is made of metal, while the rear section is fabricated from PEEK material.

An infrared thermal imager is used to capture the surface temperature evolution of the model, from which the surface heat flux distribution is derived. The boundary layer transition location and characteristics are determined based on the heat flux distribution. The effect of different nose bluntness values on the boundary layer transition is studied at Ma = 4.94. Specific freestream conditions are listed in Table 6.

Compression corner

As shown in Fig. 8, the flat plate-compression ramp model is 480 mm long and 300 mm wide, with the compression ramp located 350 mm downstream from the leading edge of the plate. The ramp is 180 mm wide, with a compression angle of 34° and a height of 30 mm (measured from the highest point of the wedge surface to the flat plate). The front section and base of the model are made of steel to ensure rigidity and strength, while the rear section of the flat plate and the compression ramp are made from PEEK material.

Flow conditions are provided in Table 6. Infrared thermography is used in this experiment to measure the surface heat flux. Liquid crystal shear stress technology determines the surface friction distribution, while oil flow visualization captures surface streamlines. Schlieren photography reveals shock wave structures, and Kulite dynamic pressure sensors measure surface fluctuation characteristics.

Turbulence over civil aircraft

This dataset includes numerical simulation data based on DES and wind tunnel experimental data, covering the RAE2822 transonic airfoil, S809 wind turbine airfoil, 30P30N airfoil, CRM wing-body, HiLiftPW-3, CHN-T1, M6 wing, NACA0012 airfoil, NPU airfoil, and cylinder.

DES data of civil aircraft

The Reynolds number corresponding to civil aircraft is typically on the order of tens of millions, which presents significant challenges for numerical simulation of wall-bounded turbulence. Reynolds-averaged methods (RANS) are capable of simulating the mean flow and are widely used in engineering applications. However, if further focus is placed on flow separation, unsteady pulsations, or aerodynamic noise, unsteady simulation methods with scale resolution are required. Due to the computational cost at high Reynolds numbers, DNS and LES are not feasible. Therefore, we employ a DES-based method for numerical simulations, using the China open-source CFD software PHengLEI14 with the improved delayed DES (IDDES) model, which is constructed based on Spalart-Allmaras (SA)/ shear-stress transport (SST) model. The IDDES model is suitable for solving complex turbulence at high Reynolds numbers. Roe scheme is employed for spatial discretization and LU-SGS method is used for time discretization. The simulation cases and flow conditions are summarized in Table 7. All of our cases are external-flow simulations, for which we impose standard far-field boundary conditions at the domain inlet, without synthetic or prescribed turbulent inlet conditions. Turbulence then develops naturally downstream. The resolved turbulence naturally develops downstream through boundary-layer instabilities, separation, and shear-layer roll-up without prescribed inlet fluctuations.

RAE2822 airfoil

RAE2822 airfoil15 has been a challenging case for studying SWBLI in transonic flow. It serves as an excellent example to assess the combined effects of numerical schemes and turbulence models. Extensive research on this airfoil has been conducted in both academic and industrial fields, and a rich set of experimental data is available, making it ideal for investigating transonic flow phenomena.

Numerical simulations are performed using the SA-IDDES method. The flow condition is shown in Table 7. The Reynolds number is based on the airfoil chord length and the flow conditions of the far field. The wall is treated as no-slip adiabatic wall, the far-field boundary condition is set as non-reflecting boundary condition, and spanwise slip boundary conditions are imposed. The shape of the airfoil is shown in Fig. 9, and the computational grid consists of approximately 26 million cells, with grid details presented in Fig. 10. The far-field boundary lies 20 c from the wall of airfoil, while the spanwise extensions are 0.1 c (200 cells).

S809 airfoil

The S809 airfoil16 is a laminar airfoil designed for horizontal-axis wind turbine blades and is one of the 25 airfoils developed by the National Renewable Energy Laboratory (NREL). It serves as the blade airfoil in a series of unsteady aerodynamic experiments conducted by NREL for horizontal-axis wind turbines, making it a key object of study for understanding the aerodynamic performance of wind turbine airfoils.

Numerical simulations are performed using the SA-IDDES method. The flow condition is shown in Table 7. The Reynolds number is based on the airfoil chord length and the flow conditions of the far field. The wall is treated as no-slip adiabatic wall, the far-field boundary condition is set as non-reflecting boundary condition, and spanwise periodic boundary conditions are imposed. The schematic of the airfoil is shown in Fig. 11, and the computational mesh, comprising approximately 9 million cells, is detailed in Fig. 12. The far-field boundary lies 30 c from the wall of airfoil, while the spanwise extensions are 0.4 c (80 cells).

