Abstract

The deterioration and deformation of brittle rock generally appear in railway tunnels with the operation of large buried deep tunnel. To investigate the macro-micro fracture and acoustic emission evolution characteristics of brittle rock, this paper conducted the uniaxial compression, scanning electron microscope (SEM), and acoustic emission (AE) signal monitoring under different loading rates. The results showed that the loading rate has an obvious enhancement effect on mechanical parameters. The increased loading rate extends the elastic deformation and improves the bearing strength, elastic modulus and deformation modulus. The fracture patterns include shear fracture, composite fracture, and tension fracture. The oblique shear fracture is transformed into composite fracture and tension fracture with the loading rate increasing. The microscopic fracture shows that increasing loading rate inhibits the evolution of oblique shear fractures and promotes the expansion of tensile fractures. The roughness level of tensile fractures is significantly lower than that of oblique shear fracture and composite fracture. The AE parameters and deformation behavior are characterized by simultaneous evolution. The AE amplitude changes from low-level and low-density distribution to high-level and high-density distribution as the loading rate increases. The AE activity intensity of tensile fracture is significantly greater than that of oblique shear fracture and composite fracture. The warning timeliness of cumulative AE events and cumulative AE energy is generally earlier than the AE b-value under the same loading rate, and the early warning timeliness of cumulative AE events is similar to that of cumulative AE energy.

Similar content being viewed by others

Introduction

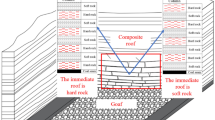

The Tokyo Declaration adopted by the International Conference on the Utilization of Urban Underground Space held in Tokyo (1991) pointed out that the 21st century is the century of underground space development and utilization. China’s underground space engineering has ushered in rapid development in the 21st century1–2. The Chinese mainland has about 15,800 km of railways in operation by the end of 2023, the number of railway tunnels exceeds 20,000, and the operating mileage reaches more than 20,000 km. Besides, China has planned more than 5000 railway tunnels, with a total length of more than 15,000 km. However, the degradation and deformation of brittle rock at tunnel bottom has become a prominent problem in tunnel construction with the large-scale operation of large-buried railway tunnels3–4. The expansion deformation of the surrounding rock mass has caused the invert lifting disasters of Yunding Tunnel5, Fuchuan Tunnel1. Therefore, studying the macro-micro fracture mechanism and acoustic emission characteristics of hard rock during fracture can effectively reveal the damage evolution law and acoustic precursor characteristics of damage instability.

The aging fracture of surrounding rock under disturbance stress is a progressive evolution process of fracture initiation, expansion and fracture. The stress loading rates of surrounding rock construction, structural extrusion, and rock burst has a significant impact on the mechanical characteristics in actual engineering6–7. The mechanical behavior of rock material that changes with the change of stress loading rate is called loading rate effect. The existing studies8–9 have fully studied the loading rate effect of soft rock, showing that soft rocks have an obvious loading rate effect of deformation strength characteristics, and the transformation law of destruction form from brittleness to ductility to brittleness. However, this has been unable to meet the growing practical engineering needs, especially the brittle surrounding rock disasters gradually prominent under disturbing loads. For this purpose, Qi et al.10 revealed that the peak strength of brittle sandstone is strengthened with the loading rates, and the loading rate effect appears only when the basalt loading rate is in a specific state. Cho et al.6 showed that the dynamic tensile strength of brittle tuff increases with the increase of strain rate under loading rate. Yang et al.11 explored the effect of rock loading rate based on crack extension and propagation of brittle red sandstone. Fuenkajorn et al.12 analyzed the variation characteristics of elastic parameters of hard limestone under different loading rates. Martin and Malan13–14 concluded that the compressive strength of brittle rock decreases with the decrease of loading rate. The above conclusions indicated that the effect of strain rates or loading rates on the mechanical properties of brittle rocks mainly occurred in the damage development process, and the loading rate effect plays an important role in the study of rock mechanical properties.

The acoustic emission (AE) signal caused by fracture contains important information of carrying capacity failure7,15–16, those mechanical effects such as rock blasting and mechanical excavation often lead to significant mechanical damage17,18,19. Cheng et al.16 investigated the micro - cracking morphology, AE response characteristics and dynamic fracturing mechanism of natural brittle sandstone containing layer structure under compression. Zhou et al.19 studied the damage progression and AE response characteristics in brittle failure of granite and sandstone. Sagasta et al.20 investigated the statistical characteristics between mechanical properties and acoustic emission parameters of coal rock. Yuan et al.15 studied the AE characteristics during shear deformation of brittle rock structural planes based on particle flow code. Cheng et al.7 revealed the strain performance and fracture response characteristics of hard rock under cyclic loading. Yang et al.11 studied the AE response characteristics and the statistical relationship between characteristic parameters and stress path. Chen et al.21 researched the effect of stress paths on AE characteristics, failure mechanism and progressive damage of hard - brittle rock. Liu et al.22 studied the damage evolution of brittle marble from AE signal and the damage threshold. Yao et al.23 studied the AE characteristics and failure prediction of post-high-temperature granite. In addition, Gan et al.24 investigated the development of granite internal cracks and change characteristics of AE characteristic parameters and average frequency (AF) values. Zhang et al.25 studied the aging deformation characteristics and its variation pattern of AE b-value of marble under the variable loading rates. The conclusions can be drawn from the above research that with the continuous in-depth development of underground space engineering, mechanical engineering problems of hard brittle rock frequently occur in many rock mass projects, such as mechanical disturbance and rock mass structural adjustment inducing internal stress redistribution and resulting in strength deterioration or instability failure of hard rock. AE is an important means to monitor the deformation characteristics of rock mass and reveal the fracture modes, it is necessary to investigate the macro-micro fracture mechanism and AE characteristics of brittle rock induced by loading rate effect, so as to provide some theoretical reference for the study of rock mass instability response and signal warning under disturbance loads.

