Abstract

This research primarily focuses on the strength indicators of the bearing structures of ADM-1 special self-propelled rolling stock. The special self-propelled rolling stock used by Uzbek railroads reaching the end of their functional life is a pertinent problem as Uzbekistan's railway system is growing rapidly, but there is a lack of enough funds to buy new special self-propelled rolling stock. Hence, it is vital to fix the issues with ADM-1 special self-propelled rolling stock by overhauling them. At the outset, the researchers divided the frame of a special a self-propelled rolling stock into multiple sections. Subsequently, these individual sections were analyzed closely to spot out issues. The precise location of the fatigue defect occurrence on the longitudinal beams was determined by the analysis of the individual sections of the special self-propelled rolling stock. During the motor carriage's modernization, which is an approach to extend the service life and improve the durability of special self-propelled rolling stock, this analysis helped in pinpointing exactly the location on the frame where the stress measurements had to be calculated. Pre- and post-modernization calculations were carried out on the vehicle to determine the optimal placement of the reinforcing plates. Additionally, normative calculations were also conducted and a new design mode distinct from the repair loads was implemented. The computation results revealed that the fatigue resistance reserve coefficient and service life value prior to the bearing structure’s modernization in section 1 were below the required values of n = 1.5 and 1.49, respectively. All the sections of the load-bearing structure fulfilled the fatigue resistance reserve coefficient standards after the modernization. The computational model of the motor carriage's structural strength was created in the ANSYS Workbench platform. This research intends to enhance the strength determination procedures and provides recommendations for design and restoration of modern structures of special self-propelled rolling stock.

Similar content being viewed by others

Introduction

Globally, railway accounts for 78% of the overall cargo transported, and hence, the issues of increasing reliability and resource-saving by modernizing the structural units of the railway equipment in service during their overhaul, with the intent of extending their useful life are of significance in Uzbekistan. One of the main objectives of global anti-crisis programs is to try and attain "accelerated implementation of modernization, technical and technological reequipment of enterprises, improvement of reliability of materials, wide introduction of modern flexible technologies". This is the reason why there is an increased emphasis on the realization of scientific research towards the direction of non-destructive forecasting of properties and resources.

In Uzbekistan’s railway industry, there is a special focus on issues such as resource-saving, particularly on extending the service life of special self-propelled rolling stock to make sure the entire railway network operates without interruptions.

Modernization of the rolling stock, including automatic carriages, as well as the application of cost-effective methods, will help in reducing the overall cost of transportation. Hence, the introduction of modern techniques and scientific developments to improve the dynamic performance of materials and structures of railway rolling stock is vital.

As the service life of ADM-type motor carriages at JSC "Uzbekistan Temir Yollari", comes to an end by 2025, it is expected that there will be a mass failure of all operating equipment. Hence, an objective analysis and feasible solutions to extend the service life of ADM-type special self-propelled rolling stock on the Uzbek Railways is pertinent and have thus been proposed in this study.

Literature review

The design and modernization of mechanical components, chassis, and spring suspension systems in special self-propelled rolling stock intend to achieve several key objectives. These key objectives include expanding the existing functional capabilities, enhancing reliability, and improving the overall strength and durability.

Drawing upon the basic principles put forth in the theory of vibrations as specified by Wang1, Chernysheva2, Jing3, Gong4, the modelling of dynamic processes becomes possible.

Fundamental research on the strength calculations of the bearing structure of rolling stock has been carried out by foreign researchers like Lovska5, Hubar6, Musayev7, Bondarenko8, Fomin9, Zayniddinov10, Vallely11, Gokhan12 and others.

Modern methods for estimating the residual life of bearing structures of rolling stock on railroads are undertaken in studies done by Lu13. In these studies, the principles of norms and rules for the operation of rolling stock beyond the specified service life are proposed. In one of the studies, the authors analyze the change in the endurance limit of the structure under the action of multi-cycle loads, which eventually leads to the loss of bearing capacity. Defects from various loads, resulting from episodic and repair loads with excessive allowable stresses, were not considered.

