Abstract

The study investigates the heat transfer and friction factor properties of ethylene glycol and glycerol-based silicon dioxide nanofluids flowing in a circular tube under continuous heat flux circumstances. This study tackles the important requirement for effective thermal management in areas such as electronics cooling, the automobile industry, and renewable energy systems. Previous research has encountered difficulties in enhancing thermal performance while handling the increased friction factor associated with nanofluids. This study conducted experiments in the Reynolds number range of 1300 to 21,000 with particle volume concentrations of up to 1.0%. Nanofluids exhibited superior heat transfer coefficients and friction factor values than the base liquid values. The highest enhancement in heat transfer was 5.4% and 8.3% for glycerol and ethylene glycol -based silicon dioxide Nanofluid with a relative friction factor penalty of ∼30% and 75%, respectively. To model and predict the complicated, nonlinear experimental data, five machine learning approaches were used: linear regression, random forest, extreme gradient boosting, adaptive boosting, and decision tree. Among them, the decision tree-based model performed well with few errors, while the random forest and extreme gradient boosting models were also highly accurate. The findings indicate that these advanced machine learning models can accurately anticipate the thermal performance of nanofluids, providing a dependable tool for improving their use in a variety of thermal systems. This study's findings help to design more effective cooling solutions and improve the sustainability of energy systems.

Similar content being viewed by others

Introduction

Global stakeholders are becoming increasingly focused on energy management to underpin sustainability and reduce overreliance on fossil fuel consumption, which remains the leading cause of greenhouse gas emissions at record levels in the atmosphere1,2. Several techniques are being used to effectively reduce dangerous gas emissions in the transport, power generation, manufacturing, and built environment sectors, which include integrating renewable energy systems and applying energy-efficient technologies. The adoption of energy-efficient devices has the potential to reduce energy consumption and adverse environmental impacts to a great extent. The fact that optimizing heat exchanger design can minimize system energy consumption and hence save money on electricity was widely known3,4,5. While the early heat transfer research effort was mostly focused on changing the exchanger surface geometry via enhancement/intensification approaches, research attention shifted decades later when new heat transfer fluids were introduced termed ‘NFs’6,7. A fluid containing a dispersion of nanometer-sized particles improved the heat transfer of the host fluid owing to higher thermal conductivity (TC). The use of micron-sized particles was previously considered more practical, but issues such as poor suspension stability, component erosion, and blockage of flow passages limited their effectiveness8. NF, by contrast, presents much better dispersion stability resulting in an optimal pressure drop without clogging the heat exchanger tubes9,10.

Experimental analysis of convective heat transfer of NFs has been well scrutinized experimentally with different nanoparticles (NPs), including Ag, Cu, Al2O3, CuO, Fe2O3, Fe3O4, SiO2, SiC, TiO2, ZrO2, CNT, and graphene. Desirable properties such as outstanding resistance to chemical attack, thermal stability, and low cost make SiO2 important for researchers' heat transfer considerations. Vajjha et al.11 reported the convective heat transfer and FF experiments with SiO2-EG/water NFs for concentrations of 2.0–4.0% volume over the Reynolds number (Re) range of 3000–16,000. Kulkarni et al.12 analyzed the effect of SiO2 diameter (20, 50, 100 nm) on turbulent heat transfer performance in EG/water base liquid. They demonstrated an increase in HTCs with NP diameter. Bontemps et al.13 determined convective heat transfer and pressure drop of SiO2/water flowing in a circular tube with imposed CHF for a maximum concentration of 19.0%. Compared to water, the results indicate a marked heat transfer increase of up to 80% in the turbulent range (Re = 10,000), while the enhancement was insignificant in the laminar regime (Re = 2400). Ferrouillat et al.14 estimated the convective HTC of SiO2 (22 nm)/water nanofluid in a tube at different fluid inlet temperatures of 20, 50, and 70 °C. Overall, for cooling and heating conditions, the researchers obtained heat transfer enhancements of 10% and 60% with NF concentrations of 2.3% and 18.9%, respectively, in the Re range of 200 to 10,000 compared to values with water. The heat transfer and pressure drop data for water-based SiO2 (30 nm) NF for flow in a helically corrugated tube with different lengths and pitch ratios has been presented by Darzi et al.15. Their experimental investigation covers the Re range between 5000 and 13,500 for 0.5% and 1.0% volume concentrations. They concluded that the HTC was lesser with SiO2 nanofluid at a higher concentration of 1.0% than at a lower particle concentration of 0.5% for flow in the plain and corrugated tube. The FF values are comparable to water when the length-to-pitch ratio increases. An experimental investigation to estimate the forced convection heat transfer characteristics of 5.0% volume SiO2 (127 nm)/water-based NFs in the Re range of 3000–100,000 was performed by Julia et al.16. A maximum heat transfer enhancement of 300% and pressure drop of up to 1000% compared to water values were observed under CHF boundary conditions. Experimental convective heat transfer and FF for SiO2/water nanofluid at 0.5–4.0% volume concentration were reported by Azmi et al.17. The fluid was maintained at a bulk temperature of 30 °C for the Reynolds range of 5000–27,000, resulting in heat transfer enhancement of about 25% at a 3.0% volume concentration. Heat transfer decreased after that as concentration increased. Conversely, the FF of NF reduced with increasing Re.

It is evident from the literature that several researchers reported experimental work in this domain and also few reported on correlation development for thermophysical properties. These nanofluids, which are made up of nanoparticles that are dispersed throughout a base fluid, have better thermal characteristics, which makes them potential candidates for enhanced heat transfer applications. Experimentation or simulation is used to gather data on critical factors such as nanoparticle concentration, temperature, fluid flow rate, and thermal conductivity18,19. However, when data is large and complex-nonlinear, it becomes difficult to model the data and find the correlation. The use of machine learning (ML) is an efficient method for predicting the convective heat transfer capacities of nanofluids20,21. The use of deep learning, and neural networks, in particular, provides a sophisticated method for locating intricate patterns within comprehensive datasets. The model is trained and tested on a split dataset, and statistics-based performance metrics are employed to evaluate the model's performance22,23. With the help of the latest methods in machine learning, like ensemble approaches the researchers can get a better understanding of the complex physics involved in heat transfer in SiO2 nanofluids as a result of the insights they receive on the significance of several factors24,25,26. In addition to aiding in evaluation, machine learning models may also be of use in optimizing processes by adjusting factors such as nanoparticle concentration or temperature to get the desired results27,28. Once it has been trained, the model can generate real-time predictions, which may provide substantial insights for experimental design and process optimization.

Researchers have concentrated on determining the convection heat transfer of SiO2/water NFs13,14,15,16,17. While water-based NFs have shown remarkable heat transfer capability, they still have drawbacks due to base fluid characteristics, as scientific evidence shows11. Glycerol, like water, has long been used as a heat transfer coolant and antifreeze agent. The viscous nature of glycerol presents challenges in thermal applications where low pumping power consumption is required, affecting overall system efficiency. Previous research has primarily focused on improving thermal performance with nanofluids; however, significant gaps exist in the optimization of ethylene glycol and glycerol-based silicon dioxide nanofluids under different flow conditions and concentrations. Specifically, little is known about the comparative heat transfer performance of these nanofluids, especially at high Reynolds numbers and varying nanoparticle concentrations. This study fills these gaps by conducting a thorough comparative analysis of the heat transfer performance of silicon dioxide nanofluids with base liquids glycerol and ethylene glycol. Experiments were carried out at 80 °C with nanofluid concentrations ranging from 0 to 1% volume. The base liquids' thermophysical properties and heat transfer coefficients were analyzed and validated with standardized instruments. A series of heat transfer experiments with nanofluids were then carried out for Re numbers as high as 13,000 under constant heat flux boundary conditions.

