Abstract

Dynamic compaction is a soil improvement technique which involves the repeated application of an impact load to a contact area of the soil surface induced by heavy weights. Experimental measurements were prepared for evaluation of the ground wave propagation induced by the rapid impact compaction. Influence of increase of subsoil stiffness during compaction and terrain configuration were investigated. When the shear strength of soil is exceeded during the penetration of the compaction footing, increase of peak particle velocities is slower but still clearly visible along the measurement line. The peak particle velocity is damped by the subsoil below 5 mm s−1 within 40–50 m from the source of excitation. Attenuation radius is affected by the terrain configuration, when terrain elevations cause the increase of acceleration amplitudes. Rigid bodies in the ground, such as foundation structures, could have similar influence. Dominant frequencies are in the interval from 20 to 40 Hz regardless the distance from the source of excitation or the density of the treated subsoil. Obtained results are preferably related to the given boundary conditions. However, wave propagation pattern and change of its characteristics during densification of the subsoil are applicable at another construction sites considering their particularities.

Similar content being viewed by others

Introduction

Soil improvement represents one of the important geotechnical tasks to ensure the stability and safety of structures such as embankments, bridges or buildings1,2,3. Beside the soil replacement, stabilization or reinforcing4, dynamic consolidation is a quick and cost-effective method to achieve the subsoil improvement in a large scale.

Dynamic compaction, also known as a dynamic consolidation, is a soil improvement technique which involves the repeated application of an impact load to a contact area of the soil surface induced by heavy machinery with weights. The principle is described by several authors5,6,7,8,9. Recently, equipment designed for dynamic compaction has undergone several modifications to increase the efficiency of the compaction. Sufficient level of compaction is important for the proper bearing capacity–deformation relationship related to the safe use of structures placed on improved geological material5. Dynamic compaction has been utilized on many constructions for a variety of geological conditions and for different applications such as transportation infrastructure or manufacturing and warehousing facilities10,11,12. Dynamic compaction utilizes the dynamic effect of high-energy blows caused by the fall of weights of varying mass that may discretely fall or cycle within a defined height interval13. The purpose of the technique is to transmit high-energy waves through a compressible soil layer, thereby improving the geotechnical parameters of the soil8,9. The effectiveness of the method depends on various factors, including soil type, compaction energy and project-specific requirements14,15.

Dynamic compaction is most effective in loose or poorly compacted soils such as loose sands, clays and granular deposits. It helps to increase the density and bearing capacity of these soils by reducing their voids and improving their shear strength16.

The energy used during compaction is critical to its effectiveness. The weight or hammer type used, the drop height and the number of blows determine the compaction energy. The energy must be sufficient to create shock waves that can effectively penetrate and compact the soil layers13,17.

Treatment depth is also an important factor in determining the effectiveness of dynamic compaction. Impacts should be applied to a depth that is sufficient to achieve the desired compaction and improved bearing capacity. For larger structures or higher design loads, deeper treatment may be required17.

Variability in thickness of soil layers with different properties or occurrence of interbedded layers with different properties cause that site-wide effectiveness may vary and other soil improvement techniques may be used.12,17.

It should be noted that the effectiveness of dynamic compaction can vary from site to site, and therefore it is important to conduct a thorough site investigation to assess the suitability and potential effectiveness of dynamic compaction for a particular project18,19,20,21,22.

There are several types of dynamic compaction technologies such as heavy tamping, rapid impact compaction (RIC) or rolling dynamic compaction (RDC) or in-pipe deep dynamic compaction8,11,12,13,16,23,24. The selection of the appropriate technique depends on factors such as geological conditions, project requirements and site constraints.

Compaction using the RIC technique is carried out from the surface where the equipment is in direct contact with the treated soil half-space using compaction footing. The method allows to improve geotechnical properties of soils to a certain depth to increase the resistance to working stresses and reduce the deformations during a service life25. In comparison with the conventional dynamic compaction techniques, the RIC method has following benefits:

-

Generally, no danger of flying debris;

-

Rapid treatment of areas with various sizes;

-

Energy is more efficiently transferred through the compaction footing, which remains in contact with the ground26,27.

RIC is suitable for the improvement of a wide range of loose soils and fills, but is not recommended for weak, low permeability soils with high moisture content28. In clayey soils and mixed fills, excessive pore pressure can be established by RIC and may take several days or more in some situations to dissipate29. Serridge and Synac, and Woodward provide an overview of RIC, design procedures and quality assessment30,31. The RIC device can also be utilized as a diagnostic tool that identifies zones that do not respond well to dynamic compaction. Such zones may include soils with high plasticity and any incompressible material. South African Institution of Civil Engineering (SAICE) provides a review of RICs with respect to machine specifications, applications, parameters affecting compaction, environmental impacts, etc.32.

