Abstract

In order to improve the service life of extrusion taps and reduce their wear, this paper adopted the coating-simulation technology to investigate the influence laws of tool coating type and coating thickness on extrusion torque, extrusion temperature and wear amount. The validity of the numerical simulation results is confirmed through internal thread extrusion experiments. The results showed that the extrusion torque and extrusion temperature of single-layer coating and composite coating showed a tendency of decreasing and then increasing with the increase of the coating thickness; the extrusion torque and extrusion temperature of the double-layer coating increased with the increase of the coating thickness; the wear amount of the three types of coatings increased with the increase of the coating thickness. The TiAlN single coating demonstrates the most pronounced impact on decreasing extrusion torque and temperature (3.82 N·m and 88.4 °C), resulting in a smooth extrusion process. The TiAlN–TiAlN double coating exhibits the lowest wear amount of 0.076 mm. The utilization of numerical simulation proves to be a dependable approach for evaluating the efficacy of tool coatings, and reasonable selection of coating type and thickness can effectively reduce the extrusion torque, extrusion temperature and wear amount.

Similar content being viewed by others

Introduction

With the development of the modern manufacturing industry, the demand for the production of precision machinery and equipment is growing, which puts higher requirements on the reliability, stability and service life of equipment1. Threaded connections, as the most common way to install important mechanical fasteners and structural components, can still ensure the performance of the connected parts after repeated assembly and disassembly2. According to statistics, the hole processing in the machining process is about 60%, of which threaded holes accounted for 50%, 60% of modern equipment and instruments have threaded connections, and threaded connections are widely used in aerospace, weaponry, marine vessels, high-speed trains and other fields3,4.

At present, the main methods for machining internal threads are cutting processing and extrusion processing, of which the most common processing method is cutting processing5. Cutting processing internal thread is a kind of processing method to remove the excess material on the workpiece to get the internal thread, such as turning internal thread, milling internal thread, and tap tapping, which has the advantages of low processing cost and wide range of application. However, the method of cutting internal threads will destroy the fiber structure of the processed metal, affect the mechanical properties, and reduce the processing accuracy6. The technology of internal thread extrusion can not only make the thread connector show higher strength and hardness, but also improve their service life7. With the concept of “Green Manufacturing”, the internal thread extrusion, as one of the technologies with the best net forming performance in the thread forming process, has been widely used in the production and manufacturing of high-performance internal thread connectors8.

In fact, the internal thread extrusion process has been widely used in various industrial manufacturing fields, but the extrusion taps can be broken due to excessive extrusion torque during the extrusion process. In order to reduce the extrusion torque in the extrusion process, this problem has been studied for a long time9. Hou et al.10 used the research method of combining simulation and test to analyze the effects of bottom hole diameter, extrusion speed and friction coefficient on the forming quality of internal thread, and the optimal combination of processing parameters was obtained by orthogonal experiment. The results showed that the optimized process parameters could significantly reduce the extrusion torque and extrusion temperature. Liu et al.11 proposed an extrusion-based process for forming AZ91D magnesium alloy internal threads. And studied the influence of different process conditions on torque. He et al.12 optimized the extrusion process parameters of M22 × 2 internal thread by orthogonal design. And it was found that the optimized process parameters reduced the maximum extrusion torque and extrusion temperature by 19.27% and 15.07%. Wang et al.13 studied the influence of extrusion tap structural parameters on tool torque and axial load by combining numerical simulation and process experiment, which effectively reduced torque and axial loads. Mei et al.14 investigated the effect of extrusion tap parameters on extrusion torque and extrusion temperature using the response surface method, and reduced the extrusion torque by optimizing the structural parameters of the extrusion tap.

Coating, as a commonly used surface treatment technique, has a great impact on tool wear and thread surface quality15. Therefore, some researchers have studied the wear mechanism of coating extrusion taps. Barooah et al.16 explored the wear mechanism of extrusion taps, proposed quantitative wear indexes and evaluation criteria for wear resistance, and compared the wear resistance of several different PVD coatings. The results showed that mechanical and bonded wear cause rapid wear in the transition zone between different positions of the extrusion tap, and the TiAlN coating had the best wear resistance. Martins et al.17 investigated the life and wear mechanism of HSS extrusion taps with different coatings. The results showed that the wear mechanism of HSS extrusion taps was plastic deformation, and abrasive wear and localized spalling occurred in TiN and TiCN coated extrusion taps. Piska et al.18 conducted extrusion experiments with extrusion taps coated with TiN coating and obtained two-dimensional surface parameters, coefficient of friction, energy consumption and forming properties. The results showed that the coating extrusion taps could extend the service life of the taps and improve the thread finish.

