Abstract

In this study, for the first time, the optimization of applied pressure for achieving the one of the best tribological properties of diamond-like carbon (DLC) coating on graphite surface using plasma-enhanced chemical vapor deposition (PECVD) method was investigated. Raman spectroscopy and microscopy methods were used to characterize the applied coating. Additionally, the mechanical properties of the coating were investigated through nanoindentation testing. The wear resistance of coating has been tested as functional test. The results indicated that with increasing gas pressure, the sp3 hybridization percentage decreases, while the ID/IG ratio increases. The average roughness values for the uncoated sample and the coated samples at working pressures of 25, 30, and 35 mTorr were obtained as 1.6, 5.1, 3, and 2.4 nm, respectively. The results of hardness and wear tests showed that these properties were optimized by reducing the applied gas pressure. The highest hardness was 11.59 GPa, and the best sample in terms of the mechanical properties of the coating was the sample applied at a gas pressure of 25 mTorr. Results show that the optimal sample in tribological performance is the one applied at a working pressure of 25 mTorr. Because this sample demonstrates the lowest coefficient of friction, and wear depth.

Similar content being viewed by others

Instruction

Graphite is a unique material with distinctive physical and chemical properties that make it suitable for various applications in different industries. The continuous use of graphite leads to rapid wear and the need for frequent replacement1. In order to increase the lifetime of graphite and prevent wear and erosion, the use of appropriate coatings seems necessary. The use of protective coatings extends the replacement time of graphite and prevents recurrent expenses. This approach not only enhances the performance of graphite but also reduces maintenance and repair costs. This practice can be effective in optimizing the use of graphite in various working conditions and industries2,3.

DLC (Diamond-Like Carbon) is a type of carbon with an amorphous structure that exhibits properties between diamond and graphite. It is formed by a combination of sp2 (similar to graphite) and sp3 (similar to diamond) bonds. DLC has become a fascinating and significant topic for researchers in recent decades due to its unique properties, including high hardness, superior wear resistance, and excellent chemical inertness. The widespread use of DLC in various fields, including the automotive industry, aerospace, and the production of cutting tools and other industrial equipment, demonstrates the significant impact of this material in enhancing the performance and lifetime of products4,5,6.

DLC films can be deposited using various methods. These methods include plasma-enhanced chemical vapor deposition (PECVD), cathodic arc deposition, ion beam deposition, mass-ion beam deposition, sputtering, and pulsed laser deposition. The choice of the appropriate method for depositing DLC films depends on the desired properties and applications7,8,9,10,11,12,13. The PECVD method is capable of producing high-performance coatings at low temperatures14. In recent years, many researchers have utilized the PECVD method for the production of DLC coatings. For instance, Fukutsuka et al. used the plasma-enhanced chemical vapor deposition (PECVD) method to deposit a-C: H:H films on stainless steel 304. They used ethylene and argon as gas sources. The results indicated that the deposition rate of this coating was approximately 4 nm/min15,16,17,18,19. In recent studies, the influence of deposition parameters such as power, voltage, pressure, and gas flow has been investigated for DLC film deposition. These parameters have been utilized to adjust the properties of DLC films and achieve films with desirable characteristics on the targeted surfaces20,21,22.

Wu et al.23 demonstrated in a study that by adjusting the deposition pressure, various microstructures of DLC films can be produced. Additionally, with an increase in pressure, the degree of graphitization in the DLC film initially increases and then decreases. Wang et al.24 the effect of deposition pressure on the uniformity, mechanical and tribological properties of DLC coatings was investigated. The results showed that with increasing deposition pressure, the coating thickness gradually increased and became more uniform in the axial direction. As the deposition pressure increased, the hardness of the coating reached 18.11 GPa at a deposition pressure of 70 mTorr. The coefficient of friction and wear rate of the coating also increased slightly with increasing deposition pressure. The results by Che et al.25 revealed that an increase in deposition pressure leads to an increase in the percentage of sp2 in a-C: H films. This results in the formation of larger carbon clusters and consequently induces structural changes in these films. In another study, Capote et al.26 investigated the impact of deposition pressure on the mechanical properties of DLC coatings. The results demonstrated that a-C: H films deposited at lower pressure exhibit higher mechanical properties and lower friction compared to films deposited at higher pressure. The reason behind this lies in the more uniform distribution and denser structure of films deposited at lower pressure. The results of Asadi et al.27 showed that DLC-coated samples had higher wear resistance than uncoated samples. At low loads (2 N and 5 N), the COF for DLC-coated samples was lower than for uncoated samples. However, at higher loads (10 N), uncoated samples showed lower COF.

