Abstract

The implementation of the Gob-Side Entry Retaining Mining Mode with Roof Cutting and Pressure Relief (GERRCPR) results in the gob connecting to the retaining roadway, creating an open space that causes significant air leakage and increases the risk of spontaneous combustion. A study was conducted during the implementation of the GERRCPR in the Xiaonan Coal Mine N1-1502 working face to investigate spontaneous combustion characteristics, along with fire prevention and extinguishing measures. To analyze gob airflow, Computational Fluid Dynamics (CFD) was employed to collect data on airflow conditions, O2 concentration, and temperature. Based on this, this study focuses on exploring the effects of nitrogen injection treatment under various rates and positions to optimize parameters for buried pipe nitrogen injection. Results indicated that within the GERRCPR, air leakage in the gob increased, leading to an increase in O2 concentration, expansion of the oxidation zone, and an elevated risk of spontaneous combustion. Air leakage primarily occurred from the retaining roadway and the working face near the intake-air roadway, peaking at a retaining roadway length of 500 m, with a flow rate of 226 m3/min. Following nitrogen injection treatment, the oxidation zone was significantly reduced, with optimal treatment achieved at a nitrogen injection depth of 70 m and a rate of 600 m3/h. Field monitoring data showed that the inertization measure of using porous long pipes, a nitrogen injection spacing of 30 m, and a nitrogen injection rate of 600 m3/h significantly decreased the O2 concentration within the gob. This reduction meets safety production requirements and outperforms the effectiveness of traditional buried-pipe nitrogen injection methods, thereby validating the simulation accuracy. Understanding the laws governing spontaneous coal combustion in the GERRCPR and enacting preventive measures for nitrogen injection can improve safety standards in mining operations. This proactive approach can effectively prevent spontaneous coal combustion accidents, resulting in substantial social benefits.

Similar content being viewed by others

Introduction

China’s energy demand is rising with the country’s increasing rate of industrialization1,2,3,4. Coal is a primary energy source and a crucial component of China’s energy structure. However, conventional coal mining practices, specifically the retention of coal pillars, result in a significant loss of coal resources and complicate mining operations5,6,7. In a bid to improve the resource recovery rates, the breakthrough technology known as GERRCPR has become vital, yielding substantial economic and social benefits. This technology not only enhances coal resource recovery but also effectively addresses the challenge posed by traditional mining methods by eliminating the need to segment coal pillars8,9,10. GERRCPR eliminates the risk of gas accumulation on roadway corners and achieves Y-type ventilation11,12,13, providing a technical solution to enhance safety in coal mining operations. However, compared to traditional recovery roadways, GERRCPR, influenced by excavation and mining processes, leads to easily fractured surrounding rocks, substantial roadway deformations14,15, changes in the surrounding rock structure after roof cutting that prevent timely support of the main roof, and enhanced communication between the retaining roadway and the gob, creating an open gob16,17,18,19. This situation results in increased air leakage and a heightened risk of spontaneous combustion within the gob20,21,22. This problem has been extensively investigated by local and international scholars. Zhang et al.19 established a mathematical model for spontaneous combustion and conducted numerical simulations under various conditions: without a retaining roadway, with a retaining roadway lacking anti-air leakage measures, and with a retaining roadway incorporating anti-air leakage measures. The findings inspired a hierarchical control and fire-prevention technology system for retaining roadways, and they showed that Y-type ventilation increases air leakage and temperature. Xu et al.23 used theoretical analysis and numerical simulation to study the uneven deformation and destruction mechanisms of retaining roadways in the gob of inclined coal seams. A collaborative support method was proposed, and field test were conducted. Bian et al.8 investigated roadway deformation issues in the 110 mining method, establishing a mechanical model for support resistance. Through numerical simulation and on-site measurements, they verified the feasibility of different support schemes. Si et al.24 used simulation to analyze the ventilation control mechanism in GERRCPR, investigating the impact of air-blocking ventilation control on the oxidation zone. The study revealed that air-blocking ventilation control significantly reduces the oxidation zone area within the gob. Zhao et al.25 utilized PFC2D and Fluent software to simulate initial crack formation between closely spaced coal seams. The analysis covered the spontaneous combustion zone distribution, unveiling a notable expansion in the area of two coexisting danger zones during upward mining compared to single-seam mining. Jia et al.26, focusing on GERRCPR with weakly bonded composite roofs, conducted numerical simulations to reveal the dynamic response of roof drilling and fracture patterns in hard rock layers. A method for roof fracturing and unloading adaptable to different states of hard rock layers was proposed. Guo et al.27 conducted experiments and concluded GERRCPR results in different gas distributions in the gob, compared to traditional methods, with an expanded spontaneous combustion zone but improved gas control. Lin et al.28 used a similar experimental platform, a multi-field coupling mathematical model, and information detection technology. They revealed the key factors influencing multi-field coupling evolution in the gob and compound thermodynamic disasters. The study further identified the causation mechanism of and identification method for compound thermodynamic disasters in the gob, highlighting current research deficiencies and challenges while proposing future research directions and goals.

