Abstract

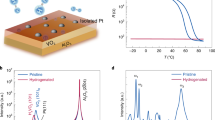

A Hydrogen fuel cell (HFC) broad range associated with Internet of Things (IoT) technologies that require slightly less and constant electricity made possible by remote climate monitoring connections. Novelty demonstrates a miniature HFC based on carbon cloth electrodes and sealing elements manufactured via 3D printing. Cobalt (II) Oxide (Co3O4)—reduced Graphene Oxide (rGO) and Platinum (Pt) based nanoparticles are coated over carbon cloth to increase the catalytic activity at the anode and cathode. Hydrogen is produced by using an aluminium foil (Al) that is stored in between the filter paper and through capillary action the sodium hydroxide pellets (NaOH) are applied and reacted with Al foil to produce hydrogen. The single HFC device working surface area of 1 × 1 cm2 effectively generates an open circuit voltage (OCV) of 1.3 V, a current density of 1.602 mA/cm2, and a peak power density of 761 mW/cm2. The fuel cell stability performance is monitored for up to 10 h. The power obtained from the HFC is stored in a supercapacitor and used to supply energy to the IoT component. The module includes a built-in sensor that monitors the temperature, pressure, and humidity. The measured data is then transmitted to a smartphone via Bluetooth.

Similar content being viewed by others

Introduction

Hydrogen fuel cell (HFCs) get a lead through efficient and extensive use of potential power in zero-emission mode1. A chemical energy source that can generate electricity via an electrochemical process and produce hydrogen2. Fuel cell technological devices, and includes hydrogen fuel cells that are capable of utilizing electric energy and reduce energy loss even when the electric vehicle is fully powered by the fuel cell. This energy has been an appealing substitute over the past few decades due to its excellent conversion of electricity productivity, minimal emissions, and relatively low cost of operation3. The development of expertise in this electrochemical approach will be necessary to go from current power schemes and rechargeable arrays to vehicles that will be converted to run on hydrogen fuel cells. It is a safe and practical method of creating, storing, and using hydrogen-based fuel cells4. Various printable techniques, commonly used in external manufacturing technologies, are employed to enhance energy sources5. Fuel cell ability to convert chemical energy into electrical energy with the most adaptable and efficient designed setup6. A fuel cell is an energy-harvesting device that offers high fuel efficiency and produces almost no emissions. Additionally, future generations will benefit more from the enhanced utilization of hydrogen fuel cells.

It has practical electronic and modest power applications and can be used in transportation7,8. The hydrogen fuel cell generates the electricity required by real-time applications. The performance of the hydrogen fuel cell, once it is fully integrated with a real-time system, has the best chance of achieving the technical goals9. Mechanisms of the fuel cell include an anode for oxidation, and a cathode for reduction, which permits ions through an electrolyte. The cathode receives free protons and electrons after hydrogen is oxidized on the anode. Once the electrons pass through the cathode, these protons fold away over the electrolyte. The proton then combines with oxygen at the cathode to produce water as a residue10. This procedure produces clean energy and does not damage the environment11.

Wang, Y. et al. developed the carbon-coated and platinum-coated surface and is used as the anode, cathode coated with manganese dioxide (MgO2) and a carbon nanotube (CNT), the fabricated hydrogen fuel cell device based on the paper-based electrode. The minimum power density from this arrangement is 4 mW/cm2,12. The efficiency of energy systems is improved by these innovative materials, designs, and technologies. Esquivel, J. P. et al. documented a hydrogen fuel cell composed of a magnesium and iron (Mg: Fe) alloy, constructed using paper-based materials. This device demonstrates a potential power density of 25 mW/cm2. Notably, its module operates without a membrane and exhibits improved efficiency in transporting H + /OH- ions to the working electrode compared to traditional devices coated with (Mg: Fe)13.