The aim of the current research is to optimize the applied pressure to achieve the one of the best tribological properties of DLC coatings on graphite surfaces using the PECVD method. This objective has been pursued by investigating the influence of applied pressure on the percentage of sp3 hybridization, ID/IG ratio, surface roughness, and mechanical properties of the coating (hardness and wear resistance).

Materials and methods

Film preparation

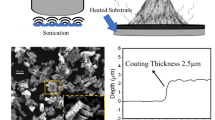

In this study, graphite disks with a diameter of 25 mm and height of 5 mm were used as substrates. The disks’ surfaces were ground with sandpaper up to 5000 grit and then polished with diamond paste. Lastly, a chemical degreasing process was conducted using Ethanol and Feron in an ultrasonic tank. Plasma-enhanced chemical vapor deposition (PECVD) (ROYAL/Model-RTSP/China) using a pre-source of 100% acetylene gas was employed to deposit a thin-film coating. Prior to coating, the surface was prepared by treatment with 250 cc/min argon gas. Once the desired vacuum was achieved, acetylene gas was introduced into the chamber to initiate plasma formation and start the deposition process. The coating was deposited for 45 min at 150 W power, an initial pressure of 6 mtorr, and working pressures of 25, 30, and 35 mtorr.

Characterization

Microstructure and crystalline phases

The microstructural analyzes of the coatings were performed using a field emission scanning electron microscope (FESEM) MIRA3 model produced by TESCAN, Czech Republic. An atomic force microscope (AFM) model Veeco-Auto Probe-CP_Research (made in the USA) was used to examine the surface roughness and topography of the coating. Also, to analyze the type and number of atomic bonds, a Raman microscope TAKRAM model P50C0R10 (made in Iran) with a power of 10–90 mW, a resolution of 6 cm−1 and a wavelength of 512 nm was used. A grazing incidence X-ray diffraction (GIXRD) analysis was performed to identify the present phases using a Bruker D8 advance X-ray diffractometer. In this test, the incident angle was set to 0.5°, and a Cu-Kα radiation source with a current of 30 mA and a voltage of 40 kV was used.

Mechanical properties

Nanoindentation testing was performed using a Hysitron Triboscope nano indenter (Bruker/ Germany) with a triangular pyramid shape probe having a Young’s modulus of 1141 GPa and a Poisson’s ratio of 0.7.

Tribological performance

Pin on disc wear tests (WTC02-TSN/Made in Iran) were performed according to ASTM G99 standard, where the pin diameter was 6 mm and made of AISI 52,100 steel, and loads of 1 and 5 N were performed with a sliding speed of 0.1 m/s and a total distance of 100 m. The coefficient of friction (COF) was measured using a load cell attached to the pin. The worn surfaces were examined using a scanning electron microscope (SEM) model VEGA3/TESCAN, Czech Republic to determine the wear mechanism. Wear depth was measured using a roughness meter (Veeco/Usa).

Discuss

Film microstructure and crystalline phases

The Raman spectra corresponding to applied coatings on various working pressures are illustrated in Fig. 1 within the range of 1200 cm−1 to 1800 cm−1. According to Fig. 1, two peaks are observable in each curve, namely: the G-band (at 1600 cm−1), corresponding to graphite E2g vibrations in sp2 carbon hybridization, and the D-band (at 1350 cm−1), associated with the breathing mode A1g in irregular carbon bonds28,29. As the position of the G-band shifts towards higher Raman shifts, the percentage of the sp3 structure exhibits a decreasing trend30. Furthermore, an increase in the ID/IG ratio indicates the enlargement of graphite clusters within the DLC coating31.

