Abstract

Thick-coal-seam with complex structures and thick-hard roof in the initial mining phase pose various challenges, including a long weighting interval, strong rock pressure, poor top coal caving performance (TCCP), and significant coal loss. These problems directly affect the safety and efficiency of the mining operations. This study employs the principles of elastic thin plates and ellipsoidal bodies to unravel the formation mechanism of strong rock pressure in thick-hard roof and the influence of parting on the TCCP. In addition, a hydraulic fracturing technique is proposed for safe-efficient recovery during the initial mining phase. The reliability of this technique is verified through numerical simulations and field experiments. The research findings reveal the following. (1) The primary causes of strong rock pressure in the mining face are attributed to a long weighting interval and wide collapse range of the main roof, and the weighting interval is primarily influenced by the thickness and tensile strength of the main roof. (2)The key factor affecting the TCCP is the cantilever beam structure formed by the fracture of the thick-hard parting, as it intersects the ellipsoidal body during coal caving. The simultaneous fracturing of both the top coal and roof can reduce the weighting interval on the working face. This process effectively decreased the strength of the thick-hard parting within the top coal, while simultaneously enhancing its load strength and eliminating the cantilever structure resulting from the parting fracture. It not only reduces the first weighting intensity but also promotes the early and proper coal release, thereby enhancing the TCCP and ensuring safe-efficient mining during the initial mining phase. (3) Aiming at the difference in the strengths of the top coal and roof, a graded hydraulic fracturing technique and system were proposed. Fracturing boreholes with a diameter of 60 mm, spacing of 10 m, and height of 20.85 m, which can economically and effectively ensure the fracturing results. Field applications have demonstrated that fractured coal and rocks in fracturing areas exhibit well-developed fractures. During the initial mining phase, the weighting interval in the working face was reduced by 20 m, resulting in a decrease in the overburden pressure and 26.9% reduction in the lumpiness of the top coal. Additionally, the recovery rate increased by 31.19%.

Similar content being viewed by others

Introduction

Coal deposits in China are characterized by complex and varied conditions. In certain mines located in Shanxi, Shaanxi, Inner Mongolia, and Xinjiang, the roof strata are particularly hard and coal seam structures are intricate, leading to strong rock pressure and poor TCCP. Both domestic and international experts have extensively investigated the characteristics of rock pressure caused by hard roof strata, factors influencing TCCP, and measures to facilitate top coal caving1,2,3,4,5.

The instantaneous collapse of thick-hard roof can result in abnormal support pressures, rockburst incidents, and abnormal gas emissions6,7,8. Liu et al.9 analyzed the impact of the immediate roof thickness on the formation of structures following the collapse of hard rock strata and elucidated the support resistance under cantilever beam and masonry beam structures. Yu et al.10 conducted a study on the four fracture modes of thick-hard roof strata under bending and shear stress. Bu et al.11 employed the theory of energy dissipation to analyze whether the abrupt release of accumulated energy constitutes the primary cause that supports impact loads. Xu et al.12 discovered that the fractures in thick-hard rock strata had an apparent depth effect on the underlying coal seams. According to Lu et al.13, the transition of micro-seismic activity from high to low frequency was identified as a precursor to fracture in hard roof strata. Ma et al.14 analyzed the fracture characteristics of roof rock mass from the laboratory point of view. Zhang et al.15 suggested mitigating the risk of an abrupt roof collapse in such strata by implementing a solid filling. Zhang et al.16 and Xie et al.17 put forward different filling materials for controlling roof pressure. Lu et al.18 and Yu et al.19 proposed the early release of advanced support pressure by fracturing hard strata through hydraulic fracturing from the ground surface. Lu et al.20 identified the transformation of hard rock strata from long-distance instantaneous sliding instability to layered short-arm stepped settlement following deep-hole blasting. Tang et al.21 utilized a noiseless blasting agent (CaO) to weaken the hard roof strata through borehole blasting.

Several factors affect the TCCP, including the burial depth22, coal strength23, dip angle24, top coal thickness25, mining height26, stress27, coal caving techniques, and spacing intervals28,29. For coal seams with complex structures, the presence of parting has a detrimental effect on TCCP30. The strength31, thickness32, and position33 of the parting layer directly influence the fragmentation of the top coal, thereby affecting the TCCP. Zhang et al.34 established an arching mechanics model for top coal with parting, and examined the mechanism of arch formation and its influence on TCCP. This study proposes strategies, such as water infusion for coal softening, increasing the working resistance, and implementing multiple cycles of caving to reduce the likelihood of arch formation. Wang et al.35 demonstrated that compressive stress-induced damage results in a noticeable decrease in the tensile strength of coal, leading to progressive failure and collapse from the bottom to the top. Song et al.36 utilized a PFC simulation to investigate the gradual failure process of the top coal during the advancement of the working face and identified a significant influence of the internal friction angle (f) and caving angle (β) on the shape of the top coal caving. Lang et al.37 observed that the top coal strength governed the extent of the limit equilibrium zone, thereby influencing the range of accelerated crack development. Wang et al.38,39 found that the rotation of principal stresses significantly promoted the brittle failure in the roof strata, resulting in enhanced top coal fragmentation and a caving effect. Furthermore, variations in roof pressure directly affect the TCCP40,41.

To improve the top coal recovery rate, experts and scholars have conducted a series of studies on methods to weaken the top coal. Xie et al.42 employed fractal geometry to describe the fracture mechanism of blasting, whereas Sun et al.43 conducted simulations and analyses to investigate the effects of different factors on the blasting–presplitting process. Furthermore, based on their study, they optimized the weakening parameters for blasting. Wang et al.44 and Yasitli et al.45,46 suggested that the top coal in the pre-blasting zone becomes more fragmented, leading to easier caving. Wu et al.47 proposed a top coal cyclic weakening technique to address the poor TCCP in hard coal seams with parting. This technique combines blasting, water infusion, and gas extraction weakening. Xie et al.48 suggested installing vibration devices on supports to effectively disrupt the arching structure formed by top coal caving. Zeng et al.49 demonstrated the positive impact of increasing the swing angle of the tail beam and time of the top coal caving to improve the TCCP. Huang et al.50 proposed a linear multi-pore and deep-hole backward hydraulic fracturing method and developed a high-pressure (60 MPa) hydraulic fracturing system for TCCP in thick—hard , and extremely thick coal seam. Moreover, the synergistic application of hydraulic blasting and fracturing proved to be effective in enhancing the quantity and range of fracture propagation51. Cheng et al.52 introduced a method that combined pre-pulse and constant-pressure fracturing to weaken the coal and rock, resulting in a crack propagation range of up to 40 m. Luo et al.53 suggested that hydraulic fracturing pre-fracture and softening of thick-hard partings in high-level strata can effectively improve the TCCP.