To improve predictive accuracy and create a transparent prediction model for this complex engineering problem, five different ML approaches were evaluated for prognostic efficiency. The methods used were LR, RF, XGBoost, AdaBoost, and DTs. To determine the most effective ML techniques, a thorough evaluation was performed using statistical techniques and scientific visualization tools such as violin plots and Taylor's diagrams. This study is unique in that it focuses on comparing the thermophysical and heat transfer properties of glycerol and ethylene glycol-based silicon dioxide nanofluids while also using advanced machine learning models to predict their performance. This study aims to fill a research gap by providing a more in-depth understanding of the behavior of these nanofluids under various conditions, as well as developing reliable predictive models to aid in thermal system design and optimization.

Experimental apparatus and method

NF preparation

SiO2 NPs powder was purchased from US Research Nanomaterials Inc., USA. EG and G with 99% high purity were obtained from R&M Chemicals. The scanning electron microscopy (SEM) image of the SiO2 was taken using a Field Emission Scanning Electron Microscope (Supra 55VP FE-SEM, Carl Zeiss). Figure 1a depicts the SEM images. As seen, the NPs are nearly spherical shaped. The particle sizes vary between 8 and 25 nm, with an average particle size estimated as 21 nm29. The EDX analysis of the selected area in the SEM image is displayed in Fig. 1b. The result indicates that the composition of SiO2 is \(100\%\) consistent with vendor specifications.

NFs are prepared in the respective base liquids, G and EG, following a two-step method14. Each quantity of NPs required for 0.5%, 0.75%, 1.0%, and 2.0% volume fractions was taken on an electronic balance (TLE 104E, Mettler-Toledo). The formulation was achieved by dispersing SiO2 in the base liquids with a magnetic agitator to stir the sample in a beaker for 30 min while adjusting the pH value. Following a similar protocol, another set of SiO2 NFs in a 60:40 by volume G and EG was prepared for comparison.

It is reported that NPs would agglomerate to form clusters and settle over time due to high surface energies30. Kinetic energy is needed to break down the particle clusters into minute sizes, according to Darzi et al.15. Given that, the samples have been subjected to an ultrasonic homogenization (Labsonic M, Sartorius AG) operating at a 30 kHz frequency for 2 h to improve the stability of the dispersions. The pH control is crucial in colloidal stability as it determines the suspension's isoelectric point (IEP). Highly acidic NF (low pH) can lead to corrosion with the long-term flow in pipes. The pH value of the NF samples varied between 6 and 7. The pH value was set to 10 by adding NH3OH to have zeta potential values away from IEP31. No dispersant was added during the preparation process to avoid altering the properties of the NF.

The stability of NFs was checked using Zetasizer (Nano ZSP, Malvern), which operates on the principle of dynamic light scattering to measure charge repulsion/attraction between dispersed particles. At pH 10, the dispersions had an average absolute zeta potential of − 33 and − 42 mV indicating that the SiO2 NFs are stable. Further, a small portion of the NFs is kept under static conditions for months and examined. G-based NFs were stable for over three months, whereas EG-based NFs were stable for up to 1 month without settling in clear storage containers.

Thermophysical property measurement

The thermal property analyzer (KD2 Pro Decagon Devices) based on the transient hot-wire method was used to evaluate the effective TC of NFs within a specified precision of 5.0%. The KS-1 probe with a 60 mm length and 1.28 mm diameter was selected, which provides a transient line heat source. The sample temperature was controlled using an isothermal bath (Vivo-RT2, Julabo), with temperature stabilization better than ± 0.1 K. A rotational rheometer (MCR 302, Anton Paar) was used for effective viscosity measurement. A double-gap concentric cylinder was employed as the measuring geometry. A gap distance of 1.0 mm was allowed between the co-axial cylinders of the system. A Peltier thermostat controlled the cell temperature with a precision of ± 0.1 K. Repeated tests were conducted LVDV-III Ultra Programmable Rheometer. A digital densitometer (DA-645, KEM) which functions on an oscillating U-tube principle, was instrumental in determining the effective density with ± 0.00005 g/cm3 accuracy. Peltier thermoelectric elements enable temperature control within the measuring cell, assuring a precision below 0.03 °C. A differential scanning calorimeter (DSC Q2000, TA Instruments) analyzed the specific heat with an accuracy of 2%. Precise heat measurement was made using the standard test method (ASTM-E1269) under a high-purity nitrogen atmosphere at a 20 °C/min heating rate in the DSC furnace. The device temperature is ± 0.01 °C. A refrigeration cooling system RCS90 was used to conduct specific heat testing at different temperatures.

All devices have been calibrated with either G/EG before the measurements with NFs. The data are collected in the range of temperatures 20–80 °C at atmospheric pressure. Three readings were obtained for each sample at each temperature, and the mean value was stated.

Table 1 shows the measured properties of G and EG. Comparisons have been made with the values reported in the literature32,33,34,35. The Hewitt33 data correlates well with thermal conductivity values within a maximum of 0.25 and 0.02% deviations for glycerol and ethylene glycol, respectively. Hewitt and Cabaleiro’s specific heat data showed a 0.9 and 5.6% variation, while the Lide thermal conductivity data deviated from the measured values by 1.3 and 0.6%. A maximum deviation in viscosity of 5.9 and 1.1% for G and EG was observed when compared with Lide35 and Quijada-Maldonado32, respectively, in the temperature range of 25 to 80 °C. The overall deviation of the calibration results in all experiments was better than 6% from the reference values. Table 2 presents the uncertainty of the measured thermophysical properties of glycerol (G) and ethylene glycol (EG) in percentage.

A comparison of the thermophysical properties of SiO2 NFs with the base liquid is shown in Fig. 2a–d. It was established that the TC enhancement was highest at 1.0% concentration with values of 4.2% and 10.7%, respectively, for G and EG-based NFs. The NF exhibited Newtonian behavior with viscosity independent of the shear rate in a similar manner to that evidenced by Tadjorodi et al.36 and Żyła and Jacek37. The viscosity of SiO2 NFs increased by 27% and 33% compared to base liquids G and EG. The suspension density increased by nearly 2% approximately. SiO2 NFs exhibited lower values of effective specific heat than their base fluids. Meanwhile, the specific heat decreased by nearly 2.7% and 1.5%, over a temperature range of 25 to 80 °C. Further, the measured density values of NFs are consistent with the calculated values using the mixing theory relation within 1.0% deviation in each case. The specific heat data deviated by 3% from the classical thermal equilibrium model. Escher et al.38 have reported a good agreement for density and specific heat values with mixture relations for water-based SiO2 NFs for a concentration of up to 31%.

The experimental data for the measured SiO2 NFs thermal conductivity, viscosity, density and specific heat was regressed to generate an empirical Eqs. (1)–(16) as a function of particle volume concertation (φ) and temperature (T) for further analysis of heat transfer as follows:

SiO2-EG nanofluid

SiO2-G nanofluid

With the parameter units \(\varphi \) (%) and \(T\) (oC).

