Abstract

Polyamide 6 (PA6) films with significant α relaxation process was selected as the model system. The creep behavior and rheological mechanism during deformation in the amorphous regions of semi-crystalline polymers are systematically investigated by carrying out creep experiments. Based on the quasi point defect (QPD) theory, the complete physical process of PA6 film creep behavior from elasticity to viscoelasticity and viscoplasticity was analyzed and modeled from the perspective of structural heterogeneity. The results demonstrate that the creep deformation of PA6 film is a typical thermo-mechanical coupling and nonlinear mechanics process, and potential creep mechanisms corresponds to stress-induced local shear deformation enhancement and thermal activation-induced particle flow diffusion. The elastic-plastic transition involved in the creep deformation process of semi-crystalline polymer originates from the activation of quasi-point defective sites in the amorphous region, the expansion of sheared micro-domains and irreversible fusion. The generalized fractional Kelvin (GFK) model is proposed, and the physical meaning of parameters is explained by combining the quasi point defect theory and creep delay spectrum(L(τ)). Finally, the effectiveness of the GFK model and the QPD theory in studying the deformation behavior of PA6 films was validated by comparing experimental data with theoretical results, which theoretically reveals the structural evolution of PA6 film during creep process.

Similar content being viewed by others

Introduction

Polyamide 6 (PA6) films is widely used in food packaging, biomedical, industrial applications and other fields because of its excellent mechanical properties and thermal stability1,2,3. Polymeric materials exhibit specific mechanical behavior caused by the complete (amorphous polymer) or partial (semi-crystalline polymer) non-crystalline state4,5. Based on the periodic structure of the crystal and the corresponding structural defects, the viewpoint that the microstructure of the polymer material determines the macroscopic properties has been widely accepted6. Presently, conventional experimental techniques employed for investigating the rheological behavior and structural heterogeneity of polymer film primarily include tensile7, torsion8, shear9, stress relaxation10 and creep11,12. Creep can accurately reflect the dynamic characteristics and energy state information of materials through strain response, and has been extensively demonstrated to be an effective method to quantitatively investigate the scientific issues related to PA6 films, including time-dependent structural relaxation, viscoelastic-viscoplastic deformation and rheology13,14. Current research work primarily focuses on the polycrystalline phenomenon and crystal structure of PA615, the unique rheological properties and energy dissipation mechanism during processing are not systematic and in-depth. In recent years, a large number of studies indicated that due to the diversity of processing conditions and the interaction between molecules, the polymer structure is heterogeneity and difficult to characterize by conventional analytical methods16. Therefore, it is essential to elucidate the rheological properties and deformation mechanisms of polymer to establish a model that can accurately describe the correlation between microstructural attributes and macroscopic mechanical properties.

In order to further investigate the structural heterogeneity and deformation correlation of materials, various molecular theories for polymer rheology based on mean-field have been proposed, such as fractional order theory17, shear transformation zone (STZ)18, quasi point defects theory19. The rheological constitutive model based on fractional-order theory, as an extension of traditional integer-order models, can accurately reflects material memory effects and nonlinear behavior by establishing stress-strain constitutive relationships. The quasi point defect theory used to describe the elastoplastic behavior of polymers can not only describe the motion of atoms/molecules in amorphous solids, but also relate the microscopic physical evolution of the deformation process to the macroscopic mechanical properties. Li et al.20 aiming at the limitations of the traditional Burgers model, they proposed an improved Fractional Derivative Burgers (FDB) model by introducing a fractional springpot, and verified the accuracy in describing the dynamic viscoelasticity of asphalt mixtures. Lin et al.21 developed a micromechanical mean-field shear transformation zone (STZ) model, found the deformation-induced material polarization is in the form of an anisotropic distribution of STZ, which is the governing mechanism of the Bauschinger effect, and systematically describe the stress response of polymers amorphous region. R. Rinaldi et al.22 established the relevant constitutive equation based on the quasi point defects theory (QPD) to modeling the viscoelastic-viscoplastic behavior of amorphous polymers. The results shows that the external thermodynamic stimuli leads to the reorganization of internal microstructure and is associated with two main relaxation processes (α, β). Zhu et al.23 conducted a wide-frequency dynamic mechanical analysis of amorphous solids and found that the Modified Fractional (MF) Model based on power-law can effectively describe the experimental data. Combined with the theory of quasi point defect, the physical interpretation of MF model is discussed. Finally, the microstructural heterogeneity of MGs was validated by discretizing the distribution of relaxation times corresponding to the experimental data. As typical semi-crystalline polymer, PA6 has an amorphous region inside, and the viscoelastic response shows obvious nonlinear characteristics, which strongly dependent on temperature, stress and strain rate24,25. Therefore, the fractional order theory and the quasi point defect theory can reasonably explain the deformation mechanism of the creep process.

In this paper, PA6 film is taken as the research object, and creep experiments under different temperature and stress conditions are carried out to investigate the variation of creep, final state creep compliance and quasi-steady state creep rate. Further, introducing fractional fundamental mechanical elements and replacing the Newton dashpot in the generalized Kelvin (GK) model with a fractional springpot element, the generalized fractional-order Kelvin (GFK) model is constructed. Used GFK model to fit the creep master curve of the PA6 film at a reference temperature of 50℃, and the long-term creep behavior of the material was successfully predicted using short-term experimental data. In order to enrich the physical interpretation of the fractional rheological constitutive model, we combine it with the QPD theory and creep delay spectrum (L(τ)) for mathematical discussions. From the perspective of structural heterogeneity, deeply investigated the transformation process of PA6 film from elasticity to viscoelasticity and viscoplasticity, and clarified the macroscopic mechanical response and microstructure change of PA6 film under thermo-mechanical coupling excitation, which provided the necessary theoretical guidance for further understanding the rheological mechanism of PA6 film during deformation.

Experimental

Materials

Raw material polyamide 6 was purchased from Hunan Yuehua Chemical Co., Ltd. (Hengyang, China) with a purity of 99.9%. The glass transition temperature(Tg): 60℃, Density(ρ): 1.158 g/cm3, Melt index(MI): 3.8 g/min, The melting temperature(Tm): 220℃.

Sample preparation

Due to the hygroscopicity of PA6, the raw material slices were firstly placed in an electrothermal constant temperature blast drying oven at 80 °C for 8 h to blow dry the surface moisture, and then placed in a vacuum drying oven at 120 °C for 12 h, observe whether the vacuum gauge changes every two hours, if the change is obvious, repeat the vacuum operation.