Modeling oxygen transfer on carbon cloth-based substrates can improve cathode performance significantly, paving the way for an extended phase of innovations14. The conversion of the metals and oxides of the metals into carbon compounds has proven to be a successful strategy for facilitating quick electron exchange and promoting the development of HFC, since it is economical, non-toxic, environmentally acceptable, and has better catalytic activity. The capability of fabricating thin film electrodes using the well-known method for the microelectronic industry as well as testing for fuel cells and electrochemical applications15. The generation of hydrogen through water electrolysis demands an enormous excess potential to develop the maximum current to conquer the slow kinetics. By enhancing the catalyst action, this potential can be utilized. Therefore, it is crucial to use effective and durable catalysts for electricity to enhance hydrogen evolution reaction (HER) efficiency for mass manufacturing, and the best catalysts for HER reaction are cobalt-based ones16. Fuel cell energy storage systems can offer a practical solution to storage problems. For longevity, high-power density, and ultra-capacitors are recommended for use in fuel cells after comparison with other energy storage technologies17. The finding of this category in fuel cell performance has led to the improvement and ongoing development of platinum-based catalysts. An advanced technique, electrolysis, uses electricity to divide hydrogen and oxygen and it opens the door to hydrogen synthesis from any energy source that may be used to produce electricity18. The main goal of this research is to precisely build hydrogen fuel cell emissions testing to produce water or vapor from the device utilizing hydrogen from various techniques of hydrogen production. Currently, one of the greatest possibilities for printed electronic equipment is meant for one-time usage and discarded after use. It is low-cost, extremely energy-dense, and sustainable to be printable as a principal fuel cell. The conventional primary fuel cell in the market for almost a century, are highly technological and inexpensive to manufacture19. Carbon-based products with extremely thin, two-dimensional morphologies, such as carbon paper, cloths, or meshes, hold great promise as electrode materials for HFC20,21,22. The combination of connecting the IoT and supercapacitor integration to store the maximum power to real-time applications. These single devices give superior performance for this hydrogen fuel cell. This directed the improvement of a simple, cost-effective fuel cell technology. This study demonstrated the functionality of a hydrogen fuel cell fabricated on a carbon fabric substrate. An aluminium foil embedded within the paper substrate acted as the hydrogen source. Pt-coated carbon cloth served as the cathode, while Co3O4-rGO catalyst-coated carbon cloth was used as the anode. Sodium hydroxide (NaOH), delivered via capillary action, functioned as the alkaline electrolyte solution. This study showcases the ability of a Co3O4 – rGO coated device to supply continuous power to a wireless network. To increase the power output of such Internet of Things (IoT)-enabled sensors, a configuration that has been specifically designed is implemented. Al foil and the electrolytes are reacted to create H2 gas, utilized as the cathode to generate electricity. The polarization efficiency is examined while the electrolyte concentrations and catalyst loading effects are adjusted and the fuel cell power and current density of the device (Table 1).

Observational techniques

Materials and chemicals

The gas diffusion electrode (GDE) is coated with platinum/carbon ink (Pt/C)-0.2mg/cm2-20%), and commercially available hydrophobic carbon cloth (CC) is also purchased from (Fuel Cell Store, USA). Polyamide (PI) film that is sold widely (Kapton 125 mm) was acquired from Dali Electronics in India. Cobalt (II) chloride hexahydrate (CoCl2-6H2O), Sodium hydroxide pellets (NaOH), and Potassium hydroxide (KOH) are purchased from Sisco Research Laboratories (SRL) in India. For 3D printing filaments, 1.75 mm in diameter is purchased from 3D Pvt. Ltd. India. All of the experimental solutions are made with 18.2 MΩ.cm Milli-Q (Isserlabs) water that has undergone double distillation (DI water). The substrate is made of grade 1 filter paper, and the hydrogen source uses food-grade (Al) foil purchased from a local store.

Device fabrication of supercapacitor

To fabricate the SC device on polyamide (PI) using Laser-induced Graphene (LIG), the PI sheet was laser scribbled, utilizing direct patterning with a CO2 universal Laser & Engraver which is shown in Fig. 1. This was accomplished by optimized power and speed settings of 2.4 W and 175 mm/s, respectively. These particular settings were selected after multiple attempts to provide the most efficient porous graphitized substrate with optimal conductivity26. The graphene-based device has significant performance in cell capacitance, operating voltage, equivalent series resistance, power density, and energy density in areal capacitance. This difference might be due to its increased ionic diffusion as a result of its large surface area, superior electrical conductivity, and evenly distributed porosity across the thin film. These properties work together to promote electrolyte ion transport, which may explain the increased capacitance reported. For device fabrication, an interdigitated structure for an electrode system has been used with Polyvinyl alcohol (PVA) based KOH gel and dry electrolyte.