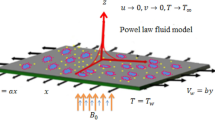

Heat transfer test setup

The experimental system has a closed-loop design composed of five essential components: the test tube, power supply, cooling arrangement, measurement system, and data acquisition. The experimental setup schematic diagram is depicted in Fig. 3. The test section involves a single stainless-steel tube with a bell-mouth entry, thermocouples, and split heaters. The test section consists of a tube 1.0 m long with outer and inner diameters of 6.35 and 4.57 mm, respectively. The outer tube surface is embedded with two-cylinder split-body electric heaters. Each heater, with a 750 W maximum power rating, is wrapped with ceramic fiber insulation and connected to a variable transformer. Eight K-type thermocouples have been used to quantify and record the temperatures at different places. Two of the thermocouples are spot welded to the test section, each at an axial distance of 150 mm from either end of the tube, to measure the wall temperature; four thermocouples at equidistant positions of 100 mm from the tube end are located to measure the surface temperatures and two thermocouples at the inlet and outlet of the test section. All thermocouples were calibrated within a normal of ± 0.1 °C.

The cooling unit comprises a chiller, circulating pump, water tank, and temperature control system. The chiller, rated at 0.74 kW, was connected to the plate-type heat exchanger to regulate the fluid temperature at the test section inlet. A 3.0 hp horizontal multistage pump (AB, Teral) circulated the fluid in the test section. A digital vortex flow meter (SV4200, IMF) with a range of 1–20 LPM is utilized to quantify the fluid flow. A volumetric cylinder made of acrylic of 1.0 L capacity with scale graduation was connected at the test-section exit as a working fluid reservoir to check the flow rate of the fluid visually. Two absolute pressure transducers (GP-100, Keyence) were installed at the pipe inlet and outlet to measure the pressure drop (∆P) across the test section. The calibration range of the sensors from 0 to 10 MPa is ± 1%. All measuring instruments in the circuit were connected to the data logger for recording output signals.

The experiments were undertaken between 6 and 12 LPM flow rates corresponding to flow Reynold numbers of 1200–22,000, while the working fluid temperature is maintained at 80 °C. All the readings are recorded at steady-state conditions. The circuit is cleaned with water and air-dried between successive experiments.

Data analysis

The heat energy \({Q}_{i}\) provided to the working fluid in the heat section is a function of electric current \(I\) and voltage:

Simultaneously, the rate of heat transfer \({Q}_{a}\) was evaluated from the mass flow rate \(\dot{m}\) and the fluid temperatures at the inlet and outlet of the tube:

Under a steady state, the energy available with the hot fluid exiting the test section should equal the heat removed by the cooling liquid in the chiller. Newton's law of cooling relation is used to evaluate the convective HTC as follows:

where the A, \({T}_{w}\) and \({T}_{b}\) are surface area, wall temperature and the fluid bulk or average temperature, respectively computed as:

The average Nusselt number was estimated based on the convective HTC \(h\), tube diameter \(D\), and TC of the fluid \(k\) as

Furthermore, the turbulent HTC can be considered from Dittus–Boelter equation in the following form:

where c, m, and n represent the coefficients suitable for NF experimental data. The \(Re\), and Prandtl number \((Pr)\) terms are defined as follows:

The NF properties used for heat transfer analysis are determined at the bulk temperature. Further details on the derived equations for the thermophysical properties of the NF are given in Ref.29. The nondimensional FF \(f\) was calculated from Darcy–Weisbach equation, which relates the ∆P, pipe length \(L\), hydraulic diameter \(D\), fluid density \(\rho \), and average velocity \(u\) as follows:

Uncertainty analysis

Analysis of the experimental uncertainty was undertaken to validate the precision of the measurements. The uncertainties in heat transfer characteristics were estimated based on the error approach presented by Beckwith et al.39, following the protocol described in17,40. The instrument and uncertainties estimated from the measured parameters are presented in Table 2.

Theoretical correlations for Heat transfer

Model 1

A correlation for Nusselt number of single-phase liquids under fully developed transition and turbulent flows is given by Gnielinski41 as:

where the fanning friction factor is given as \({f}_{F}={\left(1.58\text{ln}Re-3.28\right)}^{-2}\). Equation (25) is valid in \(the 2300\ge Re\ge {10}^{6}\) range.

Model 2

Other correlations are considered for a developing flow in a circular tube with a small velocity boundary layer thickness. Del Giudice42 developed a model for the developing flow heat transfer in a pipe exposed to uniform wall heat flux with the consideration of temperature dependence of viscosity and thermal conductivity as:

where, \({X}^{*}=\frac{L}{{D}_{h}RePr}\) \(n=0.761{\left(RePr\right)}^{0.0224}-0.000109 RePr\)

Where Pnµ is viscosity Pearson number = (β \({q}_{w}^{"}\) D/ke); β = − (dµ/dt)/µ; \({q}_{w}^{"}\) is the heat flux at the tube surface W/m2; D is the tube inner diameter; ke is the TC at tube entry temperature. Equation (26a) is valid for \(5.0 \le \text{ Pr }\le 100;\) 10–4 ≤ X* ≤ X*max. The value of \({X}_{max}^{*}\frac{1}{ 4{Pn}_{\mu }}ln\left[\frac{{\left({Re}_{b}\right)}_{max}}{{Re}_{e}}\right]\) is estimated for the experimental conditions to be 0.08.

Model 3

Muzychka and Yovanovich43 presented a model for predicting Nu in the combined entrance region of a tube valid for uniform wall flux boundary conditions given by

where, \(f\left({R}_{e}\right)=\frac{12}{ \sqrt{\epsilon \left(1+\epsilon \right)} \left[1-\frac{192\epsilon }{{\pi }^{5}}tanh\left(\frac{\pi }{2\epsilon }\right)\right]}\); \(f\left({P}_{r}\right)=\frac{0.866}{ \sqrt{\epsilon \left(1+\epsilon \right)} \left[1-\frac{192\epsilon }{{\pi }^{5}}tanh\left(\frac{\pi }{2\epsilon }\right)\right]}\); \(m=2.27+1.65{P}_{r}^{1/3}\); \({z}^{*}={L/{D}_{h}}{R}_{e}{P}_{r}\). For a circular tube, \(\epsilon =1, {C}_{1}=3.86, {C}_{2}=1.5, {C}_{3}=0.501,\) and \({C}_{4}=2\)

Equation (26b) is valid for 0 < Z* < ∞ and 0.01 < Pr < ∞.

Machine learning

The experimental data collected in the last section was employed to develop a comprehensive set of models to prognosticate the thermohydraulic behavior of Ethylene Glycol and Glycerol based non-porous SiO2 nanofluids. A battery of Python-based open-source libraries was used in the Jupytor environment. A total of five ML techniques were employed for the development of prediction-models in this case. The LR, RF, DT, XGBoost, and AdaBoost models were chosen for their various strengths: LR for simplicity and interpretability, RF, and XGBoost for excellent prediction accuracy, DT for simple decision-making, and AdaBoost for improving weak learners.

The LR was used to prepare the baseline model while the other four namely Random Forest (RF), Extreme gradient boosting (XGBoost), Adaptive boosting (AdaBoost), and Decision tree (DT) were compared against it. A brief description for each is provided as follows:

Linear regression

Linear regression (LR) is considered most basic form of supervised ML algorithm. In this case, a linear equation is fitted to the actual data for modeling the correlation with independent variables (features) and a dependent variable (target). The objective in this case is to represent their mutual relationship. It can be expressed as follows:

Herein, y is the target (dependent variable), \({x}_{1}, {x}_{2}, {x}_{3}\dots .\) are features (independent variable), \({\beta }_{0}, {\beta }_{1}, {\beta }_{2}, \dots .\) are coefficients and \(\varepsilon \) denotes the error.

LR algorithm is employed to locate the line which may provide the best fit to that minimize the sum of squared differences between the actual and predicted values.