In the governance of inertization for fire prevention in the gob, effectively suppressing the spontaneous combustion of residual coal requires the inert gas injection pipeline to be designed in such a way as to ensure that the oxidation zone is always occupied by an inert gas29,30,31,32,33,34,35. Currently, nitrogen injection methods primarily include pre-buried pipes, trailing pipes, drilling, and inserting pipes36,37,38. The selection and design of these nitrogen injection methods need to consider specific gob conditions, including shape, size, depth, and residual coal distribution. Properly configuring nitrogen injection pipelines efficiently lowers O2 concentration, averting the spontaneous combustion of residual coal and ensuring safe mine production39,40,41,42. Previous studies primarily concentrated on point source leakage issues. Nevertheless, in the GERRCPR mode, the substantial connection between the retaining roadway segment and the gob creates a line source leakage area. Owing to changes in the gob’s flow field, prevention measures for natural combustion in the gob have not been investigated in-depth. Therefore, in this study, we investigated the 1502 working face in the Xiaonan mining area. The GERRCPR was implemented, shifting the ventilation mode of the working face from the traditional “U” shape to a pattern with “one intake and two returns.” This alteration changed the gob’s leakage pattern, prompting a detailed analysis to understand the impact of the gob’s flow field changes on the overall coal mining process. CFD was employed for numerical simulation studies, analyzing governance effects under different nitrogen injection parameters. The optimization of traditional buried pipe nitrogen injection parameters was carried out, implementing uniform nitrogen injection through porous long pipes and replacing a single horizontal nitrogen injection port with multiple rows of nitrogen injection ports. This approach achieved comprehensive coverage in the gob, addressing the drawbacks of traditional nitrogen injection methods, such as discontinuous nitrogen injection locations and low utilization rates due to susceptibility to leakage. Overall, this study aimed to achieve targeted improvements to further reduce the risk of spontaneous combustion and ensure efficient resource mining and utilization. Thus, our findings provide support and guidance for technological innovation and sustainable development in the field of GERRCPR.

Engineering scenarios

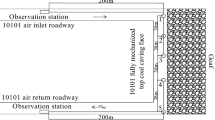

Xiaonan Coal Mine is located in the southeastern parts of Diaobingshan City, covering a mine area of 23 km2 and with a production capacity of 2.1 million t/a. The main coal seams within the mine comprise 4-2, 7-2, 14, and 15-1, and the designated test site for the 110 mining method is the N1-1502 working face. The coal seam at this working face ranges from a burial depth of 569–612 m, maintaining a consistent thickness of 1.46 m and an inclination angle ranging from 3° to 7°, averaging approximately 5°. The working face extends 210 m in the inclination direction and 1185 m in the strike direction. The retaining roadway spans a length of 760 m. It adjoins the south-wing mining area, separated by the protection coal pillar of the 15th middle roadway of North One while being adjacent to the north-wing mining area to the north. The N1-1503 working face lies to the east (not yet developed), and to the west, it is adjacent to the Daxing field. The coal in this area is gas coal, having a bright appearance, banded structure, and shell-like fracture, all indicative of good coal quality. Observations from the working face indicate no intrusions of igneous rocks, and its roof exhibits local signs of ancient river erosion. Moreover, there are no risks associated with geothermal activity or dynamic ground pressure. The spontaneous combustion tendency of the coal seam is of Type I, indicating a high susceptibility to spontaneous combustion with a natural combustion period estimated to be between 1 to 3 months. Figure 1 illustrates the layout of the working face.