30 P30N three-element airfoil

The 30P30N17 three-element airfoil is a high-lift configuration developed by McDonnell Douglas. Both the slat and flap deflection angles are set to 30°. The 30P30N airfoil exhibits highly complex flow phenomena.

Numerical simulations are performed using the SST-IDDES method. The flow condition is shown in Table 7 and other boundary conditions are the same as RAE2822 airfoil. The Reynolds number is based on the stowed chord length and the flow conditions of the far field. The computational grid consists of approximately 140 million cells, with grid details shown in Fig. 13. The far-field boundary lies 90 c from the wall of airfoil, while the spanwise extensions are 0.1 c (136 cells).

CRM wing body

Common Research Model18 (CRM) is developed through collaboration between NASA’s Subsonic Fixed Wing (SFW) aerodynamic technology team and the Drag Prediction Workshop (DPW) organizing committee. The primary goal of the CRM is to provide a benchmark geometry for the validation and verification of CFD methods. The CRM represents a typical modern transport aircraft configuration, with the wing-body combination (CRM-WB) being one of its common configurations.

Numerical simulations are conducted using the SA-IDDES method. The wall is treated as no-slip adiabatic wall, the far-field boundary condition is set as non-reflecting boundary condition, and symmetry boundary condition is applied in the spanwise direction. The Reynolds number is based on the mean aerodynamic chord (MAC) and the flow conditions of the far field. The geometric configuration is shown in Fig. 14, and the computational grid consists of approximately 40 million cells, with grid details illustrated in Fig. 15.

HiLiftPW-3

The High Lift Prediction Workshops (HiLiftPW)19 configurations are released at the AIAA High-Lift Configuration Series Conference. Its primary purpose is to evaluate the capability of modern CFD techniques in simulating the aerodynamic characteristics of transport aircraft with low-speed, high-lift configurations, and to explore the complex mechanisms of flow around high-lift configurations. Extensive experiments have been conducted on this configuration to provide guidance for the further development of CFD techniques. For related research, Li et al.20 used SA-IDDES with a 350 million-cell mesh on the NASA High-Lift Common Research Model, demonstrating DES methods’ superior accuracy over RANS in capturing vortex dynamics and surface loads.

We simulate HiLiftPW-3 using the SST-IDDES method. The flow condition is shown in Table 7 and other boundary conditions are the same as CRM-WB. The Reynolds number is based on the MAC and the flow conditions of the far field. The HiLiftPW-3 configuration is shown in Fig. 16, and the computational grid consists of approximately 90 million cells. Grid details are illustrated in Fig. 17.

CHN-T1

China Transport-1 (CHN-T1) is a standard transport aircraft model developed by the China Aerodynamics Research and Development Center (CARDC). It features a narrow-body fuselage and supercritical wings. The model includes components such as the fuselage, wings, horizontal tail, vertical tail, nacelles, pylons, and landing gear fairings21. However, the nacelles and pylons are excluded in the standard model calculations.

Numerical simulations are conducted using the SA-IDDES and SST-IDDES. The flow condition is shown in Table 7 and other boundary conditions are the same as CRM-WB. The Reynolds number is based on MAC and the flow conditions of the far field. The CHN-T1 configuration is shown in Fig. 18, and the grid contains approximately 50 million grid points.

M6 wing

The M6 wing is primarily used to validate and test the capabilities of CFD software and wind tunnel experiments22. It provides a standard test case to evaluate different methods for capturing complex aerodynamic phenomena.

Figure 19 shows M6 wing configuration. The total grid count is approximately 32 million, and the computational flow field domain extends about 41 times the wing’s span. Numerical simulations are conducted using the SA-IDDES. The flow condition is shown in Table 7 and other boundary conditions are the same as CRM-WB. The Reynolds number is based on MAC and the flow conditions of the far field.

Delta wing

NASA 65° delta wing23 is a commonly used model for research and testing purposes, extensively employed to study flow characteristics, vortex structures, and aerodynamic performance at high angles of attack. This model is typically used in wind tunnel experiments and numerical simulations to understand the flow behavior of delta-wing aircraft, especially the complex vortex phenomena under high-angle-of-attack conditions. Figure 20 shows the three-view and detailed parameters of the model.

