Abstract

To solve the problem of controlling mining in the open-pit mine end slope fire-burned area, applying multivariate function fitting to the roof and floor modeling of multi-coal seam open pit mines, introducing the factor of coal quality changes in the fire-burned area, determining coal quality information at each location through proximate analysis of coal, to establish the net profit model of the mining area, it is determined the net profit of each mining position by numerical integration, the final mining position was determined without failure by calculating the slope stability based on the numerical simulation of strength reduction. Taking the Dananhu No. 2 open-pit mine in Hami, Xinjiang, China as the engineering background, the fire-burned area III within the southern end slope boundary of the first mining area is 240 m. It was finally determined that the optimal mining position is when the advancement degree is 182 m, the ultimate pit slope angle is 25°, the three-dimensional slope stability is 1.305, the profit is 671.96 million yuan, The deep boundary of the southern end slope fire-burned area of the slope is reduced by 58 m. This paper solves the problem of end slope mining in Dananhu No. 2 mine, and maximizes its net profit under the condition of ensuring safe production.

Similar content being viewed by others

Introduction

There are a large number of fire-burned areas (FBA) distributed in the open-pit mining areas in the northwest of China. Especially in Xinjiang, which has abundant coal resources, the typical steppe climate contributes to dry and shallow coal formation when the temperature reaches a certain degree. This leads to spontaneous combustion of the coal layers, resulting in FBA within a certain regional scope1,2.

The rocks around the FBA undergo pyrolysis under high temperatures, leading to a decrease in mechanical properties3. Coal sheaths at the surface of the coal layers are prone to spontaneous combustion, which results in a decrease in coal quality, lower heat content, and a corresponding decrease in the sale price. Most open-pit mines adopt the strategy of capping and not mining when encountering these FBA, but this will result in a decrease in the recovery rate of coal resources and conflict with the concept of green mining4,5. If the entire coal is extracted, the low-quality coal would have a low sale price, which would indirectly increase the cost of mining and reduce the economic benefits of the mine. Current literature mostly focuses on the study of pyroclastic rocks, such as Yang Fan's investigation into the elemental migration and mineral phase transformation characteristics in the west of the Zhangjiaqiao coal field in the northern Ordos Basin, clarifying the mineral phases and their transformation rules in the process of thermal metamorphism6; Yu Yuanxiang's study on the characteristics of pyroclastic rocks, revealing the unloading mechanism of high slopes and determining the safety width of hydraulic coal-rock columns7; Wang's research on the pyroclastic soil after pyrolysis, determining its mass loss rate and thermal conductivity at high temperatures8. Based on previous research, the article introduces the factors of coal quality and slope stability and proposes a method to solve the problem of controlled mining of coal seams in fire-burned area.

Current status of the first mining area of Dananhu No. 2 Mine

The No. 2 open-pit mine in the west area of the Dananhu Mining Area ofthe CHN Energy Group Shenhua National Energy (herein after referred to as the Dananhu No. 2 Mine) is located in Hami City, Xinjiang, under the jurisdiction of Nanhu Township, Hami City, about 84 km from Hami City and 45 km from Nanhu Township9. Considering the production capacity of its mining process equipment and annual output, the mining area is divided into four mining areas for mining. The first mining area is located in the middle of the mining area and the south is close to the III fire area. The mining period is 44 years10. The current status of the Dananhu No. 2 Mine is shown in Fig. 1, and the relative position map of the first mining area and III fire area of the open-pit mine is shown in Fig. 2.

At present, the first mining area has just reached the stage of starting internal drainage. The main coal seams in the first mining area are the well-developed No. 16, 18, 21, 25, and 29 coal seams. However, the No. 16 and 18 coal seams are exposed in the southern end slope (SES), resulting in Part of the spontaneous combustion area appearing, and the quality of deep coal being affected. If the mining of No. 16 and 18 coal is abandoned, it will lead to the waste of coal 21, 25, and 29 in the SES. If the coal of No. 16 and 18 is mined, it is not sure whether it will produce normal coal, economic benefit value. Faced with this situation, the internal dumping site cannot be close to the stop for continuous follow-up, which has affected daily production. Therefore, it is urgent to study the mining problems in the SES FBA of the first mining area of Dananhu No. 2 Mine.