Cause analysis of spontaneous combustion

During the initial production phase, the N1-1502 working face adopted the traditional “U” type ventilation method, supplying air at a rate of 1200 m3/min. At this point, there was a pressure difference of 120 Pa in the 1502 working face, resulting in a significant air leakage within the gob. As the working face progressed to the cutting eye of the 1506 section, to increase economic efficiency, short-arm beam roofs were created through directional blasting. As the working face advanced further, the fragmented gangue was compacted, ultimately achieving a pillar-free self-forming roadway. The transportation roadway was converted to a retaining roadway, serving as the production roadway for the 1506 working face. Considering the actual gob conditions, the ventilation pattern was ultimately adjusted to the “one intake and two returns” type. Under this configuration, air was supplied through the 1502 transportation roadway at a rate of 800 m3/min. The airflow returned partly through the 1502 return-air roadway and partly through the retaining roadway via the cutting eye of the 1506 section. These adjustments resulted in changes to ventilation pathways and airflow migration patterns within the gob. As the retaining roadway length gradually increased, extending to 80 m, the gob air leakage transitioned from a point source to a line source, establishing a connection between the retaining roadway and the gob, thus creating an open space. The substantial pressure on the retaining roadway walls due to these changes in ventilation pattern in the “one intake and two returns” setup may result in air escape from the retaining roadway, thereby increasing the risk of spontaneous combustion. Therefore, to address these concerns, relying on the practical application of GERRCPR at Xiaonan Coal Mine, data were gathered from the working face, and on-site measurements of O2 concentration and the gob temperature were performed. These efforts are the foundation for effectively monitoring and predicting fire risks within the gob, aiming to mitigate potential dangers associated with spontaneous combustion.

Layout of monitoring points

To monitor the changes in gas concentrations within the gob, the “three zones” of spontaneous combustion in the gob primarily track O2 and temperature data. By setting the O2 concentration thresholds at 8% and 18%, the gob was categorized into zones related to heat dissipation, oxidation, and suffocation. The observation equipment included a rotary vane vacuum pump, a CHZ-22 gas pump with coal safety markings as auxiliary gas collection devices, chromatographic gas analysis, and thermocouple-based temperature observation. By analyzing monitoring data from the gob pipelines, the distribution of O2 concentration and temperature changes were determined, and measures were implemented to address concerns related to spontaneous combustion associated with residual coal.

Regarding the observation pipeline layout, embedded pipelines were arranged in both the intake- and return-air roadways, as illustrated in Fig. 2. Four measurement points were positioned behind the working face at distances of 50 m and 80 m deep into the gob, each with two thermocouples. The observation pipelines started 30 m behind the transportation roadway and were connected back to the air roadway, with a 30 m spacing between each measurement point on the return-air roadway. In the retaining roadway, the measurement points were spaced 20 m apart to sample and observe the spontaneous combustion situation in the gob. Each measurement point contained a pipeline gas monitoring point and a temperature monitoring point, both protected by DN40 steel pipes. The measurement points were elevated, and a perforated iron box was used to cover the probe to prevent compression. Three-way connections were established between measurement points to serve as gas extraction and temperature observation points. Every 20 m of working face advancement necessitated the pre-embedding of a 4-way pipe behind the initial set of supports on the retaining roadway, buried at depths ranging from 1 to 2 m, implementing overall monitoring of the gob.

Monitoring results and analysis

Daily, morning sampling and afternoon data analysis were conducted to examine the distribution of O2 concentration and temperature. Figure 3 illustrates the O2 concentration distribution in the open gob area formed after the connection between the retaining roadway and the gob. As the working face advanced by 300 m, the O2 levels decreased from the intake-air roadway to the return-air roadway. There was a consistent declining trend of O2 concentration from the working face toward the deeper gob, with a higher concentration nearer to the intake-air roadway due to the influence of air leakage. The retaining roadway was connected to the zone near the working face with high O2 concentration, creating a hazardous area susceptible to spontaneous combustion. Within 150 m of the working face along the intake-air roadway, the O2 concentration consistently exceeded 18%. In the deeper area of the gob along the return-air roadway, owing to minimal air leakage and higher O2 consumption from residual coal, this area primarily functioned as a heat dissipation zone. Figure 4 presents the temperature data, indicating relatively stable temperature changes along the side of the intake-air roadway. Within 100 m from the working face, the temperature had a decreasing trend followed by a slight increase, ranging between 23 and 26 °C with minimal fluctuations. Along the return-air roadway, the average temperature ranged from 35 to 38 °C. Within the initial 200 m of the working face, the temperature gradually rose with slight fluctuations. Furthermore, at 270 m from the working face, it experienced significant fluctuations, reaching relatively high points. The highest point recorded was 273 m on the return-air roadway, reaching 43.1 °C near the initial mining location of the working face, indicating that the area requires attention.

