Abstract

The proton exchange membrane fuel cells are the promising sustainable energy sources. The present study focuses on the enhancement the fuel cell performance and the protection of the stainless steel bipolar plate from the corrosion using polyaniline/Zn-Porphyrin composites coatings. The electrochemical properties (polarization and impedance) of the coated 303 stainless steel in 1.0 M H2SO4 solution have been evaluated. The coated 303 stainless steel by new composites exhibits the excellent anti-corrosion activity towards corrosive fuel cell electrolyte. The polyaniline/Zn-Porphyrin composite gives an excellent performance by adding 1.0% of Zn-Porphyrin. This composite improves the output power of the fuel cell.

Similar content being viewed by others

Introduction

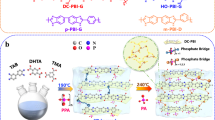

Proton-exchange membrane fuel cells (PEMFC) create power by changing over chemical energy (hydrogen and oxygen gas) to electrical power. Because of the high cost of PEMFC components, the usage of this cell is limited1. The bipolar plates are the one of the main components in fuel cell. It works as conductor for electrical current from cell to cell2. The graphite is the foremost commonly utilized material for bipolar plates manufacture3. It has many advantages such as the great corrosion resistance. On another hand, there are many problems facing the use of graphite as the bipolar plates such as its brittle texture and high gas permeability4. The use of metallic materials for constructing bipolar plates has been highly welcomed in scientific circles5,6,7. They characterize by high electrical conductivity and low cost. Most commercialized bipolar plates made nowadays are stainless steel8. Metal corrosion is a huge problem, particularly in bipolar plates9. The presence of corrosion products and passive layer on the bipolar plate’s surface decrease the performance of PEMFC. To address this problem, many scientists have developed different conductive coatings to screen the metallic bipolar plates10,11,12. These coatings prevent the bipolar plate’s corrosion and consequently improve the PEMFC performance. Researchers have taken a major step towards protect the bipolar plates using conductive polymer coatings such as polyaniline (PANI)13. This kind of polymers is characterized by good conductivity and high thermal stability14. To maximize the efficiency of PANI, the combination of carbon nanotubes (CNT) with PANI was developed by many researchers15. Ramezanzadeh16 proposed polyaniline modified GO nanosheets coatings to improve the performance of stainless steel bipolar plate. Sharma and his colleagues17 improved the corrosion Resistance stainless steel bipolar plates using composite PANI and titanium nitride nanoparticle. Jiang et al.18 investigated the graphene oxide incorporated polypyrrole(PPY) matrix. The results showed that PPY-GO composite coatings work as good anti-corrosion coatings for stainless steel bipolar plates in the aggressive solutions. Gao et al.19 reported phosphomolybdic acid doped PANI coating for corrosion protection of 303SS. Show and his colleagues20 used CNT/PTFE composite coating for stainless steel bipolar plate. This coating decreased the contact resistance and increased the output power of the fuel cell. Here, we prepared a new composite coating for stainless steel bipolar plate. The base of this composite coating is polyaniline polymer (PANI) with Zn-Porphyrin (Zn-Pr). The main functions of new composite are the increasing the corrosion resistance of stainless steel bipolar plate and the enhancing output power of the fuel cell. The porphyrin molecules have very attractive properties. Its structure defined as a group of heterocyclic macrocycle organic compounds21. The insert of metals like Zn, Ni, and Co into porphyrin macrocycle structure influence on the optical absorption spectrum and the electrical and magnetic properties21. To our knowledge, this is the first study to use PANI/Zn-Pr composites coatings for PEMFC.

Experimental

Materials

Grade 303 stainless steel (303SS) (composition %: 0.15 C; 2.0 Mn; 1.0 Si; 0.2 P; 0.15 S; 17 Cr; 8 Ni; balance Fe) was used as the bipolar plate. The 303SS was cut into rectangle shape specimens with total surface area 1.12 cm2. These specimens were cleaned according to standard methods ASTM G1–03.

Polyaniline polymer and sulfuric acid (98%) were supplied from SigmaeAldrich Co. Xylene was supplied from PRABHAT CHEMICALS Co.