In addition, the coating changes the coefficient of friction and thermal conductivity between the extrusion tap and the workpiece, which affects the extrusion torque and extrusion temperature during machining19. Oliveira et al.20 studied the effect of extrusion tap coating, extrusion speed on axial thrust, extrusion torque and analyzed the relationship between the two and internal thread microhardness and forming quality. Landeta et al.21 studied the wear of extrusion taps in the threading of steel cold forgings. Tap wear and thread quality were assessed by studying the wear of tap forming blades, measurements of thrust and torque during tapping, thread metallographic studies and coatings, and tap geometry. The results showed that the hexagonal extrusion tap coated with TiN coating can effectively reduce the extrusion torque and tap wear.

However, most of the existing studies focus on the effect of coating type on extrusion tap wear, and there are few studies combining coating type and thickness. When the coating thickness changes, the wear of extrusion taps is also affected. Therefore, it is very important to study the influence of coating type and thickness on the wear of extrusion taps.

In order to elucidate the relationship between coating type and thickness and extrusion torque, extrusion temperature and wear amount, the wear mechanism and wear type of extrusion taps are systematically analyzed. Based on the finite element analysis theory, the plastic-plastic finite element model (FEM) of extrusion tap and workpiece was established, and the influence laws of the thickness of different types coatings on the three were obtained. Finally, the numerical simulation results were experimentally verified using a torque test system and an online projection image measuring instrument. The proposed finite element model and the implemented extruding experiment provide a theoretical basis and engineering suggestions for the design of the extrusion tap coating process.

The wear mechanism of extrusion tap

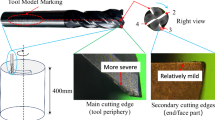

The structure of extrusion tap

The internal thread extrusion process is a method which utilizes the edge teeth of extrusion tap to make the metal in the workpiece to generate plastic deformation, and finally forms the thread. Extrusion tap as a special tool for internal thread extrusion, its structure is shown in Fig. 1. The extrusion tap can be divided into working section and clamping section22. The working section is divided into an extrusion cone section and a correction cone section, and the clamping section is divided into taper shank section and clamping handle. The working principle is that the extrusion tap extrudes the metal on the inner wall of the prefabricated bottom hole with a certain feed speed and rotational speed, so that the metal undergoes plastic flow and gradually accumulates along the surface of the extrusion prongs and teeth in the threaded groove of the extrusion tap, thus forming the internal thread.

The wear mechanism of extrusion tap

In the process of internal thread extrusion, the main wear forms of extrusion tap in extrusion of internal threads can be divided into three types: abrasive wear, adhesive wear and fatigue spalling wear23. Abrasive wear, the most important form of wear, refers to the loss of material caused by friction between the spiral surface of the extrusion tap and the hard micro-convex body of the workpiece material24. Adhesive wear is a form of wear in which metal adheres locally to the contact surfaces during sliding friction, and metal particles are dislodged from the surfaces during subsequent relative sliding. During the extrusion process, there is spiral sliding friction between the extrusion tap and the workpiece material, which can bond in the extrusion prongs to form chip tumors. In some cases, severe adhesion can occur, causing the tap base material to detach and form adhesive wear25. Fatigue spalling wear refers to a form of wear in which the extrusion tap undergoes fatigue fracture under the action of alternating contact stresses and spalling is formed. In the extrusion process, the prongs of the extrusion tap in the repeated friction and wear under the action of contact fatigue cracks, fatigue cracks with the extrusion process are gradually expanding, and ultimately the form of fatigue spalling wear26.

The working section of an extrusion tap consists of an extrusion cone section and a correction cone section. In the process of internal thread extrusion, the extrusion cone is responsible for the extrusion work. So, the force and wear of the extrusion cone are significantly greater than that of the correction cone. The most serious area of wear is the transition area between the extrusion cone and the correction cone. There are two main reasons: One is that during the processing, the material to be processed will be squeezed multiple times by the teeth of the extrusion tap. Each extrusion will cause plastic deformation of the material and increase the elastic limit of the material, and increase the hardness and strength of the material. This result will increase the load on the teeth in the transition zone. Another is in order to facilitate the extrusion tap into the workpiece, all extrusion taps have a cone-shaped guide cone section, that is, the large, medium and small diameters in the full length of the extrusion cone into a cone angle, the work cone part of the full tooth shape. As shown in Fig. 2, the grinding wheel starts from point A to move horizontally and vertically along the axis and taper of the extrusion tap, thus grinding the prismatic teeth of the extrusion tap. However, the actual tooth shape of the extrusion tap ground by the grinding wheel is different from the theoretical tooth shape, which will produce a tooth top offset in the transition zone between the extrusion cone and the correction cone. Both of them have the same pitch, but are offset from each other, which creates a pitch error. The formula for calculating the pitch error is shown in Eq. (1)27:

where, \(\Delta P\) is the pitch error, \(P\) is the actual pitch, \(\varphi\) is the guide cone angle, \(\alpha\) is the tooth angle.