Braithwaite and du Preez reported that RIC provides a technically reliable and economical alternative for improving weak soils in the depth range of 1–4 m28. Merrifield and Davies reported that RIC is applicable when it is not necessary to achieve soil improvement to great depths, for example, when the subsoil to be improved consists of a layer of loose material only a few meters deep33. A review of the effects for different soils is summarized by Becker29, Woodward31, He and Chen34 and Cheng et al.35, Wersäll et al.36 confirm that the indicative effective compaction depth for granular soils is in the interval of 2–3 times of the diameter of the compaction footing. The suitability of the method in natural sandy and gravelly soils has been investigated by Serridge and Synac30. They proved that the influence zone of RIC technology is a function of soil classification characteristics and groundwater regime.

Braithwaite and du Preez investigated the effectiveness of RIC using dynamic penetration test where soil stiffness after compaction can be 2–10 times greater than before treatment. Within the zone of influence, the number of blows of super heavy dynamic probe (DPSH) commonly improved by about 30 blows per 1 ft. (0.3 m)28.

RIC technology is a source of vibration which manifests as ground waves, similar to pile driving37. The vibration can have a detrimental effect on various adjacent and remote structures, sensitive equipment and people. In practice, the limits of vibration are mostly used depending on the type of the structure, its utilization or possible influence on people. The attenuation of the maximum particle velocities away from the source is assumed to converge to the inverse square of the radius (r−2) where r is a distance from the source of vibration38. Tara and Wilson provide a description of the monitoring and evaluation of RIC generated vibration and the effects of RIC compaction39. Yang et al.40 conducted a field test to investigate the dynamic characteristics of compaction during the compaction process. Chen et al.41 investigated the propagation and attenuation of ground waves. They applied sensors capturing the vibration of the geological environment and found that the amplitude of longitudinal vibration is larger than that of vertical and transverse vibration. There is also lower acceleration damping of the subsoil composed of coarse-grained material in comparison with the fine-grained soils. Wersäll et al.36 found out that a frequency content of ground vibrations induced by the fall of the hammer on a three-meter thick rock fill is almost independent of the soil conditions below the fill. The frequencies generated by the impact depend primarily on the dynamic characteristics of the hammer system and the ground conditions immediately beneath the footing. Theoretical analyses also suggest that parameters of the drive system, such as the hammer drop height and hammer weight, are less important for the frequency characteristics of vertical ground vibration. The ground vibration amplitude remains almost unchanged even when the drop height is increased by almost 100%. This can be explained by the fact that the upper limit of the shear resistance of the soil is reached during plastic penetration. Thus, the vibration amplitude depends on the dynamic resistance of the soil at the footing–soil interface and becomes almost independent on the applied force at failure. However, when the applied force is less than the ultimate resistance of the soil beneath the footing, the penetration is reduced and may result in higher dynamic stiffness and hence increased ground vibration. Similar behaviour can be observed at high-speed impact loading of soil specimens which is also usable at blasting-induced impact loading effects investigation42.

Ground properties, the location of the water table and the type and material characteristic of the structure are crucial for risk assessment of vibrations43. Vibration standards have been often developed empirically and are based on regional experience and they take into account geological and geotechnical conditions, building types and construction materials. Such a standard should be interpreted carefully when applied to other geographic areas. Additionally, different standards use different parameters to define limit values that must be considered when planning vibration measurements and interpreting the results. Equipment and measurement procedures also vary between standards and can have significant consequences if applied incorrectly. A comprehensive discussion of these parameters and their interpretation is provided by Chameau et al.44.

The basic quantity used for vibration analysis in construction is either the particle acceleration a(t) or the time history of the particle velocity v(t), corrected for the influence of the transducer and the measurement system. A number of techniques are available to characterize the signals, including:

-

Peak particle velocity (PPV) and duration for transient vibrations;

-

Root mean square (RMS) values for continuous vibrations;

-

Fourier, power, octave, and one-third octave spectra, and response spectra.

Identifying the PPV value is simple and provides the maximum response, but does not provide a complete description of the time history. The RMS amplitude strongly depends on the duration of the record or the segment of the record used in the calculation. That especially applies for transient region where the duration of the movements is small compared to the total length of the record. A common method of estimating the frequency content (spectrum) of a signal is to calculate the Fourier transformation of the signal. After the transformation, we can identify the peaks corresponding to the dominant frequencies in the signal and compare them with the limits of acceptable frequencies in order to prevent the occurrence of resonance in structures or a negative impact on people45.

The negative impact of vibration in the above manner is addressed by the various standards. For example, International standard ISO 4866-2010, British standards BS 7385-1993 and BS 5228-2:2009 + A1:2014, German standard DIN 4150-3:1999 and Swedish standard SS 02 52 11-1999 specify vibration limits in terms of maximum or peak particle velocity (PPV) or particular component of vibration velocity for structural vibration to prevent cosmetic cracking of structures with emphasis on short-term vibration46,47,48,49,50,51. These limits are related to the type of the structure and its utilization in particular frequency range. Measurement results of United States Bureau of Mines (USBM) show that even in the resonance zone (4–12 Hz), the residential buildings vibrated with a tolerable PPV greater than 50 mm s−1 without damage. Furthermore, a PPV of 50 mm s−1 is the highest vibration level generated in residential buildings by walking, jumping, door slamming, etc.52. USBM experiments also demonstrate vibration of soils with PPVs below 33 mm s−1 (2–5 Hz) and 100 mm s−1 (60–450 Hz) before or after resonance, respectively, of horizontal vibrations of buildings that do not cause structural damage. Compared to blasting, construction and industrial impact sources do not trigger low-frequency horizontal resonant vibration of buildings.

