Abstract

Wear properties of Al–Mg–Si alloy matrix hybrid composites made with Si-based refractory compounds (SBRC) derived from bamboo leaf ash (BLA) as complimentary reinforcement with alumina have been studied. The experimental result indicate that optimum wear loss was obtained at higher sliding speed. The wear rate of the composites increased with an increase in BLA wt. %, with the composites having 4%SBRC from BLA + 6% alumina (B4) showing the least wear loss for the different sliding speeds and wear loads considered. With increasing BLA weight percent, the composites' wear mechanism was mostly abrasive wear. Numerical optimization results using central composite design (CCD) reveal that at a wear load of 587.014N, sliding speed of 310.053 rpm and B4 hybrid filler composition level respectively, minimum responses in wear rate (0.572mm2/min), specific wear rate (0.212cm2/g.cm3) and wear loss (0.120 g) would be obtained for the developed AA6063 based hybrid composite. Perturbation plots indicate that the sliding speed have more impact on wear loss, while wear load have significant impact on the wear rate and specific wear rate.

Similar content being viewed by others

Introduction

Manufacturers are constantly in search for materials having a good strength to weight ratios for automobile and aerospace application. To this, composites materials especially aluminium metal matrix composites (AMMCs) reinforced with synthetic materials such as SiC, Al2O3 etc. are highly sought after1. Hybrid composites have been widely used by researchers to achieve an improved wear resistance when particulate reinforcement of Al2O3 was used in the design of AMMCs2. From their work authors3, reported that weight percent (wt.%) of reinforcement is the most significant factor influencing the wear rate of the composites they developed. They noted that, load and sliding speed followed concurrently in the ranking order of significant. Findings from4 concluded that the hybrid composites developed exhibit an excellent wear resistance compared to the base alloy and monolithic composite respectively. The statistical results obtained from the orthogonal array using Taguchi for sliding speed, applied load, sliding distance and wear rate further corroborate the results.

In previous studies, rice husks (RHs) were successfully utilized in the production of Si-based refractory compounds (SBRC)5. These refractory compounds were reported to contain SiC polytypes which can serve as reinforcement materials in the design of AMMCs6. The investigation on the comparison of wear and friction behaviour of aluminium matrix alloy (Al 7075) and silicon carbide based aluminium metal matrix composite under dry condition at different sliding distance was reported7. They showed from their results that the wear rate of AMMCs reinforced with SiC was about 25–45%. On the other hand, about 14% improvement in wear resistance was observed when SiC was used as reinforcement in the design of AMMC as against monolithic alloy8.

In this study, we attempt to use the SBRC derived from BLA as complimentary reinforcement with alumina using central composite design (CCD) to statistically analyse, model and optimize the experimental results. The findings from this study would contribute to the existing data base on the optimization of selected wear parameters of Si-based refractory compounds derived from bamboo leaf and alumina reinforced Aluminium 6063 (AA6063) alloy.

Materials and methods

Materials

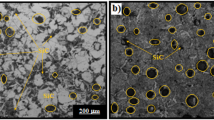

AA 6063 (Al–Mg-Si) is the base material used for this study, which was supplied as an ingot by a local vendor. The elemental composition was obtained using a spark spectrometer and the result is shown in Table 1. The reinforcement materials used in this study are alumina with a particle size range of 30 µm, and Si-based refractory compounds (SBRC) derived from bamboo leaf with particle size < 60 µm. Magnesium was used to enhance the wettability between the base material and the reinforcements. Details about the synthesis route for the development of the SBRC were previously reported by5.

Composites production

Double stir casting was used to produce the composites following the protocol reported by9. Before casting, charge calculations were done to determine the mass of alumina and SBRC of bamboo leaf ash (BLA) required to produce a 10 wt.% reinforcement. Table 2 shows the mix ratio of the reinforcements and their designation.