This paper focuses on the effect of long-term operation of railway rolling stock on the performance characteristics of its load-bearing structures. The stages of fatigue failure of low-carbon steels are studied, along with the likelihood of assessing the probability of fatigue cracks in them. It needs to be noted that the issue of fatigue failure of other elements, except for welded joints, was not considered during the study.

The issues related to the creation of a comprehensive test bench for fatigue life testing of cars are considered to assess the accumulated fatigue stresses, so a test of equivalent car mileage of 3125 million kilometers or 25 years was conducted. However, fatigue testing of cars by the proposed method requires a considerable amount of time.

Experimental and theoretical studies on the durability of new and modernized dump trucks are discussed. The analysis of damage occurrence on such cars shows that the main part of damage occurs during loading, in the case when the car body is subjected to deep impacts of large mass from a height. It is possible to reduce the level of impact loading if a protective layer of loose cargo is placed on the car floor. The question of the strength of the car beam is not considered.

The paper gave a set of tests, the selection of a test specimen for routine testing of rolling stock, the order of performance and methods of technical diagnostics and routine tests, data processing, and the evaluation of results. A comprehensive approach to the assessment of the residual service life of railroad vehicles was proposed, but no specific methodology of the part of the rolling stock was given.

As per analysis, it is evident that present research on the dynamic properties of self-propelled rolling stock relies heavily on various mathematical modeling techniques. While these studies have yielded positive results, the integration of optimization principles into the design of load-bearing structures still remains limited. This limitation is due to two reasons: the lack of robust optimization methods utilizing simple numerical models and the absence of a well-defined optimization methodology for physical models. Furthermore, the selection of the target function poses a major challenge, as optimizing the primary criterion often makes it mandatory to constrain secondary ones. To solve this problem, it is necessary to try and achieve consistency between local optimization results and customize them to a specific rolling stock type.

A closer look into the reasons for the failure of automatic locomotives operated in Uzbekistan's JSC "Uzbekistan Temir Yollari", identified that the majority were attributed to mechanical issues (about 50%), followed by electrical issues (31.8%) and hydraulic issues (18.2%) in the equipment. It is necessary to emphasize the significance of robust and stable supporting structures, specifically, the frame of the automatic carriage. Additionally, it is also mandatory to prevent malfunctions by adopting proactive measures, including frequent checks that identify potential failures, along with quality control checks throughout the operational process.

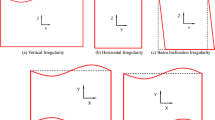

Ensuring the static and dynamic stability of the frame is vital, as it directly impacts the ability to perform essential tasks on electrified railway lines. The study hypothesizes that fatigue cracks appearing on the frame might be caused by the attachment of heavy equipment in the central section. This placement could lead to cracks under exceptional loads exceeding permissible stress levels.

Modern structural analysis has expanded significantly beyond the traditional focus of stress and strain distribution. It is vital these days to determine the lifespan of structures14,15. This research thus focuses specifically on addressing the issue of failure conditions within structures. To facilitate this, the frame of the motor carriage is regarded as a solid body. Within the field of deformable solid mechanics, two main approaches have been developed to address this issue.

The first approach involves modeling the development of defects such as pores and cracks. This model accounts for how changes in defect size impact the boundary conditions of the analyzed structural element16,17,18. The second approach estimates the degree of material damage within structural elements without explicitly considering the presence or growth of specific defects19

Materials and methods

Aligned with the overall research objectives, this research paper defines a much narrower goal, which is to generalize and analyze the structural scheme of ADM special rolling stock, enabling the development of a method for calculating locomotive lifespan during operation.

Due to the fact that the base part of the car is subjected to the most significant degradation, below is a scheme of the frame of the car.

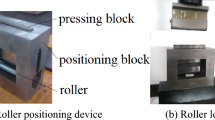

The general layout of the frame in Fig. 1 consists of a backbone beam 1, two longitudinal side beams 2, two end beams 3 (often called buffer beams), two kingpin beams 4, and several cross beams 5. The critical elements of the frame, which usually cannot be replaced, are elements 1, 2, 3, and 4. Other elements, if damaged, can be replaced with new ones during scheduled repairs. We suggest installing reinforcing pads on the non-replaceable areas of the frame to prevent crack growth.