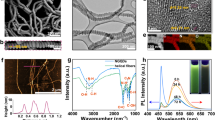

Development of the carbon-cloth electrode activation

Hydrophobic sets are induced on the electrode surface by plasma preservation for convert hydrophilic carbon fabric surface area of (1 × 1 cm2) for one minute, which facilitated the consumption of cobalt oxide (II)-reduced graphene oxide (Co3O4—rGO). The homogeneous carbon cloth-based electrodes increase the enactment for a longer epoch of time. The anode is prepared by diffusing 3 mg of (Co3O4 – rGO) complex in 2 ml of ethanol for 30 min to generate an even spreading of the catalyst ink. Once the anode carbon cloth electrode has been ready, 100 µl of catalyst ink should be dropped onto the surface and allowed to dry for 10 min in a hot air oven set to 60 °C. Platinum-coated carbon cloth is used for the GDE (Pt/C) cathode -0.2 mg/cm2—20%, which is readily available fabric and is shown in Fig. 3a,b. It has been reported that the platinum catalyst reaction can improve the performance of hydrogen production27. Grade 1 Filter paper provides a barrier between the electrodes and keeps Al foil inside the paper barrier. The wax barrier provides a correct hydrophobic zone and forces them to organize separate fuel-streaming28.

Design integration of hydrogen fuel cell device

The carbon cloth electrodes are treated with plasma and (Co3O4 – rGO) coated cloth and used as an anode and platinum cloth is used as a cathode these catalysts display increased robustness and high efficiencies for electrocatalytic H2 evolution shown in Fig. 2a,b. The implementation of creating a miniature 3D printed device is to incorporate the hydrogen fuel cell electrodes inside of the setup Fig. 2g. Wax-coated grade 1 filter paper is used to encase an (Al) foil located amongst the electrodes as shown in Fig. 2c,d. The hydrogen fuel cell coverage setup is designed by computer-aided designing (CAD) software SOLIDWORKS (2016) (https://help.solidworks.com/2016/english/whatsnew/c_welcome_solidworks_2016.htm) and converted into the (.dxf) format29.

The Flashforge creatorpro FDM 3D printer is used to print with Polylactic acid (PLA), and filaments choosing the dimensions of the bottom base cell 1.8 cm2 and top base cell 2.2 cm2 then the electrode size is (1 × 1 cm2) to fit in the 3D printed setup shown in Fig. 2f,g and Fig. 3a,b. The electrode current collector is a piece of copper tape23. To lessen the rate of corrosion during the H2 generation, 3.5 mg of (Al) foil with (11-µm) thickness and (5 × 5 mm) is encased in a paper substratum Fig. 2e. Grade 1 filter paper inlet is used to supply NaOH electrolyte (100 µl) Fig. 3c,d. There is no air leaking into the anode side completely sealed to the top base 3D printed. Furthermore, the 3D-printed bottom case featured a hole-in-the-wall to let atmospheric oxygen improve the mHFC power output, and the real-time device fabrication setup is shown in Fig. 3e.

Electrochemical technique

The electrodes are subjected to electrocatalytic examination using a potentiostat/Galvanostat (SP- 150 from Biologic, France)30. Initially, open circuit voltage (OCV) stabilization is seen by measuring OCV with a multimeter for up to 10 min. The cathodic electrode is linked to the working, anodic electrode is associated with the counter and reference electrodes, to record power performance measurements31. The HFC polarization performance was evaluated at different concentrations using Linear Sweep Voltammetry techniques (LSV) on a small 3D-printed integrated carbon cloth-based device. Due to self-pumping and air-breathing, this HFC requires time to perform consistently. An air-breathing system uses ambient air as its oxygen source, while a self-pumping mechanism allows the system to regulate its own fuel and oxidant supplies without the need for external pumps. The current will remain constant, and voltage will be supplied in this setup then electrocatalytic studies are performed with produced electrodes were conducted the complete test. For electrochemical characterization, a two-electrode configuration including an anode and cathode-modified electrode as the working electrode, accordingly, was placed in a 5 mL cell, and chronoamperometry(CA) techniques were performed in a typical potential window.

