Abstract

Climate change negative impacts on food production systems have forced large scale food producers to make available less healthy products. Although available on the markets, tomatoes are no more tasting as they used to be and providing fewer nutrients compared to then. This study investigates and compares the quality and yield of organic tomatoes (Solanum lycopersicum) produced in an insect net covered photovoltaic greenhouse against ambient production. Plant’s physical characteristics were measured, yields and nutrient content were found at harvest, and environmental conditions (temperature, relative humidity, solar irradiance and CO2) were recorded. Plants grew as high as 160 cm inside the greenhouse under an average afternoon temperature of 30.71 °C and a vapor pressure deficit (VPD) of 1.88 kPa against outside plant growth of 72 cm height under averages of 36.04 °C and 3.05 kPa. Although, inside greenhouse tomatoes were physically more attractive and firm with two times healthier tomatoes (98%), 52.39% higher content in protein, 13.31% more minerals and 13.19% more dry matter than outside tomatoes, the yield from outside environment was 4.57 times higher than that of inside due to probably the used crop variety adapted to the harsh climate. Using a crop variety optimum for greenhouse, increasing ventilation and using better fertilizers with enough irrigation could help increase productivity while keeping high fruit quality inside the greenhouse, leading to healthier fruits for food security in the Sahel.

Similar content being viewed by others

Introduction

With the pressure of climate change on food production systems, quality food availability is becoming a major concern in this era of capitalism and industrialization1,2. In fact, due to extended droughts, heavy rains and strong winds clearing farming areas, degrading soils, reducing arable lands and even rendering soils poorer, farmers are mostly compelled to use chemical fertilizers to boost productivity towards lucrativeness2,3. However, as time goes on, this practice leaves chemical residues in products with possibility of adverse effect on human health4 and might even result in products with less nutrient content2. Therefore, a more adaptive and mitigation technics to enhance food production system resilience to climate change is necessary. In the Sahel where climate change impact are causing food insecurity across lands, using greenhouse for producing market gardening products is one of the most promising adaptation technics to help control temperature, humidity, irrigation, invaders, amount of nutrients, carbon dioxide and light intensity for optimum productivity. Temperature control in tomato cultivation has an effect on growth rate as well as the vegetative and reproductive balance of the plant3,5,6. Since energy is needed to maintain these favorable conditions for plants, the greenhouse must have a reliable and sustainable source of energy. In this regard, integrated systems creating synergy between agriculture and energy have pushed towards the development of energy-efficient greenhouse with renewable energy: photovoltaic greenhouse3,5. In this paper, a simultaneous study on organic production of tomatoes (Solanum lycopersicum) inside a cooling photovoltaic greenhouse against outside environment production conditions was done while following the plants’ growth and checking up the nutritional value of fruits, stems and leaves from the various plants.

Materials and methods

Field work

Crop and field preparation

Plots of 50 m2 were used as crop cultivation area with 42.5 m2 as exploited portion on a sandy silt soil. On one of the plots was installed a cooling greenhouse with photovoltaic modules on its roof serving as power source for the evaporative coolers and the other plot was left to ambient weather conditions. The greenhouse was covered by a semi-transparent insect screen material as shown in Fig. 1. Tomatoes (Solanum lycopersicum) variety F1 Mongal obtained from SAHELIA TECHNISEM (Niamey, Niger) was used for this experiment. During the experiment, the species was handled with care and professionalism following the guidelines of the Department of Agronomy of the University Abdou Moumouni (UAM) registered under national and international legislations.

Weather data measurement

Measurements were done on Wednesday and Saturday from 1 to 5:30 pm in order to get afternoon harsh condition data. Crops were cultivated from 30th of August 2022 to 1st February 2023 covering the rainy season and the dry—cold season of Niger, a sahelian country. Data was collected during all this period. Two digital thermometers (HoldPeak HP 90–EPC) with one of them having wetted cotton attached to its thermocouple type K were used to measure dry bulb and wet bulb temperatures respectively (see Fig. 2). A CO2 measuring device (Temtop M2000C) was used to collect CO2 content in the atmosphere. Temperatures measured with normal thermometer were named dry bulb temperature (Tdb) while temperatures measured with probes covered with wetted cotton were named wet bulb temperatures (Twb).