For the extrusion tap with n edges, the formula for calculating the pitch error is shown in Eq. (2):

In general, the guiding cone angle can be chosen according to the Eq. (3):

where, \(d\) is the large diameter of the extrusion tap, \(d_{1}\) is the diameter of the extrusion cone end face, \(l_{1}\) is the length of the extrusion cone.

From Eqs. (1), (2) and (3), it can be seen that the pitch error increase with the increase of the guide cone angle and tooth angle, and increase with the increase of the number of edges.

The model about the establishment of internal thread cold extrusion

Numerical simulation, a commonly used computational method, can significantly reduce the experimental cost and improve the efficiency. The prerequisite for numerical simulation of internal thread extrusion is the establishment of FEM of internal thread extrusion. When establishing the FEM, the first step is to determine the materials of the part and the tool, then to establish the models of the workpiece and the tool, and finally to set the numerical simulation parameters.

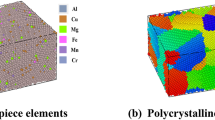

Experimental materials

The basic theory of internal thread extrusion processing is plastic deformation of materials, so there are certain requirements for the plasticity of materials. For example, the elongation at break of the material is more than 7% and the tensile strength is less than 1200 MPa. The tensile strength of 7075 aluminum alloy is 524 MPa, the yield strength is 455 MPa, and the elongation at break is more than 6%, which can meet the demand of extrusion machining of internal threads, so this paper chooses 7075 aluminum alloy as the workpiece material, and its related material properties are shown in Table 1.

Extrusion taps, as a special thread processing tool, itself needs to have high hardness and wear resistance. W18Cr4V, a high-speed steel, has the advantages of high wear resistance, high strength, high hardness and so on, which is suitable for making a variety of cutting tools. Therefore, in this paper, W18Cr4V is selected as the material of extrusion taps.

TiN coating is a general-purpose PVD coating with high hardness, high wear resistance and oxidation resistance, its color is golden yellow, hardness is 2300HV, dry friction coefficient is 0.4, and it is suitable for machining environments up to 500 °C. TiAlN coating is a hard coating with high hardness, high-temperature oxidation resistance, and good resistance to thermal shock, its color is grayish black, hardness is 3200HV, dry friction coefficient is 0.35, and it is suitable for machining environments up to 800 °C. processing environment. Therefore, in this paper, TiN coating and TiAlN coating are selected as the coating materials for extrusion taps. The coating materials properties are shown in Table 2.

Geometric model of extrusion tap

The extrusion tap is manufactured by a special thread grinder. The relative position relationship between the extrusion tap blank and the grinding wheel on the thread grinder is shown in Fig. 3, where A represents an arbitrarily point on the outer contour of the grinding wheel; L is the center distance between the tap blank and the grinding wheel along the \(x_{1}\) direction; H is the center distance between the tap blank and the grinding wheel along \(y_{1}\) direction; \(R_{m}\) is the radius of the grinding wheel; β is the angle between point A and the horizontal direction; and ω is the rotation angle of the tap blank. According to the trajectory of the outer contour of the grinding wheel, the actual shape parameters of the tap is obtained as Eq. (4)28. Based on the above parameters, the extrusion tap geometry model can be obtained.

According to the obtained parametric Eq. (1) of the cross-section of the extrusion tap, continuous coordinate data points are generated through MATLAB programming, and the data set of obtained coordinate points is imported into SolidWorks. The section profile of the extrusion tap is drawn in the software, and the geometric model of the extrusion tap is established.

FEM of internal thread extrusion

Deform-3D, a professional simulation software for metal plastic forming, is suitable for 3D material plastic flow simulation, which not only has the advantages of high robustness and powerful and flexible user interface, but also has the function mechanism of mesh adaptive delineation and workpiece volume compensation.