Simulation results and analysis

Model construction

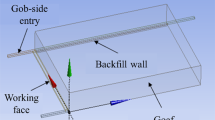

Considering the actual geological conditions of Xiaonan Mine, a uniform porous-medium gob model was constructed. This model represents a gob area measuring 300 m in length, 200 m in width, and 30 m in height. The roadway cross-section adheres to a regular rectangle, measuring 4 m in length and 3 m in height. To create this model, a hexahedral meshing was used for discretization, resulting in a total of 233,791 grid elements. The gas in the gob was assumed to be incompressible, and only convective heat transfer was considered for the gas. Consequently, the coal rock was modeled as being horizontally layered. Meanwhile, the incoming airflow was assumed to contain neither methane nor other harmful gases, as illustrated in Fig. 5. To simulate crucial parameters like porosity and viscous resistance, the retaining roadway’s one-side wall was set as an interface (interior). These parameters were obtained using PFC and subsequently imported into a CFD software for further simulation. The gob filling rate was obtained using measured data from the mine. Details of these essential parameters are presented in Table 1.

The calculation formula for the bulking coefficient is as follows:

where \( V \) is the volume change of the rock under external forces, and \( {V_0} \) is the original volume.

Analysis of the flow field in the gob

Figure 6 illustrates the distribution of wind velocity vectors. On the intake-air roadway side, the wind velocity rapidly peaked at 1.11 m/s, which was influenced by the initial velocity. At the intersection of the retaining roadway with the gob, the value reached 0.96 m/s. As it progressed deeper, the velocity gradually decreased. Air leakage causing pressure differences at both ends of the working face resulted in higher velocities at the upper and lower corners, reaching approximately 1 m/s. Simultaneously, airflow converged toward both the return air and the retaining roadway side. Within the gob, a higher compaction increased resistance to the airflow, leading to a loss of kinetic energy. Consequently, wind velocity became relatively low, especially toward the return-air roadway. In the deeper gob areas, the wind velocity almost diminished. However, on the retaining roadway side, the streamlines were more concentrated because of its connection with the gob. The increased leakage airflow changed the distribution of O2 concentration within the gob.

The progression of the working face influenced the variation in the retaining roadway length, consequently impacting airflow leakage and direction within the gob. Illustrated in Fig. 7 are simulation results depicting the leakage airflow, where positive and negative values represent airflow into and out of the gob. Before reaching the cutting eye of the 1506 working face, leakage airflow entered the gob from the upper corner of the intake-air roadway and circulated back to the working face, resulting in a relatively minimal airflow leakage of only 17 m3/min. However, after implementing GERRCPR, within the next 400 m, leakage airflow originated from the entire working face, predominantly entered the gob, and returned primarily to the retaining roadway. As the retaining roadway lengthened, the leakage airflow increased gradually, peaking at 226 m3/min when the roadway reached 500 m. However, in the following 600 m of the working face progression, the increasing length of the retaining roadway resulted in a gradual decline in the leakage airflow. Approaching the stop line, the mining pressure’s influence induced alterations to the roadway’s cross-sectional area, shape, and smoothness, resulting in increased airflow resistance and reduced kinetic energy. Consequently, the leakage airflow was significantly reduced to 143 m3/min at this stage.

Evaluating fire prevention and extinguishing with varying nitrogen injection parameters

The fire prevention and extinguishing effects within the gob are influenced by diverse nitrogen injection parameters. Numerical simulation, the working face mining method, and field data were combined to explore the impact of different nitrogen injection positions and rates on O2 concentration within the gob. The primary aim of this study was to examine the optimal nitrogen injection process with the aim of improving fire prevention effects within the gob.

Evaluating simulation outcomes for varying nitrogen injection positions

The impact of diverse nitrogen injection positions on the oxygenation zone within the gob was examined through simulations. A nitrogen injection pipeline was installed along the retaining roadway. Each pipeline comprised three evenly distributed nitrogen injection ports placed at distances of 30 m, 50 m, 70 m, and 90 m from the working face direction. The simulation conditions comprised a nitrogen injection rate of 600 m3/h. The findings revealed a reduction in O2 concentration on both the intake- and return-air roadways, with a more pronounced decrease observed on the intake-air roadway side. The oxidation zone near the return-air roadway appeared smaller and closer to the working face. Notably, the O2 concentration reached a minimum near the nitrogen injection port. Subsequently, in the deeper areas of the gob, the O2 concentration gradually increased, stabilizing at a level lower than that observed in the non-nitrogen-injected scenario. The deeper the positioning of the nitrogen injection port, the greater the tendency for the oxidation zone to shift backward. When the nitrogen injection port was positioned at 30 m from the working face, a greater proportion of the injected nitrogen returned because of air leakage, resulting in a decline in the O2 concentration below safety production requirements at the working face. However, the O2 concentration in the deeper gob areas remained relatively unchanged. At a distance of 50 m, nitrogen primarily infiltrated the gob, substantially decreasing O2 levels and diminishing the oxidation zone. However, a relatively large strip-shaped oxidation zone persisted near the retaining roadway. When positioned at 70 m, the gob’s oxidation zones were minimized, effectively reducing their extent. On the intake-air roadway side, the oxidation zone extended 22–35 m from the working face, while on the return side, it ranged from 17 to 26 m. As the distance increased to 90 m, the treatment effect deteriorated because of air leakage, resulting in an oxidation zone surpassing that observed at the 70 m position (Fig. 8).

