Abstract

With the increasing depth of coal mining, the geological stress and structure becomes more and more complex. The elevation of No.8 coal floor significantly undulates in the studied coal mine. Even though a lot of boreholes have been drilled, it remains difficult to predict the spatial distribution features and it becomes challenging to plan the tunnel for the working face. Consequently, there has been a great loss of production in the coal mine, therefore, it is of great significance to study the prediction method for coal floor elevation of the working face. The surface spline function can be regarded as an infinite flat plate deformation in pure bending. The fluctuation of the coal floor can be considered to be the result of multi-period tectonic stress applied on the coal seam, so, the prediction of elevation of the coal floor with surface spline method is feasible. An advantage of surface spline method is that any order differentiable smooth surface can be obtained without regular known lattice and boundary derivatives. In the paper, the complete expression of surface spline function is derived, which is used to predict the elevation of No.8 coal floor of the coal mine. The results show that the trend of elevation of the coal floor can be extrapolated by known data, and the maximum error is 20 m, the minimum error is 0 m, and the error of 80% of the data is less than 3 m. The general trend of the coal floor has been predicted well. However, local peaks and valleys could not be predicted correctly, therefore, the first and second order derivative are projected to predict the peaks and valleys in the head of the tunneling.

Similar content being viewed by others

Introduction

With the increasing mining depth, the geological condition of the coal seams is more and more complex. The plastic and rheology deformation of coal seam is common in deeply exploited coal mines1. The coal miners have a major problem with roadway excavation hanging over their head, because when the coal seam greatly undulates, miners can’t predict the elevation of the coal seam before excavation2. In this condition, many methods such as geophysical exploration methods, drilling methods and so on have been used to estimate the approximation of the geological surface. Drilling can ascertain the elevation of the coal seam floor, however, it takes too much money and time3. The geophysical exploration methods such as direct current resistivity, electromagnetism, seismology, etc., can also be used to predict the elevation of the coal seam floor, but the accuracy is too low to be used to practical production4,5.

The prediction of the distribution of the geological body underground is one of the most active fields in mathematical geology6. An urgent problem to be solved is predicting the fluctuation of the coal seam with existing borehole data in deeply exploited coal mines, so as to guide coal mining7. The spatial distribution of the coal seam is determined by the shape of its roof and floor, therefore, the prediction of the coal shape can be used to predict the surface of the coal seam floor. Such problems can be reduced to the approximate estimation of geological surfaces, therefore, the prediction problem of the coal seam floor could be solved by a numerical method8. The deformation of the coal seam will implicitly influence the fluid flow transport properties due to the coupled stress-permeability evolution. 3D reconstruction technology was used to simulate the deformation and water transport with geometrical coal model9. Fan et al. focused on the horizontal stress variation with respect to the primary depletion under uniaxial strain conditions based on a gas–solid coupling model incorporated with swelling effect. Skurtveit studied the deformation mechanism involved during shear-enhanced compaction and controlling parameters for yield stress at varying confining pressures for sandstone/sand with different grain sizes, porosities, and packing10,11,12.

The surface spline function forms a smooth geological surface by interpolating 3D discrete geological data13,14. The requirements of conditions for spline function are too harsh to be satisfied in coal mining practices15. Our purpose here is to give an example of predicting the floor undulation of the coal mine base by the surface spline method16,17. A vital merit of the function is that the point coordinates are not arranged regularly and the boundary conditions adopted are natural boundary conditions, and the derivate boundary condition is not needed18,19. The manuscript in the form of deduction of surface spline function covers the comprehensive description of the full expression and advantages for computational performance on prediction of elevation of substantial fluctuation in coal seam floor. Thus, this manuscript appears to be unique and useful for technical readers to attain a high level of comprehension on calculational approaches.

The paper is structured as follows. A background about the prediction of the distribution of the geological body based on the mathematical models and the surface spline function have been already given in Sect. “Introduction”. Once used for the interpolation calculation of aircraft surface, the mathematical principle of the surface spline function is introduced along with the full expression in Sect. “Methods”. In Sect. “The generality of the study region”, the generality of the study region and the rock mechanical property is offered. In addition, with the elevation of coal seam floor of excavated roadway, the spatial distribution of coal seam floor is introduced, and the location of unexcavated roadway is also presented in this part. In Sect. “Results and discussions”, the elevation of coal seam floor of unexcavated roadway is calculated by surface spline function. For comparing the computational accuracy, the elevation calculated by other two method is also shown. The result shows that it is an effective method to predict the elevation and tendency of the coal seam, and the first order derivative and second order derivative are also discussed to predict the peaks and valleys of coal seam. Finally, a summary of the main conclusions related to the elevation prediction of coal seam floor is given in Sect. “Conclusions”.

