Abstract

Advanced modified polyacrylonitrile (PAN) membrane with high adsorption property for heavy metal ions was designed and fabricated for the first time. The introduced diazoresin-ethylenediaminetetraacetic acid (DR-EDTA) layer could effectively absorb the metal ion, such as Cu2+, Pb2+, Hg2+ in the waste water. The effects of layers, metal ion concentration, pH, temperature and cycle time were investigated. The results showed that the adsorption isotherms for Cu2+ were well fitted by Langmuir model. The maximum adsorption capacity of the modified membrane for Cu2+ was approximately 47.6 mg/g. In addition, the prepared PAN-(DR-EDTA)3 membrane could be regenerated more than 720 h based on their adsorption/desorption cycles. The results demonstrated that the modified PAN membrane could be used as effective adsorbents for heavy metal removal from waste water.

Similar content being viewed by others

Introduction

Nowadays, the industrial treatments of wastewaters flow into our living environment, which is non-biodegradable and carcinogenic1. It has been regarded as a serious environmental concern which can cause all sorts of diseases2,3,4,5. The trace heavy metal ions existed in raw wastewater which outflow from chemical laboratory, steam-electric power plants, metallurgy, mineral processing, nuclear fuel industry and so on6,7. The heavy metal ions generally exist in acidic solutions which is difficult to separate from the waste water8. Various methods have been developed to remove the heavy metal ions, including adsorption, filtration9, membrane separation10, ion exchange11, and so on. The adsorption is commonly used method due to its economic viability, simplicity and environmental protection12,13. Adsorption materials reported were not highly efficient and expensive and required to be used in severe or aggressive conditions14. Therefore, challenges still lie in the design of the polymer membrane structure.

Several adsorbents have been reported such as activated carbon15 and graphene oxide16. However, the adsorbents had some drawbacks such as high attrition rate, costly regeneration. And the limited sorption capacity of the adsorbents still limited in their practical applications to remove heavy mental ions16. Marta Izquierdo et al. investigated the performance of Posidonia oceanica for Cu2+ biosorption in the presence of EDTA. The presence of EDTA in the wastewater decreased the Cu2+ 17.

Recently, the PAN fiber membranes have been applied in many aspects, such as microfiltration18, ultrafiltration19,20,21, desalination22,23,24. However, the pure PAN fiber membrane could not absorb metal ions effectively, which restricted their further application in water treatment. To address this challenge, many attempts were performed on the surface modification of pure PAN membrane. For example, Sheng et al.25 thio-functionalized the surface of polyacrylonitrile with the selective and enhanced adsorption for Hg2+ and Cd2+. However, the adsorption for other heavy metal ions was unsatisfactory. Gang et al.26 prepared a highly selective and efficient chelating fiber with the surface modified by bis(2-pyridylmethyl)amino group. The prepared membrane could be easily recycled or reused toward the metal ions. Pimolpun et al.27 used NaOH ethanolic/aqueous solution to modify the surface of PAN fiber to introduce imine conjugated sequences, which could chelate metal ions. Unfortunately, the preparation processes of membranes were complicated and costly. In addition, although these membranes could absorb the metal ions to some degree, enhanced adsorption capacity of the membrane was limited as for the number of grafted functional absorb groups in the polymer chain.

Herein, we introduced DR-EDTA layers on the surface of the pure PAN fiber membrane through layer-by-layer method. As shown in Fig. 1, the diazo resin with diazo groups could adsorbed the –COOH groups in PAN and EDTA by electrostatic interaction. Photo-crosslinking reaction occurred between diazo groups and–COOH groups after exposure processing. The EDTA could absorb metal ions and water simultaneously owning to the chelate ability and hydrophilic property. More importantly, membrane absorbance capacity toward metal ion could be controlled via DR-EDTA layers. Besides, the modified PAN membrane could absorb different heavy metal ions selectively. In this work, a novel kind of PAN-based modification membrane was prepared. The structure of PAN fiber membrane was characterized by FTIR, SEM and AFM. The adsorption performance of the as-prepared membrane, including the modification layer number effect, temperature effect, recycling properties as well as the water flux were thoroughly investigated.