In the process of studying the components of the frame of a motor carriage, instead of the limit of deterioration of the standard σ − 1, we consider the limit of deterioration of the frame element, σD−1, diagnosed using the following formula:

In engineering practice, the following formula for determining the \(K_{\sigma D}\) coefficient, taking into account the above factors, is accepted 20:

where Kσ is the best stress concentration index (ratio of the wear limit of a folded standard to the wear limit of a standard with a stress concentrator), calculated using the following formula:

Here, ασ is an abstract index of stress concentration, diagnosed from nomograms (for example, in 21, q is an index of material susceptibility to stress concentration; Kd is an index of influence of unconditional dimensions of transverse separation or scaling agent (ratio of the limit of deterioration of a specimen of a specified cross-section to the limit of deterioration of a specimen with an ordinary diameter), determined for the basis of nomograms; KF is the index of influence of the plane finish property (ratio of the limit of deterioration of the specimen with the examined quality of the plane finish to the limit of deterioration of the specimen, due to which the Where hypocycloid was obtained) and is determined on the basis of nomograms; Kv is the index of influence of easy hardening (ratio of the limit of deterioration of the specimen with the examined plane finish to the limit of deterioration of the unhardened specimen) and is determined on the basis of nomograms. The values of the material impressiveness index to the concentration of forces for the sake of various material images22 are given in Table 1.

The data in Table 1 shows that the more serviceable the material design and the less clear the transferred material appear to be, the more sentimental it is to stress concentration (the closer the actual force concentration index Kσ is to the abstract stress concentration factor ασ).

The following formula is proposed for the conversion factor of the fatigue limit KσD:

where K1 is the coefficient taking into account the heterogeneity of the material; K2 is the coefficient that takes into account the internal stresses of the material of the part.

Fatigue strength is evaluated by a conditional safety factor.

The formulas of safety factor can now be written separately for normal and tangential stresses 23,24,25:

The following notations are introduced in these formulas:

σms, τms are the average normal and tangential stresses of the cycle at which the endurance diagram has a fracture;

\(K^{\prime}_{\sigma D} = \frac{1}{{K_{\sigma D} }}\), \(K^{\prime}_{\tau D} = \frac{1}{{K_{\tau D} }}\);

\(\psi_{\sigma }\) is the coefficients characterizing the sensitivity of the material to the cycle asymmetry.

The fatigue safety factor is determined using the following formula 26:

A part is considered serviceable if n determined by Equation (4) is not lower than the minimum permissible value of the safety factor [n]; i.e., the strength condition has the form n ≥ [n] 27. In most cases in mechanical engineering, [n]=1.5/2.5. On the other hand, if n >> [n], i.e., n is much higher than the minimum permissible value, then the part is over-sized and can be lightened if its dimensions are determined by strength conditions but not by the stiffness conditions as well as structural and technological considerations. The mechanical characteristics of the steel frame of the ADM-1 railcar are given in the Table 2.

The main parameters for determining the safety factors by sections are given in Table 2.

Methodology of calculation of residual fatigue life of the frame of motor carriages

Modernization of rolling stock

This study investigates the feasibility of adopting a practical approach to modernization for special self-propelled rolling stock. The focus of this research lies on identifying and addressing the critical weaknesses in the frame through techniques like welding cracks and installing reinforcing plates. These specific intervention procedures aim to achieve a significant extension of service life of the rolling stock.

Additionally, the modernization procedures aim to reduces the stress levels in critical areas of the frame, enhancing the overall durability of the rolling stock. By revamping the existing fleet in a cost-effective manner, this approach to modernization will result in a reliable and efficient railway transportation system.

Design

In this study, the authors on the basis of the generalized fatigue strength calculation methodology, offer a methodology for estimating the residual life of the frame of motor carriages with expired service life.