Build function model

Comparison of deep realms in the first mining area

As shown in Fig. 3, the stripping operation in the first mining area of Dananhu No. 2 Mine has entered the FBA III which has seriously affected the normal production and economic benefits of the open-pit mine. In order to study the optimized mining plan of the FBA, it is first necessary to determine the reasonable mining realm of the FBA and simulate the changes in the deep realm of the first mining area under two extreme mining conditions: the first one is to consider the coal spontaneous combustion caused by 16 and 18 coals. Due to the decline in slope stability caused by the decline in quality and changes in rock mechanical parameters, the mining of the coal resources covered by the FBA III in the SES is abandoned; the second case is to mine according to the preliminary design, and all coals in the SES 16 and 18 are mined to the boundary, the end slopes of both mining methods are designed using the 25° slope foot in the preliminary design. The comparison of changes in the deep realm between the two methods is shown in Fig. 4.

Estimation of coal resources in the study area

According to the two mining plans, the mining software 3dmine was used to estimate the amount of main mining coal seams overlain in the area, as shown in Table 1.

It can be seen from the above table that the SES has covered more than about 50.00Mt of normally mineable coal resources and nearly 10.00Mt of coal resources with different degrees of spontaneous combustion.

Construction of multivariate functions of coal seam roof and floor

From the above analysis, it can be seen that the Abbreviated SES of the first mining area of Dananhu No. 2 Mine has covered a large amount of coal resources, especially for the main mining coal seams in this area. This part of the reserves was caused by spontaneous combustion at the outcrops of the uppermost No. 16 and No. 18 coal seams. The coal quality of the No. 16 and 18 coal seams in this area has declined to varying degrees. The surrounding rocks are affected by the FBA III, resulting in a decrease in mechanical parameters. The mining of the No. 21, 25, and 29 coal seams in the SES of the main coal seam will also be affected by burnt rock. If the SES is mined according to the initially designed slope, it may face two situations: as coal 16 and 18 are mined to the boundary, changes in coal quality will cause an increase in mining costs. Complete mining of 16 and 18 Coal may not be the optimal solution in terms of economic benefits11; excessive mining may lead to an increase in the exposed area of burnt rock, causing the SES to be unstable12,13,14. According to the green mining principle of open-pit mines, how to reasonably mine the coal seam in the SES of the side FBA and recover the underlying main mining coal seam has become a problem that needs to be solved.

When constructing the block model of coal seam and rock, assuming that the relevant mechanical parameters of rock, stratum, coal seam are consistent in trend and tendency, then the external influencing factors become the change of coal quality under the spontaneous combustion of coal seam and the decline of rock-related mechanical parameters affected by burning.

Since the outcrop areas of the 16 and 18 coal seams are affected by the FBA III, resulting in a decline in coal quality, the coal produced after mining will sell for varying degrees lower than the normal price, and coal below 18 is No. 21 coal with better coal quality. For the mining of coal seams in this area, it is not comprehensive to simply use the stripping ratio to measure the mining benefits. Therefore, changes in coal quality of spontaneously igniting coal seams 16, 18 and main mining coal seams with better coal quality 21, 25, 29 are introduced. The economic benefits generated by controlling the mining of coal ≮ the sum of other costs incurred by stripping and transportation15. For the slope location after mining, due to the changes in the properties of the burnt rock, if the initial boundary slope is observed, it will lead to the slope is unstable. Therefore, in the end, the stability of the boundary slope should be the primary goal, and economic benefits should be the secondary goal. The relationship between the boundary mining location, slope stability, and economic benefits should be comprehensively considered and analyzed.

It is planned to construct the net present value function of the main mining coal seams No. 16, 18, 21, 25, and 29, and analyze the most appropriate advance rate by determining the profit of each mining location. Furthermore, adding slopes under the above conditions Stability is a factor that comprehensively considers the optimal location of the coal seam at the SES. In this way, we can achieve the maximum economic benefit of SES mining and the optimal position of deep mining.

The smaller the block size in the model, the higher the accuracy, the larger the storage space required for data, and the slower the computer runs. Normally, the size of the block depends on the type, scale, and mining method of the ore body. Each cuboid with a certain volume is superimposed to form a block model, and the block needs to be divided into smaller sub-blocks at the edge of the well field so that The blocks at the edge of the wellfield are closer to coal seams. Despite this, a certain error still occurs when constraining the edges, which is more obvious when dealing with coal seams with more complex occurrences16.

