Abstract

The present study evaluates the amelioration of fat clay by blending it with cohesive non-swelling soil (CNS) and cohesionless silty sandy soil (Kassu). The fat clay sample with a liquid limit (LL) of 50 and a plasticity index (PI) of 26 was collected from Narowal, while CNS and Kassu samples were procured from Lahore's outskirts. Geotechnical tests on the virgin soil indicated its unsuitability for construction. Laboratory tests, including modified Proctor compaction, unconfined compression, California bearing ratio (CBR), and one-dimensional consolidation, were performed on samples blended with 0–35% CNS or Kassu in 5% intervals. The LL and PI of fat clay decreased significantly with the addition of 35% CNS (LL: 50–32%, PI: 24 to 13) and Kassu (LL: 50–29%, PI: 24–12). The CBR value increased from 4 to 7%, making the blended soil suitable for subgrade use. Unconfined compression tests showed a strength increase from 102 to 185 kPa with 35% CNS and up to 140 kPa with 25% Kassu. Compaction tests revealed improved maximum dry unit weight and reduced optimum moisture content. Swell potential decreased from 4 to 1.2 and 0.26% with CNS and Kassu additions. Regression models predict swell pressure and ultimate swell potential. The study concludes that blending fat clay with CNS and Kassu significantly improves its geotechnical properties, with CNS being more effective in controlling swell characteristics.

Similar content being viewed by others

Introduction

Failure of civil engineering structures such as buildings, roads, railway tracks, runways, walkways, embankments, and canal linings have been reported owing to volumetric expansion and shrinkage upon drying and wetting, respectively, for fat clays1,2,3,4.Consequently, billions of dollars are lost throughout the world annually e.g., only in the United States an economic loss of about 9 billion USD per annum has been reported5. Similar damages to structures constructed on fat clays have also been reported in Pakistan; for instance, significant infrastructural loss at Shah Abdul Latif University, Khairpur and Gomal University, Dera Ismail Khan was documented by Farooq6. Fat clays are present at various locations of Pakistan including but not limited to Dera Ghazi khan, Dera Ismail Khan, Sialkot, Narowal and Gujranwala7,8. The use of such fat clays without stabilization as embankment material leads to failure9. Sylvestre et al. reported that various man-made structures have experienced considerable damage due to up-heave from water absorbed by fat clays10. Heave depends on the climatic condition, moisture content at the time of construction, classification and mineralogical composition of subgrade soil and overburden pressure at the foundation level11,12.

Various methods to counteract/ reduce the heave include chemical stabilization13,14,15,16,17, compaction control18,19,20, mixing with sand21, bio-cementation and bio-chemical treatment22,23,24, soil replacement25, applying additional overburden pressure26, chemical modification with various additives27,28,29,30, and inclusion of geosynthetics31. Notable improvements in engineering characteristics of fat clays are reported using various cementitious stabilizers such as cement and lime32. Blending various wastes including sediments, fly ash, ground granulated blast furnace slag, granite waste powder and powdered glass with virgin soils proved to be an effective technique to reduce their toxicity and improve the strength characteristics of fat clays33,34,35,36.

However, all these stabilizers require special processing for production, and often use of such materials escalates the construction cost. Therefore, it is desirable to use locally available cheap natural materials that do not require any processing for manufacturing. Though some work has been done on the stabilization of fat clay by mixing sandy soils, however, limited data is available regarding the use of cohesive non-swelling (CNS) soil for the stabilization of fat clays. Different researchers mixed CNS with fat clays for stabilizing them37,38,39 and some have used CNS cushions for mitigating swelling problems40,41. Yao et al.37 used CNS to inhibit the effect of fat clay and concluded that the electrical environment and additional surcharge of the CNS layer counter the swelling characteristics of underneath clay. Kandhunuri and Rajasekhar38 investigated the blending of expansive clay with CNS and concluded that consistency limit reduced, swell potential and swell pressure decreased with an increase in CNS content.

Stabilization of expansive or fat clay soils using sandy materials has been investigated by several researchers as an effective method to improve soil properties like adding sand to expansive clayey soils has been shown to reduce swelling potential and improve consistency limits. Studies have examined the effects of different sand contents (10–70%) and grain sizes on the swelling behavior and consistency limits of bentonite clay40.The addition of sand can reduce the maximum dry density but increase the California Bearing Ratio (CBR) of fat clays. Researchers have tested blends with 10–20% sand content along with other additives like cement to stabilize fat clay for subgrade applications41.

Fly ash has also been used in combination with sand to stabilize expansive soils. Studies show that increasing fly ash content reduces maximum dry density and increases optimum moisture content when stabilizing sandy soils42. Deep soil mixing techniques using additives like vermiculite and asphalt emulsion have been applied to stabilize fat clayey soils, with the aim of reducing plasticity index and improving strength43.