Three-view of the delta wing37.

The mesh is unstructured, with a total of approximately 32 million cells (for a half-model). Numerical simulations are conducted using the SST-IDDES. The flow condition is shown in Table 7 and other boundary conditions are the same as CRM-WB. The Reynolds number is based on MAC and the flow conditions of the far field.

Experimental data of airfoil and cylinder

Flow conditions for experimental data of airfoil and cylinder are shown in Table 8. These experiments are conducted in the wind tunnel laboratories from three institutions in China.

Experiments of Northwestern Polytechnical University (NPU) airfoil and NACA0012 airfoil at moderate-to-high Reynolds numbers are conducted in the NF-3 low-speed wind tunnel at National Key Laboratory of Aircraft Configuration Design, Northwestern Polytechnical University. The NF-3 wind tunnel is a closed-loop wind tunnel with a direct-current motor system and an all-steel structure, measuring 84 meters in total length. The wind tunnel comprises an inlet section, a contraction section, a diffusion section, a power section, and three interchangeable test sections. The wind tunnel’s primary test section has a rectangular cross-section with dimensions of 8 m × 1.6 m × 3 m (length × width × height) and a contraction ratio of 20. The incoming freestream turbulence intensity is 0.045%, with a wind speed range of 10 m/s to 100 m/s.

Experiments of NACA0012 airfoil at low Reynolds numbers are conducted in the low-speed wind tunnel at Key Laboratory of Education Ministry for Power Machinery and Engineering, Shanghai Jiaotong University. The test section dimensions are 2 m × 0.3 m × 0.3 m (length × width × height). An 800 mm long exit section is installed downstream of the test section to mitigate the effects of wind tunnel exit reflections on the test results. The experimental centrifugal fan is driven by a 1.5 kW variable-frequency motor, with wind speed adjustable in the range of 2 to 30 m/s through a digital frequency converter. The velocity in the core region is maintained with an average deviation of less than 0.7%, and the background turbulence intensity in the freestream core region remains below 0.6%.

Experiments of cylinder are conducted in the No. 2 precision wind tunnel (SMC-WT2) of the Joint Laboratory of Wind Tunnel and Wave Flume at Harbin Institute of Technology. The wind tunnel is a closed-circuit type with a test section measuring 0.8 m × 1.2 m × 3.0 m (length × width × height). The wind speed ranges from approximately 3.0 to 23 m/s, with a turbulence intensity of less than 0.4%. To accommodate experiments at lower wind speeds, rectifying grids can be added to the contraction and diffusion sections of the wind tunnel, allowing the minimum wind speed to be adjusted to approximately 1.0 m/s.

NPU airfoil

The experimental model is constructed with a metal framework and a fiberglass-reinforced skin. The model has a total length of 1595 mm and a chord length of 600 mm. Surface pressure taps are densely distributed near the leading and trailing edges, with a total of 100 pressure taps on the airfoil surface. The inner diameter of each tap is 0.7 mm, and the outer diameter is 1.2 mm. The wake rake is positioned at 1.26 times the chord length from the trailing edge of the airfoil.

Pressure measurement, transition detection, and particle image velocimetry (PIV) experiments are conducted on the NPU airfoil model, shown in Fig. 21, under Rec = 4.1 × 105~2.8 × 106, α = −4°~30°. Using static pressure measurement techniques, surface pressure data for the NPU airfoil are obtained. From these, lift coefficients, drag coefficients, moment coefficients, and lift-to-drag ratio curves are further calculated. Two-dimensional PIV techniques are employed to capture the velocity field around the NPU airfoil, providing statistical characteristics of the flow field. The obtained data included the distribution of velocity fluctuation fields, time-averaged fields, and the flow separation behavior under different flow conditions. Finally, naphthalene sublimation transition detection technology is employed to determine the transition positions on both the upper and lower surfaces of the airfoil under varying Reynolds numbers and angles of attack.

NACA 0012 airfoil at moderate to high Reynolds number

The NACA0012 airfoil is a traditional symmetric airfoil with a relative thickness of 12%. Pressure measurements, transition detection, and PIV experiments are conducted on the NACA0012 airfoil model, shown in Fig. 22, under Rec = 4.1 × 105~2.8 × 106, α = −4°~30°. The measurement techniques and data types are consistent with those used for the NPU airfoil.

