Abstract

Emulsified asphalt mixtures’ cold mix and paving features facilitate asphalt pavements in fulfilling dual-carbon and energy-saving demands. Anionic emulsifiers can enhance emulsion stability, ensure uniform dispersion of oil and water, possess good decompression viscosity, thickening, and lubricating properties, and maintain good stability under acidic conditions. Nevertheless, anionic emulsified asphalt is restricted in engineering applications due to problems like its storage stability. In this paper, eight anionic emulsifiers and two preparation procedures were chosen for stability tests. Through static tests, storage tests, sieve residue tests, and laser particle size tests, the impacts of emulsifiers on the storage stability and dispersion of asphalt were analyzed. Waterborne epoxy resin exhibits excellent adhesive properties, mechanical properties, chemical resistance, and heat stability. A fluorescence microscope test, static and storage test, laser particle size test, and cementation test were employed to explore the effects of different preparation processes and waterborne epoxy mixing ratios on emulsified asphalt’s storage stability, dispersion stability, and structural stability. The results showed that: (1) the emulsified asphalt prepared with the BWH-02 emulsifier exhibits the best storage stability, and blending with 20% of the waterborne epoxy modifier can notably enhance the bonding properties; (2) the shear strength of the BWH-02 waterborne epoxy emulsified asphalt prepared can reach 1.543 MPa, and the tensile viscosity can reach 0.848 MPa; (3), The emulsified asphalt prepared by the process of modification has better storage stability than that prepared by the side of the emulsification process. Moreover, the storage stability of emulsified asphalt prepared by emulsification and modification is superior to that of the emulsification and modification process. This research provides theoretical and technical support for popularizing and applying cold-mixed cold-paving asphalt mixtures.

Similar content being viewed by others

Introduction

Emulsified asphalt, a material with extensive application prospects, boasts the merits of energy conservation and convenient construction and exhibits a yearly increasing trend1,2,3,4,5,6,7. According to the properties of emulsifier molecules, emulsified asphalt can be categorized into three types: anionic, cationic, and nonionic. Anionic emulsified asphalt is extensively employed in preparing materials like CA mortar, cold mix, paving mixtures, and spray-applied quick-setting waterproofing coatings8,9,10,11. Although anionic emulsified asphalt is inexpensive and accessible from diverse sources, it is relatively less stable, and its performance might deteriorate after long-term storage or long-distance transportation.

Researchers have conducted more experiments to explore the various properties of anionic emulsifiers. Shi et al. investigated the stability of emulsified asphalt prepared with two dodecyl sulfate emulsifiers using storage stability, particle size distribution, and differential scanning calorimetry (DSC)12. Wang examined the effect of anionic emulsifiers on the stability of emulsified asphalt through surface tension, storage stability, and dynamic shear rheology tests and elucidated the differences in the stability of emulsified asphalt from a molecular viewpoint by establishing a ternary model and analyzing a series of indices, such as the interaction energy, roughness, relative concentration distribution, and the mean-square displacement (MSD)13. Conversely, Yuan and others explored the mobility of water molecules in the emulsifier head groups based on molecular dynamics. They determined that the metal cations Ca2+ and Mg2+ reduce the stability of asphalt emulsions14. Wang et al. evaluated the effect of two types of asphalt emulsions, anionic and cationic, on the properties of two kinds of cement emulsified asphalt mortar (CEAM), low and high modulus CEAM, at different asphalt cement ratios (A/C)15. Kong explored through molecular simulation and conductivity experiments the effect of five anionic emulsifiers with the same hydrophobic and different hydrophilic groups on the adsorption on the surfaces of the main chemical components of the aggregates (calcium carbonate: CaCO3, silicon dioxide: SiO2) with the same hydrophobic and different hydrophilic groups16. Huang et al. discovered that the emulsified asphalt prepared with an anionic emulsifier, stabilizer, and defoamer at 3.0%, 0.1%, and 0.1%, respectively, with a soap configuration temperature of 40 °C, an asphalt temperature of 130 °C, and a shear time of 90 s had a superior emulsified asphalt storage stability17. Li et al. endeavored to alter the stability of anionic emulsified asphalt by adding lignin and found that the process requires a stabilizer18. Most of the current research focuses on exploring the factors influencing the stability of anionic emulsified asphalt or the preparation conditions. However, there is a lack of consensus on the choice of anionic emulsifier type, which is universally applicable and has better stability performance in practical engineering applications.