In view of the stable existence of the main mining coal seam at the SES of the Dananhu No. 2 open-pit mine, this paper plans to use multiple integrations to estimate the amount of coal in the boundary before and after mining. Before that, in order to calculate the reserves at each mining stage, it is necessary to fit the surface and coal seam roof and floor into multivariate functions respectively. The first hexagram of the three-dimensional rectangular coordinate system was constructed on the constructed roof and floor model of the main mining coal seam, and 80 three-dimensional coordinates were extracted for the roof and floor of the coal seam respectively. Considering that part of the surface in the study area has been peeled off, in order to improve the ground surface model Accuracy, 144 three-dimensional coordinates are taken for analysis. The coal seam roof and floor elevation model is shown in Fig. 5.

Import the obtained three-dimensional coordinate point data into Matlab for polynomial fitting. The fitting results of the roof and floor of each coal seam are shown below. In order to ensure that the fitting results can truly reflect the existence of the coal seam as much as possible and avoid over-fitting, polynomial fitting is performed. Choose twice for the highest number of times. Take the 16-coal roof and floor as an example, see Figs. 6 and 7.

The coefficient of determination (R2) represents the proportion of change in the response variable y explained by the independent variable X in the linear regression model. The larger the R2, the greater the variation explained by the linear regression model. To determine whether the above model is successfully constructed, its residuals need to be analyzed. From the above 3D coordinate point residual, we plot the residuals histogram respectively, as shown in Fig. 8.

It can be clearly seen from Fig. 8 above that the roof and floor residual histograms of the coal seam model conform to the normal distribution, and their R2 are 0.9441 and 0.9747 respectively, which are at a very high level. Although there are certain abnormal data, this abnormal data is due to the real endowment of the coal seam. It is caused by the existing conditions, so there is no need to eliminate it. Therefore, it is judged that the model is successfully established.

From this, we can determine that the dependence of the established change pattern of the response function of the roof and floor of the 16 coal seams on the two predictors can be expressed by the following two formulas:

The formula (1) is the change pattern of the response function of the 16 coal seam roof, and its coefficient of determination is R2 = 0.8122. The formula (2) is the change pattern of the response function of the 16 coal seam floor, and its coefficient of determination is R2 = 0.8140, both are at a high level.

Final pit slope fitting surface function:

Current end slope fitting surface function:

The fitting functions of other coal seam roofs and floors can be deduced in the same way and will not be described again.

Based on the actual situation on site and the delineation of the initial boundary, and comprehensively considering the actual construction work and production progress on site, 2D location maps of the SES at the current, the current situation to the boundary end slope, and the preliminary design to the boundary end slope were made, as shown in the Fig. 9 shown.

As shown in the picture, the current situation in 2024, the pink line is the position of the backing in 2024, and the blue line is the position of the slope in the original design. At present, after June, the current status of the stope is the location of the pink line, at this time, we are faced with the difficult question of whether the SES should continue to push southward.

In order to solve the above problems and maximize the economic benefits of SES mining, the factor of coal quality changes in the 16 and 18 coal-burning areas was introduced. The economic benefits were not only measured by the economically reasonable stripping ratio but also by the normal coal quality. As a reference object, by constructing the changes of 16 and 18 coal combustion kcal in the study area, the coal quality in the area is determined, and the coal price at this time is further determined to construct the economic benefit change curve of mining the area17.

The number of drill holes in the study area and the locations of drill holes for subsequent supplementary surveys are selected based on the geological survey as shown in Fig. 10.

In the shallow outcrop area of SES, coal seam samples were taken from different areas of the same coal seam, and coal quality tests were conducted to determine the coal quality indicators of 16 coal and 18 coal.

First, according to "GB/T 482-2008 Coal Seam Coal Sample Collection Method", fresh coal samples were collected from newly exposed coal walls in non-fired areas and non-weathered work areas as standard comparison coal samples. After being sealed on site, they were transported to the ground and sent to the laboratory18. After the coal samples are transported to the laboratory, they are crushed and screened. According to different experimental needs, the coal samples are sealed in ziplock bags of different particle sizes for later use, as shown in Fig. 11.