Researchers and experts have extensively studied the pressure characteristics and control strategies for hard roof strata, factors influencing the top coal caving, and techniques for enhancing the TCCP. However, there is a lack of research specifically focusing on the TCCP and promotion measures for complex coal seams with multiple partings beneath thick-hard roof strata. This study combines the characteristics of thick-hard roof strata with complex structural thick-coal-seam to clarify the formation mechanism of strong rock pressure in thick-hard roof strata as well as the influence mechanism of partings on the TCCP. With a focus on safety and efficiency, a coordinated control technology and solution for roof and top coal are proposed, and its reliability is verified by numerical simulation and field test. The synergistic effect of reducing initial weighting and improving top coal caving during initial mining is clarified, and safe and efficient mining of thick coal seam with complex structure during initial mining is realized. The research results can provide theoretical and practical basis for coal seam mining under similar conditions.

Engineering geology

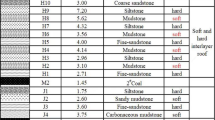

The selected mine is located at the eastern margin of the middle section of the Hedong Coalfield in Shanxi, China. Extraction of five coal seams was authorized, namely, 9#, 10#, 11#, 12#, and 13#. Mining operations have already been completed for the 9# coal seam, and the current focus is on extracting the 10# coal. The interlayer distance between the coal seams is in the range 3.5–16 m. The 10# coal has an average dip angle of 2.5° and average thickness of 10.56 m. It is characterized by the occurrence of five to nine parting layers, constituting 32% of the total thickness of the coal seam. The working face adopts top coal caving mining, and the machine-mining height was 3.9 m. The main roof is comprised of coarse sandstone with an average 9.89 m thickness and 84.4 MPa strength. Influenced by the mining arrangement, the initial mining phase of the 10# coal seam is situated either entirely or partially beneath the protective coal pillar at the 9# coal boundary. The roof of the 10# coal seam exhibits high strength and good integrity, making it less susceptible to immediate collapse after mining. However, when the roof has a large exposed area, instantaneous collapse can pose the risk of strong rock pressure. Additionally, the inability to effectively transfer the load from the roof to the coal seam results in difficult fracture of the thick-hard partings within the top coal and significantly influences the TCCP.

The I011004 fully mechanized working face is positioned beneath the goafs of I010905 and I010902, working face length is 230 m, and covering an initial mining area of 48 × 110 m, which is situated below the protective coal pillars. The coal seam consists of five partings layers of mudstone and carbonaceous mudstone. The arrangements of the working face and strata thickness are shown in Fig. 1. Based on the results of on-site sampling and testing, the 10# coal seam is composed of sandy mudstone and coarse sandstone as its immediate and main roofs, respectively, with average compressive strengths of 38.7 and 75.8 MPa, respectively. The immediate and main floors are comprised of sandstone, exhibiting an average strength of 42.6 MPa. The coal and the partings compressive strengths of 9.84 and 32.5 MPa, respectively, and the tensile strength is 1.43 MPa and 2.1 MPa respectively. Currently, the mine employs hydraulic supports (model ZYF13000/25/42D) with a rated working resistance of 13,000 kN. Based on the experience gained from the adjacent working faces, it is evident that the first weighting interval is approximately 50 m, which leads to a significant stress manifestation.

Mechanism for safe-efficient initial mining of coal seam with complex structure and thick-hard roof

Mechanism of strong rock pressure formation during initial mining in thick- coal-seam working faces with thick-hard roof

(1) First weighting interval in thick-coal-seam working faces with thick-hard roof.

Under normal conditions, as the working face advances, the roof strata gradually collapse and fill the goafs. However, several challenges arise in the thick-coal-seam with hard-roof. First, owing to the large void space left after coal mining, the immediate roof collapse fails to completely fill the goaf. Second, the main roof is relatively rigid and resists timely collapse. When the main roof is exposed over a considerable distance, its sudden collapse, combined with the large void space below, can generate violent air currents, leading to potential casualties and equipment damage. The initial collapse of a hard roof can be simplified as a thin-plate model supported on all four sides. A coordinate system was established with the center of the roof as the origin, as illustrated in Fig. 2.

When the main roof weighting interval is large, owing to the large space below it, a hurricane can easily form at the moment of collapse, which causes casualties and equipment losses.

As shown in Fig. 2, the roof boundary conditions are as follows:

where a and b are half the lengths of the hard roof in the advancing and face directions, respectively, and w is the deflection of the roof stratum. Combined with the thin-plate theory of elastic mechanics, the deflection equation of the roof when the four sides are fixed can be calculated as:

where q is the load of the hard roof and its bearing layer and D is the bending stiffness of the hard roof.

where E, h, and μ are the elastic modulus, thickness, and Poisson's ratio of the hard roof, respectively.

The stress σx of the hard roof along the face advancing direction is expressed as:

As the working face advances, cracks appear in the center of the long side of the upper surface of the hard roof, which then collapses. At this time, the maximum tensile stress σxmax of the roof appears at z = h/2, y = 0, x = ± a (a = l/2, l is first weighting interval) and satisfy σxmax = σt (σt is the hard roof tensile strength), then we can get:

The first weighting interval is primarily influenced by factors, such as the length of the working face, the main roof thickness, bearing load and tensile strength, as indicated by Eq. (5). To visually analyze the impact of different factors on the first weighting interval, the relationships between these influencing factors and first weighting interval were calculated, as depicted in Fig. 3.