The SBRC of BLA and alumina (Al2O3) particles were preheated at a temperature range of 200–300 °C in other to remove the moisture and aid the wettability with the base alloy melt. The Aluminium 6063 ingots were introduced into a crucible furnace operated at 760 ± 30 °C and the melt was allowed to cool in a semi-solid state in the furnace at about 600 ± 20 °C. A temperature probe was used to regulate the furnace temperature. At the temperature earlier stated, preheated SBRC of BLA, Al2O3, and 0.15 wt. % magnesium powders were added and stirred manually for 10–15 min. The composite slurry was then superheated to 790 ± 30 °C and a second stirring was achieved through a mechanical stirrer. The stirring process was obtained using 350 rpm motorized stirrer for 15 min to aid the distribution of the particles in the molten Al–Mg-Si alloy. The liquefied composites were then cast into ready sand moulds with chills inserted as reported by9,10.

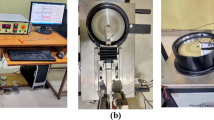

Wear test

The wear test of the composites was achieved using a Taber Abrasion wear testing machine (TSE-A016) following ASTM G195-18 standard11. The wear test required mounting disc-shaped arranged samples having 200 mm diameter and 5 mm thickness on the turntable platform of the wear machine. The samples were rapt at a constant pressure by two abrasive wheels lowered onto the sample surface. The turntable rotates with the samples which drive the abrasive wheels in contact with its surface. The rubbing action between the sample and the abrasive wheel generates loose composite wear debris as the rotating motion continues. The test was piloted for 15 min, and the weights of the samples were recorded before and after the tests. The Taber Wear Index was thereafter evaluated using the relation12

where the initial and final weights are in grams, and the time of the test cycle in minutes.

Statistical analysis, modeling, and optimization of wear parameters

Central composite design (CCD) type of the response surface methodology (RSM) experimental design of the Design Expert Software file version 11.1.2.0 was used to statistically analyses, model and optimize the experimental results. A reduced cubic design model was applied during the analysis. The considered wear process parameters (speed & load) were set as the independent variables (numeric factors A & B) and the hybrid filler weight ratios (%wt) as the categoric factor (C) with five levels (C1, B2, B3, B4 & C2). Wear rate (mm2/min), specific wear rate (cm2/g.cm3), and mass loss (g) were set as the response variables (Responses 1 to 3). Forty-five (45) experimental runs were performed to obtain the responses of the dependent variables/composite wear properties. Statistical significance of the experimental results was evaluated using ANOVA. Diagnostic plots and model graphs were used to analyze the developed statistical models. Numerical optimization solution shows the optimal level of the composite and wear parameters/factors that will result in minimum wear rate.

Ethics approval

Collection of plant material, comply with relevant institutional, national, and international guidelines and legislation.

Results and discussion

Wear loss

Representative plots showing the variations in wear loss for the different speeds used in this study are as presented in Figs. 1, 2, and 3 respectively. It is evident from Figs. 1 and 2 that an optimum wear loss were recorded at higher speed. The rate of material removal was observed to be high as the speed increases, thus increasing the wear loss. Sample B4 had the least wear loss for the different speed used. The lesser the material removal rate was as a result of the resistance to microcutting by the composite owing to the reinforcement history. It is further noted in Fig. 3 that there is a transition domain from mild to severe wear as compared to the trend in Figs. 1 and 2 respectively (lower loads). Furthermore, the transition from mild to severe wear shifts to higher wear loss at constant load of 750 N under varying speeds. The sliding wear regime could be classified into three categories which are ultra-mild, mild and severe wear. As load increases with increasing sliding speed, it is common to observe an increase in the wear rates/loss. Most time, severe wear rate/loss is about three orders magnitude higher than mild wear. From Fig. 3, it could be observed that wear loss increased by about three other magnitude from sliding speed of 250 rpm to 750 rpm. It is also noted that at higher load application, the variation in the wear loss was within the range of 30–75%. The reduction in the wear loss was as a result of the oxide phases in the reinforcement materials. This observation was corroborated by the findings from Idusuyi & Olayinka13.