Results and Discussion

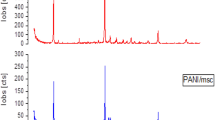

The surface modification of PAN fiber with DR-EDTA layers were successfully performed by method of layer-by-layer self-assembly method. The structure of the modified PAN fiber membrane was analysised by FITR. As shown in Fig. 2, the characteristic peak of PAN fiber membrane at 2245 cm−1 and 1735 cm−1 could be caused by stretching modes of –CN and methyl acrylate units, respectively. After reaction, the adsorption band of The PAN cross-linked with DR and EDTA layers at 2245 cm−1 was remarkably reduced. This indicated that not all the –CN groups participate in the hydrolysis, which implied modification mainly occurred on surface of PAN fiber membrane. The stretching band of benzene skeleton in DR was observed at 1646 cm−1 which confirmed successful graft of DR layer28,29,30. Newly appeared peak at 3525 cm−1 were assigned to the combination of –OH and tertiary amino group. Additionally, the peak at 1735 cm−1 corresponded to the stretching vibration of –COO− was observed which suggested that photo-crosslinking was occurred between PAN and DR, DR and EDTA, respectively. The peak between 3500–4000 cm−1 attributed to water. The water was removed after UV exposure. It was confirmed that EDTA layers were grafted on the surface of PAN fiber membrane.

In order to evaluate the adsorption capacity of the prepared membranes, fiber PAN membrane with different modification layers was investigated. As illustrated in Fig. 3a, the copper uptake of the modified PAN membranes increased from 21.9 mg/g to 50.3 mg/g within five modification layers. This could be attributed to the fact that the introduced EDTA chelating groups could effectively coordinate with the metal ions. Better chelating ability of PAN membranes was achieved with increased DR-EDTA layers. Especially, the copper ion uptake could reach 37.54 mg/g when the modified layer was three, comparable to the similar work27. The increase of copper adsorption capacity was attributed to the introduction of DR-EDTA layers due to chelation groups. As a result, adsorption capacity of PAN membrane increased with increased DR-EDTA layers.

The water flux of modified PAN membrane was measured (under an operating pressure of 19.79 KPa) and was shown in Fig. 3b. The water fluxes of PAN-(DR-EDTA)0, PAN-(DR-EDTA)1, PAN-(DR-EDTA)2, PAN-(DR-EDTA)3, PAN-(DR-EDTA)4 and PAN-(DR-EDTA)5 fiber membrane were 733.30, 1049.80, 1085.94, 1068.85, 679.30, 350.30 g·m−1·h−1, respectively. Especially, the water fluxes of PAN-(DR-EDTA)1, PAN-(DR-EDTA)2 and PAN-(DR-EDTA)3 exhibited 143%, 148% and 146% higher than that of the pure fiber membrane, respectively. The improved water flux was mainly attributed to the increased hydrophilic groups in DR and EDTA. The water flux of PAN membrane reached a relatively stable value within three DR-EDTA layers. This phenomenon was due to the comprehensive results originating from the introduced hydrophilic groups in DR-EDTA layer and the blockage on the porous PAN fiber. However, the water flux of PAN sharply declined with the DR-EDTA layer increased above four. Because the latter factor gradually dominates role, inhibiting the water penetration through the modified PAN fiber membrane. Combining the adsorption capacity and the water flux for the modified PAN fiber membrane, the optimized PAN-(DR-EDTA)3 fiber membrane was selected as the investigated object below.

Dependence of copper adsorption on concentration of adsorbent was carried out under the condition (pH = 6.5, temperature = 25 °C and adsorption time = 720 min). Figure 4a presented the copper adsorption capacity for pure PAN membrane and PAN-(DR-EDTA)3. the amount adsorbed of pure PAN membrane increased from 21.7 mg/g to 23.5 mg/g when the initial concentration of copper changed from 10 mg/L to 50 mg/L. The PAN-(DR-EDTA)3 was increased from 35.16 mg/g to 43.54 mg/g. It could be observed that the adsorption capacity of pure PAN membrane did not increased too high. For the PAN-(DR-EDTA)3, the adsorption capacity varied much with increase of initial concentration of copper. The increase was attributed to the resistance of the copper ions absorption decrease with the increase of the inmetal ions concentration.