The changes in the percentage of sp3 and the ID/IG ratio are shown in Fig. 2. Due to the direct relationship between sp3 hybridization and coating hardness, as the G-band peak shifts towards lower raman shifts, resulting in an increase in the percentage of sp3, the coating hardness also increases. Considering the ease of pages slippage in aromatic structures, increasing the size of these clusters can reduce the COF. Therefore, a decrease in the ID/IG ratio signifies smaller aromatic clusters and higher hardness of the sample. Aromatic clusters (La) can be measured using Eq. (1)32.

According to this equation, the values of aromatic cluster sizes for the coatings applied at working pressures of 25, 30, and 35 mTorr are determined to be 0.848, 1.084, and 1.121 nm, respectively. It is evident that the size of graphite clusters increases with an increase in working pressure. Therefore, among the three examined samples, the coating applied at a pressure of 25 mTorr has the lowest values of the ID/IG ratio and the highest values of sp3 hybridization percentage. With an increase in working pressure, the ID/IG ratio shows an increasing trend, while the percentage of sp3 hybridization in the coating exhibits a decreasing trend. Furthermore, from Fig. 2b, it is evident that with a decrease in working pressure, the internal stress in the structure has experienced a decreasing trend. This reduction in internal stress can lead to an improvement in the mechanical properties of the coated surface, as lower internal stress conditions make it more difficult for cracks to grow in these samples. However, it’s important to consider that for achieving higher fracture toughness, compressive stress can be favorable. The internal stress can be calculated using Eq. (2):

To more accurately investigate the crystalline structure of the samples, GIXRD analysis was used, and the resulting diffraction patterns are shown in Fig. 3. According to these diffraction patterns, two diffraction peaks for diamond can be observed at angles of around 45 and 76 degrees, corresponding to diffraction from the (111) and (220) crystal planes of diamond, respectively33,34. Additionally, a peak is observed at an angle of around 44 degrees, which corresponds to diffraction from the (111) plane of the graphite structure34. As shown in the figure, it is clear that with increasing applied gas pressure, the intensity of the peaks related to the diamond phase decreases, while the intensity of the peaks related to the graphite phase increases simultaneously. This phenomenon indicates an increased tendency for the formation of the graphite phase due to the decrease in the stability of the diamond phase under growth conditions35.

In Fig. 4, AFM images of the coated samples are shown. Considering Fig. 4a, which corresponds to the uncoated sample, it is evident that the highest peak heights and the deepest trough depths are less than 30 nanometers, indicating an increase after the application of the coating. According to the figure, it is evident that with an increase in working pressure, the blue and white-colored areas have become more extensive, while the red and black-colored regions have become smaller. This indicates the formation of DLC grains on the surface, and the size of these grains exhibits an increasing trend with increasing pressure. According to the results of this test, the Ra values for the uncoated sample and the samples applied at working pressures of 25, 30, and 35 mTorr are 1.6, 5.1, 3, and 2.4 nm, respectively. Additionally, the RMS values for these three samples are 2.1, 6.7, 3.9, and 2.9 nm, respectively. It is evident that with the application of the coating and an increase in the coating pressure, surface roughness parameters have shown a decreasing trend. This may significantly impact wear properties and will be further investigated.

In Fig. 5, FESEM images of the coated samples are shown. In the figure, the presence of particles with quasi-spherical morphology and varying grain sizes indicates the formation of DLC coatings36,37,38. In general, the application pressure can control the orientation of carbon particles in the DLC structure. This orientation can lead to desirable mechanical and tribological properties such as high hardness, low friction, and wear resistance. Pressure control can also strengthen the bonds between carbon particles in the DLC structure, with stronger bonds leading to increased strength and hardness of the coating. Based on this figure, it is evident that with an increase in pressure, the particle size has increased39. This indicates a higher growth rate of particles compared to nucleation rate with increasing pressure, confirming the results obtained in the AFM test. On this basis, the average particle size for the samples at working pressures of 25, 30, and 35 mTorr has been obtained as 237.97 ± 41.8, 255.73 ± 87.74, and 328.13 ± 93.67 nm, respectively. Considering the inevitable existence of defects and voids in the structure of DLC coatings40,41, these images indicate that the increase in coating pressure results in an enlargement in the size and number of structural voids. In other words, the coating density decreases with increased pressure. This reduction in density may have a significant impact on the final properties of the coating. Furthermore, the thickness of the coating for these three samples is reported in the images. It is evident that the coating thickness exhibits a decreasing trend as the coating pressure increases. This may be attributed to the fact that higher coating pressure leads to more turbulence in the coating chamber, thereby preventing particles from adhering to the coating surface and increasing its thickness.