On the other hand, the poor performance of CNS materials in the improvement of fat clays as a cushion to reduce swelling potential or improve performance of canals in expansive soils has also been documented by various researchers44,45,46. Meanwhile, the performance of some soils that do not meet the criteria of CNS material was observed to be adequate in mitigating fat clays47,48.

A novel study in this area could make significant contributions by systematically investigating the effects of sand content, gradation, and mineralogy on the engineering properties of various fat clayey soils. Developing predictive models for optimizing sand-clay mixtures based on soil properties and target performance criteria would be highly beneficial for practical applications. Additionally, assessing the engineering performance of sand stabilization compared to chemical stabilization methods would contribute to more sustainable geotechnical practices. Such a comprehensive study would provide valuable insights for geotechnical engineers in designing more effective and sustainable stabilization solutions for fat clays using locally available sandy materials, addressing current knowledge gaps and advancing the field of soil stabilization.

Thus, a proper investigation is required before using any local CNS for the improvement of fat clays. Moreover, in some regions, the soils do not meet the criteria of CNS as per Katti et al.48 criteria, however, they could be a promising candidate for mitigating the swelling behavior of clays. Therefore, the investigation must be advanced to evaluate the efficacy of other locally available soils in ameliorating fat clays. This research is mainly focused to evaluate the comparative effectiveness of using CNS and cohesionless soil (locally termed as Kassu) to mitigate sudden disasters due to fat clays. The major objectives of this study include improvement in geotechnical properties including swell and consolidation characteristics, unconfined compression strength and CBR of fat clays blended with CNS or Kassu. The findings of this research will be highly useful and applicable for the amelioration of fat clays to be used as a foundation as well as road subgrade material.

This research article is organized as follows: Introduction section outlines the background, significance, and objectives of the study. Methods and Materials section details the procedures and techniques used for sample preparation and testing. Results and Discussion section presents and analyzes the findings of the tests conducted. In the regression models section to predict Swell Potential and Swell Pressure, predictive models based on the experimental data have been proposed and validated. Finally, the Conclusion section summarizes the key findings, implications, and potential areas for future research.

Materials and methods

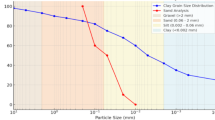

The swelling clay used in this research work was procured from the vicinity of Narowal city, Punjab Province, Pakistan. Undisturbed and representative disturbed samples were collected at a depth of 1–1.5 m and carefully transported to the geotechnical engineering laboratory at University of Engineering & Technology, Lahore. A cohesive non-swelling (CNS) and cohesionless soil (Kassu) samples were collected from the outskirts of Lahore city-Pakistan (Fig. 1). Physical properties of the swelling clay, CNS and Kassu samples are given in Table 1. Grain size distribution curves of the virgin soil, CNS and Kassu soil samples are also given in Fig. 2. The swelling clay sample is classified as fat clay (CH) according to the unified soil classification system (USCS) and A-7-6 as per the American Association of State Highway and Transportation Officials (AASHTO) while the CNS is classified as lean clay (CL) and A-6 as per USCS and AASHTO classification, respectively. Kassu sample is classified as non-plastic silt (ML) and A-4 as per respective classification systems. Based on the test results carried out on the swelling clay sample, it can be concluded that it cannot be used as a suitable subgrade material in road or foundation construction. The swelling clay was blended with CNS and Kassu in varying proportions ranging between 0 and 35% at an interval of 5% to constitute the composite samples. Following tests were performed on the compoite samples following relevant ASTM procedures, like particle size analysis (ASTM D-6913)49, consistency limit tests (ASTM D-4318)50, specific gravity test (ASTM D-854)51.

For the Modified Proctor Compaction Test (ASTM D-1557)52, disturbed soil samples were air-dried, pulverized, and sieved through a No. 4 sieve. The soil was then mixed with water to various moisture contents, homogenized, and compacted in five layers using a 4.54 kg rammer dropped from a height of 457 mm. For the Unconfined Compression Test (ASTM D-2166)53, the soil was similarly air-dried, pulverized, and sieved through a No. 4 sieve. The soil was mixed with water, placed in cylindrical molds, compacted, extruded, and cured for one day at room temperature. In the California Bearing Ratio (CBR) test (ASTM D-1883)54, the air-dried and pulverized soil was sieved, mixed with optimum moisture content, compacted into CBR moulds, and CBR moulds were soaked in water for 96 hours before testing. For the One-Dimensional Consolidation Test (ASTM D-2435)55, the soil was air-dried, pulverized, mixed with water, and compacted into consolidation rings. The samples were then saturated with distilled water for 24 hours before testing. These procedures ensured that the samples were prepared consistently and in accordance with ASTM standards (Fig. 2).