(a) Effect of concentration on adsorption capacity, (pH: 6.5, temperature: 25 °C and adsorption time: 720 min) (b) Effect of pH on adsorption capacity (Cu2+ concentration: 20 mg/L, temperature: 25 °C and adsorption time: 720 min) and (c) Effect of temperature on adsorption capacity. (Cu2+ concentration: 20 mg/L, pH:6.5, and adsorption time: 720 min).

Adsorption isotherm models such as Langmuir and Freundlich31 were used to analyze the experimental data of the sorption of Cu2+ onto PAN membranes. The Langmuir model:

It could be expressed by:

where c e (mg/L) was the equilibrium concentration; q e (mg/g) was the equilibrium adsorption capacity; q m (mg/g) was the maximum adsorption capacity; k1 (L/mg) was the constant related to the free energy of adsorption. The Freundlich model:

where k2 was Freundlich constants related to the adsorption capacity and n was Freundlich constants related to the adsorption intensity.

The Langmuir and Freundlich parameters (Supplemental Fig. S1) were calculated from the the slopes and intercepts of the lines and the data was shown in Table 1. It was clear that the data for the adsorption of Cu2+ on to the PAN membrane were well fitted to the Langmuir model. The Freundlich constant (1/n) was smaller than 1 which indicates a favorable process32. The q m calculated from the Langmuir model were 47.6 mg/L for Cu2+. The adsorption capacities of other sorbents were shown in Table 2. The comparative results showed that the PAN membrane had higher absorbency.

To investigated the copper adsorption capacity of the PAN fiber membrane in harsh environment, the influence of pH and temperature for the PAN-(DR-EDTA)3 were studied. As illustrated in Fig. 4b, the copper adsorption capacity of PAN-(DR-EDTA)3 increased from 36.3 mg/g to 37.4 mg/g when the pH changed from 4.0 to 6.5. This could be owning to the fact that the acid effect became weaker at higher pH, leading to the increase of conditional stability constant for the EDTA-Copper system. Nevertheless, the hydrolytic reactions would occur for the copper ion at higher pH (>7.0), through which the copper ion compound (Cu(OH)2) precipitate out from the waste water33,34. Moreover, the nitrogen-containing group (−NR3/−NR2H) in DR under the acid environment would easily be protonated, and could repel the metal ions penetration through the fiber membrane via the Donnan effect. Based on these considerations, the copper uptake of the PAN-(DR-EDTA)3 membrane obtain a much lower adsorption capacity toward copper ion in comparison with the value under the alkaline environment. Because of the mixed coordination effect for the EDTA-Copper and the acid effect for the metal ion26, the PAN-(DR-EDTA)3 fiber membrane possess a maximum copper ion uptake capacity of 37.4 mg/g when the pH was 6.5.

As shown in Fig. 4c, the copper adsorption capacity of the PAN-(DR-EDTA)3 fiber membrane increased with temperature (at pH = 6.5). The free volume of polymer would increase with temperature, further improving copper ion uptake of polymer32,35,36. Especially, the copper ion uptake of PAN-(DR-EDTA)3 could reach 46.2 mg/g at 65 °C, which increased by 24% in comparison with 37.4 mg/g of the fiber membrane at 23 °C. The obtained results suggested that the polymer adsorption for copper ions can be regulated with the temperature, showing good application flexibility.