According to "GB/T 213–2008 Determination of calorific value of coal", the experimental results determine that the high calorific value Qgr,ad of the air drying base of coal seams 16 and 18 of the standard working coal seam is 23.36 MJ/Kg and 24.07 MJ/Kg. Based on the drilling information at the selected location in the SES, the coal quality of the 16th and 18th coal seams were extracted respectively, and five industrial indicators of coal were analyzed. The average value of the three sample tests extracted from each borehole is selected as the high-level calorific value of the air-drying base of the coal in the area, and the change in calorific value at the location shown in the borehole in the area is obtained, as shown in Fig. 12.

Moisture(Mad), ash(Aad), volatile matter(Vad), and fixed carbon(FCad) in coal industry analysis are selected, and four coal quality analysis indicators are used to calculate the calorific value(Qad)19. Through the experimental results, firstly, the drilling data in each area are processed and converted according to the calorific value of the standard coal sample; secondly, the calorific value data of each location in the same interval, such as [0,100], is averaged to represent the location of the area. The average calorific value of the coal seam, and finally the fluctuation changes in coal quality in the study area [0,700] were determined through numerical fitting.

The data of each borehole are converted according to the coal sample data collected by the work team, and finally, the coal quality change curves of study areas 16 and 18 are obtained. Those that exceed the standard are calculated according to 1, and those that do not exceed the standard are calculated according to the standard. This represents the calorific value of the coal seam in the area. The changes in coal quality in each area are shown in Fig. 13.

The calorific value Qad of the drilling data in this area is fitted into a three-dimensional polynomial function curve through data fitting, thereby simulating the coal quality changes in the X-axis direction of the study area. This curve function is shown in Fig. 14.

As can be seen from the above figure, coals 16 and 18 both have spontaneous combustion to a certain extent. Due to the elevation position of coal 16, there are large fluctuations in coal quality along the mining direction, and the coal quality changes between [0.25,1]; 18 As the main mining coal seam below coal 16, coal is also subject to partial spontaneous combustion, but the overall fluctuation is not large, and the coal quality is between [0.9,1].

The fitting surface of the coal seam roof and floor and the coal quality change curve are shown in Fig. 15.

According to the surface function of the roof and floor of the coal seam and using the numerical integration method, we can determine the volume of stripped rock and the total tonnage of coal mined in the study area. Before that, determine the x-axis coordinates of the intersection line between each curved surface and the slope, as shown in Fig. 16.

Take the stripping and mining of coal above 16 as an example:

Topsoil stripping volume above 16 coal:

As the advancement Δx changes, the topsoil stripping volume formula is as follows:

The volume of 16 coal mined:

As the advancement Δx changes, the formula for mining 16 coal volume is as follows:

Taking into account the fluctuations in coal quality of 16 and 18 coal, it is necessary to bring in the bulk density and coal quality. Using the coal quality curve of Coal 16, which was fitted based on the “Overall changes in coal quality in the study area” as shown in Fig. 14, along with the bulk density and price of the coal, these values are substituted into Eq. (7). The economic benefits of mining each block are then calculated using a differential method. When the advancement degree is Δx, the positive economic benefit of mining 16 coal is:

Simplify to get:

Among them, γ represents the bulk density of coal and pc represents the pit price of coal. The volume integral formula of the underlying coal seam and rock formation is obtained sequentially by using multiple integration methods, which will not be described again here.

Mining net profit model construction

At present, the volume stripped at the location of the mining area and the volume and quality generated by the amount of coal extracted are deduced. The following is to build a mathematical model between the total profit and the advancement rate. Considering that the mining process stops at transporting coal to the pit entrance, the commercial coal for this project is determined to be one type: blended coal, with a yield of 95.793% and γ is 1.34 t/m3, pc is 108.6 yuan/t. Considering that the dumping site within the eastern dump area has an irregular boundary and is currently in the initial stage of dumping, it has not affected the recovery of coal seams in the study area. Therefore, the issue of secondary stripping is not taken into account when constructing the economic model. Mining costs mainly come from four parts: Puncture blasting, mining and loading, transportation, and dumping. The profit is calculated based on the actual annual unit cost of the mine at full production. Some parameters are as shown in Table 2.

The total profit model of this region is:

Objective function:

Curves showing the variation of the operational stripping ratio and net profit with advancement are presented, as shown in Fig. 17.