Fatigue strength is assessed by the fatigue resistance reserve factor, which is calculated using the following formula:

where \(\sigma_{a,N}\) is the endurance limit (in amplitude) for the control zone at a symmetrical cycle and steady-state loading mode at the basic number of cycles N0 = 107; \(\sigma_{{a,{\text{e}}}}\) is the amplitude of dynamic stress of the conditional symmetrical cycle, reduced to the basic number of cycles N0, equivalent to the damaging effect of the real mode of operational stresses for the design service life; [n] is the minimum allowable reserve factor of fatigue resistance for the selected zone.

The calculated value \(\sigma_{a,N}\) is determined using the following formula:

where \(\sigma_{a,N}\) is the endurance limit (by amplitude) for the control zone at symmetric cycle and steady-state mode of loading at basic number of cycles \(N_{0} = 10^{7}\); \(\overline{\sigma }_{a,N}\) is the median value of endurance limit of the control zone; \(Z_{p}\) is the quantile of distribution \(\sigma_{a,N}\) corresponding to one-sided probability of 95%, \(Z_{p}\) = 1.645; \(V_{{\sigma_{a,N} }}\) is the coefficient of variation of endurance limit in the material.

The value \(\overline{\sigma }_{a,N}\) is determined using the following formula:

where \(\overline{\sigma }_{ - 1}\) is the average (median) value of the endurance limit of a smooth standard specimen under a symmetrical bending cycle on the basis of No = 107; \((\overline{k}_{\sigma } )_{k}\) is the average value of the total coefficient of reduction in the endurance limit in the selected control zone in relation to the endurance limit of a smooth standard specimen, \((\overline{k}_{\sigma } )_{k}\) determined according to the following.

The sought value of durability by the criterion of fatigue strength for the selected zone was determined using the following formula:

where m is degree index in the equation of the fatigue curve in amplitudes. For welded structures made of rolled steel without strengthening treatment of seams, m = 4; Tк is the required value of design life; \(N_{c1}\),\(N_{c2}\),\(N_{c3}\) is the number of cycles for 1 year of operation for longitudinal, vertical, repair, and other loads; \(\sigma_{aj}^{I}\),\(\sigma_{ak}^{II}\),\(\sigma_{ah}^{III}\) is the amplitudes of dynamic stresses, reduced to a symmetric cycle, equivalent to experimentally obtained asymmetric cycles from shock longitudinal loads (in j ranges), from oscillations on the spring suspension (in k ranges), from test internal pressure, repair loads (in n ranges); Pj,k,n is the probability (frequency) of occurrence of amplitudes at corresponding stresses; N0 is the basic number of cycles. Below is Fig. 2 which shows the algorithm for solving formula (8).

Algorithm for calculation of fatigue strength of the bearing structure of motor carriages.

In order to determine the safety margin of the frame of the motor carriage, a spatial model was built. In this case, the ANASYS Workbench software package was used. The strength calculation was carried out using the finite element method.

All numerical parameters for the calculation of the frame of the motor carriage in operation were taken on request from Joint Stock Company (JSC) "Uzbekistan Temir Yollari".

The initial data for the calculation were taken as follows: the value of the material time resistance limit in the control zone and the average (median) value of the endurance limit of a smooth standard specimen under a symmetric bending cycle on the basis of no for the points under study: \(\sigma_{B}\) = 355 MPa, \(\overline{\sigma }_{ - 1}\) = 160 MPa. The main parameters for determining safety factors for sections are given in Table 3

Results of the study

To confirm the obtained values, the authors carried out the results of fatigue strength calculation in ANSYS Workbench system28.

To calculate the fatigue strength, the SN approach was chosen, i.e., the fatigue curve is specified by a sequence of points of stress amplitudes under a symmetric cycle of loading and durability, and the Goodman model was chosen to account for the effect of cycle asymmetry.

The finite element model of the ADM-1 railcar was created using the program, which is shown in Fig. 3.

When finding the stress distribution in this problem, we use three-dimensional finite elements (solid type).

The data in Table 4 are obtained from the experimental test results from Fig. 4. Determining the fatigue curve of a material under symmetrical loading, especially under cyclic bending conditions, usually involves experimental tests. These data are experimental test results. Fatigue curves provide important information about the fatigue behavior of a material under cyclic loading conditions. In the design process, it is used to estimate the durability and reliability of the components made of the material.