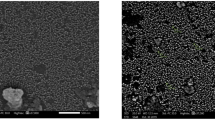

The morphology and topography of the pure PAN and PAN-(DR-EDTA)3 fiber membrane was measured by SEM and AFM (Fig. 5). As could be seen in Fig. 5a and d, similar with the pure PAN membrane, a typical symmetric sponge-like PAN-(DR-EDTA)3 fiber membrane was observed, with interconnected porous structure. However, the pores density of the PAN-(DR-EDTA)3 was higher than that of the pure PAN membrane due to the introduced DR-EDTA layers37. In addition, the hydrophilicity of the PAN fiber membrane would increase mainly due to the introduced –COOH groups in EDTA. As a result, the water flux of the modified PAN fiber membrane changed caused by these two contradictory factors, consistent with the results in Fig. 3b. The surface morphology of PAN-(DR-EDTA)3 was more rough than the pure PAN membrane (Fig. 5b,e). After calculation on the AFM surface of the fiber membrane, the average interface roughness (Ra) value for the pure PAN and the PAN-(DR-EDTA)3 fiber membrane were 15.9 nm and 57.6 nm, respectively (Fig. 5c,f). These results further confirmed that the DR-EDTA layer was successfully grafted on the pure PAN fiber membrane. More importantly, the increased roughness of the modified PAN membrane could increase the contact area between the copper ion/water and the chelating groups in DR-EDTA. And therefore, enhanced copper ion/water uptake of the PAN membrane was obtained. The SEM images of membrane with different DR-EDTA layer coating was shown in Supplemental Fig. S2. The pores in the membrane became smaller with the number of DR-EDTA layers increased.

To investigate the surface wettability of the PAN membrane, the hydrophilicity of the membrane with different layers of DR-EDTA has been studied. As shown in Supplemental Figure S3, the introduced DR-EDTA layer could remarkably improve the hydrophilicity of the pure PAN fiber membranes, and then greatly enhance the PAN fiber membrane water flux.

To investigated the stability of the modified PAN membrane, the fiber membrane adsorption/desorption experiments toward copper ions were measured for 720 h. Figure 6 showed the copper adsorption capacity during the testing process. It showed that the PAN-(DR-EDTA)3 membrane still maintains a strong adsorption capacity for copper ions (37.12 mg/g) after 10 times adsorption-desorption test, in comparison with its initial value (37.47 mg/g). These results proved that the PAN-(DR-EDTA)3 membrane possess stable absorption/desorption ability for copper ions, implying the good reusability of the as-prepared fiber membrane.

The thermogravimetric analysis (TGA) of the pure PAN and PAN-(DR-EDTA)3 fiber membrane was shown in Supplemental Fig. S4. Compared pure fiber PAN membrane, thermal stability of PAN-(DR-EDTA)3 changed.

Except for the superior adsorption ability toward copper ion, the adsorption ability of the PAN-(DR-EDTA)3 fiber membrane for other heavy metal ions (Cd2+, Hg2+, Pb2+) were also investigated (Supplemental Fig. S5). The PAN-(DR-EDTA)3 membrane could simultaneously absorb the different metal ion. This could be attributed to the different coordination ability between the grafted EDTA and the metal ion.

Methods

Materials

PAN membrane were purchased from Shandong Jinhui film Polytron Technologies Inc. Diazo-resin (DR, Mn = 2500) was synthesized according to a method reported elsewhere38. EDTA, cresol red, ammonia chloride and sodium diethyldithiocarbamate trihydrate were all obtained from Sinopharm group Co. ltd.

Characterization

Scanning electron microscopy (SEM, JEOL JSM-6309LV), operating at a 20 kV accelerating voltage, was used to characterize the inner structure of PAN membrane and the surface characterization of the coatings was characterized by atomic force microscope (AFM, CSPM 5500, China). FTIR spectra of PAN membrane was measured in Bruker alpha type infrared spectrometer. Thermogravimetric curves of PAN membrane and modified membrane were obtained on SDTQ600 comprehensive thermal analyzer. Contact angles of PAN membrane were characterized with an automated contact angle goniometer (Dingsheng JY-82), which was recorded at 20 s after a water drop to get a steady reading. APuxi TU-1810 UV-Vis spectrometer was detected for UV-vis absorbance of copper solution.Citrate buffer solution was used as acidity regulators.

Pretreatment of PAN membrane

The PAN membrane was cut into several parts and each paragraph was four to five centimeter. The parts were hydrolyzed by immerging in NaOH solution (1 M) for 1 h and washed by distilled water until the pH of solution was 7. Finally, the parts were dried in vacuum.