Under the action of waterborne epoxy resin and curing agent, the emulsified asphalt forms a three-dimensional network structure, which retains the construction convenience of emulsified asphalt after modification and enhances the thermal stability, bond strength, and waterproofing properties of waterborne epoxy resin19,20,21,22,23. Kong evaluated the bonding effect of waterborne epoxy resin emulsified asphalt (WEREA) at different temperatures, application rates, and soaking times. The study results showed that WEREA significantly improved the bond strength and shear strength of the bonded layer, exhibiting minimal temperature sensitivity. The optimum concentration of WEREA was 20% and the application amount was 0.9 kg/m24. Yang analyzed the effect of WER on the microstructure, rheological properties, and low-temperature stability of emulsified asphalt, and found that WER had a certain detrimental effect on the low-temperature performance of emulsified asphalt. Therefore the content of the modifier should be strictly controlled25. Song investigated the effects of emulsion pH, asphalt temperature, and shear time on the emulsified asphalt storage stability and asphalt droplet size. The results showed that the emulsion pH, asphalt temperature, and shear time had a significant effect on the particle size of emulsified asphalt droplets and its storage stability, and the optimal conditions for the preparation of emulsified asphalt were determined: emulsion pH of 3.2, asphalt temperature of 137.3 °C, and shear time of 74 s. This study showed that the emulsified asphalt droplet storage stability and storage stability of emulsified asphalt were significantly affected by the emulsifier content, asphalt temperature, and shear time26. In this experiment, a superior waterborne epoxy anionic emulsified asphalt was prepared by blending with waterborne epoxy resin for modification. Currently, the modification of emulsified asphalt is primarily employed in two manners: to emulsify the matrix asphalt to form emulsified asphalt, and then add modifiers for modification, known as modification after first emulsification. Another approach is adding the modifier while emulsifying the matrix asphalt, which is modified during emulsification. Li et al. investigated the impact of waterborne epoxy content on the microstructure and rheological properties of the residual asphalt in the emulsion by establishing an ontological model of modified asphalt emulsion27. Ji and others utilized a three-factor, three-level orthogonal test to determine the optimal oil-water ratio, emulsifier dosage, and waterborne epoxy resin dosage28. Xue and others compared the curing time and adhesion of waterborne epoxy-modified emulsified asphalt at different temperatures and with different waterborne epoxy resin dosages. They studied the variation rule of the viscosity of waterborne epoxy-modified emulsified asphalt to varying temperatures with time29. Meng and others investigated the effect of different waterborne epoxy resin dosages on the performance of composite-modified emulsified asphalt by analyzing the three major indexes of residue on sieve, storage stability, evaporation residue, and Brønsted viscosity through indoor tests30. Nevertheless, the emulsified asphalt preparation process research mainly focuses on factors such as the oil-water ratio, shear conditions, and the amount of modifier added. The difference in the stability of modified emulsified asphalt prepared by the two processes of first emulsification and then modification and modification during emulsification, as well as the extent of this difference, has not been thoroughly examined.

Given these research gaps, eight common anionic emulsifiers underwent a static observation and a 5-day storage test to evaluate storage stability. The residue-on-sieve and laser particle size tests were employed to determine dispersion stability. After selecting the anionic emulsifier, the stability of waterborne epoxy anionic (modified) emulsified asphalt under two preparation processes and various waterborne epoxy mixing ratios was compared. Additionally, the centrifugal test was utilized to simulate the long-term usage of the modified emulsified asphalt, and the particle structure of the modified emulsified asphalt was observed with an inverted fluorescence microscope test. Ultimately, the structural stability of the modified emulsified asphalt was assessed using Marshall shear tests and concrete specimen pullout tests. The main technical flow chart of this study is presented in Fig. 1.

Materials

The primary raw materials of emulsified asphalt are matrix, emulsifier, additives, and water31. In this paper, 70# matrix asphalt is selected, as presented in Table 1, and the related technical indexes refer to the <Technical Specifications for Highway Asphalt Pavement Construction> (JTG F40–2004)32,33. The anionic emulsifier solution requires adding an alkali to adjust the pH to an appropriate range; in this paper, flake pyrophoric alkali, namely NaOH, is employed as an alkali adjusting aid. Many emulsified asphalt tests recommend using distilled water; however, considering the project site and cost, distilled water is not suitable for large-scale application, thus tap water is selected.

Anionic emulsifiers

The emulsifier determines the asphalt emulsification effect and the basic properties of the emulsion34. This paper selected eight types of anionic emulsifiers for testing: LT-PA, T14, BWH-02, JY-04, JL-A01, JL-A03, BH-Y, and LSF-01 emulsifiers. Their technical indexes are presented in Table 2, and the physical appearance of the products is depicted in Fig. 2.

Water-based epoxy resin

Waterborne epoxy asphalt is a thermosetting polymer material with epoxy resin and asphalt curing agent. Compared to ordinary asphalt, it possesses the traits of superior thermal stability, robust resistance to deformation, exceptional fatigue resistance, and high indirect tensile strength, and it can be effectively bonded with aggregate35,36,37,38,39. The relevant technical specifications of the chosen waterborne epoxy resins are presented in Table 3, and the composition of the waterborne epoxy resin itself and its corresponding curing agent is depicted in Fig. 3.

Preparation process parameters

Emulsified bitumen

The quantity of matrix asphalt was fixed at 302.5 g, the maximum dosage range recommended by the manufacturer was employed for the emulsifier, the milling duration was 3 min, the soap temperature was 60 °C, and the asphalt temperature was 140 °C. The conditions of the preparation technical parameters are presented in Table 4, and the process of test sample preparation is elaborated in Fig. 4.

Water-based epoxy emulsified asphalt

In the test, a preferred anionic emulsifier was ascertained after comprehensive analysis to prepare waterborne epoxy-modified emulsified asphalt. For illustration and analysis, the method of emulsification followed by modification is denominated as preparation process I, and the preparation process of emulsification and modification simultaneously is referred to as preparation process II. After modification, the stability of the preferred anionic emulsified asphalt was appraised by gradually blending 5–20% of waterborne epoxy resin into the emulsified asphalt under these two distinct preparation processes. The particulars of the component ratios of the waterborne epoxy-emulsified asphalt are presented in Table 5.

Test methods

Emulsified asphalt storage stability test

Storage stability is a crucial indicator of whether asphalt can be stored for an extended period40,41. The stability of the prepared emulsified asphalt was initially assessed using a static observation storage stability test, and the observations were documented for up to 14 days. Due to the wide range of emulsifiers, several products with inferior stability were eliminated from the test.