According to GB/T 28253-2012, a model of four-edge extrusion tap of M5 × 0.8 is established. The workpiece is a cylinder with radius of D = 15 mm and thickness of h = 10 mm, on which there is a prefabricated bottom hole with diameter of d = 4.6 mm. The workpiece material is 7075 aluminum alloy, and its model is defined as a plastic body, ignoring the elastic deformation. The extrusion tap is also set as a plastic body. In order to improve the simulation speed and the accuracy of the results, both the workpiece and the extrusion tap are divided into 4 nodes tetrahedral meshes, and the extrusion processing area is locally refined with a refinement ratio of 0.0001. The convergence of mesh density is analyzed before grid division. The analysis results show that the mesh convergence requirements can be met when the mesh number of workpiece is 100,000 and the mesh number of extrusion tap is 50,000. Therefore, set the number of workpiece mesh to 100,000 and the number of extrusion tap mesh to 50,000. The boundary condition of the workpiece is set to the peripheral unit node is fixed, that is, the speed of X, Y, Z are set to 0. In the coating settings module, select the material and thickness of the coating for the extrusion tap and generate the coating grid. The rotational speed of the extrusion tap is set at 60r/min, and the feed speed is set at 0.8 mm/s. The friction conditions are set to shear friction with a friction coefficient of 0.12 and a thermal conductivity of 5 W/(m·K).

In the simulation control, the mode is set to Deformation and Heat Transfer, the number of simulation steps is 1600, and the data is saved every 10 steps to prevent the running file from being too large. In order to ensure the convergence of the simulation, the step size is set to 0.02 mm, which is approximately equal to 1/3 of the minimum cell length. The deformation solver uses the Conjugate-Gradient Solver and uses the direct iterative method to solve. Figure 4 shows the FEM of internal threads extrusion.

In order to analyze the wear of the extrusion tap and further predict the performance of extrusion taps coated with different materials and different thicknesses, it is necessary to solve the Archard wear model. The Archard wear model is a wear design calculation model proposed by Archard, a famous British scholar. It means that when a solid abrasive grain slides on the surface under the action of normal load at a certain speed for a certain distance, the depth of the abrasive grain pressed into the abraded surface, i.e. the wear depth W, is obtained. The model can be applied to abrasive wear, adhesive wear, fatigue wear and corrosive wear, and it is a kind of wear analysis model for soft materials in the friction process of hard materials relative to soft materials. The mathematical expression for this wear model is shown in Eq. (5)29:

In the internal thread extrusion FEM, W is the wear depth of the extrusion tap; P is the interfacial pressure at the contact between the extrusion tap and the workpiece; v is the relative slip velocity between the extrusion tap and the workpiece; dt is the time increment; K is the wear coefficient of the coating material; H is the hardness of the coating material; and a, b, and c are constants, where a = 1, b = 1, and c = 2.

The validation of FEM for internal thread extrusion

In order to verify the reasonableness and correctness of the FEM of internal thread extrusion, it is necessary to verify it experimentally. The correctness of the finite element model is verified by comparing the extrusion torque, extrusion temperature and the wear position of the extrusion tap during the numerical simulation and experiment.

As shown in Fig. 5, the equipment is the BSV05 torque test system developed by Guangdong Boost New Material Technology Co., Ltd. This equipment collects the extrusion torque and extrusion temperature during the processing through the torque sensor and temperature sensor, and detects the working dynamics of the extrusion tap through the camera in real time. Finally, the change curves of extrusion torque and extrusion temperature are obtained through the data analysis software. In the experiment, the workpiece is a 7075-aluminum alloy plate with a bottom hole diameter of 4.6 mm. The tool is M5 × 0.8 HSS extrusion tap without coating. The lubricant is a high performance semi-synthetic aluminum-magnesium alloy lubricant with a concentration of 5%. The extrusion speed is 60 r/min.

From Fig. 6, it can be seen that the numerical simulation results of extrusion torque and extrusion temperature are 3.91N·m and 86.85 °C, and the experimental results are 4.16N·m and 80.3 °C. The relative error between the numerical simulation results of extrusion torque and the test results is 6.39%, and the relative error between the numerical simulation results of extrusion temperature and the test results is 7.54%.