Mechanical properties

Hardness and elastic modulus

In Fig. 6, depth-indentation curves for both the uncoated and coated samples are shown. It is worth noting that the maximum force was set at 1 mN to ensure that the indentation depth does not exceed half of the coating thickness in the samples. The precise value of the parameter from Eq. (2) can be extracted42:

In the mentioned equation, Ac represents the contact area of the indenter, and P is the maximum applied load.

Considering the results shown in the figure, it is evident that the presence of DLC coating has increased surface hardness, and the increase in coating pressure has led to a reduction in hardness. The hardness values obtained for the coatings in Fig. 6b are close to those reported in similar studies43,44,45. The increase in surface hardness after applying DLC coating has also been confirmed by other researchers in various studies46,47,48. The decrease in hardness with an increase in coating pressure may be due to the increase in the dimensions of aromatic clusters in the coating structure, as demonstrated in the results of the raman spectroscopy test. Furthermore, due to the presence of structural defects and higher sp3 hybridization at grain boundaries, the hardness in these regions was found to be higher. The increase in grain size with increasing coating pressure, and consequently, the decrease in the number of these boundaries within a constant area, has led to an overall reduction in the coating hardness. Leyland et al.49 demonstrated that the elastic strain to failure (H/E) plays a key role in controlling wear. Johnson et al.50 further found that the ratio of plastic strain to failure (H3/E2) is an indicator of the coating’s resistance to plastic deformation. As shown in Fig. 6c, the value of H/E at a gas pressure of 25 mTorr was 0.114, indicating the best wear resistance among the coated samples. The value of H/E decreased with increasing gas pressure, reaching 0.096 at a gas pressure of 35 mTorr. The changes in H3/E2 followed a similar trend to H/E, indicating better toughness of the coating at 25 mTorr gas pressure compared to other coatings.

Tribological performance

Coefficient of friction

In Fig. 7, the COF charts for the coated samples are shown. In Fig. 7a, it is evident that the coated sample at a pressure of 25 mTorr has the lowest COF values. This could be attributed to the small size of the grains and the low ID/IG ratio. Indeed, the higher intensity of the G peak in this sample signifies a more graphitic structure. Given that graphite layers can easily slide over each other due to weak van der Waals bonds, this results in a very low COF51. Furthermore, in this figure, the sample coated at 35 mTorr shows a higher COF compared to the other DLC-coated samples. This can be attributed to the larger particle size in this sample, as evidenced by the FESEM results. Indeed, the larger particle size leads to an increase in the contact area between the pin and the surface, resulting in a higher COF24. The larger the particles, the greater the number of real contact points between two surfaces. These contact points increase the resistance to relative motion between the two surfaces, resulting in a higher coefficient of friction. Additionally, on surfaces with larger particles, the stress distribution is irregular. This can lead to high localized stresses and an increased probability of surface failure. The sudden decrease in COF before approximately 5 m of pin wear on the disc in the 30 mTorr sample (Fig. 7a) may be due to the graphitization of DLC caused by the heat generated from friction, which has reduced the COF. This phenomenon has also been observed in other studies52,53. According to Fig. 7b, as the applied load increases to 5 N, the coated sample at 25 mTorr pressure exhibited the lowest COF value. The low COF in this sample has had a significant impact on its tribological properties, leading to enhanced wear resistance. Moreover, the reduced COF noise in the graph related to the coating applied at 25 mTorr, compared to the other two coatings, may indicate that the pin was in complete contact with the coating, demonstrating high wear resistance. Also, here, the COF values in the samples applied at 30 and 35 mTorr have increased due to the larger grain size in these samples. As the load increases, the DLC coating particles break down into rougher particles, and these rougher particles increase the friction between the surfaces. The presence of a sinusoidal trend and repetitive pattern in these two samples also indicates coating detachment and re-adhesion. This is likely due to the low coating thickness or the presence of defects such as voids, microcracks, and impurities in the coating, which can create weak points and increase the likelihood of coating delamination, as observed in the FESEM results.