The dried PA6 raw materials were melt-extruded by a single screw extrusion casting machine (FDHU35, Guangzhou General Experimental Analysis Instrument Co., Ltd., Guangzhou, China) to prepare a casting film with uniform thick and impurity-free casting film. The machine temperature is set at 250–255 °C to ensure that the raw material is completely melted, and the screw speed is 30 rpm to control the stretching degree of the film in the casting direction, so that to make it as uniform as possible to reduce the degree of anisotropy. After extrusion, the PA6 melt was cooled on a casting roller with a set temperature of 30℃, and then the casting film with a thickness of 0.250–0.300 mm was obtained by traction and winding. For convenience, the casting direction is machine direction (MD), and the vertical casting direction is transverse direction (TD). In addition, the mechanical response of thermoplastics depends on the thermomechanical history of the sample26. An effective way to determine the isoconfigurational testing conditions (materials in the same aging state) is to perform rejuvenating annealing process on the material, that is, heating the material above Tg and maintain for a period of time, then cooling to room temperature (25℃) to reduce the internal residual stress and eliminate the thermal history. This process can also eliminate potential orientations of macromolecular chains but may result in noticeable changes in sample dimensions. We follow another procedure, the sample was aged below Tg to ensure a stable quasi isoconfigurational state, then stored at 25 °C. Therefore, storage and in situ aging can be ignored in this aged during the mechanical test. For convenience, the test direction is uniformly selected in the MD direction.

Testing and characterization

The thermal properties of PA6 film were tested by differential scanning calorimeter (Q20, TA, New Castle, DE, USA) in nitrogen atmosphere. The mass of the sample is 4–6 mg, the temperature is increased from 25 °C to 300 °C at a heating rate of 10 °C/min, holding for 10 min, and then cooling to 25 °C. The melting temperature (Tm), the initial crystallization temperature (Tc) and melting enthalpy (ΔHm) were measured. Crystallinity27 can be calculated using Eq. (1):

Where Kc is crystallinity, ΔH* m was the theoretical melting enthalpy change value of the material when PA6 is completely crystallized, which is 230 J/g28.

X-ray diffractometer (Smart-lab SE, Rigaku, Tokyo, Japan) was used to test the PA6 film to determine the semi-crystalline properties of the sample. The test environment is a reflection mode and Cu Kα radiation (λ = 0.154 nm), the operating voltage and current are 40 kV and 30 mA, respectively, the test range is 5 ~ 40°, and the scanning rate is 2°/min.

Dynamic mechanical analysis refers to the technique of applying alternating loads on the material to measure the corresponding strain response29. Temperature scanning at single frequency of PA6 film was carried out by dynamic thermomechanical analyzer (DMA 242 E, NETZSCH, Selb, Germany) equipped with a stretching fixture, observed the changes of E′, E″ and tanδ with temperature. The sample size is 13.5 × 5 × 0.26mm3, the temperature range is 25–180 °C, the heating rate is 3°C/min, the frequency is 1 Hz, and the absolute target amplitude is 20 μm.

Creep experiments of PA6 film were conducted under different stress and temperature using dynamic mechanical analyzer. (1) At the temperature of 30 °C, the creep of PA6 film under different stress (1 MPa, 2 MPa, 3 MPa, 4 MPa, 5 MPa) was tested, as shown in Fig. 1 (a), test conditions are shown in Table 1. (2) The creep of PA6 film at different temperatures (30 °C, 33 °C, 37 °C, 40 °C, 50 °C) was investigated at a constant stress of 3 MPa, as shown in Fig. 1 (b), test conditions are shown in Table 2. The loading time of each group was 60 min, and the samples were isothermally treated at the test temperature for 5 min before the start to reach equilibrium. To ensure that the test results are within the linear viscoelastic range, the initial strain amplitude of the material is set at 0.1%, and a pre-strain of 2%.

Results analysis and discussion

Figure 2(a) shows the DSC curves of PA6 film after one thermal cycle, Tm and Tc were 220 °C and 195 °C, respectively. According to Eq. (1), the crystallinity of PA6 film is 19.98%.

Existing studies30 have shown that strain-induced crystallization (SIC) occurs in PA6 film after stretching, and the XRD patterns under different stretching ratio conditions all show strong diffraction peaks at 24 degrees, reflecting the increased degree of crystallization and structural ordering. From Fig. 2(b), the XRD pattern shows the characteristics of wide and low diffraction peak intensity in the range of 15–25 degrees, which also indicates that PA6 film has semi-crystalline properties. At this time, the PA6 molecules are irregularly arranged, but there are still large-scale amorphous regions inside.

Figure 3 shows the DMA curve of PA6 film. It can be observed that PA6 film has higher storage modulus (E″) at room temperature, about 1200 MPa, exhibits a close molecular structure and has strong rigidity. The change of the loss modulus (E′) is directly related to the energy dissipation of the material in a period, which can reveal the microscopic mechanism and dynamic process of the atomic motion caused by the external alternating load. In the temperature range of-120–15 °C and 15–100 °C, E′ corresponds to the PA6 secondary transition (β relaxation) and glass transition (α relaxation), respectively. In the glass state, due to the low temperature, the energy of molecular motion is very low, PA6 chain segments are in a frozen state, only smaller moving units, such as side groups, branched chains, etc., move, and accompanied by a certain amount of energy dissipation. As the temperature increases, the energy of the thermal movement of the molecules is sufficient to overcome the site barriers of rotation within the main chain. At this time, the chain segment motion is excited, and the molecular conformation of PA6 film changes, from glass state to rubber state, which manifests itself as a decrease in stiffness and accompanied by more energy dissipation. In DMA curve, the temperature at which the loss factor (tanδ) peaks correspond to the glass transition temperature (Tg)31, the Tg of PA6 film is 57.25 °C.

Figure 1 shows the creep curve of PA6 film under different loading stress and temperature, the creep of PA6 film shows obviously the initial creep stage of strain rate decreasing with time and the (quasi) steady-state creep stage of strain rate almost constant, which maybe caused by the set loading time or insufficient stress. From Fig. 1 (a), it can be observed that with increasing stress, the initial length of creep increases accompanied by a longer duration. From Fig. 1 (b), with the increase of temperature, the initial creep time and deformation of PA6 film are more significant, which is similar to the experimental trend under different stress conditions, but the steady-state creep stage is gentle. Therefore, it can be infer that the creep of PA6 film at different temperatures is basically completed in the initial stage. Under the condition of low temperature and stress, PA6 film has obvious rigidity and good creep resistance, and the elastic deformation dominates the creep process. When the temperature gradually increases, the creep resistance of PA6 decreases sharply, and the viscoelastic deformation further dominates the creep deformation.

Based on the above experimental results, the influence of temperature and stress on the creep of PA6 film is very significant, but the mechanism of a certain influencing factor under thermal-mechanical coupling excitation is not clear. Therefore, we attempt to investigate in depth the influence of stress and temperature on the creep of PA6 film from different perspectives, aiming to reveal the evolution of creep mechanisms under thermomechanical coupling. To highlight the role of stress, introduce the concept of creep compliance(J(t)), Eq. (2), which is defined as the ratio of strain to stress at any given time (t) during the creep process.