To investigate the macro-micro fracture and acoustic emission evolution characteristics of brittle rock, this paper conducted the uniaxial compression, scanning electron microscope (SEM), and AE signal monitoring under different loading rates, mainly analyzed the fracture deformation and strength characteristics, fracture patterns of rock structural planes, AE characteristic parameter of brittle rock. The precursory information of fracture instability of brittle rock was discussed according to the AE signal characteristics. The research results have a certain significance for improving the aging fracture response characteristics of hard rock in underground space engineering.

Experimental Procedure

Sample preparation

The similarity principle is often used for the experimental study of specific surrounding rock characteristics, which can reduce the influence of the physical characteristic differences of natural rock mass under controlled test conditions. With reference to the production experience of existing rock-like materials7, using high-strength cement (produced by Qinling Cement Factory), fine-grained quartz sand, high-purity iron ore powder and engineering accelerator (Red Star brand 8604, composed of alum mud, aluminum oxide clinker and quick lime, and the content is 5-7%) as the base materials, and brittle rock meeting the test densification requirements were prepared according to a weight ratio of 5 : 1 : 0.25 : 0.12.

The cubic rock mass with an initial size of 400 mm (Length) × 300 mm (Width) × 120 mm (Height) was made by using a small frequency shaking table to vibrate the mixed material. The standard samples with a size of φ50 mm (Diameter)× 100 mm (Height) was made by core drilling and grinding technology after 28 days of maintenance in a humid environment, and the non-parallelism of end surface was less than 0.02 mm. Figure 1 showed the schematic diagram of standard sample testing. The basic properties parameters of brittle rock samples are counted in Table 1. A total of 30 standard samples were obtained and those samples with large differences were removed by weighing and wave velocity testing.

Experimental equipment

Uniaxial compression test and acoustic emission monitoring were completed in rock mechanics and Engineering Laboratory of Xi’an University of Architecture and Technology. The test system included TAR-1500 stress loading system, AE monitoring system, and equipment control platform, as shown in Fig. 2.

The stress loading system was a TAR-1500 high temperature and high pressure rock rheometer produced by Changchun Chaoyang Test Equipment Co., LTD., China. The maximum loading stress and loading speed were 1000 kN and 0–80 mm/min, respectively. The stress and displacement resolution were 0.01 kN and 0.0001 mm, respectively. The AE monitoring system was a SAEU2S-1016-4 multi-channel acoustic emission monitor (64 channel) produced by Beijing Shenghua Company. The acquisition frequency range and acquisition accuracy were 0–3 MHz and 16 bit, respectively. The AE amplifier model was broadband universal SAEPA2, and the common amplification factor was 40 dB. The AE parameters obtained of rock fracture include AE amplitude, AE event and AE energy. The scanning electron microscope test of rock fracture was completed in Jiangsu Key Laboratory of Eco-environmental Materials. The equipment of Scanning Electron Microscope (SEM) test was a ZEISS-Sigma 300 type field emission scanning electron microscope, and the resolution, magnification and storage resolution are 1 nm@30 kV, 10-1000000×, 32 k × 24 k pixels, respectively.

This study focuses on the influence of loading rate on the mechanical parameters, fracture patterns and AE response characteristics of brittle rock. Four testing conditions including 2 × 10− 3 mm/s, 4 × 10− 3 mm/s, 6 × 10− 3 mm/s and 8 × 10− 3 mm/s were considered for the loading rate (Ra). The experimental procedure is as follows. ①Test preparation: Physical parameters such as size, density and wave velocity of standard samples were tested. The number and grouping were shown in Table 1. ②The AE probe was fixed on sample surface by coupling agent (Vaseline) and fixed with tape. The sampling threshold was set to 40 dB and sampling interval was 100 ms. The sample was assembled with the AE probe and installed on the mechanical testing machine. ③Stress loading: The sample was prestressed with 0.30 kN so that the end face of the sample was in close contact with the pressure head. The loading rate of 2 × 10− 3 mm/s, 4 × 10− 3 mm/s, 6 × 10− 3 mm/s and 8 × 10− 3 mm/s were used to fracture the sample, and the mechanical parameters and AE signals were obtained. Three parallel tests were carried out for each group loading rate to reduce the test contingency.

Results and analysis

Fracture deformation and strength characteristics

Stress-strain curves characteristics

Figure 3 shows the axial stress-strain curves of typical samples at different loading rates. It can be seen that the stress-strain curve morphology is basically similar, and the evolution path includes four typical stages of compaction stage, elastic deformation stage, plastic deformation stage and failure stage. The mechanical characteristics of the prefabricated sample are similar to those of the hard rock7–8,15, showing brittle failure characteristics. The stress-strain curve at the beginning of stress loading shows a concave trend, and the sample stiffness is improved after the internal fissure is compressed. Because the pouring material wrapped the quartz sand to form the cement body of different strength, the sample appears stress concentration and then causes the microrupture. The microcracks are mainly derived from the transition region with weak strength1,11,14, resulting in a small stress drop on the stress-strain curve. The increased stress induces the internal cracks to be compressed further, and the stress-strain curve increases approximately linearly with the further increase of sample compactness, indicating that the sample is dominated by elastic deformation. The greater the loading rate is, the more obvious the elastic deformation is. This is because the sample does not have enough time to deform when the loading rate increases, and the sample stiffness is strengthened to improve the bearing strength.