Results and discussion

Structural characterization

The construction of CC electrodes resembles that of a textile, according to scanning electron microscopy (SEM) results shown in Fig. 4. SEM analysis is performed on the plain carbon cloth in Fig. 4a, cathode catalyst platinum–carbon coated CC electrodes, and the cobalt oxide-rGO coated anode catalyst CC electrodes Fig. 4b,c. Image analysis of cobalt oxide-rGO manifests the prediction of nanoparticles shown in Fig. 4d. An energy-dispersive X-ray analyzer (EDAX) also observes the elementary examination of electrodes. The EDAX examination of the anode proved that Co-13%, O-33%, and C-55% are present. The elements Pt (21%) and carbon (80%) made up the cathode.

Concentrations of the electrolyte and the catalyst study

Energy production requires the presence of electrolytes, particularly fluid and water-based ones. Depending on their optimal pH, these electrolytes belong to the alkaline (7–14) groups. The most widely used electrolytes are alkaline solutions like sodium hydroxide (NaOH) for fuel cells32. Anodic and cathodic electrode function area is assessed with chronoamperometric (CA) analysis to find the power performance of the device. Initially, in linear sweep voltammetry studies (LSV), the concentration effect of NaOH is examined between concentration windows of 0.4 mM to 3 mM, and its resultant values related to current density were measured. The step of hydrogen fusion slowed and the concentration of NaOH representation, the device effectiveness was also reduced as a result of the (Al) foil quick decline. Alkaline-based pH 7.2 used with 2 mM NaOH provided a better concentration effect than shown in OCV and delivered a significant maximum current density of 8 µA/cm2 shown in Fig. 5a. The analysis of the current density at each loading, indicated by different catalytic constants, is performed using the 1 mg/mL to 5 mg/mL of catalyst. In Fig. 5b, these (Co3O4–rGO) showed that a catalyst loading of 4 mg/mL produced a greater current density of 16 µA/cm2. Overloading the catalyst may accelerate internal deterioration processes in the fuel cell, such as flattening of nanoparticles, catalyst clustering, and electrode erosion. The stability and durability of the fuel cell are often reduced by these processes. The effect of fuel cell enactment diminished at a high loading because diffusion of the higher catalyst loading of reacting molecules led to lower adsorption which decreased activation energy and decreased hydrogen fuel cell performance and monitored with higher catalyst loading33.

Performance of aluminium foil thickness study

Two (Al) foil investigations used 3.5 mg of 11 µm thickness and 6.2 mg of 18µm thickness for the hydrogen fuel cell, and performance is related to looking into this effect. The (Al) foil affects how quickly hydrogen is supplied while the gadget is in use. It will take an extended time of around 10 to 20 min for the (Al) foil to react with the alkaline medium, later the hydrogen supply is decreased as (Al) foil thickness grows because (Al) oxide forms over the surface of the foil, and that oxide layer will affect the further oxidation of the electrode and it will reduce hydrogen production. The peak power density is higher with the 11 µm (Al) foil (1 × 1 cm2) than with the 18 µm thickness. Reaction rates increase overall if thinner foils allow for improved mass transfer and gas diffusion inside the fuel cell. Materials with a thinner gauge can disperse heat more efficiently, avoiding overheating and preserving ideal operating temperatures. The devices are connected and get a maximum OCV of 545 mV when using 3.5 mg of 11 µm thickness (Al) foil, and a maximum power density of 71 µW/cm2 as revealed in Fig. 6a. The hydrogen utmost power density of the polarization curve max OCV is 385 mV and was determined using the 18 µm thickness shown in Fig. 6b with a concentrated power density of 21.61 µW/cm2. The (Al) foil remains exposed to NaOH, the reaction takes the longest period to complete, and as soon as the reaction reaches its height, the (Al) foil begins to corrode, and hydrogen production will slowly decrease. In comparison, the 11 µm thickness has produced more hydrogen, and if the foil thickness is increased further, the alkaline medium reaction does not take place for as long.

Electrochemical impedance spectroscopy (EIS) analysis

To comprehend the electron transfer mechanism of utilizing carbon cloth electrodes with NaOH electrolytes, the impedance study was carried out with two electrode systems. This study made it easier to understand and measure the charge transfer resistance (Rct) of electrode/electrolyte interfaces over a broad frequency range34. The carbon cloth-based hydrogen fuel cell Nyquist plots Fig. 7b show how the electrolyte used—NaOH, for example, Fig. 7a, which represents its equivalent circuit—affects the Rct value. For the NaOH electrolytes, the corresponding Rct values were 135 Ω. According to the experiment, the NaOH electrolyte used in the carbon cloth-based hydrogen fuel cell has a greater oxygen diffusion coefficient, a faster kinetic reaction, and higher ion conductivity.