Figure 4 is the creep compliance-time curve of PA6 film under different stress and temperature. As a typical nonlinear deformation process, creep compliance of PA6 film shows a process of decreasing, increasing and then decreasing with the increase of stress. Because at lower temperatures, the increase in stress from 1 MPa to 2 MPa and from 3 MPa to 5 MPa is not sufficient to induce a more significant creep deformation. At this time, the change range of strain is less than that of stress, which leads to the decrease of creep compliance with the increase of stress. It can be seen that the effect of stress will be more obvious in the high temperature. At the same stress, the creep compliance continuously increases with the rise in temperature, which can be explained by the intensified influence of temperature on the creep process, thereby resulting in a sustained elevation in strain amplitude.

The creep compliance data at the end of creep (t = 60 min) is referred to as the final creep compliance (Jend), which provides a more intuitive description of the evolution, as shown in Fig. 5. At T = 30 °C, the Jend of PA6 film under different stress conditions also shows a trend of decreasing first, increasing and then decreasing with the increase of stress. When the constant stress is 3 MPa, the Jend always increases with temperature, from 4.83 × 10−3MPa−1 at 30 °C to 14.47 × 10−3MPa−1 at 50 °C, which is consistent with the trend shown in Fig. 4.

The above conclusion can also be illustrated through another physical quantity, quasi-steady creep rate (\({\varepsilon _{SS}}\)). After t = 30 min, the creep of PA6 film basically reaches the steady state stage, since we choose the derivative of creep strain increment against time at the moment of t = 50 min on the corresponding creep-time curve as the quasi steady state creep rate. From Fig. 6, the \({\varepsilon _{SS}}\) increases from 2.71 × 10−6s−1 under low stress to 4.55 × 10−5s−1 under high stress, representing a percentage increase of 1578%, which can be explained that high stress are accompanied by a more pronounced strain response, i.e. the creep strain per unit time increases. It is worth noting that the creep curves at a stress of 4 MPa have not yet reached the quasi-steady state creep stage at t = 50 min, resulting in a larger \({\varepsilon _{SS}}\) at this condition than the results at 5 MPa. The slight decrease of \({\varepsilon _{SS}}\) at different temperatures indicates that the creep of PA6 film has been basically completed in the initial stage, but the internal deformation mechanism still needs further investigate.

The experimental data from Fig. 4 (b) were transformed into logarithmic time coordinates. Then, based on the principle of time-temperature superposition32, taking 50 °C as the reference temperature (Tr), applying the minimum area method between curves33, the creep compliance curves at temperatures of 33 °C, 37 °C, 40 °C, and 50 °C were horizontally shifted to obtain the creep compliance master curve of PA6, as shown in Fig. 7. It is also possible to verify that PA6 film is a thermo-rheologically simple material.

The horizontal moving distance of each curve is called the horizontal shift factor (aT). Furthermore, using the Williams-Landel-Ferry (WLF)34 (Eq. (3)) and the Arrhenius (Eq. (4))35 to fit the experimental data, as shown in Fig. 8. It is found that the fitting results and the horizontal shift results of the experimental data are in good agreement. By comparing the Eq. (3) and Eq. (4), let C2 = Tr, C1=(1/2.303)(Ea/R×Tr), it can be found that WLF and Arrhenius are exactly the same, and then it can be assumed that both the Arrhenius and the WLF can be used as a method for the study of the rheological properties of PA6 films. The nonlinear part of the master curve is related to the dynamic heterogeneity, strain-hardening effects, and temperature-dependent relaxation, but the mechanism needs further investigation. Besides, the master curve spans four orders of magnitude, so that the long-term creep behavior of the material can be predicted based on short-term experimental data.

Theoretical model

Generalized fractional Kelvin (GFK) model

The fractional rheological model is a viscoelastic constitutive model based on fractional calculus, widely used in materials science and engineering analysis due to its ability to accurately describe the viscoelasticity and complex mechanical behavior of materials with fewer parameters36,37. Koeller38 proposed a springpot element to describe viscoelastic behavior instead of Hooke spring and Newton dashpot in the classical viscoelastic model, and its mechanical response is:

where E is the elastic modulus of the material, η is the viscosity of the material, and τ = η/E is the average relaxation time of the springpot, Dα denotes the Riemann-Liouville fractional derivative39, α is the fractional order, 0 < α < 1. The springpot element is shown in Fig. 9. When α = 0, Eq. (5) degenerates to the case of Hooke spring, it degenerates to the case of Newton dashpot when α = 1. The springpot element can characterize the transition of material properties from solid to fluid states, and the model parameters have clear physical meanings.

In order to overcome the shortcomings of the traditional model in describing the nonlinear behavior and improve the characterization ability of fractional rheological models, replace the Newton dashpot in the Generalized Kelvin model with the fractional springpot element, and construct the Generalized fractional Kelvin (GFK) model. The GFK model is composed of a Hooke spring, n fractional Kelvin bodies and a fractional springpot element in series, as shown in Fig. 10.

Under the action of stress σ, the strain of the model is \({\varepsilon _0},{\varepsilon _1},{\varepsilon _2}, \cdot \cdot \cdot ,{\varepsilon _n},{\varepsilon _{n+1}}\), respectively. Where:\({\varepsilon _0}=\sigma /{E_0}\), \({\varepsilon _{n+1}}=\sigma /\left( {{E_{2n+1}}{\tau ^{{\alpha _{n+1}}}}{{\text{D}}^{{\alpha _{n+1}}}}} \right)\). The strain of Hooke spring and fractional springpot in series is obtained, \({\varepsilon _c}={\varepsilon _0}+{\varepsilon _{n+1}}\), the constitutive equation is:

Under the unit step load, the creep compliance of Hooke spring and fractional springpot in series can be obtained by Laplace transform of Eq. (6):

Where\(\Gamma ( \cdot )\)is the gamma function40. Subsequently, the constitutive relationships of the intermediate n fractional Kelvin bodys are discussed. Taking the first fractional Kelvin body (Fig. 11) as an example.

Under the action of stress σ, the strain of spring and springpot is \({\varepsilon _1}\), and the stress is\({\sigma _1}\) and \({\sigma _2}\), respectively, then the total stress of the fractional order Kelvin body is \(\sigma ={\sigma _1}+{\sigma _2}\), and the constitutive relation equation is:

The creep compliance of fractional Kelvin body can be obtained by Laplace transform of Eq. (8) under unit step load:

Here we introduce the two-parameter Mittag-Leffler function, Eq. (10), which has following properties41, Eq. (11).

Comparing Eq. (9) with the Laplace transform formula of the Mittag-Leffler function and using Eq. (10), fractional kelvin body creep compliance Jk(t) expression is obtained:

Finally, combining Eq. (7) and Eq. (12), obtain the total J(t) of the GFK model:

Where \({\tau _i}\) denotes the relaxation time of the i th fractional Kelvin body, which is used to describe the stress state of the rheological unit in the PA6 film. In the fitting process, the model parameters need to be fitted according to the experimental data, and fully taking into account the material characteristics. If fewer fractional Kelvin units are selected, the complex behavior of the material may not be captured, resulting in a poor fitting effect. On the contrary, too many units lead to over-fitting problems and reduce the generalization ability of the model. Therefore, in order to better characterize the microstructural heterogeneity and nonlinear characteristics of the system, improve the prediction accuracy of the model we will employ the GFK model with 5 fractional Kelvin units to fit the creep compliance data of the PA6 film.