Figure 3 also shows that the internal stress concentration becomes more prominent in plastic deformation stage, and the rapid expansion of microcracks leads to continuous stress drop in the stress-strain curve. It should be noted that the stress-strain curve at this stage does not show a significant yield deformation trend due to the typical brittle characteristics of samples. The continuous increase of stress induces the intersection behavior of new cracks and primary cracks, and the rapid accumulation of damage results in continuous stress drop, and brittle fracture occurs near the peak stress. The loading rate has the strengthening characteristic of rock burst phenomenon. The sample at a relatively low loading rate has a sufficient time for stress adjustment, and the fracture expansion is accompanied by frequent energy accumulation and release16,19, and no obvious rock burst occurs. The increase of loading rate leads to the accumulation of internal strain energy greater than the release amount, the cracks expansion process produces continuous rock burst behavior and the local surface forms the missing area due to rock mass ejection.

Mechanical properties

Figure 4 presents the columar distribution characteristics of peak stresses with different loading rates, and the average peak stress was characterized here. Figure 4 reveals that the average peak stress increases from 49.59 MPa to 58.50 MPa with an increase of 17.97% when the loading rate increases from 2 × 10− 3 mm/s to 4 × 10− 3 mm/s. The peak stress is increased from 66.34 MPa to 75.29 MPa with an increase of 13.49% when the loading rate increases from 6 × 10− 3 mm/s to 8 × 10− 3 mm/s. It can be concluded that the peak stress has an acceleration rate effect, but the gradual slowdown of peak stress increase indicates that the sample has a certain adaptation process to the loading rate. The main manifestation is that the strengthening effect of peak stress is weakened and gradually tends to be stable when the actual loading rate is greater than a certain critical loading rate, which is consistent with the conclusions25. The growth multiple in Fig. 4 is characterized by the normalized value of average peak stress, and the regression analysis shows that the normalized value is exponentially related to the loading rate.

The modulus characteristics of brittle rock can reveal the response law of material damage to the loading rate, and the average peak stress was characterized here. Figure 5 shows the columar distribution characteristics of elastic modulus and deformation modulus with different loading rates. Figure 5a illustrates that the average elastic modulus increases from 5.81 GPa to 5.97 GPa with an increase of 2.76% when the loading rate increases from 2 × 10− 3 mm/s to 4 × 10− 3 mm/s. The average elastic modulus is increased from 6.18 GPa to 6.28 GPa with an increase of 1.62% when the loading rate increases from 6 × 10− 3 mm/s to 8 × 10− 3 mm/s. It is concluded from Fig. 5b that the deformation modulus is 90.30-97.56% of the elastic modulus, and the evolution trend of deformation modulus and elastic modulus of brittle rock is consistent with the previous studies1,25.

Fracture patterns of rock structural planes

Macroscopic cracks morphology

Figure 6 presents the macroscopic cracks morphology and fracture sketches of typical samples under different loading rates, the method of delineating the cracks is shown in Fig. 6a. It can be seen from Fig. 6b,c that the samples present typical oblique shear fracture under the low-level loading rates (2 × 10− 3-4 × 10− 3 mm/s), and form multiple macroscopic oblique shear cracks (ab, cd, ef, etc.). The local oblique shear cracks appear when the local stress cannot resist the expansion deformation, and the secondary fracture expansion intensifies the formation of fracture zone. This is due to the fact that the internal cracks have sufficient time to slip and expand7, resulting in a phenomenon of intersection and expansion of main cracks. The fracture sketches illustrated that the penetrating oblique shear fracture (ef) intersects with the local oblique shear fracture (gh) when the loading rate is 2 × 10− 3 mm/s, and then induces the local secondary fracture group, as shown in Fig. 6b. The penetrating oblique shear fracture (ed and ef) induces a triangular fracture zone when the loading rate is 4 × 10− 3 mm/s, as shown in Fig. 6c. It can be considered that the fracture types and cracks proportion at low-level loading rates are relatively balanced, and the fracture degree is roughly the same.

Figure 6d shows that the proportion of oblique shear cracks decreases and the tensile cracks increases under moderate loading rate of 6 × 10− 3 mm/s. The sample shows a characteristics of oblique shear-tensile composite failure, and the fracture degree is significantly greater than that in Fig. 6b,c. The fracture sketch shows that the increased loading rate induces more major fractures and secondary cracks, and the intersection expansion of tension cracks (eh, kj) and oblique shear cracks (gh, il) results in a fracture zone. The increased loading rate leads to the ejection failure of cracks tip and rock fracture, and more secondary cracks are derived from major fractures and connected to form macroscopic cracks. This is due to the fact that some oblique shear cracks does not fully develop under moderate loading rate, and expanded along the tension cracks in the process of sliding deformation12,21. The coupling stress effect of oblique shear and tension results in the conical crushing state of the end.

Figure 6e reveals that at a high-level loading rate of 8 × 10− 3 mm/s, tension fractures are predominant and oblique shear fractures rarely occur. Compared with oblique shear fracture and composite fracture, the number of apparent cracks and the fracture degree increase in tensile fracture samples. The accumulation rate of strain energy at high-level loading rate increases7,11, resulting in significant rock-burst phenomenon in local fracture instantaneously. The fracture sketches illustrate that the damage end of sample is obviously crushed and the strip rock falls significantly, and the master control crack shows typical split failure.

Morphology characteristic of microscopic fracture

Figure 7 presents the microscopic fracture morphology of typical samples. It can be seen from Fig. 7a that the sample is mainly oblique shear fracture and the fracture surface is relatively rough when the loading rate is 2 × 10− 3 mm/s. The slipping and oblique shear behavior between rock structures cause the formation of continuous major cracks and fracture zones, and the lengths of major cracks are 96.24 μm, 109.65 μm, 125.49 μm, respectively. The elliptical fracture zone is roughly located in the potential intersection area of major cracks. This is due to the loading effect which leads to the dislocation cracking of cemented body15, and the inclined shear cracks derived from the colloidal and crystal leads to the fracture separation of bedrock block and the formation of fracture zone. The roughness of 4 × 10− 3 mm/s sample is decreased compared with 2 × 10− 3 mm/s sample, and the number and length of major cracks are decreased by 33.33% and 50.19%, respectively. It can be seen that the improvement of loading rate weakens the oblique shear deformation, and the relative increase of local tension cracks exacerbates the tearing between the rock strata, leading to the consistent friction scratches on the local structural surface.