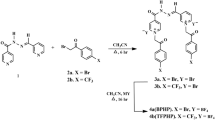

Zn-Porphyrin (Fig. 1) was synthesized according to the reported procedure22.

PANI/Zn-Pr composites preparation and application of coating

The xylene (10 ml) and Zn-Pr powder (0.5, 0.8 and 1.0 gm) were mixed using mechanical stirrer (part 1). The xylene and PANI (1:1 ratio) (90 ml) were mixed using a high speed mechanical stirrer (part 2). The final composite was obtained by mixing part 1 and part 2 using mechanical stirrer followed by ultrasonication (3.0 h) and then ground for 1.0 h to obtain the desired fineness. PANI/Zn-Pr composites coatings were applied on the whole surface of clean 303SS using spray gun (Walther PILOT). The coated 303SS samples were cured at 343 K for 1.0 h.

The dry thickness of the PANI and PANI/Zn-Pr composites films was in the range 53 ± 5 μm using Elcometer 456 gauge (Elcometer Co).

Permeability Testing Cups (BYK Instruments) offer a simple method to check the permeability of PANI/Zn-Pr composites coatings within a 24 h period.

Electrochemical measurements

The anti-corrosion of new PANI/Zn-Pr composite coating was evaluated using potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) techniques.

The polarization curves were recorded using recommended scan rate (1.25 mV s−1) in the potential range ± 250 mV with regard to the open circuit potential.

EIS plots were recoded in the the frequency range 0.01 Hz–100 kHz at the open circuit potential. The AC voltage amplitude was 10 mV. Electrochemical data were collected using Potentiostat/Galvanostat (model Gill AC, 947, ACM).

The electrochemical experiments were repeated at least 3 times to ensure accuracy. All values are presented in the form of mean values and standard deviation.

PEMFC performance measurements

For the PEMFC performance test, the laboratory single cell fuel cell testing stations from Fuel Cell Store was used. In this cell, H2 and O2 gas were flow with rate 150 ml/min. Bare 303SS and coated 303SS were used as bipolar plates. Nafion 117 was used as the proton electrolyte membrane. Platinum particles on acetylene black powder (as support) were used as the catalyst on the surface of anode and cathode electrodes.

Results and Discussion

Anti-corrosion performance of PANI/Zn-Pr composites

We first recoded the polarization responses of uncoated stainless steel bipolar plate 303SS in 1.0 M H2SO4 solution. The same experiments were applied for coated 303SS by neat PANI and PANI/Zn-Pr composites. All these curves are collected in Fig. 2.

The corrosion potential (Ecorr) and corrosion current density (jcorr) were extracted form Tafel curves23 (see Table 1) to assess anti-corrosion performance of PANI/Zn-Pr composites.

The jcorr values of coated 303SS by neat PANI and PANI/Zn-Pr composites were much lowers than that of the control 303SS. The incorporation of Zn-Pr molecules into PANI leads to increase its anti-corrosion performance. This is clearly shown through the considerable decrease of jcorr values form 5.90 μA cm−2 to 0.15 μA cm−2. It was noted also there is a significant shift in Ecorr to more noble direction in the cases of PANI/Zn-Pr composites, indicating the protective effect of new composites24. Here, the composites layer covered both cathodic and anodic sites on the surface of 303 SS and caused the shifting in the Ecorr values.

We calculated anti-corrosion efficiencies (ηj%) of coatings from the Eq. (1)25.

where jocorr and jccorr are the corrosion rates for uncoated and coated 303 SS, respectively.

In the case of coated samples with neat PANI, the ηj% was 77.02% (see Table 1). The use of PANI/Zn-Pr composites leads to enhance the anti-corrosion efficiency of PANI. The maximum efficiency was obtained at 1.0% of Zn-Pr (Table 1).

The permeability of composites coatings is an important property to measure the electrolyte transfer through a coatings film. The presence of pores across the PANI coating is responsible for allowing corrosive cell electrolyte permeation. Therefore, blocking these pores can result in effectively hindering the corrosion of bipolar plates. In this respect, the dispersion of Zn-Pr particles in the texture of PANI coating leads to low electrolyte permeability of the PANI/Zn-Pr composites compared to neat PANI coating (see Table 2).