Quasi point defect (QPD) theory

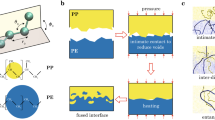

Polymer amorphous regions exhibit unique physical and mechanical properties, with their microstructure showing dynamic heterogeneity in response to external loading conditions. These characteristics are challenging to characterize using traditional analysis methods. The exploration of the macroscopic deformation mechanism needs to fully consider the internal deformation unit. Perez et al.42,43,44 proposed the quasi point defect theory based on the concept of “defects” combining macroscopic mechanical properties with microscopic atomic/molecular motion, which can be used to describe the rheological behavior of polymers amorphous region. According to this theory, due to the disorder of the amorphous state, certain regions within the material, referred to as quasi point defects, exhibit fluctuations in density, enthalpy, and entropy at the nanoscale. Therefore, under thermal-mechanical coupling, the microstructural deformation of solids will preferentially occur at these quasi point defect sites. In addition, this theory introduces the nucleation, growth, contraction, and fusion processes of sheared micro-domains (SMDs), which can quantitatively describe the complete transition of amorphous region of material from anelastic to yield deformation under the influence of thermal-mechanical coupling from a physical perspective, as shown in Fig. 12.

“quasi point defects” theoretical model of amorphous materials22, (a) “quasi point defects” sites in amorphous materials, (b) “quasi point defects” are activated in a multi-coupling field, (c) The formation, expansion and merging of SMDs and the induction of new “quasi point defects” sites.

Figure 12(a) can be interpreted as showing that under the thermal-mechanical coupling, the quasi-point defect sites within amorphous region of the PA6 film are activated to cause local molecular or atomic rearrangement, resulting in molecular conformational changes, such as the bending and stretching of the segments, which in turn leads to the formation of SMDs. At this stage, the molecular conformation changes little, mainly reversible elastic deformation. The molecular chain elongates under the action of external force, but it can be restored after the external force is removed. According to Fig. 12(b), the diffusion effect occurs under high temperature, with increased thermal motion of the molecular chains leading to the activation of more quasi point defect sites, and promoting the expansion of SMDs. This is because the thermal excitation causes the chain segments to deform and rearrange in the shear region, thereby increasing the volume of SMDs. Under sustained stress, the molecular chains around SMDs deform along the maximum shear plane. This deformation is viscoelastic, meaning the deformation progresses occurs over time, and after the external load is removed, the SMDs gradually recover, indicating that the changes in molecular conformation at this stage are reversible. As SMDs continue to expand along the maximum shear plane (Fig. 12 (c)), their size will grow to a critical value due to the limitation of space and matrix elasticity. When the adjacent sheared micro-domains contact, they will irreversibly merge to form larger shear region. The merging of SMDs and plastic flow lead to permanent molecular conformational changes and plastic deformation of the material.

Under the framework of quasi point defect theory, there are the following assumptions about the defect concentration and molecular motion mechanism of materials amorphous region: (1) When the temperature is lower than the glass transition temperature (Tg), the model system is in a frozen state (isostructural state), and the quasi point defect concentration (Cd) is a fixed value. When the temperature is higher than Tg, Cd increases with increasing temperature. (2) The motion of structural units in polymer amorphous region exhibits a hierarchical effect, where the most active structural units move first. The parameters used to measure the degree of hierarchical motion correlation are characterized by correlation factors (χ), the value is between 0 and 1, as the value approaches 1, the correlation between hierarchical motions within the system becomes weaker. It should be noted that below the Tg, the χ remains almost unchanged with temperature, and it can be considered that the defect concentration in the material remains unchanged below Tg45. In amorphous systems, α relaxation is generally considered to correspond to large-scale molecular or atomic concerted motion, and β relaxation is the precursor motion of α relaxation. The relaxation time (\({\tau _\beta }\)) corresponding to β relaxation and temperature (T) follow the Arrhenius law(Eq. 14)46:

Where \({E_\beta }\) is the activation energy of β relaxation. Under the stress field, the amorphous solid structure unit follow:

Where \({\sigma _0}\) is the yield limit of the material.

SMDs are activated and expanded under the excitation of thermo-mechanical coupling, corresponding to viscoelastic deformation. After unloading, SMDs shrinks corresponds to viscoelastic deformation recovery. Adjacent SMDs merging corresponds to viscoplastic deformation, which is irreversible. The whole deformation process of the model system can be described as the sum of the initial elastic deformation component (\({\varepsilon _{el}}\)), Eq. (16), β relaxation deformation component (\({\varepsilon _\beta }\)), Eq. (17), α relaxation viscoelastic deformation component (\({\varepsilon _{ve}}\)) and viscoplastic deformation component (\({\varepsilon _{vp}}\)), Eqs. (18) and (19).

Furthermore, based on the quasi-point defect theory, the total deformation creep compliance expression is:

Where \({J_{el}}\) is the instantaneous elastic compliance and is numerically equal to the reciprocal of the unrelaxation elastic modulus (Eel ) of the model, \({A_\beta }\) is β relaxation deformation strength, \({A_{ve}}\) is viscoelastic deformation strength, \({A_{vp}}\) is viscoplastic deformation strength, \({\tau _\beta },{\tau _{ve}},{\tau _{vp}}\) are the characteristic time corresponding to the deformation process, respectively. It is noteworthy that, due to variations in sizes, densities, and energy distributions of point defects, β relaxation cannot consider a single characteristic time distribution. Within this theoretical framework, the characteristic time distribution of β relaxation follows a spectrum of characteristic times is employed with a distribution following the Gumbel probability law47, the basic distribution form is Eq. (21).

Where B is the distribution width parameter, in the [0,1], \(\left\langle \tau \right\rangle\) is the mean value of characteristic time, \({W_i}\) is the probability weight corresponding to the \({\tau _i}\). From Fig. 13, the Gumbel distribution can be regulated by changing the B value.Visibly, the characteristic relaxation time gradually tends to be concentrated with the increase of B, and the asymmetry(“left-dense, right-relaxed”) also reflects the dynamic heterogeneity of β relaxation. Considering the characteristic time distribution of β relaxation, Eq. (14) can be expressed as:

The contribution of β relaxation to creep compliance is:

Equation (20) is further expressed as:

Data fitting analysis and discussion

The creep curves at 33 °C-3 MPa were fitted using the GFK model (Eq. (25)), as shown in Fig. 14. The model calibration method was performed using the Quasi-Newton (BFGS) method combined with a Universal global optimization (UGO) algorithm, the fitted parameters are presented in Table 3. The fitting results show that the GFK model agrees well with the experimental data, and the fitting degree (R2) is above 0.99, indicating that the fractional rheological model has a strong advantage in simulating the rheological behavior of viscoelastic materials and can accurately describing the creep deformation of PA6 film.