The stress state corresponds to bending, so the data on the fatigue resistance of the beam material, given in Table 4, were used.

To ensure the correct interpretation and understanding of the data presented in Figs. 5, 6 and 7, the load and fastening parameters are as follows: type of applied load: bending. Information about the size of the load: Fa = 345 kN. In static condition, under a symmetric bending cycle. In the process of simulation, the rail axes of the frame are fixed.

Based on the results of solving the static problem for this structure, the stress and strain fields are found. As an example, Fig. 5 shows the results of the static calculation of the given structure at the resultant load equal to Fa = 345 kN in the form of stress intensity distribution (equivalent stress according to the hypothesis of specific energy of shape change). The color palette in the right part of the figure specifies the correspondence of colors to different intervals of stress levels. Stress values are given in MPa.

This Fig. 7 presents the distribution of the safety factor across different sections of the railcar frame.

The safety factor is calculated based on the stress amplitude and fatigue life data derived from the finite element analysis. It provides a visual representation of the safety margins under the given load conditions

Figures 5, 6 and 7 show the results of fatigue life (life) and stress amplitude safety factor (safety factor).

The maximum and minimum values of fatigue resistance characteristics are summarized in Table 5.

Discussion of the results of programmatic and theoretical studies of automotor cars

Our research was carried out on ADM-1-type railcar, which were in long-term operation on the railroads of Uzbekistan.

In order to determine the cracks occurring in the frame of the railcar during operation, we divided the frame of the special self-propelled rolling stock into sections. In-depth statistical and analytical analysis of non-replaceable structural elements of the frame by sections was carried out (Tables 5 and 6).

The calculation results of fatigue resistance reserve factor (formula) and durability by fatigue strength criterion (formula 7) are shown in Table 6.

We calculate the endurance limit (by amplitude) for the control zone in a symmetric cycle and the steady-state mode of loading in the basic number of cycles using the expression (7):

The endurance limit (by amplitude) for the control zone at a symmetric cycle and steady-state mode of loading at the basic number of cycles is 133.68 MPa.

From Table 6, it is established that the fatigue resistance reserve coefficient calculated by Formula (6) and the service life value calculated by Formula (9) before modernization of the bearing structure of railcars only in section 1 have values less than the required n=1, 5 and Tk = 30 years, respectively, (1.49 and 29.8 years). After modernization, all sections of the bearing structure meet the requirements for the fatigue resistance reserve factor and the value of service life. Thus, the residual resource of the bearing structure of special self-propelled rolling stock after overhaul with a service life extension is not less than 10 years, during which the guaranteed trouble-free operation of this type of rolling stock is provided.

The proposed method is the calculation of the fatigue strength characteristics of the load-bearing system in special self-propelled rolling stock in the ANSYS Workbench system, according to which it is established that at an acting load of 345 kN, the highest stresses occur in sections 1 and 11 (section A–A) and section 4 (section D–D) of the main frame sidewall. The equivalent amplitude stress in sections 1 and 11 is within 114 MPa, the durability is estimated at 198,770 cycles, and the safety factor is 0.75 (corresponding to failure). Modernization of the frame with the application of reinforcing pads allowed us to reduce stresses in the specified zones by 23% (92.7 MPa). To increase the durability up to 1,000,000 cycles, it is recommended to increase the value of the safety factor above one.

This table summarizes the fatigue resistance reserve coefficients and the design service life both before and after the modernization of the railcar frame.

The values in this table are based on more comprehensive calculations that include not only the safety factors but also the endurance limits and other parameters according to formulas (6) and (9).

These calculations take into account the median values of endurance limits, coefficients of variation, and the required service life, which are not directly illustrated in Fig. 6.

The key difference lies in the scope and depth of the calculations:

Figure 6 focuses on the safety factor distribution, which provides an immediate visual insight into how safe each section of the frame is under the specified loading conditions.

Table 6 includes a detailed assessment of the fatigue resistance reserve and the calculated service life before and after modernization, considering additional factors and criteria.

Thus, while Figure 6 provides a snapshot of the current safety status, Table 6 offers a more detailed and longitudinal view of the frame's durability and safety over its expected service life.