Evaluating simulation outcomes for varying nitrogen injection rates

Following the “Technical Specifications for Nitrogen Fire Prevention and Extinguishing in Coal Mines” and relying on the theory of the oxidation zone, a nitrogen injection calculation model was developed. The model considered the geological and mining parameters specific to the mine. It was developed to calculate the nitrogen injection rate by using actual air leakage data to meet the fire extinguishing criterion of reducing O2 concentration to 8%. The formula for determining the nitrogen injection rate is as follows:

where \( {Q_n} \) signifies nitrogen injection rate, measured in m3/h. \( {Q_0} \) represents the air leakage rate in the oxidation zone of the gob. Its value is 7 m3/min. \( {C_1} \) denotes average O2 content in the oxidation zone. Its value is 13%. \( {Q_n} = 60{Q_0}\frac{C}{1 - C} \) represent fire prevention inerting index of the oxidation zone in the gob. Its value is 8%. \( {C_n}\) is the fire prevention requirement for nitrogen injection purity. Its value is 97%. \( K \) denotes reserve coefficient, with a value of 1.3.

The simulations were based on the calculation formulas from the “Technical Specifications for Nitrogen Fire Prevention and Extinguishing in Coal Mines” and the actual on-site conditions. Four nitrogen injection rates were used to perform the simulations: 400 m3/h, 500 m3/h, 600 m3/h, and 700 m3/h. The nitrogen injection was located on the intake-air roadway side, 70 m away from the working face, using one porous long pipe that evenly distributed nitrogen through three injection ports. The simulation results in Fig. 9 show that as the nitrogen injection rate increases, the overall O2 concentration decreases, and the oxidation zone compresses toward the working face. At a nitrogen injection rate of 400 m3/h, the oxidation zone’s width on the retaining roadway side measured 33 m, while the O2 concentration on the return-air roadway remained relatively unchanged. Upon reaching a flow rate of 600 m3/h, the average O2 concentration within the gob was effectively maintained below 8%, meeting fire prevention and inertization standards. Moreover, the oxidation zone remained at a safe distance from the working face, adhering to production safety requirements. Increasing the flow rate further to 700 m3/h reduced the oxidation zone’s width. However, the oxidation zone on the return air side excessively approached the working face, potentially posing a safety risk.

Application

During the mining stage, the KJ428 mine-distributed laser fire monitoring system was used to monitor the gob for potential fires. A step-by-step buried pipe nitrogen injection method was implemented. This approach involved designing two sets of one-loop step-by-step porous long nitrogen injection pipelines along the transportation roadway, starting from the initiation of the cutting eye and continuing throughout the working face’s progression until the mining completion. Before the initial set of supports, Φ108 mm nitrogen injection pipelines were pre-buried. At intervals of 30 m along the transportation roadway during mining operations, an additional set of pipelines was pre-buried to align with the working face’s length. Following the collapse of the working face into the gob, the closest pre-buried pipelines would activate to continuously inject nitrogen, covering a range of 30–70 m from the working face. Considering technical, economic, and safety aspects, the nitrogen injection rate was set at 600 m3/h, as illustrated in Fig. 10. This setup was established by combining numerical simulations with actual monitoring data. Parameters such as a step distance of 30 m, nitrogen purity exceeding 97%, and a reliable bundle pipe system were established. Various methods were employed, including manual monitoring and sampling analysis. Carbon monoxide (CO) gas was identified as the primary indicator for early fire prediction and forecasting. Additionally, CO and olefinic gases were used as standard gases to determine the stage and severity of spontaneous combustion. These measures facilitated fire prediction and forecasting, ensuring the stable advancement of the working face.

To achieve efficient nitrogen filling, the design of the current pre-buried pipeline is optimized using simulation data. The nitrogen pipeline system is designed with 8-hole groups, comprising 6 individual nitrogen injection drill holes within each group. These holes are uniformly positioned around the pipe at a 60° angle and a radius of 1 cm. To ensure a uniform diffusion of nitrogen within the gob, the spacing between each column of pipes is set at twice the diffusion radius of nitrogen; this configuration prevents overlap between the two sets of nitrogen release points.