Random Forest

Random Forest (RF) is a type of ensemble learning system. It is developed for regression type complex problems. In the training phase, RF generates a large number of decision trees, each of these is trained on a random portion of the training data and characteristics.

Let we denote, a training data set denoted as ‘X’ having n samples and m features. In this case y is the target variable, T denotes total count of decision trees in the test forest, Xi denotes a random subset taken out from training data X, sampled with replacement in case when i ranges from 1 to T. Similarly in case of features Fj denotes the random subset wherein, the j ranges from 1 to T.

In case of each decision tree i, a sample for training denotes as (Xi, yi) is randomly selected from (X,y). Then a decision tree Di is trained on (Xi, yi) employing a split criterion on the basis of least MSE.

The final prediction using a RF-based model is expressed as:

In this case \(\widehat{y}\) is the forecasted output Di(x) denotes the forecast from i-th decision tree for input x.

To summarize, RF regression employs the aggregate of several DTs trained on random subsets of data to generate robust and precise forecasts for regression problems.

Decision Tree

Decision Tree (DT) is a fundamental and flexible ML method which can be used for regression of data. DT creates a hierarchical tree framework having core nodes denoting feature-based decisions while leaf nodes represent the predicted values.

Let us denote a training data set as 'X' with n samples and m features. In this scenario, y is the goal variable, D is the DT model.

In the training phase, the DT splits the feature space recursively into subgroups on the basis of feature values. At each node, the DT selects the feature and split threshold to keep the MSE as low as possible. In the regression work, the prediction is done by traversing the tree from root to leaf node and assigning the mean value of the target variable inside the leaf node to the input sample.

Mathematically, the DT-based forecast can be expressed in simple terms as:

It can be summarized that DT-based regression separates the feature space recursively and then makes forecast using the mean target variable value inside each zone, resulting in interpretable and simple regression models.

Extreme gradient boosting

Extreme gradient boosting (XGBoost) belongs to the gradient boosting family of ML. XGBoost is known for its exception prediction performance. In the gradient boosting process, it sequentially combines weak learners so as to form a robust prognostic model. XGBoost make use gradient descent approach for minimizing the loss function ‘L’ such that

In this case, the \(\theta \) represents the parameters of model, whereas \({y}_{i} and \widehat{{y}_{i}}\) denotes the actual and predicted values. K denotes the number of weak learners in form of trees, and \(\Omega ({\text{f}}_{k})\) denotes the regularization term applied to each tree.

XGBoost uses the additive approach for model building as:

Herein, \({\text{f}}_{k}({\text{x}}_{i})\) represents the prediction of the k-th tree in case of i-th sample.

Regularization techniques like L1 and L2 are used for controlling the complexity of the individual trees.

Herein, T is number of leaves in tree, \(\omega \) denotes the leaf weights, and \(\gamma \) and \(\lambda \) are regularization parameters.

XGBoost also provides insights into feature importance by calculating the gain, which assesses the importance of each feature to the model's performance.

To summarize, XGBoost improves the model's accuracy by successively minimizing a loss function with gradient descent and incorporating regularization approaches to control model complexity. Its ability to offer feature importance and handle missing values render it an effective tool for regression problems across multiple domains.

Adaptive boosting

Adaptive boosting (AdaBoost) combines multiple weak leaners h(x) to form a strong predictor f(x). In mathematical terms the final predictor F(x) is a weighted sum of learners of weaker learners:

Herein, T is the total number of weal learners, \({\alpha }_{1}\) is the weight allotted to the t-th weak learner, and \({h}_{1}(x)\) is the prediction of t-th weak learner.

In the training phase, AdaBoost allots weight to each instance of training \(({x}_{i}, {y}_{i})\), in case when \({x}_{i}\) denotes the input while \({y}_{i}\) denotes true label. In starting phase all weights are set equally as:

\({{w}_{i}}^{(1)}= \frac{1}{N}\);where N is the total count of instances.

AdaBoost fits a weak learner to the training data \({w}_{i}\) in each iteration t, it subsequently computes the weighted error \({\varepsilon }_{t}\) of each weak learner.

Herein, 1(\(\cdot \)) is the indicator function. The weight \({\alpha }_{t}\) of the t-th weak learner can be estimated as:

Subsequently, the AdaBoost updates of training instances on the basis of misclassification error:

In the end, the weight of weak learners is merged to develop the final predictor, F(x). This process continues until a predetermined number of iterations are completed or the errors has been appropriately reduced44.

Result and discussions

Experimental test validations

The experimental setup was validated by a comparison of data undertaken with water. The experimental Nusselt number values for the flow of water, as presented in Fig. 4, were compared with the correlation of Gnielinski41. The data correlated well with the predicted values within ± 7.4%. Further validation was carried out by contrast of the experimental FF with Eq. (27) for turbulent flow in rough pipes45. An excellent concordance of the experimental data was observed. Following the validation for water, heat transfer experiments progressed with the 30GW base liquid and NF concentrations of 0.25, 0.5, 0.75, and 1.0% for flow range 6 to 12 LPM.

HTC and FF

The variation of HTC with flow rate for different concentrations of SiO2 NFs is presented in Fig. 5. The base and NF HTC enhanced with flow rates. The increase in heat transfer reached a maximum for the three NFs at a 1.0% volume. Lower viscous SiO2-EG NFs exhibited significant HTC enhancement over the base liquid, compared to higher viscous SiO2-G NFs for similar conditions. The increase in HTC of SiO2-EG and SiO2-G NFs was determined as 5.9% and 1.9%, respectively, for a 1.0% volume fraction at a 12 LPM flow rate. This behavior could be explained by the flattening of the velocity profile and delay in boundary layer development in the fully developed region, among others46,47. The NF heat transfer augmentation can also be attributed to the effective TC increases caused by reduced viscosity near the wall, amplifying NPs' surface area, and particle reconfiguration48,49.

Figure 6 displays the variation of Nu with Re for various SiO2 volume fractions. The figure shows a similar value increase over the base liquid for all nanofluids. The evolution rate is more significant for SiO2-EG in the turbulent flow than SiO2-G NFs at higher Re in the laminar flow range. Increasing the concentration enhances the Nu, possibly due to particle migration, TC enhancement, and lessening of boundary layer thickness. The enhancement in Nu at Re of 19,000 and 2,300 with 1.0% volume of the NFs are 1.4 and 1.1%, respectively. The findings are consistent with the results of SiO2/water in the laminar range, where the heat transfer improvement is relatively minuscule with growth in Re38,50.

Figure 7 depicts a comparison of base liquid Nu with single-phase theory. As observed, the correlation closely predicts the Nu of the base liquids. The average absolute values of the deviations between Del Giudice et al.42 and Muzychka and Yovanovich43 from the experimental data are 1.6 and 3.8% for SiO2-EG, respectively, while the deviations are 0.9 and 6.8% for SiO2-G NFs. The variation of the observed values from those estimated with Muzychka and Yovanovich's43 correlation increased with the Re. At a Re of 22,000, for instance, a maximum absolute deviation of 1.84% was determined. As the results show, the correlations for single-phase flow can be used to forecast the base liquid HTC with the slightest deviation. Similar experimental evidence can be found in the work of Hwang et al.46. The FF variation with the Re is illustrated in Fig. 8. The FF decreases marginally with concentration and significantly with the Re. The FF of 20.6% decrement with SiO2-EG and 4.6% increase with SiO2-G NFs with 1.0% NF compared to base liquid at 13,000 and 2000 Re, respectively. The decrease in SiO2-EG nanofluid FF might be due to the turbulent nature of flow as compared to SiO2-G at 1.0% concentration. At 1.0% concentration, the viscosity of SiO2-G is approximately 10 times greater than SiO2-EG, and flowing in the laminar range of Re might be the reason for enhancement in FF.