It can be inferred from the elastic modulus and relaxation time distributions that the internal microstructure of PA6 film is more likely to be activated under sustained stress, which manifests as shear thinning. From the fractional-order (α) distribution pattern obtained from the fitting, the fractional springpot mainly simulate the elastic characteristics, while the fractional order Kelvin bodies simulate the evolution of PA6 film from viscoelastic to viscoplastic.

In order to further investigate the creep mechanism, the creep compliance of PA6 film are fitted by GFK model, as shown in Fig. 15. Then, the fitted value and logarithmic time are substituted into Eq. (26) to obtain the creep delay spectrum(L(τ)) of PA6 film to provide a more accurate description of the creep behavior48, as shown in Fig. 16.

The delay spectrum directly represents the contribution of the fractional Kelvin bodies corresponding to different delay time τ to the creep compliance in the form of a weight function, and these extreme can represent the concentration of the delay process. This is more meaningful than exploring the fitted the model parameters (E, τ, α).

It can be observed from Fig. 16 that the distribution of the creep delay spectrum varies significantly under different stress and temperature conditions, indicating that the creep behavior of PA6 film is affected by multi-field coupling. From Fig. 16 (a), it can be seen that the delay time does not change much in the peak width and height of the delay spectrum under different stresses, and follows a similar distribution. In addition, the maximum value of L(τ) decreases and shifts to the left as the stress increases. At the same time, L(τ) becomes wider, which means that the delay time is distributed over a wider time range and the system becomes more disordered. The reason may be that PA6, as a thermoplastic, typically exhibits a high creep rate, high stress may cause induce viscoelastic flow behavior, that is, molecular chain slip and plastic deformation increase, which in turn results in a more disordered internal structure. In the low-stress state, the deformation of PA6 films primarily involves elastic and viscoelastic behavior. By comparison, the creep delay spectrum curve of 1 MPa exhibits a significantly larger peak at τ = 0.5 min, which can be inferred that the PA6 film is more dependent on temperature under low stress state, further indicates that the creep mechanism in this state is mainly dominated by thermal activation. However, the temperature has little effect at the high stress state and the stress further dominates the creep process. From Fig. 16 (b), the temperature threshold of the delay spectrum of PA6 at τ = 0.5 min can be determined, once the temperature exceeds this threshold, the τ will follow a highly similar distribution characteristics. The peak of 40 °C and 50 °C creep delay spectrum curve at τ = 0.5 min can be explained as the thermal activation effect leads to more active molecular motion in the material, the microstructure of the PA6 film changes, and then shows more creep delay effect at high temperature. In addition, the peak value of the τ between 10 min and 30 min in the creep delay spectrum at different temperatures increases significantly with the increase of temperature, which can be explained by the fact that the material exhibits more viscous characteristics after loading at high temperature, and more viscoelastic deformation transforms into viscoplastic deformation. In further summarizing the creep deformation transition process of PA6 film controlled by stress and temperature, the shortest τ of less than 0.5 min corresponds to the instantaneous elastic response of the system, while τ between 0.5 and 10 min correspond to viscoelastic response. The distribution intensity of the longer relaxation time of more than 10 min is significantly improved, indicating that the creep deformation is gradually dominated by the viscoplastic response.

According to Eq. (25), there is a coupling relationship between the different parameters, and this means that adjusting one parameter can affect the others. Therefore, while the L(τ) (Eq. (26)) and its numerical changes can be provided, relying solely on adjusting one parameter to match the real situation may be difficult. Nevertheless, the GFK model is advantageous in describing the rheological behavior of PA6 films because it not only automatically satisfies thermodynamic constraints but also accounts for memory effects through fractional-order operators. At the same time, the rich evolution of delay time distributions in L(τ) also provides an opportunity to explore the physical origins of the GFK model.

Creep delay spectrum (L(τ)) of PA6 film obtained by Eq. (26) in creep experiments, (a) L(τ) under different stress, (b) L(τ) at different temperatures.

In order to explain the physical meaning of the fractional rheological constitutive model, combine it with the quasi point defect theory to further enrich the content of the GFK model from the perspective of microstructure evolution, and to reveal the physical nature of the transition in the creep mechanism of PA6 film under the thermal-mechanical coupling. Firstly, the characteristic parameters α and χ of the GFK model and the QPD model are extracted for comparative discussion to explore the relationship between the two. Although the GFK model, as a phenomenological constitutive equation, may render excessive discussion of its numerous complex parameters meaningless, according to the definition of fractional calculus, the value of the fractional-order (α) can still reflect the macroscopic properties of the material to some extent. When α = 0, the fractional springpot degenerates into the form of a Hooke spring, meaning that the motion of the molecules or atoms inside the material is completely correlated, and the macroscopic properties of the model system are closer to the ideal solid49. In quasi point defect theory, the parameter χ in Eq. (24) can correspond to α in Eq. (25), which is closely related to the concentration of quasi-point defects, reflecting the short-range order of the material in the amorphous region, and can quantitatively characterize the change of atomic mobility and concentration of quasi-point defects during creep. When χ = 0, the material is completely ordered, corresponding to the ideal crystal. At this time, the motion of the internal structural unit of the material is affected by the motion of all other motion units around it, and the concentration of punctual defects in the system is the smallest. As mentioned above, χ is a fixed value below Tg. In previous reports45, researchers usually use the slope of the linear relationship between ln(tanδ) and ln(ω) at a given temperature to determine the χ, and found that the values of χ below Tg are between 0.3 and 0.4 for most materials. Considering the similarity of fractional order and correlation factor, the numerical range of both is between 0 and 1, and the meaning is consistent. Therefore, the quasi point defect theory (QPD) model was used to fit the 50 °C creep master curve of the PA6 film (Fig. 7), and the curve fitted using Eq. (20) as shown in Fig. 17, the parameters obtained from the fitting are shown in Table 4, it was determined that the value of χ below Tg in this work is 0.36, which is basically consistent with other work in the references, and also validates the rationality of the method. Considering the specificity of the temperature selected by the model, PA6 film undergo localize microcrystallineization before α relaxation, which leads to the evolution of creep compliance slightly deviates from the theoretical prediction value. Fortunately, there is a certain limit to the deviation, DSC and XRD results show that there is still a large-scale amorphous region within the PA6. Therefore, the intrinsic correlation between the rheological behavior in the amorphous region and the dynamic mechanical relaxation behavior of PA6 film can still be constructed by the QPD model.

Creep compliance- logarithmic time master curve of PA6 for 50℃ fitted by QPD model (Eq. (19)), illustration is the Creep compliance-time master curve.