The microscopic breaks at moderate loading rate produces brittle shear or tear behavior, and the smooth sections forms the slip fracture marks, as shown in Fig. 7c. Compared with 4 × 10− 3 mm/s, the number of smooth fractures in 6 × 10− 3 mm/s increases and the cracks length decreases significantly. It can be seen from the oblique shear deformation between rock structures gradually transition to tensile deformation. The tensile behavior induces the cement body to tear and forms two approximately parallel main fractures with lengths of 50.08 μm and 42.56 μm, respectively. The compression-shear coupling induces a rock stripping zone on sample surface, and the local stress concentration causes some secondary cracks but does not intersect with the main cracks. The wedging effect13–14 caused by the difference of bearing strength of cemented body leads to the cracking of rock structure. Compared with oblique shear fracture and composite fracture, the roughness of tension fracture is significantly reduced, and a major crack with a length of 45.16 μm is derived around the fracture area. It can be concluded that the increase loading rate obviously inhibits the evolution of oblique shear fracture and promotes the expansion of tensile fracture, and the microscopic fracture morphology is consistent with the macroscopic fracture pattern.

Aging response characteristics of AE signal

Statistical relationship between AE amplitude and stress

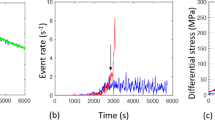

Figure 8 shows the evolution characteristics of AE amplitude with different loading rates, the increased loading rate leads to a simultaneous response of AE amplitude to stress-strain curve. Figure 8a,b reveals that at low-level loading rates of 2 × 10− 3-4 × 10− 3 mm/s, the small porosity in the compaction phase results in nonsignificant AE activity, and the AE amplitude is sparsely distributed. The stress concentration in the elastic deformation stage causes crack initiation, resulting in local AE activity and the distribution density of AE amplitude increases slightly. The cracks near the peak stress expand frequently with the accumulation of strain energy, the AE activity is significantly enhanced and the maximum AE amplitude reaches 95.88–99.56 dB.

From Fig. 8c,d, it can be seen that under the medium-level and high-level loading rates of 6 × 10− 3-8 × 10− 3 mm/s, the AE activity in the compaction stage are significantly increased, and the AE amplitude and distribution density are significantly increased. The AE amplitude in the elastic deformation and plastic deformation stages show a high level-high density distribution. The maximum AE amplitudes around the peak stress are 101.26 dB and 105.98 dB, respectively, indicating that the fracture propagation degree are significantly improved at higher loading rates. By comparison, it can be seen from Fig. 8 that the AE amplitude at low-level loading rate are manifested as a low-level and low-density band distribution, but the band distribution characteristic is weakened with the increased loading rate. This is due to the weak micro-crack propagation at a lower loading rate, the cracks propagation induces local AE activity and periodic crack propagation leads to a band distribution of AE signals. The higher loading rates lead to frequent crack propagation and significant AE activity, resulting in a high-level and high-density band distribution.

Correlation between AE events and failure modes

Figure 8 also counts the evolutionary characteristics of AE events under different loading rates. The distribution of AE events and stress paths of different fracture patterns have consistent timeliness characteristics. The cumulative AE events are characterized by periodic response characteristics with a four evolutionary stages including AE calm stage (I stage), AE active stage (II stage), AE quasi-calm stage (III stage)8,17,25 and AE burst stage (IV stage). The AE activity degree is positively correlated with stress levels. The AE activity at lower stress level was relatively weak and the cumulative number of AE events is in a quiet stage. The AE activity at moderate stress levels gradually intensifies and the cumulative number of AE events enters an active stage. The strain energy near the peak stress is rapidly released, the penetration behavior of macroscopic fracture leads to the AE activity into the burst stage, and the cumulative AE events shows the sudden response characteristic. The periodic response characteristics of AE events reveals the aging fracture law of samples.

It can be seen from Fig. 8a,b that the AE activity at the beginning of loading is relatively weak, the cumulative AE events growth (I stage) is not significant and the AE calm stages last for 246.29 s and 124.50 s, respectively. The increased axial stress cause the accumulation of internal damage, and the first surge of cumulative AE events around 36.09%σc and 22.68%σc are 3.10 × 104 and 3.02 × 104, respectively. The crack propagation is rapid in the plastic deformation stage, and the cumulative AE events in the active stage (II stage) occurs for the second surge around 48.97%σc and 35.79%σc, which are 7.39 × 104 and 6.76 × 104, respectively. The internal fractures are penetrated when the samples are close to rupture, the maximum cumulative AE events after AE activity enter burst stage reach 26.26 × 104 and 25.47 × 104, respectively. Figure 8c,d showed that the growth rate of cumulative AE events further accelerates when the loading rate increases to 6 × 10− 3 mm/s and 8 × 10− 3 mm/s. The first surge occurs after the AE quiet stage last 105.82 s and 87.62 s, and its cumulative AE events are 5.19 × 104 and 5.31 × 104, respectively.