In general, the vibration limit of 50 mm s−1 can be used for structural vibrations and the basic limit of 2.5 mm s−1 should be used for assessment of dynamic settlement in collapsing soils. Low ground vibration PPVs are particularly important in collapsing soils because they can induce dynamic settlement. These criteria do not take into account the effects of plastic deformation of the subsoil from external or internal sources of vibration. Therefore, a combination of the standard application with an assessment of possible dynamic settlement of subsoil is preferable. Of course, vibration limits must be adapted to local conditions and experience53,54,55.

Considering the above mentioned findings, authors prepared an experiment to investigate the dynamic response of the subsoil to rapid impact compaction. To investigate the influence of the soil compaction on the ground wave propagation, a field with sufficient thickness of gravel deposits with similar characteristics along the profile was chosen. The paper analyses the effect of distance from the source of vibration, terrain shape and the change of soil stiffness during compaction on the wave propagation. Outputs represent a background for proper adoption of RIC technique in terms dynamic effect of the compaction on the environment.

Methods

Experimental measurements were prepared for evaluation of the ground wave propagation induced by the rapid impact compaction with use of accelerometers situated on the terrain at different distances to record the attenuation of the impact energy while travelling through the ground. Influence of increase of the subsoil stiffness during the compaction and the terrain configuration (a slope of the construction pit) together with the position of the actual compaction site with respect to the already compacted positions on the wave propagation were investigated.

Test site

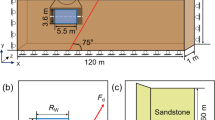

For the in-situ tests, a construction pit with dimensions of 56 × 16 m was prepared. Top soil layer was removed to expose the subsoil mass which was treated by the dynamic compaction. The geology profile is represented by a top cover of fine-grained soils mainly to a depth of 0.3–0.8 m. The thickness of the lower gravel layer is approximately 13.7 m. In the area of interest geological exploratory boreholes V-1 and V-2 were drilled to a depth of 12.0 m. Close to the boreholes, a penetration testing was performed. From the boreholes, disturbed soil samples were taken for grain size analysis and the groundwater level was measured. From the grain size analysis, the soil samples were classified as G-F—gravel with admixture of fine particles. The grain size analysis chart is plotted in Fig. 1.

Four dynamic penetration probes DPT-1 to DPT-4 to a depth of 4.5 m were carried out in accordance with ISO 22,476-2:2005 prior to dynamic compaction (DPT-1 and DPT-3) and after subsoil treatment (DPT-2 and DPT-4). The sounding was carried out using heavy dynamic probe (DPH) with a 50 kg hammer. During penetration, the rod with a cone tip is continuously ramming to the tested soil with regular hammer strikes and the number of strikes required to ram the rod by every 10 cm is recorded. At the same time, the torque Mv is measured with a torque wrench each time a rod segment is added. As illustrates Fig. 2, the dynamic penetration probes limit the effect of dynamic compaction to a depth of approx. 2.0 m below footing which is indicated by increasing dynamic cone resistance qdyn derived from the record of number strikes per 10 cm penetration. Considering the diameter of the compaction footing of 2.0 m, the influence zone depth is roughly equal to the footing diameter which is shallower than proposed by other authors36.

Experimental procedure

Compaction plan is based on the practical experience for the given compaction equipment. During compaction at each site, a record of the ground wave propagation was obtained at each of the sensor position arranged in the line. The positions of the sensors A to H remained unchanged during the whole compaction process. The compaction sites (numbers 1 to 15) were uniformly distributed with the axis raster of 3.0 m (Fig. 3). The order of numbers represents the sequence of compaction sessions. According to the data analysis and mutual position of compaction sites, the sites designated I–IV will be further presented in more detail.

RIC equipment parameters

RIC equipment consisted of a hydraulic excavator with a reinforced base, to the boomer of which is attached a compaction hammer. The weight of the hammer generates vibrations when repeatedly hits the compaction footing which remains in contact with the ground during compaction. These blows bring the soil particles to a more compacted state what leads to higher bearing capacity and deformation resistance.

This technique allows a production rate of 1500–10,000 m2 of improved soil in 12 h depending on compaction requirements and parameters of compacted soil. Within the compaction hammer, 9- to 16-ton weights are hydraulically lifted up to a predetermined height of up to 1.5 m, then lowered onto the compaction footing by means of hydraulic acceleration. This operation is performed 40–80 times per minute. The number of strokes is selected depending on the soil density and the requirements of the project. For granular soils, it typically ranges from 20 to 90 strokes in one place. On the test site, a hammer weighing 16 tons, which fell from a height of 1.2 m, was used. The diameter of the footing was 2.0 m (Fig. 4).