As shown in Fig. 3, the first weighting interval is positively correlated with the thickness and tensile strength of the main roof, whereas it is negatively correlated with the bearing load of the main roof and the working face length. Among these factors, the variation in the thickness of the main roof has the greatest impact on the first weighting interval, followed by the tensile strength of the main roof, while the length of the working face has the least influence on the first weighting interval. Considering the geological conditions of the working face, by substituting σt = 4.5 MPa, h = 9.89 m, b = 115 m, and q = 0.28 MPa into Eq. (5), we obtained a = 24.8 m, indicating that the first weighting interval l is 49.6 m. After a normal advancement of 50 m in the I011004 working face, a large block of the massive main roof collapsed downward, posing a significant safety hazard to production. By compromising the integrity of the main roof, inducing its layered collapse, and reducing its tensile strength, the first weighting interval can be effectively reduced, and the risk of strong rock pressure on the working face can be mitigated.

(1) First weighting intensity in thick-coal-seam working face with thick-hard roof.

During the first roof weighting, the primary load-bearing components of the support system included the top coal, partings, false roof, immediate roof, and load transmitted to the support system when the main roof fractured. The mechanical models of the support system and surrounding rock are illustrated in Fig. 4, where M1 is the machine mining height, M2 is the thickness of the top coal and the partings, Σhi΄ is the total thickness of the false roof and immediate roof, Σhi΄΄ is the total thickness of the main roof and its load-bearing layers, Q is the load carried by the fractured blocks of the main roof and its load-bearing layers, and lc is the distance for support control over the roof.

The main roof load Pc acting on the support is:

Support load P is:

where γm、hm and γg、hg are the bulk density and the thickness of the top coal and the parting, respectively. According to the field production geological conditions and strata thickness, γm = 14.5 kN/m3, γm = 24 kN/m3, hm = 3.7 m, hg = 0.9 m, Σhi΄γ = 165.36 kPa, Σhi΄΄γi΄΄ = 403.32 kPa, lc = 5.98 m, l = 49.6 m, from which we obtained Pc = 836.315 kPa, P = 1076.925 kPa through substitution calculation.

Support working resistance F is::

where Sc is the support center distance, 1.75 m, and k is the support efficiency, which is typically set to 0.85. After the calculations, the hydraulic support resistance of I011004 working face during the first weighting was determined to be 13,258.85 kN, which exceeds the rated working resistance of hydraulic support,, indicating a safety risk. Therefore, appropriate measures need to be implemented to reduce the rock pressure.

Influence mechanism of parting on TCCP

Thick and extremely thick coal seams often contain parts of varying thicknesses. It is generally believed that when the strength of the parting is lower than that of the coal, it collapses simultaneously with the lower coal body as an intermediate weak layer and does not significantly affect the TCCP. However, when the strength of the parting exceeds that of the coal and reaches a certain thickness, it directly affects the TCCP. The greater the strength and thickness of the parting, the more significant is the impact on the TCCP. Based on "Engineering geology", it is evident that the parting strength in the mine exceeds that of the 10# coal, and the maximum thickness of the parting exceeds 0.5 m. Therefore, it may have a certain impact on the TCCP. The different thicknesses of the parts within the top coal layer are shown in Fig. 5 (a). When the parting thickness is relatively small, the top coal below the parting loses contact owing to delamination or caving, and the overlying coal undergoes advanced deformation and becomes a load-bearing layer on the thin parting. This causes the top coal to fracture into slabs, blocks, and caves simultaneously with the overlying top coal. Conversely, when the parting is thicker, it provides support to the overlying top coal and cannot break in a timely manner during mining, resulting in the formation of a cantilever beam structure, which affects TCCP above the parting.

As shown in Fig. 5b, the force of the thick parting layer can be simplified as a cantilever beam model. According to the material mechanics, the maximum bending moment Mmax of the cantilever beam in the parting layer is

where L is the cantilever length of the parting that affects the top coal caving, m; qm is the load of top coal acting on parting, MPa; and qg is the parting weight, MPa.

The maximum tensile stress of the cantilever beam is

where hg΄ is the parting thickness, m.

Therefore, σmax = Rt, the cantilever beam structure is broken, and the following can be obtained:

where hm΄ is the thickness of the top coal above the parting (m) and Rt is the tensile strength of the parting (MPa).

After solving the above equation, the critical parting thickness of the parting that affects the top coal caving hg ΄΄can be calculated as:

When the parting thickness exceeds hg΄΄, it will affect the TCCP.

Mechanism of top coal safety and high-recovery during initial mining

During the initial mining phase, ensuring the safety and high-recovery of the top coal is reflected in two aspects: (1) weakening the roof strata to reduce the first weighting interval and intensity, thereby guaranteeing safety mining; and (2) increasing the normal caving distance while enhancing the TCCP of the thick-coal-seam with complex structures, thereby improving the top coal recovery rate during the initial mining phase.

(1)Increasing the normal caving distance.

Based on the production experience at the mine site, it was observed that before the first weighting, the roof strata remained intact, whereas the TCCP was poor because it contained multiple layers of partings. Only a portion of the top coal near the immediate vicinity of the support can cave under the influence of the support. After the roof first weighs, the top coal can cave normally because of the influence of rock pressure. Therefore, the implementation of appropriate measures to weaken the roof strata and reduce the first weighting interval has two purposes. First, it reduces the weighting intensity and hanging distance, thereby enhancing safety. Secondly, it increases the normal caving distance and improves the top coal recovery rate during the initial mining phase, as shown in Fig. 6.

(2) Improving TCCP of thick-coal-seam with complex structure.

According to the ellipsoid theory, under normal conditions, the caving of the top coal after mining forms an ellipsoidal shape. However, when the cantilever beam length formed by the thick parting is significant, particularly when it exceeds the ellipsoidal, it hinders the caving of the overlying top coal, as shown in Fig. 7a. When the long cantilever beam structure is disrupted or eliminated, its impact on the TCCP is reduced, as shown in Fig. 7b. Therefore, improving the TCCP in complex coal seams reduces the cantilever beam length. When the thickness of the parting is fixed, there are two methods to reduce the cantilever beam length: (1) reducing the strength of the parting itself, and (2) increasing the bearing load of the parting.