The time-history curves of AE active stage and AE quasi-calm stage become steeper compared with the low-level loading rates, as shown in Fig. 8c,d, indicating that there is a high-frequency and high-level of AE activity near the continuous stress drop caused by progressive fracture. According to the Fig. 8, the proportions of oblique shear fracture, composite fracture and tension fracture in the AE active stage and AE quasi-calm stage are 69.07% (average), 73.58% and 82.66%, respectively. It can be seen that the increased loading rate induces early fracture penetration, resulting in AE activity entering the active stage earlier and the damage evolution stage lasting longer. The small-scale fracture expands to the macroscopic rupture surface when the bearing reaches the limit, the AE activity enters the AE burst stage (IV stage) and the cumulative AE event shows a large surge trend. The cumulative AE events at different loading rates are 26.19 × 104, 25.47 × 104, 55.19 × 104, 86.81 × 104, respectively. The AE intensity of tensile fracture is significantly greater than that of oblique shear fracture and composite fracture, which is consistent with the established studies19–20.

Correlation between AE energies and failure modes

Figure 9 indicates the statistical relationships between AE energy and AE b-values under different loading rates. It can be seen that the variation law of cumulative AE energy and cumulative AE events have similar response laws to stress, indicating that there is significant correlation between AE characteristic parameters. Figure 9a,b shows that the fracture propagation at low-leave loading rates of 2 × 10− 3 mm/s and 4 × 10− 3 mm/s are slow, resulting in relatively weak AE activity and overall solitary AE energy. The increased axial stress leads to the step-like development of the cumulative AE energy in the compaction stage and elastic deformation stage, and the AE energy burst or energy fluctuation mainly occurs in the stress drop (36.09%σc, 35.79%σc) and instability failure stage (92.36%σc). The maximum cumulative AE energy near peak stress are 21.29 × 105 mV·s and 30.29 × 105 mV·s.

Figure 9c reveals that when the loading rate reaches a medium-level, the fracture propagation is relatively accelerated and AE activity is enhanced. The cumulative AE energy is increased significantly when macroscopic failure is about to occur, and maximum cumulative AE energy reach 36.45 × 105 mv·s, which is 45.77% higher than that at lower loading rates shown as in Fig. 9a,b. Figure 9d indicates that the increment of cumulative AE energy at high-level loading rate of 8 × 10− 3 mm/s is increased significantly, showing the characteristics of group seismic type. The cumulative AE energy around the peak stress is 56.26 × 105 mV·s with an increase of 54.34% compared to 6 × 10− 3 mm/s. It is concluded that the cumulative AE energy is positively correlated with the loading rate, which is consistent with the rockburst emitted.

Discussion

AE parameters as precursor for brittle fracture

Existing research26,27,28,29 believed that the AE b-value characterizes the fracture magnitude-frequency relationship of rocks. The relationship between AE-b value and fracture magnitude is expressed as:

where Me is the fracture magnitude Me=A/2021, A is the AE amplitude (dB). N is AE active greater than Me. a and b are the theoretical parameters.

The increased b-value indicates that small-scale fracture dominates the failure trend, otherwise large-scale fracture is the predominant. The weakly variable b-value indicates that the cracks proportion produced by small-scale fracture and large-scale fracture is relatively balanced. Figure 9 shows the statistical relationships between AE energy and AE b-values under different loading rates, and the AE-b value performs a typical phased response characteristics for loading stress. The AE-b values undergo the ascending phase (OA), fluctuation phase (AB) and sudden decline phase (BC) with the increased loading time, which represents the dynamic evolution process from microscopic cracks initiation to macroscopic fracture penetration.

The deformation at the initial loading stage is relatively stable, the rock structure is mainly composed of small-scale fracture and the AE activity is in a calm period, resulting in a relatively low-level ascending of AE b-value. The proportion of small-scale fracture gradually increases with the stress increasing, resulting in a fluctuating gradual increase in AE b-value and entering a high-level fluctuation state. The AE b-value near peak stress is sudden decayed, indicating that continuous loading lead to small-scale fractures incubating into large-scale fractures, and cracks propagation presents an unstable extension state. The formation of local macroscopic fracture surface means that the large-scale fractures begin to dominate the fracture trend, and the occurrence of continuous stress drop intensifies the sudden drop in AE b-values. Therefore, the sudden drop of AE b-values in the yield deformation stage has an early warning effect on progressive fracture.

In addition, AE b-value has the aging response characteristics to stress drop, and the occurrence of local stress drop aggravates the sudden drop of AE b-value. When the loading rate is 4 × 10− 3 mm/s, the AE b-value decreases by 10.49%, 17.08%, 27.97% and 17.14% at 22.68%σc, 35.79%σc, 53.51%σc and 90.26%σc, respectively. When the loading rate is 6 × 10− 3 mm/s, the AE b-values are decreased by 24.54% and 9.91% at 69.60%σc and 86.97%σc, respectively. The maximum AE b-values under different loading rates are 1.0852, 1.0824, 1.1049 and 1.1247, respectively. The tensile fracture are generally larger than the composite fracture and oblique shear fracture, and Yuan et al.15 reached a consistent conclusion. This is due to the intensification of tearing effect caused by tension behavior and penetration of large-scale cracks, resulting in a sudden drop in AE b-values, which is similar to the evolution law of creep b-value in previous studies24.

The RA and AF values of AE signal are important parameters for identifying the fracture category. The statistical theory24 expresses the RA and AF values as:

where RT (Rise Time) is the rising time of AE signals (s). A is the corresponding AE amplitude (dB). AEcounts are the AE ring counts. DT (Duration time) is the duration time of AE signal (s).