From the operational stripping ratio curve model and the advancement model related to profit and coal quality established above, it is evident that using only the economically reasonable stripping ratio for evaluation is not accurate. When mining the coal seams in the SES of the first mining area, at a site advancement of 193 m, the maximum overall net profit value of the mine is 676,607,690 yuan. However, it is unreasonable to determine the propulsion degree as 193 m based on this. The SES is affected by the fire area, resulting in a reduction in the quality of some coal seams and changes in some rock mechanical parameters. Part of this area is burnt rock formed by the baking of normal rocks. If excessive mining results in excessive exposure of the burnt rock position, it will cause Slope instability is also undesirable, so it is necessary to introduce slope stability analysis under changes in mechanical parameters and calculate the overall advancement by combining the two factors.

Analysis of slope stability in the study area

Experimental analysis of mechanical parameters of burnt rock

To determine the slope stability caused by burning in the study area, it is first necessary to determine the changes in rock mechanical parameters of normal rocks in the area and the locations affected by fire. Rock mechanical parameter experiments were conducted through on-site sampling. The results obtained are as follows:

Burnt rock mass has very developed cracks, its physical and mechanical properties are greatly different from those of the original rock, its water absorption rate is large, and it has poor frost resistance and disintegration resistance. It rapidly disintegrates and peels off under the influence of large temperature differences, alternating freeze–thaw atmospheric environment and groundwater, causing rock mass destruction.

The typical samples taken are shown in Fig. 18.

The sample is prepared as a cuboid with a length, width, and width of 5 cm and a height of 10 cm for rock deformation testing. The longitudinal (axial) and transverse (radial) deformation of the sample is measured under the action of longitudinal pressure, and the elasticity of the rock is calculated based on this. Modulus and Poisson's ratio. As shown in Fig. 19.

The stress–strain curve of the burnt rock derived through experimental instruments is shown in Fig. 20.

Based on the experimental results and the current situation of the open-pit mine, the relevant rock mechanical parameters in the SES of the first mining area were determined as shown in Table 3.

2D slope stability analysis of typical sections

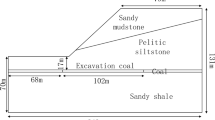

To study the stability of the SES composite overall slope under different advancement degrees, as shown in Fig. 21, a typical profile 1 was selected on the SES burned rock slope to establish a slope model, as shown in Fig. 22. The rigid body limit equilibrium theory is used to quantitatively analyze the slope stability under different advancement rates20.

Among them, the rock formations are distributed nearly horizontally, and the trailing edge of the slope is the FBA. The thickness of the burnt rock on the section slope is 120 m, and the slope angle is 25° according to the final slope angle21. Considering that the SES is a fire area, and is an external dumpsite-end composite slope, with a service life of 44 years, the safety reserve factor of this area is determined to be 1.30. Four locations were selected with advancing degrees of 60 m, 120 m, 180 m, and 240 m respectively for simulated mining in the SES. The simulation results are shown in Fig. 23, 24, 25, 26, 27.

As the advancement becomes larger, the stability of the slope becomes worse and worse, which is consistent with the inference made in advance. When the advancement is 240, the slope stability coefficient is 1.170, which does not meet the selected end safety reserve coefficient. At this time The slip surface is arc sliding, and the exposed position is the fire area. In order to further improve the accuracy of the 180 ~ 240 m area, it is subdivided into interval [180, 240], and one advancement is selected every ten meters for simulated mining. The results are shown in Figs. 28, 29, 30, 31, 32, 3322.

It can be seen from the figure that the control of the burnt rock on the slope surface is very obvious. As the advancement deepens, the stability of the slope gradually decreases from the position close to the fire area to the position where it enters the fire zone. When in the zone position, the stability coefficient decreases rapidly, and its change process is as shown in Fig. 34.

It can be seen from the slope stability change curve that when the mining reaches 193 m, that is, when the net profit is maximum, the slope stability coefficient is 1.27, which does not meet the selected safety and stability coefficient. When the advancement distance is 182 m, the slope stability coefficient is 1.27. The stability coefficient is 1.30, which is consistent with the selected safety and stability coefficient.

The slope stability and net profit curve are shown in Fig. 35.

3D slope stability verification

To further verify the stability coefficient of this location, it is planned to further analyze this location by establishing a 3D slope model: the model is meshed using the free meshing method, and then the surface division in the griddle is selected for refinement, using triangles. The minimum side length is set to 10 m, and the maximum side length is set to 20 m. The grid file is a regular tetrahedron during output, and the output file is Flac3D6.0. The divided grid is as shown in Fig. 36. The three-dimensional displacement cloud diagram of the slope is shown in Figs. 37 and 38.