Preparation of the DR-EDTA-coated membranes

The hydrolyzed PAN membranes were immersed in DR solution (1 mg/mL) for 24 h. Then the membranes were immersed into distilled water for 5 times to remove extra DR. Similarly, the above membranes were treated with EDTA solution (1.5 mg/mL) for 24 h and washed by distilled water and dried in vacuum. Finally, the photo-crosslinking of the DR/EDTA coating on the membranes were carried out. The scheme of grafting DR and EDTA onto the PAN membrane surface was shown in Fig. 1.

Preparation of the multilayer DR-EDTA-coated membranes

The above PAN-(DR-EDTA)1 membranes were immersed into distilled water. DR and EDTA solutions were taken in turns to deal with PAN membrane. And then the membrane was exposed under UV curing system alternately to obtain the multilayer DR-EDTA-coated membranes.

The metal ions adsorption

The adsorption measurements of the modified PAN membranes were carried out by UV-Vis spectrophotometry according to the refercences reported. Adsorption experiments were carried out in a series of beakers of 50 mL. The beakers contained expected amount of heavy metal ion solution and were stirred on the heating magnetic stirrer. The effects of contact time (0–720 min), concentration (10, 20, 30 and 40 mg/L), solution pH (4, 4.5, 5, 5.5, 6 6.5 and 7) and temperature (25 °C, 30 °C, 35 °C, 40 °C, 45 °C, 50 °C, 55 °C and 60 °C) were investigated. The pH value was adjusted using hydrochloric acid sodium hydroxide. After required adsorption time, the solution was dealt with sodium diethyldithiocarbamate trihydrate. The copper concentration could be analysed by using a UV–vis spectrophotometer after extraction. The adsorption capacity was calculated using31:

where the C0(mg/L) and C1(mg/L) were the copper ion concentration before and after adsorption, respectively, V(L) was the volume of aqueous solution and M(g) was the weight of the adsorbent.

Conclusions

In summary, an advanced PAN-based membrane with enhanced adsorption property for heavy metal ions was prepared by layer-by-layer self-assembly method. The introduced DR-EDTA layer could effectively absorb the metal ion in the waste water. The adsorption property of the polyacrylonitrile-based membrane could be controlled by adjusting the modification layers. The maximum adsorption capacity of PAN-(DR-EDTA)3 toward Cu2+ was approximately 47.6 mg/g. In addition, the PAN-(DR-EDTA)3 membrane exhibit superior reusability after 720 h adsorption-desorption test, showing a very promising prospect for wastewater treatment39.

References

Hsu, T.-C., Yu, C.-C. & Yeh, C.-M. Adsorption of Cu2+ from water using raw and modified coal fly ashes. Fuel 87, 1355–1359, https://doi.org/10.1016/j.fuel.2007.05.055 (2008).

Kılıç, M., Kırbıyık, Ç., Çepelioğullar, Ö. & Pütün, A. E. Adsorption of heavy metal ions from aqueous solutions by bio-char, a by-product of pyrolysis. Applied Surface Science 283, 856–862, https://doi.org/10.1016/j.apsusc.2013.07.033 (2013).

Chakravarty, P., Sarma, N. S. & Sarma, H. P. Biosorption of cadmium(II) from aqueous solution using heartwood powder of Areca catechu. Chemical Engineering Journal 162, 949–955, https://doi.org/10.1016/j.cej.2010.06.048 (2010).

Vanhorn, J. & Huang, H. Uranium(VI) bio-coordination chemistry from biochemical, solution and protein structural data. Coordination Chemistry Reviews 250, 765–775, https://doi.org/10.1016/j.ccr.2005.09.010 (2006).

Y.C.S. Economic Treatment of Cadmium(II)-Rich Hazardous Waste by Indigenous Material. Journal of Colloid & Interface Science 173, 66–70 (1995).

Kadirvelu, K., Thamaraiselvi, K. & Namasivayam, C. Removal of heavy metals from industrial wastewaters by adsorption onto activated carbon prepared from an agricultural solid waste. Bioresource Technology 76, 63–65 (2001).

Hongxia, Z., Zheng, D. & Zuyi, T. Sorption of thorium(IV) ions on gibbsite: Effects of contact time, pH, ionic strength, concentration, phosphate and fulvic acid. Colloids and Surfaces A: Physicochemical and Engineering Aspects 278, 46–52, https://doi.org/10.1016/j.colsurfa.2005.11.078 (2006).