Plant physical properties

The plants’ physical data collection started 1 week after transplantation. With the aid of a measuring tape and a digital mass balance, plants’ height and fruits weight were recorded twice a week on Wednesdays and till constant heights were observed during harvesting period.

Fertilizer, irrigation and intake

The fertilizer used was made up of dung and soil collected from a sheep rearing area (see Fig. 3) as this kind of natural fertilizer is highly rich in nitrogen as mentioned by many researchers such as Górecki & Górecki7. This Sheep dung based fertilizer is readily available and highly used by local farmers since most of them are shepherds. 31.32 kg of sheep or small ruminant based fertilizer was used over the exploited area both inside and outside greenhouse at the beginning before the transplantation of the nursery. 5.22 kg of the fertilizer was added at the flowering stage in order to prepare for the fruiting stage. The irrigation of the field was done manually using water sprinkling cans (every morning and late afternoon), one of the most used irrigation method in the area. Water sprinklers could provide about 3 L per meter square. The amount of water was doubled (from 3 to 6 L) at the fruiting stages since it’s at this stage that tomato crop needed more water for fruit production.

Vapor pressure deficit

Vapor pressure is the water vapor content of air measured as pressure. Transpiration is essential for photosynthesis, nutrient uptake and plant cooling. VPD expresses how temperature and relative humidity affects plant’s growth, stress and diseases. The maximum amount of water vapor that can exist in the air at a given temperature is defined as saturated vapor pressure (SVP) at 100% relative humidity and the actual water vapor pressure in the air at that same temperature and current relative humidity is known as AVP. The difference between these two pressures is called the vapor pressure deficit (VPD). VPD could also be calculated through the difference between water vapor pressure at dry bulb temperature (VPDdry bulb) and water vapor pressure at wet bulb temperature (VPDwet bulb).

where VPD is the vapor pressure deficit in Pascal (Pa), AVP is actual vapor deficit, SVP is saturated vapor deficit, VPDdry bulb is VPD at dry bulb temperature and VPDwet bulb is VPD at wet bulb temperature.

Laboratory work

Physico-chemical characterization of the cultivation soil and used fertilizer

Samples of soil and fertilizer used were taken to the Agriculture department laboratory for analysis. Two types of components were sought for: (1) physical characterization and (2) chemical composition.

Physical characterization: granulometry and particle size analysis

The Granulometry of the cultivation soil through its composition of clay, silt and sand constituted the physical characterization. The particle size analysis was done by the Robinson pipette method which is based on the difference in sedimentation rate between the lighter and bigger particles. In this method, a sample is pipetted at different times and at different suspension depths of the sample in a test tube. Organic matter is removed beforehand because of its binding characteristics.

Chemical composition

The chemical composition in terms of mineral matter, organic matter, phosphorous, nitrogen and carbon content of samples were determined. The characterization method followed steps of the manual of the soil science laboratory of Abdou Moumouni University.

Potential hydrogen (pH) The pH was measured respecting the ratio (m, v) 1/2.5 which consists of putting 20 g of sol in 50 mL of distilled water. The mixture is left to stand for two (2) hours. This stage is called saturation. Thus, the pH of the solution is measured using a pH meter.

Total phosphorus Four (4) steps determined the measurement of total phosphorus. It follows these steps: mineralization, extraction, color development and reading. Mineralization consists of heating for five (5) hours, a solution of 5 g of soil and 10 mL of nitric acid (HNO3). The solution obtained is filtered using a Wattman filter paper. Then, on five (5) mL of filtrate obtained from the extraction are added 10 mL of ammonium molybdate ((NH4)2MoO4) and one (1) mL of sodium chloride cyanide (NCNaCl)3. Finally, the reaction medium is topped up to 50 mL with distilled water. The solution obtained is blue in color. This solution is read using a spectro-chlorometer.

Available phosphorus The available phosphorus analysis has three phases. The first phase is extraction. It consists of homogenizing 5 g of soil and 35 mL of extraction solution. The solution obtained is filtered using Wattman filter paper. The second step is the color development and the third stage is reading. These last two steps are the same as those of total phosphorus.