Wear rate

The variation in the wear rate of the composites are as presented in Figs. 4, 5, and 6 respectively for different speeds. It can be seen from this result that the reinforcement materials tend to restrict plastic deformation, hence forming a layer in the composites developed. At lower load application, the oxide film formed appeared to be at the formative stage, this enhances the wear rate formation. A similar trend was reported from the work of Radhika et al.14. However, as the load increases, more particles are being pulled out of the reinforcement, thereby leading to plastic deformation. Previous studies by Uthayakumar et al.15 reported that particle pulled out of the reinforcement could form a third body abrasion condition.

Specific wear rate

The specific wear rate of the composites at different load applications and speeds are as presented in Figs. 7, 8, and 9 respectively. The specific wear rate (cm2/g.cm3) is a measure of the total area or amount of materials that are cut off from the surface of the hybrid composite by one Newton load/force16. It could be observed from Fig. 9, that the lowest specific wear rate of 3.587 × 10–9 cm2/g.cm3 was obtained by B4 hybrid composite at the maximum wear load of 750N and sliding speed of 500 rpm. Increased specific wear rate as observed for the C2 composite having a single reinforcement content of 10wt.% SBRC-BLA could be attributed to catastrophic ploughing and dislodging of the revealed reinforcement particles from the topmost surface of the composites as soon as they come in contact with the progressively sliding abrasive disc16.

Statistical analysis, modelling and optimization of wear properties and parameters

The design summary, showing the build information for the factor and response variables are presented in Tables 3, 4 respectively.

Analysis of variance (ANOVA) and fits statistics

The validity of the developed predictive models is tested statistically using the analysis of variance technique (ANOVA). ANOVA is useful for establishing the statistical adequacy, significance and practical usefulness of the various factors and the response variables. ANOVA also ascertain the impacts of the experimental wear parameters and filler contents on the wear performance of the studied composites. The relationship between the factors and the dependent response variables (wear properties) in improving the properties of the developed metal matrix composites was established. The results of ANOVA and summary of fit statistics are presented in Tables 5, 6, and 7. From the Tables, it could be observed that there is a significant effect between the factors and response variables based on a 95% confidence level. The P-values (probability values) obtained for all the response variables for each of the factor were less than 0.0500 which is an indication that the developed model terms are significant. Values greater than 0.1000 indicate the model terms that are not significant. The F-values presented for all the response variables are also significant, and is a good sign that the input parameters has a positive impact on the responses17,18. The fitness of the designed model with respect to their response output is represented by Adjusted R2, Predicted R2, and Adeq precision. For accuracy to be obtained from a design model, the difference between the adjusted R2 and predicted R2 value will be less than 0.219,20, hence, it could be seen that a reasonable agreement existed in the responses analyzed in this work. An adequate signal to noise is obtained for all the response output. According to statistical rule, a desirable Adeq precision ratio should be greater than 4 for an adequate signal to be obtained19,21,22. Therefore, the ratio of the analyzed response variables is seen to be greater than 4, which clearly indicate that the developed models are adequate to navigate the design space.