Visa, M., Bogatu, C. & Duta, A. Simultaneous adsorption of dyes and heavy metals from multicomponent solutions using fly ash. Applied Surface Science 256, 5486–5491, https://doi.org/10.1016/j.apsusc.2009.12.145 (2010).

Hu, M. & Mi, B. Enabling graphene oxide nanosheets as water separation membranes. Environmental science & technology 47, 3715–3723, https://doi.org/10.1021/es400571g (2013).

Han, Y., Xu, Z. & Gao, C. Ultrathin Graphene Nanofiltration Membrane for Water Purification. Advanced Functional Materials 23, 3693–3700, https://doi.org/10.1002/adfm.201202601 (2013).

Zhenfeng, C., Yonghui, W., Na, W., Weihua, Y. & Tongwen, X. Development of a Novel Hollow Fiber Cation-Exchange Membrane from Bromomethylated Poly(2,6-dimethyl-1,4-phenylene oxide) for Removal of Heavy-Metal Ions. Ind. Eng. Chem. Res. 49, 3079–3087 (2010).

Dong, Z. et al. Bio-inspired surface-functionalization of graphene oxide for the adsorption of organic dyes and heavy metal ions with a superhigh capacity. J. Mater. Chem. A 2, 5034–5040, https://doi.org/10.1039/c3ta14751g (2014).

Humelnicu, D., Bulgariu, L. & Macoveanu, M. On the retention of uranyl and thorium ions from radioactive solution on peat moss. Journal of hazardous materials 174, 782–787, https://doi.org/10.1016/j.jhazmat.2009.09.120 (2010).

Carmen, Z. Application of waste materials as ‘low cost’ sorbents for industrial effluent treatment: a comparative overview. Int. J. Materials and Product Technology. 50, Nos 3/4 (2015).

Singh, K. P., Mohan, D., Sinha, S., Tondon, G. S. & Gosh, D. Color removal from wastewater using low-cost activated carbon derived from agricultural waste material. Ind. Eng. Chem. Res. 42, 1965 (2003).

Zhiwei, Z. et al. Surface functionalization graphene oxide by polydopamine for high affinity of radionuclides. Colloids Surf. A. 482, 258–266 (2015).

Izquierdo, M., Gabaldón, C. & Marzal, P. Modeling of the effect of EDTA on copper(II) biosorption onto Posidonia oceanica waste in batch and fixed-bed systems. Journal of the Taiwan Institute of Chemical Engineers. 45, 665–673 (2014).

Zhang, J. et al. Graphene oxide/polyacrylonitrile fiber hierarchical-structured membrane for ultra-fast microfiltration of oil-water emulsion. Chemical Engineering Journal 307, 643–649, https://doi.org/10.1016/j.cej.2016.08.124 (2017).

Tham, H. M., Wang, K. Y., Hua, D., Japip, S. & Chung, T.-S. From ultrafiltration to nanofiltration: Hydrazine cross-linked polyacrylonitrile hollow fiber membranes for organic solvent nanofiltration. Journal of Membrane Science 542, 289–299, https://doi.org/10.1016/j.memsci.2017.08.024 (2017).

Yang, Y., Li, X., Shen, L., Wang, X. & Hsiao, B. S. Ionic Cross-Linked Poly(acrylonitrile-co-acrylic acid)/Polyacrylonitrile Thin Film Nanofibrous Composite Membrane with High Ultrafiltration Performance. Industrial & Engineering Chemistry Research 56, 3077–3090, https://doi.org/10.1021/acs.iecr.7b00244 (2017).

Zhang, F., Gao, S., Zhu, Y. & Jin, J. Alkaline-induced superhydrophilic/underwater superoleophobic polyacrylonitrile membranes with ultralow oil-adhesion for high-efficient oil/water separation. Journal of Membrane Science 513, 67–73, https://doi.org/10.1016/j.memsci.2016.04.020 (2016).

Ren, J. & McCutcheon, J. R. Polyacrylonitrile supported thin film composite hollow fiber membranes for forward osmosis. Desalination 372, 67–74, https://doi.org/10.1016/j.desal.2015.05.018 (2015).