Carbon Carbon is analyzed using the Walkley–Black method. This method involves heating for 30 min a solution containing 1 g of soil, 10 mL of potassium dichromate (K2Cr2O7) and 10 mL of hydrochloric acid (HCl). The latter is dosed with the sulphate ferric ammonium (NH4Fe (SO4)).

Nitrogen Nitrogen is analyzed by the KJELDHAL method. This method consists of heating for 15 min a solution containing 5 g of soil and 10 mL of sulfuric acid (H2SO4) to which is added the KJELDHAL catalyst. Then, the heated solution is made alkaline by adding soda. This is distilled with a KJELDHAL distiller.

Fruit quality test

Experimental materials

Mortar and pestle were used to grind plant samples followed by laboratory equipment such as an oven and a desiccator and furnace (model Heraeus). A mineralizer (VELP Scientifica DK 8) and distillation/titration equipment (VELP Scientifica) were used during the analysis process. Some chemicals were used during the lab process such as concentrated H2SO4, KJELDHAL standard tablets, distilled water, NaOH, an indicator (EDTA) as described in the test method section.

Dry matter content test: wet sample basis

Beakers were washed, dried into an oven and weighed. Then, fresh tomatoes were weighed, cut into small pieces and put into an oven for 2 days till they dry off at 105 °C. The result is grinded into powder and weighed.

Dry matter content test: dry sample basis

Beakers were put into an oven to dry up for 15 min at 105 °C before being transferred into a desiccator for 15 min again to cool down. Beakers were removed and weighed immediately removed from desiccator. Beakers filled with 2 g of samples were put into an oven for 24 h at 105 °C. The whole was weighed as soon as brought out of the oven.

where % DM represents the percentage of dry matter in the sample and % RH is the percentage of moisture in the sample. m sample is the mass of the initial sample used, m empty is the mass of empty beaker and m f is the final mass of beaker containing the sample.

Mineral matter content test

Empty pots were calcinated in an oven at T = 550–600 °C in order to remove any humidity trace for 15 min, then, the oven was left to cool for another 15 min. Samples (1 g) was placed into pot and weighed before bringing the whole back to the furnace (Heraeus model) for calcination for 2 h. Cooling for 30 min or to room temperature was allowed.

where % MM represents the percentage of mineral matter in the sample. m sample is the mass of the initial sample used, m empty is the mass of empty pot and m f is the final mass of pot containing the sample.

Protein and nitrogen content test

Samples (0.2 g) were weighed and put into tubes with a witness standard solution as a parallel additional tube. KJELDHAL standard tablets were added into each of the tubes with 10 mL concentrated H2SO4. All were put into the mineralizer (model VELP Scientifica DK 8) set at 420 °C for 30 min and left to cool down to room temperature overnight.

After mineralization, each sample was distilled via a distillation machine followed by titration.

where % Protein and % Nitrogen represent the percentages of protein and nitrogen in the sample. m sample is the mass of the initial sample used, m empty is the mass of empty container.

Power system

Solar modules were installed on the roof of the greenhouse for powering the cooling system. In fact, 12 solar photovoltaic modules of 260W each and 4 batteries of 200 Ah were installed for the energy source for the cooling system in order to meet a demand of 4200 Wh per day.

Rights and permissions

This experiment used seeds of tomato species (Solanum lycopersicum) acquired from SAHELIA TECHNISEM (Niger) which grants appropriate permission to purchaser of the product to use the species following IUCN policy, national and international legislations and does not in any case threaten species likelihood of survival or cause extinction. More information on the seeds datasheet is available on www.sahelia-sem.com/acces.htm.

Results and discussion

Soil and fertilizer analysis

Samples of soils were analyzed. The samples were taken at 10 cm depth. Neutral soil was soil sample that was sieved and rendered fine using a fine mesh (about 1 mm). Soil samples were taken from cultivation areas inside and outside the greenhouse.

The results from soil analysis are presented in the Tables 1, 2 and 3. The samples presented high amount of sand (82.96%) for outside soil and 87.25% for greenhouse soil. Silt content in all soils varied between 16.41% (for outside soil) and 12.07% (for greenhouse soil) while clay content was below 1%. The high percentage of sand against little traces of silt makes the soil have a sandy silk texture. Therefore, the soil is porous, very permeable to water and air, which leads to good aeration, good soil drainage and good root development.