The relationship between the GFK model and the QPD model is further discussed based on the characteristic parameters α and χ obtained from Tables 3 and 4. From the point of view of dynamic heterogeneity, there are various regions of different sizes within PA6 films in which molecules or atoms move at different rates, resulting in different relaxation times in these regions. The multiple fractional orders present in the GFK model parameters represent localized relaxation in different regions, and each α corresponds to a single characteristic relaxation time, the localized relaxation behavior of these different regions contributes to the overall relaxation, reflecting the microstructural heterogeneity of the material. Further, in order to explore the fractional order physical meaning in the GFK model, it can be understood that each fractional Kelvin body or fractional springpot in the model corresponds to a deformed region within the material, and the macroscopic characteristics of the local region are reflected by the fractional order value. The above conclusions can be illustrated by combining the number of parameters α in Eq. (25) and the number of peaks in the creep delay spectrum. Therefore, the true variation of the intrinsic relaxation time can be further explored by increasing the number of Kelvin bodies in the GFK model, but the complexity of the model needs to be predicated on the amount of data, and the number of parameters should not be more than the number of data points, or else it may lead to the loss of predictive ability due to overfitting. In the QPD model, on the other hand, whether below or above Tg, the value of the parameter χ reflects more the effect of these localized relaxation regions on the overall relaxation of the material, characterizing the overall structural heterogeneity of the material.

From the illustration of Fig. 17, the shape of the master curve is similar to the trend of the creep curve at other temperatures, the temperature change has no significant effect on the overall morphology of the creep curve and the relaxation width, and this similarity reflects that the creep behavior of the material is dominated by stress at the investigated temperature. PA6 β relaxation as a precursor motion to α relaxation, involving only side group and branched chain rotation rather than large-scale molecular movements. Therefore, the contribution of temperature-induced β relaxation to the creep behavior can be reasonably neglected. Based on the above information, the distribution width (B) is set to 0.50, the creep curves of PA6 are predicted using the QPD model(Eq. (24)), as shown in Fig. 18.

It can be observed from Fig. 18 that the theoretical curve obtained based on the quasi-point defect theory creep compliance expression is basically consistent with the experimental data at low temperature (30 °C) stage and the early stage of creep, with the increase of temperature or loading time, the effect of physical aging on the creep behavior of PA6 film is significant, the creep process is suppressed. The reason that the fit is not as good can be explained by the fact that there are still crystalline regions in the PA6 film structure. Finally, the data fitted by the QPD model are decoupled to obtain the instantaneous elastic, viscoelastic and viscoplastic compliance components corresponding to different stress and temperature conditions. The results are shown in Table 5.

From Table 5, it can be observed that under the same stress conditions, with the increase of temperature ( 37 °C to 50 °C ), both Jel and Jve have a significant decrease, while Jvp has the opposite trend. This indicates that at high stress conditions, the increase of temperature will make the viscoelastic deformation of the model system more transformed into viscoplastic deformation, which is consistent with the conclusions obtained from the previous creep compliance spectrum. The evolution trend of viscoplastic creep compliance Jvp with stress exhibits significant deviation from that observed at various temperatures, notably decreases from 6.60 × 10−5 at 1 MPa to 5.36 × 10−6 at 5 MPa, and the value shows a cross-order of magnitude change. This can be explained by the fact that with the increase of temperature, the molecular thermal motion inside the material is intense, the intermolecular interaction force is weakened, more quasi point defect sites are activated and the concentration increases, further the increase of irreversible fusion of sheared micro-domains leads to the increase of viscoplastic deformation component. The unique change trend of Jvp intuitively reflects that the transition process of creep deformation mode of PA6 film is the result of multi-coupling, which also provides more quantitative explanation for the transition process of deformation mode.

In the following article, further attempts will be made to explain the aforementioned variations using the quasi-point defect theory. Under the influence of thermo-mechanical coupling, quasi-point defects within PA6 are activated, leading to localized atomic rearrangements along the maximum shear plane and resulting in the formation of sheared micro-domains. Due to the structural heterogeneity of the amorphous region of the polymer, the activation difficulty of different quasi-point defect sites is different. Under sustained stress, the volume of the sheared micro-domains increases, which is closely related to the diffusion effect. At this time, the temperature plays a leading role, which is a typical thermal activation process. The SMDs size will reach the critical value due to the limitation of space and the surrounding elastic matrix. Adjacent SMDs boundaries contact and irreversibly merge, which can be considered as the physical source of viscoplastic deformation of polymers. In summary, low stress only induces the nucleation and growth of sheared micro-domains, which gradually retracts to the original state after removing the applied load, and this stage of deformation is a typical viscoelastic deformation process related to time. At high temperature and high stress conditions, the SMDs undergo irreversible fusion, resulting in deformation unrecoverable. In this stage, the viscosity of the model system decreased significantly, the viscoplastic component increased further, which led to the creep behavior of PA6 film exhibits increasingly pronounced nonlinear characteristics.

Conclusions

In this paper, PA6 film prepared by extrusion casting method as the research object. The crystallinity was quantitatively calculated to be 19.98% by DSC and XRD characterization, which proved the semi-crystalline nature of the PA6 film. The creep experiments under different temperature and stress conditions were carried out to investigate the variation of creep compliance and creep delay spectrum. The Newton dashpot in the generalized Kelvin model is replaced by the fractional springpot element, obtain the generalized fractional Kelvin (GFK) to realize the accurate description of the creep constitutive relation of PA6 film. Based on the quasi point defect theory, the physical meaning of the fractional rheological model is comparatively discussed, the relationship between the elastic-plastic transformation and microstructure evolution of PA6 film under thermo-mechanical coupling is revealed.

(1) The creep behavior of PA6 film showed a strong dependence on both stress and temperature. The final creep compliance and the quasi-steady creep rate both exhibit an overall upward trend with increasing temperature and stress. When the temperature is low, the increase of stress from 1 MPa to 2 MPa and from 3 MPa to 5 MPa is not enough to lead to more significant creep deformation, resulting in a downward trend of creep compliance with the increase of stress. The quasi steady creep rate increases from 2.71 × 10−6s−1 under low stress state to 4.55 × 10−5s−1 under high stress state, with a percentage increase of 1578%, indicating that high stress leads to faster creep rate.

(2) The creep delay spectrum of the PA6 film was calculated using the data fitted by the GFK model to more accurately describe the dynamic information of the creep behavior of the PA6 film, and found that the creep mechanism was mainly dominated by thermal activation, resulting in the PA6 film was more dependent on temperature under low stress conditions. The fractional Kelvin unit in the GFK model is mainly used to characterize its viscoelastic properties. In the creep delay spectrum, the peak value of the relaxation time between 10 min and 30 min increases significantly with the increase of temperature, which can be explained that the material exhibits more viscous properties after being subjected to high temperature, and more viscoelastic deformation changes to viscoplastic deformation.