Polarization performance

Improved factors, including electrolyte content and catalyst loading, are used to analyze the HFC performance to optimize the power output at various concentration levels. Using the chronoamperometry (CA) method, the power curves are drawn by reducing the OCV from maximum to 0 mV and noting each potential state current density value35. The hydrogen production started within 10 min, and the manufactured HFC produced a constant voltage of 1300 mV observed in devices when the electrolyte was applied through paper-based inlets. A high-power density of 761 mW/cm2 and a maximum current density of 1.60 mA/cm2 are observed using the 11µm thickness of (Al) foil with continuous flow of electrolyte and polarization performance shown in Fig. 8. The polarization curves show the mass transfer losses and activation that take place during hydrogen production. The voltages are checked from maximum OCV to 0 mV throughout this measurement and the equivalent current is determined for each voltage conversion. Then multiplying these gathered numbers, the power curve is plotted.

The fuel cell products allow us to test the starting values of each assembly of cells under a certain scenario and, based on real-time experience, specify failure thresholds. These investigations are completed using improved concepts, like electrolyte concentration study, and catalyst loading parameters before determining overall performance. Single-cell HFC harvested the power density of 25.6 µW/cm2 at 480 mV36.

Stability analysis

A discharge analysis study is used to determine the device consistent performance. The stability of the generated HFC is examined over time using a standard cloth substrate and a single HFC configuration used through continuous electrolyte supply through capillary action. The hydrogen fuel cell open circuit voltage in a single device connection (1.3 V) is measured over a period for an analysis of the practical values of stable performance up to 560 min and is shown in Fig. 9

Afterward, the device stability began to deteriorate quickly as the fuel cell. To construct the experiment, the hydrogen fuel cell was given a dependable and unfailing OCV for up to 10 h later a progressive reduction in output. The hydrogen fuel cell is more constant over intervals than a fuel cell based on paper because carbon cloth maintains the catalyst performance on the surface and keeps the constant electron transfer period and the connection of the device is calculated using different analysis methods.

Printed circuit boards (PCBs) assembly with IoT module

Printed circuit boards (PCBs) are robust, nonconductive boards on a substrate-based construction. PCB has been designed with Easy EDA software version 6.5.40 (https://easyeda.com/page/download) and the primary functions of PCBs are to mechanically maintain and link electrical parts in a circuit. Necessary components are placed on the PCBs by the design standards and requirements to meet the final design form factor. The form factor is an aspect of any hardware design that describes the overall size, shape, and other pertinent physical characteristics of the PCB and the designed file size is 78.98 × 56.87 mm. This design was useful for miniaturizing and connecting with IoT components for further implementation in small-scale applications.

Hydrogen fuel cell integration with supercapacitor

The graphene-based device has significant performance in areal capacitance. This difference might be due to its increased ionic diffusion as a result of its large surface area, superior electrical conductivity, and evenly distributed porosity across the film37. These properties work together to promote electrolyte ion transport, which may explain the increased capacitance reported. An interdigitated configuration comprising two graphitized electrodes on a polyimide flexible substrate has been employed in the fabrication of a device and this setup utilizes a PVA-KOH electrolyte.

The components are integrated with the PCB board and with the help of IoT nodes to enable the Power in HFC and supercapacitor integration further. To integrate the Internet of Things, an open-source Arduino-embedded microcontroller was used to construct monitoring for a standard circuit in this research shown in Fig. 10. The presence of an integrated energy storage mechanism allows for longer power storage and continuous circuit operation. A supercapacitor was selected in this case over a battery because of its greater energy capacity, quicker charging time, and longer lifespan. The energy density and power density are shown in the 2.31 μWh/cm2 and 0.2 mW/cm2 at 0.5 mA/cm2 and the supercapacitor can able to hold the potential window of 0.8 V to 1.5 V34. That was selected while also considering the power needs of the Internet of Things circuit and the power management unit (PMU) used. This complete setup of supercapacitor charging time was around 15 min from the fuel cell the circuit will enable the Bluetooth connection and we can monitor the device performance with a mobile phone.