Test results and discussion

Classification tests, modified Proctor compaction test and California bearing ratio, unconfined compression, swell potential and swell pressure and consolidation tests were performed on all the virgin as well as composite samples. The results of the various laboratory tests have been discussed in the following sub-sections:

Consistency limit test results

Variation in the liquid limit (LL) and plasticity index (PI) of swelling clay with CNS soil and Kassu is shown in Fig. 3. LL and PI of swelling clay blended with 35% CNS is reduced from 50 to 32% and 24 to 13, respectively. Classification of the sample changed from fat clay (CH) to lean clay (CL) as per USCS classification with the addition of 35% CNS. Reduction in LL and PI is attributed to low values of consistency limits of CNS soil. The blending of Kassu with swelling clay reduces LL value to 29% and PI value to 12. This reduction in consistency limits is attributed to the non-plastic nature of Kassu.

The reduction in Liquid Limit (LL) and Plasticity Index (PI) of treated swelling clay with cohesive non-swelling (CNS) soil, despite of its high fine-grain content (57% silt and 32% clay), is due to the inherent properties of CNS soil. The fine-grained particles in CNS soil fill the voids present in the swelling clay, leading to a denser and more stable soil structure. This reduces the water absorption capacity and plasticity of the swell clay, thereby lowering its LL and PI. Additionally, the silt and clay particles in CNS soil provide a more cohesive matrix that limits the expansive behavior of swell clay.

Modified Proctor test results

Modified Proctor compaction method was chosen over the Standard Proctor compaction in this study to determine the Optimum Moisture Content (OMC) and Maximum Dry Unit Weight (MDUW) because it simulates higher compaction energy levels typically encountered in field conditions. This method provides a better representation of the soil behavior under actual construction scenarios, leading to more accurate predictions of its performance. The higher compaction energy of the Modified Proctor test ensures that the soil reaches its maximum density and strength, which is crucial for evaluating the improvement in the geotechnical properties of swelling clay when treated with different additives.

Modified Proctor tests were carried out on virgin as well as on the blended samples and compaction curves of CNS blended samples are presented in Fig. 4a while compaction curves of Kassu treated samples are presented in Fig. 4b. The compaction curves revealed that the maximum dry unit weight of CNS-treated swelling soil is improved from 17.4 to 18.0 kN/m3 when 0–35% CNS is mixed with it and OMC is reduced from 13.8 to 13%. The maximum dry unit weight of swelling soil treated with Kassu is improved from 17.4 to 18.1 kN/m3 with the addition of 35% Kassu; meanwhile, the decrease in OMC is observed to be about 1.1%. There is a subtle increase of about 3.3–4.0% in maximum dry unit weight and decrease of 0.06–0.08% in OMCof these blended samples. Variations in dry unit weight (DUW) and optimum moisture content (OMC) when fat clay mixed with 35% CNS are shown in Fig. 4c(i) while variation of DUW and OMC of fat clay mixed with 35% kassu are shown in Fig. 4c(ii).

The improvement in the compaction characteristics of swell clay, indicated by increased MDUW and reduced OMC, when blended with CNS and Kassu soils, can be attributed to the finer particles filling the voids between the swelling clay particles. This leads to a denser soil structure with lower void ratios. CNS and Kassu soils, with their specific particle size distribution and plasticity properties, enhance the packing of the soil grains, resulting in higher dry densities. Additionally, the reduced OMC is due to the improved moisture retention and distribution within the soil matrix, which facilitates better compaction at lower moisture levels.

California bearing ratio (CBR) test results

Three point CBR tests following ASTM D-1883 standard were performed on virgin and composites samples. The test requires that three specimens of one sample are compacted in five layers by applying 10blows/layer, 30 blows/layer and 65 blows/layer at optimum moisture content obtained through modified Proctor test and then soaked in water for 96 h. Dry unit weight and CBR values thus obtained are plotted and CBR against maximum dry unit weight obtained through modified Proctor test (56 blows/ layer in five layers) is determined from the curve plotted from the results of three point CBR test. Figure 5a presents a typical three point CBR curve plotted between dry unit weight and CBR values for a sample blnded with 30% CNS. The CBR value of 7% at maximum dry unit weight is determined from Fig. 5a. Similarly, dry unit weight versus CBR curves are plotted for all the samples and CBR value corresponding to modified Proctor dry unit weight are determined. The variation of CBR with percentage of different additives mixed with swelling clay is presented in Fig. 5b. The CBR of the virgin sample is 4%indicating that it is not a suitable subgrade/embankment material as per NHA which requires a minimum CBR of 7%. With the addition of 30% CNS, the CBR value is increased to 7% and the blended sample meets the requirement of suitable subgrade material (CBR = 7) as per National Highway Authority (NHA) specifications 56. Also, CBR of the sample blended with 25% Kassu is 7%, which also fulfills the suitable subgrade criteria as per NHA specifications. It can be inferred that swelling clay can be used as a road subgrade material provided it is blended with at least 30% of CNS or 25% Kassu as an optimum dosage.