Next, the preferred anionic emulsifiers were assessed using a more precise 5-day storage stability test approach. The test outcomes were computed and regarded as absolute values by Eq. (1), and each set of tests was conducted twice. The test setup is shown in Fig. 5.

where SS is the specimen storage stability, PA is the specimen evaporated residue content (%) in the upper branched portion after storage, and PB is the specimen evaporated residue content (%) in the lower branched portion of the specimen after storage.

Emulsified asphalt dispersion stability test

Studies on dispersion have determined that the particle size distribution of emulsified asphalt particles has a crucial impact on its stability performance42,43. The emulsified asphalt sieve residue test is devised to assess the overall dispersion effect of emulsified asphalt from a macroscopic perspective; the test adheres to the relevant test procedures and methods of T0652-1993. For the emulsified asphalt obtained from the five emulsifiers prepared, a sample of approximately 500 g was taken after 24 h, and the number of solids remaining on the sieve mesh after passing through a 1.18 mm sieve was ascertained. The test results were computed according to Eq. (2) and using the test configuration in Fig. 6.

where Pr is the mass of the remaining residue on the sieve (%), m is the test mass of emulsified asphalt (g), m1 is the mass of the filter sieve, and the metal disk (g), and m2 is the combined mass of the filter sieve, the metal disk and the residue on the sieve (g).

The microscopic angle test was conducted employing a Bettersize2000LD laser particle size distributor for the wet particle size determination to ascertain the particle size of asphalt in an aqueous medium. The test apparatus is elaborated in Fig. 7. This test was intended to analyze emulsified asphalt particles’ average particle size and particle size distribution.

Water-based epoxy emulsified asphalt long-term storage stability

The centrifugal stability test is employed to simulate the long-term storage stability of waterborne epoxy-emulsified asphalt, and the centrifugal speed and time are required to be pre-tested for determination. After centrifugation, the tubes were placed in an incubator at 50 °C, and the quantity of residual solids after drying was documented. The test refers to the <Highway Engineering Asphalt and Asphalt Mixture Test Procedures> (JTGE20-2011) regarding the evaluation method for the storage stability of emulsified asphalt. The centrifugal test tube of the test is presented in Fig. 8a, and the centrifuge is depicted in Fig. 8b.

Water-based epoxy emulsified asphalt dispersion stability test

An inverted fluorescence microscope was utilized to observe the particle size distribution of waterborne epoxy-emulsified asphalt from a microscopic perspective, with the device depicted in Fig. 9a and the principle illustrated in Fig. 9b. Under the fluorescence microscope, the epoxy particles presented as yellowish-green. At the same time, the bitumen appeared black44. Images of emulsified asphalt with 5%, 10%, 15%, and 20% epoxy doping under the two processes were captured to compare and observe the dispersion state and spatial structure of waterborne epoxy resin particles in the emulsified asphalt45.

Water-based epoxy emulsified asphalt binder performance test

Emulsified asphalt and cement can effectively collaborate46,47. To obtain the binder property of emulsified asphalt, the Marshall specimen straight shear test and cement specimen tensile test are chosen in this study48. In this paper, the specimens are fabricated by constructing a homemade straight shear apparatus, referring to the pavement interlayer material shear tester49, by coating the butted surfaces of AC13 Marshall specimens molded and maintained by the standard method with ample emulsified asphalt. The coated Marshall specimen is positioned at both ends of the straight shear apparatus, as shown in Fig. 10a, and the axial pressure, as depicted in Fig. 10b, is applied using the SNS universal testing machine. Record the maximum pressure at the moment of failure and calculate its shear stress according to Eq. (3), which represents the shear strength.

where τ is the asphalt shear strength (MPa), F is the vertical load (N).

In this paper, the static mechanical properties of waterborne epoxy-modified asphalt at room temperature were assessed concerning the mortar tensile strength test in the <Standard for Test Methods of Basic Properties of Construction Mortars> (JGJ/T70–2009)50. Two 40 × 40 mm mortar specimens were employed, clamped after coating emulsified asphalt between them, and maintained at 50 °C for 48 h to obtain the specimens. Tensile tests were conducted using a universal testing machine at a loading rate of 5 mm/min51. The loading pattern is presented in Fig. 11. The tensile bond strength was computed according to Eq. (4). Three specimens were fabricated for each proportion, and the average value was calculated based on the test results with an accuracy control of 0.01 MPa.

where fat is the tensile bond strength of the mortar (Mpa), Fmax is the maximum load at the time of specimen (N) destruction, and A is the bond area.

Results and discussion

Effect of emulsifier on the stability of emulsified asphalt

The results obtained after 14 days of the static stabilization test are presented in Fig. 12. After 14 days of standing, the emulsified asphalt prepared by BWH-02 and BH-Y still had no crust on the surface, no emulsion delamination, and only a small amount of asphalt particles at the bottom of both metal vessels. Skinning, emulsion delamination, or asphalt clumping occurred after different standing periods for the remaining emulsifiers. The initial observations indicated that the stability of the emulsified asphalt prepared by these eight emulsifiers is as follows: BWH-02 > BH-Y > LSF-01 > JY-A4 > JL-A01 > LT-PA > T14 > JLA03. The test identified three types of emulsifiers, LT-PA, T14, and JL-A03, which showed poor performance during standing, with obvious crusting and cohesive asphalt lumps that required a glass rod to be pried apart.