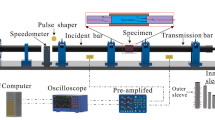

Measurement instrumentation

Dynamic measurements were performed using DEWETRON 32-channel DEWE3-A4 system (Fig. 5). The DEWE3-A4 system can be divided into several independent parts, each with several input channels, all having a frequency range of 10–200 Hz. Since the DEWE3-A4 measurement system contains XR acquisition modules, all inputs achieve a dynamic range of 160 dB with ideal linearity and phase matching. The system was equipped with multi-analyser input channels and transducers designed for experimental modal analysis purposes.

The measurement set consisted of two DeltaTron 8344 low-frequency accelerometers (positions A and B in Figs. 3 and 6a) and six DeltaTron 8340 high-sensitivity accelerometers (positions C to H in Figs. 3 and 6b). The main recorded quantity was the acceleration over time with the density of time record of 1 ms. The placement of the sensors took into account the measuring range of each sensors type, where the sensors with the larger range were placed more closely to the compaction site.

The sensors were fixed by rigid threaded connections to steel ground anchors, which were driven 40 cm into the ground before the measurements. A detail of the sensor mounting is shown in Fig. 6c. The installation of the sensors on the ground anchors allowed measurements in the vertical direction.

The DeltaTron 8344 is piezoelectric accelerometer designed and optimized for low frequency and low-level measurements with transfer of primary calibration data from as low as 10 mHz–3000 Hz. It features low-noise, built-in constant current line drive (CCLD) preamplifiers with transducer electronic datasheet (TEDS). The design consists of three piezoelectric elements and three seismic masses arranged in a triangular configuration around a triangular centre post. They are held in place by a clamping ring that isolates the configuration from the base. The ring also prestresses the piezoelectric elements to give a high degree of linearity. The piezoelectric element used is PZ 27, zirconate lead titanate, and the hermetically sealed housing is made of stainless steel, AISI316-L, and has an M5-threaded hole for mounting on the base. Measuring range is ± 26 m s−2 peak.

Type 8340 is a piezoelectric annular shear design accelerometer with integral electronics with weight of 775 g and the sensitivity of 1 V/ms−2. The transducer features a MIL-C-5015, 2-pin top connector, case isolation and a hermetically sealed stainless steel housing. The transducer has been designed with a high sensitivity and signal-to-noise ratio for measurements on large structures at very low frequencies and measuring low-level seismic activity. The sensor is calibrated in the frequency range from 5 to 1500 Hz. Measuring range is ± 4.9 m s−2 peak.

Results

Each compaction session involved several initial pre-compaction strokes, 70 main compaction strokes with full-energy compaction and a final post-compaction strike. The fall height as well as the impact energy was lower at the pre-compaction and post-compaction blows compared to the main compaction blow. The time interval between the blows was 1 s. Attenuation of the ground lasted less than 0.1 s so there was no interference of the waves induced by particular blows56. The typical wave acceleration record for one hammer blow is plotted in Fig. 7.

The compaction procedure is related to the utilized RIC technology. Pre-compaction blows are necessary mainly due to the stabilization of the device. The post-compaction stroke is performed due to the utilization of the remaining kinetic energy in the equipment. Pre-compaction and post-compaction strokes were excluded from further data processing. The typical wave acceleration record for one compaction session at the site 10 is plotted in Fig. 8.

Generally, an increase of peak values of vertical acceleration is visible throughout the compaction at particular site with increasing number of blows and related increase of subsoil density (Figs. 8 and 9).

Figure 10 illustrates the wave acceleration for different sensor positions for compaction site 10 (III) which represents different distance of sensor from the source of excitation. Charts display complete compaction session at one site including pre- and post-compaction blows.

For analysis of frequency spectrum, Fast Fourier Transformation (FFT) was utilized. Fast Fourier transform is a common method for signal processing, in which time-domain signal is transformed into frequency-domain:

where f(t) is original signal, T is period of the original signal, ejωt is function of complex variable.

The acceleration signals from different compaction sites transformed by FFT procedure are plotted in Fig. 11. It can be seen that the dominant frequency interval in the subsoil do not change with increasing number of compaction blows, while the amplitude of the vibration waves changes with the increase of the number of compactions, in which the amplitude of the wave first increases and then decreases. According to the analysis, this is because the degree of compaction does not increase linearly with the increase in the number of compaction impact, but when the degree of compaction reaches a certain value, it will fluctuate up and down around a certain value if it the soil is impacted again8.

Dominant frequencies for a tampering devices are generally between 5 and 10 Hz considering the measurements instrumented at the buildings57. For the RIC equipment, the frequencies are generally between 20 and 30 Hz. Since RIC frequencies are higher than typical natural frequencies of residential houses, we can expect less vibration amplification58.