Powering customized IoT module integrated with supercapacitor

The specific IoT module was powered by fuel cell energy of 1.3 V collected after the supercapacitor was charged up to 1.3 V. The ATmega328P microcontroller, NRF24L01 wireless transceiver module (2.4 GHz), and BME280 sensor made up the entire Internet of IoT circuit. The integrated BME280 sensor measured a variety of environmental factors, including temperature. This embedded sensor was turned on by harnessing this energy using the PMUs, the fuel cell first fully charged the supercapacitor. Subsequently, the customized Ultra-Low-Power (ULP) Internet of Things (IoT) Node was turned on Ref.38, and it began transmitting the relevant data such as humidity, pressure, and temperature—in a sequential manner, sending packets every 20 s. An ultra-low power (ULP) digital converter-digital converter (DC-DC) (CJMCU-25504, China) circuit is used to raise the potential range.

The combined board includes electrical energy parameters (DC-DC converter), programmable maximum power point tracking (MPPT), and built-in energy storage from the hydrogen fuel cell38. Usually, the input voltage is raised by the HFC connected to the booster circuit until it reaches its highest level. It took 20 min to increase the initial potential start from 1.3 V to 3.1 V then it reached the microcontroller, temperature sensor, and Bluetooth. The detected information from the sensors was subsequently recorded on a smartphone with an available NRF interaction which used an integrated Bluetooth communication module. The user interface of the app showed the information gathered at the moment. Utilizing the BLE beacon internet, which employs low-energy Bluetooth wireless communication to send signals in the form of packets to other nearby smart gadgets, gathering information from the sensors was communicated. Figure 11 shows the entire scheme, which consists of a fuel cell, PMUs, an IoT module, and a mobile device with an interaction. The complete device operation Video is shown in the supplementary.

The manufactured HFC is attached to the supercapacitor and connected to the DC-DC booster to increase power up to 3V, which is subsequently connected to the 1.5 V real-time digital watch. Next, as seen in Fig. 12, enabling the 2 V light-emitting diode (LED) supply. The present HFC is possibly used in real-time, the watch is powered by the harvested energy. The upgraded production control terminal is then connected to the digital watch and LED to enable the real-time testing circuit.

Conclusions

In this work, a miniaturized HFC device fabricated with CC-based electrodes was developed with (Co3O4–rGO) and verified for efficiency in terms of energy recovery employed for monitoring the temperature and humidity via Internet of Things (IoT) technology and the (Al) foil is employed inside the filter paper and that reaction was the source of as a hydrogen production. This novel catalyst for HFC could be a valuable energy foundation for low-power applications due to its maximum OCV of 1.3 V and power density of 761 mW/cm2. However, more power output and stability can be obtained in 10 h by varying the quantity of (Al) foil used for hydrogen production with the help of the NaoH electrolyte. LIG-based supercapacitor integration with HFC has useful output in its affordable and simple-to-manufacture components, and it is effective in a range of low-power and data broadcast applications. Moreover, an adapted IoT module featuring an integrated environment monitoring IoT sensor was powered to show the instantaneous use of energy production. Using (PMUs), which controlled the electrical charge gathered from the HFC, this sensor could detect the ambient temperature, tension, and moisture. This PMU features MPPT, configurable DC-to-DC voltage transformation, and supercapacitor energy storage. The findings demonstrate that a device wireless detector may be operated effectively using the power generated by the HFC, transmitting messages to a smartly mobile device and an application. More design modifications, stacked architecture, and printable catalytic nanocomposite are also desired to maximize the generation of energy.

Data availability

The data generated or analyzed during this study are included in this published article [and its supplementary information files].

References

Robledo, C. B., Oldenbroek, V., Abbruzzese, F. & van Wijk, A. J. M. Integrating a hydrogen fuel cell electric vehicle with vehicle-to-grid technology, photovoltaic power and a residential building. Appl. Energy 215, 615–629 (2018).

Manoharan, Y. et al. Hydrogen fuel cell vehicles; Current status and future prospect. Appl. Sci. (Switzerland) 9, 2296 (2019).

Moore, R. M., Hauer, K. H., Ramaswamy, S. & Cunningham, J. M. Energy utilization and efficiency analysis for hydrogen fuel cell vehicles. J. Power Sources 159, 1214–1230 (2006).