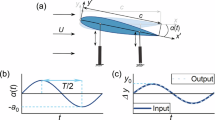

NACA 0012 airfoil at low reynolds number

The low-Reynolds-number experiments for the NACA0012 airfoil are conducted using TR-PIV measurements coordinated by a LabVIEW program. The airfoil used in the experiments has a chord length of 150 mm. Measurements are carried out at angles of attack of 8°, 10° and 12°, with Reynolds numbers of 77,000, 117,000, and 157,000, respectively. The PIV flow fields near the airfoil are successfully obtained.

Cylinder

For experiment of cylinder, freestream velocity ranges from 3 m/s to 15.8 m/s, targeting a rigid hollow cylinder with an outer diameter of 0.12 m, a spanwise length of 0.78 m, and a wall thickness of 3 mm, corresponding to a Reynolds number range of 2.43 × 104 to 1.26 × 105. Quartz sand particles with a mesh size of 36 are applied to roughen the surface of the test object. The flow in this experiment spans subcritical, critical, and supercritical states, ensuring comprehensive data covering all Reynolds number characteristics. PIV is utilized to measure the wake velocity field, and pressure data are acquired via pressure taps distributed circumferentially. A total of 36 pressure taps is evenly spaced at 10° intervals. A schematic diagram of the model and measurement region is shown in Fig. 23. The PIV measurement cross-section is selected to be at a spanwise distance of 1D (0.12 m) from the cylinder’s mid-span.

Experimental setup38. (a) Diagram of the model, (b) Measurement region.

Turbulence over turbomachinery blade

ILES Data of Turbine Blade

For the flow problems in aeroengine, a high-fidelity hp spectral element method based on Discontinuous Galerkin (DG) is adopted. This method has advantages such as low dissipation, low dispersion, small numerical errors, the ability to adapt to complex structures, and ease of large-scale parallelization. Implicit large eddy simulation is employed for turbulence simulations. By introducing appropriate numerical dissipation, it mimics the effect of unresolved turbulent scales on the resolvable flow scales, avoiding the direct use of subgrid models.

Based on the above method, typical turbine blades such as the VKI LS89, T106A, and T106C are used as test cases. ILES simulations are conducted to capture boundary layer transition, wake, and wake interference in turbulent flow with high temporal and spatial resolution.

The computations are conducted using ATHOS24,25. The solver supports linear tensorial elements (e.g., linear quadrilateral and hexahedral elements) and achieves up to third-order spatial accuracy. Correction functions are selected to restore configuration-based nodal DG schemes. ILES simulations of the three blade configurations utilize an HLLC Riemann solver within the flux reconstruction framework of the DG method. A fourth-order five-step Runge-Kutta scheme is used for explicit time advancement. All cases are computed using unstructured grids. Numerical simulation data are summarized in Table 9.

T106A turbine blade

ILES of the T106A turbine cascade26 is conducted, with periodicity in the spanwise direction, focusing on transition and separation flows. It has been extensively studied in the literature and serves as a standard test case in international workshops on high-order computational fluid dynamics methods. The configuration is shown in Fig. 24.

The flow in the T106A turbine cascade is subsonic, with computations conducted at a Reynolds number of 60,000. The Reynolds number is based on the blade chord length and the flow conditions at the exit boundary. The incoming turbulence intensity is very low, and the flow exhibits characteristics of laminar separation and reattachment transition. The blade walls are modelled as adiabatic boundaries, and other boundary conditions are shown in Table 9. The computational grid consists of 2,755,296 elements, and the grid layout is illustrated in Fig. 25. The spanwise width of the grid is 0.1 c, which is discretized with 10 high-order DG cells, and it is the same for the next two cases.

T106C turbine blade

The geometry of the T106C turbine stator, as shown in Fig. 26, involves subsonic flow. The Reynolds number, based on the blade chord length and exit boundary conditions, is 80,000. The blade wall is treated with an adiabatic boundary condition, and other boundary conditions are shown in Table 9. The grid consists of 3,019,032 elements, and the grid schematic is shown in Fig. 27.

LS89 turbine blade

High-pressure turbine blade LS8927, as shown in Fig. 28, was extensively studied in experiments conducted by Arts et al.27, focusing on turbine blades without cooling under various Mach numbers, Reynolds numbers, and free-stream turbulence intensities. These conditions provide a challenging yet suitable test case for predicting transition and heat transfer on the blade surface. The flow conditions in the current study are MUR129, with an inlet turbulence intensity of 0.8%. The Reynolds number is 1.13 × 106, based on the blade chord length and exit boundary conditions. The wall temperature is 297.75 K, with an isothermal boundary condition applied to the blade surface, and other boundary conditions are shown in Table 9. The grid consists of 6,592,050 elements, and the grid schematic is shown in Fig. 29.