We adopted strict burial standards of a step-by-step, porous long-pipe nitrogen injection pipeline. Hence, the pipeline could withstand stress and pressure as the working face advanced. The results indicated a significant decrease in the concentration of O2 within the gob, as illustrated in Fig. 11. The O2 concentration exhibited a distinct spatial gradient. Within the range of 0 to 10 m near the intake-air roadway, the O2 concentration peaked to 20.7%, gradually decreasing from the center of the nitrogen injection pipe toward both sides. Near the nitrogen injection point, the O2 concentration approached zero. In the gob, more than 50 m away from the intake-air roadway, the O2 concentration decreased significantly, reaching a minimum of 2.6%. This observation indicates the effective diffusion of the injected nitrogen into the deeper section of the gob. Overall, most parts of the gob had O2 concentrations below 8%, primarily forming a suffocation zone. These results are generally consistent with the simulation results, validating the accuracy of the simulation.

Conclusion

To effectively minimize the risk of spontaneous combustion during coal mining, nitrogen injection treatment was applied to a gob, leveraging on-site measurements and numerical simulations. The numerical simulations aided us in determining nitrogen injection parameters and optimizing the nitrogen injection pipeline to improve the overall injection effect. The conclusions of the study are as follows:

-

1.

In the GERRCPR condition, the connection between the retaining roadway segment and the gob resulted in an open gob area. This exhibited a decreasing trend in O2 concentration from the intake-air roadway toward the return-air roadway. However, higher O2 concentrations were noted close to the intake-air roadway because of air leakage. The retaining roadway segment was connected to the zone with higher O2 concentration near the working face, forming a hazardous area prone to spontaneous combustion. Within 150 m of the working face, O2 concentration generally remained above 18%. Notably, at a 273 m distance in the return-air roadway, a high-temperature area reached 43.1 °C, close to the initial mining position of the working face. This underscores the crucial need for intensified monitoring and enhanced safety management measures.

-

2.

The simulation of the airflow within the gob area revealed various patterns. On the intake-air roadway side, the initial wind speed had an effect on the airflow velocity, which peaked at 1.11 m/s. At the intersection of the retaining roadway and the gob, the velocity was 0.96 m/s. The presence of air leakage induced a pressure difference at the working face, causing the airflow to converge from the intake to the return-air roadway. Within the gob, the airflow experienced resistance due to high pressure, resulting in relatively sparse streamlines. Conversely, on the retaining roadway side, the streamlines appeared denser. The gob’s air leakage varied with the working face advancement and the length of the retaining roadway. Initially, the air leakage rose; however, it subsequently decreased. Before advancing to the 1506 working face, the airflow leakage was relatively small, being only 17 m3/min. The value peaked to 226 m3/min when the length of the retaining roadway was 500 m. As the working face approached the stopping line, the roadway underwent deformation due to the influence of mining pressure, leading to a reduction in air leakage to 143 m3/min.

-

3.

The nitrogen injection position and rate impacted the distribution of O2 concentration. When setting a nitrogen injection point at 70 m from the working face and using a flow rate of 600 m3/h, notable reduction occurred in the spontaneous combustion zone. This reduction resulted in a span of 22–35 m along the intake-air roadway and 17–26 m on the return-air roadway, effectively mitigating the risk of spontaneous combustion. Consequently, the average O2 concentration in the gob remained below 8%, achieving effective fire prevention and inerting the gob. The oxidation zone maintained a secure distance from the working face, meeting production safety requirements. In the engineering implementation phase, optimizing the design of the hole arrangement and individual holes within the step-by-step buried nitrogen injection pipeline involved creating 8 hole groups, each containing 6 individual nitrogen injection drill holes. Each hole was positioned at an angle of 60° and had a radius of 1 cm, achieving a uniform diffusion within the gob and improving the effectiveness of the nitrogen injection. Not only can this effectively prevent spontaneous combustion and ensure production safety, but it can also enhance the economic efficiency of a mine’s production.

Data availability

All data generated or analysed during this study are included in this article.

References

Wang, S. et al. Coal energy status change and green low-carbon development under the goal of “double carbon”. Coal J. 48(07), 2599–2612. https://doi.org/10.13225/j.cnki.jccs.cn23.0260 (2023).

Wang, J. 40 Years and prospects of fully mechanized caving mining in China. Coal J. 48(01), 83–99. https://doi.org/10.13225/j.cnki.jccs.2022.1490 (2023).