Further, the glycerol experiences greater friction within its adjacent fluid layers and exerts excellent flow resistance than ethylene glycol on external energy exposure. Also, the glycerol molecules' chemical (hydrogen) bonding is significantly robust, which means more external energy would be needed to break the intermolecular attraction forces and cause the liquid particles to move. A theoretical analysis was undertaken following the technique explained by Sharma et al.30 to understand the flow characteristics in detail.

From the Figs. 9 and 10, the surface temperature decreases with increasing flow rate and Re. Figure 9 shows the surface temperature variation with flow rate for SiO2-G and SiO2-EG NFs. The wall temperature of SiO2-G is comparatively lower than SiO2-EG NFs for specific concentrations. The NF heat capacity of SiO2-G is approximately 17% greater than SiO2-EG, which might be the cause for the lower wall temperatures observed. Also, the flow velocities with G are lower than with EG, which might be another reason for lower wall temperatures with SiO2-G. The surface temperature does not vary significantly for SiO2-G compared to SiO2-EG NF with Re in Fig. 10.

The effect of concentration has been investigated for the evolution of nondimensional flow velocity with dimensionless length, as shown in Fig. 11, established in the earlier work by Sharma et al.51. The velocity profile of SiO2-G is relatively flatter than SiO2-EG NFs. Albeit, the flattening of dimensionless velocity was more pronounced with SiO2-G NF owing to the motion of the NPs, as compared to the base liquid. NPs can move either towards the tube wall or the axis region, depending on the magnitude of the density ratio of the NPs to the base liquid. The velocity profile flattens as the NPs move more rapidly than the fluid; the NPs migrate toward the tube wall. When the fluid moves quickly, the particles drift toward the axis of the tube46,51. Figure 12 display the predicted dimensionless temperature distribution as a function of dimensionless distance. As can be seen, the temperature decreases with concentration.

The NF temperature profile of SiO2-G NF shows a higher temperature than the base liquid profile. The NF is associated with a decreasing temperature gradient in the flow vicinity away from the tube surface. One may compare the temperature gradients of SiO2-EG and SiO2-G nanofluids as illustrated in Fig. 13. Results show a logarithmic growth of the temperature gradient as the Re increase for SiO2-G NFs. At the same time, the SiO2-EG NFs display an inverse trend. More striking was the increasing temperature gradients for SiO2-G NF. The Nu does not vary significantly for the G and EG-based NFs. These findings concord with the earlier observation of higher HTCs with low-viscosity NFs10.

Machine learning-based model prediction

The experimental data and results collected in the experimental analysis part were used to create predictive models for friction factor and Nu number. The dataset typically contains information about Reynold’s numbers and Prandtl numbers estimated from the test setting and results. This data serves as the foundation for training and testing the predictive models. Often, it is necessary to preprocess raw experimental data to eliminate missing numbers, outliers, and other issues52,53. For preparing the dataset for model training, Python tools such as Pandas are utilized to clean and organize it. Understanding the structure of the dataset is crucial in order to gain valuable insights. With Python libraries such as Matplotlib and Seaborn, visualizations become effortless. This allows one to explore the connection between various factors, identify trends, and gain insights into the underlying patterns within the data.

Data pre-analysis

The correlation heatmaps for the data used in this study are shown in Fig. 14. It can be observed that There is a clear positive correlation between the Reynolds number and the Nusselt number, having a correlation coefficient of 0.73. This indicated that increasing the Re number will help in increasing the rate of heat transfer. On the other hand, a correlation coefficient of − 0.33 was observed between Re numbers and friction factors, indicating a negative correlation. The Prandtl number indicates a negative correlation (− 0.41) with the Nu number and a positive correlation (0.43) with the FF.

The descriptive statistical as listed in Table 3, offer insights into the characteristics of the dataset. For the variable Re number, it was noted that a mean value of 8154.069 and a standard deviation of 6569.183. The IQR spans from the 25th percentile at 2209.716 to the 75th percentile at 14,498.13. In the case of Re a negative kurtosis was observed, indicating a slightly flatter shape compared to a normal distribution. In the case of Pr number, a mean value of 117.947 and a standard deviation of 94.784 were observed. The IQR spans from 26.614 to 246.968, with a median value (50th percentile) of 80.166. The kurtosis for Pr is negative, indicating a distribution that is slightly flatter than the normal distribution54,55.

On the other hand, in the case of the Nu number, the mean was estimated at 28.115, and the standard deviation of 2.288. The kurtosis value in the case of Nu was also negative, suggesting a distribution that is slightly flatter than normal. Also, in the case of friction factor, a mean value of 0.176 was observed a standard deviation of 0.052. The IQR spans from 0.135 to 0.208, with a median value of 0.168. However, in the case of Ff is positive, demonstrating a slightly peaked distribution compared to the normal distribution.

Overall, these descriptive statistics provide a comprehensive overview of the dataset, including measures of central tendency, dispersion, and shape of the distributions for each variable.

Nusselt number model

A predictive model for the Nu number was built following the completion of the data analysis, which included the use of a correlation heatmap and descriptive statistical analysis. A random split of the data was performed at a ratio of 70:30 for the purpose of training and testing the model. The five ML approaches LR, RF, XGBoost, AdaBoost, and DT were employed for the development of prediction models. Following the completion of the models, they were utilized for the purpose of prediction. At the end of the Nu number models, the comparative findings depicting actual vs predicted Nu results are displayed in Fig. 15a–e. Figure 15a demonstrates the contrast between the actual values and the values predicted for LR-based model, and Fig. 15b for DT, Fig. 15c for RF, Fig. 15d for XGBoost, and the Fig. 15e for AdaBoost. It can be observed that except LR all other models performed in a satisfactory manner; however, the XGBoost-based model was more superior than the other models56,57,58.

The statistical evaluation of the Nu models developed with various methods was conducted and the results are listed in Table 4. In case of LR-based model a training MSE of 1.9 and a test phase MSE of 2.26 were observed. This indicates a poor level of performance indicating that the error caused by LR is substantially larger in comparison to that of other models. Given that the R2 values for LR are 0.651 for training and 0.35 for testing, it may be inferred that LR only explains a moderate amount of the variance in Nu. In the case of DT-based model, it showed a flawless performance, demonstrating MSE as 0 and R2 as 1. These values indicates that there were almost nil prediction errors. The DT-based Nu model demonstrated stellar performance during model testing also. It displayed a Test MSE of 0.095 and a Test R2 of 0.97259,60.

The performance of RF-based models was good as it had a train MSE of 0.0108 and a Test MSE of 0.069, indicating only a few errors throughout both the training and testing phases of the model development process. The R2 values in the case of RF were fairly high, at 0.998 during training and 0.98 for testing. This shows that RF may capture a significant portion of the volatility in Nu. Furthermore, XGBoost performs very well, as indicated by its Train MSE of 0.00001 and Test MSE of 0.045, both of which imply a low number of errors. With a training value of 0.9999 and a testing value of 0.9871, the XGBoost-based model’s R2 values are very high, suggesting that the model has an excellent link to the data. Given that AdaBoost has a Train MSE of 0.276 and a Test MSE of 0.4451, indicating that it has few mistakes, its performance is fairly excellent. AdaBoost's R2 values of 0.9496 for training and 0.8725 for testing indicate that the model fits the training data well, while the test data shows a minor reduction in performance61,62,63.