The chemical composition of the soil samples showed that the organic matter content in the greenhouse (0.41%) is less compared to open air (1.10%). This can result from the high microorganisms’ activity in the greenhouse, provoking more organic matter mineralization with additional CO2 emission8,9.

Available phosphorus (34.1 ppm) is high in the sheep based fertilizer because phosphorus content is usually high in most organic manures. Indeed, it was seen that phosphorous content in sheep manure highly correlates (R2 = 0.992) with its important organic matter8. Thus, amended soils nutrients contents are influenced by used manure. The resulted available phosphorous is high inside the greenhouse (18.3 ppm) compared to outside (6.4 ppm). This can be explained by the fact that climate conditions variations influence available phosphorous in soil as well as its uptake by plants. The important available phosphorous inside the greenhouse can result from the greenhouse conducive microclimate conditions which can limit phosphorus uptake compare to outside. However, previous investigations have shown that high humidity could also provoke an increase of phosphorous uptake8,9,10,11. Therefore, further investigation is needed to better-understand how climatic parameters impact soil nutrient availability and its uptake by plants.

Table 4 shows the composition of the organic fertilizer used in amending the soil. In fact, this fertilizer is derived from sheep dung. The analysis showed a high amount of phosphorous (335.5 ppm for total phosphorous, 34.1 ppm for available phosphorous), a high amount of mineral matter (28.40%) and an important organic matter (71.60%). In replacement of cow dung, people in Niger usually use sheep dung to amend soils due to its availability as most Nigeriens rear sheep at home. Besides, many research proved that sheep-based fertilizer such as sheep dung and wool is a good source of nitrogen, sulphur, carbon and phosphorous, and rich in decomposed matters essential for plants growth7. Moreover, the use of natural fertilizer helps overcome phyto sanitarian issues while restoring the biological dynamic equilibrium12. However, since organic matter can easily be decomposed to produce abundant free radicals so as to absorb soil nutrients, the application of phosphorous rich fertilizer should be adjusted accordingly10.

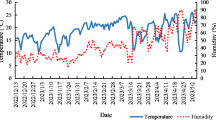

Climatic conditions analysis

The temperature pattern presented in Fig. 4 shows that outside temperature was much higher than that of the greenhouse as expected (average of 36.04 °C for outside against 30.71 °C for inside greenhouse). Meanwhile, Wet bulb temperature ranged from 17.50 to 28 °C for greenhouses’ microclimate and from 20.30 to 32.10 °C for outside environment (Tables 5 and 6). In fact, from Tables 5 and 6, the lowest temperature during afternoon observed inside greenhouse was 25.4 oC against 28.9 oC and average relative humidity was 68.88% against 52.83% for inside greenhouse and outside environment respectively. Furthermore, it was observed that water out of the cooling process became cooler since it took away some of the heat via heat transfer process13. The temperature of the Water recovered ranged from 19.50 to 21.50 oC (Fig. 5) and was closer to the wet bulb temperatures. Reusing that water for the next cooling process could improve cooling efficiency14 although filtration is necessary.

The light irradiance inside the greenhouse averaged to 80.33 w/m2. This was much lower than outside conditions which were 555.71 w/m2. In fact, this incident light intensity reduction could be explained by the fact that the greenhouse cladding material has the ability to reduce incident light by up to 92.80%. The availability of light is known to be a limiting factor in the productivity of sheltered crops cultivation as experimented by Iraqi et al. and Vallières5,6. Figure 6 shows the incident light intensity inside and outside the greenhouse.

CO2 is essential for photosynthesis. Figure 7 shows the CO2 content inside the greenhouse against outside environment. The amount of CO2 inside greenhouse was higher than that of outside which were 912.10 ppm for inside GnH and 898.08 ppm for outside. Plants gathered in confined environments can cause gases content within the microclimate to increase as the rule of greenhouse gases emission. Besides, plants emit CO2 during the evapotranspiration process, and the elevation of CO2 content in the environment increases the mineralization of nutrients (Nitrogen, phosphorous, sulfur) in the soil organic matter10 which is an important process and vital part of soil fertility.