Zhang, Z. Study on the necessity and application strategy of promoting dry coal preparation in China under the background of ’ double carbon’. China Coal. 49(09), 23–27. https://doi.org/10.19880/j.cnki.ccm.2023.09.004 (2023).

Huang, Z. et al. Current situation and development trend of coalbed methane development technology in China. Coal J. 47(09), 3212–3238. https://doi.org/10.13225/j.cnki.jccs.SS22.0669 (2022).

Chi, Y. Coal Mine Mod. (01), 12–13+17. https://doi.org/10.13606/j.cnki.37-1205/td.2021.01.005 (2021).

Cui, Y. Research on End Entry Retaining Technology for Non-pillar Mining (Xi 'an University of Science and Technology, 2014).

Ji, X. Optimization of Working Face Mining Scheme for Deep Mining-Separating-Filling Integrated Mine (China University of Mining and Technology, 2020). https://doi.org/10.27623/d.cnki.gzkyu.2020.001014.

Hui, W. B. et al. Research and application of mechanical models for the whole process of 110 mining method roof structural movement. J. Cent. S. Univ. 29(9), 3106–3124 (2022).

Eryu, W., Xiang, C. & Xiao, Y. Research and application of an innovative 110 mining method in gob-side half coal rock entry retaining. Shock Vib. 2021, 1–8 (2021).

Zhu, X. et al. Analysis of the range of “three zones” of spontaneous combustion in goaf under “110 construction method”. Shaanxi Coal 42(06), 8–12+23 (2023).

Li, Y., Jing, Z. & Jia, J. Study on air leakage law in goaf under “Y” ventilation mode of gob-side entry retaining with roof cutting and pressure relief. J. Nat. Disasters 31(03), 184–189. https://doi.org/10.13577/j.jnd.2022.0319 (2022).

Krawczyk, J. & Janus, J. The numerical simulation of a sudden inflow of methane into the end segment of a longwall with Y-type ventilation system. Arch. Min. Sci. 59(4), 941–957 (2014).

Xiao, G. et al. Measurement and numerical simulation of coal spontaneous combustion in gob under Y-type ventilation mode. ACS Omega 7(11), 9406–9421 (2022).

Liu, H. et al. Characteristics of overburden failure and fracture development in goaf under the condition of roof cutting and roadway formation. J. China Univ. Min. Technol. 51(01), 77–89. https://doi.org/10.13247/j.cnki.jcumt.001355 (2022).

Zhai, Ch. et al. Fracturing mechanism of coal-like rock specimens under the effect of non-explosive expansion. Int. J. Rock Mech. Min. Sci. 103, 145–154 (2018).

Song, Y. et al. Effects of particle size on compressive deformation characteristics of broken rock mass in gangue rib of automatically formed gob-side entry retaining. Powder Technol. 430, 118987 (2023).

Xi, Z. et al. Study on nitrogen injection fire prevention and extinguishing technology in spontaneous combustion gob based on gob-side entry retaining. ACS Omega 8(33), 30569–30577 (2023).

Miao, Ch. et al. Prediction model of lean coal adsorption of power plant flue gas. ACS Omega 9(10), 12101–12115. https://doi.org/10.1021/acsomega.3c10005 (2024).

Zhang, G., Lu, X. & Wang, W. Study on spontaneous combustion law and prevention and control technology of residual coal in goaf of gob-side entry retaining in spontaneous combustion coal seam. Coal Technol. 42(04), 108–113. https://doi.org/10.13301/j.cnki.ct.2023.04.023 (2023).

Wang, Y. et al. Division of spontaneous combustion “three zones” in goaf of fully mechanized caving face with multi interlayer roof. Min. Saf. Environ. Prot. 50(01), 97–102. https://doi.org/10.19835/j.issn.1008-4495.2023.01.017 (2023).

Li, L. et al. Unique spatial methane distribution caused by spontaneous coal combustion in coal mine gobs: An experimental study. Process Saf. Environ. Prot. 116, 199–207 (2018).

Xu, J. et al. Surface relaxivity estimation of coals using the cutting grain packing method for coalbed methane reservoirs. Powder Technol. 427, 118768 (2023).

Qiang, X., Li, J., Chen, C, et al. Nonuniform deformation instability mechanism of gob-side entry retained in inclined coal seam and stability control. Appl. Sci. 13(15) (2023).

Si, J. et al. Numerical simulation of coal spontaneous combustion plugging and air control mechanism in gob-side entry retaining. Min. Saf. Environ. Prot. 49(02), 40–45. https://doi.org/10.19835/j.issn.1008-4495.2022.02.007 (2022).