(3) The creep master curve at the reference temperature of 50 °C was fitted by the compliance expression obtained by the quasi point defect theory to determine the correlation factor χ = 0.36, and found that the long-term creep behavior of PA6 film can also be reasonably predicted. The results show that the rheological and dynamic mechanical relaxation behavior can be discussed within this theoretical framework, thus revealing the structural heterogeneity of amorphous region of semi-crystalline polymer. The elastic-plastic transition involved in the creep deformation process of PA6 film can be explained as the activation of quasi-point defect sites, the expansion and irreversible fusion of sheared micro-domains through thermal-mechanical coupling. This also provides a new idea for the potential correlation between the rheological deformation mechanism and the microstructure evolution of the material.

Data availability

Data is provided within the manuscript files.

References

Liu, M. et al. Fabrication of flame retardant nylon 6 film composites with superior gas barrier property and puncture resistance. Compos. Commun.47, 101883. https://doi.org/10.1016/j.coco.2024.101883 (2024).

Picouet, P. A., Fernandez, A., Realini, C. E. & Lloret, E. Influence of PA6 nanocomposite films on the stability of vacuum-aged beef loins during storage in modified atmospheres. MEAT SCI.96, 574–580. https://doi.org/10.1016/j.meatsci.2013.07.020 (2014).

Aulova, A. et al. Mechanical properties and drug permeability of the PA6 membranes prepared by immersion precipitation from PA6 - formic acid - water system. J. MEMBRANE SCI.562, 67–65. https://doi.org/10.1016/j.memsci.2018.05.022 (2018).

Molnár, J. et al. Structural investigation of semicrystalline polymers. POLYM. TEST.95, 107098. https://doi.org/10.1016/j.polymertesting.2021.107098 (2021).

Narayan, S. & Anand, L. Fracture of amorphous polymers: a gradient-damage theory. J. MECH. PHYS. SOLIDS. 146, 104164. https://doi.org/10.1016/j.jmps.2020.104164 (2021).

Deng, L. & Chen, G. Recent progress in tuning polymer oriented microstructures for enhanced thermoelectric performance. NANO ENERGY. 80, 105448. https://doi.org/10.1016/j.nanoen.2020.105448 (2021).

Li, B. et al. Investigation on the Tensile Rheological Behavior of PA6 Film based on Fractional Order Model. MATER. RES. EXPRESS. 10, 105302. https://doi.org/10.1088/2053-1591/acfd11 (2023).

Barriere, T., Cherouat, A., Gabrion, X. & Holopainen, S. Short- to long-term deformation behavior, failure, and service life of amorphous polymers under cyclic torsional and multiaxial loadings. INT. J. Plast.147, 103106. https://doi.org/10.1016/j.ijplas.2021.103106 (2021).

Tao, G. & Xia, Z. Fatigue behavior of an epoxy polymer subjected to cyclic shear loading. Mater. Sci. Engineering: A. 486, 38–44. https://doi.org/10.1016/j.msea.2007.08.044 (2008).

Liu, J. et al. Investigation on the rheological behavior of PA6 film during biaxial stretching. Mater. Today Commun.38, 107616. https://doi.org/10.1016/j.mtcomm.2023.107616 (2024).

Fairhurst, A., Thommen, M. & Rytka, C. Comparison of short and long term creep testing in high performance polymers. POLYM. TEST.78, 105979. https://doi.org/10.1016/j.polymertesting.2019.105979 (2019).

Slouf, M., Steinhart, M., Nemecek, P. & Gajdosova, V. Hodan. Correlations between Microscale Indentation Creep and Macroscale Tensile Creep of Polymers. MATERIALS. 16, 834. https://doi.org/10.3390/ma16020834 (2023).

Liu, Y. Investigation on the creep behavior of PA6 film based on the fractional differential model. J. Elastomers Plast.53, 599–611. https://doi.org/10.1177/0095244320959805 (2021).

Yu, C., Kang, G. & Chen, K. A hygro-thermo-mechanical coupled cyclic constitutive model for polymers with considering glass transition. INT. J. Plast.89, 29–65. https://doi.org/10.1016/j.ijplas.2016.11.001 (2017).

Uematsu, H. Enhancement of flexural properties of carbon fiber-reinforced polyamide 6 via oriented crystallization of polyamide 6 among carbon fibers. Compos. Part A: Appl. Sci. Manufac.176, 107837. https://doi.org/10.1016/j.compositesa.2023.107837 (2024).

Hartley, A. D., Drayer, W. F., Ghanekarade, A. & Simmons, D. S. Interplay between dynamic heterogeneity and interfacial gradients in a model polymer film. J. Chem. Phys.159, 20. https://doi.org/10.1063/5.0165650 (2023).

Su, X., Yao, D. & Xu, W. A new method for formulating linear viscoelastic models. INT. J. ENG. SCI.156, 103375. https://doi.org/10.1016/j.ijengsci.2020.103375 (2020).

Richard, D., Kapteijns, G., Giannini, J. A. & Manning, M. L. Lerner. Simple and broadly Applicable Definition of Shear Transformation zones. PHYS. REV. LETT.126, 015501. https://doi.org/10.1103/PhysRevLett.126.015501 (2021).

Rinaldi, R. Modeling of the mechanical behavior of amorphous glassy polymer based on the quasi-point defect theory—part II: 3D formulation and finite element modeling of polycarbonate. INT. J. NONLIN MECH.46, 507–518. https://doi.org/10.1016/j.ijnonlinmec.2010.12.006 (2011).

Li, X. Fractional derivative burgers models describing dynamic viscoelastic properties of asphalt binders. CONSTR. BUILD. MATER.408, 133552. https://doi.org/10.1016/j.conbuildmat.2023.133552 (2023).

Lin, J., Qian, J., Xie, Y., Wang, J. & Xiao, R. A mean-field shear transformation zone theory for amorphous polymers. INT. J. Plast.163, 103556. https://doi.org/10.1016/j.ijplas.2023.103556 (2023).

Rinaldi, R., Gaertner, R., Chazeau, L. & Gauthier, C. Modelling of the mechanical behaviour of amorphous glassy polymer based on the quasi point defect theory—part I: Uniaxial validation on polycarbonate. INT. J. NONLIN MECH.46, 496–506. https://doi.org/10.1016/j.ijnonlinmec.2010.11.004 (2011).

Zhu, F. Physics-motivated fractional viscoelasticity model for dynamic relaxation in amorphous solids. INT. J. Plast.164, 103588. https://doi.org/10.1016/j.ijplas.2023.103588 (2023).

Koyanagi, J., Hasegawa, K., Ohtani, A., Sakai, T. & Sakaue, K. Formulation of non-linear viscoelastic–viscoplastic constitutive equation for polyamide 6 resin. Heliyon. 7, e06335. https://doi.org/10.1016/j.heliyon.2021.e06335 (2021).

Zink, T., Kehrer, L., Hirschberg, V., Wilhelm, M. & Böhlke, T. Nonlinear Schapery viscoelastic material model for thermoplastic polymers. J. APPL. POLYM. SCI.139, 52028. https://doi.org/10.1002/app.52028 (2022).