Wear width

Wear width is considered as a criterion for wear resistance, where an increase in the width of wear indicates a reduction in the coating’s resistance to wear. In Fig. 8, SEM images related to the wear width of the samples and also the region within the worn part under two different loads, 1 N and 5 N, are shown. The SEM images in Fig. 8a, b clearly demonstrate the presence of adhesive wear mechanisms in the uncoated sample, indicating its weak wear resistance. The reason can be attributed to the structure of graphite. Graphite is composed of thin sheets of carbon atoms that are weakly bonded together. This weak structure can lead to the crumbling and separation of graphite sheets due to wear, which can result in adhesive wear. Increasing the applied load exacerbated these effects, a behavior typically observed at higher loads54,55.

The effects of the adhesive wear mechanism are again observed in the images related to the coated samples at different pressures. These wear effects have shown an increasing trend with the rise in pressure. However, compared to the uncoated sample, the wear effects are less pronounced in the coated samples, indicating a desirable wear resistance in the coated samples. In fact, the increase in hardness and the reduction in COF with decreasing applied coating pressure have led to the transformation of the adhesive mechanism into the sliding mechanism in the applied DLC coatings. Also, during sliding, fine particles become porous together and these dense particles can create smooth surfaces and protect against wear56,57. Under high pressures, coating particles with high kinetic energy impact the surface and penetrate deeper into the substrate. This leads to high compressive stresses within the coating and between the coating and substrate, and these high stresses can lead to cracking within the coating, which can ultimately lead to failure39. The increase in wear width with the increase in applied coating pressure is another evidence of the reduction in the tribological properties in these samples. The wear width has decreased from values of 254 and 294 μm in the uncoated sample to values of 162 and 279 μm in the coated sample at an applied pressure of 25 mTorr on both 1 and 5 N loads. However, the wear width for the sample at 30 mTorr on 1 and 5 N loads is 220 and 305 μm, respectively. Additionally, for the coated sample at 35 mTorr, it is 427 and 554 μm on the same loads. This indicates an increase in wear width for the coatings applied at higher pressures. Comparing the uncoated sample and the coated sample at a pressure of 35 mTorr shows that by increasing the load to 5 N, in both samples, the dominant mechanism is adhesive wear, and in the coated sample, the weak resistance of the coating has led to breakage and brittleness of the coating. Also, the width of wear in the coated sample was twice more than the uncoated sample, which is another reason for the weak resistance of this sample against wear.

Wear depth

In Fig. 9, the graph of wear depth is shown on two loads of 1 N and 5 N. Considering the figure, it is evident that in both loads of N 1 and N 5, the coating applied at a working pressure of 35 mTorr has the highest wear depth, indicating minimal wear resistance in this sample. As demonstrated, this is due to the high COF in this particular sample. Indeed, the high COF has caused the coating to peel off the surface, and the coating particles act as an abrasive, severely subjecting the surface to friction. Therefore, the wear properties of the coating applied at a working pressure of 35 mTorr are even weaker compared to the uncoated sample. This is despite the fact that with a decrease in working pressure, both the penetration depth and wear width have decreased. Increasing the coating pressure introduces significant compressive stresses into the coating. If these stresses exceed the coating’s tolerance limit, it can lead to cracking and delamination39. The sample applied at a pressure of 25 mTorr exhibits the least penetration depth and wear width, making it an optimal sample in terms of wear properties. It is also evident in this figure that an increase in applied load has led to an increase in penetration depth and wear width in the samples. The difference between these parameters is more pronounced in the sample applied at higher working pressure due to its weaker wear properties. The mechanism of improvement in wear properties with a reduction in applied pressure can be attributed to various factors. According to the results of Raman spectroscopy, it was revealed that a decrease in gas pressure led to an increase in the percentage of sp3 hybridization. Additionally, the nanoindentation test results showed a higher hardness for coatings applied at lower gas pressures. This increased hardness is considered one of the highly influential factors in enhancing wear properties. On the other hand, the smaller size of grains in the coated sample at lower pressure has resulted in a reduction in COF. This lower COF is another reason contributing to the improvement in wear properties of this sample.