Figure 8 presents the vapor pressure deficit (VPD) pattern inside and outside the greenhouse. VPD of outside environment was higher than that of the inside greenhouse. Under normal circumstances low vapor pressure deficits (VDP) are limiting factors in the productivity of sheltered crops since the absorption of nutrients from the growing medium is directly related to the flow of water through the plant directed by the evapotranspiration as quoted in Iraqi et al.5 and Vallières6. The average values from the experiment were 508.88 Pa for greenhouse microclimate and 1270.51 Pa for Outside environment. These values of VPD are similar to the ones obtained by Lu et al. who found a maximum of 1.4 kPa against 1.8 kPa in our case15.

Productivity analysis

Plant progression

Figures 9, 10, 11 and 12 present the physical aspects of plants’ studied during their growth stages. Due to good weather conditions created by greenhouse’s microclimate, tomatoes crops grew higher and could reach a height of 160 cm inside greenhouse (GnH) compared to a maximum of 80 cm high under ambient conditions. The combination of favorable light intensity (average = 80.33 w/m2), relative humidity (average = 68.88%) and temperature (average = 30.17 °C) within the microclimate allowed leaves to open up and reach an area of 60 cm2 inside GnH against 15 cm2 outside (Tables 7 and 8). The number of leaves formed by various plants followed the same trend. In fact, from the GnH, a maximum of 72 leaves (big composite leaves) was observed against 58 leaves (small composite leaves) outside greenhouse. The higher VPD outside (3.04 kPa) means insufficient relative humidity implying that atmospheric air is pulling out much and faster water from the plant. This is one of the reasons why outside plants had shorter height than inside greenhouse plants with shorter leaves area. Besides, leaves stomatal develop better under relatively low VPD16.

Yield

Fruit harvesting started about 48 days after transplantation under ambient conditions against 81 days inside greenhouse. Light availability and low ventilation within the greenhouse were advanced, at first, to be the cause of this delay in fruiting stage within the greenhouse. Plants kept increasing in height and leaves size inside the greenhouse till reaching 1 m away from the roof. In another report, the experiment of Iraqi et al. and Vallières confirmed that the availability of light is known to be a limiting factor in the productivity of sheltered crops cultivation5,6. As mention by Carlinie et al. certain radiations are necessary for plants’ growth17. Besides, tomatoes plants needed a ventilation or aeration especially during flowering stage. Lower wind inside the greenhouse influenced the formation of fruits.

The delay in fruiting stage and lower productivity could be linked to the tomatoes variety which was Mongal hybrid F1 variety for the Sahel harsh condition. In fact, this variety is mostly used by local farmers due to its harsh whether condition resilience. Because of those unpredicted source of delay, less fruit were produced within the greenhouse compare to outside conditions in whole. In fact, expanded over a hectare, a production of 12.217 tons could be reached outside whereas inside the greenhouse, 2.673 tons could be reached (see Table 9). However, the crop loss is more than two times outside compared to inside the greenhouse.

Higher yield outside the greenhouse could be due to the fact that plantations were done during the rainy season making availability for rain water, wind and sun radiations optimum for outside productivity. Moreover, this variety is suitable for productivity during rainy season. The variation of the outside temperature affected the leaves growth making them not growing well as shown the Figs. 9, 10, 11 and 12, making the environment harsh in the afternoons compared to morning and nights as shown by a high temperature of 36.04 °C and high VPD of 3.04 kPa.

A break period was observed in Fig. 13 between 16 and 19th week, which was the intermediate period of time between rainy season and cold season. The fact that continuous production was done over two successive seasons on the same soil, a reduction of productivity was observed (see Fig. 13 and Table 9).

Fruit quality and nutritional value analysis

Organoleptic characteristics

A cut of various fruits showed that fruits from the greenhouse were more intense in color than the ones cultivated outside. Besides, the fruits were smelling good, giving a firm feeling at touch and tasting good. All these characteristics have an effect on the nutritional values of harvest products (see Fig. 14). On one hand, under outside conditions, tomatoes turned from green to yellow and to light red or red color when ripe. On the other side, under greenhouse microclimate, tomatoes were turning from green to red then deep or intense red color when ripe. This is explained by the fact that the excessive sunshine exposure under outside environment had an effect on certain nutrients and pigments present in the fruit that carry some of the aspects of the fruit’s quality. Photosynthetic pigments such as flavonoids, carotene and anthocyanin can easily be deteriorated under high exposure to intense sunshine18,19. Besides, fruits from the greenhouse were found to be of higher quality and much fresh looking than fruits from outside environment through quality analysis. That is because fruit quality relies on the optimization of fruit-water relation in response to environmental stress as indicated by Guichard et al.20. The fruit-water balance is the result of sap influxes through the phloem and xylem tissue of the pedicel, and water efflux by transpiration20.