Experimental data of compressor blade

A series of experiments of compressor blade are conducted at the high-performance compressor cascade laboratory of Northwestern Polytechnical University. The test platform is a continuous high subsonic linear cascade wind tunnel. The wind tunnel is equipped with a complete boundary layer suction system, which allows flexible control of the inlet flow quality and the axial velocity density ratio in the test section. The maximum test section size is 100 mm × 300 mm, with an inlet Mach number range from 0.3 to 0.95 and an adjustable inlet flow angle range from 0° to 90°.

Both the A1 and A2 blades are subsonic compressor blade independently designed by NPU. The geometry and parameter definitions of these blades are shown in Fig. 30. They are characterized by a narrow diffusion passage and a high-curvature geometric profile. The summary of the flow conditions is presented in Table 10.

The wind tunnel platform is equipped with advanced measurement tools and devices, including steady and dynamic state total pressure probes, multi-hole aerodynamic probe, hot-wire anemometry, oil-flow visualization techniques, PIV, optical Pressure-Sensitive Paint (PSP) pressure measurement technology, and multi-channel pressure scanning acquisition systems. The measurement accuracy and range of the wind tunnel tests have been thoroughly validated through extensive compressor cascade wind tunnel experiments.

Data assimilation

Experiments can measure various flow field physical quantities, but it is challenging to obtain comprehensive multi-physics distributions, especially three-dimensional field. Additionally, experimental measurement results are often limited in spatial resolution and scope. These limitations can be addressed using data assimilation methods, which supplement turbulence databases. This project investigates data assimilation calculations to enhance flow field information.

By constraining experimental sparse data through data assimilation, inaccessible data can be obtained, including global three-dimensional flow field distributions, spatial pressure and density distributions, and Reynolds stress distributions. Data assimilation can also reproduce experimentally measurable data, such as local velocity and pressure, to compare and validate experimental data, thereby assessing the accuracy of data assimilation.

Three data assimilation methods are used for the cases in Table 11. For 30P30N three-element airfoil and delta wing, a continuous adjoint-based data assimilation method is employed to correct the additional body force term of the RANS equations. For the S805/S809 airfoil and M6 wing cases, data assimilation methods based on optimization algorithms or ensemble Kalman filtering are used to correct the turbulence model coefficients. For NASA hump, discrete adjoint method is employed to inverse the corrected terms of turbulent transport equation of SST model.

30P30N three-element airfoil

The flow over the 30P30N three-element airfoil is used as a benchmark case to evaluate the proposed data assimilation model to reconstruct the global flow field from sparse wall pressure measurements17,28. Continuous adjoint-based data assimilation method is employed. The geometry and grid are shown in Fig. 31. Following a grid independence test, a grid resolution of 500 × 240 was adopted in the streamwise and wall-normal directions.

Geometry and grid of 30P30N three-element airfoil28.

Delta wing

The computational domain of the delta wing is shown in Fig. 32. The grid of data assimilation contains 2.3 million grid points. The same data assimilation method as the30P30N case is used for this case.

Computational domain of the delta wing28.

S805/S809 airfoil

The S80529 and S80916 airfoils are important subjects for studying the aerodynamic performance of wind turbine airfoils. The configurations and mesh layout are illustrated in Fig. 33, with approximately 34,000 grid points used in the numerical simulation during data assimilation. The teaching–learning-based optimization (TLBO) method was employed to optimize nine empirical parameters of the SA model, enhancing the alignment between the simulated surface pressure distribution and experimental data30.

S805/S809 configurations and grids30. (a) Geometry, (b) Grid.

M6 wing

The geometry and computational grid of the M6 wing are shown in Fig. 19, with a grid size of approximately 2.4 million. The ensemble Kalman filter algorithm was used to optimize the empirical parameters of the SA model. Unlike the assimilation for the S805/S809 case, this case optimizes seven parameters of the original SA model, excluding those related to transition. The observational data consist of experimental pressure coefficients at seven spanwise sections of the wing, with specific section parameters.

NASA-hump

The NASA-hump case involves an incompressible flow with large separation at a high Reynolds number. Experimental data31 and LES data32 for this case have been accumulated in recent years, making the data rich and suitable for data assimilation. The baseline SST model tends to overestimate the size of the separation region (delayed reattachment point) in this case. This issue also arises in many other cases, making this case study highly representative.