Electrochemical impedance spectroscopy

To exclude the effect of anti-corrosion and conductivity activities caused by the addition of Zn-Pr, we measured the electrochemical impedance responses (Nyquist plot) of bare 303SS, neat PANI and PANI/Zn-Pr composites in 1.0 M H2SO4 solution. All measurements were achieved after 7 days.

We found that the Nyquist plots for bare 303SS comprise of two capacitive loops (see Fig. 3). The best an equivalent circuit described this case is given in Fig. 4.

The electrolyte resistance was represented by Rs. The passive film resistance and capacitance were represented by Rf and Cf, respectively. Rct and Cdl are charge transfer resistance and double layer capacitor related to 303SS/H2SO4 solution interface26. We noted that the Nyquist plots for coated samples by the neat PANI and PANI/Zn-Pr composites were changed to one capacitive loop (at high frequencies) and straight line (at low frequencies) (Fig. 5)27. This line is due to diffusion impedance of the coating barrier layer (Zd)28. The equivalent circuit described, the PANI and PANI/Zn-Pr composites (0.5% Zn-Pr) is shown in Fig. 6. In this case, Cc and Rc represent the capacitance and resistance of the coating layer, respectively.

By incorporation 1.0% of Zn-Pr into PANI coating, the Zd part for diffusion process was disappeared and the equivalent circuit was represented only by Cc and Rc elements (see Fig. 7).

All the equivalent circuit elements for uncoated and coated samples are listed in Tables 3 and 4.

Initially the Rc value of PANI coatings is comparatively low than for passive film Rf. This implies that the PANI coatings have considerable conductivity if it compares with the passive layer formed on the bare 303SS18,29. By incorporation Zn-Pr into PANI coating, the coating resistance Rc increased and the coating capacitance CC decreased.

Here, Zn-Pr particles repair the PANI coating flaws and block the passage of corrosive solution towards 303 SS substrate and caused the changing in the Rc and CC values.

This indicates that Zn-Pr plays a vital role in enhancing the anti-corrosion property of PANI coatings. Furthermore, at 1.0% of Zn-Pr, the PANI coating become a very good barrier for restriction the diffusion of corrosive solution.

PEMFC performance

To assess the effect of the PANI/Zn-Pr composites coating on the PEMFC Performance, we explored the reliance of the current density on the output cell voltage and the power density for single PEMFC cell using uncoated or coated 303SS bipolar plates. This data was showed in Fig. 8(a,b).

The open voltage for all samples was 0.805 V. Generally, the out voltage cell decreased with current density increasing due to IR drop30. The out voltage in the case of coated 303SS bipolar plates by PANI/Zn-Pr composites was significantly decreased comparing with bare bipolar plates and neat PANI bipolar plates (see Fig. 8(a)).

The supreme power density for single PEMFC cell using uncoated 303SS bipolar plates is 435 mW cm−2 (Fig. 8(b)). This value was increased to 720 and 1353 mW cm−2 in the case of neat PANI and PANI/Zn-Pr composite, respectively. This confirms that the using of PANI-Zn-Pr composite leads to increase the performance of PEMFC cell.

Mechanism and explanation

The above results reveal the strong effect of Zn-Pr on the anti-corrosion effect of PANI coating for 303SS bipolar plates, leading to an increased PEMFC performance.

The 303SS bipolar plates suffered from the corrosion and dissolution during the immersion in cell electrolyte. In addition, the passive film formed during the corrosion process, led to the increase in the contact resistance and the membrane electrodes contamination31,32.

The PANI coating plays as a barrier for 303SS bipolar plates. Where this coating decreases the contact between the 303SS surface and corrosive electrolyte. But the performance of PANI coating is not high enough to prevent the bipolar plate’s corrosion due to the presence of pores in the texture of PANI polymer33. These pores allow the passage of corrosive solution to contact with the bipolar plates34. The corrosive ions enhance the active dissolution of 303SS35,36. These ions may lead to pitting corrosion and induce metal failure37.