Wen, Z. et al. Research on the coupled hazardous zones of coal self-ignition and CH4 blast in gob during upward mining. Case Stud. Therm. Eng. 52, 103733 (2023).

Jia, H., Wang, L., Bloomberg, et al. Mechanism and application of ' roof control-pressure relief ' classification of gob-side entry retaining with weakly bonded composite roof. J. China Univ. Min. Technol. 52(06), 1191–1202 (2023). https://doi.org/10.13247/j.cnki.jcumt.20230196.

Guo, M., Wang, F. & Liu, H. Study on the temporal and spatial evolution law of spontaneous combustion “three zones” in goaf based on dynamic grid. Coal Technol. 42(06), 167–171. https://doi.org/10.13301/j.cnki.ct.2023.06.038 (2023).

Lin, B., Li, Q. & Zhou, Y. Research progress on multi-field evolution of gas and coal spontaneous combustion composite thermodynamic disaster in goaf of coal mine. Coal J. 46(06), 1715–1726. https://doi.org/10.13225/j.cnki.jccs.hz21.0264 (2021).

Guo, M., Wang, W. & Cheng, Z. Study on fire prevention and extinguishing technology of gob-side entry retaining with roof cutting and pressure relief in spontaneous combustion coal seam. Coal Technol. 42(06), 117–122. https://doi.org/10.13301/j.cnki.ct.2023.06.028 (2023).

Xu, J. et al. Investigation of the mechanical damage of low rank coals under the impacts of cyclical liquid CO2 for coalbed methane recovery. Energy. 239, 122145 (2022).

Wang, Ch. & Cheng, Zh. Research on fire prevention and extinguishing technology of fully mechanized mining face with large mining height in spontaneous combustion coal seam. China Mine Eng. 50(05), 75–78. https://doi.org/10.19607/j.cnki.cn11-5068/tf.2021.05.019 (2021).

Lulu, S. et al. Effect of high-temperature environment of mine gob on pore and fracture of coal. Fuel. 325, 124810 (2022).

Hong, Z. et al. Optimization of key parameters for continuous and precise nitrogen injection in gob based on response surface methodology. Environ. Sci. Pollut. Res. Int. 30(14), 40189–40205 (2023).

Wang, C., Han, B. & Xue, J. Application of nitrogen injection technology in mine fire prevention and extinguishing. Coal Eng. 52(S1), 104–106 (2020).

Bai, G. et al. Effect of CO2 injection on the gas desorption and diffusion kinetics: An experimental study. Energy 288, 129921 (2024).

He, F. & Bi, J. Study on the balance point of gas and fire co-governance in goaf of low permeability spontaneous combustion coal seam. Energy Technol. Manag. 42(06), 1–4 (2017).

Shuai, L., Yu, X., Li, C., et al. Enhancement of coalbed methane via nitrogen injection in a coal mining area: A laboratory and field study. J. Energy Eng. 149(6) (2023).

Wei L, Feng Z, Tie G, et al. Efficient prevention of coal spontaneous combustion using cooling nitrogen injection in a longwall gob: An application case. Energy. 281 (2023).

Wei, Z., Wen, J., Yan, L., et al. Study of diffusion coefficients and molecular adsorption laws for the slit-hole coal model under the thermal-gas-liuid coupling effect with hot nitrogen injection. Mol. Phys. 120(8) (2022).

Zhang, T., Li, H. & Yang, B. Study on curtain grouting fire prevention and extinguishing technology during the retracement of final mining in fully mechanized caving face. Energy Technol. Manag. 48(05), 104–106 (2023).

Jin, Y. et al. Research on the influence of nitrogen injection parameters on the prevention and control of coal spontaneous combustion in goaf based on FLUENT. Coal Technol. 37(11), 230–233. https://doi.org/10.13301/j.cnki.ct.2018.11.088 (2018).

Haoran, G. et al. Underground coal seam gas displacement by injecting nitrogen: Field test and effect prediction. Fuel 306, 121646 (2021).

Acknowledgements

The authors greatly acknowledge the National key research and development program (No. 2018YFC0807901).

Funding

This project received funding from the National key research and development program (2018YFC0807901).

Author information

Authors and Affiliations

Contributions

X.Z., Y.C., G.B. and S.Z. were responsible for checking the rationality of the content of the paper, and Z.J. was mainly responsible for the writing and conception of the paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jing, Z., Zhou, X., Li, Y. et al. Research on the technology of uniformly injecting nitrogen into the porous long pipes in the gob of the gob-side entry retaining mining mode with roof cutting and pressure relief. Sci Rep 14, 18205 (2024). https://doi.org/10.1038/s41598-024-69297-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-69297-4