The increase in California Bearing Ratio (CBR) values for the blended samples is a direct result of the improved compaction and reduced plasticity of the swelling clay when mixed with CNS and Kassu soils. The addition of these soils enhances the load-bearing capacity by creating a more stable and dense soil structure. The fine particles in CNS and Kassu soils fill the voids within the swelling clay, reducing its expansion potential and increasing its resistance to deformation under load. This results in higher CBR values, indicating improved strength and stability of the treated soil.

Unconfined compression test results

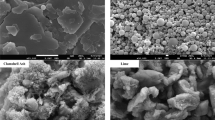

Unconfined compression tests were performed on blended samples compacted at maximum dry unit weight obtained through a modified Proctor test and are reported in Fig. 6a and b. The unconfined compression strength (UCS) value increased from 102 to 185 kPa with the addition of 35% CNS soil as shown in Fig. 6c. The rate of increase of strength is about 24.5% with the addition of 0–20% CNS, while the rate of increase of strength is about 45.6% with the addition of CNS from 20–35%. However, in the case of Kassu-treated soil, the UCS value increases up to 140 kPa with the addition of 25% Kassu as presented in Fig. 6c. With further increase in Kassu %, the value of UCS decreases indicating the excess amount of non-plastic material resulting in the decrease in strength of the samples due to a decrease in cohesion. Figure 6d shows the cracks patrens in results of USC tests of fat clay, CNS, and kassu soil samples.

(a) Unconfined compression strength versus swelling clay with CNS (0–35%) (b) Unconfined compression strength versus swelling clay with kassu (0–35%) (c) Unconfined compression strength versus %age of additive (0–35%) (d) Visualization of cracks patterns after unconfined compression strength tests (a) fat clay; (b) CNS; and (c) Kassu soil.

There is an increase in Unconfined Compressive Strength (UCS) of virgin clay blended with 35% CNS soil, which signifies an increase in the undrained shear strength of the swelling clay. This behaviour is attributed to enhanced inter-particle bonding and reduced water absorption. The fine particles in CNS soil create a denser and more cohesive soil matrix, which improves overall stability and strength of the soil sample. Similarly, for Kassu-treated samples, the presence of silt and clay particles contributes to a denser packing of soil grains, reducing the expansive behavior and increasing the soil's ability to withstand higher compressive loads. The improved compaction and reduced plasticity of the treated soil result in higher UCS values, indicating enhanced mechanical properties.

The failure patterns indicate significant differences between the virgin clay and the treated samples. In untreated swelling clay, the failure is typically more brittle with prominent, wide cracks forming at steep angles, indicating higher expansiveness and lower shear strength. Upon blending with CNS and Kassu, the treated samples exhibit a denser and more cohesive structure, resulting in narrower and more evenly distributed cracks. This change in failure pattern reflects an improvement in the structural integrity and shear strength of the swell clay due to the amelioration.

Swell potential and swell pressure test results

Swell test was carried out on undisturbed and remolded soil samples compacted at moisture content and dry unit weight equal to undisturbed soil sample. A seating pressure of 6.9 kPa is applied and the sample is saturated.Time-swell curves for swelling clay treated with CNS soil and Kassu are presented in Fig. 7a and b, respectively. The swell potential of 4.11% and swell pressure of 96.6kPa are recorded for the virgin clay sample. To calculate the swell potential of the virgin clay, we first measure the initial height (Hi) of the sample, which is 20 mm. After soaking, the final height (Hf) of the sample is 20.82 mm. The increase in height (ΔH) is thus 0.82 mm. Using the formula for swell potential (SP), which is given by Eq. 1, we substitute the measured values: ( 20.82 mm − 20 mm ) / 20 mm × 100 (20.82 mm − 20 mm)/20 mm × 100. Simplifying this expression, we find that ( 0.82 mm ) / 20 mm × 100 = 4.1%. Therefore, the swell potential of the virgin clay is 4.1%.

The swell potential is reduced to 0.26% and1.16% with the addition of 35% CNS and Kassu, respectively, which is less than the limit of 2% as set forth by the U.S. Department of Housing and Urban Development (HUD, 1971) specifications 57. Swell pressure is reduced to 9.5 kPa in the case of 35% CNS blended sample while it is reduced to 36 kPa in the case of 35% Kassu blending. The variations of swell potential and swell pressure with the addition of both the additives are presented in Figs. 8 and 9, respectively. It can be inferred from Fig. 8 that for the same percentage of CNS and Kassu addition, reduction in swell potential is more incase of CNS addition. More effectiveness of CNS than Kassu is attributed to the enhanced cohesion between CNS and swelling clay particles as CNS contains clay particles having cohesive forces which are absent in Kassu as it is cohesion less soil. More specifically, it can be inferred from Fig. 8 that swell potential reduced from 4.11% to 1%, 25% CNS is required to be mixed with expansive soil but for the same reduction in swell potential the quantity of Kassu required to be mixed with expansive clay is more than 35%. Similarly, swell pressure of expansive clay is effectively reduced from 96.6 kPa to 9.5 kPa when mixed with 0–35% of CNS and for Kassu it is reduced to 36 kPa.