The geometric features and boundary conditions of this case study are shown in Fig. 34. The case is solved using the incompressible solver in DAFoam (similar to OpenFOAM’s SimpleFoam). The discrete adjoint method is employed for data assimilation. The grid used is the structured grid provided by NASA (409 × 109, a third-level dense grid), with a total grid count of 44,064.

NASA hump and boundary condition39.

Data Records

The database AeroFlowData is hosted on website https://aeroflowdata.nwpu.edu.cn/. The currently released data is close to 100 TB. The dataset includes three-dimensional instantaneous and averaged flow field variables, surface pressure distributions, friction distributions, oil flow patterns, spatial schlieren images, and more. Details of each dataset are listed in Table 12.

Technical Validation

We provide a comparison between numerical simulation results and experimental results in the attachment. Validation comparisons are conducted for hypersonic DNS data of compression corner at Ma = 2.9, DES data of 30P30N, ILES data of T106A turbine blade, and data assimilation of delta wing and S805/809 airfoils. From the figures in the following, it can be observed that these numerical simulation methods exhibit high accuracy, which supports its use for further data-driven modeling studies.

For the validation of the DNS simulation method, we provide a comparison of surface pressure distribution between the computed and experimental results for compression corner at Ma = 2.9. As shown in Fig. 35, the predicted shock position and separation zone plateau align well with the experimental data of Bookey et al.33.

Comparison of surface pressure distribution for compression corner at Ma = 2.911.

For the validation of the DES simulation method, we present a comparison of the computed and experimental surface pressure distributions for the 30P30N three-element airfoil. As shown in Fig. 36, the numerical results closely match the experimental data34.

For the validation of the ILES simulation method, we present a comparison of the computed and experimental surface pressure distributions for T106A turbine blade26. As shown in Fig. 37, the numerical results closely match the experimental data.

For the validation of the DA method, we present the comparison of surface pressure distribution between DA and experiment for the delta wing. As shown in Fig. 38, the results of DA closely match the experimental data of Konrath et al.23.

Comparison of pressure coefficient of EXP23, wall-modeled LES, and DA for delta wing.

Additionally, we present the DA results for the separated flow over the S805/S809 airfoils at a high angle of attack. As shown in Fig. 39, the accuracy of pressure coefficient is significantly improved after data assimilation.

Comparison of pressure distribution for the S805/S809 airfoils30. (a) S809, α = 12.2°, (b) S809, α = 14.2°, (c) S805, α = 12.2°, (d) S805, α = 15.2°.

Usage Notes

The data are mainly in Tecplot, OpenFOAM, and OpenCFD formats, which can be directly visualized via Tecplot or ParaView software or conversed by post-processing programs. Besides turbulence data, the non-dimensionalization methods of physical quantities for each case are available on AeroFlowData website. The website also provides data-reading programs that allow direct reading of data files using Fortran, Matlab, or Python for post-processing and data-driven modeling. Registration for data access is open to any qualified researcher. After creating an account, all files can be downloaded without fee.

Code availability

The database and post-processing codes are available at https://aeroflowdata.nwpu.edu.cn/.

References

Li, Y. et al. A Public Turbulence Database Cluster and Applications to Study Lagrangian Evolution of Velocity Increments in Turbulence. J. Turbul., N31 (2008).

Perlman, E., Burns, R., Li, Y. & Meneveau, C. Data Exploration of Turbulence Simulations Using a Database Cluster. (Proceedings of the 2007 ACM/IEEE Conference on Supercomputing, Reno, USA, 2007).

Computational Aerodynamics Institute of China Aerodynamics Research and Development Center. Verification and Validation Calibration Model Database. 1.0. (2023).

McConkey, R., Yee, E. & Lien, F. S. A Curated Dataset for Data-Driven Turbulence Modelling. Sci. Data 8 (2021).

Dang, G., Liu, S., Guo, T., Duan, J. & Li, X. Direct Numerical Simulation of Compressible Turbulence Accelerated by Graphics Processing Unit: An Open-Access Database of High-Resolution Direct Numerical Simulation. AIP Advances 12 (2022).

Li, X.-L., Fu, D.-X. & Ma, Y.-W. Direct Numerical Simulation of a Spatially Evolving Supersonic Turbulent Boundary Layer at Ma=6. Chin. Phys. Lett. 23, 1519–1522 (2006).