Methods

Surface spline function

Surface spline function, also known as thin plate spline interpolation function, is one of the most efficient methods to date for global interpolation of scattered data, which has been used in interpolating the calculation of aircraft surfaces20.

where D denotes the bending strength of plate.

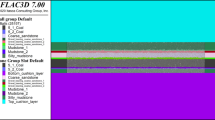

The deformation of the coal mine is similar to the change of a large flat surface after stress, which is shown in Fig. 1. Let Qx, Qy denote the stress components σ31 = σ13 and σ32 = σ23 on the veneer across the section of the axis perpendicular to x, y respectively, then

The deformation (deflection) depends on the point load pi of independent n points (xi, yi, i = 1, 2,…,n). For calculating the deformation of a point, polar coordinates of x = r⋅cosθ and y = r⋅sinθ are introduced. Suppose the point load locates at the origin of coordinates. There is a total shear 2πrQr on the concentric circle where the radius is r. The value of the total shear force is equal to P and the direction is opposite, that is

Converting (2) into polar coordinate

Thus

Continuous integrating three times:

In the center of the plate r = 0, \(\frac{dW}{{dr}} = 0\), so, c2 = 0, then

where A and B are undetermined coefficient, p is point load.

Deformation produced by n points load is superimposed by n solver

where \(r_{i}^{2} = \left( {x - x_{i} } \right)^{2} + \left( {y - y_{i} } \right)^{2}\).

Away from the points load, the surface spline will be flat or nearly flat. With the condition, some equilibrium equations can be derived. Let \(x = r\cos \theta ,y = r\sin \theta\), thus

Based on series expansion

Get

as a result

where C is constant term. The residual term r-1, r-2 etc. can be neglected when r is very large. For the quadratic term and the cubic terms, which are r2 In r2, r2 and r2 In r2, the coefficients are zero. The following equation can be obtained

If let

With formula (14)–(17), formula (8) changed into

Substituting the point load for the distributed load, and taking into account the need for higher order differentiation, the term \(r_{i}^{2} {\text{In}}r_{i}^{2}\) can be substituted for \(r_{i}^{2} {\text{In(}}r_{i}^{2} + \varepsilon )\), in which ε is a small amount. Then

ε is an empirical regulation parameter, which is determined according to actual condition. ε should be smaller if the curvature of the surface changes greatly, otherwise it will be a little bigger.

Formula (18) is the complete expressions of surface spline function, where n + 3 unknown numbers that is Fi(i = 1,2,…,n), a0,a1,a2. With the n data and formula from (10)–(12), the n + 3 unknown numbers could be obtained by solving the equations as follows:

The generality of the study region

Geographical location of the coal mine

The coal mine that we studied lies on the northern fringe of Datong Coalfield in Shanxi province (Fig. 2), 27 km west of Datong city, which is convenient for transportation. The central geographical coordinates are 40°06′N and 113°0′. The shape of the study area, where mine working faces are higher than 890 m above sea level, is an irregular rectangle with a size 13.8 km long from south to north and 8 km wide form east to west. It is located at the north of the Shanxi plateau. The ground elevation is 1177.6 m above sea level. The terrain consists of low hilly landforms and is higher in the northwest and southeast and lower in the middle. The relative height difference is 206.5 m.

Formation lithology

Most of the surface of the mine field is covered by loose sediments of the Quaternary. The geological stratum in the area includes upper Archean Jining group, Cambrian, Carboniferous, Jurassic and Quaternary. The Jurassic, Carboniferous and Permian strata are the main coal-bearing formations. The main lithology from old to new is mica gneiss and hornblende gneiss of upper Archean Jining group, marl and limestone of Cambrian, iron aluminum mudstone and clastic rock of Carboniferous, and sandstone of Jurassic.

There is a rock wall 3.8 km long and 10 m wide in the southeast of the coal mine, which was uncovered during mining of the Jurassic coal seam. The structure is granular and stomatal. The metamorphism range of the coal seams on both sides is less than 1 m. It has little effect on coal seam mining21.

Geological structure

The research area is on the east side of the Luliang meridional structural belt. To the north it is connected to the Tianshan ~ Yinshan tectonic belt. It is the joint part of the east–west tectonic system and the New China Department. The coal mine lies in the north of Datong coalfield. The geological structure is very complicated, and is known as the ‘geological museum’ of Datong coalfield. The general strike is NE ~ SW. The collapse column is developed. There is intrusion of magmatic rocks. The geological structure type of the coal mine is medium22,23.