Consolidation test results

One dimensional consolidation test results revealed an inverse relation between compression index (Cc) and percentage of additive. The variation of Cc with the percentage of additives is given in Fig. 10. Both the additives are effective in reducing the value of Cc, however, reduction in Cc is more prominent in the case of Kassu as compared to CNS. The probable reason of higher reduction in Cc value in case of Kassu treated samples may be attibuted to higher resistance to deformation as compared to CNS treated samples. The e-log p curves of consolidation test results are shown in Fig. 11 (a and b) when fat clay treated with different percentages of Kassu and CNS.

Regression Models to predict Swell Potential and Swell Pressure

Relation between swell potential and swell pressure

The regression analysis has been carried out on the test data between swell potential and swell pressure and a correlation has been proposed between swell potential and swell pressure and is presented in Fig. 12. The correlation coefficient of 0.95 indicates that 95% of the values of the dataset can be predicted using the proposed correlation given in Eq. (2). The Eq. (2) may be effectively used to estimate the swell pressure from the swell potential value determined by swell test.

Prediction of ultimate swell potential from swell vs time data

Swell~time histories of swelling clay treated with CNS and Kassu plotted in Fig. 7(a and b) are in the form of non-linear curves. These curves may be transformed into almost perfect linear lines by dividing the time by percent swell and ploting the data of time/percent swell vs time.The relationship between time/percent swell (t/s) and time (t) of all the samples is presented in Figs. 13 and 14. An almost perfect liner relationship is obtained for all cases, justifying that the shape of the time~percent swell curve can be treated as a rectangular hyperbola and can be written as in Eq. (3).

where t is time, s is percent swell, a and b are Y-intercept and slope of the straight line, respectively. Looking at Figs. 13 and 14, the Y-intercept may be taken as zero, so the Eq. (3) reduces to 1⁄s=b, where 1/b may be taken as the ultimate percent swell (Sult)and finally may be written by Eq. (4)

where Sult is the ultimate percent swell and b is the slope of the straight line plotted between time/percent swell (t/s) and time (t) data of a swell test provided the Y-intercept is zero. Therefore, by taking the reciprocal of the slope of the straight lines in Figs. 13 and 14, the ultimate percent swell can be predicted using the relation given by Eq. (4). This relationship is very useful and one can predict the ultimate percent swell even from a partial/incomplete swell test data as the slope of the line is constant. By applying Eq. (3) and Eq. (4), the ultimate percent swell (Sult) has been determined from all the cases plotted in Figs. 13 and 14 and compared with experimently measured ultimate percent swell values. The measured and predicted ultimate percent swell (Sult) for CNS and Kassu-treated soils are given in Fig. 15. It can be inferred from Fig. 15 that a good agreement exists between measured and predicted ultimate percent swell values.

Field implication of prediction models

Predictive models between swell potential ~ swell pressure and ultimate swell potential have been presented by Eq. (2) and Eq. (4). These empirical models may be used to predict the behaviour of swelling soils. However, caution is needed when using these relations or prdicted values may be chcked by performing few tests in the laboratory

Conclusions

The current study has been carried out to study the effect of additives, i.e., CNS and Kassu on engineering characteristics of swelling clays. Classification and quality assessment tests were performed on swelling clay blended with CNS and Kassu. On the basis of the study, following conclusions have been drawn:

-

i.

The consistency limit tests revealed a significant reduction in the Liquid Limit (LL) and Plasticity Index (PI) of swelling clay when blended with CNS soil and Kassu. Specifically, blending 35% CNS reduced the LL from 50 to 32% and the PI from 24 to 13, changing the soil classification from fat clay (CH) to lean clay (CL) according to USCS standards. Similarly, the addition of Kassu soil reduced the LL to 29% and the PI to 12. These reductions are attributed to the fine-grained particles in CNS soil filling the voids in the swell clay, reducing water absorption and plasticity, and to the non-plastic nature of Kassu.

-

ii.

Modified Proctor compaction tests showed that the maximum dry unit weight (MDUW) and optimum moisture content (OMC) of both CNS and Kassu-treated swell clay improved. For CNS-treated soil, the MDUW increased from 17.4 kN/m3 to 18.0 kN/m3, with a decrease in OMC from 13.8 to 13%. Similarly, Kassu-treated soil showed an increase in MDUW from 17.4 kN/m3 to 18.1 kN/m3, with a 1.1% decrease in OMC. These improvements are due to the fine particles enhancing soil compaction and reducing void ratios.