Silva, J., Meltzer, D., Liu, J., Cox, M. & Maia, J. The influence of thermo-mechanical history on structure development of elastomeric and amorphous glass thermoplastic polyurethanes. Polym. Eng. Sci.54, 1383–1393. https://doi.org/10.1002/pen.23673 (2014).

Doumeng, M., Makhlouf, L. & Berthet, F. A comparative study of the crystallinity of polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. POLYM. TEST.93, 106878. https://doi.org/10.1016/j.polymertesting.2020.106878 (2020).

Liu, Y., Liu, Y. & Li, X. Effect of Hot stretching on microstructure and Mechanical Properties of Nylon 6 films. Mater. Rep.35, 06194. https://doi.org/10.11896/cldb.19120228 (2021).

Koomson, C., Zeltmann, S. E. & Gupta, N. Strain rate sensitivity of polycarbonate and vinyl ester from dynamic mechanical analysis experiments. Adv. Compos. Hybrid. Mater.1, 341–346 https://doi.org/10.1007/s42114-018-0026-5. (2018).

Li, B. Investigation on the correlation between Biaxial stretching process and macroscopic properties of BOPA6 Film. POLYMERS. 16, 961. https://doi.org/10.3390/polym16070961 (2024).

Yin, B., Hu, X., Luo, W. & Song, K. Application of fractional calculus methods to asymmetric dynamical response of CB-Filled rubber. POLYM. TEST.61, 416–420. https://doi.org/10.1016/j.polymertesting.2017.06.002 (2017).

Billon, N., Federico, C. E., Rival, G., Bouvard, J. L. & Burr, A. Time–temperature Superposition Principle in Shearing tests compared to tension conditions for polymers close to Glass Transition. INT. J. MOL. SCI.24, 3944. https://doi.org/10.3390/ijms24043944 (2023).

Liu, X. A Novel Approach for constructing Master curves of Rheological simple materials. Chin. J. Solid Mech.36, 223–232. https://doi.org/10.19636/j.cnki.cjsm42-1250/o3.2015.03.005 (2015).

Williams, M. L., L, R. F. & Ferry, J. D. The temperature dependence of relaxation mechanisms in amorphous polymers and other Glass-forming liquids. J. Am. Chem. Soc.14, 3701–3707. https://doi.org/10.1021/ja01619a008 (1955).

Laidler, J. & Keith The development of the Arrhenius equation. J. CHEM. EDUC.61, 494. https://doi.org/10.1021/ed061p494 (1984).

Xu, H. & Jiang, X. Creep constitutive models for viscoelastic materials based on fractional derivatives. COMPUT. MATH. APPL.73, 1377–1384. https://doi.org/10.1016/j.camwa.2016.05.002 (2017).

Jalocha, D. A nonlinear viscoelastic constitutive model taking into account of physical aging. MECH. TIME-DEPEND MAT.26, 21–31. https://doi.org/10.1007/s11043-020-09473-x (2022).

Koeller, C. R. Applications of Fractional Calculus to the theory of viscoelasticity. Trans. Asme J. Appl. Mech.51, 299–307. https://doi.org/10.1115/1.3167616 (1984).

Dilmi, M., Dilmi, M. & Benseridi, H. Variational formulation and asymptotic analysis of viscoelastic problem with Riemann-Liouville fractional derivatives. MATH. METHOD APPL. SCI.44, 2294–2313. https://doi.org/10.1002/mma.5775 (2021).

Parmar, R. A class of Extended Mittag–Leffler functions and their Properties related to Integral transforms and Fractional Calculus. Mathematics. 3, 1069–1082. https://doi.org/10.3390/math3041069 (2015).

Nazir, A. On generalized fractional integral with multivariate Mittag-Leffler function and its applications. Alexandria Eng. J.61, 9187–9201. https://doi.org/10.1016/j.aej.2022.02.044 (2022).

Perez, J. Quasi-punctual defects in vitreous solids and liquid-glass transition. SOLID STATE IONICS. 39, 69–79. https://doi.org/10.1016/0167-2738(90)90028-P (1990).

Cavaille, J. Y., Perez, J. & Johari, G. P. Molecular theory for the rheology of glasses and polymers. Phys. Rev. B39, 2411–2422. https://doi.org/10.1103/PhysRevB.39.2411(1989).

Gauthier, C., David, L. & Ladouce, L. Nonlinear mechanical response of amorphous polymers below and through glass transition temperature. J. APPL. POLYM. SCI.65, 2517–2528. https://doi.org/10.1002/(SICI)1097-4628(19970919)65:12<2517::AID-APP22>3.0.CO;2-W (1997).

Hao, Q., Qiao, J. & Jean-Marc, P. Dynamic relaxation characteristics and high temperature Flow Behavior of Zr-based Bulk Metallic Glass. Chin. J. Theoretical Appl. Mech.52, 360–368. https://doi.org/10.6052/0459-1879-20-004 (2020).

Nigmatullin, R. R. Detection of collective motions in dielectric spectra and the meaning of the generalized Vogel–fulcher–Tamman equation. Phys. B: Condens. Matter. 404, 255–269. https://doi.org/10.1016/j.physb.2008.10.047 (2009).

Chabert, E., Ershad Langroudi, A., Gauthier, C. & Perez, J. Mechanical response in amorphous and semicrystalline poly (ethylene terephtalate) and modelling in frame of quasi point defect theory. Plast. Rubber Compos.30, 56–67. https://doi.org/10.1179/146580101101541444 (2010).

Lv, L., Lin, H. & Jin, T. Experimental study on the effects of hygrothermal aging on the indentation creep behaviors of PMMA. POLYM. TEST.93, 106991. https://doi.org/10.1016/j.polymertesting.2020.106991 (2021).

Meng, R., Yin, D. & Drapaca, C. S. A variable order fractional constitutive model of the viscoelastic behavior of polymers. INT. J. NONLIN MECH.113, 171–177. https://doi.org/10.1016/j.ijnonlinmec.2019.04.002 (2019).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NO. 11872179), the Natural Science Foundation of Hunan Province (NO. 2020JJ5136, NO. 2024JJ7134), the Hunan Provincial Education Department (NO. 21B0535), and the Hunan provincial Innovation Foundation For Postgraduate (NO. CX20240909) are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

B.L.: Writing – original draft, Software, Investigation, Formal analysis; G.L.:Writing – review & editing, Supervision, Funding acquisition, Conceptualization; Y.L.(Yuejun Liu): Supervision, Funding acquisition; K.C.:Methodology, Supervision; Y.L.(Yuankang Li): Formal analysis; Z.X.:Formal analysis; H.Y.:Formal analysis; L.C.:Software, Investigation; All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, B., Liao, G., Liu, Y. et al. Investigation on the creep mechanism of PA6 films based on quasi point defect theory. Sci Rep 14, 22169 (2024). https://doi.org/10.1038/s41598-024-73513-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-73513-6