The incorporation of Zn-Pr with PANI polymer to form PANI/Zn-Pr composite, leads to efficiency coating barrier. The main role of Zn-Pr is the reducing the pores in the PANI polymer texture10,38. This will significantly affect on the degree of contact between the 303SS surface and corrosive electrolyte.

Additionally, the presence of Zn-Pr molecules act as a conductive path though PANI polymer, leading to the increase in the output power of the PEMFC cell39,40. The conducting characterization of Zn-Pr molecules is due to the aromaticity of the macrocycle, leading to the electrons mobility though the PANI/Zn-Pr composite41,42.

Conclusions

PANI/Zn-Pr composites coatings have been developed, which is effective to significantly increase the output power of the PEMFC cell and decrease the degree of contact between the 303SS bipolar plates and corrosive electrolyte. Anti-corrosion properties of PANI/Zn-Pr composites were confirmed using polarization experiments to define their anti-corrosion efficiency. The highest anti-corrosion activity of the PANI/Zn-Pr composite (i.e. 99.41%) was obtained at 1.0% of Zn-Pr. EIS data also further confirmed that the Zn-Pr plays a significant role in enhancing the coating resistance of PANI. The use of coated 303SS bipolar plates by PANI/Zn-Pr composites leads to increase the output density for single PEMFC cell. Therefore, the new PANI/Zn-Pr composites are considered effective coatings for bipolar plates in future PEMFC technologies.

References

Napoli, R., Gandiglio, M., Lanzini, A. & Santarelli, M. Techno-economic analysis of PEMFC and SOFC micro-CHP fuel cell systems for the residential sector. Energ. Buildings 103, 131–146 (2015).

Tawfik, H., Hung, Y. & Mahajan, D. Metal bipolar plates for PEM fuel cell—A review. J. Power Sources 163, 755–767 (2007).

Jiang, L. et al. Design and testing criteria for bipolar plate materials for PEM fuel cell applications. Mater. Res. Soc. Symp. Proc. 393, 151–155 (1995).

Mehta, V. & Cooper, J. S. Review and analysis of PEM fuel cell design and manufacturing. J. Power Sources 114, 32–53 (2003).

Antunes, R. A., Oliveira, M. C. L., Ett, G. & Ett, V. Corrosion of metal bipolar plates for PEM fuel cells: A review. Int. J. Hydrogen Energy 35, 3632–3647 (2010).

Karimi, S., Fraser, N., Roberts, B. & Foulkes, F. R. A Review of Metallic Bipolar Plates for Proton Exchange Membrane Fuel Cells: Materials and Fabrication Methods. Adv. Mater. Sci. Eng. 2012, 1–22 (2012).

Yuan, X. Z., Wang, H., Zhang, J. & Wilkinson, D. P. Bipolar plates for PEM fuel cells-from materials to processing. J. New Mater. Electrochem. Syst. 8, 257–267 (2005).

Kumagai, M., Myung, S.-T., Kuwata, S., Asaishi, R. & Yashiro, H. Corrosion behavior of austenitic stainless steels as a function of pH for use as bipolar plates in polymer electrolyte membrane fuel cells. Electrochim. Acta 53, 4205–4212 (2008).

Jiang, L. et al. Electropolymerization of camphorsulfonic acid doped conductive polypyrrole anti-corrosive coating for 304SS bipolar plates. Appl. Surf. Sci. 426, 87–98 (2017).

Deyab, M. A. Corrosion protection of aluminum bipolar plates with polyaniline coating containing carbon nanotubes in acidic medium inside the polymer electrolyte membrane fuel cell. J. Power Sources 268, 50–55 (2014).

Kahveci, E. E. & Taymaz, I. Experimental study on performance evaluation of PEM fuel cell by coating bipolar plate with materials having different contact angle. Fuel 253, 1274–1281 (2019).

Ren, Y. J. & Zeng, C. L. Effect of conducting composite polypyrrole/polyaniline coatings on the corrosion resistance of type 304 stainless steel for bipolar plates of proton-exchange membrane fuel cells. J. Power Sources 182, 524–530 (2008).

Qiu, C., Liu, D., Jin, K., Fang, L. & Xie, G. J. Robertson, Electrochemical functionalization of 316 stainless steel with polyaniline-graphene oxide: Corrosion resistance study. Mater. Chem. Phys. 198, 90–98 (2017).