-

iii.

The California Bearing Ratio (CBR) tests indicated that the virgin sample has CBR value of 4% and is unsuitable as subgrade material as per NHA specifications. However, blending 30% CNS increased the CBR value to 7%, meeting the NHA criteria for suitable subgrade material. Similarly, blending 25% Kassu achieved a CBR value of 7%, also meeting NHA standards. The improved CBR values result from the enhanced load-bearing capacity and reduced expansion potential of the treated soils.

-

iv.

The Unconfined Compression Strength (UCS) test results showed a significant increase in strength for both CNS and Kassu-treated soils. The UCS value increased from 102 to 185 kPa with the addition of 35% CNS soil, with strength increasing by about 24.5% for 0% to 20% CNS addition and about 45.6% for 20% to 35% CNS addition. In the case of Kassu-treated soil, the UCS value increased up to 140 kPa with 25% Kassu addition, with further increases reducing UCS due to decreased cohesion from excess non-plastic material. These increased UCS values indicate enhanced undrained shear strength and overall mechanical properties of the treated soils.

-

v.

Swell tests demonstrated that the swell potential of virgin clay was reduced from 4.11 to 0.26% with 35% CNS and to 1.16% with Kassu, meeting HUD specifications of less than 2%. The swell pressure decreased from 96.6 kPa to 9.5 kPa with 35% CNS and to 36 kPa with 35% Kassu. CNS was more effective in reducing swell potential due to enhanced cohesion between CNS and clay particles. For a similar reduction in swell potential, 25% CNS was required compared to more than 35% Kassu.

-

vi.

One-dimensional consolidation test results revealed an inverse relationship between the compression index (Cc) and the percentage of additive. Kassu-treated samples exhibited a more pronounced reduction in Cc compared to CNS-treated samples, attributed to higher resistance to deformation in Kassu-treated samples.

-

vii.

Regression analysis established a strong correlation (coefficient of 0.95) between swell potential and swell pressure, resulting in the equation: Swell Pressure (kPa) = 24.5 × Swell Potential (%). This equation can be used to predict swell pressure from swell potential.

-

viii.

Swell-time curves were transformed into linear relationships for predicting ultimate swell potential. The relationship is given by the equation: Sult = 1/b, where Sult is the ultimate swell potential and b is the slope of the linear swell-time curve. This method allows for the prediction of ultimate swell potential from partial swell test data.

-

ix.

Finally, predictive models for swell potential and swell pressure, as well as ultimate swell potential, were developed. These models can be used to estimate the behavior of swelling soils, though caution is advised and predicted values should be validated with laboratory tests.

Data availability

The experimental data used to support the findings of this study is included within the article.

References

Jain, A., Choudhary, A. & Jha, J. Influence of rice husk ash on the swelling and strength characteristics of expansive soil. Geotech. Geol. Eng. https://doi.org/10.1007/s10706-019-01087-6 (2020).

Singh, M., Trivedi, A. & Shukla, S. Strength Enhancement of the Subgrade Soil of Unpaved Road with Geosynthetic Reinforcement Layers. Transp. Geotech. https://doi.org/10.1016/j.trgeo.2019.01.007 (2019).

Mokhtari, M. & Dehghani, M. Swell-shrink behavior of expansive soils, damage and control. Electron. J. Geotech. Eng. 17, 2673–2682 (2012).

Mowafy, Y. M., Bauer, G. E. & Sakeb, F. H. Treatment of Expansive Soils: A Laboratory Study. (1985).

Steinberg, M. Geomembranes and the Control of Expansive Soils in Construction. (1998).

Israr, J., Farooq, K. & Mujtaba, H. Modelling of swelling parameters and associated characteristics based on index properties of expansive soils. Pakistan Journal of Engineering and Applied Sciences (2014).

Nawaz, M., Aziz, M. & Israr, J. Orientation of deposition planes and shear strength of typical clays from Pakistan. Iran. J. Sci. Technol. Trans. Civ. Eng. 44, 931–939. https://doi.org/10.1007/s40996-019-00267-x (2020).

Rashid, I. Characterization and mapping of expansive soils of Punjab (University of Engineering and Technology, 2015).

Puppala, A. J. & Pedarla, A. Innovative ground improvement techniques for expansive soils. Innov. Infrastruct. Solut. 2, 1–15. https://doi.org/10.1007/s41062-017-0079-2 (2017).

Sylvestre, O., Bilodeau, J.-P. & Doré, G. Effect of frost heave on long-term roughness deterioration of flexible pavement structures. Int. J. Pavement Eng. 20, 704–713. https://doi.org/10.1080/10298436.2017.132659 (2019).

Damian, G., Lanzerstorfer, C., Damian, F. & Iepure, G. Distribution of heavy metals and minerals in the various size fractions of soil from CopșaMică România. Water, Air, Soil Pollut. 229, 1–14. https://doi.org/10.1007/s11270-018-3862-6 (2018).