There are four normal faults in the coal mine, which is fault F1, fault F2, fault F3 and fault F4. The fault F1 lies in the southwest with 2.1 km in length in the mine, extends NW, dips NW, and the maximum drop is 27 m. The fault F2 lies in the southwest with 1.6 km in length in the mine, extends NE, dips SE, and the maximum drop is 11 m. The fault F3 lies in the southwest with 2.2 km in length in the mine, extends NEE, dips NW, and the maximum drop is 16 m. The fault F4 lies in the north with 0.55 km in length in the mine, extends NE, dips NW, and the maximum drop is 10 m. As is shown in the Figs. 3 and 4.

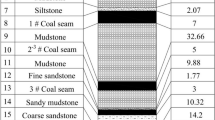

The coal-bearing strata and rock mechanical property of No.8 coal seam

The thickness of the coal-bearing strata is 0–8.10 m, average 3.52 m. The hardness of No.8 coal floor is semi-hard to weak. The false roof appears sporadic and the immediate roof distributes in almost the whole area. The main roof distributes all of the area except northwest and part of southeast area24. The data on the rock mechanical property of No.8 coal seam is shown in the Table 1.

Results and discussions

Results

With boreholes (ST304, Pu26) and roadways, the elevation data of the coal floor reveals that the tunneling direction has been predicted based on surface spline method, which is shown in Table 2. From Table 2, we can see that the maximum error of predictive elevation value of the haulage roadway and air-return roadway is 20 m, and the minimum error is 0 m. Compared to the exposed elevation, the errors of 80% predictive elevation is less than 3 m. The trend of the coal floor has been predicted well.

The elevation of the unexplored area can also be calculated by traditional interpolation methods, such as kriging, inverse distance weighted, spline, discrete smooth interpolation, etc. These methods are either based on principles of statistics or weighted average etc. The surface spline function is deducted from thin plate spline interpolation, which is good at simulating deformation naturally. Therefore, compared to surface spline function, the precision of traditional interpolation methods is not high enough. We have predicted the elevation of the coal floor with data based on 2 boreholes and 50 elevations exposed by drivage with kriging method and surface spline function. The contour of elevation of the coal floor is predicted by kriging method and surface spline function, which is shown as Figs. 5 and 6. In Figs. 5 and 6, the two straight lines represents the haulage roadway and air-return roadway. The symbol × out of the blue rectangle represents the elevation point exposed by roadways, and the symbol × in the blue rectangle represents the elevation point predicted by Kringing method (Fig. 5) and surface spline function (Fig. 6).

In order to comparing the computational accuracy intuitively, the spatial distribution of surface of the coal seam floor(enclosed by blue rectangle in Fig. 6) is also simulated by surface spline function, kriging method and trend surface analysis (Fig. 7). According to Fig. 7, the surface spline function leads to a better match compared to the other two methods, which simulates the fluctuation of coal seam floor realistically. In Fig. 7b, because the kriging method is mainly used for interpolation, the three boreholes data around the working face is added into the surface construction. Thus, there is a big error in the middle part of the surface. In Fig. 7c, the main trendency of the coal seam floor has been predicted, but the strike deviates from the direction of regional structure. Furthermore, the surface is too smooth to be used for characterizing the coal seam floor.

The spatial distribution of coal seam floor (enclosed by blue rectangle in Fig. 6) predicted by surface spline function, kriging method and trend surface analysis method.

The elevation of the coal seam floor exposed by drivage and predicted by surface spline function are also drawn in the form of 2D curve, which is shown in Figs. 8 and 9. The horizontal axis represents the roadway and the coordinate value represents the distance along the heading direction of the roadway. The vertical axis represents the floor elevation of the coal seam. The blue star represents the exposed floor elevation of the coal seam in the coal lane. The red circle indicates the elevation data of the exposed seam floor. The blue curve is the fitting curve of the seam floor elevation. The red curve is the fitting curve for predicting the elevation of the coal seam floor.

Curve of coal seam floor of haulage roadway (The blue * represents the elevation point calculated by surface spline function. The blue ◦ represents the real elevation point exposed by drivage. The arrow represents the direction of laneway excavation. The symbol ① ~ ⑥are interpreted in the Table 3).

Curve of coal seam floor of air-return roadway (The blue * represents the elevation point calculated by surface spline function. The blue ◦ represents the real elevation point exposed by drivage. The arrow represents the direction of laneway excavation. The symbol ① ~ ⑥are interpreted in the Table 3).