Owing to the significant variations in the coal seam thickness and parting positioning, it is challenging to accurately locate the thick parting layers. Additionally, the roof strata on the working face are relatively hard, resulting in a larger first weighting interval and increased risk. Therefore, measures must be taken to reduce the weighting intervals. Considering these factors, a comprehensive approach can be employed during the initial mining phase, involving both pre-fracturing of the top coal and roof strata, and simultaneous weakening. This approach serves two purposes. First, it shortens the weighting interval of the working face and applies a load from the pre-fractured roof strata onto the parting. Second, it decreases the strength of the parting, thus reducing the cantilever beam length formed by the fracture of the parting. These measures are aimed at achieving safe and high-recovery production during the initial mining phase. Given the high technical requirements and difficulty of achieving ideal effects at the coal-rock and coal-parting interfaces of blasting pre-splitting, a comprehensive consideration suggests adopting hydraulic fracturing techniques to weaken both the roof strata and parting.

Determination of fracturing horizon

Based on the analysis in “Mechanism of top coal safety and high-recovery during initial mining”, it can be determined that the height of the borehole, that is, the fracture zone height, needs to satisfy two conditions: (1) effectively reduce the length of the cantilever beam formed by thick parting by inducing collapse in the fractured zone, and (2) fracture at least to the main roof level to reduce the first weighting interval. The height of the fracture zone required to satisfy the parting breaking level is calculated as:

where Lg is the length of the thick parting, which has no influence on the TCCP, m; ΣHm is the thickness of the top coal above the parting, which has an impact on the TCCP, m; ΣHg is the thickness of partings above the parting layer, which has an influence on the TCCP, m; and γi、Hi are the bulk density (MN/m3) and thickness (m) of the i-stratum above the coal seam, respectively. (Fig. 8a).

The critical cantilever beam length (L) of the parting across the ellipsoid can be obtained via a coordinate transformation according to the following equation for the coal-caving ellipsoid (Fig. 8b) 54:

where H΄ is the distance between the parting and floor, m; a΄, b΄ are the half of the major axis and minor axis of the coal-caving ellipsoid; and θ is the axis deviation angle of ellipsoid.

The average tensile strength of the partings on this working face is 2.1 MPa. Based on the calculations, the layer of parting that affects the TCCP is 0.55 m thick and located 1.55 m below the roof. L was determined to be 1.5 m. The working face coal caving interval is 0.8 m, therefore Lg should be less than 0.8 m. Consequently, the fracture height for breaking this parting was calculated to be 13.67 m. Considering the thickness of the immediate roof and main roof, the fracturing horizon was determined to be 16.25 m away from the coal. Considering a coal thickness of 4.6 m, the actual height of the fracture borehole was approximately 20.85 m, as shown in Fig. 8c.

Technical schemes for safe and high-recovery during initial mining

Optimization of hydraulic fracturing parameters

The key parameters affecting the effectiveness of hydraulic fracturing are the borehole diameter and spacing. Owing to the limitations in the physical experiments, this section employs the particle flow code (PFC) fluid–solid coupling to simulate and analyze the optimal borehole diameter and spacing. Harder rock formations are less prone to fracturing. Therefore, even though the rock layers requiring fracturing may vary in lithology, it is only necessary to explore the optimal parameters of the rock strata with the highest strength. Considering the working face depth and lateral stress coefficient, vertical and horizontal stresses of 2.4 and 3.6 MPa, respectively, were chosen. The mechanical parameters of the primary roof (coarse sandstone) were used to set the model particle parameters, the particle parameters in the model were calibrated based on the laboratory test results. Based on the empirical data, the initiation pressure for the boreholes was determined to be 20 MPa.

Optimal borehole diameter

A 10 m × 10 m model was used to simulate the propagation patterns of the hydraulic fractures under five different borehole diameters in the range 40–80 mm. Figure 9 illustrates the development of hydraulic fractures for the various borehole diameters. The main fractures generally propagate horizontally, and the final length of the fracture increases with the larger borehole diameters. The fracture count and propagation length were statistically analyzed, as shown in Fig. 10. As shown in Fig. 10a, with an increase in the borehole diameter, the initial water filling volume and contact area of the borehole walls increased. This led to a longer time being required for the single fracture initiation point to reach the failure conditions, resulting in a decrease in the incremental growth of the fracture count during the initial simulation stage. Simultaneously, the increased borehole surface area led to an increase in the number of final fractures and the equilibrium time. Figure 10b shows that the fracture length increases with the borehole diameter; however, the growth rate of the fracture length diminishes beyond 60 mm. Considering both the economic and time costs, a borehole diameter of 60 mm was selected.

Optimal borehole spacing

A hydraulic fracture propagation study was conducted using a 20 m × 10 m model, considering three borehole spacing conditions: 7.5, 10, and 12.5 m. The simulation aimed to monitor the development and connectivity of fractures and determine their quantities under varying borehole spacing. In the simulation process, we counted the operation steps of radial fractures and radial fractures penetration in three kinds of borehole spacing, which were defined as three stages of crack propagation process: crack initiation, development and interconnection. The results are shown in Fig. 11. During the initiation stage, a significant number of microcracks are generated near the borehole, leading to a rapid increase in the total fracture count within a short time. In the development stage, the main fractures begin to extend, and the number of fractures steadily increases. During the connectivity stage, the interconnected nature of the fractures results in an abrupt secondary increase in the number of fractures. A decrease in the borehole spacing leads to a higher final fracture count. Specifically, at a borehole spacing of 7.5 m, two primary fractures exhibit "ring-shaped" connectivity within the spacing range. With a spacing of 10 m, the fractures propagate horizontally, while at 12.5 m spacing, the fractures are distributed in a three-pronged pattern around the borehole, developing diagonally without intermediate connectivity. Considering these findings, an optimal borehole spacing of 10 m was determined based on a comprehensive assessment of factors, such as economic and time costs.