It can be observed that both RF and XGBoost stand out as the best models for predicting the Nu model, on the basis of statistical evaluations. This is owing to the fact that they produce low error metrics and high R2 values for both the training and test datasets. Because these models can correctly capture the complexities of the data and generate accurate predictions for the Nu model, they are suitable for regression applications.

The models were further tested using visual description by employing Taylor’s diagram and violin plots to compare their performance. Figure 16 depicts Taylor’s diagram while the violin plots for all models are depicted in Fig. 17. In the case of Nu model prediction during training, it can be observed that both DT and XGBoost-model performed superior to other models but the XGBoost-based model was best. Similarly, in the case of model testing, the XGBoost was the best model among the five-model tested in this case. The improved performance of RF and XGBoost models is primarily attributable to their robustness in dealing with complex, nonlinear interactions, as well as their ability to prevent overfitting using ensemble approaches. The violin plots were drawn for each of the models as depicted in Fig. 17a for the training phase while Fig. 17b shows violin plots for the testing phase. Hereto, it could be observed that the XGboost–based model was superior to other models as can be observed by the shape of violin plots as well as median lines on the plots.

Friction factor model

In the case of friction factor also, the five machine learning algorithms (LR, RF, XGBoost, AdaBoost, and DT) were employed for the creation of prediction models. After the models were completed, they were used to make predictions. Figure 18a–e show the comparison findings from the Nu number models, illustrating real vs expected Nu outcomes. Figure 18a shows the difference between the actual and predicted values for the LR-based model, followed by Fig. 18b for DT, 18c for RF, 18d for XGBoost, and 18e for AdaBoost. Except for LR, the other models performed satisfactorily; nonetheless, the XGBoost-based model outperformed the others.

The statistical evaluation of the friction factor models built using various approaches was performed, and the results are presented in Table 5. In the case of an LR-based model, the training MSE was 0.0022, while the test phase MSE was 0.00252. This shows a low degree of performance, implying that the error generated by LR is significantly bigger than that of other models. Given that the R2 values for LR are 0.232 for training and − 0.022 for testing, it can be concluded that LR only explains a small fraction of the variance in friction factor. The DT-based model performed flawlessly, with an MSE of zero and an R2 of one. These figures suggest that there were virtually no forecast mistakes. The DT-based Nu model performed admirably throughout model testing as well. It had a Test MSE of 0.00014 and an R2 of 0.94.

RF-based models performed well, with a train MSE of 0.00001 and a test MSE of 0.00007, indicating only a few errors during the model generation process. The R2 values for RF were rather high, at 0.994 during training and 0.97 during testing. This suggests that RF may capture a considerable percentage of the volatility in Nu. Furthermore, XGBoost works admirably, as seen by its Train MSE of 0.000002 and Test MSE of 0.0001, both of which suggest a smaller error. The R2 values for the XGBoost-based model are extremely high, with a training value of 0.999 and a testing value of 0.958, indicating that the model has a strong relationship to the data. Given that AdaBoost has a Train MSE of 0.00026 and a Test MSE of 0.00036, showing that it makes few errors, its performance is rather good. AdaBoost's R2 values of 0.906 for training and 0.852 for testing suggest that the model fits the training data well, while the test data reveals a modest loss in performance.

Statistical studies show that both RF and XGBoost are the best models for predicting the Nu model. This is due to the fact that they provide low error metrics and strong R2 values across both the training and test datasets. These models are appropriate for regression applications because they can accurately capture data complexity and give reliable predictions for the Nu model.

The models were further examined visually using Taylor's diagram and violin plots to compare their performance. Figure 19 illustrates Taylor's diagram, and Fig. 20 depicts the violin plots for all models. In terms of friction factor model prediction during training, both the RF and the XGBoost models outperformed the other models, but the XGBoost-based model was the best. Similarly, in terms of model testing, the XGBoost outperformed the other five models evaluated. Violin plots were constructed for each model as shown in Fig. 20a for the training phase, and Fig. 20b for the testing phase. Previously, it was noted that the XGBoost-based model outperformed other models, as seen by the shape of the violin plots and the median lines on the plots.

Conclusions

The work presents a convective heat transfer coefficient and friction factor assessment of ethylene glycol and glycerol-based non-porous silicon dioxide nanofluid flow in a tube under constant heat flux boundary conditions. The experiments were conducted for Reynolds numbers between 1300 and 21,000 and concentrations ranging from 0 to 1.0% volume at approximately 80 °C. The heat transfer coefficient and friction factor data were analyzed based on experimental thermophysical properties correlations. To model and predict the complex and nonlinear data acquired during experiments, prognostic model development using five machine learning techniques was employed. The following are the main results of the study:

-

Maximum heat transfer enhancements of 5.9% and 1.9% were determined at a 12 L per minute flow rate of silicon dioxide-ethylene glycol in the turbulent and silicon dioxide-glycerol nanofluids in the laminar range of Reynolds numbers for 1.0% concentration at approximately 80 °C.

-

Factors such as thermal conductivity enhancement, particle migration, Brownian motion of nanoparticles, and thinning of boundary layer thickness possibly play an important role in heat transfer augmentation. Single-phase flow correlations can predict the Nusselt number of silicon dioxide-ethylene glycol and silicon dioxide-glycerol nanofluids favorably.

-

The friction factor decreases with concentration for silicon dioxide-ethylene glycol nanofluid and the Reynolds number. Turbulent flow silicon dioxide-ethylene glycol yields lower friction factor values than laminar flowing silicon dioxide-glycerol nanofluids with 1.0% volume. Silicon dioxide-glycerol nanofluids presented lower surface temperatures, lower temperature gradients, and flattened velocity profiles.

-

Random forest-based models had good performance, with a training mean squared error of 0.0108 and a test mean squared error of 0.069. Extreme gradient boosting performed well, with a training mean squared error of 0.00001 and a test mean squared error of 0.045, implying a low number of errors.

-

Both random forest and extreme gradient boosting were the best models for predicting the Nusselt number model, owing to their low error metrics and high R-squared values. Models were further tested using visual descriptions, with extreme gradient boosting being the best model in both training and testing.

-

Random forest-based models performed well, with a training mean squared error of 0.00001 and a test mean squared error of 0.00007, indicating few errors during the model generation process. Extreme gradient boosting performed admirably, with a training mean squared error of 0.000002 and a test mean squared error of 0.0001, suggesting a smaller error.

-

Adaptive boosting's performance was good, with a training mean squared error of 0.00026 and a test mean squared error of 0.00036, indicating a good fit to the training data. Random forest and extreme gradient boosting were the best models for predicting the Nusselt number model due to their low error metrics and strong R-squared values across both the training and test datasets.

-

Visual examination of the models using Taylor's diagram and violin plots showed that the extreme gradient boosting-based model was the best in terms of friction factor model prediction during training and in terms of model testing.

Data availability

The data is available within the manuscript.

References

Hoang, A. T. et al. Energy-related approach for reduction of CO2 emissions: A critical strategy on the port-to-ship pathway. J. Clean. Prod. 355, 131772. https://doi.org/10.1016/j.jclepro.2022.131772 (2022).

Thu, N. T. P., Hanh, P. H., Dinh, N. Van, Luong, H. D. & Hue, D. T. M. Factors affecting CO2 emissions in Vietnam. Environ. Ecol. Res. 10, 307–313 (2022).

Said, Z., Rahman, S., Sharma, P., Amine Hachicha, A. & Issa, S. Performance characterization of a solar-powered shell and tube heat exchanger utilizing MWCNTs/water-based nanofluids: An experimental, numerical, and artificial intelligence approach. Appl. Therm. Eng. 212, 118633 (2022).