Hu, K., Chen, X., Chen, J. & Ren, X. Laboratory investigation of the effect of nano-silica on unconfined compressive strength and frost heaving characteristics of silty clay. Soil Mech. Found. Eng. 55, 352–357. https://doi.org/10.1007/s11204-018-9548-7 (2018).

Tiwari, N. & Satyam, N. An experimental study on the behavior of lime and silica fume treated coir geotextile reinforced expansive soil subgrade. Eng. Sci. Technol. Int. J. 23, 1214–1222 (2020).

Moayedi, H. & Nazir, R. Malaysian experiences of peat stabilization, state of the art. Geotech. Geol. Eng. 36, 1–11 (2018).

Tataranni, P. et al. A laboratory and field study on 100% Recycled Cement Bound Mixture for base layers. Int. J. Pavement Res. Technol. 11, 427–434 (2018).

Zhang, M. et al. Calcium-free geopolymer as a stabilizer for sulfate-rich soils. Appl. Clay Sci. 108, 199–207 (2015).

Qureshi, H. M. (2006) Chemical stabilization of expansive soil, M.Sc Thesis, Civil Engineering Department, University of Engineering and Technology, Lahore, Pakistan (2006)

Rashid, I., Farooq, K., Mujtaba, H. & Khan, A. H. Treatmentofexpansive clays through compaction control. Pakistan J. Sci. 65, 103 (2013).

Farooq, k. and Mujtaba, H. Mitigation of Swelling Characteristics of Expansive Clay by Controlling Initial Placement Condition, Proceedings 14thAsian Regional Conference, Hong Kong, China. 348–353, (2011).

Rojas, E., Romo, M. P. & Cervantes, R. Analysis of deep moisture barriers in expansive soils I: Constitutive model formulation. Int. J. Geomech. 6, 311–318 (2006).

Farooq, K. & Virk, K. A. Improvement of engineering characteristics of expansive clays by sand mixing. in Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering (Volumes 1, 2, 3 and 4) 785–788 https://doi.org/10.3233/978-1-60750-031-5-785(IOS Press, 2009).

Sharma, M., Satyam, N. & Reddy, K. R. Investigation of various gram-positive bacteria for MICP in Narmada Sand India. Int. J. Geotech. Eng. 15, 220–234 (2021).

Ikeagwuani, C. C. & Nwonu, D. C. Emerging trends in expansive soil stabilisation: A review. J. Rock Mech. Geotech. Eng. 11, 423–440 (2019).

Liu, Y. et al. Utilization of cementitious material from residual rice husk ash and lime in stabilization of expansive soil. Adv. Civ. Eng. 2019(1), 5205276 (2019).

Chen, F. H. Foundations on Expansive Soils (Elsevier, Amsterdam, 2012).

Chen, Y.-G., Zhu, C.-M., Ye, W.-M., Cui, Y.-J. & Wang, Q. Swelling pressure and hydraulic conductivity of compacted GMZ01 bentonite under salinization–desalinization cycle conditions. Appl. Clay Sci. 114, 454–460 (2015).

Guda, S. Efficacy of cement-stabilized GBS and GGBS cushions in improving the performance of expansive soils. Jordan Journal of Civil Engineering, 10, (2016).

Murty, V. R. & Praveen, G. V. Use of chemically stabilized soil as cushion material below light weight structures founded on expansive soils. J. Mater. Civ. Eng. 20, 392–400. https://doi.org/10.1061/(ASCE)0899-1561 (2008).

Puppala, A. J., Wattanasanticharoen, E. & Hoyos, L. R. Ranking of four chemical and mechanical stabilization methods to treat low-volume road subgrades in Texas. Transp. Res. Rec. 1819, 63–71 (2003).

Cokca, E. Use of class c fly ashes for the stabilizationof an expansive soil. J. Geotech. Geoenviro. Eng. 127, 568–573 (2001).

Camargo, F. F., Edil, T. B. & Benson, C. H. Strength and stiffness of recycled materials stabilised with fly ash: a laboratory study. Road Mater. Pavement Des. 14, 504–517 (2013).

Yin, J. & Lai, C. K. Strength and stiffness of Hong Kong marine deposits mixed with cement. Geotech. Eng. 29, 29–44 (1998).

Mujtaba, H., Aziz, T., Farooq, K., Sivakugan, N. & Das, B. M. Improvement in engineering properties of expansive soils using ground granulated blast furnace slag. J. Geol. Soc. India 92, 357–362. https://doi.org/10.1007/s12594-018-1019-2 (2018).

Mujtaba, H. et al. Sustainable utilization of powdered glass to improve the mechanical behavior of fat clay. KSCE J. Civ. Eng. 24, 3628–3639. https://doi.org/10.1007/s12205-020-0159-2 (2020).