Feng, C., Xu, J., Li, M., Tang, Y. & Gao, C. Studies on a novel nanofiltration membrane prepared by cross-linking of polyethyleneimine on polyacrylonitrile substrate. Journal of Membrane Science 451, 103–110, https://doi.org/10.1016/j.memsci.2013.10.003 (2014).

Park, S.-J. et al. Fabrication of polyamide thin film composite reverse osmosis membranes via support-free interfacial polymerization. Journal of Membrane Science 526, 52–59, https://doi.org/10.1016/j.memsci.2016.12.027 (2017).

Deng, S., Zhang, G., Liang, S. & Wang, P. Microwave Assisted Preparation of Thio-Functionalized Polyacrylonitrile Fiber for the Selective and Enhanced Adsorption of Mercury and Cadmium from Water. ACS Sustainable Chemistry & Engineering 5, 6054–6063, https://doi.org/10.1021/acssuschemeng.7b00917 (2017).

Xu, G., Xie, Y., Cao, J., Tao, M. & Zhang, W.-Q. Highly selective and efficient chelating fiber functionalized by bis(2-pyridylmethyl)amino group for heavy metal ions. Polym. Chem. 7, 3874–3883, https://doi.org/10.1039/c6py00335d (2016).

Kampalanonwat, P. & Supaphol, P. Preparation of Hydrolyzed Electrospun Polyacrylonitrile Fiber Mats as Chelating Substrates: A Case Study on Copper(II) Ions. Industrial & Engineering Chemistry Research 50, 11912–11921, https://doi.org/10.1021/ie200504c (2011).

Li, Z., Siguang, J. & Minghua, L. Configuration and photochemical reaction of a bolaamphiphilic diacid with a diazo resin in monolayers and Langmuir–Blodgett films. J. Colloid Interface Sci. 261, 417, https://doi.org/10.1016/S0021-9797(03)00112-7 (2003).

Hong, Z. & Jinfeng, W. et al. Fabrication of covalently attached ultrathin films based on dendrimers via H-Bondeng attraction and subsequent UV Irradiation. Macromol. Rapid Commun. 22, 583–586, https://doi.org/10.1002/1521-3927(20010501)22:83.0.CO;2-O (2001).

Jiyeon Kim, Jin Joo, & Soo-Young Park. Preparation of Asymmetric Porous Janus Particles Using Microfluidics and Directional UV Curing. Part. Part. Syst. Charact. 30, 981–988, https://doi.org/10.1002/ppsc.201300194.

Kalavathy, M. H. & Miranda, L. R. Comparison of copper adsorption from aqueous solution using modified and unmodified Hevea brasiliensis saw dust. Desalination. 255, 165–174, https://doi.org/10.1016/j.desal.2009.12.028 (2010).

Chandra, V. et al. Water-dispersible magnetite-reduced graphene oxide composites for arsenic removal. ACS Nano 4, 3979–3986, https://doi.org/10.1021/nn1008897 (2010).

Zhang, F. S., Nriagu, J. O. & Itoh, H. Mercury removal from water using activated carbons derived from organic sewage sludge. Water research 39, 389–395, https://doi.org/10.1016/j.watres.2004.09.027 (2005).

Kabiri, S., Tran, D. N., Azari, S. & Losic, D. Graphene-Diatom Silica Aerogels for Efficient Removal of Mercury Ions fromWater. ACS applied materials & interfaces 7, 11815–11823, https://doi.org/10.1021/acsami.5b01159 (2015).

Higuchi, H., Yu, Z. & Jamieson, A. M. Thermal history and temperature dependence of viscoelastic properties of polymer glasses: Relation to free volume quantities. Polym. Phys. 33, 2295–2305 (1995).

Losi, G. U. & Knauss, W. G. Free volume theory and nonlinear thermoviscoelasticity. Polym. Eng. Sci. 32, 542–557 (1995).

Li, W., Liu, P., Zou, H., Fan, P. & Xu, W. pH sensitive microporous polypropylene membrane prepared through ozone induced surface grafting. Polymers for Advanced Technologies 20, 251–257, https://doi.org/10.1002/pat.1258 (2009).

Chao, Z., Jinyu, C. & Weixiao, C. Synthesis and characterization of diphenylamine diazonium salts and diazoresins. Die Angewandte Makromolekulare Chemie. 259, 77–82 (1998).

Choudalakis, G. & Gotsis, A. D. Free volume and mass transport in polymer nanocomposites. Curr. Opin. Colloid Interface Sci. 17, 132–140, https://doi.org/10.1016/j.cocis.2012.01.004 (2012).

Li, Y. H. et al. Competitive adsorption of Pb2+, Cu2+ and Cd2+ ions from aqueous solutions by multiwalled carbon nanotubes. Carbon 41, 2787–2792 (2003).

Yang, S. T. et al. Folding/aggregation of graphene oxide and its application in Cu2+ removal. J. Colloid Interface Sci. 351, 122–127 (2010).

Yuan, Y., Zhang, L. G., Zhang, G., Zhang, F. & Fan, X. Poly(amidoamine) modified graphene oxide as an efficient adsorbent for heavy metal ions. Poly. Chem. 4, 2164 (2013).

Mi, X. et al. Preparation of graphene oxide aerogel and its adsorption for Cu2+ ions. Carbon 50, 4856–4864 (2012).

Yu, B. et al. Adsorption behavior of copper ions on graphene oxide–chitosan aerogel. J. Environ. Chem. Eng. 1, 1044–1050 (2013).

Bystrzejewski, M., Pyrzynska, K., Huczko, A. & Lange, H. Carbon-encapsulated magnetic nanoparticles as separable and mobile sorbents of heavy metal ions from aqueous solutions. Carbon 47, 1201–1204 (2009).

Ge, Y., Li, Z., Xiao, D., Xiong, P. & Ye, N. Sulfonated multi-walled carbon nanotubes for the removal of copper(II) from aqueous solutions. J. Ind. Eng. Chem. 20, 1765–1771 (2014).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (21574072, 21375069, 21675091, 21404065), the Natural Science Foundation for Distinguished Young Scientists of Shandong Province (JQ201403), the Taishan Young Scholar Program of Shandong Province (tsqn20161027), the Key Research and Development Project of Shandong Province (2016GGX102028, 2016GGX102039), the Project of Shandong Province Higher Educational Science and Technology Program (J15LC20), the Scientific Research Foundation for the Returned Overseas Chinese Scholars of State Education Ministry (20111568), the People’s Livelihood Science and Technology Project of Qingdao (166257nsh, 173378nsh), the Innovation Leader Project of Qingdao (168325zhc), the China Postdoctoral Science Foundation (2016M590618), the Postdoctoral Scientific Research Foundation of Qingdao (2016001), the China Postdoctoral Science Foundation (2017M622135) and the First Class Discipline Project of Shandong Province.

Author information

Authors and Affiliations

Contributions

B.Y., H.C. and S.Y. conceived and designed the experiments. X.Z. and S.Y. conducted the experiments. B.Y., H.C., S.Y. and X.Z. discussed the results. X.Z., S.Y., Q.T. and X.Z. wrote the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, X., Yang, S., Yu, B. et al. Advanced Modified Polyacrylonitrile Membrane with Enhanced Adsorption Property for Heavy Metal Ions. Sci Rep 8, 1260 (2018). https://doi.org/10.1038/s41598-018-19597-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-018-19597-3

This article is cited by

-

A comprehensive review of polyacrylonitrile membranes: modifications and applications

Polymer Bulletin (2024)

-

Adsorption performance of silver ion on acrylic grafted carboxymethyl chitosan/dialdehyde starch

Adsorption (2024)

-

Capability characterization of pectin-amidoxime-Fe composites for fluoride removal in real conditions and column studies for practical use

International Journal of Environmental Science and Technology (2023)

-

Membranes constructed by metal–ligand complexation for efficient phosphorus removal and fouling resistance in forward osmosis

Advanced Composites and Hybrid Materials (2022)

-

Enhancing performance of polyacrylonitrile membranes for pervaporation dehydration of ethanol by tailoring morphology and process parameters

Korean Journal of Chemical Engineering (2022)