Alazwari, M. A., Abu-Hamdeh, N. H. & Salilih, E. M. Exergetic performance analysis on helically coiled tube heat exchanger-forecasting thermal conductivity of SiO2/EG nanofluid using ANN and RSM to examine effectiveness of using nanofluids. J. Therm. Anal. Calorim. 144, 2721–2733 (2021).

Huminic, G. & Huminic, A. Application of nanofluids in heat exchangers: A review. Renew. Sustain. Energy Rev. 16, 5625–5638 (2012).

Ahmed, S. F. et al. Nanomaterials as a sustainable choice for treating wastewater. Environ. Res. 214, 113807 (2022).

Wang, X., Xu, X. & Choi, S. U. S. Thermal conductivity of nanoparticle-fluid mixture. J. Thermophys. Heat Trans. 13, 474–480 (1999).

Daungthongsuk, W. & Wongwises, S. A critical review of convective heat transfer of nanofluids. Renew. Sustain. Energy Rev. https://doi.org/10.1016/j.rser.2005.06.005 (2007).

Trisaksri, V. & Wongwises, S. Critical review of heat transfer characteristics of nanofluids. Renew. Sustain. Energy Rev. https://doi.org/10.1016/j.rser.2005.01.010 (2007).

Gupta, M., Arora, N., Kumar, R., Kumar, S. & Dilbaghi, N. A comprehensive review of experimental investigations of forced convective heat transfer characteristics for various nanofluids. Int. J. Mech. Mater. Eng. https://doi.org/10.1186/s40712-014-0011-x (2014).

Vajjha, R. S., Das, D. K. & Kulkarni, D. P. Development of new correlations for convective heat transfer and friction factor in turbulent regime for nanofluids. Int. J. Heat Mass Transf. 53, 4607–4618 (2010).

Kulkarni, D. P., Namburu, P. K., Ed Bargar, H. & Das, D. K. Convective heat transfer and fluid dynamic characteristics of SiO2–ethylene glycol/water nanofluid. Heat Transf. Eng. 29, 1027–1035 (2008).

Bontemps, A. et al. Experimental study of convective heat transfer and pressure loss of sio2water nanofluids part 2: Nanofluid characterization—imposed wall Tmperature. In 2008 2nd International Conference on Thermal Issues in Emerging Technologies, ThETA 2008 https://doi.org/10.1109/THETA.2008.5167176 (2008).

Ferrouillat, S., Bontemps, A., Ribeiro, J. P., Gruss, J. A. & Soriano, O. Hydraulic and heat transfer study of SiO2/water nanofluids in horizontal tubes with imposed wall temperature boundary conditions. Int. J. Heat Fluid Flow 32, 424–439 (2011).

Darzi, A. A. R., Farhadi, M., Sedighi, K., Shafaghat, R. & Zabihi, K. Experimental investigation of turbulent heat transfer and flow characteristics of SiO2/water nanofluid within helically corrugated tubes. Int. Commun. Heat Mass Transf. 39, 1425–1434 (2012).

Julia, J. E. et al. Measurement and modelling of forced convective heat transfer coefficient and pressure drop of Al2O3- and SiO2-water nanofluids. In Journal of Physics: Conference Series Vol. 395 (2012).

Azmi, W. H. et al. Experimental determination of turbulent forced convection heat transfer and friction factor with SiO2 nanofluid. Exp. Therm. Fluid Sci. 51, 103–111 (2013).

Said, Z. et al. Nanotechnology-integrated phase change material and nanofluids for solar applications as a potential approach for clean energy strategies: Progress, challenges, and opportunities. J. Clean Prod. 416, 137736 (2023).

Sharma, K. V. et al. Prognostic modeling of polydisperse SiO2/Aqueous glycerol nanofluids’ thermophysical profile using an explainable artificial intelligence (XAI) approach. Eng. Appl. Artif. Intell. 126, 106967 (2023).

Deymi, O. et al. Toward empirical correlations for estimating the specific heat capacity of nanofluids utilizing GRG, GP, GEP, and GMDH. Sci. Rep. 13, 20763 (2023).

Deymi, O. et al. Employing ensemble learning techniques for modeling nanofluids’ specific heat capacity. Int. Commun. Heat Mass Transf. 143, 106684 (2023).

Cortinas-Lorenzo, K. & Lacey, G. Toward explainable affective computing: A review. IEEE Trans. Neural Netw. Learn Syst. https://doi.org/10.1109/TNNLS.2023.3270027 (2023).

Belle, V. & Papantonis, I. Principles and practice of explainable machine learning. Front. Big Data https://doi.org/10.3389/fdata.2021.688969 (2021).

Notovich, A., Chalutz-Ben Gal, H. & Ben-Gal, I. Explainable artificial intelligence (XAI): Motivation, terminology, and taxonomy. In Machine Learning for Data Science Handbook 971–985 https://doi.org/10.1007/978-3-031-24628-9_41 (Springer International Publishing, 2023).

Wang, H. et al. Solar irradiance forecasting based on direct explainable neural network. Energy Convers. Manag. 226, 113487 (2020).

Joseph, L. P., Joseph, E. A. & Prasad, R. Explainable diabetes classification using hybrid Bayesian-optimized TabNet architecture. Comput. Biol. Med. 151, 106178 (2022).

Kałużny, J. et al. Machine learning approach for application-tailored nanolubricants’ design. Nanomaterials 12, 1765 (2022).

Bemani, A., Madani, M. & Kazemi, A. Machine learning-based estimation of nano-lubricants viscosity in different operating conditions. Fuel 352, 129102 (2023).

Akilu, S., Baheta, A. T., Minea, A. A. & Sharma, K. V. Rheology and thermal conductivity of non-porous silica (SiO2) in viscous glycerol and ethylene glycol based nanofluids. Int. Commun. Heat Mass Transf. 88, 245–253 (2017).

Metin, C. O., Lake, L. W., Miranda, C. R. & Nguyen, Q. P. Stability of aqueous silica nanoparticle dispersions under subsurface conditions. In Nanotechnology 2010: Bio Sensors, Instruments, Medical, Environment and Energy—Technical Proceedings of the 2010 NSTI Nanotechnology Conference and Expo, NSTI-Nanotech 2010, Vol. 3 (2010).

Darzi, M. E., Golestaneh, S. I., Kamali, M. & Karimi, G. Thermal and electrical performance analysis of co-electrospun-electrosprayed PCM nanofiber composites in the presence of graphene and carbon fiber powder. Renew. Energy 135, 719–728 (2019).

Quijada-Maldonado, E., Meindersma, G. W. & De Haan, A. B. Viscosity and density data for the ternary system water(1)-ethanol(2)- ethylene glycol(3) between 298.15 K and 328.15 K. J. Chem. Thermodyn. 57, 500–505 (2013).

Hewitt, G. F. Heat Exchanger Design Handbook 2008. (2008).

Thulukkanam, K. Heat Exchanger Design Handbook, 2nd ed. https://doi.org/10.1201/b14877 (2013).

Lide, D. R. CRC Handbook of Chemistry and Physics, Internet Version 2005 (CRC Press, Taylor and Francis, 2005).

Tadjarodi, A. & Zabihi, F. Thermal conductivity studies of novel nanofluids based on metallic silver decorated mesoporous silica nanoparticles. Mater. Res. Bull. 48, 4150–4156 (2013).

Żyła, G. & Fal, J. Viscosity, thermal and electrical conductivity of silicon dioxide–ethylene glycol transparent nanofluids: An experimental studies. Thermochim. Acta 650, 106–113 (2017).