Figure 10 displays the distribution characteristics of RA-value and AF-value under different loading rates. It can be seen that the loading rate has a consistent effect on the influence of RA-AF-values and AE amplitude and shows a band distribution, indicating that there are differences in the evolution of internal cracks in different fracture patterns. The samples in the compaction and elastic stages are mainly small-scale fracture germination with a low AE activity intensity, the RA-AF values are roughly low strength-low density fluctuation. The increased loading rate promotes the transition from oblique shear fracture to tension fracture, resulting in a negative correlation between RA-values and loading rate and positive correlation between AF-values and loading rate. It should be noted that the rock materials have a typical elastic deformation development stage30, and the internal single fracture shifts to tension-shear composite fracture, and the AF-RA values increase due to the macroscopic main fracture propagation process. The AE activity from plastic deformation to failure gradually enters the AE burst stage, and the penetration behavior of macroscopic main fracture leads to a relatively high-intensity and high-density increase in RA-values, while the AF-values maintain a relatively high-frequency and high-intensity level. It is concluded that for tension fracture the AF-values are mainly based on the high-frequency and high-intensity distribution, and the RA-values are generally at a low-level. For oblique shear fracture and composite fracture the AF-value are mainly distributed at relatively low-frequency and low-intensity, and the distribution density and amplitude intensity of RA-values are enhanced.

Warning timeliness analysis of AE parameters

The AE characteristic parameters well reflect the fracture evolution characteristics of different fracture patterns, and there is a time-sensitive response law of AE parameters before approaching failure. Therefore, the abrupt changes in AE activity indicate a gradual fracture of rock structure25, and the obvious mutation point of AE characteristic parameters including cumulative AE events, cumulative AE energy, and AE b-values can be used as the precursor point of instability failure. Existing studies16,22 showed that AE parameters have an early warning effect on rock fracture, such as a short AE active period caused by local failure1,8, an AE quasi-calm period before fracture20, and an explosive or active period of AE activity during fracture. However, complexity and uncertainty of rock mass deformation lead to the fact that the AE parameters have not yet reached a consensus on the early warning characteristics rock mass with different fracture modes.

Besides, Fig. 8 reveals that cumulative AE events have significant stage response characteristics for progressive fracture including AE calm period, AE active period, AE quasi-calm phase and AE burst period. The AE b-values in Fig. 9 also shows the typical stage response characteristics, and the AE b-values undergo the rising phase, fluctuation phase and sudden decline phase with the increased loading time. Therefore, it is concluded that there are certain differences in the early warning characteristics of fracture behavior of AE parameters under the same loading stress. This conclusions are proved by the study of fracture characteristics of granite and hard sandstone16,24. The large abrupt drop of AE b-values shows the occurrence of large-scale fracture, indicating a sudden instability failure. Figure 9 reveals that multiple sudden drops in AE b-values near peak stress indicate the impending instability failure, but relying on the sudden drop of AE b-values alone as a instability precursor may reduce the reliability of early warning31. According to the damage mechanics theory, the sudden drop of AE b-value in the stress range of 90%σc to 95%σc is used as the determination basis for the fracture instability. Figures 8 and 9 show that when the cumulative AE events and cumulative AE energy increase by more than 60%, continuous stress drop in the stress time-history curve at the plastic deformation stage indicates the penetration of macroscopic cracks. The AE amplitude and RA-AF values could not be used for quantitative evaluation of instability failure, but could be used as auxiliary parameters32.

The precursor point information of instability failure at different loading rates are summarized in Table 2. The AEc−events and AEc−energy are cumulative AE events and cumulative AE energy, respectively. t and σ are correspond to time and stress, respectively. It can be seen from Table 2 that the precursor point information of instability failure corresponding to cumulative AE events, cumulative AE energy and AE b-value is consistent with the loading rates increasing. The larger the loading rates, the closer the precursor points represented by the cumulative AE events, cumulative AE energy, and AE b-values are to the peak stress. This is mainly because the increased loading rate has a strengthening effect on the sample and then increases the damage stress3,10. It can be concluded that the early warning time of cumulative AE events and accumulated AE energy is generally earlier than the AE b-value, which can reveal the earlier fracture of brittle rock. The warning timeliness of cumulative AE events and cumulative AE energy under the same loading rates is generally better than that of AE b-values, and the early warning timeliness of cumulative AE events is similar to that of cumulative AE energy.

However, the brittle rock fracture has variability characteristic and the transient fracture is relatively significant, and rock mass instability prediction only relying on acoustic emission characteristic parameters may have low accuracy or missed report21,25,32. The monitoring data in Table 2 indicates that when the loading rate is 4 × 10− 3 mm/s the time corresponding to the b-value is very close to that corresponding one to the cumulative AE events, 601.96 s and 600.81 s, respectively. Whereas, for 6 × 10− 3 mm/s the values are 458.80 s for the b-value and 457.41 s for the cumulative AE energy, which can be considered very close as well. The problem mentioned above may be the deficiency of this study or the need to be further studied. To reveal the precursor point information of instability failure of brittle rock, it is necessary to study the warning timeliness analysis of AE parameters in depth combined with the microshock acoustic emission data from the engineering site.

Conclusions

This paper took the brittle rock material under different loading rates as the research object, and the macro-micro fracture mechanism and acoustic emission characteristics of brittle rock induced by loading rate effect were analyzed based on the uniaxial compression, scanning electron microscope, and AE signal monitoring. The following conclusions are drawn:

-

(1)

The loading rate has an obvious enhancement effect on mechanical parameters. The increased loading rate extends the elastic deformation and improves the bearing strength. The decrease of increment of mechanical parameters indicates that the brittle rock has a certain adaptation process to the loading rate. The enhancement effect is weakened and gradually becomes stable when the actual loading rate is greater than a certain critical loading rate.

-

(2)

The main fracture patterns include oblique shear fracture, composite fracture and tension fracture. The oblique shear fracture is transformed into composite fracture and tension fracture with the loading rate increasing, and the rock burst phenomenon is more significant. The microscopic fracture morphology characteristic shows that increasing loading rate inhibits the evolution of oblique shear fractures and promotes the expansion of tensile fractures. The roughness level of tensile fractures is significantly lower than that of oblique shear fracture and composite fracture.