Ho, W.-Y., Pan, H.-J., Chang, C.-L., Wang, D.-Y. & Hwang, J. Corrosion and electrical properties of multi-layered coatings on stainless steel for PEMFC bipolar plate applications. Surf. Coatings Technol. 202, 1297–1301 (2007).

Luo, C., Xie, H., Wang, Q., Luo, G. & Liu, C. A Review of the Application and Performance of Carbon Nanotubes in Fuel Cells. Journal of Nanomaterials, Article ID 560392, 1–10 (2015).

Ramezanzadeh, B., Mohamadzadeh Moghadam, M. H., Shohani, N. & Mahdavian, M. Effects of highly crystalline and conductive polyaniline/graphene oxide composites on the corrosion protection performance of a zinc-rich epoxy coating. Chem. Eng. J. 320, 363–375 (2017).

Sharma, S., Zhang, K., Gupta, G. & Santamaria, D. G. Exploring PANI-TiN Nanoparticle Coatings in a PEFC Environment: Enhancing Corrosion Resistance and Conductivity of Stainless Steel Bipolar Plates. Energies 10, 1–13 (2017).

Jiang, L., Syed, J. A., Lu, H. & Meng, X. In-situ electrodeposition of conductive polypyrrole-graphene oxide composite coating for corrosion protection of 304SS bipolar plates. J. Alloys Compd. 770, 35–47 (2019).

Gao, Y. Z., Syed, J. A., Lu, H. B. & Meng, X. K. Anti-corrosive performance of electropolymerized phosphomolybdic acid doped PANI coating on 304SS. Appl. Surf. Sci. 360, 389–397 (2016).

Show, Y. & Takahashi, K. Stainless steel bipolar plate coated with carbon nanotube (CNT)/polytetrafluoroethylene (PTFE) composite film for proton exchange membrane fuel cell (PEMFC). J. Power Sources 190, 322–325 (2009).

Kadish, W., Smith, K. M. & Guilard, R. Handbook of Porphyrin Science; World Scientific Publishing Co.: Singapore, Volume 44 (2016).

Deyab, M. A. et al. Synthesis and characteristics of alkyd resin/M-Porphyrins nanocomposite for corrosion protection application. Prog. Org. Coat. 105, 286–290 (2017).

Deyab, M. A., Zaky, M. T. & Nessim, M. I. Inhibition of acid corrosion of carbon steel using four imidazolium tetrafluoroborates ionic liquids. J. Mol. Liq. 229, 396–404 (2017).

Deyab, M. A. M. Corrosion Inhibition and Adsorption Behavior of Sodium Lauryl Ether Sulfate on L80 Carbon Steel in Acetic Acid Solution and Its Synergism with Ethanol. J. Surfact. Deterg. 18, 405–411 (2015).

Deyab, M. A., Keera, S. T. & El Sabagh, S. M. Chlorhexidine digluconate as corrosion inhibitor for carbon steel dissolution in emulsified diesel fuel. Corros. Sci. 53, 2592–2597 (2011).

Prajila, M., Rugmini Ammal, P. & Joseph, A. Comparative studies on the corrosion inhibition characteristics of three different triazine based Schiff’s bases, HMMT, DHMMT and MHMMT, for mild steel exposed in sulfuric acid. Egypt. J. Pet. 27, 467–475 (2018).

Deyab, M. A. Decyl glucoside as a corrosion inhibitor for Magnesium–air battery. J. Power Sources 325, 98–103 (2016).

Wang, Y. et al. Preparation and performance of electrically conductive Nb-doped TiO2/polyaniline bilayer coating for 316 L stainless steel bipolar plates of proton-exchange membrane fuel cells. RSC Adv. 8, 19426–19431 (2018).

Moghadam, M. H. M., Sabury, S., Gudarzi, M. M. & Sharif, F. Graphene oxide‐induced polymerization and crystallization to produce highly conductive polyaniline/graphene oxide composite. J. Polym. Sci. Pol. Chem. 52, 1545–1554 (2014).