Conclusions

Our investigation focused on identifying recurring frame failure locations in special self-propelled rolling stock, that were beyond the point of restoration. From this analysis, it became evident that there was a propensity for crack development in long beams supporting heavy equipment. To address these critical frame sections, we propose the installation of proper reinforcing liners to mitigate the issues of further crack propagation.

A computational model of the frame's strength was developed using the ANSYS Workbench program suite. This model incorporated not only standard loading modes but also the number of loading cycles for one year of operation, including longitudinal, vertical, and repair loads. The uniqueness of this model lies in its consideration of repair loads acting on the frame of special self-propelled rolling stock, making it significantly different from existing models.

According to the results of the stress state assessment, it was determined that the most critical point on the frame is section 1 of the longitudinal beams, while the maximum design stress was 132 MPa. A method for determining the faults in the frame of a special self-propelled rolling stock and increasing the strength of the longitudinal beam of a special self-propelled rolling stock was proposed. Its uniqueness is that the defect is eliminated by welding the crack and installing reinforcing plates during the modernization of the special self-propelled rolling stock.

Based on the results, it is proposed to introduce this method of repair, combining both restoration and reinforcement, for all types of special self-propelled rolling stock operated in Uzbekistan.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Wang, P., Wu, X. & He, X. Vibration-theoretic approach to vulnerability analysis of nonlinear vehicle platoons. IEEE Trans. Intell. Transp. Syst. 24(10), 11334–11344 (2023).

Chernysheva, Y., & Gorskiy, A. Methods proposed for analysis of vibrations of railway cars. In International Scientific Siberian Transport Forum. 418–426. (Springer, 2021).

Jing, L., Wang, K. & Zhai, W. Impact vibration behavior of railway vehicles: A state-of-the-art overview. Acta Mech. Sin. 4, 1–29 (2021).

Gong, D. et al. Modal vibration decomposition method and its application on multi-mode vibration control of high-speed railway car bodies. J. Franklin Inst. 359(10), 4699–4726 (2022).

Lovska, A., Fomin, O., Chechet, A. & Soloviova, O. Determining the features of loading the improved bearing structure of a platform wagon for the transportation of military equipment. Bocтoчнo-Eвpoпeйcкий жypнaл пepeдoвыx тexнoлoгий 3(7–105), 20–26 (2020).

Hubar, O., Markul, R., Tiutkin, O., Andrieiev, V., Arbuzov, M., & Kovalchuk, O. Study of the interaction of the railway track and the rolling stock under conditions of accelerated movement. In IOP Conference Series: Materials Science and Engineering. Vol. 985(1). 012007. (IOP Publishing, 2020).

Musayev, J., Zhauyt, A., Ismagulova, S. & Yussupova, S. Theory and practice of determining the dynamic performance of traction rolling stock. Appl. Sci. 13(22), 12455 (2023).

Bondarenko, I., Lukoševičius, V., Keršys, R. & Neduzha, L. Investigation of dynamic processes of rolling stock–track interaction: Experimental realization. Sustainability 15(6), 5356 (2023).

Fomin, O., Lovska, A., Kudelya, V. & Smyrnova, I. Determining the dynamic loading and strength of the bearing structure of a covered wagon when firing from it. Bocтoчнo-Eвpoпeйcкий жypнaл пepeдoвыx тexнoлoгий 4(7–106), 33–41 (2020).

Zayniddinov, N. & Abdurasulov, S. Durability analysis of locomotive load bearing welded structures. Sci. Innov. 1(A8), 176–181 (2022).

Vallely, P. A Holistic Approach to Remote Condition Monitoring for the Accurate Evaluation of Railway Infrastructure and Rolling Stock (Doctoral dissertation, University of Birmingham, 2020).

Gökhan, N. U. R. et al. BUSER transcutaneous electric nerve stimulator device design. NESciences 8(1), 18–30 (2023).

Lu, Y. & Ishida, T. Implementation and evaluation of a high-presence interior layout simulation system using mixed reality. Int. J. Veh. Struct. Syst. 10(1), 50–63 (2020).