The magnitude of the peak particle velocities is proportional to the relative density of the soil. This is confirmed by the increase in magnitude of the peak signals with each succeeding impact as the relative density is increased with each successive hammer blow (Fig. 12). The peak particle velocity of the soil adjacent to the compaction site increases with increasing compaction59.

The attenuation of the amplitude away from the source is assumed to approximate the inverse squared radius (r−2). The densifying effect is most dominant during the first seven to eight blows. Thereafter the effect diminishes steadily38.

Attenuation of the ground wave with the distance from the source of excitation is strongly affected by the slope at the border of the construction pit. Therefore, attenuation curve for the first and the last main compaction blow is plotted separately for the sensor positions inside and outside the pit (Fig. 13). The attenuation curve can be constructed with high reliability considering the coefficient of determination R2.

Discussion

Dynamic penetration probes proved the increase of the subsoil resistance after compaction. This effect is more prominent in the upper soil layers with lower initial dynamic cone resistance. However, the influence zone extends to a smaller depth than proposed by other authors and is roughly equal to the diameter of the compaction footing for given geological conditions.

An increase of peak values of vertical acceleration and corresponding peak particle velocities is related to the increasing density of the subsoil during compaction which is in agreement with other authors36. After initial steeper increase, the peak values oscillate with certain deviation around a trend line that can be plotted with slight increase of the values during the compaction session. This phenomenon is less pronounced at records with larger distance between the compaction site and the sensor.

For the utilized equipment, the dominant frequencies are generally between 20 and 40 Hz which is in agreement with other authors (Table 1). It should be noted that these values are related to the given compaction equipment, geological conditions and terrain configuration. Rigid bodies, such as foundation structures, affect the wave propagation in the ground and together with the upper structure also affect the overall response of the system, including dominant frequencies57.

Damping of the soil represents crucial parameter for attenuation effect during dynamic phenomena. It significantly influences wave transfer thought the ground and structure–soil interaction as well61. Wave attenuation can be, with certain level of reliability, estimated by analytical approach based on assumption of wave attenuation with increasing distance62. Numerical and experimental approach can also be adopted63,64,65. This is basically with agreement with presented study outputs. With different position of the driven pile tip or compaction footing, some deviations in the wave attenuation can occur because of refraction or reflection of the wave at geological layer boundaries. Therefore, a test site with as little soil parameter change as possible was selected. Rate of attenuation is also higher closer to the source of excitation (Fig. 13)62.

Attenuation of the ground wave with the distance from the source of excitation is also affected by the terrain configuration and required larger distance to fully diminish the ground particle oscillation. A safe distance depends on the response of the structure to the ground wave which can be controlled by the trenches to interrupt the path of the Rayleigh waves at the terrain57. Buried barriers are more effective for vibration mitigations at larger frequencies66. The mitigation capacity of these barriers is not significant for loading frequencies smaller than 5 Hz which limits their applicability at RIC method.

Slopes around the construction pit also caused the increase of the acceleration amplitudes at the sensors above the slope which should be taken into account in design of mitigation measures.

Conclusions

Rapid impact compaction is a cost-effective and time-efficient method used to improve the soil parameters to satisfy bearing capacity, reduce excessive settlement, and resist liquefaction on reclaimed soil at intermediate compaction depths. For given gravel subsoil, soil improvement doesn’t reach the depth proposed by other authors. Additionally, the level of improvement depends on the initial bulk density of treated soil. Density increase from compaction is smaller with increasing initial soil density.

Measurements proved the relation between the densification of soil and increasing amplitude of acceleration and peak particle velocity. When the shear strength of soil is exceeded during the penetration of the compaction footing, increase of peak particle velocities is slower but still clearly visible at every observation point. The initial energy, or potential energy, is the same for every blow but the resulting impact energy differs depending on the soil deformation or deceleration of the hammer. This factor was not observed because of lack of sensors on the compaction machine. Adding the sensors is a focus for next stage of experiments.

There was observed no significant influence of the already compacted soil mass on the wave path between the actual compaction site and the sensor positions on the wave propagation.

Negative effect of compaction expressed by the peak particle velocities should be mitigate by appropriate measures, such as trenches to interrupt the path of the surface waves. According to data, the peak particle velocity is damped by the subsoil below 5 mm s−1 within 40–50 m from the source of excitation. Utilization of particular measure depends on the response limit of affected structure. Attenuation radius is affected by the terrain configuration, when terrain elevations cause the increase of acceleration amplitudes. Rigid bodies in the ground, such as foundation structures, could have similar influence and can cause an increase of PPV.

Dominant frequencies are in the interval from 20 to 40 Hz regardless the distance from the source of excitation or the density of the treated subsoil.

Obtained results are preferably related to the given boundary conditions such as geological profile and terrain configuration. However, wave propagation pattern and change of its characteristics during densification of the subsoil are, according to other authors, applicable at another construction sites considering their particularities.