Figure 7 shows the wear process of the extrusion tap during internal thread extrusion. As shown in Fig. 7a, up to step 90, the extrusion cone of the extrusion tap enters the workpiece but does not extrude the workpiece, and no wear of the extrusion tap occurs. Starting from step 90, the extrusion tap begins to extrude the workpiece, and the extrusion process is completed at step 680. During this process, the wear of the extrusion tap gradually increases, and at step 680, the extrusion tap reaches the maximum wear. In the process from step 680 to step 1470, only the correction cone of the extrusion tap is correcting the thread profile, so only the correction cone is worn at this time. However, the maximum wear amount of the correction cone does not exceed the wear amount of the extrusion cone. From Fig. 7b, it can be seen that the wear of the extrusion tap mainly occurs on its ridges, which are concentrated on the four edges. The maximum wear is 0.0114 mm, which occurred in the transition area between the extrusion cone and the correction cone. From Fig. 7c, it can be seen that the maximum wear position of the extrusion tap that completes one extrusion experiment is located on the ridge of the transition area between the extrusion cone and the correction cone.

In conclusion, the relative error between the numerical simulation results and the experimental results is less than 8%, and the wear position of the extruded tap in the numerical simulation and experimental are the same as that in the theoretical analysis, indicating that the finite element model of internal thread extrusion is accurate.

Results and discussion

In order to analyse the effects of extrusion tap coating type and thickness on extrusion torque, extrusion temperature and tap wear, numerical simulation of internal thread extrusion was carried out in this section according to the experimental scheme. The numerical simulation results of extrusion torque, extrusion temperature and wear under different coating types and thicknesses were obtained, and the accuracy of the numerical simulation results was verified by experiments.

Experimental design scheme

In order to determine the influence of coating thickness on the quality of internal thread extrusion forming, this paper carries out numerical simulation of internal thread extrusion of extrusion tap with six kinds of coatings, such as TiN, TiAlN, TiN-TiN, TiAlN-TiAlN, TiN-TiAlN, TiAlN-TiN. The experimental program is shown in Table 3.

Influence of single-layer coating thickness on extrusion forming quality

The influence of single layer coating with different coating thickness on extrusion forming quality is shown in Fig. 8. As the Fig. 8a shows, for the extrusion tap coated with TiN coating, the extrusion torque increase with the increase of the coating thickness, and the extrusion torque is minimized at 3.81 N·m for the coating thickness of 2 μm. For the extrusion tap coated with TiAlN coating, the extrusion torque decreases first and then increase with the coating thickness, and the extrusion torque is the smallest when the coating is 3 μm, which is 3.69N ·m. From Fig. 8b, the extrusion temperature decreases first and then increase with the increase of coating thickness. When TiN coating thickness is 2 μm, the extrusion temperature is the smallest, which is 79.99℃. When the TiAlN coating thickness is 3 μm, the extrusion temperature is the smallest, which is 82.83℃. From Fig. 8c, it can be seen that the wear amount increases with the increase of the coating thickness, but it is drastically reduced compared with the uncoated extrusion tap, in which the extrusion tap coated with TiAlN coating have the smallest wear amount, which is 5.82 × 10−6 mm.

Influence of double layer coating thickness on extrusion forming quality

The influence of double coating thickness on extrusion forming quality is shown in Fig. 9. As shown in Fig. 9a, for the extrusion tap coated with TiN-TiN and TiAlN-TiAlN coating, the extrusion torque increase with the increase of the coating thickness. And the extrusion torque is the smallest when the coating thickness is 1 μm, 3.78 N·m and 3.84 N·m, which is less than the extrusion torque generated by uncoated extrusion tap. From Fig. 9b, it can be seen that the extrusion temperature of extrusion taps coated with TiN-TiN and TiAlN-TiAlN coating shows a tendency of decrease and then increase with the increase of coating thickness. The extrusion temperature of extrusion taps coated with 2 μm thickness TiN-TiN coating is the minimum, which is 85.1℃, and extrusion taps coated with 3 μm thickness TiAlN-TiAlN coating is the minimum, which is 83.47℃, both of which are less than the extrusion temperature of uncoated extrusion tap. Similarly, as can be seen from Fig. 9c, the wear amount of the two kinds of extrusion taps coated with double coating increase with the increase of coating thickness, and the wear amount of the extrusion taps coated with TiAlN-TiAlN coating is the least, which is 5.49 × 10−6 mm.