Li, X.-L., Fu, D.-X., Ma, Y.-W. & Gao, H. Acoustic Calculation for Supersonic Turbulent Boundary Layer Flow. Chin. Phys. Lett. 26 (2009).

Liang, X. & Li, X. Direct Numerical Simulation on Mach Number and Wall Temperature Effects in the Turbulent Flows of Flat-Plate Boundary Layer. Communications in Computational Physics 17, 189–212 (2015).

Li, X., Tong, F.-L., Yu, C.-P. & Li, X.-L. Statistical Analysis of Temperature Distribution on Vortex Surfaces in Hypersonic Turbulent Boundary Layer. Phys. Fluids 31 (2019).

Li, X., Fu, D. & Ma, Y. Direct Numerical Simulation of Hypersonic Boundary-Layer Transition over a Blunt Cone. AIAA J. 46, 2899–2913 (2008).

Li, X., Fu, D., Ma, Y. & Liang, X. Direct Numerical Simulation of Shock/Turbulent Boundary Layer Interaction in a Supersonic Compression Ramp. Science China-Physics Mechanics & Astronomy 53, 1651–1658 (2010).

Settles, G. S. & Lu, F. K. Conical Similarity of Shock Boundary-Layer Interactions Generated by Swept and Unswept Fins. AIAA J. 23, 1021–1027 (1985).

Settles, G. S. & Kimmel, R. L. Similarity of Quasiconical Shock-Wave Turbulent Boundary-Layer Interactions. AIAA J. 24, 47–53 (1986).

Zhao, Z. et al. Phenglei:A Large Scale Parallel CFD Framework for Arbitrary Grids. Chinese Journal of Computers 42, 2368–2383 (2019).

Cook, P., Firmin, M. & McDonald, M. Aerofoil Rae 2822: Pressure Distributions, and Boundary Layer and Wake Measurements. (RAE, 1977).

Somers, D. M. Design and Experimental Results for the S809 Airfoil. Report No. NREL/SR-440-6918, (National Renewable Energy Lab.(NREL), Golden, CO (United States), 1997).

Ashton, N., West, A. & Mendonça, F. Flow Dynamics Past a 30p30n Three-Element Airfoil Using Improved Delayed Detached-Eddy Simulation. AIAA J. 54, 3657–3667 (2016).

Tinoco, E. N. et al. Summary Data from the Sixth Aiaa Cfd Drag Prediction Workshop: Crm Cases. Journal of Aircraft 55, 1352–1379 (2018).

Rumsey, C. L., Slotnick, J. P. & Sclafani, A. J. Overview and Summary of the Third Aiaa High Lift Prediction Workshop. Journal of Aircraft 56, 621–644 (2019).

Li, Q., Sun, X. & Wang, G. Detached-Eddy Simulation of the Vortex System on the High-Lift Common Research Model. Phys. Fluids 36 (2024).

Yaobing, Z., Jing, T., Jiangtao, C. & Youqi, D. Aerodynamic Characteristics Prediction of Chn-T1 Standard Model with Unstructured Grid. Acta Aerodynamica Sinica 37, 262–271 (2019).

Schmitt, V. & Charpin, F. Agard Advisory Report No. 138: Experimental Data Base for Computer Program Assessment. AGARD Advisory Report (1979).

Konrath, R., Klein, C., Engler, R. & Otter, D. Analysis of Psp Results Obtained for the Vfe-2 65° Delta Wing Configuration at Sub-and Transonic Speeds. 44th AIAA Aerospace Sciences Meeting and Exhibit, 60 (2006).

Huynh, H. T. A Flux Reconstruction Approach to High-order Schemes Including Discontinuous Galerkin Methods. (18th AIAA computational fluid dynamics conference, Miami, USA, 2007).

Wang, F. On the Implicit Large Eddy Simulation of Turbomachinery Flows Using the Flux Reconstruction Method. Comput. Fluids 284 (2024).

Stadtmüller, P. Investigation of Wake-Induced Transition on the Lp Turbine Cascade T106a-Eiz. DFG-Verbundprojekt Fo 136 (2001).

Arts, T., De Rouvroit, M. L. & Rutherford, A. Aero-Thermal Investigation of a Highly Loaded Transonic Linear Turbine Guide Vane Cascade. (von Karman Institute for Fluid Dynamics, 1990).