The emulsified asphalt prepared with the remaining five emulsifiers underwent a 5-day storage stability test. The test results, calculated following Eq. 1, are depicted in Fig. 13. The findings indicated that the 5-day storage stability of the two emulsifiers, BWH-02 and BH-Y, was approximately 0.1% and 0.29%, respectively. This was notably superior to that of the other three emulsifiers. The 5-day storage stability of JY-A4 emulsified asphalt amounted to 5.59%, which does not fulfill the requirements for the storage stability of emulsified asphalt in the < Technical Specification for Highway Asphalt Pavement Construction> (JTGF40-2011). The storage stability test results were ranked as BWH-02 > BH-Y > JL-A01 > LSF-01 > JY-A4, aligning with the static stability test outcomes.

Effect of emulsifier on the dispersion of emulsified asphalt

The dispersibility of emulsified asphalt fabricated with five emulsifiers was assessed, and the test outcomes were computed under Eq. (2) and presented in Fig. 14. In line with the principle of the sieve residue test, the lower the sieve residue, the superior the emulsification effect. The sieve residues of emulsified asphalt produced by BWH-02 and BH-Y were 0.01% and 0.05% respectively, significantly lower than those of the other three emulsifiers. The sieve residue of the five emulsified asphalts was ranked as follows: BWH-02 < BH-Y < JL-A01 < LSF-01 < JY-A4.

The particle size distribution curves of the five emulsified asphalts were determined using the laser particle size meter as presented in Fig. 7. In these curves, the frequency of particle distribution about size is significant, with the peak positions indicating the most prevalent size ranges. Figure 15a. reveals that the particle size range of the prepared emulsified asphalt is primarily concentrated in the 1–2 μm range, featuring a small particle size, favorable dispersion, and good emulsion stability. Figure 15b demonstrates the trend of the cumulative content of each emulsified asphalt. When the interval is 1–2 μm, more than 60% of the emulsified asphalt particles pass through. The relevant data are presented in Fig. 15c. Notably, the emulsified asphalt prepared using the JY-A4 asphalt emulsifier has a broad particle size distribution, ranging from 1 to 100 + µm, suggesting that the particle size is not uniform. The dispersion is poor, with particles of 1–2 μm accounting for only 17.2%. In contrast, for the emulsifiers prepared by BWH-02 and JL-A01, the proportion of emulsified asphalt particles at 1–2 μm is approximately 66%. The proportion of emulsified asphalt particles at 1–2 μm is as high as 83.08% for the emulsifiers prepared by BH-Y. This indicates that these emulsifiers have a more concentrated particle size distribution and smaller particle sizes, and thus exhibit better stability. However, the storage stability test results suggest that BH-Y and JL-A01 are slightly less superior to the emulsified asphalt prepared with the BWH-02 emulsifier. Nevertheless, the amount of BH-Y emulsifier required in the preparation process is 2.3 times that of BWH-02 and 1.7 times that of JL-A01.

In addition, based on the data in Fig. 15d, the emulsified asphalt prepared with the BH-Y emulsifier has the smallest particle size of 1.64 μm. The emulsified asphalts prepared with the BWH-02 and the JL-A01 emulsifier have comparable particle sizes ranging from 1.9 to 2.0 μm. The emulsified asphalt prepared with the JY-A4 emulsifier has the largest particle size of 7.647 μm. The average particle size change trend aligns with the particle size distribution law, suggesting that the lower particle size percentage can serve as a reference index for evaluating emulsified asphalt’s particle size distribution law. Emulsified asphalt with a smaller particle size is less influenced by gravity settling, thereby having better storage stability; conversely, emulsified asphalt with a larger particle size is more prone to the influence of gravity, which ultimately results in its poor storage stability.

Summary: In 4.1–4.2, static observation of the storage stability test excluded the three emulsifiers LT-PA, T14, and LT-A03 with poor storage performance. The 5d storage stability test of emulsified asphalt prepared by the remaining five emulsifiers showed good to poor performance as follows: BWH-02 > BH-Y > JL-A01 > LSF-01 > JY-A4, and the results of the sieve residue test were from less to more as follows: BWH-02 < BH-Y < JL-A01 < LSF-01 < JY-A4. Based on the comparison of the results of the laser particle size analysis, it was found that BH-Y The emulsified asphalt emulsifier prepared by the smallest particle size of 1.63 μm, BWH-02, JL-A01 emulsifier prepared by the emulsified asphalt particle size is comparable to the size of about 1.9 μm, which in the difference between the two models are ≥ 5 μm. taking into account the BWH-02 emulsified asphalt emulsifier storage stability and its asphalt particles are more homogeneous, and finally comprehensively determined in the subsequent experimental research, the BWH-02 emulsifier was adopted.

Effect of preparation process on the stability of waterborne epoxy emulsified asphalt

The results of the static stability test are presented in Fig. 16. Upon analysis and observation, it was discovered that the stability of the modified emulsified asphalt prepared through emulsification followed by modification is superior to that of modification during emulsification. Cross-sectional comparisons revealed that the waterborne epoxy emulsified asphalt obtained by Process I did not exhibit significant variations within the 5–20% dosage range. Nevertheless, the waterborne epoxy emulsified asphalt obtained by Process II presents an obvious crust phenomenon when 5% waterborne epoxy is doped. As the amount of waterborne epoxy resin increases, the thickness of the crust on the asphalt surface escalates, and the asphalt even appears to be in a consolidated state when the doping amount reaches 20%. Longitudinal comparisons indicated that the waterborne epoxy-modified emulsified asphalt obtained by Process II is significantly less stable.