Ribeiro, J. P., Tavares, S. M. & Parente, M. Stress–strain evaluation of structural parts using artificial neural networks. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 235(6), 1271–1286 (2021).

Xiu, R., Spiryagin, M., Wu, Q., Yang, S. & Liu, Y. Fatigue life assessment methods for railway vehicle bogie frames. Eng. Fail. Anal. 116, 104725 (2020).

Yasbolaghi, R. & Khoei, A. R. Micro-structural aspects of fatigue crack propagation in atomistic-scale via the molecular dynamics analysis. Eng. Fract. Mech. 226, 106848 (2020).

Kim, J. J., Kim, A. R. & Lee, S. W. Artificial neural network-based automated crack detection and analysis for the inspection of concrete structures. Appl. Sci. 10(22), 8105 (2020).

Popović, Z., Lazarević, L., Mićić, M. & Brajović, L. Critical analysis of RCF rail defects classification. Transport. Res. Proc. 63, 2550–2561 (2022).

Li, D. et al. Automatic defect detection of metro tunnel surfaces using a vision-based inspection system. Adv. Eng. Inform. 47, 101206 (2021).

B.П., К. Pacчeты дeтaлeй мaшин и кoнcтpyкций нa пpoчнocть и дoлгoвeчнocть. Maшинocтpoeниe (1985).

B.T., T. Coпpoтивлeниe ycтaлocти мeтaллoв и cплaвoв. (1987).

Биpгep И.A., Шopp Б.Ф., И. Г. Б. Pacчeт нa пpoчнocть дeтaлeй мaшин. Vol. 640 (1993).

Кapзoв Г. П. , Mapгoлин Б. З., Ш. B. A. Физикo-мexaничecкoe мoдeлиpoвaниe пpoцeccoв paзpyшeния. Caнкт-Пeтepбypг Пoлитexникa 391 c. ил (1993).

Кoгaeв, B. П. Pacчeты нa пpoчнocть пpи нaпpяжeнияx, пepeмeнныx вo вpeмeни. M.: Maшинocтpoeниe 364 c.

Ceлинoв B. И. Пoдeлитьcя Пpoeктиpoвaниe пoдвeшивaния вaгoнoв Учeб. пocoбиe для вyзoв ж.-д. тpaнcпopтa. 250 c (1999).

Дyдкин E.П. Экcпepимeнтaльнo-тeopeтичecкиe ocнoвы выбopa пapaмeтpoв xoдoвыx чacтeй вaгoнoв пpoмышлeнныx жeлeзныx дopoг(пo ycлoвиям взaимoдeйcтвия c кoнтpyкциeй пyти) : Aвтopeфepaт диccepтaции нa coиcкaниe yчeнoй cтeпeни. (1991).

Cидняeв H. И. Teopия плaниpoвaния экcпepимeнтa и aнaлиз cтaтиcтичecкиx дaнныx. 495 c (2023) (Google Scholar).

Tickoo, S. ANSYS Workbench 2021 R1: A Tutorial Approach (2021).

Funding

This work was supported by the Agency of innovative development under the Ministry of higher education of the Republic of Uzbekistan (women's grant number AL-662204208).

Author information

Authors and Affiliations

Contributions

Conceptualization, Z.M.; methodology, Z.M. and F.Sh.; software, Z.M. and G.I.;resources, Z.M. and Z.E.; data curation, D.M. and A.B.; writing-original draft preparation, Z.M. and Sh.F.; writing—review and editing, J.K. and Z.E.; visualization, Z.M.; supervision, Z.M. and Sh.F.; project administration, Z.M; funding acquisi-tion, Z.M, Sh.F., D.M., A.B., K.J. and G.I. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Mukhamedova, Z., Fayzibayev, S., Mukhamedova, D. et al. Calculating the fatigue strength of load-bearing structures of special self-propelled rolling stock. Sci Rep 14, 19205 (2024). https://doi.org/10.1038/s41598-024-70169-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-70169-0

Keywords

This article is cited by

-

Experimental study on fatigue behavior of casting beams in railway applications

Journal of Infrastructure Preservation and Resilience (2025)