From the analysis of the above figure, it can be seen that for edge failure in the FBA, the burnt rock area has greater control over the stability of the broken surface. As the advance increases, the stability of the slope gradually decreases, and the slope is exposed in the FBA. The decline is particularly obvious at the surface position, and the slope consolidation slip is arc sliding. When mining reaches the outcrop position of the FBA, the landslide pattern tends to be layer-cutting-bedding sliding along the bottom plate with the burned rock as the weak layer. When the mining position is 182 m, the slope stability is 1.305. Continued mining will reduce its stability to below 1.3.

The SES deep realm optimization

Through the above research, it was determined that the advancement was 182 m. At this time, the deep realm of the study area shrank back by 58 m. The changes are shown in Fig. 39.

Conclusion

-

(1)

This article innovatively introduces the multivariate function fitting into constructing the solid surface of the coal seam roof and floor. Through the extraction of three-dimensional data points and the integration of MATLAB tools, the coal seam roof, and floor data are quantitatively analyzed and the calculation error is reduced;

-

(2)

By introducing the factor of coal quality fluctuation in the end slope FBA, the coal quality function that changes with the change of propulsion degree is established, and finally, the net profit model of the mining area is constructed to replace the traditional stripping ratio for optimization, and the coal quality and net profit under each mining position are determined.

-

(3)

Considering the influence of slope stability on the end slope propulsion, referring to the constructed net profit mathematical model, the final mining propulsion is determined to be 182 m, the overall stability of the composite slope at the boundary position is 1.305, and the net profit of mining at this position is 671.96 million yuan.

-

(4)

Compared with the initial design mining boundary, the optimized deep boundary of the southern end slope is reduced by 58 m. Unnecessary stripping and mining of low-quality coal is avoided.

-

(5)

This paper solves the dilemma of mining in the FBA of Dananhu No. 2 mine, and maximizes the net profit of the study area under the premise of ensuring safe production. Its practical relevance is ensured.

-

(6)

Considering that the main content of the paper is the mining of coal seam at the end slope of coal seam fluctuation changes in the FBA, the focus of this paper is to replace the traditional stripping ratio change model with the net profit model constructed by coal quality fluctuation and how to introduce the multivariate function fitting method to establish the visualization model of coal seam roof and floor, so in the final evaluation of slope stability in the paper, the paper adopts a more intuitive, clear and clear method, and uses numerical simulation software to directly clarify the stability of the slope at the end of mining. Compared with determining the change and distribution of pores and fractures in coal23, the monitoring of the crack width on the slope surface by photogrammetry greatly shortens the time24, Still the follow-up research in this paper can further discuss the above two factors in depth.

-

(7)

For the stripped waste materials, due to the loose and porous structure of the burnt rock, the stability of the inner dump and backfill part of the open-pit mine is poor, and considering the safety issues, it is necessary to study the optimization of the backfill materials further25 and the increase of backfill intensity to improve the further recovery rate of limited resources.26

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Ziling, S. et al. Dust emission rules and dust suppression technology in open-pit coal mine fire rock mining and installation work. J. Liaoning Univ. Eng. Technol. (Nat. Sci. Ed.) 40(05), 401–408 (2021).

Hai, W. Research on water damage control technology for burnt rock aquifers in hidden fire areas. Coalfield Geol. Explor. 52(05), 88–97 (2024).

Jia, Z. Z. et al. Study on blasting fragmentation mechanism of burnt rock in open-pit coal mine. Sci. Rep. 14, 5034 (2024).

Ziling, S. et al. Research on fuzzy evaluation of ecological environment assessment system for green mining of open-pit coal mines. Coal Sci. Technol. 47(10), 58–66 (2019).

Bai Runcai, Fu. et al. Safety-green-efficient-low-carbon collaborative mining technology system for open-pit coal mines. J. Coal 49(01), 298–308 (2024).

Fan, Y. et al. Geochemistry and metamorphic mineral phase characteristics of burnt rocks in shallow coal seams. J. Northwest Univ. (Nat. Sci. Ed.) 54(02), 329–344 (2024).

Yuanxiang, Yu., Guang, Q. & Pan, C. Research on unloading mechanism and stability of burnt rock high slope in open-pit mine. J. Xi’an Univ. Sci. Technol. 43(05), 941–951 (2023).