Singla, M. K., Nijhawan, P. & Oberoi, A. S. Hydrogen fuel and fuel cell technology for cleaner future: A review. Environ. Sci. Pollut. Res. 28, 15607–15626 (2021).

Mooraj, S. et al. 3D printing of metal-based materials for renewable energy applications. Nano Res. 14, 2105–2132 (2021).

Jayapiriya, U. S. & Goel, S. Influence of cellulose separators in coin-sized 3D printed paper-based microbial fuel cells. Sustain. Energy Technol. Assess. 47, 101535 (2021).

Sürer, M. G. & Arat, H. T. Advancements and current technologies on hydrogen fuel cell applications for marine vehicles. Int. J. Hydrogen Energy 47, 19865–19875 (2022).

Haseli, Y. Maximum conversion efficiency of hydrogen fuel cells. Int. J. Hydrogen Energy 43, 9015–9021 (2018).

Grady, C. et al. Design tool for estimating adsorbent hydrogen storage system characteristics for light-duty fuel cell vehicles. Int. J. Hydrogen Energy 47, 29847–29857 (2022).

Foorginezhad, S. et al. Sensing advancement towards safety assessment of hydrogen fuel cell vehicles. J. Power Sources 489, 229450 (2021).

Evrin, R. A. & Dincer, I. Thermodynamic analysis and assessment of an integrated hydrogen fuel cell system for ships. Int. J. Hydrogen Energy 44, 6919–6928 (2019).

Wang, Y. et al. A flexible paper-based hydrogen fuel cell for small power applications. Int. J. Hydrogen Energy 44, 29680–29691 (2019).

Esquivel, J. P. et al. Single-use paper-based hydrogen fuel cells for point-of-care diagnostic applications. J. Power Sources 342, 442–451 (2017).

Fu, Y. L. et al. Pore-scale modeling of oxygen transport in the catalyst layer of air-breathing cathode in membraneless microfluidic fuel cells. Appl. Energy 277, 115536. https://doi.org/10.1016/j.apenergy.2020.115536 (2020).

Tian, Y., Zou, Q. & Lin, Z. Hydrogen leakage diagnosis for proton exchange membrane fuel cell systems: Methods and suggestions on its application in fuel cell vehicles. IEEE Access 8, 224895–224910 (2020).

Li, X. et al. Vanadium doped nickel cobalt phosphide as an efficient and stable electrode catalyst for hydrogen evolution reaction. J. Electroanal. Chem. 902, 115812 (2021).

Wu, T. et al. Hydrogen energy storage system for demand forecast error mitigation and voltage stabilization in a fast-charging station. IEEE Trans. Ind. Appl. 58, 2718–2727 (2022).

Pedersen, C. M. et al. Benchmarking Pt-based electrocatalysts for low temperature fuel cell reactions with the rotating disk electrode: Oxygen reduction and hydrogen oxidation in the presence of CO (review article). Electrochim. Acta 179, 647–657 (2015).

Jiang, Y., Wang, X., Zhong, L. & Liu, L. Design, fabrication and testing of a silicon-based air-breathing micro direct methanol fuel cell. J. Micromech. Microeng. 16, S233–S239 (2006).

Ning, X., Zhou, X., Luo, J. & Zhan, L. PtBi on carbon cloth as efficient flexible electrode for electro-oxidation of liquid fuels. J. Electroanal. Chem. 904, 115958 (2022).

Rao, L. T., Rewatkar, P., Dubey, S. K., Javed, A. & Goel, S. Automated pencil electrode formation platform to realize uniform and reproducible graphite electrodes on paper for microfluidic fuel cells. Sci. Rep. https://doi.org/10.1038/s41598-020-68579-x (2020).

Li, S., Cheng, C. & Thomas, A. Carbon-based microbial-fuel-cell electrodes: From conductive supports to active catalysts. Adv. Mater. https://doi.org/10.1002/adma.201602547 (2017).

Rewatkar, P., Enaganti, P. K., Rishi, M., Mukhopadhyay, S. & Goel, S. Single-step inkjet-printed paper-origami arrayed air-breathing microfluidic microbial fuel cell and its validation. Int. J. Hydrogen Energy 46, 35408–35419 (2021).

Rao, L. T., Dubey, S. K., Javed, A. & Goel, S. Metal-free Al-air microfluidic paper fuel cell to power portable electronic devices. Int. J. Energy Res. 45, 7070–7081 (2021).