Dry matter content

Tables 10 and 11 presented results of dry matter test from tomatoes fruits. Fruits from inside greenhouse had an average dry matter of 5.921% whereas fruits from outside had 6.409%. Both results were within the range of 5–8% as indicated in Guichard et al. (2005). This difference is usually dependent on genotype and environment. The water content of those fruits being between 92 and 95%, assured that those fruits were mature20. On dry basis, the same trend was followed whereby fruits from inside greenhouse (GnH) were having higher humidity content (13.111% against 11.383% for outside). The other parts of crops had other trend depending on many parameters. In fact, leaves inside GnH had higher moisture content (5.683%) than outside ones whereas the outside stems were more moist (5.747%) than inside ones.

Mineral matter content

Table 12 presents mineral matter content from crops cultivated inside and outside greenhouse. From all parts and all areas, fruits had the least mineral matter content compared to other parts of the crops followed by stems. Leaves had accumulated amount of mineral matter which explains the reason for the highest percentage of mineral matter found in them. However, crops cultivated outside had a bit less mineral matter than stems (14.229% for leaves against 15.055% for stems).

Protein and nitrogen content

Fruits from inside greenhouse had higher content of nitrogen and protein than those from outside greenhouse (4.757% Nitrogen and 29.728% Protein against 2.264% Nitrogen 14.153% Protein) probably due to sun exposure which can have an effect on nitrogenous compounds. In other term, inside greenhouse fruits had 2.493% more Nitrogen and 15.575% more protein than outside environment. This is also confirmed through the fruits colors observed previously with inside greenhouse fruit being more intense in red color (see Fig. 14). Leaves from inside greenhouse crops had higher nitrogen and protein contents compared to leaves from outside greenhouse. In fact, the absorption of nutrients from the growing medium is directly related to the flow of water through the plant directed by the evapotranspiration as quoted in Iraqi et al.5 and Vallières6.

Conclusion

Using a hybrid variety, tomato fruits under favorable season appeared to provide better yield than under conditioned microclimate of greenhouse due to many reasons such as fruits’ variety, the composition of incident sun radiations, aeration and irrigation. However, many losses of tomatoes fruits were observed from outside environment cultivation. Tomatoes fruits from the greenhouse was of higher quality with higher protein, vitamin, mineral and fiber content than the ones produced outside, and which was said to be due to stable and favorable climatic conditions within the greenhouse microclimate.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Shenge, K. C. et al. Contamination of tomatoes with coliforms and Escherichia coli on farms and in markets of Northwest Nigeria. J. Food Prot. 78, 57–64 (2015).

Pieper, J. R. & Barrett, D. M. Effects of organic and conventional production systems on quality and nutritional parameters of processing tomatoes. J. Sci. Food Agric. 89, 177–194 (2009).

Ureña-sánchez, R., Callejón-ferre, Á. J., Pérez-alonso, J. & Carreño-ortega, Á. Greenhouse tomato production with electricity generation by roof-mounted flexible solar panels. Sci. Agric. 69, 233–239 (2012).

Gravel, V., Dorais, M. & Ménard, C. Organic fertilization and its effect on development of sweet pepper transplants. HortScience 47, 198–204 (2012).

Iraqi, D., Gauthier, L., Dorais, M. & Gosselin, A. Influence du déficit de pression de vapeur et de la photopériode sur la croissance, la productivité et la composition minérale de la tomate de serre. Can. J. Plant Sci. 77, 267–272 (1997).

Vallières, M. Comparaison de Méthodes de Refroidissement et de Déshumidification Pour une Production en serre de Tomates Biologiques (Universite LAVAL, 2018).

Górecki, R. S. & Górecki, M. T. Utilization of waste wool as substrate amendment in pot cultivation of tomato, sweet pepper, and eggplant. Polish J. Environ. Stud. 19, 1083–1087 (2010).