It can be clearly seen from the two figures that the trend of elevation prediction of the coal seam floor is in compliance with the trend of elevation exposed by drivage. As the distance from the heading faces area increases, the errors of predicted elevation became higher, that is, there is a higher reliability near the known area. However, with the distance increasing, the precision of prediction of the coal seam floor becomes lower.

Discussions

With the surface spline function, the elevation information for the coal seam floor in an unknown area is analyzed, however, there is still a problem with the prediction. In the process of roadway tunneling, it is impossible to accurately predict the angle of roadway tunneling, therefore, the accuracy of elevation of the coal seam floor in front of the roadway excavation needs to be improved. Considering the continuity and gradual change of undulation of the coal floor, the undulating characteristics of the coal seam floor in front of roadway excavation were judged by the first and second derivatives of the coal seam floor in the direction of roadway excavation.

Predicting the change in the coal seam floor by surface spline function requires takes the excavation head as the reference point, and takes the heading direction of the roadway as the x-axis, and takes the vertical direction as the y-axis. The dip angle is greater than 0, which means that the space of coal seam floor is inclined and upward distributed in front of roadway excavation. The dip angle is less than 0, which means that the space of the coal seam floor in front of the roadway is inclined downward. The method to predict dip change of the coal seam by first and second derivatives at the heading head is shown in Table 3. For example, the first derivative of floor elevation of the coal seam in front of tunneling is equal to 0, and the second derivative is greater than 0, a local maximum elevation of the coal seam floor has been reached. The elevation of the coal seam floor in front of roadway excavation is about to decrease. The conditions are shown in Figs. 8 and 9.

Conclusions

The main conclusions can be summarized as follows:

-

(1)

The coal seam floor is regarded as a pure bending deformation surface of an infinite flat plate. Based on elasticity mechanics, the spline function approximating the surface of the coal seam floor has been deduced. Compared to common geological surface interpolating algorithm, the surface spline function fits the spatial distribution of the coal seam floor surface well. It plays an important role in guiding the tunneling of the coal face where the coal floor seam fluctuates greatly.

-

(2)

With the existing elevation data of the coal seam floor (4 drilling data and 46 elevation data exposed by roadway drivage), the surface spline function is applied to predict the tendency of coal seam elevation of a mine in North China. The results show that the trend of elevation of the coal floor can be extrapolated by known data, and the maximum error is 20 m, the minimum error is 0 m, the error of 80% data is less than 3 m. On the whole, the spatial distribution of the coal seam floor at the work face can be predicted well, however, the prediction accuracy is poor where the coal seam undulation changes dramatically.

-

(3)

The spline surface function is used to predict the floor elevation of the coal seam in front of the tunneling roadway. However, the latest exposed elevation data of the coal seam floor are not fully used for prediction in roadway drivage. Therefore, based on the variation characteristics of the first and second derivatives of the coal seam floor, which indicate the spatial variation direction of the coal seam floor in the front of the excavation it can further provide technical support for the roadway excavation in a coal mine with severe fluctuation in the coal seam.

Data availability

The data used to support the findings of this study are available from the corresponding authors, upon reasonable request.

References

Johnson, M. J. The L2-approximation order of surface spline interpolation. Math. Comput. 70(234), 719–737 (2000).

Terracol, M. et al. Hybrid methods for airframe noise numerical prediction. Theor. Comput. Fluid Dyn. 19, 197–227 (2005).

Zhao, Y. X. et al. Failure mechanisms in coal: Dependence on strain rate and microstructure. J. Geophys. Res Solid Earth 119, 6924–6935 (2015).

Chen, W. et al. Novel hybrid integration approach of bagging-based fishers linear discriminant function for groundwater potential analysis. Nat. Resour. Res. 28, 1239–1258 (2019).

Drougkas, A., Roca, P. & Molins, C. Numerical prediction of the behavior, strength and elasticity of masonry in compression. Eng. Struct. 90, 15–28 (2015).

Fan, L. & Liu, S. M. Numerical prediction of in situ, horizontal stress evolution in coalbed methane reservoirs by considering both poroelastic and sorption induced strain effects. Int. J. Rock. Mech. Min. 104, 156–164 (2018).

Fang, A., Bao, M. H., Chen, W. Q. & Dong, J. H. Assessment of surface ecological quality of grassland mining area and identification of its impact range. Nat. Resour. Res. 30(2), 1–19 (2021).

Yu, Z. W. A new method for interpolation geological surface. J. China U. Min. Technol. 4, 69–75 (1987).