Further research is aimed at the investigation of the compaction equipment characteristics, such as fall height and frequency, and their influence on the wave propagation trough the various types of ground.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Farbák, M., Chromčák, J., Bačová, D. & Odrobiňák, J. Investigation of actual in-plane geometric imperfections of steel tied-arch bridges. Appl. Sci.13, 1–21. https://doi.org/10.3390/app13116393 (2023).

Koteš, P., Zahuranec, M., Prokop, J., Strauss, A. & Matos, J. Measurement of corrosion rates on reinforcement using the field test. Ce/Papers6, 1053–1058. https://doi.org/10.1002/cepa.2022 (2023).

Nguyen, G. Determination of stress in spread foundation subsoil by various approaches. Civ. Environ. Eng.11, 29–37. https://doi.org/10.1515/cee-2015-0004 (2015).

Sulovská, M. & Stacho, J. Analysis of geogrid reinforced structures with a passive facing system using different computational methods. Civ. Environ. Eng.17, 500–512. https://doi.org/10.2478/cee-2021-0052 (2021).

Moon, J.-S., Jung, H. S., Lee, S. & Kang, S.-T. Ground improvement using dynamic compaction in Sabkha deposit. Appl. Sci.9, 1–16. https://doi.org/10.3390/app9122506 (2019).

Tophel, A., Walker, J. P., Dutta, T. T., Bodin, D. & Kodikara, J. Model development to predict dynamic interactions of roller and geomaterial using simulated roller compaction. Transp. Geotech.39, 1–12. https://doi.org/10.1016/j.trgeo.2023.100946 (2023).

Vink, J. W. & Dijkstra, J. W. CDC compaction at berth 9 quay extension felixstowe. UK Proc. Eng.143, 1468–1476. https://doi.org/10.1016/j.proeng.2016.06.173 (2016).

Yao, J., Yue, M., Ma, H. & Yang, C. Wave propagation characteristics and compaction status of subgrade during vibratory compaction. Sensors23, 1–18. https://doi.org/10.3390/s23042183 (2023).

Zhang, L., Yang, G., Zhang, D., Wang, Z. & Jin, J. Field test and numerical simulation of dynamic compaction of high embankment filled with soil-rock. Adv. Civ. Eng.1–9, 2019. https://doi.org/10.1155/2019/6040793 (2019).

Han, J. Shallow and deep compaction. In Principles and practice of ground improvement (ed. Han, J.) 73–116 (Wiley, 2015).

Nicholson, P. Objectives and Improvements from Soil Densification. In Soil improvement and ground modification methods (ed. Nicholson, P.) 63–69 (Butterworth Heinemann, 2015).

Zhou, C. et al. Evaluation on improvement zone of foundation after dynamic compaction. Appl. Sci.11, 1–23. https://doi.org/10.3390/app11052156 (2021).

Jin-feng, Z., Yu-ming, S. & Zhang-qi, X. Dynamic stress properties of dynamic compaction (DC) in a red-sandstone soil–rock mixture embankment. Environ. Earth Sci.76, 1–30. https://doi.org/10.1007/s12665-017-6743-1 (2017).

Alnaim, A. et al. A systematic framework for evaluating the effectiveness of dynamic compaction (DC) technology for soil improvement projects using cone penetration test data. Appl. Sci.12, 1–13. https://doi.org/10.3390/app12199686 (2022).

Cheng, X. et al. A calculation model for vibration effect induced by resonance-free vibratory hammer method. Buildings12, 1–16. https://doi.org/10.3390/buildings12122204 (2022).

Pan, J. L. & Selby, A. R. Simulation of dynamic compaction of loose granular soils. Adv. Eng. Soft.33, 631–640. https://doi.org/10.1016/S0965-9978(02)00067-4 (2002).

Pourjenabi, M. & Hamidi, A. Numerical modeling of dynamic compaction considering critical distance from adjacent structures. In Advances in soil dynamics and foundation engineering (eds Qiu, T. et al.) 97–106 (ASCE, 2014).

Bačová, D., Ižvoltová, J., Šedivý, Š & Chromčák, J. Different approach for the structure inclination determination. Buildings13, 1–12. https://doi.org/10.3390/buildings13030637 (2023).

Dobeš, P. Calibration of TDR test probe for measuring moisture in the body of the railway substructure and its subgrade. Civ. Environ. Eng.11, 84–94. https://doi.org/10.1515/cee-2015-0011 (2015).

Drusa, M. & Bulko, R. Rock slide monitoring by using TDR inclinometers. Civ. Environ. Eng.12, 137–144. https://doi.org/10.1515/cee-2016-0019 (2016).

Ižvolt, L. & Dobeš, P. Analysis of measuring the deformation resistance of the subgrade surface of a modernised line Považská Teplá-Žilina. Civ. Environ. Eng.16, 210–218. https://doi.org/10.2478/cee-2020-0020 (2020).

Niemiec, D., Bulko, R. & Mužík, J. The meshfree localized Petrov-Galerkin approach in slope stability analysis. Civ. Environ. Eng.15, 79–84. https://doi.org/10.2478/cee-2019-0011 (2019).