Scheme and technology of graded hydraulic fracturing

Layout scheme of hydraulic fracturing drilling

Based on the previous calculations and simulation analyses of the hydraulic fracturing borehole parameters, the boreholes were arranged in the working face with a borehole diameter of 60 mm and spacing of 10 m. To ensure effective fracturing, the boreholes in the open-off cut of the working face were categorized as: L-holes (long holes) and S-holes (short holes). These holes are arranged alternately, with the L-holes used to fracture the roof strata by generating hydraulic fractures at the coal-rock interface to reduce the strength and block size of the coal-rock mass. S-holes are used to penetrate the roof so that the pressure in the broken roof can be transmitted to the working face and top coal caving can be promoted. The fracturing procedure initially involved fracturing the L-holes and subsequently performing the secondary fracturing of the S-holes. Additionally, to enhance the number of hydraulic fractures near the T-junction and open-off cut, facilitating the collapse of the roof, S-holes and A-holes (auxiliary holes) were implemented in the two roadways. The drilling arrangement is shown in Fig. 12. A specific analysis of the drilling layout is as follows.

-

(1)

Fracturing boreholes L: Six boreholes are arranged on the open-off cut recovery side with a spacing of 10 m. The borehole depth was 40 m, with a vertical inclination angle of 30° and vertical height of 20 m.

-

(2)

Fracturing boreholes S: Six boreholes are arranged on the open-off cut recovery side with a spacing of 10 m. The borehole depth is 35 m, with a vertical inclination angle of 40° and vertical height of 22.5 m. Additionally, three boreholes are positioned in the haulage roadway with a borehole depth of 35 m and spacing of 10 m. These three boreholes have a vertical inclination angle of 40°, and the two boreholes adjacent to the open-off cut recovery side have an additional 20° horizontal inclination angle.

-

(3)

Fracturing boreholes A: Two boreholes are placed in the haulage roadway following the fracturing boreholes S. These boreholes have a depth of 40 m and spacing of 5 m. The vertical inclination angle is 30°, and the horizontal inclination angles are 30° and 80°.

Design of graded fracturing technology and system

The hydraulic fracturing water injection system consists of high-pressure water injection equipment in the roadway and fracturing boreholes within the coal-rock strata. The key processes included the hole sealing, water injection fracturing, and pressure maintenance expansion. Considering the difference in the strength between the top coal and roof and aiming to optimize the water resource utilization in the mine, a graded-fracturing approach is implemented. Specifically, goaf water resources are used to fracture the top coal, whereas an activated fluid was employed to fracture the roof, as illustrated in Fig. 13. The system consists of three components: water supply, storage, pressurization, and fracturing. When the target of fracturing is the top coal, the system uses pressurized pumps to inject pretreated goaf water for fracturing. When fracturing the roof, a mixture of goaf water and additives is thoroughly blended to form an activation fracturing fluid. The fluid is then pressurized using a high-pressure pump for fracturing. This system achieves two objectives: first, it recycles the pre-existing water resources of the mine, thereby reducing the water pollution at the working face; second, it optimizes the fracturing effectiveness by adjusting the composition of the activation fracturing fluid based on the different fracturing conditions of the roof. This hierarchical approach achieves cost-effective fracturing results through a graded supply of water and implementation of fracturing operations. When the caving property of top coal is poor and there is no thick-hard roof, only top coal is fractured; when the top coal is easy to caving, but there is a thick-hard roof, only the roof is fractured; when the top coal is not easy to caving and there is a thick-hard roof, the graded hydraulic fracturing technology of top coal and roof is adopted.

Characteristics of roof collapsing and top coal caving before and after fracturing

Model establishment

The computational model shown in Fig. 14a was established using the PFC2D. The model dimensions were set to 80 m × 35 m, with the bottom edge being a fixed support boundary, sides being simple support boundary, and top edge being a free surface. The initial particle velocities inside the model were set to 0, and the acceleration due to gravity, g, was taken as 9.8 m/s2. Coal and rock layers corresponding to the field geological conditions were generated in the model, with smooth joints added between the different layers. A servo program was used to simulate the lateral stress acting on both sides of the model, and the overlying strata load was represented by an equivalent load layer. The particle parameters in the model were calibrated based on the laboratory test results, and their specific values are listed in Table 1. Because of the presence of the numerous near-horizontal joint planes in the roof coal and strata, hydraulic fractures are prone to propagating along these weak planes during the fracturing process. To simulate the subsequent roof collapse and top-coal caving after fracturing, the PFN command of the PFC software was used to add equivalent fractures to the fracturing area. The orientation distribution of these fractures follows a Gaussian distribution, with angles uniformly distributed from 0° to 35°and their sizes uniformly distributed from 2 to 3 m. The final distribution of added fractures is shown in Fig. 14b.

Characteristics of roof and top coal migration

The roof strata collapsed during mining before and after hydraulic fracturing, as shown in Fig. 15. It can be observed that prior to fracturing, when the working face advanced 30 m, the main roof remained relatively intact, whereas the large blocks of the top coal started to fall. Only when the working face reached approximately 50 m did the main roof break for the first time, starting from the top coal to normal caving. After fracturing, near-horizontal fractures are generated, and the vertical fractures induced by mining continue to expand and connect, gradually forming a three-dimensional network of fractures. This network cuts the roof strata from a beam-like structure to an irregular multilayer composite structure. When the working face advances 30 m, roof collapse occurs on the main roof. The state of the TCCP improved significantly compared with the pre-fracturing condition, and the majority of the top coal could be recovered after the first weights of the working face. Based on the statistical analysis of the top coal recovery rates, the overall recovery rate follows a pattern of initially increasing, then decreasing, and eventually stabilizing. After the first weighting, the maximum top coal recovery rate was 94.67%, and the recovery rate during the stable stage was approximately 93%.

The distance from the farthest point of fracture development ahead of the top coal to tail beam of the support is defined as the advanced fracturing zone. The displacement field of the top coal and range of the advanced fracturing zone before and after fracturing are shown in Fig. 16. From Fig. 16a,b, it can be observed that after fracturing, the top coal and roof transitioned from a vertical downward collapse to oblique sliding towards the goaf. This caused the top coal above the tail beam to be continuously compressed towards the goaf, resulting in an increased horizontal displacement of the top coal particles. This accelerated the rate of coal release and facilitated the easy discharge of coal. However, this reduces the pressure of the fractured top coal above the roof beam from moving towards the goaf, thereby increasing the overall amount of top coal released.