In process II, the thickness of the surface crust increments with the gradual rise in the quantity of waterborne epoxy resin. Through subsequent observation, it is found that this crust thickens and grows with the increase in storage time. There are two speculated reasons for this phenomenon. Firstly, during the process of the water-based epoxy undergoing secondary shearing by the colloid mill, the internal stability of the colloid mill is high, causing the temperature of the water-based epoxy resin and water to evaporate, resulting in a reduction in ζ-potential and emulsion breakage. Secondly, the density of the water-based epoxy emulsified asphalt is lower, gradually floating to the surface of the emulsified asphalt. Moreover, the water-based epoxy resin is a high polymer material with a greater interfacial tension, which has an adsorption effect on asphalt particles. Its interfacial tension is higher, and so is the adsorption of asphalt particles.

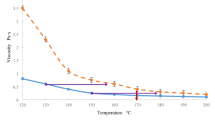

The results of the centrifugation test are presented in Fig. 17, where the horizontal coordinate indicates the amount of waterborne epoxy added, and the vertical coordinate represents the residual solids content of the asphalt after the centrifugation process is completed. under diverse preparation process conditions, the residual quantity of waterborne epoxy emulsified asphalt progressively reduces as the amount of waterborne epoxy resin augments, suggesting that its centrifugal stability improves with the increase in the amount of waterborne epoxy resin. For both preparation approaches, the disparity in centrifugal stability between the two gradually diminishes with the rise in waterborne epoxy resin. Nevertheless, concerning centrifugal stability, the emulsified asphalt prepared by Process I is marginally superior to the waterborne epoxy emulsified asphalt prepared by Process II. The discrepancy between the two is most pronounced, particularly in the 5% and 10% waterborne epoxy resin dosages. However, with a 15% dosage, the gap between the two gradually lessens and stabilizes. Hence, the long-term storage performance of waterborne epoxy-emulsified asphalt was assessed by the centrifugal stabilization test and the waterborne epoxy-emulsified asphalt prepared by Process I was determined to possess more superior long-term storage stability. ADDITIONAL NOTE: The pre-test results are depicted in Fig. 18, and the median centrifugal speed of 4000 r/min was chosen for comprehensive consideration, with the centrifugation time set at 10 min.

Effect of preparation process on the dispersion of waterborne epoxy emulsified asphalt

In the inverted fluorescence microscope test, the particle distribution of waterborne epoxy-modified emulsified asphalt was observed using a 400x fluorescence microscope, and the results are presented in Fig. 19, where the yellowish-green light dots represent waterborne epoxy resin particles. Cross-sectional comparisons revealed that the epoxy curing compounds were microparticulate at lower dosages, and the particle area and density of the curing compounds gradually increased with the escalating dosage. When the dosage of waterborne epoxy resin surpasses 15%, the epoxy particles cease to be rounded and assume an irregular shape. Longitudinal comparisons indicated that the waterborne epoxy resin particles were more rounded and homogeneous under Process II but were more substantial than in Process I. Nevertheless, the desired spatial mesh crosslinking structure did not materialize at any waterborne epoxy resin dosage ranging from 5 to 20%. After analysis, this phenomenon is primarily attributed to two reasons: Firstly, the compatibility of the waterborne epoxy resin with the matrix emulsified asphalt is inadequate, mainly as the curing time required for the waterborne epoxy resin is inconsistent with the emulsion breaking time of the emulsified asphalt. When the emulsified asphalt completes the emulsion film breaking, in the waterborne epoxy resin particles, due to the slow emulsion and asphalt film breaking, the content cannot overflow, leading to the inability of the waterborne epoxy resin to be cured to form a spatial mesh structure. Secondly, the flexible waterborne epoxy resin employed in the test could not establish a crosslinked structure with the emulsified asphalt because breaking the emulsion and spilling water is more challenging than the rigid waterborne epoxy resin.

According to the outcomes of the laser particle size test, the particle size of emulsified asphalt upon the addition of waterborne epoxy resin exhibited a decreasing tendency in both preparation processes, as depicted in Fig. 20. The waterborne epoxy emulsified asphalt fabricated by Process I possesses a smaller particle size compared to the emulsified asphalt produced by Process II within the 5–20% waterborne epoxy resin dosage range. With the escalation of the waterborne epoxy dosage, the particle size of the emulsified asphalt prepared by Process I initially increased and gradually decreased. Through data analysis, the emulsified asphalt prepared by Process II demonstrated a comparable pattern, where the particle size fluctuations of the waterborne epoxy emulsified asphalt within the approximately 3.0 μm range are relatively minor, and the particle size fluctuations are more stable. Nevertheless, the particle size is larger than that of the waterborne epoxy-emulsified asphalt prepared by Process I. The emulsified asphalt prepared by Process II presented a similar trend. Irrespective of the preparation process, the particle size of the emulsified asphalt became smaller than that of the matrix emulsified asphalt after incorporating the waterborne epoxy resin. Additionally, the cause of this decreasing, then increasing, and subsequently reducing trend might be associated with the accumulation of the waterborne epoxy-emulsified asphalt and the formation of internal chemical bonds, which requires further exploration.