Ali, A. M., Yousef, A., Hassan, M., Khaled, M. A. & Bayomi, M. Phosphorus sources and sheep manure fertilization for soil properties enhancement and sugar beet yield. Gesunde Pflanz. 2023, 2785–2795 (2023).

Ywih, H., Ahmed, O. H., Muhamad, N. & Majid, A. Improving phosphorus availability in an acid soil using organic amendments produced from agroindustrial wastes. Sci. World J. 2014, 6 (2014).

Yu, K., Chen, X. & Pan, G. Dynamics of soil available phosphorus and its impact factors under simulated climate change in typical farmland of Taihu. Environ. Monit. Assess https://doi.org/10.1007/s10661-015-5087-0 (2016).

Sena, L. P. et al. Analysis of nutritional components of eight famine foods of the Republic of Niger. Plant Foods Hum. Nutr. 52, 17–30 (1998).

Modolon, T. A., Boff, P., Boff, M. I. C. & Miquelluti, D. J. Homeopathic and high dilution preparations for pest management to tomato crop under organic production system. Hortic. Bras. 30, 51–57 (2012).

Djibrilla, A. S. M., Abdoulkader, A. H., Illyassou, K. M., Aissetou, D. Y. & Rabani, A. Investigation of evaporative cooling pad material from hyphaene Thebaica fibers. J. Eng. Res. Rep. 21, 64–75 (2021).

Djibrilla, A. S. M., Abdoulkader, A. H., Illyassou, K. M., Aissetou, Y. & Rabani, A. Performance of evaporative cooling pads made from different plant materials of Sub-Saharan Area (NIGER). LC Int. J. STEM 02, 38–49 (2021).

Lu, N. et al. Control of vapor pressure deficit (VPD) in greenhouse enhanced tomato growth and productivity during the winter season. Sci. Hortic. (Amsterdam) 197, 17–23 (2015).

Amitrano, C., Rouphael, Y., Pannico, A., De Pascale, S. & De Micco, V. Reducing the evaporative demand improves photosynthesis and water use efficiency of indoor cultivated lettuce. Agronomy 11, 1396 (2021).

Carlini, M., Honorati, T. & Castellucci, S. Photovoltaic greenhouses: Comparison of optical and thermal behaviour for energy savings. Math. Probl. Eng. 2012, 10 (2012).

Pharmawati, M. & Wrasiati, L. P. S phytochemical screening and ftir spectroscopy on crude extract from Enhalus acoroides leaves. Malays. J. Anal. Sci. 24, 70–77 (2020).

Saldaña, M., Valenzuela, S. A., Moor, S. R., Metola, P. & Anslyn, E. V. K-5 thin-layer chromatography: Three-dimensional analysis of pigments from plant materials using an interlocking building-block photography box. J. Chem. Educ. 97, 4414–4419 (2020).

Guichard, S., Gary, C., Leonardi, C. & Bertin, N. Analysis of growth and water relations of tomato fruits in relation to air vapor pressure deficit and plant fruit load. J. Plant Growth Regul. 24, 201–213 (2005).

Acknowledgements

The authors would like to show gratitude to their partners AUF (Agence Universitaire de la Francophonie) and WASCAL (West African Science Service Centre on Climate Change and Adapted Land Use) for the financial support.

Author information

Authors and Affiliations

Contributions

A.S.M.D. Paper writing and revision, data acquisition and analysis, field work, technical work, laboratory work (including manipulations, chemicals and analysis tools); A.R. Paper revision, Work supervision, technical support and laboratory work support (including materials, chemical and accessibility); K.M.I. Paper revision, Work supervision, technical support and laboratory work support (including materials and chemical); S.M.I. data collection, data acquisition, data analysis, crop acquisition and field work; K.N.A. data collection, data analysis, laboratory work support (including materials, expertise and accessibility); A.H.A. Work supervision, technical support, design and development. D.Y.A. Work supervision, technical support and field availability.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Djibrilla, A.S.M., Rabani, A., Illyassou, K.M. et al. Improving tomatoes quality in the Sahel through organic cultivation under photovoltaic greenhouse as a climate change adaptation and mitigation strategy. Sci Rep 14, 19396 (2024). https://doi.org/10.1038/s41598-024-54427-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-54427-9