A comparative analysis of Figs. 15 and 16 reveals that as the working face advances to approximately 22 m, the stress release resulting from the broken of the main roof leads to the unloading of the coal ahead of the supports. Simultaneously, the active space gradually increases, and the damaged zone rapidly develops, leading to a rapid increase in the amount of top coal released during this stage. As the working face advances to approximately 28 m, the development of the advanced fracture zone slows within this stage, gradually reaching a peak at 17.6 m. A significant amount of loose top coal above the support beam moves towards the coal discharge port. When the working face reaches approximately 32 m, the complete fracture of the main roof causes the redistribution of stress in the coal wall. The range of the peak supporting stress gradually stabilizes, and the range of the advanced fracture zone also tends to stabilize.

Field test results of graded hydraulic fracturing

Drilling to peep at fracturing effect

To monitor the top coal caving effect on the working face, post-fracturing observations of the development of fractures within the coal-rock mass along the borehole walls were conducted using a panoramic borehole viewer. The results are shown in Fig. 17; it can be observed that the degree of fracture development gradually decreases with an increase in the borehole depth. Most of the top coal exhibits sufficient fracture expansion under pressure from the overlying strata, resulting in relatively broken top coal. In the immediate roof, there are numerous sections with well-developed fractures, indicating favorable fracture propagation. On the main roof, the fractures are evenly distributed, accounting for approximately 25% of the total observed length.

TCCP and roof weighting

The statistics for the top coal lumpiness, recovery rate, and roof weighting before and after fracturing are shown in Fig. 18. The top coal lumpiness size is expressed by its equivalent diameter, and the calculation formula is as follows:

where, dc, Mc and Pc are all parameters of caving coal block, which are equivalent diameter, block mass and density respectively.

As shown in Fig. 18a, the top coal lumpiness size decreased significantly after fracturing. The proportion of the top coal with an equivalent diameter larger than 0.8 m decreases from 9 to 2% before and after fracturing, effectively reducing the likelihood of blockage at the coal discharge port. Moreover, the mean lumpiness size decreases from 0.52 m to 0.38 m, resulting in a reduction of 26.9%. This reduction in lumpiness significantly reduces the occurrence of arching and bridging of loose material, minimizing incidents, such as tearing, overloading, and damage to underground coal conveyors, thus enhancing the safety of mining operations.

As shown in Fig. 18b, without the implementation of fracturing-induced caving measures, the top coal recovery rate before the initial broken of the main roof remained relatively low. Only approximately 30% of the top coal with parting could be fractured and released for recovery under repeated hydraulic-powered support. After the initial broken of the main roof and subsequent entry into normal mining, the recovery rate experienced a secondary increase of approximately 90%. With the adoption of fracturing-induced caving measures, both the first weighting interval and periodic weighting interval were reduced; the height of the caving zone increased. As the face advanced to approximately 20 m, a significant improvement in the top coal recovery rate was observed. By the time the face reached approximately 35 m, the recovery rate peaked at 95.26%. Subsequently, it stabilized and remained at approximately 93%. Within the initial 50 m of face advancement, the top coal recovery rate increased from 45.99% to 77.18%.

As shown in Fig. 18c, the first weighting interval for fracturing-induced caving at the face is approximately 30 m, whereas the periodic weighting interval is approximately 20 m. These values indicate a reduction of approximately 20 m in the first weighting interval compared with that in the other cases without the fracturing measures. Additionally, the resistance of the roof supports at the ends of the face was significantly lower than that in the middle of the face. This finding suggests that fracturing-induced fragmentation of the coal-rock mass can effectively reduce the support pressure, thereby reducing the likelihood of coal rib spalling and roof falls between supports.

Conclusion

In this study, we addressed the issues of strong rock pressure and low top coal recovery during the initial mining stage of coal seams with complex structures and hard roof strata. Considering the characteristics of coal seam extraction, we elucidated the mechanisms behind the strong rock pressure and poor TCCP during the initial mining phase. To mitigate these challenges, we propose a hydraulic fracturing system and methodology for the top coal and roof and develop an understanding of roof collapse and top coal movement patterns before and after fracturing. The key findings are summarized as follows.’

-

(1)

A comprehensive model for analyzing the mechanical behavior of a four-sided fully supported hard roof and the interaction between the supports and surrounding strata was developed. The factors influencing the first weighting interval were identified in descending order of their impact: the main roof thickness, tensile strength, bearing load and the working face length. The formation mechanism of the strong rock pressure during the initial mining phase was revealed. Additionally, based on the theory of ellipsoids, it was determined that the main factor affecting the TCCP in the thick-hard roof strata of coal seams with complex structures is the formation of cantilever beam structures through the fracture of thick-hard partings.

-

(2)

The simultaneous fracturing of both the top coal and roof can reduce the weighting interval on the working face. This process effectively decreased the strength of the thick-hard parting within the top coal, while simultaneously enhancing its load strength and eliminating the cantilever structure resulting from the parting fracture. It not only reduces the first weighting intensity but also promotes the early and proper coal release, thereby enhancing the TCCP and ensuring safe and efficient production during the initial mining phase. The optimal fracturing height determined to be 20.85 m above the working face.

-

(3)

An optimal borehole diameter of 60 mm was determined using the PFC hydraulic fracturing fluid–solid coupling model. Fractures propagation in hydraulic fracturing was divided into three stages: initiation, development, and interconnection of fractures. The minimum spacing for the fracture interconnection was 10 m. Considering the variation in the roof fracturing conditions, a graded fracturing technology and system were proposed for fracturing the top coal and roof. A three-level fracturing borehole layout incorporating long, short, and auxiliary holes was developed using goaf water and activated water.

-

(4)

The formation of near-horizontal fractures after hydraulic fracturing caused the roof to collapse into layers, resulting in an increased load on the coal seam. This promotes the migration of coal towards the coal discharge port, thereby increasing the rate and overall quantity of the top coal caving. During the first weighting period, the extent of the advanced failure zone initially increased, then decreased, and finally stabilized. The field application results demonstrate that hydraulic fracturing facilitates the extensive expansion of roof fractures, reduces the occurrence of large coal blocks, and decreases the average lumpiness size by 26.9%. The first weighting interval was reduced from 50 to 30 m compared to the other unfractured working faces, effectively shortening it by 20 m. Within the first 50 m of the mining advance, the top coal recovery rate significantly improved from 45.99% to 77.18%, representing a remarkable enhancement of 31.19%.