Nagula, S., Nguyen, M., Grabe, J., Kardel, J. & Bahl, T. Field measurements and numerical analysis of vibroflotation of sand. Géotechique72, 882–898. https://doi.org/10.1680/jgeot.20.p.195 (2022).

Li, P., Sun, X., Yu, J., Kong, G. & Chen, J. Experimental and analytical study on the reinforcement mechanism of in-pipe deep dynamic compaction in loose sandy soil. Acta Geotech.19, 1–18. https://doi.org/10.1007/s11440-024-02340-w (2024).

Khaled, O. E., Maalej, O. & Spyropoulos, E. Vibration caused by rapid impact compaction experimental versus numerical results. Int. J. Civ. Infr.4, 1–8. https://doi.org/10.11159/ijci.2021.001 (2021).

Dijkstra, J., Laumen, T. & van Paassen, L. Optimizing the relationship between CDC compaction induced settlement data and the average CPT cone resistance after compaction. In 19th Southeast Asian Geotechnical Conference & 2nd AGSSEA Conference, (AGSSAE, 2016).

Kalloe, D. V. Improving the quality control of Cofra Roller Compaction: A study on the relation between the impact acceleration and the soil compaction (Doctoral dissertation) (Delft University of Technology, 2020).

Braithwaite, E. J. & du Preez, R. W. Rapid impact compaction in Southern Africa. Geology for Engineering, Urban Planning, and the Environment (1997).

Becker, P. J. Assessment of rapid impact compaction for transportation infrastructure applications (Doctoral dissertation) (Iowa State University, 2011).

Serridge, C. J. & Synac, O. Application of the rapid impact compaction (RIC) technique for risk mitigation in problematic soils. In The 10th IAEG International Congress (2006).

Woodward, J. An introduction to geotechnical processes (ed. Woodward, J.) (Spon Press, 2005).

South African Institution of Civil Engineering SAICE. Innovative new ground improvement method uses controlled dynamic compaction. Civ. Eng.14, 3–6 (2006).

Merrifield, C. M. & Davies, M. C. R. A study of low-energy dynamic compaction: Field trials and centrifuge modelling. Géotechnique50, 675–681. https://doi.org/10.1680/geot.2000.50.6.675 (2000).

He, Z. & Chen, Q. Seismic mitigation effect for large-space underground structures considering spatially varying soil properties. J. Civ. Eng. Man.30, 19–32. https://doi.org/10.3846/jcem.2024.19784 (2024).

Cheng, S.-H., Chen, S.-S. & Ge, L. Method of estimating the effective zone induced by rapid impact compaction. Sci. Rep.11, 1–16. https://doi.org/10.1038/s41598-021-97912-1 (2021).

Wersäll, C., Bodare, A. & Massarsch, R. Frequency content of vertical ground vibrations caused by surface impact. In The Ninth International Conference on Testing and Design Methods for Deep Foundations (2012).

Tavasoli, O. & Ghazavi, M. Wave propagation and ground vibrations due to non-uniform cross-sections piles driving. Com. Geotech.104, 13–21. https://doi.org/10.1016/j.compgeo.2018.08.010 (2018).

Parvizi, M. Soil response to surface impact loads during low energy dynamic compaction. J. Appl. Sc.9, 2088–2096. https://doi.org/10.3923/jas.2009.2088.2096 (2009).

Tara, D. and Wilson, P. Rapid impact compactor ground improvement, vibration monitoring and densification assessment. In Final report submitted to rapid impact compactors Ltd., (Thurber Engineering Ltd., 2004).

Yang, C., Zhang, L., Han, Y., Cai, D. & Wei, S. Study on the transmission and evolution Characteristics of vibration wave from vibratory roller to filling materials based on the field test. Appl. Sci.10, 1–16. https://doi.org/10.3390/app10062008 (2020).

Chen, A., Cheng, F., Wu, D. & Tang, X. Ground vibration propagation and attenuation of vibrating compaction. J. Vibroeng.21, 1342–1352. https://doi.org/10.21595/jve.2019.20388 (2019).

Liu, X., Zhang, X., Kong, L., Chen, C. & Wang, G. Mechanical response of granite residual soil subjected to impact loading. Int. J. Geomech.21, 04021092. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002055 (2021).

Massarsch, K. R. & Fellenius, B. H. Ground vibrations from pile and sheet pile driving, Part 1 – building damage. International conference on piling and deep foundation, Deep Foundations Institute (2014).

Chameau, J.-L., Rix, G. J. & Empie, L. E. Measurement and analysis of civil engineering vibrations. Fourth international conference on case histories in geotechnical engineering, https://api.semanticscholar.org/CorpusID:62778378 (1998).

Massarsch, K. R. & Fellenius, B. H. Ground vibrations from pile and sheet pile driving, Part 2 – review of vibrations standards. International conference on piling and deep foundations, Deep Foundations Institute (2014).