Li, S., He, C., Wang, W. & Liu, Y. Flow Enhancement from Wall Pressure Observations: A Compressible Continuous Adjoint Data Assimilation Model. Phys. Fluids 35 (2023).

Somers, D. M. Design and Experimental Results for the S805 Airfoil. (National Renewable Energy Lab.(NREL), Golden, CO (United States), 1997).

Shan, X., Liu, Y., Cao, W., Sun, X. & Zhang, W. Turbulence Modeling Via Data Assimilation and Machine Learning for Separated Flows over Airfoils. AIAA J. 61, 3883–3899 (2023).

Naughton, J. W., Viken, S. & Greenblatt, D. Skin-Friction Measurements on the Nasa Hump Model. AIAA J. 44, 1255–1265 (2006).

Avdis, A., Lardeau, S. & Leschziner, M. Large Eddy Simulation of Separated Flow over a Two-Dimensional Hump with and without Control by Means of a Synthetic Slot-Jet. Flow Turbul. Combust. 83, 343–370 (2009).

Bookey, P., Wyckham, C., Smits, A. & Martin, P. New Experimental Data of STBLI at DNS/LES Accessible Reynolds Numbers. (43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, USA, 2005).

Pascioni, K., Cattafesta, L. N. & Choudhari, M. M. An Experimental Investigation of the 30P30N Multi-element High-lift Airfoil. (20th AIAA/CEAS aeroacoustics conference, Atlanta, USA, 2014).

Duan, J., Tong, F., Li, X. & Liu, H. Decomposition of Mean Skin Friction in Incident Shock Wave/Turbulent Boundary Layer Interaction Flows at Mach 2.25. Chinese Journal of Aeronautics 36, 178–194 (2023).

Zhang, J., Guo, T., Dang, G. & Li, X. Direct Numerical Simulation of Shock Wave/Turbulent Boundary Layer Interaction in a Swept Compression Ramp at Mach 6. Phys. Fluids 34 (2022).

Konrath, R., Klein, C., Engler, R. & Otter, D. Analysis of PSP results obtained for the VFE-2 65° delta wing configuration at sub-and transonic speeds. (44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, USA, 2006).

Mi, J., Jin, X. & Li, H. Cascade-Net for Predicting Cylinder Wake at Reynolds Numbers Ranging from Subcritical to Supercritical Regime. Phys. Fluids 35 (2023).

Wu, C., Zhang, S. & Zhang, Y. Development of a Generalizable Data-Driven Turbulence Model: Conditioned Field Inversion and Symbolic Regression. AIAA J. 63, 687–706 (2025).

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 92152301).

Author information

Authors and Affiliations

Contributions

Weiwei Zhang: Conceptualization, Project administration, Funding acquisition, Supervision, Methodology, Writing – Review & Editing. Xianglin Shan: Writing – Original Draft, Data Curation, Formal analysis, Methodology (Data assimilation). Yilang Liu: Supervision, Methodology (Data assimilation), Writing – Review & Editing. Xiao Zhang: Software, Data Curation, Formal analysis, Writing – Review & Editing. Zhenhua Wan: Methodology (DES of civil aircraft), Writing – Review & Editing, Validation. Xinliang Li: Methodology (Hypersonic DNS), Writing – Review & Editing, Validation. Xinguo Sha and Junbo Zhaoi: Methodology (Hypersonic Experiments), Writing – Review & Editing, Validation. Hui Xu: Methodology (ILES of Engine Blades), Writing – Review & Editing, Validation. Chuangxin He and Yingzheng Liu: Methodology (Data assimilation), Writing – Review & Editing, Validation. Zhenhua Xia: Methodology (DES of civil aircraft), Writing – Review & Editing, Validation. Wenfeng Li: Methodology (Experiment of airfoils), Writing – Review & Editing, Validation. Limin Gao: Methodology (Experiment of compressor blades), Writing – Review & Editing, Validation. Xiaowei Jin and Hui Lin: Investigation (Experiment of cylinder), Writing – Review & Editing, Validation. Fei Liao: Supervision, Writing – Review & Editing. Yufei Zhang: Methodology (Data Assimilation), Writing – Review & Editing, Validation. Gang Chen: Supervision, Writing – Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licens/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, W., Shan, X., Liu, Y. et al. High-Reynolds-Number Turbulence Database: AeroFlowData. Sci Data 12, 1500 (2025). https://doi.org/10.1038/s41597-025-05846-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41597-025-05846-4