Data availability

The raw data of the study can be obtained from the corresponding author on enquiry.

References

Liu, J., Liu, C., Yao, Q. & Si, G. The position of hydraulic fracturing to initiate vertical fractures in hard hanging roof for stress relief. Int. J. Rock Mech. Min. Sci. 132, 104328 (2020).

Duan, H., Zhao, L., Yang, H., Zhang, Y. & Xia, H. Development of 3D top coal caving angle model for fully mechanized extra-thick coal seam mining. Int. J. Min. Sci. Technol. 32(5), 1145–1152 (2022).

Wang, J. et al. Key technologies and equipment for a fully mechanized top-coal caving operation with a large mining height at ultra-thick coal seams. Int. J. Coal Sci. Technol. 2(2), 97–161 (2015).

Rajwa, S., Janoszek, T. & Prusek, S. Influence of canopy ratio of powered roof support on longwall working stability-a case study. Int. J. Min. Sci. Technol. 29(4), 591–598 (2019).

Guo, F. Variations of entries and bolting technologies, a case study based on a field monitoring of a longwall face. Eng. Geol. 331, 107458 (2024).

Wang, W. et al. Fracture failure analysis of hard-thick sandstone roof and its controlling effect on gas emission in underground ultra-thick coal extraction. Eng. Fail. Anal. 54, 150–162 (2015).

Wang, H. et al. Investigation on the movement and fracture characteristics of an extra-thick hard roof during longwall panel extraction in the yima mining area. China. Geofluids. 2021, 1–18 (2021).

He, Z. et al. Numerical and field investigations of rockburst mechanisms triggered by thick-hard roof fracturing. Rock Mech. Rock Eng. 55(11), 6863–6886 (2022).

Liu, C., Li, H. & Mitri, H. Effect of strata conditions on shield pressure and surface subsidence at a longwall top coal caving working face. Rock Mech. Rock Eng. 52(5), 1523–1537 (2019).

Yu, M., Zuo, J., Sun, Y., Mi, C. & Li, Z. Investigation on fracture models and ground pressure distribution of thick hard rock strata including weak interlayer. Int. J. Min. Sci. Technol. 32(1), 137–153 (2022).

Bu, Q., Tu, M., Zhang, X., Zhang, M. & Zhao, Q. Analysis of energy accumulation and dispersion evolution of a thick hard roof and dynamic load response of the hydraulic support in a large space stope. Front. Earth Sci. 10, 884361 (2022).

Xu, C. et al. Apparent-depth effects of the dynamic failure of thick hard rock strata on the underlying coal mass during underground mining. Rock Mech. Rock Eng. 52(5), 1565–1576 (2019).

Lu, C., Liu, Y., Liu, G. & Zhao, T. Stress evolution caused by hard roof fracturing and associated multi-parameter precursors. Tunn. Undergr. Space Technol. 84, 295–305 (2019).

Ma, Q. et al. Numerical study of mechanical properties and microcrack evolution of double-layer composite rock specimens with fissures under uniaxial compression. Eng. Fracture Mech. 289(2), 109403 (2023).

Zhang, J., Li, B., Zhou, N. & Zhang, Q. Application of solid backfilling to reduce hard-roof caving and longwall coal face burst potential. Int. J. Rock Mech. Min. Sci. 88, 197–205 (2016).

Zhang, L.et al. Experimental investigation on the mixture optimization and failure mechanism of cemented backfill with coal gangue and fly ash. Powder Technology. 440,119751; https://doi.org/10.1016/j.powtec.2024.119751 (2024).

Xie, G. et al. Study on the green disposal of industrial high salt water and its performance as activator to prepare magnesium-coal based solid waste backfill material for mine. J. Cleaner Prod. 2024, 141933. https://doi.org/10.1016/j.jclepro.2024.141933 (2024).

Lu, Y., Gong, T., Xia, B., Yu, B. & Huang, F. Target stratum determination of surface hydraulic fracturing for far-field hard roof control in underground extra-thick coal extraction: a case study. Rock Mech. Rock Eng. 52(8), 2725–2740 (2019).

Yu, B., Gao, R., Kuang, T., Huo, B. & Meng, X. Engineering study on fracturing high-level hard rock strata by ground hydraulic action. Tunn. Undergr. Space Technol. 86, 156–164 (2019).

Lu, A. et al. Mechanism of hard-roof rock burst control by the deep-hole blasting: numerical study based on particle flow. Shock Vib. 2021, 1–14 (2021).

Tang, W. et al. The influence of borehole arrangement of soundless cracking demolition agents (scdas) on weakening the hard rock. Int. J. Min. Sci. Technol. 31(2), 197–207 (2021).

Wang, K., Zhao, T., Yetilmezsoy, K. & Zhang, X. Cutting-caving ratio optimization of fully mechanized caving mining with large mining height of extremely thick coal seam. Adv. Civ. Eng. 2019, 1–11 (2019).

Alehossein, H. & Poulsen, B. Stress analysis of longwall top coal caving. Int. J. Rock Mech. Min. Sci. 47(1), 30–41 (2010).

Yang, S., Zhang, J., Chen, Y. & Song, Z. Effect of upward angle on the drawing mechanism in longwall top-coal caving mining. Int. J. Rock Mech. Min. Sci. 85, 92–101 (2016).

Wang, J., Yang, S., Li, Y., Wei, L. & Liu, H. Caving mechanisms of loose top-coal in longwall top-coal caving mining method. Int. J. Rock Mech. Min. Sci. 71, 160–170 (2014).

Wang, J., Zhang, J. & Li, Z. A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int. J. Rock Mech. Min. Sci. 88, 273–285 (2016).

Basarir, H. F., Oge, I. & Aydin, O. Prediction of the stresses around main and tail gates during top coal caving by 3d numerical analysis. Int. J. Rock Mech. Min. Sci. 76, 88–97 (2015).

Liu, C. & Li, H. Numerical simulation of realistic top coal caving intervals under different top coal thicknesses in longwall top coal caving working face. Sci. Rep. 11(1), 13254 (2021).

Zhang, Q. et al. Optimizing simulation and analysis of automated top-coal drawing technique in extra-thick coal seams. Energies 13(1), 232 (2020).