International Organization for Standardization. (2010). Technical vibration and shock vibration of fixed structures – Guidelines for the measurement of vibrations and evaluation of their effects on structures (ISO 4866:2010).

British Standards Institution. Evaluation and Measurement for Vibration in Buildings–Part 2: Guide to damage levels from groundborne vibration (BS:7385-2:1993).

British Standards Institution Code of practice for noise and vibration control on construction and open sites–Part 2: Vibration (BS 5228-2:2009).

British Standards Institution. Code of practice for noise and vibration control on construction and open sites–Part 2 Vibrations (BS 5228–1:2009+A1:2014).

German Institute for Standard. Vibrations in Buildings–Part 3: Effects on structures (DIN 4150-3:2016-12).

Swedish Institute for Standards. Vibration and shock – Guidance levels and measuring of vibrations in buildings originating from piling, sheet-piling, excavating and packing to estimate permitted vibration levels (SS 02 52 11-1999).

Siskind, D. E. Vibrations from blasting (International Society of Explosives Engineers, 2005).

Adam, D., Adam, C., Falkner, F. J. & Paulmichl, I. Vibration emission induced by rapid impact compaction. In Proceedings of the 8th International Conference on Structural Dynamics (2011).

Svinkin, M. R. Tolerable limits of construction vibrations. Pract. Per. Struct. D. and Constr.20, 1–7. https://doi.org/10.1061/(ASCE)SC.1943-5576.0000223 (2015).

Svinkin, M. R. A choice of proper criteria for soil and structural vibrations from construction and industrial sources. In 19th International Conference on Soil Mechanics and Geotechnical Engineering, (ISSMGE, 2017).

Hwang, J.-H. & Tu, T. Y. Ground vibration due to dynamic compaction. Soil Dyn. Earthq. Eng.26, 337–346. https://doi.org/10.1016/j.soildyn.2005.12.004 (2006).

Lav, M. A., Yüksel, E. & Karadoğan, F. Vibrations due to dynamic compaction. In Fifth International Conferences on Recent Advances in Geotechnical Earthquake Engineering and Soil Dynamics, Missouri University of Science and Technology (2010).

Lauzon, M., Morel, J., Briet, S. & Beaton, N., F. Ground vibrations induced by dynamic compaction and rapid impact compaction. In 14th Pan-American Conference on Soil Mechanics and Geotechnical Engineering, (ISSMGE, 2011).

Neilson, R. D., Rodger, A. A., Oliver, K. D., Wright, R. H. & Elliott, R. M. Vibration assessment of high speed dynamic compaction. In Ground dynamics and man-made processes: Prediction, design and management (ed. Skipp, B. O.) (Thomas Telford, 1998).

Allen, S. The low energy dynamic compaction of soil (Doctoral dissertation) (University of Wales, 1996).

Alver, O. & Eseller-Bayat, E. E. Effect of soil damping on the soil–pile–structure interaction analyses in cohesionless soils. Appl. Sci12, 1–16. https://doi.org/10.3390/app12189002 (2022).

Grizi, A., Athanasopoulos-Zekkos, A. & Woods, R. D. Ground vibration measurements near impact pile driving. J. Geotech. Geoenviron. Eng.142(04016035), 1–11. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001499 (2016).

Lai, C. G., Rix, G. J., Foti, S. & Roma, V. Simultaneous measurement and inversion of surface wave dispersion and attenuation curves. Soil Dyn. Earthq. Eng.22, 923–930. https://doi.org/10.1016/S0267-7261(02)00116-1 (2002).

Lee, J.-S., Zeng, W., Lambert, M. F. & Gong, J. Calibration of frequency-dependent wave speed and attenuation in water pipes using a dual-Sensor and paired-IRF approach. J. Water Resour. Plann. Manag.150, 1–10. https://doi.org/10.1061/JWRMD5.WRENG-6382 (2024).

Zheng, X. et al. Elastic surface wave attenuation in layered soil by metastructures. Low-Carbon Mater. Green Constr.2, 1–10. https://doi.org/10.1007/s44242-024-00037-7 (2024).

Esmaeili-Moghadam, A. & Rafiee-Dehkharghani, R. Ground-borne vibration screening in layered dry and saturated grounds using optimal inclined wave barriers. Soil Dyn. Earthq. Eng.162, 1–16. https://doi.org/10.1016/j.soildyn.2022.107448 (2022).

Acknowledgements

This work was supported by the Grant National Agency VEGA of the Slovak Republic under Grant No. 1/0009/2023.

Author information

Authors and Affiliations

Contributions

F.G., J.M., F.M. and M.Š. performed the in situ tests. F.B. and J.P. performed data analysis. J.V. analysed test outputs and wrote the original paper. J.M. revised the draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Vlček, J., Gago, F., Mihálik, J. et al. Investigation of dynamic effect of rapid impact compaction. Sci Rep 14, 21364 (2024). https://doi.org/10.1038/s41598-024-72728-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-72728-x