Wang, G., Jiang, C. H., Shen, J. N., Han, D. Y. & Qin, X. J. Deformation and water transport behaviors study of heterogenous coal using CT-based 3D simulation. Int. J. Coal Geol. 211, 103204 (2019).

Oriol, F., Lluís, C. & Alberto, S. Optimum and robust 3D facies interpolation strategies in a heterogeneous coal zone (Tertiary as Pontes basin, NW Spain). Int. J. Coal Geol. 71, 185–205 (2007).

Skurtveit, E., Torabi, A., Gabrielsen, R. H. & Zoback, M. D. Experimental investigation of deformation mechanisms during shear-enhanced compaction in poorly lithified sandstone and sand. J. Geophys. Res Solid Earth 118, 4083–4100 (2013).

Ni, X. M., Yang, C. X., Wang, Y. B. & Li, Z. C. Prediction of spatial distribution of coal seam permeability based on key interpolation points: A case study from the southern Shizhuang area of the Qinshui basin. Nat. Resour. Res. 30, 1547–1559 (2021).

Peche, A., Graf, T., Fuchs, L. & Neuweiler, I. A coupled approach for the three- dimensional simulation of pipe leakage in variably saturated soil. J. Hydrol. 555, 569–585 (2017).

Zhang, Z. T. et al. An anisotropic coal permeability model that considers mining-induced stress evolution, microfracture propagation and gas sorption-desorption effects. J. Nat. Gas Sci. Eng. 46, 664–679 (2017).

Mostaghimi, P. et al. Cleat-scale characterisation of coal: An overview. J. Nat. Gas Sci. Eng. 39, 143–160 (2017).

Khani, A., Baghbanan, A. & Hashemolhosseini, H. Numerical investigation of the effect of fracture intensity on deformability and REV of fractured rock masses. Int. J. Rock Mech. Min. 63, 104–112 (2013).

Hay, A., Yu, K. R., Etienne, S., Garon, A. & Pelletier, D. High-order temporal accuracy for 3D finite-element ALE flow simulations. Comput. Fluids 100, 204–217 (2014).

Baer, F. & Boudra, D. Numerical prediction and modification of cyclone scale precipitation. Mon. Weather Rev. 105, 603–617 (1977).

Dyke, M. V., Klemetti, T. & Wickline, J. Geologic data collection and assessment techniques in coal mining for ground control. Int. J. Min. Sci. Technol. 30, 131–139 (2020).

Ouartassi, B., Doyon, B. & Heniche, M. Numerical prediction of oil mineral aggregates dispersion in the estuary of ST-Lawrence river. J. Phys. 1743, 012033 (2021).

Al-Wardy, W. & Zimmerman, R. W. Effective stress law for the permeability of clay-rich sandstones. J. Geophys. Res. Solid Earth 109, B4 (2004).

Espinoza, D. N., Vandamme, M., Pereira, J.-M., Dangla, P. & Vidal-Gilbert, S. Desorption-induced shear failure of coal bed seams during gas depletion. Int J. Coal Geol. 137, 142–151 (2015).

Liu, S. & Harpalani, S. Determination of the effective stress law for deformation in coalbed methane reservoirs. Rock Mech. Rock Eng. 47, 1809–1820 (2013).

Shi, J. Q. & Durucan, S. Modelling laboratory horizontal stress and coal permeability data using S&D permeability model. Int J. Coal Geol. 131, 172–176 (2014).

Acknowledgements

The authors acknowledge funding from the National Natural Science Foundation of China [41972254], the Natural Science Foundation of Henan Province [202300410179], and the China Postdoctoral Science Foundation [2019M662494]. Supported by the Key Scientific Research Projects of Higher Education Institutions of Henan Province [19A170005] and the Fundamental Research Funds for the Universities of Henan Province [NSFRF200337, NSFRF200103].

Funding

This work was supported by the National Natural Science Foundation of China [41972254], and Natural Science Foundation of Henan Province [202300410179], Supported by the Key Scientific Research Projects of Higher Education Institutions of Henan Province [19A170005] and the Fundamental Research Funds for the Universities of Henan Province [NSFRF200337, NSFRF200103].

Author information

Authors and Affiliations

Contributions

Z.Y. and J.C. collected the elevation data. Z.Y. wrote the manuscript. J.X. and Z.X. improved the figures in the manuscript.

Corresponding author

Ethics declarations

Competing interests

The author declares no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, Z., Xu, J., Xu, Z. et al. Prediction of elevation of substantial fluctuation in coal seam floor based on surface spline function and its derivative. Sci Rep 12, 12658 (2022). https://doi.org/10.1038/s41598-022-12656-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-12656-w