Graphical analysis of model

Design-Expert software provides various graphs to help interpret the selected fit model. Diagnostic plots and model graphs were used to analyze and interpret the fit models. Normal probability plots (Figs. 10A-C) show the linear effect of changing the level of one factor. The normal probability plots are designed to indicate whether the residuals follow a normal distribution, thus follow the straight line. Though, some scatter may be expected even with normal data. Definite patterns, like an “S-shaped” curve are clear indication that a transformation of the response may provide a better analysis. In this case, all the responses exhibit a linear distribution. The predicted versus actual model graphs of Figs. 11A-C show the actual observed response values versus the predicted response values and detect observations that are not easily predicted by the model. It could be observed that the data points are split evenly by the 45-degree line, indicating that the design models are sufficient to predict the responses16,23. For response surface designs, the primary model graphs are the 3D and contour plots. The contour plot is a two-dimensional (2D) representation of a response variable plotted against combinations of numeric factors. It can show the relationship between the responses and the numeric factors24. The 3D Surface plot is a projection of the contour plot giving shape in addition to the color and contour. Figure 12A–C are interactive 3D surface plots, showing the degree of interaction among the factors and the response variables at the specified categoric factor level (B4). An interaction occurs when the response is different depending on the settings of the two numeric factors (Load and speed)25. They will appear with two non-parallel lines, indicating that the effect of one factor depends on the level of the other. The perturbation plot of Fig. 13A–C is employed to compare the effects of all the factors at a particular point in the design space. The response is plotted by changing only one factor over its range while holding all the other factors constant. By default, Design-Expert sets the reference point at the midpoint (coded 0) of all the factors. This can be changed to be any point (perhaps the optimal run conditions) by using the Factors Tool. A steep slope or curvature in a factor shows that the response is sensitive to that factor. A relatively flat line shows insensitivity to change in that particular factor18,20. If there are two or more factors, the perturbation plot could be used to find those factors that most affect the response. From the perturbation curves (Fig. 13A–C), it could be stated that the variation in speed does not have marked impact on the wear rate and specific wear rate, but does on the wear loss. Axes on the contour plots are chosen based on these influential factors.

Parametric optimization solution

Numerical Optimization criteria is set to optimize any combination of one or more goals. The goals may apply to either factor or response variables. The possible goals normally set during numerical optimization are: maximize, minimize, target, within range, none (for responses only) and set to an exact value (factors only). A minimum and a maximum level (lower and upper limits) must be provided for each parameter included in the optimization. The “importance” of a goal can be changed in relation to the other goals. The default is for all goals to be equally important at a setting of 3 pluses (+ + +). Table 8 summarizes the criteria constraints applied to find the optimal settings and solutions for the numerical optimization process. From the numerical optimization report, one solution that best meet the specified criteria is chosen as the optimal solution. This is most times the solution that have the highest desirability scores, indicating there is an island of acceptable outcomes. The optimal solution is presented graphically using contour and overlay plots (Figs. 14, 15). The overlay graph produces a single plot highlighting the “sweet spot”, where all response criteria can be met. It is also used to show the limits of failure in a process17,18,20. The contours are plotted at the limits specified by the criteria. Bright yellow colour by default defines the acceptable factor settings, while grey colour by default identifies the unacceptable factor settings. The selected numerical optimization solutions are carried over and displayed on the contour and overlay plots as flags if the graph is on the correct slice. The results of numerical optimization indicate that at a load, speed and hybrid filler composition level of 587.014N, 310.053 rpm and B4(4%SBRC-BL + 6% alumina) respectively, optimal responses in wear rate (0.572mm2/min), specific wear rate (0.212cm2/g.cm3) and wear loss (0.120 g) would be obtained for the developed AA6063 based composite.

Conclusion

Hybrid composites of AA6063 reinforced with varying weight concentrations of Al2O3 and SBRC from bamboo leaf ash was successively developed by double stir casting technique. The hybrid composites reinforced with 6% alumina + 4%SBRC from BLA, designated as B4 exhibited better abrasive wear properties for all the considered wear parameters. The application of statistical design model based on central composite design type of RSM to simulate wear experiments is effective and adequately predict the abrasive wear response of the hybrid reinforced aluminium 6063 composites under the considered test conditions (varying load, speed and hybrid filler weight compositions). The optimally predicted and experimental values of wear rate are in good agreement, as both best experimental and predicted optimal wear properties were obtained by B4 weight ratio of the hybrid reinforcements at all imposed wear parameters (load and speed), validating the remarkable capability of the chosen design model type in relation to the present investigation.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Kanayo, K., Akintunde, I. B., Apata, P. & Adewale, T. M. Fabrication characteristics and mechanical behaviour of rice husk ash – Alumina reinforced Al-Mg-Si alloy matrix hybrid composites. Integr. Med. Res. 2, 60–67. https://doi.org/10.1016/j.jmrt.2013.03.012 (2013).