Influence of composite coating thickness on extrusion forming quality

The influence of different composite coating thickness on extrusion forming quality is shown in Fig. 10. From Fig. 10a, it can be seen that the extrusion torque of extrusion taps coated with TiN-TiAlN and TiAlN-TiN coating shows a tendency of decrease and then increase with the increase of coating thickness. The extrusion torque of extrusion taps coated with 2 μm thickness TiN- TiAlN coating is the minimum, which is 3.55 N·m and extrusion taps coated with 3 μm thickness TiAlN-TiN coating is the minimum, which is 3.69 N·m, both of which are less than the extrusion torque of uncoated tap. From Fig. 10b, it can be seen that the extrusion temperature of extrusion taps coated with TiN-TiAlN and TiAlN-TiN coating shows a tendency of decrease and then increase with the increase of coating thickness. The extrusion temperature of extrusion taps coated with 3 μm thickness TiN- TiAlN coating and TiAlN-TiN coating is the minimum, which are 85.1 °C and 82.83 °C As can be seen from Fig. 10c, the wear amount of the two kinds of extrusion taps coated with compsite coating increase with the increase of coating thickness, and the wear amount of the extrusion taps coated with TiN-TiAlN coating is the least, which is 6.38 × 10−6 mm. However, the increase in wear of extrusion taps coated with TiN-TiAlN coating is much greater than TiAlN-TiN coating.

As shown in Table 4, the extrusion torque and extrusion temperature of single-layer coating and composite coating decreased first and then increased with the increase of coating thickness. The extrusion torque and extrusion temperature of double layer coating increase with the increase of coating thickness. The wear amount of the three types of coating increase with the increase of coating thickness. This is because the thermal conductivity of TiN and TiAlN coatings is less than that of the extrusion tap base tool material, which creates a certain thermal barrier effect and reduces the temperature during the extrusion process to a certain extent30. However, the thermal barrier effect only works at lower coating thicknesses and is outweighed by the increase in extrusion tap diameter if the coating thickness is higher.

The experimental results of extrusion torque and extrusion temperature

In order to prove the accuracy of the numerical simulation results, a large number of experiments are carried out. Since too many experiments would take a lot of time and increase the cost, we only use 3 μm M5 × 0.8 HSS extrusion taps with different coating types for the internal thread extrusion experiments.

The results of numerical simulation and experiments on the extrusion torque and extrusion temperature are shown in Fig. 11. In the internal thread extrusion experiment, the TiAlN coating exhibited the smallest extrusion torque of 3.82 N·m and extrusion temperature of 83.6 °C, as shown in Fig. 11. Conversely, the TiAlN-TiN coating has the largest extrusion torque of 4.71 N·m and TiN-TiAlN coating has highest extrusion temperature of 88.6 °C.

In addition, the extrusion torque in the experiment is slightly higher than in the numerical simulation, while the extrusion temperature is slightly lower. The overall trend remains consistent. This is because the numerical simulation in internal thread extrusion is performed in an ideal state. However, workpiece machining accuracy, machine tool vibration, machine tool accuracy, measurement accuracy, and the effect of lubricating fluid will affect the test results. A large number of experiments have shown that the error of the internal thread extrusion test mainly comes from the machining error of the workpiece bottom hole diameter and the influence of the lubricating fluid31. However, the maximum relative errors of extrusion torque and extrusion temperature for numerical simulation and experiment are 7.42% and 7.54%, respectively, which are less than 8%. Therefore, a relative error of 10% or less between the numerical simulation results and the experimental results would indicate that the numerical simulation results are correct32.

The experimental results of the extrusion tap wear

From the above theoretical study, it can be seen that the maximum wear of the extrusion tap occurs in the transition region between the extrusion cone and the correction cone. When extrusion tap wear occurs, the size of the transition area must be reduced. So, in this paper, the large diameter of the transition area between the extrusion cone and the correction cone is measured instead of the wear of the extrusion tap. Also, because the large diameter of the extrusion tap after a single extrusion process is so small that it cannot be measured directly. Therefore, it is necessary to perform 50 extrusion processes and then measure the large diameter of the transition area. The wear of the extrusion tap is determined by comparing the change in the large diameter before and after the experiments.

As shown in Fig. 12, the large diameter of the extrusion taps before and after the experiments are measured using an online projected image measuring instrument TM-X5000 manufactured by Keyence. The measurement results are shown in Table 5, it can be seen that the uncoated extrusion tap had the greatest wear, with the diameter reduced from 5.158 to 4.818 mm, and the wear was 0.34 mm. TiAlN-TiAlN has the smallest wear, with the diameter decreasing from 5.151 to 5.075 mm, and the wear is 0.076 mm. Barooah16 found that the wear resistance of single-layer TiAlN is better than that of other single-layer coatings, but experiments showed that double-layer TiAlN-TiAlN coating has the best wear resistance in three type coatings.