Liang, Y. et al. Study on roof-coal caving characteristics with complicated structure by fully mechanized caving mining. Shock Vib. 2019, 1–20 (2019).

Bai, Q., Tu, S. & Wang, F. Characterizing the top coal cavability with hard stone band(s): Insights from laboratory physical modeling. Rock Mech. Rock Eng. 52(5), 1505–1521 (2019).

Zhou, Y., Zhang, D., Fan, G., Zhang, S. & Zhang, S. Feasibility study on fully mechanized large mining height long wall top-coal caving mining in ultra-thick (20–30 m), parting-rich coal seams: a case study of the laosangou mining field in China. Energy sources. Part A Recov. Util. Environ. Effects 2020, 1–24 (2020).

Chi, M., Zhang, D., Fan, G., Zhang, W. & Liu, H. Prediction of top-coal caving and drawing characteristics by the analytic hierarchy process-fuzzy discrimination method in extra-thick coal seams. J. Intell. Fuzzy Syst. 33(4), 2533–2545 (2017).

Zhang, N., Liu, C., Wu, X. & Ren, T. Dynamic random arching in the flow field of top-coal caving mining. Energies 11(5), 1106 (2018).

Wang, Z., Tang, Y. & Gong, H. Longwall top-coal caving mechanism and cavability optimization with hydraulic fracturing in thick coal seam: a case study. Energies 14(16), 4832 (2021).

Song, Z., Konietzky, H. & Herbst, M. Drawing mechanism of fractured top coal in longwall top coal caving. Int. J. Rock Mech. Min. Sci. 130, 104329 (2020).

Lang, D. et al. Influence of the coal seam strength on the boundary of a top coal limit equilibrium zone in a fully mechanized top coal caving stope. Min. Metall. Explor. 38(6), 2375–2392 (2021).

Wang, J., Wang, Z. & Li, Y. Longwall top coal caving mechanisms in the fractured thick coal seam. Am. Soc. Civil Eng. 8(20), 1–14 (2020).

Wang, J., Wang, Z. & Yang, S. Stress analysis of longwall top-coal caving face adjacent to the gob. Int. J. Min. Recl. Environ. 34(7), 476–497 (2020).

Le, D., Oh, J., Hebblewhite, B., Zhang, C. & Mitra, R. A discontinuum modelling approach for investigation of longwall top coal caving mechanisms. Int. J. Rock Mech. Min. Sci. 106, 84–95 (2018).

Gao, M. et al. Field experiments on fracture evolution and correlations between connectivity and abutment pressure under top coal caving conditions. Int. J. Rock Mech. Min. Sci. 111, 84–93 (2018).

Xie, H. & Zhou, H. Application of fractal theory to top-coal caving. Chaos Solit. Fractals 36(4), 797–807 (2018).

Sun, Q., Shan, C., Wu, Z. & Wang, Y. Case study: mechanism and effect analysis of presplitting blasting in shallow extra-thick coal seam. Arch. Min. Sci. 67(3), 381–399 (2022).

Wang, J., Liu, F. & Wang, Z. Experimental investigation on the movement mechanism of top coal in steeply inclined ultra-thick coal seams. Acta Mech. Sin. 37(4), 631–648 (2021).

Yasitli, N. & Unver, B. 3d numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 42(2), 219–235 (2005).

Unver, B. & Yasitli, N. Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 66(4), 227–252 (2006).

Wu, Z. et al. A case study of cyclic top coal weakening process based on highly tough coal seam with partings. Shock Vib. 2021, 1–17 (2021).

Xie, Y. & Zhao, Y. Numerical simulation of the top coal caving process using the discrete element method. Int. J. Rock Mech. Min. Sci. 46(6), 983–991 (2009).

Zeng, Q., Zhu, Y., Yang, Y., Li, Z. & Wan, L. Influence of coal caving time and tail beam swing angle on the evolution of the coal gangue boundary line during top coal caving. Shock Vib. 2022, 1–14 (2022).

Huang, B., Wang, Y. & Cao, S. Cavability control by hydraulic fracturing for top coal caving in hard thick coal seams. Int. J. Rock Mech. Min. Sci. 74, 45–57 (2015).

Huang, B., Liu, C., Fu, J. & Guan, H. Hydraulic fracturing after water pressure control blasting for increased fracturing. Int. J. Rock Mech. Min. Sci. 48(6), 976–983 (2011).

Cheng, Q. et al. Combination of pre-pulse and constant pumping rate hydraulic fracturing for weakening hard coal and rock mass. Energies 13(21), 5534 (2020).

Luo, H. et al. Mechanism and application of hydraulic fracturing in the high-level thick and hard gangue layer to improve top coal caving in fully mechanized caving mining of an ultra-thick coal seam. Minerals 12(12), 1605 (2022).

Chang, Z. et al. Study on a Mechanical Model of a Long Cantilever Beam Structure Formed by the Fracture of Thick Partings Transversely Penetrating a Coal-Caving Ellipsoid and Its Application. Rock Mech. Rock Eng. 57(2), 1153–1169 (2023).

Acknowledgements

This work was supported by the National Key Research and Development Program of China (No. 2018YFC0604705), and the National Natural Science Foundation of China (No.52104140).

Author information

Authors and Affiliations

Contributions

ZC. C. and XF. W. wrote the main manuscript text. ZC. C., DD. Q. and XY. C. analysised the formals. JZ. Y and ZJ.N. Conducted numerical simulations. ZC.C., XF. W., JY. W. and CL.Q performed the research and analyzed the data.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chang, Z., Wang, X., Qin, D. et al. Safety and high-recovery mechanisms and application research for initial mining of thick-coal-seam with complex structure and thick-hard roof. Sci Rep 14, 19638 (2024). https://doi.org/10.1038/s41598-024-70085-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-70085-3

Keywords

This article is cited by

-

Investigation on overburden failure and subsurface subsidence characteristics in fully mechanized top-coal caving of “Three-Soft” Thick coal seams

Scientific Reports (2025)

-

Main disaster-causing strata of composite hard roof and bidirectional, high-low position blasting technology for rockburst prevention

Geomechanics and Geophysics for Geo-Energy and Geo-Resources (2025)