Uyyuru, R. K., Surappa, M. K. & Brusethaug, S. Effect of reinforcement volume fraction and size distribution on the tribological behavior of Al-composite/brake pad tribo-couple. Wear 260, 1248–1255. https://doi.org/10.1016/j.wear.2005.08.011 (2006).

Vedrtnam, A. & Kumar, A. Fabrication and wear characterization of silicon carbide and copper reinforced aluminium matrix composite. Mater. Discov. 9, 16–22. https://doi.org/10.1016/j.md.2018.01.002 (2017).

Suresh, R. Comparative study on dry sliding wear behavior of mono (Al2219/B4C) and hybrid (Al2219/B4C/Gr) metal matrix composites using statistical technique. J. Mech. Behav. Mater. 29, 57–68. https://doi.org/10.1515/jmbm-2020-0006 (2020).

Adediran, A.A., Alaneme, K.K., Oladele, I.O., & Akinlabi, E.T. Processing and structural characterization of Si-based carbothermal derivatives of rice husk. Cogent Eng 2018; https://doi.org/10.1080/23311916.2018.1494499.

Adediran, A.A., Alaneme, K.K., Oladele, I.O., Akinlabi, E.T., & Bayode, B.L. Effects of milling time on the structural and morphological features of Si-Based refractory compounds derived from selected Agro-Wastes. Mater Today Proc 2020. https://doi.org/10.1016/j.matpr.2020.05.416.

Singh, K. K., Singh, S. & Shrivastava, A. K. Comparison of wear and friction behavior of aluminum matrix alloy (Al 7075) and silicon carbide based aluminum metal matrix composite under dry condition at different sliding distance. Mater. Today Proc. 4, 8960–8970. https://doi.org/10.1016/j.matpr.2017.07.248 (2017).

Walczak, M., Pieniak, D. & Zwierzchowski, M. The tribological characteristics of SiC particle reinforced aluminium composites. Arch. Civ. Mech. Eng. 15, 116–123. https://doi.org/10.1016/j.acme.2014.05.003 (2015).

Alaneme, K. K. & Bodunrin, M. O. 6063 metal matrix composites developed by two step – stir casting process. Acta. Tech. Corveniensis Bull. Eng. 6, 105–110 (2013).

Alaneme, K. K., Ademilua, B. O. & Bodunrin, M. O. Mechanical properties and corrosion behaviour of aluminium hybrid composites reinforced with silicon carbide and bamboo leaf ash. Tribol. Ind. 35, 25–36 (2013).

ASTM International. ASTM G195–18, Standard Guide for Conducting Wear Tests Using a Rotary Platform Abraser. West Conshohocken, PA, USA: 2018.

Alaneme, K. K. & Odoni, B. U. Mechanical properties, wear and corrosion behavior of copper matrix composites reinforced with steel machining chips. Eng. Sci. Technol. Int. J. 19, 1593–1599. https://doi.org/10.1016/j.jestch.2016.04.006 (2016).

Idusuyi, N. & Olayinka, J. I. Dry sliding wear characteristics of aluminium metal matrix composites: A brief overview. J. Mater. Res. Technol. 8, 3338–3346. https://doi.org/10.1016/j.jmrt.2019.04.017 (2019).

Radhika, N. & Subramaniam, R. Wear behaviour of aluminium/alumina/graphite hybrid metal matrix composites using Taguchi’s techniques. Ind. Lubr. Tribol. 65, 166–174. https://doi.org/10.1108/00368791311311169 (2013).