Conclusions

This paper investigated the wear mechanism of extrusion taps, established a plastic-plastic finite element model between extrusion taps and workpieces, and carried out numerical simulations of internal thread extrusion. It was found that the maximum wear of the extrusion tap is located in the transition area between the extrusion cone and the correction cone, and the influence of coating thickness on extrusion torque, extrusion temperature and wear amount was obtained. The extrusion experiments were carried out on different extrusion taps with coating thicknesses of 3 μm. It was found that TiAlN-coated taps exhibited the minimum torque (3.82 N·m) and temperature (83.6 °C), and the wear amount of the TiAlN–TiAlN coating was the smallest (0.076 mm). However, enhancing the wear resistance of extrusion taps requires further investigation into novel coating materials, innovative coating techniques, and the impact of non-uniform coating thickness on wear resistance, ultimately aiming to improve the anti-wear performance of extrusion taps.

Data availability

The data that support the findings of this study are available on request from the corresponding author,upon reasonable request.

References

Hou, Y. J., Zuo, D. W., Sun, Y. L., Wang, L. & Li, L. Distributional analysis of residual stresses with the Ti–6Al–4V internal trapezoidal thread torsional vibration extrusion. Int J Adv Manuf Technol. 156, 4289–4430. https://doi.org/10.1007/s00170-019-04472-w (2019).

Brandão, G. L. et al. State of the art on internal thread manufacturing: A review. Int J Adv Manuf Technol. 110(11–12), 3445–3465. https://doi.org/10.1007/s00170-020-06107-x (2020).

Liu, M., Ji, Z., Bao, L. & Li, X. Influence of process parameters on the height and performance of magnesium alloy AZ91D internal thread by assisted heating extrusion. Materials (Basel) https://doi.org/10.3390/ma15082747 (2022).

Ţălu, Ş et al. Fractal geometry of internal thread surfaces manufactured by cutting tap and rolling tap. Manuf. Lett. 23, 34–38. https://doi.org/10.1016/j.mfglet.2019.12.001 (2020).

Dogrusadik, A. Effect of cutting conditions and thread mill diameter on cutting temperature in internal thread milling of Al7075-T6. Sadhana 47, 157. https://doi.org/10.1007/s12046-022-01935-x (2022).

Lu, T. et al. Experimental investigations of threads surface integrity manufactured by cutting insert and with internal thread rolling head. CIRP J Manuf Sci Tecnol. 31, 334–341. https://doi.org/10.1016/j.cirpj.2020.06.007 (2020).

Miao, H. et al. Present situation of the anti-fatigue processing of high-strength steel internal thread based on cold extrusion technology: A review. Chin J Mech Eng-en. 30(2), 231–240. https://doi.org/10.1007/s10033-017-0080-x (2017).

Xu, H. et al. A study of precision grinding of micro-pitch internal thread for planetary roller screw mechanism. J Manuf Process. 106, 35–50. https://doi.org/10.1016/j.jmapro.2023.09.070 (2023).

Miao, H. et al. Optimization of tap parameters for internal thread cold extrusion of high strength steel based on genetic algorithm. Key Eng. Mater. 898(431–432), 434–437. https://doi.org/10.4028/www.scientific.net/KEM.431-432.434 (2010).

Hou, H. L. et al. Numerical simulation and process optimization of internal thread cold extrusion process. Materials (Basel) https://doi.org/10.3390/ma13183960 (2020).

Liu, M. et al. Finite element analysis of extrusion process for magnesium alloy internal threads with electromagnetic induction-assisted heating and thread performance research. Materials (Basel) https://doi.org/10.3390/ma13092170 (2020).

He, Q. et al. Research and optimization of process parameters for internal thread forming based on numerical simulation and experimental analysis. Materials (Basel) https://doi.org/10.3390/ma15093160 (2022).

Wang, J. W., Li, C. & Xu, X. W. Simulation of load and optimization of tool parameters for aluminum alloy thread extrusion forming. Modular Mach. Tool Autom. Manuf. Tech. https://doi.org/10.13462/j.cnki.mmtamt.2021.10.037 (2021).

Mei, M. Y. et al. Influence of extrusion tap parameters on the forming quality of internal thread cold extrusion. Int J Adv Manuf Technol. 125(9–10), 4765–4777. https://doi.org/10.1007/s00170-023-11022-y (2023).

Bustillo, A. et al. Datamining modeling for the prediction of wear on forming-taps in the threading of steel components. J. Comput Des Eng. 3(1), 337–348. https://doi.org/10.1016/j.jcde.2016.06.002 (2016).

Barooah, R. K. et al. Investigation on wear mechanisms of PVD coatings for form taps in threading of Al–Si alloy. Wear. 464–465, 203528. https://doi.org/10.1016/j.wear.2020.203528 (2021).