Escher, W. et al. On the cooling of electronics with nanofluids. J. Heat Transf. https://doi.org/10.1115/1.4003283 (2011).

Beckwith, T. G., Buck, N. L. & Marangoni, R. D. Mechanical Measurements Vol. 5 (Addison-Wesley, 1993).

Sundar, L. S. & Sharma, K. V. Turbulent heat transfer and friction factor of Al2O3 Nanofluid in circular tube with twisted tape inserts. Int. J. Heat Mass Transf. 53, 1409–1416 (2010).

Gnielinski, V. New equations for heat and mass transfer in turbulent pipe and channel flow. Int. Chem. Eng. 16, 359–367 (1976).

Del Giudice, S., Savino, S. & Nonino, C. Nusselt number correlations for simultaneously developing laminar duct flows of liquids with temperature dependent properties. In Journal of Physics: Conference Series, Vol. 547 (2014).

Muzychka, Y. S. & Yovanovich, M. M. Laminar forced convection heat transfer in the combined entry region of non-circular ducts. J. Heat Transf. 126, 54–61 (2004).

Ebrahimi, M., Deymi, O., Hadavimoghaddam, F. & Hemmati-Sarapardeh, A. Modeling gypsum (calcium sulfate dihydrate) solubility in aqueous electrolyte solutions using extreme learning machine. J. Water Process Eng. 57, 104664 (2024).

Colebrook, C. F. Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civil Eng. 11, 133–156 (1939).

Hwang, K. S., Jang, S. P. & Choi, S. U. S. Flow and convective heat transfer characteristics of water-based Al2O3 nanofluids in fully developed laminar flow regime. Int. J. Heat Mass Transf. 52, 193–199 (2009).

Chandrasekar, M., Suresh, S. & Chandra Bose, A. Experimental studies on heat transfer and friction factor characteristics of Al2O3/water nanofluid in a circular pipe under laminar flow with wire coil inserts. Exp. Therm. Fluid Sci. 34, 122–130 (2010).

Sesha Talpa Sai, P. H. V., Chaitanya Lahari, M. L. R., Sharma, K. V. & Narayanaswamy, K. S. Counterflow HE analysis of Cu and SiO2 nanofluids in the developing flow region. Heat Transf. 51, 3456–3494 (2022).

Marulasiddeshi, H. B., Kanti, P. K., Prakash, S. B. & Sridhara, S. N. Investigation of entropy generation and thermohydraulic characteristics of Al2O3–CuO hybrid nanofluid flow in a pipe at different inlet fluid temperatures. Int. J. Therm. Sci. 193, 108541 (2023).

Kanti, P. K., Sharma, K. V., Minea, A. A. & Kesti, V. Experimental and computational determination of heat transfer, entropy generation and pressure drop under turbulent flow in a tube with fly ash-Cu hybrid nanofluid. Int. J. Therm. Sci. 167, 107016 (2021).

Sharma, K. V., Azmi, W. H., Kamal, S., Sarma, P. K. & Vijayalakshmi, B. Theoretical analysis of heat transfer and friction factor for turbulent flow of nanofluids through pipes. Can. J. Chem. Eng. 94, 565–575 (2016).

Berberich, J., Kohler, J., Muller, M. A. & Allgower, F. Data-driven model predictive control with stability and robustness guarantees. IEEE Trans. Autom. Control 66, 1702–1717 (2021).

Tariq, Z. et al. Data-driven machine learning modeling of mineral/CO2/brine wettability prediction: Implications for CO2 geo-storage. In SPE Middle East Oil and Gas Show and Conference, MEOS, Proceedings. https://doi.org/10.2118/213346-MS (2023) .

Cain, M. K., Zhang, Z. & Yuan, K.-H. Univariate and multivariate skewness and kurtosis for measuring nonnormality: Prevalence, influence and estimation. Behav. Res. 49, 1716–1735 (2017).

Liao, W., Luo, Y. & Chen, T. Thermal-hydraulic performance analysis of outward convex corrugated tubes based on skewness and kurtosis. Int. J. Therm. Sci. 165, 106970 (2021).

Qiu, Y. et al. Performance evaluation of hybrid WOA-XGBoost, GWO-XGBoost and BO-XGBoost models to predict blast-induced ground vibration. Eng. Comput. 38, 4145–4162 (2022).

Chen, T. & Guestrin, C. XGBoost: A scalable tree boosting system. In Proceedings of the ACM SIGKDD International Conference on Knowledge Discovery and Data Mining vols. 13–17-August-2016, 785–794 (Association for Computing Machinery, 2016).

Said, Z., Sharma, P., Bora, B. J. & Pandey, A. K. Sonication impact on thermal conductivity of f-MWCNT nanofluids using XGBoost and Gaussian process regression. J. Taiwan Inst. Chem. Eng. 145, 104818 (2023).

Kotsiantis, S. B. Decision trees: A recent overview. Artif. Intell. Rev. https://doi.org/10.1007/s10462-011-9272-4 (2013).

Sun, X. et al. Modeling and optimization of vegetable oil biodiesel production with heterogeneous nano catalytic process: Multi-layer perceptron, decision regression tree, and K-nearest neighbor methods. Environ. Technol. Innov. 27, 102794 (2022).

Kumar, K. P., Alruqi, M., Hanafi, H. A., Sharma, P. & Wanatasanappan, V. V. Effect of particle size on second law of thermodynamics analysis of Al2O3 nanofluid: Application of XGBoost and gradient boosting regression for prognostic analysis. Int. J. Therm. Sci. 197, 108825 (2024).

Zhang, M., Chen, W., Yin, J. & Feng, T. Lithium battery health factor extraction based on improved Douglas-Peucker algorithm and SOH prediction based on XGboost. Energies 15, 5981 (2022).

Siqueira-Filho, E. A., Lira, M. F. A., Converti, A., Siqueira, H. V. & Bastos-Filho, C. J. A. Predicting thermoelectric power plants diesel/heavy fuel oil engine fuel consumption using univariate forecasting and XGBoost machine learning models. Energies 16, 2942 (2023).

Acknowledgements

The authors acknowledge the first author's financial support from Universiti Teknologi PETRONAS through an FRGS grant (0153AB-K01) and Graduate Assistantship (GA).

Author information

Authors and Affiliations

Contributions

SA.: conceptualization, methodology, data curation, writing—original draft. KVS: writing—review and editing, resources, supervision. ATB: writing—review and editing, resources, methodology. PKK.: writing—original draft, writing—review and editing. PP: Project administration, supervision, Validation, writing—review.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Akilu, S., Sharma, K.V., Baheta, A.T. et al. Machine learning analysis of thermophysical and thermohydraulic properties in ethylene glycol- and glycerol-based SiO2 nanofluids. Sci Rep 14, 14829 (2024). https://doi.org/10.1038/s41598-024-65411-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-65411-8

Keywords

This article is cited by

-

Density and Thermal Conductivity Measurements of Alcohol/Water-Based Ternary Nanofluids Containing GO–Al2O3–SiO2 Nanoparticles

International Journal of Thermophysics (2026)

-

PTEN as a prognostic factor for radiotherapy plus immunotherapy response in nasopharyngeal carcinoma

Journal of Nanobiotechnology (2025)

-

Machine and deep learning models for predicting high pressure density of heterocyclic thiophenic compounds based on critical properties

Scientific Reports (2025)

-

Estimating Pipe Friction Factors Using Machine Learning Approaches

Iranian Journal of Science and Technology, Transactions of Civil Engineering (2025)

-

An imperative need for machine learning algorithms in heat transfer application: a review

Journal of Thermal Analysis and Calorimetry (2025)