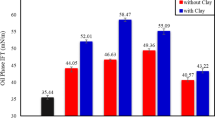

Influence of preparation process on cementation properties of waterborne epoxy emulsified asphalt

The Marshall straight shear and bond strength tests are presented in Figs. 21 and 22, respectively. The horizontal coordinates denote the waterborne epoxy dosage, while the vertical coordinates signify the shear strength at shear damage and the tensile bond strength at pullout damage, respectively. In conclusion, the shear strength and tensile bond strength of waterborne epoxy emulsified asphalt under the two preparation processes increase gradually with the rising dosage of waterborne epoxy.

According to Fig. 21, the shear strength of waterborne epoxy emulsified asphalt prepared by emulsification followed by modification rose from 0.586 to 1.375 MPa with the increment of waterborne epoxy doping, and the overall shear strength growth rate amounted to 134%. On average, for every 1% increase in waterborne epoxy resin, the shear strength ascended by 6.7%. The shear strength of the waterborne epoxy emulsified asphalt fabricated by side emulsification and modification climbed from 0.586 to 1.543 MPa, with an overall shear strength growth rate of 163%. On average, for every 1% increase in the quantity of waterborne epoxy resin employed, the strength rose by 8.1%. The outcomes demonstrated that in terms of shear strength, preparing waterborne epoxy resin emulsified asphalt with emulsification and modification surpassed the preparation process of emulsification followed by modification. The greater the amount of waterborne epoxy, the better the shear performance of asphalt. This might be attributed to the fact that when waterborne epoxy is scarce, excessive emulsified asphalt will form a sliding surface in the interlayer, thereby reducing the bond shear strength. With the rise in the dosage of waterborne epoxy, the proportion of emulsified asphalt becomes smaller, no asphalt film thickness is formed between the layers, and the bond shear strength becomes larger.

According to Fig. 22, as the amount of waterborne epoxy gradually increases, the adhesive tensile strength of the waterborne epoxy emulsified asphalt prepared by emulsification followed by modification rises from 0.341 to 0.785 MPa, with an overall growth rate of tensile strength of 130%. On average, for every 1% increase in waterborne epoxy resin, the tensile bond strength is increased by 6.5%. The tensile strength of the waterborne epoxy emulsified asphalt bond prepared by emulsification and modification increases from 0.34 to 0.848 MPa, with an overall tensile strength growth rate of 149%, and for every 1% increase in the dosage of waterborne epoxy resin, the average strength is increased by 7.4%. The overall adhesive tensile strength of waterborne epoxy emulsified asphalt prepared by side emulsification and modification is superior to that of the process prepared by first emulsification and then modification. The increasing trend of both methods might be that when the waterborne epoxy dosing is less, the proportion of emulsified asphalt is more significant. This may lead to a more disordered distribution of asphalt particles and an agglomeration phenomenon, disrupting the equilibrium and continuity between the waterborne epoxy resin and asphalt, thereby damaging the bonding layer.

Conclusions

In this paper, an anionic emulsifier is proposed to prepare emulsified asphalt with excellent storage stability, and its strength is evaluated under diverse waterborne epoxy dosing and preparation process conditions. The main conclusions are summarized as follows:

-

(1)

Through comparing the outcomes of the static storage test, 5-day storage stability test, residue on sieve test, and laser particle size test among 8 emulsifiers, it is revealed that BWH-02 emulsified asphalt exhibits no evident unity or crusting phenomenon, possesses the least amount of evaporation residue, and has the smallest quantity of residue on the sieve after sieving. Additionally, the size and distribution of the particle size under the laser particle size analysis are more uniform. Consequently, it is ultimately proposed that the emulsifier prepared with the BWH-02 type yields the optimal storage stability of anionic emulsified asphalt.

-

(2)

The dispersion and stability of waterborne epoxy anionic emulsified asphalt prepared using the BWH-02 emulsifier are assessed. The obtained waterborne epoxy emulsified asphalt demonstrates better storage stability through the preparation process of first emulsification after modification. It shows no skin formation or precipitation during short-term storage, and the overall trend of long-term storage stability is superior to the modification followed by emulsification. Additionally, with the emulsification followed by the modification process, the particle size of the emulsified asphalt is smaller and more stable.

-

(3)

When the epoxy resin dosage was the same, the emulsified asphalt prepared through emulsification and modification exhibited better shear resistance (with an average increase of 1.4%) and adhesion (with an average growth of 0.9%) than that prepared by emulsification and modification. Based on the results of the storage stability test and cementation performance test, for the preparation of BWH-02 type waterborne epoxy anionic emulsified asphalt, a recommended external mixing dosage of 20% for waterborne epoxy is suggested, offering better performance and greater economic efficiency.

In this study, the storage and dispersion stability of eight anionic emulsified asphalts were investigated from macroscopic and microscopic perspectives, and an anionic emulsifier with superior performance was selected. Furthermore, to explore the practical engineering significance of the anionic emulsifier, this paper also investigated the storage stability, dispersion stability, and structural stability of waterborne epoxy anionic emulsified asphalt about the optimal addition amount of waterborne epoxy resin and the selection of the preparation process. It provides a theoretical basis for the material preparation, process selection, and parameter determination of anionic emulsified asphalt in actual cold mix engineering applications.

Outlook

The strengths of the study are: (1) a more comprehensive study of the emulsified asphalt prepared by commercially available anionic emulsifiers in the dispersion, and storage differences in the anionic emulsified asphalt in the future has a certain significance in guiding the study of anionic emulsified asphalt researchers. (2) through the fluorescence microscope test, laser particle size meter, centrifuge, static observation test, shear strength, tensile bonding strength test, a more in-depth study of the anionic emulsified asphalt with water-based epoxy dosage under the two preparation processes, the microstructure, particle size, storage stability, long-term storage stability, adhesion properties, shear performance on the differences.