Martins, P. S. et al. Study of wear behavior and tool life in different taps during the internal threading of a nodular iron engine crankshaft. Int J Adv Manuf Technol. 120(11), 7803–7814. https://doi.org/10.1007/s00170-022-09290-1 (2022).

Piska, M. & Sliwkova, P. Surface parameters, tribological tests and cutting performance of coated HSS taps. Procedia Eng. 100, 125–134. https://doi.org/10.1016/j.proeng.2015.01.350 (2015).

Tallai, P., Csuka, S. & Sipos, S. Thread forming tools with optimised coatings. Acta Polytech Hung. 12(1), 55–66 (2015).

De Oliveira, J. A., Ribeiro Filho, S. L. M. & Brandão, L. C. Investigation of the influence of coating and the tapered entry in the internal forming tapping process. Int J Adv Manuf Technol. 101(1–4), 1051–1063. https://doi.org/10.1007/s00170-018-3011-9 (2019).

Fernández Landeta, J. et al. Wear of form taps in threading of steel cold forged parts. J. Manuf. Sci. Eng. https://doi.org/10.1115/1.4029652 (2015).

Monka, P. et al. Study of a tap failure at the internal threads machining. Eng Fail Anal. 100, 25–36. https://doi.org/10.1016/j.engfailanal.2019.02.035 (2019).

Barooah, R. K. et al. Wear of form taps in threading of Al–Si alloy parts: Mechanisms and measurements. Wear. 442–443, 203153. https://doi.org/10.1016/j.wear.2019.203153 (2019).

Esteves Júnior, R. C. et al. Research on the wear mechanisms during the high-speed tapping in 316L stainless steel. Int J Adv Manuf Technol. 112(1–2), 419–436. https://doi.org/10.1007/s00170-020-06368-6 (2020).

Dwivedi, D. K. Adhesive wear behaviour of cast aluminium–silicon alloys: Overview. Mater Des. 31(5), 2517–2531. https://doi.org/10.1016/j.matdes.2009.11.038 (2010).

Yin, X., Liu, Y. & Zhao, S. Tool wear and its effect on the surface integrity and fatigue behavior in high-speed ultrasonic peening milling of Inconel 718. Tribol Int. https://doi.org/10.1016/j.triboint.2022.108070 (2023).

Wan, N. et al. Numerical and experimental investigation of the influence of the machining parameters on residual stress distribution of internal thread cold. CIRP J Manuf Sci Technol. 40, 142–154. https://doi.org/10.1016/j.cirpj.2022.10.005 (2023).

Chen, X. et al. Research on metal flow law and strengthening mechanism of cold extrusion internal thread. J Braz Soc Mech Sci. 44(3), 109. https://doi.org/10.1007/s40430-022-03418-w (2022).

Shen, L., Zhao, J., Zhang, Y. Q. & Quan, G. Z. Performance evaluation of titanium-based metal nitride coatings and die lifetime prediction in a cold extrusion process. High Temp Mater Process. 40(1), 108–120. https://doi.org/10.1515/HTMP-2021-0019 (2021).

Hao, G. et al. Finite element simulation of orthogonal cutting of H13-hardened steel to evaluate the influence of coatings on cutting temperature. Coatings. 14, 293. https://doi.org/10.3390/coatings14030293 (2024).

Demmerling, A. L. & Söffker, D. Improved examination and test procedure of tapping torque tests according to ASTM D5619 using coated forming taps and water-mixed metalworking fluids. Tribol Int. https://doi.org/10.1016/j.triboint.2019.106151 (2020).

Zhang, S. et al. The planetary rolling process of forming the internal thread. Int J Adv Manuf Technol. 107(7–8), 3543–3551. https://doi.org/10.1007/s00170-020-05289-8 (2020).

Funding

This document is the results of the research project funded by the Shaanxi Provincial Natural Science Basic Research Project (2023-JC-YB-452).

Author information

Authors and Affiliations

Contributions

Miaoyuan Mei. planned the research content and wrote papers. Hongling Hou. established the finite element model. Lirong Zhang. numerical simulation. Tao Huang. did data sorting and analysis. Shi Liu. conducted experiments. Yongqiang Zhao revised research content and the paper.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mei, M., Hou, H., Zhang, L. et al. Numerical simulation and experimental investigation of coating influence on extrusion tap wear. Sci Rep 14, 18259 (2024). https://doi.org/10.1038/s41598-024-69258-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-69258-x