Wang, Y. et al. Printing Al-air batteries on paper for powering disposable printed electronics. J. Power Sources 450, 227685 (2020).

Srikanth, S. et al. Droplet-based lab-on-chip platform integrated with laser ablated graphene heaters to synthesize gold nanoparticles for electrochemical sensing and fuel cell applications. Sci. Rep. https://doi.org/10.1038/s41598-021-88068-z (2021).

Cheekatamarla, P. K. & Finnerty, C. M. Reforming catalysts for hydrogen generation in fuel cell applications. J. Power Sources 160, 490–499 (2006).

Chen, Y. et al. Enhanced performance of microbial fuel cells by using MnO2/Halloysite nanotubes to modify carbon cloth anodes. Energy 109, 620–628 (2016).

Wang, Y., Kwok, H., Pan, W., Zhang, H. & Leung, D. Y. C. Innovative paper-based Al-air batteries as a low-cost and green energy technology for the miniwatt market. J. Power Sources 414, 278–282 (2019).

Jayapiriya, U. S. & Goel, S. Body-worn enzymatic biofuel cell with automated pencil drawn bioelectrodes for energy harvesting from human sweat. J. Micromech. Microeng. https://doi.org/10.1088/1361-6439/ac537f (2022).

Peng, L. & Wei, Z. Catalyst engineering for electrochemical energy conversion from water to water: Water electrolysis and the hydrogen fuel cell. Engineering 6, 653–679 (2020).

Liu, Y. et al. A comprehensive review on recent progress in aluminum–air batteries. Green Energy Environ. 2, 246–277. https://doi.org/10.1016/j.gee.2017.06.006 (2017).

Tang, J. M. et al. High performance hydrogen fuel cells with ultralow Pt loading carbon nanotube thin film catalysts. J. Phys. Chem. C 111, 17901–17904 (2007).

Awasthi, H., Renuka, H., Srivastava, A. K. & Goel, S. Laser-induced graphene-based flexible interdigital electrode realizing micro supercapacitor sustainable in different temperatures. Energy Stor. https://doi.org/10.1002/est2.405 (2023).

Tang, J. M. et al. High performance hydrogen fuel cells with ultralow pt loading carbon nanotube thin film catalysts†. J. Phys. Chem. C 111, 17901–17904 (2007).

Vanmathi, S., Jayapiriya, U. S. & Goel, S. Miniaturized 3D Printed Carbon Cloth-Based Hydrogen Fuel Cell. (2022).

Reber, D., Kühnel, R. S. & Battaglia, C. High-voltage aqueous supercapacitors based on NaTFSI. Sustain. Energy Fuels 1, 2155–2161 (2017).

Pattipaka, S. et al. A nanoscale surface engineered magneto-mechano-triboelectric nanogenerator enabled by reliable pattern replication for self-powered IoT devices. Sustain Energy Fuels https://doi.org/10.1039/d3se01206a (2024).

Acknowledgements

The Central Analytical (CAL) lab at BITS-Pilani, Hyderabad, India, assisted with material characterizations, for which the authors are thankful. This project was supported by BITS BioCyTiH Foundation project BBF/BITS(H)/FY2022-23/BCPS-112 offers funding for the endeavor.

Author information

Authors and Affiliations

Contributions

V.S. wrote the main manuscript text and V.S., H.A., A.P. and S.G. helped with various parts of the work. S.G. investigated and projects and received the financial support. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Supplementary Video 1.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Vanmathi, S., Awasthi, H., Pal, A. et al. IoT enabled carbon cloth-based 3D printed hydrogen fuel cell integrated with supercapacitor for low-power microelectronic devices. Sci Rep 14, 16953 (2024). https://doi.org/10.1038/s41598-024-67759-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-67759-3

This article is cited by

-

Miniaturized Microbial Fuel Cells for Smart Devices: Application and Power Generation

International Journal of Precision Engineering and Manufacturing-Green Technology (2025)

-

Tungsten(VI) Oxide Sulfide/Poly(o-aminothiophenol) Nanosheet Composite: An Efficient Photocathode for Sustainable Hydrogen Generation from Red Sea Water

Journal of Electronic Materials (2025)

-

Flexible carbon cloth electrode: pioneering the future of electrochemical sensing devices

Advanced Composites and Hybrid Materials (2025)