Conclusion

The applied gas pressure in the PECVD process is one of the crucial and influential parameters on the final properties of DLC coating, especially its wear properties. In this research, it was determined that the percentage of sp3 hybridization decreases with an increase in pressure. In contrast, the values of ID/IG and internal stress of the coating showed an increasing trend with an increase in gas pressure. The sizes of aromatic clusters for the samples coated at pressures of 25, 30, and 35 mTorr were determined to be 0.848, 1.084, and 1.121 nm, respectively. Also, the results of AFM and FESEM tests showed an increase in roughness and a decrease in particle size with the reduction of applied gas pressure. The hardness also exhibited an increasing trend with a reduction in pressure, while wear depth and wear width showed an increasing trend with an increase in pressure. These observations indicate that the optimal sample in terms of tribological properties is the one applied at a working pressure of 25 mTorr. This sample demonstrates the highest hardness, the lowest COF, and ultimately the lowest wear. Furthermore, it is recommended that future research efforts focus on the development of computational wear models to predict the wear performance of DLC coatings with varying gas pressures. Such models can significantly facilitate the optimization of PECVD processes and the design of high-performance DLC coatings for various tribological applications.

Declaration.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Funding.

The authors did not receive support from any organization for the submitted work.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Jara, A. D., Betemariam, A., Woldetinsae, G. & Kim, J. Y. Purification, application and current market trend of natural graphite: A review. Int. J. Min. Sci. Technol.29, 671–689 (2019).

Polat, S. & Atun, G. Enhanced cycling stability performance for supercapacitor application of NiCoAl-LDH nanofoam on modified graphite substrate. J. Ind. Eng. Chem.99, 107–116 (2021).

Guo, Q. et al. Characterization of Yb2SiO5-based environmental barrier coating prepared by plasma spray–physical vapor deposition. Ceram. Int.48, 19990–19999 (2022).

Rajak, D. K., Kumar, A., Behera, A. & Menezes, P. L. Diamond-like carbon (DLC) coatings: classification, properties, and applications. Appl. Sci.11, 4445 (2021).

Weicheng, K., Zhou, Y. & Jun, H. Effect of carburizing treatment on microstructural, mechanical and tribological performances of Cr doped DLC coating deposited on Ti6Al4V alloy. Ceram. Int.47, 34425–34436 (2021).

Kasiorowski, T. et al. Microstructural and tribological characterization of DLC coatings deposited by plasma enhanced techniques on steel substrates. Surf. Coat. Technol.389, 125615 (2020).

Lu, Y., Huang, G. & Xi, L. Tribological and mechanical properties of the multi-layer DLC film on the soft copper substrate. Diam. Relat. Mater.94, 21–27 (2019).

Paramanik, B. & Das, D. The effect of CO2 addition to the (C2H2 + H2) gas system on the low-temperature growth of diamond-like carbon (DLC) with prominent nano-diamond phase. Mater. Today: Proc.62, 5057–5060 (2022).

Wongpanya, P., Silawong, P. & Photongkam, P. Nanomechanical properties and thermal stability of Al–N-co-doped DLC films prepared by filtered cathodic vacuum arc deposition. Surf. Coat. Technol.424, 127655 (2021).

Aslan, N., Kurt, M. S. & Koç, M. M. Morpho-structural and optoelectronic properties of diamond like carbon–germanium (DLC-Ge) composite thin films produced by magnetron sputtering. Opt. Mater.126, 112229 (2022).

Qiang, L., Zhang, B., Zhou, Y. & Zhang, J. Improving the internal stress and wear resistance of DLC film by low content Ti doping. Solid State Sci.20, 17–22 (2013).

Huang, B. et al. Effect of deposition temperature on the microstructure and tribological properties of Si-DLC coatings prepared by PECVD. Diam. Relat. Mater.129, 109345 (2022).

Tyagi, A. et al. A critical review of diamond like carbon coating for wear resistance applications. Int. J. Refract. Hard Met.78, 107–122 (2019).

Yoshiyuki, S. Electrically conductive amorphous carbon coating on metal bipolar plates for PEFC. Surf. Coat. Technol.202, 1252–12555 (2007).

Seker, Z., Ozdamar, H., Esen, M., Esen, R. & Kavak, H. The effect of nitrogen incorporation in DLC films deposited by ECR Microwave plasma CVD. Appl. Surf. Sci.314, 46–51 (2014).

Woehrl, N., Ochedowski, O., Gottlieb, S., Shibasaki, K. & Schulz, S. Plasma-enhanced chemical vapor deposition of graphene on copper substrates. AIP Adv.4, 047128 (2014).

Capote, G., Mastrapa, G. C. & Trava-Airoldi, V. J. Influence of acetylene precursor diluted with argon on the microstructure and the mechanical and tribological properties of aC: H films deposited via the modified pulsed-DC PECVD method. Surf. Coat. Technol.284, 145–152 (2015).

Caschera, D. et al. Influence of PECVD parameters on the properties of diamond-like carbon films. Thin Solid Films519, 4087–4091 (2011).

Fukutsuka, T. et al. Carbon-coated stainless steel as PEFC bipolar plate material. J. Power Sources174, 199–205 (2007).

Huang, L., Yuan, J. T., Wang, Z. H. & Yu, B. B. Effect of the temperature on diamond-like carbon (DLC) thin film based on LIS. Appl. Mech. Mater.421, 212–216 (2013).

Nguyen, T. et al. Influence of argon gas pressure and target power on magnetron plasma parameters. Diam. Relat. Mater.18, 995–998 (2009).

Li, C., Huang, L. & Yuan, J. Effect of sp3 content on adhesion and tribological properties of non-hydrogenated DLC films. Mater13, 1911 (2020).

Wu, S. et al. Effect of deposition pressure on the microstructure and corrosion resistance of diamond-like carbon films prepared by plasma enhanced chemical vapor deposition. Int. J. Electrochem. Sci.15, 830–838 (2020).

Wang, X. et al. Effect of deposition pressures on uniformity, mechanical and tribological properties of thick DLC coatings inside of a long pipe prepared by PECVD method. Surf. Coat. Technol.375, 150–157 (2019).

Che, J., Yi, P., Peng, L. & Lai, X. Impact of pressure on carbon films by PECVD toward high deposition rates and high stability as metallic bipolar plate for PEMFCs. Int. J. Hydrogen Energy45, 16277–16286 (2020).

Capote, A., Capote, G., Corat, E. J. & Trava-Airoldi, V. J. Effect of low-pressure deposition on the mechanical and tribological properties of aC: H films deposited via modified pulsed-DC PECVD with active screen as an additional cathode. Surf. Coat. Technol.445, 128716 (2022).

Al-Asadi, M. M. & Al-Tameemi, H. A. The effect of diamond like carbon coating on the wear resistance at dry sliding conditions. Mater. Res. Express9, 116504 (2022).

Fuge, G. M., May, P. W., Rosser, K. N., Pearce, S. R. J. & Ashfold, M. N. R. Laser Raman and X-ray photoelectron spectroscopy of phosphorus containing diamond-like carbon films grown by pulsed laser ablation methods. Diam. Relat. Mater.13, 1442–1448 (2004).

Tai, F. C., Lee, S. C., Wei, C. H. & Tyan, S. L. Correlation between ID/IG ratio from visible Raman spectra and sp2/sp3 ratio from XPS spectra of annealed hydrogenated DLC film. Mater. Trans.47, 1847–1852 (2006).

Joao, T. Residual stress analysis by different tensions of DLC films on TiAl6V4 and 3016 steel alloys. 68th Congress ABM33, 822–829 (2013).

Tai, F. C., Lee, S. C., Wei, C. H. & Tyan, S. L. Correlation between ID/IG ratio from visible Raman spectra and sp2/sp3 ratio from XPS spectra of annealed hydrogenated DLC film. Mater. Trans.47, 1847–1852 (2006).

Qi, M. et al. Effect of various nitrogen flow ratios on the optical properties of (Hf:N)-DLC films prepared by reactive magnetron sputtering. AIP Adv.7, 085012 (2017).

Zhu, X., Yan, H., Zhang, M. & Wei, Q. A new cubic superhard large-cell carbon allotrope: c-C200. Results Phys.19, 103457 (2020).

Assouar, B. et al. High-frequency surface acoustic wave devices based on AlN/diamond layered structure realized using E-beam lithography. J. Appl. Phys.101, 114507 (2007).

O’Bannon, E. et al. The transformation of diamond to graphite: Experiments reveal the presence of an intermediate linear carbon phase. Diam. Relat. Mater.108, 107876 (2020).

Lepicka, M., Grądzka-Dahlke, M., Pieniak, D., Pasierbiewicz, K. & Niewczas, A. Effect of mechanical properties of substrate and coating on wear performance of TiN- or DLC-coated 316LVM stainless steel. Wear382, 62–70 (2017).

Khamseh, S., Alibakhshi, E., Ramezanzadeh, B. & Ganjaee Sari, M. A tailored pulsed substrate bias voltage deposited (a-C: nb) thin-film coating on GTD-450 stainless steel: Enhancing mechanical and corrosion protection characteristics. J. Chem. Eng.404, 126490 (2021).

Khamseh, S. et al. Magnetron-sputtered copper/diamond-like composite thin films with super anti-corrosion properties. Surf. Coat. Technol.333, 148–157 (2018).

Liu, J. Q. et al. Effect of sputtering pressure on the surface topography, structure, wettability and tribological performance of DLC films coated on rubber by magnetron sputtering. Surf. Coat. Technol.365, 33–40 (2019).

Cao, L., Liu, J., Wan, Y. & Pu, J. Corrosion and tribocorrosion behavior of W doped DLC coating in artificial seawater. Diam. Relat. Mater.109, 108019 (2020).

Al-Samarai, R. A. & Al-Douri, Y. Porosity effect on the tribological properties of Al-Si alloys for diamond-like carbon coating of cold sprayed. J. King Saud Univ. Eng. Sci. (2021).

Guillonneau, G., Kermouche, G., Bergheau, J. M. & Loubet, J. L. A new method to determine the true projected contact area using nanoindentation testing. CR MECANIQUE343, 410–418 (2015).

Milan, P. B. et al. Copper-enriched diamond-like carbon coatings promote regeneration at the bone–implant interface. Heliyon6, 03798 (2020).

Cao, H. et al. Effect of Ti transition layer thickness on the structure, mechanical and adhesion properties of Ti-DLC coatings on aluminum alloys. Mater11, 1742 (2018).

Moolsradoo, N. & Shuichi, W. Deposition and tribological properties of sulfur-doped DLC films deposited by PBII method. Adv. Mater. Sci. Eng.1, (2010).

Chang, S. H., Lai, Y. C., Huang, K. T. & Liu, C. M. Characteristics of DLC/oxynitriding duplex-treated V8 tool steel by DC-pulsed PECVD. Surf. Eng.6, 516–523 (2019).

Lubwama, M. et al. Adhesion and composite micro-hardness of DLC and Si-DLC films deposited on nitrile rubber. Surf. Coat. Technol.206, 4881–4886 (2012).

Wu, Y., Zhou, S., Zhao, W. & Ouyang, L. Comparative corrosion resistance properties between (Cu, Ce)-DLC and Ti co-doped (Cu, Ce)/Ti-DLC films prepared via magnetron sputtering method. Chem. Phys. