Abstract

This study investigates the development of novel nanocomposite films based on a blend of polyethylene oxide (PEO) and polyvinyl alcohol (PVA) loaded with varying weight percentages of copper cobaltite nanoparticles (CuCo2O4 NPs). The primary objective was to fabricate these nanocomposites using a solution casting technique and explore the influence of CuCo2O4 content on their structural, optical, electrical, and dielectric properties. Spinel-type CuCo2O4 NPs were synthesized via the hydrothermal method and incorporated into the PEO/PVA blend. X-ray diffraction (XRD) analysis revealed the transformation of the polymer matrix towards an amorphous state with increasing CuCo2O4 content. UV–Vis spectroscopy studies demonstrated a decrease in both the direct and indirect band gaps of the nanocomposites, suggesting potential applications in optoelectronic devices. Impedance spectroscopy measurements revealed a significant enhancement in ionic conductivity (three orders of magnitude higher than the pristine blend) for the nanocomposite film containing 1.8 wt% CuCo2O4. The real permittivity (ε′) and imaginary permittivity (ε″) of the polymer nanocomposites exhibited a decrease with increasing frequency due to the interplay of various polarization mechanisms. Notably, incorporating 1.8 wt% CuCo2O4 nanoparticles led to a remarkable improvement in energy density compared to the pristine blend. Additionally, a significant decrease in the potential barrier was observed. These findings demonstrate the successful fabrication of PEO/PVA-CuCo2O4 nanocomposite films with enhanced optical, electrical, and dielectric properties. The observed improvements suggest promising applications for these materials in energy storage devices and potentially in optoelectronic devices like light-emitting diodes.

Similar content being viewed by others

Introduction

Science's investigation of matter at nanoscale dimensions (1–100 nm) is known as nanotechnology. Numerous scientific and industrial applications have made substantial use of nanomaterials1,2. Nanotechnology will undoubtedly contribute significantly to the improvement of current industrial processes3,4. Polymer thin films have captivating the scientific community in recent decades due to their vast potential in diverse applications such as fuel cells, supercapacitors, energy storage/conversion devices, and sensors5,6,7. It is intended that devices be developed for these applications to provide polymer electrolytes with high ionic conductivity at ambient temperature. On the other hand, solid polymer electrolytes have certain drawbacks that restrict their use in energy storage capacitors, such as limited ionic conductivity and electrochemical stability. Many techniques, including mixing with another polymer, adding plasticizers, mild acids, nanofiller, etc., are being used to increase the ionic conductivity of the polymer nanocomposites (PNCs). Currently, there has been extensive research on polymer electrolytes using various materials such as chitosan, PVA, PVC, PVDF, and HFP8,9,10. In this particular study, PVA is chosen as the host matrix due to its unique characteristics including good film-forming ability, non-toxic nature, wide temperature range suitability, and electrical and optical properties dependent on nanofillers11,12. Additionally, PEO is a linear semi-crystalline polymer known for its exceptional thermal and chemical durability. PEO, also known as polyethylene oxide, possesses exceptional attributes that make it an attractive material for an applications wide range. Notably, its water solubility, ionic conductivity, crystallizability, and remarkable diffusibility contribute to its potential in various industries. Additionally, the -O group present in PEO facilitates a high level of crystallinity. One effective approach to decreasing the crystallinity of PEO is by blending it with an amorphous polymer like PVA13,14. Because polymer nanocomposites have more interfacial atoms and defects than bulk materials, their electrical properties are different. To characterize the electrical properties of polymeric materials, the AC impedance procedure is used. The dielectric property of composites is influenced by factors such as the size, and shape of conducting nanofillers, preparation method, as well as volume fraction and interfacial interaction between nanofiller and polymers. In order for energy storage capacitors (i.e., electrochemical devices) to function properly, they require a high dielectric permittivity. Recent studies have reported high dielectric constants in various materials, including polymer/polymer (or organic/polymer) composites, ceramics, and ceramic/polymer composites15. However, the high dielectric loss of the PNCs containing one-dimensional fillers was a disadvantage. Additionally, a new class of material with enhanced stability and enhanced optical, magnetic, dielectric, and electrical properties is made possible by polymer-coated inorganic materials, and this material has significant uses in field emission techniques, thermoelectric, infrared spectroscopy, and photovoltaics16. In order to enhance the thermo-mechanical characteristics of solid polymer electrolytes, inorganic nanofillers can be incorporated17,18. These nanofiller additives create an association between surface functional groups of polymer network, reducing crystallinity and promoting the charge carriers movement. In the end, this raises the electrode–electrolyte interface's efficacy. According to Liu et al.19, a conductive network is formed within the polymer matrix through rapid ionic conduction on the inorganic nanofillers surface. Several studies have shown that addition fillers like TiO2, ZnO, SiO2, and Fe2O3 can enhance mechanical, thermal stability, and electrical properties20,21. The extent to which conductivity is improved depends on both the nanofiller materials used and the grain size of the nanofillers. The filler materials being used and the filler grains' size determine how much conductivity increases15,22. According to Jeedi et al.23, an increase in the specific surface area of nanofiller grains leads to a corresponding increase in conductivity. Higher ionic conductivity is a result of the large surface area, which causes a high degree of disorder in the amorphous phase in PEO/PVdF. Copper cobaltite (CuCo2O4) is a promising nanofiller material for polymer nanocomposites (PNCs). Depending on its stoichiometry and synthesis methods, CuCo2O4 can exhibit either n-type or p-type doping characteristics. In the context of energy storage devices, n-type doping is particularly desirable as it facilitates the movement of positively charged ions (cations) within the electrolyte24. This enhanced ionic conductivity is crucial for efficient device operation. The CuCo2O4 NPs electrodes were fabricated using different nanostructured morphologies in order to enhance their electrochemical properties for applications in supercapacitors and catalysis. A recent study by Liu et al. demonstrated the effectiveness of copper cobaltite with a microsphere morphology consisting of well-defined porous nanoplates as highly efficient electrode materials for supercapacitor applications25.

While CuCo2O4 has shown promise in energy storage applications, limited research has explored its potential when incorporated into polymer electrolytes like PEO/PVA. This study bridges this gap by investigating the impact of CuCo2O4 nanoparticle inclusion on the structural, dielectric, and electrical properties of PEO/PVA blend films. Our focus lies in understanding the interplay between CuCo2O4 morphology and the resulting composite properties, aiming to optimize these materials for high-performance energy storage applications. The enhanced dielectric properties observed in our preliminary studies suggest the potential of this PEO/PVA-CuCo2O4 nanocomposites as efficient electrolytes in supercapacitors and other energy storage devices.

Experimental section

Materials

The PVA (C2H4O)n was acquired from E-Merck in Germany and has a molecular weight of 14,000 g mol−1. PEO powder was acquired from ACROS in New Jersey, USA, with a molecular weight was 40,000 g mol−1. AR,Co(CH3COO)2·4H2O, Congo red(CR) Methyl blue(MB), AR,Cu(CH3COO)2·H2O, and Urea were acquired from Hi-media company. Double-distilled water (DDW) was used to synthesize all of the reagents.

Synthesis of CuCo2O4 NPs

CuCo2O4 NPs were prepared using a hydrothermal technique that is both efficient and environmentally friendly26. Using this method, 40 ml of distilled water were mixed with 0.8 g of Cu(CH3COO)2⋅H2O (0.1 M) and 2 g of Co(CH3COO)2⋅4H2O (0.2 M). The mixture was then stirred for 30 min. Meanwhile, 20 ml of distilled water were used to dissolve 0.3604 g of urea. The precursor solution was gradually mixed with the urea mixture while being stirred continuously until the solution's color lightened to pink. After that, the mixture was placed inside the autoclave lined with Teflon and heated to 120 °C for six hours. To obtain the precipitate, the solution was filtered after 6 h. The resulting precipitate was calcined at 450 °C after being dried at 75 °C and cleaned with ethanol and water. CuCo2O4 nanoparticles were produced by finely powdering the final product.

Preparation of nanocomposite films

Using a magnetic stirrer, 1.5 g of PVA was dissolved in 40 ml of DDW at 80 °C for eight hours to create the polymer blend (50%PEO/50%PVA). Using a magnetic stirrer, 1.5 g of polyethylene oxide (PEO) was dissolved in 40 ml of distillation over eight hours. Following the addition of CuCo2O4 NPs to the polymer matrix, PVA was combined with each molecule of PEO to create a polymer blend. The same process was then used to create hybrid nanocomposites. To obtain a uniform dispersion, 0.1 g of CuCo2O4 NPs was suspended in DDW and sonicated for 30 min before being mixed with the polymeric matrices. The desired CuCo2O4 NPs concentration M (0.2, 0.8, 1.4, and 1.8 wt%) was estimated employing the following equation:

where mb and md are the weight of the blend (50%PEO + 50%PVA) and the dopant material (CuCo2O4 NPs), respectively. All five films, including the pure PEO/PVA blend and nanocomposites containing varying amounts (0.2 wt%, 0.8 wt%, 1.4 wt% and 1.8 wt% CuCo2O4-PEO/PVA), were placed in a petri-dish under ambient conditions for seven days to allow for complete drying. Once the water had evaporated, the self-standing PNCs films were carefully peeled off from each sample. The resulting thickness of the self-standing CuCo2O4-PEO/PVA film measured approximately 120 μm.

Characterization

X-ray diffraction analysis of the films was performed using a PA Nalytical X'Pert PRO X-ray Diffractometer. Cu-Kα radiation with a wavelength of 1.5416 Å was utilized, and the scan range was set from 2θ = 15° to 55°, all at room temperature (RT). Distribution of CuCo2O4NPs was determined using a transmission electron microscope (TEM) with an acceleration voltage of 80 kV, specifically the JEOL JSM-100 CX from Shimadzu Co., Japan. A scanning electron microscope (JEOLJSM-6510LV, USA) was used to analyze the surface morphology of the nanocomposites films. Furthermore, optical absorption measurements of the nanocomposites samples were conducted using a JASCO V-630-Japan UV–visible spectrophotometer. Finally, broadband dielectric spectroscopy using the Novo Control Turnkey Concept 40 System was utilized to assess the dielectric properties and impedance of the films at RT.

Results and discussion

XRD describes

An essential system for assaying the structure–property connections of CuCo2O4 NPs and polymer nanocomposites is XRD spectroscopy. XRD measures were conducted to probe the crystal-clear structure of CuCo2O4 NPs, PEO/PVA, and PEO/PVA-CuCo2O4 films, as illustrate in Fig. 1. Figure 1a displays XRD patterns of CuCo2O4 NPs. The diffraction peaks at 2θ = 18.90°, 31.34°, 36.95°, 38.64°, 44.89°, 59.55°, and 65.45° can be assigned to the (111), (220), (311), (222), (400), (511), and (440) plane of the spinel CuCo2O4 (JCPDS No.: 71-0816)27 respectively, and there are no signs of second phases, suggesting that the synthesized material is fairly pure. Moreover, the Scherrer equation is utilized to determine the average crystal size (D) of CuCo2O4 NPs28:

where β is the peak's full width at half maximum (FWHM), λ is the X-ray wavelength (λ = 0.15406 nm), and the diffraction peak's half angle, expressed in degrees, is indicated by θ. The crystal size of CuCo2O4 NPs at the peak corresponding to the plane (311) is found to be 12 nm. The PEO/PVA mix, as shown in Fig. 1b, is a typical semi-crystalline polymer that exhibits diffraction at peaks at 2θ = 19.82° and 23.13° corresponded to lattice plains of (112) and (222) (PCPDF File Nos. 49–2200 and 49–220), respectively29. It can also be noted that these peaks have dropped in intensity and grown in broadness with the gradational rise in dopant content. This indicates a lowering of the degree of crystallinity which increases the amorphous nature of the samples. This indicates reduce in the crystallinity degree, leading to a rise in the amorphous nature of the films. This could be explained by the nanofiller's tiny particles, which interfere with the chain's reorganization and increase ionic conduction because of their potent interaction with PEO/PVA nanoparticles. This finding suggests an overall enhancement in crystallinity, potentially accompanied by a shift in the crystallization pattern within the amorphous regions. This demeanor suggests that the amorphous region between the CuCo2O4 NPs and the polymer matrix is where the complexation takes place30. This enhances the ionic optical and electrical properties of polymer nanocomposites due to the stir of the polymeric chains within the amorphous phase31, which will be displayed later. The addition of 1.4% and 1.8%CuCo2O4 NPs in the PEO/PVA matrix introduces distinct XRD peaks, corresponding to various crystal planes of these nanoparticles. These peaks can be witnessed at 2θ = 31.34°, 36.95°, 38.64°, 44.89°, 59.55°, and 65.45° which are corresponded to the planes of pure CuCo2O4 NPs.

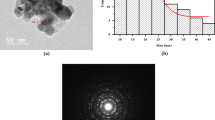

TEM and SEM

TEM micrographs are among the best tools for researching the size and shape of nanoparticles. Figure 2a displays the CuCo2O4 TEM image. Upon examination, the CuCo2O4 was discovered to have an agglomerated, spherical morphology, with an average crystallite size ranging from 5 to 17 nm. This matches the measurements from the XRD. The average particle size of the CuCo2O4 NPs from the TEM results is larger than from the XRD results when the data from the two instruments are compared. This is because the XRD indicates the size of the crystallites, whereas the TEM provides the particle size that may contain multiple crystallites29,32.

A scanning electron microscope (SEM) was used to examine the surface morphology of polymer films. Figure 2b–d shows the SEM micrographs of the PEO/PVA/CuCo2O4 nanocomposite films. Every polymer samples exhibited a surface morphology that was smooth. Furthermore, the polymer samples scans demonstrated the uniform dispersion of CuCo2O4 nanoparticles. Since the boundaries between the PEO and PVA phases cannot be observed, it is evident that the pure PEO/PVA has a uniform surface morphology that reveals a relatively smooth surface, confirming its homogeneous composition and lack of phase separation; in other words, they are miscible (see Fig. 2b). Figure 2c–f shows the morphology of polymer nanocomposite samples with different contents of CuCo2O4 in the polymer blend. The highly conductive polymer blend modifications in the morphology of crystalline-structure more than demonstrate that the nanoparticles and polymer matrix have complexed33. As a result, the smoother form and higher amorphous content of the polymer–nanoparticles matrix promote faster ion transport34. On the other hand, the PEO/PVA blend surface becomes rougher when loading CuCo2O4 NPs (Fig. 2c–f). CuCo2O4 is found in the white sections, whereas the black regions were polymer-rich, according to observations of the black and white regions. Additionally, 1.8 wt% CuCo2O4 loaded film was found to have the highest particle count when compared to other loading contents, and there was some degree of CuCo2O4 NPs agglomeration. Consequently, the acquired SEM results are consistent with the outcomes of the XRD tests.

UV-spectroscopy characteristics

Figure 3 displays the optical absorption spectra of (PEO/PVA-CuCo2O4) polymer nanocomposites with varying weight percentages of nanofillers. The PEO/PVA film's spectra revealed an absorption band at 210 nm. The observed absorption band at 210 nm likely originates from electronic transitions within the PEO/PVA backbone structure35. As the concentration ratio of CuCo2O4 rises, the intensity of this absorption band improves. As the concentration of CuCo2O4 increases, the spectra show a red shift in the absorption edge, which denotes a change in the optical band gap energy. PEO/PVA-CuCo2O4 nanocomposites' high energy may be caused by the arrangement of the cations' and anions' internal molecular bonds36. Additionally, the absorbance edge, which is a defining trait of the charge transfer complex (CTCs) formation between blended polymer chains and distributed CuCo2O4 NPs37,38. This outcome confirms the PNCs material's remarkably wavelength-controllable absorbance behavior, indicating that it could prove to be a viable choice for the development of flexible devices that employ spectral shorting in the future.

Optical constants

Optical energy gap (Eg)

Figure 4a,b showcase the direct and indirect optical energy band gaps, determined by analyzing the tangent of the optical absorption edge. The direct energy band gap (Eg) of the particles is revealed through the absorption spectra, and its value is calculated using the following equation39,40:

As represented by Eq. (1), the exponent n takes on distinct values for direct (n = 0.5) and indirect (n = 2) allowed transitions in the material. These values are precisely determined by extrapolating the linear portion of the Tauc plots (Fig. 4a,b) near the absorption edge until it intersects the energy axis. The extracted n values for both transitions are conveniently compiled in Table 1. Increasing CuCo2O4 NPs concentration narrowed both direct and indirect bandgaps in the films. CuCo2O4 NPs are added to PEO/PVA-CuCo2O4 nanocomposites to lower the bandgap by giving electrons new energy levels to occupy. The CuCo2O4 NPs added to the PEO/PVA polymer matrix cause a systematic decrease in the optical band gap by creating a new energy state inside the optical bandgap41. The emergence of new energy levels may facilitate electron migration from the valence bands into newly generated local states42,43. This improves the material's semi-conducting behavior by making it simpler for electrons to move from the valence band to the conduction band.

Urbach energy

The band tail energy (EU) or Urbach energy introduces spectral dependency at the absorption edge47. The EU, which may be computed as follows44, connects the crystal defects, localized states band tails, and disorders of microstructural lattice.

Here α is the absorption coefficient. The prepared samples' logarithm of α is displayed against photon energy (hv) (in eV) in Fig. 5. The absorption coefficient (α) at band borders is exponentially related to hv in accordance with the Urbach law49. Table 1 lists the computed EU values for each of the PEO/PVA-CuCo2O4 polymer nanocomposites with a different weight percentage of nanofiller. It is clear that when the CuCo2O4 content in the PEO/PVA blend rises, so does the EU value. This attests to a growth in both the disordering degree of the polymer film structure and the localized states in the forbidden band gaps and thus a decrease in optical energy gap values. Besides, there is a more significant possibility of transitions from tail to tail and from band to tail45.

Electrical conductivity spectra

Figure 6 depicts the conductivity of PEO/PVA with varying CuCo2O4 NPs content at different frequencies. CuCo2O4-PEO/PVA nanocomposites exhibit an increase in AC conductivity as the applied frequency increases. In dielectric materials, active grains divide inactive grain borders, according to Maxwell–Wagner's double-layer model. In other words, a PEO/PVA layer which has a low conducting nature because of the defects creation in grain boundaries-separates the conducting CuCo2O4 nanoparticles46,47. At high frequencies, these conducting grains are active, while at inferior frequencies, fewer conduct boundaries are active. Because the less conducting grains are active at inferior frequencies, CuCo2O4-PEO/PVA nanocomposites have reduced AC conductivity at lower frequencies. The CuCo2O4-PEO/PVA nanocomposites' AC conductivity is enhanced at higher frequencies due to the increased activity of conducting grains48. As the content of CuCo2O4 NPs grows in the PEO/PVA, the conductivity also rises gradually. This happens because the CuCo2O4 NPs spread in the pure blend and create more conductive paths. The conductivity of such nanocomposite is affected by various factors such as the size, dispersion, shape, and type of nanoparticles49,50. Increased amorphization of the polymer nanocomposite enhances ion movement, resulting in improved conductivity by lowering energy barriers12. Furthermore, for all films, the figure shows how conductivity of electrical rises with frequency. At low frequencies, the system's conductivity is essentially constant, but at high frequencies, it depends on frequency and exhibits a power law as explained by Jonscher51:

At high frequencies of applied field, the conductivity of charge carriers enhances linearly due to their freer movement as compared to lower frequencies52. Moreover, loss factors play a dominant role at more heightened frequencies, leading to a relatively more heightened conductivity at those frequencies53. Comparable patterns have been noted in numerous polymeric nanocomposites54,55.

Dielectric characteristics

The dielectric and electrical properties are crucial for using polymer nanocomposite materials in polymer technologies for energy storage, insulation, and advancements in flexible electronic devices38,56. It is necessary to conduct laboratory measurements of the electrical properties of the composite dielectric materials to identify if they transition from insulator to conductor under the effect of the applied electric field. The response of a dielectric material can be analyzed using ε* = ε′ − iε″. In each cycle of an alternating electric field, the dielectric permittivity (ε′) represents the energy stored, while the dielectric loss (ε″) denotes the energy lost. We can calculate the ε′ and ε″ using the following equations46,57:

where ω = 2πf illustrates the frequency of angular, εo is the free space permittivity, and C is the investigated sample capacitance. In Fig. 7a,b, we can see the ε′ and ε′′ spectra for PEO/PVA and PEO/PVA-x wt% CuCo2O4 nanocomposites at room temperature. The high value of the ε′ was observed at a lower frequency. Because of the shift in the conductivity/permittivity values for the CuCo2O4 and the host PEO/PVA blend, it is believed that the interfacial polarization (IP) "Maxwell–Wagner–Sillars (MWS) mechanism" that is present within the hybrid inorganic–organic structures is responsible for this maximum value of ε′ at inferior frequency22,58. As the frequency increased, the values of ε′ for all samples (Fig. 7a) decreased. At higher frequencies, the dipoles' inability to rotate in the applied field direction causes ε′ to decrease. Furthermore, the dipolar ordering of polar PEO/PVA was impacted by CuCo2O4's electrostatic interactions with the dipolar groups of the PEO/PVA blend, resulting in a change in the values of ε′ for the doped PEO/PVA59. Figure 7b shows the behavior of the ε″ of CuCo2O4 nanoparticles dispersed in PEO/PVA at room temperature with varying weight percentages. The ε″ follows the same trend as the real part of the ε′, but with higher values at lower frequencies. The high value of ε″ at low frequency indicates the presence of a disordered phase, which is due to the amorphous nature of the nanofiller. The sample with 1.8% CuCo2O4-PEO/PVA exhibited the most amorphous nature compared to the other samples, as evidenced by the maximum value of ε″. Other relaxation mechanisms are masked by the sharp rise at low frequency, which suggests deposition of free charge due to effects of electrode polarization. The increase in ε″ with nanofiller contenst may be caused by a decrease in relaxation time and dipole relaxation23. The higher dielectric constant improvement of the 1.8% CuCo2O4-PEO/PVA sample is caused by the mobile ion's greater localization with charge carriers or by the percolated network formation within the polymer chain60.

Energy storage density

One can compute the density energy (U) by using Eq. (8)61.

εo is permittivity ~ 0.885 × 10–12 NV/m and E is strength of field ~ 1 V/mm. Figure 8 displays the values of energy density at various frequencies of PEO/PVA, and PEO/PVA-CuCo2O4 nanocomposites samples. Notably, we find that as the concentrations of CuCo2O4 NPs increase, so does the energy density of the PEO/PVA blend. With 0.2% CuCo2O4, 0.8% CuCo2O4, 1.4% CuCo2O4, and 1.8% CuCo2O4, the energy density of PEO/PVA grows from 4.9 × 10–3 J/m3 for pure blend to 4.8 × 10–2 J/m3, 9.8 × 10–2 J/m3, 17.7 × 10–2 J/m3 and 23.5 × 10–2 J/m3, respectively. This is because PEO/PVA-CuCo2O4 films transfer charges far faster than pure blends do. CuCo2O4 exhibits an induced abundance of polarization modes due to electric dipole interactions. Based on the observed improvements in dielectric properties, we propose that the interaction between CuCo2O4 nanoparticles and the PEO/PVA matrix might lead to enhanced interfacial polarization. This could involve mechanisms such as the alignment of polar groups at the interface or the creation of additional interfacial dipoles. These findings support the idea of improving the dielectric responses and energy storage capabilities within the host by introducing CuCo2O4 NPs. These alterations imply that PEO/PVA-CuCo2O4 films are good choices for employment in dielectric devices.

The energy required to expel an electron from a location into infinity is known as the maximum height potential barrier (Wm). It can be calculated using the following formula62:

The Boltzmann constant is denoted by k_B, and the slope of log (ε′′) against log (f) in Fig. 9 was used to estimate m, by the following equation61:

The potential barrier Wm decreased with CuCo2O4 content. It is decreased from 0.254068 eV for pure PEO/PVA to 0.145292 eV, 0.12071 eV, 0.11443 eV, and 0.10334 eV for PEO/PVA/0.2% CuCo2O4, PEO/PVA/0.8% CuCo2O4, PEO/PVA/1.4% CuCo2O4 and PEO/PVA/1.8% CuCo2O4, respectively. According to XRD data, the addition of CuCo2O4 NPs modified the PEO/PVA structure, which resulted in a reduction in the potential barrier. This lowered the energy needed to hop between charge carriers and verified the improvement in AC conductivity62.

Complex modulus study (argand plot)

To ascertain the nature of the relaxation process, the prepared films are plotted using the Cole–Cole diagram (Argand plots), as shown in Fig. 10. It is evident that semicircles with centers that do not terminate on the real part of the electric modulus (M′) axis characterize the patterns for all films. Polymers usually show a relaxation time distribution and deviate from a semicircular shape. Every prepared film exhibits a semi-circular arc that is depressed. The center of this arc, which is on the x-axis (M′ axis), represents the polymer nanocomposite's electric relaxation. The radius of the depressed semi-circular arc was associated with the conductivity of the films. The radius of the arc and the conductivity of the polymer matrix were intimately connected63. The Argand plot's semi-circular arc is influenced by the polymer electrolytes' relaxation and ionic conductivity64. As the polymer nanocomposites' nanofiller content rises, the radius of the semicircle arcs decreases. A reduction in the semicircle arc by radius suggests that the polymer nanocomposites' ion relaxation time has reduced. In the Argand plot, a higher conducting sample has a lower semicircle arc and a shorter relaxation time65. Figure 10 makes it clear that when the content of CuCo2O4 NPs in PEO/PVA increases; the arc length decreases, revealing an increase in conductivity. This study demonstrates that PEO/PVA with 1.8 wt% CuCo2O4 added has a higher conductivity than other films. The blend's Argand curves attempt to move in the origin direction as the concentration of CuCo2O4 is raised. This suggests that the nature of non-Debye of the polymer nanocomposites is followed. The non-Debye nature occurs due to the many interchanges between the dipoles and ions and the contribution of more than one type of polarization, relaxation mechanism.

Conclusion

The casting approach was utilized to fabricate polymer nanocomposites (PEO/PVA-CuCo2O4) by varying the weight percentage of CuCo2O4 nanofillers. The properties of these nanocomposites were comprehensively investigated. XRD analysis was conducted on the synthesized nanocomposites with varying CuCo2O4 NPs concentrations to probe their structural characteristics. The presence of nanofillers influenced the semi-crystalline nature of PEO/PVA, resulting in reduced crystallinity, indicative of interaction between the nanofillers and the polymer blend. The impact of nanofillers on the optical properties, specifically the direct and indirect band gaps, was evaluated using Tauc plots. Increasing the concentration of CuCo2O4 nanofillers led to a decrease in both direct and indirect band gaps, from 4.98 eV and 4.46 eV for the pure blend to 4.23 eV and 3.67 eV for PEO/PVA-1.8% CuCo2O4, respectively. Additionally, the Urbach energy increased with higher nanofiller content. The AC conductivity behavior of the materials was analyzed across a range of frequencies, following Jonscher's power law. The AC conductivity of the PEO/PVA blend increased with frequency, reaching its peak at 1.8% CuCo2O4-PEO/PVA. The study revealed strong molecular dipolar polarization at higher radio frequencies and a frequency-dependent dielectric permittivity primarily influenced by interfacial polarization at lower frequencies. Based on these characterization results, the synthesized polymer nanocomposites demonstrate promising applications in optoelectronics, energy storage devices, and microelectronics due to their tailored structural and electrical properties.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on request.

References

Mariyam, S. et al. Nanotechnology, a frontier in agricultural science, a novel approach in abiotic stress management and convergence with new age medicine-A review. Sci. Total Environ. 912, 169097. https://doi.org/10.1016/J.SCITOTENV.2023.169097 (2024).

Kumar, D. et al. Review on interactions between nanomaterials and phytohormones: Novel perspectives and opportunities for mitigating environmental challenges. Plant Sci. 340, 111964. https://doi.org/10.1016/J.PLANTSCI.2023.111964 (2024).

Kim, D.-Y. et al. Extracellular synthesis of silver nanoparticle using yeast extracts: Antibacterial and seed priming applications. Appl. Microbiol. Biotechnol. 108, 150. https://doi.org/10.1007/s00253-023-12920-7 (2024).

Mariyam, S., Bhardwaj, R., Khan, N. A., Sahi, S. V. & Seth, C. S. Review on nitric oxide at the forefront of rapid systemic signaling in mitigation of salinity stress in plants: Crosstalk with calcium and hydrogen peroxide. Plant Sci. 336, 111835. https://doi.org/10.1016/J.PLANTSCI.2023.111835 (2023).

Bhavsar, S., Patel, G. B., Singh, B., Singh, F. & Singh, N. L. A comparative study on gamma and carbon ion irradiations induced modification in structural and electrical properties of PVA/H3PO4/SiO2 nanocomposite polymer electrolyte. Radiat. Phys. Chem. 192, 109916. https://doi.org/10.1016/J.RADPHYSCHEM.2021.109916 (2022).

Aziz, S. B., Abidin, Z. H. Z. & Arof, A. K. Effect of silver nanoparticles on the DC conductivity in chitosan–silver triflate polymer electrolyte. Phys. B Condens. Matter. 405, 4429–4433. https://doi.org/10.1016/J.PHYSB.2010.08.008 (2010).

Liang, S., Yang, J., Zhang, X. & Bai, Y. The thermal-electrical properties of polyvinyl alcohol/AgNO 3 films. J. Appl. Polym. Sci. 122, 813–818. https://doi.org/10.1002/app.34060 (2011).

Karaman, B. & Bozkurt, A. Enhanced performance of supercapacitor based on boric acid doped PVA-H2SO4 gel polymer electrolyte system. Int. J. Hydrog. Energy. 43, 6229–6237. https://doi.org/10.1016/J.IJHYDENE.2018.02.032 (2018).

Hema, M. & Tamilselvi, P. Lithium ion conducting PVA:PVdF polymer electrolytes doped with nano SiO2 and TiO2 filler. J. Phys. Chem. Solids. 96–97, 42–48. https://doi.org/10.1016/J.JPCS.2016.04.008 (2016).

Patel, G. B., Singh, N. L. & Singh, F. Modification of chitosan-based biodegradable polymer by irradiation with MeV ions for electrolyte applications. Mater. Sci. Eng. B. 225, 150–159. https://doi.org/10.1016/J.MSEB.2017.08.023 (2017).

Alghamdi, H. M. & Rajeh, A. Synthesis of CoFe2O4/MWCNTs nanohybrid and its effect on the optical, thermal, and conductivity of PVA/CMC composite as an application in electrochemical devices. J. Inorg. Organomet. Polym. Mater. 32, 1935–1949. https://doi.org/10.1007/s10904-022-02322-z (2022).

Alghamdi, H. M. et al. Modification and development of high bioactivities and environmentally safe polymer nanocomposites doped by Ni/ZnO nanohybrid for food packaging applications. J. Mater. Res. Technol. 19, 3421–3432. https://doi.org/10.1016/J.JMRT.2022.06.077 (2022).

Alzahrani, H. S., Al-Sulami, A. I., Alsulami, Q. A. & Rajeh, A. A systematic study of structural, conductivity, linear, and nonlinear optical properties of PEO/PVA-MWCNTs/ZnO nanocomposites films for optoelectronic applications. Opt. Mater. 133, 112900. https://doi.org/10.1016/J.OPTMAT.2022.112900 (2022).

Elashmawi, I. S., Abdelrazek, E. M., Hezma, A. M. & Rajeh, A. Modification and development of electrical and magnetic properties of PVA/PEO incorporated with MnCl2. Phys. B Condens. Matter. 434, 57–63. https://doi.org/10.1016/J.PHYSB.2013.10.038 (2014).

Alqarni, L. S., Alghamdi, A. M., Elamin, N. Y. & Rajeh, A. Enhancing the optical, electrical, dielectric properties and antimicrobial activity of chitosan/gelatin incorporated with Co-doped ZnO nanoparticles: Nanocomposites for use in energy storage and food packaging. J. Mol. Struct. 1297, 137011. https://doi.org/10.1016/J.MOLSTRUC.2023.137011 (2024).

Ota, J. & Srivastava, S. K. Polypyrrole coating of tartaric acid-assisted synthesized Bi2S3 nanorods. J. Phys. Chem. C https://doi.org/10.1021/JP072906Y (2007).

Solarajan, A. K., Murugadoss, V. & Angaiah, S. Dimensional stability and electrochemical behaviour of ZrO2 incorporated electrospun PVdF-HFP based nanocomposite polymer membrane electrolyte for Li-ion capacitors. Sci. Rep. 7, 45390. https://doi.org/10.1038/srep45390 (2017).

Tominaga, Y., Asai, S., Sumita, M., Panero, S. & Scrosati, B. A novel composite polymer electrolyte: Effect of mesoporous SiO2 on ionic conduction in poly(ethylene oxide)–LiCF3SO3 complex. J. Power Sources. 146, 402–406. https://doi.org/10.1016/J.JPOWSOUR.2005.03.035 (2005).

Hu, Q. et al. Engineering nanoparticle-coated bacteria as oral DNA vaccines for cancer immunotherapy. Nano Lett. 15, 2732–2739. https://doi.org/10.1021/acs.nanolett.5b00570 (2015).

Mohamed Ali, T., Padmanathan, N. & Selladurai, S. Effect of nanofiller CeO2 on structural, conductivity, and dielectric behaviors of plasticized blend nanocomposite polymer electrolyte. Ionics (Kiel) 21, 829–840. https://doi.org/10.1007/s11581-014-1240-y (2015).

Deka, M. & Kumar, A. Electrical and electrochemical studies of poly(vinylidene fluoride)–clay nanocomposite gel polymer electrolytes for Li-ion batteries. J. Power Sources 196, 1358–1364. https://doi.org/10.1016/J.JPOWSOUR.2010.09.035 (2011).

Alsulami, Q. A. & Rajeh, A. Synthesis of the SWCNTs/TiO2 nanostructure and its effect study on the thermal, optical, and conductivity properties of the CMC/PEO blend. Results Phys. 28, 104675. https://doi.org/10.1016/J.RINP.2021.104675 (2021).

Jeedi, V. R. et al. Alumina Nanofiller functionality on electrical and ion transport properties of PEO-PVdF/KNO3/SN nanocomposite polymer electrolytes. Results Chem. 5, 100814. https://doi.org/10.1016/J.RECHEM.2023.100814 (2023).

Chen, Y.-C., Chen, Y.-J., Dong, P.-H. & Hsu, Y.-K. Benchmarked photoelectrochemical water splitting by nickel-doped n-type cuprous oxide. ACS Appl. Energy Mater. 3, 1373–1380. https://doi.org/10.1021/acsaem.9b01781 (2020).

Ramesh, S. et al. Sheet-like morphology CuCo2O4 bimetallic nanoparticles adorned on graphene oxide composites for symmetrical energy storage applications. J. Alloys Compd. 892, 162182. https://doi.org/10.1016/J.JALLCOM.2021.162182 (2022).

Jeghan, S. M. N., Do, J. Y. & Kang, M. Fabrication of flower-like copper cobaltite/graphitic-carbon nitride (CuCo2O4/g-C3N4) composite with superior photocatalytic activity. J. Ind. Eng. Chem. 57, 405–415. https://doi.org/10.1016/J.JIEC.2017.08.049 (2018).

He, Z. et al. Polyacrylamide gel synthesis and photocatalytic performance of CuCo2O4 nanoparticles. Mater. Lett. 288, 129375. https://doi.org/10.1016/J.MATLET.2021.129375 (2021).

Kumar, D. et al. Comparative investigation on chemical and green synthesized titanium dioxide nanoparticles against chromium(VI) stress eliciting differential physiological, biochemical, and cellular attributes in Helianthus annuus L. Sci. Total Environ. 930, 172413. https://doi.org/10.1016/J.SCITOTENV.2024.172413 (2024).

Alsulami, Q. A. Structural, dielectric, and magnetic studies based on MWCNTs/NiFe2O4/ZnO nanoparticles dispersed in polymer PVA/PEO for electromagnetic applications. J. Mater. Sci. Mater. Electron. 32, 2906–2924. https://doi.org/10.1007/s10854-020-05043-6 (2021).

Alghamdi, H. M. et al. Effect of the Fe2O3/TiO2 nanoparticles on the structural, mechanical, electrical properties and antibacterial activity of the biodegradable chitosan/polyvinyl alcohol blend for food packaging. J. Polym. Environ. 30, 3865–3874. https://doi.org/10.1007/s10924-022-02478-2 (2022).

Abutalib, M. M. & Rajeh, A. Influence of MWCNTs/Li-doped TiO2 nanoparticles on the structural, thermal, electrical and mechanical properties of poly (ethylene oxide)/poly (methylmethacrylate) composite. J. Organomet. Chem. 918, 121309. https://doi.org/10.1016/J.JORGANCHEM.2020.121309 (2020).

Kumar, D., Dhankher, O. P., Tripathi, R. D. & Seth, C. S. Titanium dioxide nanoparticles potentially regulate the mechanism(s) for photosynthetic attributes, genotoxicity, antioxidants defense machinery, and phytochelatins synthesis in relation to hexavalent chromium toxicity in Helianthus annuus L. J. Hazard. Mater. 454, 131418. https://doi.org/10.1016/J.JHAZMAT.2023.131418 (2023).

Alsalmah, H. A., Rajeh, A., Farea, M. O. & Nur, O. Synthesis and characterization of PEG/CS-AgNO3 polymer nanocomposites for flexible optoelectronic and energy storage applications. Polym. Compos. 45, 5164–5175. https://doi.org/10.1002/pc.28118 (2024).

Ye, L. Y., Liu, Q. L., Zhang, Q. G., Zhu, A. M. & Zhou, G. B. Pervaporation characteristics and structure of poly(vinyl alcohol)/poly(ethylene glycol)/tetraethoxysilane hybrid membranes. J. Appl. Polym. Sci. 105, 3640–3648. https://doi.org/10.1002/app.26446 (2007).

Mohammed, N. J., Rasheed, Z. S., Hassan, A. S. & Hassan, A. S. Improvement optical properties of PVA/TiO2 and PVA/ZnO nanocomposites. Al-Mustansiriyah J. Sci. 29, 118–123. https://doi.org/10.23851/mjs.v29i3.629 (2019).

Alsalmah, H. A., Alruqi, A. B., Nur, O. & Rajeh, A. Developing polymer nanocomposite films of ZnO/NiFe2O4 nanohybrids, polyvinyl pyrrolidone, and chitosan for flexible electromagnetic applications and energy storage devices. Ceram. Int. 50, 28794–28804. https://doi.org/10.1016/J.CERAMINT.2024.05.190 (2024).

Alharbi, E. M. & Rajeh, A. Processing polymer film nanocomposites of poly(vinylidene fluoride)/poly(ethylene oxide) and cobalt oxide nanoparticles for flexible energy storage systems. Opt. Quantum Electron. 56, 1167. https://doi.org/10.1007/s11082-024-07134-8 (2024).

Charan, C. P., Sengwa, R. J. & Saraswat, M. Synergistic effect of polymer blend compositions on the structural, thermal, optical, and broadband dielectric properties of P(VDF-HFP)/PEO/ZnO polymer nanocomposites. Chem. Phys. Impact. 8, 100410. https://doi.org/10.1016/J.CHPHI.2023.100410 (2024).

Almehmadi, S. J. et al. Improving the optical, photoluminescence, and electrical properties of PEO/NaAlg-WO3 nanocomposites for optoelectronic and nanodielectric applications. J. Mater. Res. Technol. 26, 2310–2318. https://doi.org/10.1016/J.JMRT.2023.08.044 (2023).

Alharbi, E. M. & Rajeh, A. Tailoring the structural, optical, dielectric, and electrical properties of PEO/PVA blend using graphene nanoplates for energy storage devices. J. Mater. Sci. Mater. Electron. 33, 22196–22207. https://doi.org/10.1007/s10854-022-08999-9 (2022).

Alhussain, H., Alghamdi, A. M., Elamin, N. Y. & Rajeh, A. Recent progress in enhanced optical, mechanical, thermal properties, and antibacterial activity of the Chitosan/Polyvinylalcohol/Co3O4 nanocomposites for optoelectronics and biological applications. J. Polym. Environ. https://doi.org/10.1007/s10924-024-03191-y (2024).

Dhayal, V. et al. Optical and electrical properties of biocompatible and novel (CS–GO) polymer nanocomposites. Opt. Quantum Electron. 53, 53. https://doi.org/10.1007/s11082-020-02723-9 (2021).

Kacem, E. et al. Structural, optical, and thermal studies of Poly(vinylidene fluoride-co-hexafluoropropylene) and Polyvinylpyrrolidone composite doped Ag/ZnO mixed nanoparticles for flexible optoelectronic devices. Opt. Mater. 146, 114560. https://doi.org/10.1016/J.OPTMAT.2023.114560 (2023).

Choudhary, R. et al. Comprehensive journey from past to present to future about seed priming with hydrogen peroxide and hydrogen sulfide concerning drought, temperature, UV and ozone stresses—a review. Plant Soil https://doi.org/10.1007/s11104-024-06499-9 (2024).

Soliman, T. S. & Abouhaswa, A. S. Synthesis and structural of Cd0.5Zn0.5F2O4 nanoparticles and its influence on the structure and optical properties of polyvinyl alcohol films. J. Mater. Sci. Mater. Electron. 31, 9666–9674. https://doi.org/10.1007/s10854-020-03512-6 (2020).

Alghamdi, H. M. & Rajeh, A. Comparative analysis of the structural, optical, mechanical, and electrical properties of PMMA/PU blend-based nanocomposites with FeVO4 nanofiller for energy storage devices. Polym. Adv. Technol. 34, 3711–3721. https://doi.org/10.1002/pat.6173 (2023).

Al-Sagheer, L. A. M. & Rajeh, A. Synthesis, characterization, electrical, and magnetic properties of polyvinyl alcohol/carboxymethyl cellulose blend doped with nickel ferrites nanoparticles for magneto-electronic devices. Polym. Compos. 44, 7156–7169. https://doi.org/10.1002/pc.27624 (2023).

Muthusamy, A. et al. Preparation, electrical and magnetic properties of poly(m-phenylenediamine)/ZnFe2O4 nanocomposites. J. Supercond. Nov. Magn. 31, 497–504. https://doi.org/10.1007/s10948-017-4220-4 (2018).

Al-Sulami, A. I. et al. Nanocomposites comprising PVA/CMC matrix and CNTs/Fe2O3 nanohybrid: A comparative investigation of structural, optical, electrical, and dielectric properties as an application in advanced electrochemical and optoelectronic devices. Mater. Chem. Phys. 315, 128971. https://doi.org/10.1016/J.MATCHEMPHYS.2024.128971 (2024).

AlSulami, F. M. H. et al. Structural, optical, dielectric and electrical properties of flexible nanocomposite based on NaAlg/PEO composite and AgNO3 NPs for energy storage applications and optoelectronic devices. Opt. Mater. 152, 115515. https://doi.org/10.1016/J.OPTMAT.2024.115515 (2024).

Al-Muntaser, A. A. et al. Fabrication and characterizations of nanocomposite flexible films of ZnO and polyvinyl chloride/poly(N-vinyl carbazole) polymers for dielectric capacitors. Arab. J. Chem. 16, 105171. https://doi.org/10.1016/J.ARABJC.2023.105171 (2023).

Bhajantri, R. F., Ravindrachary, V., Harisha, A., Ranganathaiah, C. & Kumaraswamy, G. N. Effect of barium chloride doping on PVA microstructure: Positron annihilation study. Appl. Phys. A. 87, 797–805. https://doi.org/10.1007/s00339-007-3923-y (2007).

Jebli, M. et al. Structural and morphological studies, and temperature/frequency dependence of electrical conductivity of Ba 0.97 La 0.02 Ti 1–x Nb 4x/5O3 perovskite ceramics. RSC Adv. 11, 23664–23678. https://doi.org/10.1039/D1RA01763B (2021).

Al-Muntaser, A. A. et al. Boosting the optical, structural, electrical, and dielectric properties of polystyrene using a hybrid GNP/Cu nanofiller: Novel nanocomposites for energy storage applications. J. Mater. Sci. Mater. Electron. 34, 678. https://doi.org/10.1007/s10854-023-10104-7 (2023).

Morsi, M. A., Rajeh, A. & Al-Muntaser, A. A. Reinforcement of the optical, thermal and electrical properties of PEO based on MWCNTs/Au hybrid fillers: Nanodielectric materials for organoelectronic devices. Compos. Part B Eng. 173, 106957. https://doi.org/10.1016/J.COMPOSITESB.2019.106957 (2019).

Farea, M. O. et al. Gamma irradiation boosted the optical and electrical properties of PVP/NaAlg/Au ternary nanocomposite films for flexible optoelectronic devices. Polym. Bull. 80, 9195–9215. https://doi.org/10.1007/s00289-022-04498-3 (2023).

Alsalmah, H. A. et al. Hybrid GO/TiO2 nanoparticles reinforced NaAlg/PVA blend: Nanocomposites for high-performance energy storage devices. Polym. Adv. Technol. 34, 2831–2840. https://doi.org/10.1002/pat.6105 (2023).

Sengwa, R. J., Choudhary, S. & Dhatarwal, P. Nonlinear optical and dielectric properties of TiO2 nanoparticles incorporated PEO/PVP blend matrix based multifunctional polymer nanocomposites. J. Mater. Sci. Mater. Electron. 30, 12275–12294. https://doi.org/10.1007/s10854-019-01587-4 (2019).

Morsi, M. A., Abdelaziz, M., Oraby, A. H. & Mokhles, I. Effect of lithium titanate nanoparticles on the structural, optical, thermal and electrical properties of polyethylene oxide/carboxymethyl cellulose blend. J. Mater. Sci. Mater. Electron. 29, 15912–15925. https://doi.org/10.1007/s10854-018-9677-9 (2018).

Alsalmah, H. A., Rajeh, A. & Nur, O. Optical, conductivity, dielectric, and magnetic properties of polymer nanocomposite based on PAM/cs matrix and ZnFe2O4 NPs for use in magneto-electronic and energy storage capacitor devices. Ceram. Int. 50, 12167–12174. https://doi.org/10.1016/J.CERAMINT.2024.01.120 (2024).

Abdelhamied, M. M. et al. Synthesis of flexible polymer nanocomposites based on methyl cellulose/copper oxide with desired dielectric properties for electrical applications. Inorg. Chem. Commun. 157, 111245. https://doi.org/10.1016/J.INOCHE.2023.111245 (2023).

Alotaibi, B. M., Atta, A., Atta, M. R., Abdeltwab, E. & Abdel-Hamid, M. M. Preparation, structural characteristics and dielectric studies of polyaniline/lead sulfide composite materials. Indian J. Phys. https://doi.org/10.1007/s12648-023-02794-w (2023).

Anandha Jothi, M., Vanitha, D., Nallamuthu, N., Manikandan, A. & Asath Bahadur, S. Investigations of lithium ion conducting polymer blend electrolytes using biodegradable cornstarch and PVP. Phys. B Condens. Matter. 580, 411940. https://doi.org/10.1016/J.PHYSB.2019.411940 (2020).

Siva, V., Vanitha, D., Murugan, A., Shameem, A. & Bahadur, S. A. Studies on structural and dielectric behaviour of PVA/PVP/SnO nanocomposites. Compos. Commun. 23, 100597. https://doi.org/10.1016/J.COCO.2020.100597 (2021).

Shenbagavalli, S., Muthuvinayagam, M., Jayanthi, S. & Revathy, M. S. Investigations on Al2O3 dispersed PEO/PVP based Na+ ion conducting blend polymer electrolytes. J. Mater. Sci. Mater. Electron. 32, 9998–10007. https://doi.org/10.1007/s10854-021-05658-3 (2021).

Acknowledgements

This work was funded by the University of Jeddah, Jeddah, Saudi Arabia, under grant No. (UJ-23-DR-166). Therefore, the authors thank the University of Jeddah for its technical and financial support.

Author information

Authors and Affiliations

Contributions

H.M.A.: supervision, conceptualization, methodology, writing—original draft, writing—review and editing. Formal analysis. A.R.: visualization, investigation, data curation, writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Alghamdi, H.M., Rajeh, A. Synthesis and improved optical, electrical, and dielectric properties of PEO/PVA/CuCo2O4 nanocomposites. Sci Rep 14, 18925 (2024). https://doi.org/10.1038/s41598-024-69982-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-69982-4

Keywords

This article is cited by

-

Folic Acid-Coated Zinc Ferrite-Incorporated PVA Nanocomposite Films for Flexible Optoelectronics

Journal of Electronic Materials (2026)

-

Green tea dye ligands to transfer toxic lead metal ions to precipitated metal complexes for polymer composite applications

Scientific Reports (2025)

-

Tunable band gap and ionic conductivity in PMMA and PANI blend with WO₃ nanocomposites for optoelectronics and energy storage devices

Scientific Reports (2025)

-

Optical and electrical properties of SeO2 and NiO nanoparticles boosted the polymeric blend of PVDF and PVP for optoelectronic applications

Scientific Reports (2025)

-

PVA/Bi2WO6 Nanocomposites: Evaluation of Bi2WO6 Filler Composition on Thermal, Optical, Electrical and Photoluminescence Characteristics

Journal of Inorganic and Organometallic Polymers and Materials (2025)