There are many shortcomings in the research process: (1) in the study of the emulsifier on the stability of emulsified asphalt in the process, only the manufacturer recommended the highest emulsifier dosage and did not study the other emulsifier dosage on its performance. (2) in the study of the preparation process and waterborne epoxy resin dosage on the waterborne epoxy emulsified asphalt performance research process, did not study the first modified and then emulsified the impact of the preparation process as well as more than 20% of the waterborne epoxy dosage of the modified asphalt.

Data availability

Date availability statement:The data that support the findings of this study are available on request from the corresponding author, [Yi Peng], upon reasonable request.

References

Wu, M. & You, Z. Molecular dynamics models to investigate the diffusion behavior of emulsified asphalt. J. Constr. Build. Mater.409, 134061 (2023).

Gomez, C., Taboada, H. A. & EspirituS, J. F. To be green or not to be green? Ethical tools for sustainability engineering; proceedings of the 2013 ASEE Annual Conference & Exposition, F, C. (2013).

Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: a literature review. J. Constr. Build. Mater.211, 539–555 (2019).

Hettiarachchi, C. et al. A comprehensive review on the utilization of reclaimed asphalt material with warm mix asphalt technology. J. Constr. Build. Mater.1, 227 (2019).

Sanjeevan, S. Long-term performance evaluation of cold inplace recycling (CIR) technique in Nevada. J. Dissertations & Theses - Gradworks (2013).

Tang, F. et al. Study on the effect of demulsification speed of emulsified asphalt based on surface characteristics of aggregates. J. Mater.11(9), (2018).

Li, Y. et al. Performance evaluation of aged asphalt rejuvenated with waste cooking oil on rheological and chemical characteristics[J]. Intell. Transp. Infrastruct.3, liae002 (2024).

Yan, B., Yan, B. & Li, Y. Effect of emulsified asphalt on dynamic viscoelastic properties of CA mortar. J. New. Build. Mater.46(6), 148–152 (2019).

Wang, Q. et al. Study the performance of cold mix and cold pave waterborne epoxy emulsified asphalt mixtures. J. Thermosett. Resin34(6), 31-544.

Li, Z. et al. Novel asphalt pavement with directional heat conduction for melting of ice and snow in plateau and cold areas [J]. Intell. Transp. Infrastruct.2, liad010 (2023).

Kong, L. et al. Study on the influence of spent-catalysts microphysical properties on FCC/asphalt interface interaction [J]. Intell. Transp. Infrastruct.2, liad027 (2023).

Shi, S. et al. Stability of dodecyl sulfate emulsified asphalt: the overlook effect of dissociated counterions. J. Mol. Liquids392, 123462 (2023).

Wang, S. et al. Effect of ionic emulsifiers on the properties of emulsified asphalts: an experimental and simulation study. J. Constr. Build. Mater.347, 128503 (2022).

Yuan, Y. et al. How calcium and magnesium ions affect the stability of asphalt with anionic emulsifiers: a molecular dynamics study. J. Constr. Build. Mater.400, 132770 (2023).

Wang, Z. et al. Effects of asphalt emulsion on properties of fresh cement emulsified asphalt mortar[J]. Constr. Build. Mater.75, 25–30 (2015).

Kong, L. et al. Exploration of molecular dynamics for the adsorption of anionic emulsifier on the main chemical composition surface of aggregate [J]. Constr. Build. Mater.292, 123210 (2021).

Huang, W. et al. Research on storage stability of anionic emulsified asphalt. J. J. Chongqing Jiaotong Univ. (Natural Sci. Edition)40(3), 98–102 (2021).

Li, X. et al. Progress of lignin asphalt emulsifier research. J. Mater. Herald37(z2), 569–572 (2023).

Yang, G. et al. Waterborne epoxy resin–polyurethane–emulsified asphalt: Preparation and properties. J. Mater. Civil Eng.31(11), 04019265 (2019).

Wang, P. et al. Effect of waterborne epoxy resin on properties of modified emulsified asphalt and its microstructure. J. Mater. Civil Eng.33(8), 04021177 (2021).

Wang, L. et al. Effects of epoxy resin value on waterborne-epoxy-resin-modified emulsified asphalt mixture performance. J. Appl. Sci.14(4), 1353 (2024).

He, L., Hou, Y. & Yang, F. Study of the properties of Waterborne Epoxy Resin Emulsified asphalt and its modification mechanism. J. Mater. Civil Eng.35(6), 04023145 (2023).

Kong, L. et al. Microscale mechanism and key factors of waterborne epoxy resin emulsified asphalt enhancing interlayer bonding performance and shear resistance of bridge deck pavement. J. Constr. Build. Mater.419, 135570 (2024).

Kong, L. et al. Microscale mechanism and key factors of waterborne epoxy resin emulsified asphalt enhancing interlayer bonding performance and shear resistance of bridge deck pavement[J]. Constr. Build. Mater.419, 135570 (2024).

Yang, F. et al. Preparation and performance evaluation of waterborne epoxy resin modified emulsified asphalt binder[J]. Case Stud. Constr. Mater.1, e03548 (2024).

Song, L. et al. Influence of preparation processes on the droplets size characteristics and storage stability of emulsified asphalt[J]. Matéria (Rio De Janeiro). 29 (2), e20240049 (2024).

Li, R. et al. Microstructure characterisation and constitutive modelling of waterborne epoxy resin modified bitumen emulsion. Int. J. Pavement Eng.23(14), 5077–5086 (2022).

Ji, J. et al. Performance of emulsified asphalt micro-surface treatment modified by water-based epoxy resin. J. Chang’an Univ. (Natural Sci. Edition)37(5), 23–30 (2017).

Xue, Y. et al. Performance study of waterborne epoxy modified emulsified asphalt for micro-surface treatment. J. Road. Constr. Mach. Constr. Mech.37(6), 1–48 (2020).

Meng, Y. et al. Preparation and properties of water-based epoxy resin/styrene-butadiene rubber composite modified emulsified asphalt. J. Sci. Technol. Eng.21 (13), 5524–5531 (2021).

Pi, Y. et al. Composition design and performance evaluation of emulsified asphalt cold recycled mixtures. J. Mater.12 (17), 2682 (2019).

Standard, C. Standard test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. J. JTG E20; Ministry of Transport of the People’s Republic of China (Beijing, China, 2011).

Technical Specifications for Construction of Highway Cement Concrete Pavements. M. Technical Specifications for Construction of Highway Cement Concrete Pavements (2003).

Jang, Y., et al. Evaluation on vertical vibration compaction method of ATB-30 asphalt mixture. J. Build. Mater.17, 638–643 (2014).

Wei, J. et al. Study on the durability of acid rain erosion-resistant asphalt mixtures. J. Mater. (Basel Switzerland)15(5), 1 (2022).

Zhang, J. et al. Laboratory investigation on the microstructure and performance of SBS modified epoxy asphalt binder. J. Constr. Build. Mater.270, 3 (2020).

Lu, Q. & John, B. Alternate uses of epoxy asphalt on bridge decks and roadways. J. Constr. Build. Mater.78, 18–25 (2015).

Kong, H. & LEE, A. S. Characterization of liquid state sulfur polymer/epoxy blend as asphalt pavement materials. J. Ind. Eng. Chem.53, 386–391 (2017).

Abd El-Rahman, A. et al. Modifying asphalt emulsion with different types of polymers for surface treatment applications [J]. Pet. Sci. Technol.35(14), 1473–1480 (2017).

Yu, J. et al. Modification of asphalt rubber with nanoclay towards enhanced storage stability. J. Mater.11 (11), 2093 (2018).

Gao, L. et al. Influence of binder property and mortar thickness on high-temperature performance of cold recycled mixtures with asphalt emulsion. J. Mater.12 (17), 2718 (2019).

Wang, F. et al. Experimental study on the stability of asphalt emulsion for CA mortar by laser diffraction technique. J. Constr. Build. Mater.28(1), 117–121 (2012).

Chen, C., Lin, L. & Ma, T. Effects of oil/asphalt emulsion formulation on particle size and stability. J. Transp. Res. Record. 2677 (1), 587–598 (2023).

Brzakalski, D. et al. Where ppm quantities of silsesquioxanes make a difference—silanes and cage siloxanes as TiO2 dispersants and stabilizers for pigmented epoxy resins. J. Mater.15 (2), 494 (2022).

Ji, J. et al. Preparation and properties of waterborne epoxy-modified emulsified asphalt binder (WEMEAB) [J]. J. Test. Eval.48(4), 3172–3187 (2020).

Li, C. et al. Comparative research on Tensile properties of cement–emulsified asphalt–standard sand (CAS) mortar and cement–emulsified asphalt–Rubber particle (CAR) mortar. J. Mater.13(18), 4042 (2020).

Xiao, J. et al. Effect of cement and emulsified asphalt contents on the performance of cement-emulsified asphalt mixture. J. Constr. Building Mater.220, 577–586 (2019).

Zhou, Q. et al. Characterisation of waterborne epoxy resin-emulsified asphalt blends. J. Build. Mater.21(3), 414–419 (2018).

Tian, T. et al. Development and performance evaluation of a high-permeability and high-bonding fog-sealing adhesive material. J. Mater. 14(13), 3599 (2021).

Xie, H. F., Li, C. X. & Wang, Q. J. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. J. Constr. Build. Mater.326, 28 (2022).

Wu, H. et al. Investigation on one-component waterborne epoxy emulsified asphalt (OWEEA) used as bonding material. J. Build.14(2), 503 (2024).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (grant number:52208425), the National Natural Science Foundation of China (grant number:52078091), Chongqing Construction Science and Technology Plan Project(grant number: Chengkezi 2023 No.1–1).

Author information

Authors and Affiliations

Contributions

Yi Peng: conceptualization, methodology, formal analysis, investigation, resources, data curation, writing (original draf), supervision, project administration, funding acquisition. Jinke Miao: conceptualization, methodology, data curation, formal analysis, writing (original draf), project administration. Xinyi Yu: methodology, formal analysis, investigation, resources. Yifan Yang,. Qingguo Yang : methodology, validation, investigation, resources. Lingyun Kong: methodology, validation, investigation, resources. Weina Wang: methodology, validation, investigation, resources, funding acquisition, project administration. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Peng, Y., Miao, J., Yu, X. et al. The effect of anionic emulsifiers’ diversity and manufacturing processes on the stability and mechanical properties of the water-based epoxy-emulsified asphalt. Sci Rep 14, 22268 (2024). https://doi.org/10.1038/s41598-024-73009-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-73009-3