Ullah, I. et al. Integrated recycling of geopolymerized quarry dust and bagasse ash with facemasks for the balanced amelioration of the fat clay: A multi-waste solution. Environ. Earth Sci. 82, 516. https://doi.org/10.1007/s12665-023-11219-0 (2023).

Shah, S. H. A. et al. Laboratory and in situ stabilization of compacted clay through granite waste powder. Sustainability 14, 14459 (2022).

Yao, H. et al. Inhibition effect of swelling characteristics of expansive soil using cohesive non-swelling soil layer under unidirectional seepage. J. Rock Mech. Geotechn. Eng. 12, 188–196 (2020).

Kandhunuri, S. & Rajasekhar, P. Investigation on soil-mixtures comprising of expansive soils mixed with a cohesive non-swelling soil. Int. J. Mag. Eng. Technol. Manag. Res. 2(12), 604–611 (2015).

Rani, C. S. & Suresh, G. Plasticity and compaction characteristics of soil mixtures comprising of expansive soils and a cohesive non-swelling soil. Int. J. Eng. Res. Appl. 3, 1519–1527 (2013).

Louafi, B. & Bahar, R. SAND: An additive for stabilzation of swelling clay soils. Int. J. Geosci. 3(4), 719–725. https://doi.org/10.4236/ijg.2012.34072 (2012).

Alayaki, F. M., Al-Tabbaa, A. & Ayotamuno, M. J. Stabilisation of Niger delta fat clay with blend of binders for subgrade application-part 1. Nigerian J. Technol. 36(3), 740–748 (2017).

Mahvash, S., López-Querol, S. & Bahadori-Jahromi, A. Effect of class F fly ash on fine sand compaction through soil stabilization. Heliyon 3, e00274 (2017).

Amarta, A. G., and A. K. Somantri. "Stabilization to Plasticity Index by Deep Soil Mixing Using Vermiculite and Asphalt Emulsion." International Seminar of Science and Applied Technology (ISSAT 2020). Atlantis Press, 2020.

Nagarkar, P. K. Apshankar, S. G. Kulkarni, M. V. Kulkarni, D. J. Performance of canals in expansive soils. Proceedings of the 6th international conference on expansive soils. CRC Press, 371–5 (1987).

Subba Rao, K. S., Sivapullaiah, P. V. & Gurumurthy, J. V. An appraisal of CNS material as a cushion to reduce swelling potential. in Proc., IGC 57–60 (1994).

Sahoo, J., Pradhan, P. & Rao, K. Behavior of stabilized soil cushions under cyclic wetting and drying. Int. J. Geotech. Eng. 2, 89–102 (2008).

Katti, R. K. Search for solutions to problems in black cotton soils. Indian Geotech. J. 9(1), 1–80 (1979).

Katti, R. K. Katti, D. R. & Katti, A. R. Behavior of saturated expansive soil and control methods (Taylor & Francis, 2002).

ASTM D6913: Standard test methods for particle-size distribution (gradation) of soils using sieve Analysis. ASTM International, West Conshohocken, PA. (2017)

ASTM D4318: Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International, West Conshohocken, PA (2017)

ASTM D854: Standard Test Methods for Specific Gravity of Soils. ASTM International, West Conshohocken, PA (2017)

ASTM D1557: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using. ASTM International, ASTM Internation, West Conshohocken, PA (2021)

ASTM D2166: Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International, West Conshohocken, PA (2016)

ASTM D1883: Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International, West Conshohocken, PA (2021)

ASTM D2435: Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading. ASTM International, West Conshohocken, PA (2021)

National Highway Authority (NHA), General Specification, Government of Pakistan. 109–2 (1998). https://seismicconsolidation.com/wp-content/uploads/2020/03/nha-general-specification-e-35-volum-ii.pdf

Day, R.W. (2006) Foundation Engineering Handbook: Design and Construction with the 2006 International Building Code. McGraw Hill, Singapore p.9.3

Acknowledgements

The authors highly acknowledge the support of Department of Civil Engineering, University of Engineering and Technology, Lahore, Pakistan for providing laboratory facilities, library access and research environment to accomplish the study. Also, this study is partially funded/ supported by Future University, Egypt (FUE).

Author information

Authors and Affiliations

Contributions

K.F. contributed for “Conceptualization, formulating methodology and top supervision of the entire study”. H.M. carried out “formal analysis and writing-original draft preparation. S.Z.A. contributed to writing—review and editing. M.M.S. provided his input for investigation and data analyses. A.M. carried out final review, editing and visualization.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Farooq, K., Mujtaba, H., Ashiq, S.Z. et al. Amelioration of fat clay treated with CNS and cohesionless soils. Sci Rep 14, 20097 (2024). https://doi.org/10.1038/s41598-024-70444-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-70444-0