Uthayakumar, M., Aravindan, S. & Rajkumar, K. Wear performance of Al–SiC–B4C hybrid composites under dry sliding conditions. Mater. Des. 47, 456–464. https://doi.org/10.1016/j.matdes.2012.11.059 (2013).

Edoziuno, F. O. et al. Tribological performance evaluation of hardwood charcoal powder reinforced polyester resin with response surface modelling and optimization. Tribol Ind 43, 574–89 (2021).

Nwaeju, C. C., Edoziuno, F. O., Adediran, A. A., Nnuka, E. E. & Akinlabi, E. T. Development of regression models to predict and optimize the composition and the mechanical properties of aluminium bronze alloy. Adv. Mater. Process. Technol. 00, 1–18. https://doi.org/10.1080/2374068X.2021.1939556 (2021).

Adzor, S. A., Nwaeju, C. C. & Edoziuno, F. O. Optimization of tensile strength for heat treated micro-alloyed steel weldment. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2021.11.282 (2021).

Olorundaisi, E., Jamiru, T. & Adegbola, T. A. Response surface modelling and optimization of temperature and holding time on dual phase steel. Mater. Today Proc. https://doi.org/10.1016/j.matpr.2020.07.408 (2020).

Nwose, S. A., Edoziuno, F. O. & Osuji, S. O. Statistical analysis and response surface modelling of the compressive strength inhibition of crude oil in concrete test cubes. Alger J. Eng. Technol. 04, 99–107. https://doi.org/10.5281/zenodo.4696030 (2021).

Edoziuno, F. O. et al. Optimization and development of predictive models for the corrosion inhibition of mild steel in sulphuric acid by methyl-5-benzoyl-2-benzimidazole carbamate (mebendazole). Cogent. Eng. 7, 1714100. https://doi.org/10.1080/23311916.2020.1714100 (2020).

Fatoba, O. S., Adesina, O. S., Farotade, G. A. & Adediran, A. A. Modelling and optimization of laser alloyed AISI 422 stainless steel using taguchi approach and response surface model ( RSM ). Curr. J. Appl. Sci. Technol. 23, 1–16. https://doi.org/10.9734/CJAST/2017/24512 (2017).

Odoni, B. U., Edoziuno, F. O., Nwaeju, C. C. & Akaluzia, R. O. Experimental analysis, predictive modelling and optimization of some physical and mechanical properties of aluminium 6063 alloy based composites reinforced with corn cob ash. J. Mater. Eng. Struct. 7, 451–465 (2020).

Edoziuno, F. O., Akaluzia, R. O., Odoni, B. U. & Edibo, S. Experimental study on tribological (dry sliding wear) behaviour of polyester matrix hybrid composite reinforced with particulate wood charcoal and periwinkle shell. J. King Saud Univ. Eng. Sci. https://doi.org/10.1016/j.jksues.2020.05.007 (2020).

Edoziuno, F. O. et al. Optimization and development of predictive models for the corrosion inhibition of mild steel in sulphuric acid by methyl-5-benzoyl- 2-benzimidazole carbamate (mebendazole). Cogent. Eng. 7, 1714100. https://doi.org/10.1080/23311916.2020.1714100 (2020).

Author information

Authors and Affiliations

Contributions

This work was carried out in collaboration between all authors. O.S.A. A.A.A. and F.E. designed the study, performed the experiment, interpreted results and wrote the first draft of the manuscript. O.S.A., O.O.S. & B.A.O. managed the analyses of the study, managed literature searches and graphical editing. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Adesina, O.S., Adediran, A.A., Edoziuno, F.O. et al. Statistical modeling of Si-based refractory compounds of bamboo leaf and alumina reinforced Al–Si–Mg alloy hybrid composites. Sci Rep 13, 5416 (2023). https://doi.org/10.1038/s41598-023-31364-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-023-31364-7