-

(3)

The AE parameters and deformation behavior are characterized by simultaneous evolution. AE amplitude changes from low-level and low-density distribution to high-level and high-density distribution. The cumulative AE events and cumulative AE energy are positively correlated with the increased loading rate. The AE activity intensity of tensile fracture is significantly greater than that of oblique shear fracture and composite fracture.

-

(4)

The AE characteristic parameters well reflect the fracture evolution characteristics, and there is a time-sensitive response law of AE parameters. The warning timeliness of cumulative AE events and cumulative AE energy under the same loading rate is generally earlier than that of AE b-value, and the early warning timeliness of cumulative AE events is similar to that of cumulative AE energy.

Considering that brittle rock fracture has variability characteristic and the transient fracture is relatively significant, it is necessary to study the warning timeliness analysis of AE parameters in depth combined with the microshock acoustic emission data from the engineering site to reveal the precursor point information of instability failure of brittle rock.

Data availability

The datasets used during the current study available from the corresponding author on reasonable request.

References

Tian, X. X., Song, Z. P., Wang, H. Z., Cheng, Y. & Wang, J. B. Deformation and mechanical characteristics of tunnel - slope systems with existing anti - slide piles under the replacement structure of pile-wall. Tunn. Undergr. Space Technol.153, 105995. https://doi.org/10.1016/j.tust.2024.105995 (2024).

Tian, X. X., Song, Z. P., Wang, H. Z., Zhang, Y. W. & Wang, J. B. Evolution characteristics of the surrounding rock pressure and construction techniques: A case study from Taoshuping tunnel. Tunn. Undergr. Space Technol.125, 104522. https://doi.org/10.1016/j.tust.2022.104522 (2022).

Yu, J. et al. Time-dependent deformation mechanism for swelling soft rock tunnels in coal mines and its mathematical deduction. Int. J. Geomech.20, 04019186. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001594 (2020).

Song, Z. P., Cheng, Y., Zhang, Z. K. & Yang, T. T. Tunnelling performance prediction of cantilever boring machine in sedimentary hard-rock tunnel using deep belief network. J. Mt. Sci-Engl. 20, 2029–2040. https://doi.org/10.1007/s11629-023-7931-y (2023).

Duan, S. Q. et al. A new perspective on the semi-quantitative meso-structural failure mechanism of deep weak interlayer zone under different stress paths. Rock. Mech. Rock. Eng.57, 3171–3195. https://doi.org/10.1007/s00603-024-03760-6 (2024).

Du, M. Q., Wang, X. C., Zhang, Y. J., Li, L. & Zhang, P. In-situ monitoring and analysis of tunnel floor heave process. Eng. Fail. Anal.109, 104323. https://doi.org/10.1016/j.engfailanal.2019.104323 (2020).

Cho, S. H., Ogata, Y. J. & Kaneko, K. Strain-rate dependency of the dynamic tensile strength of rock. Int. J. Rock. Mech. Min. Sci.40 (5), 763–777. https://doi.org/10.1016/S1365-1609(03)00072-8 (2003).

Cheng, Y. et al. Strain performance and fracture response characteristics of hard rock under cyclic loading. Geomech. Eng.26, 551–563. https://doi.org/10.12989/gae.2021.26.6.551

Zhou, X. P. & Zhang, J. Z. Damage progression and acoustic emission in brittle failure of granite and sandstone. Int. J. Rock. Mech. Min. Sci.143, 104789 (2021).

Zhang, J. Z., Zhou, X. P., Zhou, L. S. & Berto, F. Progressive failure of brittle rocks with non-isometric flaws: insights from acousto - optic - mechanical (AOM) data. Fatigue Fract. Eng. M. 42, 1787–1802 (2019).

Qi, C. Z., Wang, M. Y. & Qian, Q. H. Strain-rate effects on the strength and fragmentation size of rocks. Int. J. Impact Eng.36, 1355–1364. https://doi.org/10.1016/j.ijimpeng.2009.04.008 (2009).

Yang, M. Z., Huang, H. X. & Yang, Y. Effect of rock loading rate based on crack extension and propagation. Sci. Rep-UK. 12, 8755. https://doi.org/10.1038/s41598-022-12759-4 (2022).

Fuenkajorn, K., Sriapai, T. & Samsri, P. Effects of loading rate on strength and deform ability of Maha Sarakham salt. Eng. Geol.135, 10–23. https://doi.org/10.1016/j.enggeo.2012.02.012 (2012).

Martin, C. D. The strength of massive Lac du Bonnet granite around underground openings. PhD Tesis, Manitoba, Canada: Department of Civil and Geological Engineering, University of Manitoba (1994).

Malan, D. F. Time-dependent behavior of deep level tabular excavations in hard rock. Rock. Mech. Rock. Eng.32, 123–155 (1999).

Yuan, W., Cheng, Y., Min, M. & Wang, X. Study on acoustic emission characteristics during shear deformation of rock structural planes based on particle flow code. Comput. Part. Mech.11, 105–118. https://doi.org/10.1007/s40571-023-00611-z (2023).

Cheng, Y. et al. Micro-cracking morphology and dynamic fracturing mechanism of natural brittle sandstone containing layer structure under compression. Constr. Build. Mater.425, 136051. https://doi.org/10.1016/j.conbuildmat.2024.136051 (2024).

Wu, K. et al. Determination of stiffness of circumferential yielding lining considering the shotcrete hardening property. Rock. Mech. Rock. Eng.56, 1–12. https://doi.org/10.1007/s00603-022-03122-0 (2023).