Wang, S. et al. Response of thermal conductivity of loess after high temperature in northern Shaanxi burnt rock area, China. Environ. Sci. Pollut. Res. 30, 33475–33484 (2023).

Li, J. Research on Optimization of Coal Seam Blasting Scheme in Dananhu No. 2 Open-Pit Mine (Liaoning University of Engineering and Technology, 2023).

Li, C. et al. Research on rock step perforation blasting technology in the fire area of Dananhu No. 2 Mine. China Metal Bull. 12, 173–175 (2019).

Liu, G. et al. Optimization of working slope configuration in seasonal operations of cold regions open-pit mine[J]. Alex. Eng. J. 87, 533–542 (2024).

Wang, D. et al. Prediction method for surface deformation around soft base dumpsite based on viscoelastic theory. Coal Science and Technology 1–12 (2024).

Li, J. et al. Research on the slope instability and slip mechanism and its control induced by overlying rock migration in Bianbang coal mining. Coal Science and Technology 1–16 (2024).

Ma, L. et al. Research on the stability of the dump site in the inclined base considering anti-sliding coal pillars. Coal Science and Technology 1–8 (2024).

Guangwei, L. et al. Dynamic control of working shaft morphology and optimization of propulsion intensity in seasonal stripping open-pit coal mines. Coal Sci. Technol. 51(10), 45–54 (2023).

Cao, B. et al. Research on boundary optimization of adjacent mining areas in open pit coal mine based on calculation of sectional stripping ratio. Sci. Rep. 13, 21286 (2023).

Honglei, W. et al. Development status and application progress of comprehensive online detection technology of coal quality and quantity. Coal Sci. Technol. 52(02), 219–237 (2024).

GB/T 482–2008. Sampling of Coal Seams.

Vilakazi, L. & Madyira, D. Estimation of gross calorific value of coal: A literature review. Int. J. Coal Prep. Util. https://doi.org/10.1080/19392699.2024.2339340 (2024).

Jia, L. et al. Landslide risk evaluation method of open-pit mine based on numerical simulation of large deformation of landslide. Sci. Rep. 13, 15410 (2023).

Guo, X. Research on the Stability of Water-Rich Burned Rock Slopes in Open-Pit Coal Mines (General Institute of Coal Science and Technology, 2021).

Wang, W. et al. Study of roof water inrush control technology and water resources utilization during coal mining in a karst area. Mine Water Environ. 42, 546–559 (2023).

Li, Z. et al. Microstructure evolution in bituminous-coal pyrolysis under in situ and stress-free conditions: A comparative study. Geomech. Geophys. Geo-energy Geo-resour. 10, 134 (2024).

Klyuev, R. V., Brigida, V. S., Lobkov, K. Y., Stupina, A. A. & Tynchenko, V. V. On the issue of monitoring crack formation in natural-technical systems during earth surface displacements. MIAB. Mining Inf. Anal. Bull. 11–1, 292–304 (2023).

Ma, L. et al. Dynamics of backfill compressive strength obtained from enrichment tails for the circular waste management. Resour. Conserv. Recycl. Adv. 23, 200224 (2024).

Brigida, V. S. et al. Efficiency gains when using activated mill tailings in underground mining. Metallurgist 67(3), 398–408 (2023).

Acknowledgements

This research was funded by the National Natural Science Foundation of China (51474119), the Liaoning Technical University of Engineering and Technology Ordos Research Institute campus-site science and technology cooperation cultivation project (YJY-XD-2023-027), and the Liaoning Technical University of Engineering and Technology Collaborative Innovation Center for Mining Major Disaster Prevention and Environmental Restoration Open Project (CXZX-2024-01).

Author information

Authors and Affiliations

Contributions

Y.W.: Methodology, Software, Validation, Investigation, Writing-original draft, Writing-review & editing, Visualization. Z.S.: Conceptualization, Formal analysis, Writing-review & editing, Supervision, Project administration, Funding acquisition. J.F.: Validation, Supervision. X.Z.: Investigation, Resources, Funding Acquisition. Y.Z.: Validation, Data curation. S.X.: Supervision, Resources. Y.L.: Resources. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wen, Y., Song, Z., Fan, J. et al. Research on controlled mining of end slope fire-burned area in open-pit mine. Sci Rep 14, 21152 (2024). https://doi.org/10.1038/s41598-024-72017-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-72017-7