Zhang, J. PEM Fuel Cell Electrocatalysts and Catalyst Layer (Springer, London), pp. 359–361. (2008).

Deyab, M. A. Effect of halides ions on H2 production during aluminum corrosion in formic acid and using some inorganic inhibitors to control hydrogen evolution. J. Power Sources 242, 86–90 (2013).

Deyab, M. A. Hydrogen generation during the corrosion of carbon steel in crotonic acid and using some organic surfactants to control hydrogen evolution. Int. J. Hydrog. Energy 38, 13519–13511 (2013).

Zhang, K. & Sharma, S. Site-Selective, Low-Loading, Au Nanoparticle–Polyaniline Hybrid Coatings with Enhanced Corrosion Resistance and Conductivity for Fuel Cells. ACS Sustain. Chem. Eng. 5, 277–286 (2017).

Abaci, S. & Nessark, B. Characterization and corrosion protection properties of composite material (PANI + TiO2) coatings on A304 stainless steel. J. Coat. Technol. Res. 12, 107–120 (2015).

Deyab, M. A. Electrochemical investigations on pitting corrosion inhibition of mild steel by provitamin B5 in circulating cooling water. Electrochim. Acta 202, 262–268 (2016).

Deyab, M. A., Essehli, R. & El Bali, B. Performance evaluation of phosphate NaCo(H2PO3)3.H2O as a corrosion inhibitor for aluminum in engine coolant solutions. RSC Adv. 5, 48868–48874 (2015).

Foad El-Sherbini, E. E., Abd-El-Wahab, S. M., Amin, M. A. & Deyab, M. A. Electrochemical behavior of tin in sodium borate solutions and the effect of halide ions and some inorganic inhibitors. Corros. Sci. 48, 1885–1898 (2006).

Deyab, M. A. Effect of carbon nano-tubes on the corrosion resistance of alkydcoating immersed in sodium chloride solution. Prog. Org. Coat. 85, 146–150 (2015).

Deyab, M. A., De Riccardis, A. & Mele, G. Novel epoxy/metal phthalocyanines nanocomposite coatings for corrosion protection of carbon steel. J. Mol. Liq. 220, 513–517 (2016).

Deyab, M. A., De Riccardis, A., Bloise, E. & Mele, G. Novel H2Pc/Epoxy nanocomposites: Electrochemical and mechanical property investigation as anti-corrosive coating. Prog. Org. Coat. 119, 31–35 (2018).

Collman, J. P. et al. Conductive polymers derived from iron, ruthenium, and osmium metalloporphyrins: The shish-kebab approach. Proc. Natl. Acad. Sci. 83, 4581–4585 (1986).

Collman, J. P. et al. Synthetic, electrochemical, optical, and conductivity studies of coordination polymers of iron, ruthenium, and osmium octaethylporphyrin. J. Am. Chem. Soc. 109, 4606–4614 (1987).

Author information

Authors and Affiliations

Contributions

Study concept, design analysis, interpretation of data, preparation the electrode, electrochemical experiments, wrote the main manuscript text by M.A. Deyab. Preparation of Zn-Porphyrin, material characterization analysis by G. Mele Critical review of manuscript for important intellectual content – All authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Deyab, M.A., Mele, G. Stainless steel bipolar plate coated with polyaniline/Zn-Porphyrin composites coatings for proton exchange membrane fuel cell. Sci Rep 10, 3277 (2020). https://doi.org/10.1038/s41598-020-60288-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-020-60288-9

This article is cited by

-

Photocatalytic Applications of Cardanol-Derived meso-Metalloporphyrins Based g-C3N4 Nanocomposites

Catalysis Letters (2025)

-

ZnPb/C composites coating layer on stainless steel for bipolar plate of unitized regenerative fuel cells

Carbon Letters (2025)

-

Innovative approach to corrosion protection using cardanol and vanillin porphyrins in alkyd resins

Journal of Polymer Research (2025)

-

Chemical, electrochemical, and quantum investigation into the use of an organophosphorus derivative to inhibit copper corrosion in acidic environments

Scientific Reports (2024)

-

Advantages of CoS2 nano-particles on the corrosion resistance and adhesiveness of epoxy coatings

Scientific Reports (2024)