Wu, K., Zheng, X. M., Zhao, N. N. & Shao, Z. S. Effect of compressible layer on time-dependent behaviour of soft-rock large deformation tunnels revealed by mathematical analytical method. Appl. Math. Model.126, 1–16 (2024).

Cheng, Y. et al. Investigating the aging damage evolution characteristics of layered hard sandstone using digital image correlation. Constr. Build. Mater.353, 128838. https://doi.org/10.1016/j.conbuildmat.2022.128838 (2022).

Sagasta, F. et al. Acoustic emission energy b-value for local damage evaluation in reinforced concrete structures subjected to seismic loadings. Mech. Syst. Signal. Pr. 102, 262–277. https://doi.org/10.1016/j.ymssp.2017.09.022 (2018).

Chen, Z. Q., He, C., Hu, X. Y. & Chun, C. M. Effect of stress paths on failure mechanism and progressive damage of hard-brittle rock. J. Mt. Sci-Engl. 18, 2486–2502. https://doi.org/10.1007/s11629-020-6554-9 (2021).

Liu, X. et al. Creep damage evolution of marble from acoustic emission and the damage threshold. Front. Earth Sci-Switz. 8, 58. https://doi.org/10.3389/feart.2020.00058 (2020).

Yao, W. et al. Study on acoustic emission characteristics and failure prediction of post - high - temperature granite. J. Test. Eval. 48, 20190575. https://doi.org/10.1520/JTE20190575 (2020).

Gan, Y. X., Wu, S. C., Ren, Y. & Zhang, G. Evaluation indexes of granite splitting failure based on RA and AF of AE parameters. Rock. Soil. Mech.41, 2324–2332. https://doi.org/10.16285/j.rsm.2019.1460 (2020). (Chinese).

Zhang, L. M., Ma, S. Q., Ren, M. Y. & Jiang, S. Acoustic emission frequency and b value characteristics in rock failure process under various confining pressures. China J. Rock. Mech. Eng.34, 2057–2063. https://doi.org/10.13722/j.cnki.jrme.2015.1044 (2015). (Chinese).

Crampin, S. & Gao, Y. The physics underlying Gutenberg-Richter in the earth and in the moon. J. Earth Sci.26, 134–139. https://doi.org/10.1007/s12583-015-0513-3 (2015).

Chen, Z. et al. Acoustic emission analysis of crack type identification of corroded concrete columns under eccentric loading: A comparative analysis of RA-AF method and gaussian mixture model. Case Stud. Constr. Mat.18, e02021. https://doi.org/10.1016/j.cscm.2023.e02021 (2020).

Friedrich, L. F. et al. Analysis of acoustic emission activity during progressive failure in heterogeneous materials: experimental and numerical investigation. Appl. Sci.12, 3918. https://doi.org/10.3390/app12083918 (2022).

Jing, G., Marin, M. P. & Lacidogna, G. Study of time–frequency domain of acoustic emission precursors in rock failure during uniaxial compression. Signals. 5, 105–117. https://doi.org/10.3390/signals5010006 (2024).

Zhao, K. et al. Study on early mechanical properties and damage constitutive model of tailing-cemented backfill with different fibers. China J. Rock. Mech. Eng.41, 282–291. https://doi.org/10.13722/j.cnki.jrme.2021.0369 (2022). (Chinese).

Liu, X. L., Pan, M. C., Li, X. B. & Wang, J. P. Acoustic emission b–value characteristics of granite under dynamic loading and static loading. China J. Rock. Mech. Eng.36, 3148–3155. https://doi.org/10.13722/j.cnki.jrme.2016.0272 (2017). (Chinese).

Cheng, Y., Song, Z. P., Xu, Z. W., Yang, T. T. & Tian, X. X. Failure mechanism and infrared radiation characteristic of hard siltstone induced by stratification effect. J. Mt. Sci-Engl. 21, 700–716. https://doi.org/10.1007/s11629-023-8444-4 (2024).

Acknowledgements

The authors thank the Basic Science Research Project of Higher Education Institutions in Jiangsu (No. 24KJB560024), 2023 High-level Talent Research Project from Yancheng Institute of Technology (No. xjr2023019), Science and Technology Innovation Team of Shaanxi Innovation Capability Support Plan (No. 2020TD005), Scientific Research Program Funded by Shaanxi Provincial Education Department (No. 23JK0594), Shaanxi Provincial Natural Science Foundation (No. 2024JC-YBQN-0480), and Science and Technology Research and Development Plan Project from China Railway Construction Co., LTD. (No. 2023-C16).

Author information

Authors and Affiliations

Contributions

Y.C.: Methodology, Experimental design, Validation, Writing–original draft, Writing–review & editing. C.L.: Methodology, Data curation, Writing-review & editing. Y.S.: Experimental design, Writing–review & editing, Resources, Funding acquisition. L.C.: Investigation, Data curation, Writing–review & editing. Xingan Lu: Methodology, Data curation, Writing–review & editing. W.Q.: Investigation, Data curation, Writing–review & editing. T.W.: Methodology, Experimental design, Validation, Writing–review & editing. B.Z.: Validation, Writing–original draft, Writing–review & editing. Z.L.: Methodology, Data curation, Writing-review & editing. Z.S.: Methodology, Resources, Funding acquisition, Experimental design, Writing-review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cheng, Y., Li, C., Sun, Y. et al. Macro-micro fracture mechanism and acoustic emission characteristics of brittle rock induced by loading rate effect. Sci Rep 14, 23657 (2024). https://doi.org/10.1038/s41598-024-73190-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-73190-5

Keywords

This article is cited by

-

Study on the failure behavior of saturated sandstone based on AE and avalanche characteristics

Scientific Reports (2025)

-

Adaptive damage analysis method for ultimate bearing capacity of steel truss structures with box section

Scientific Reports (2025)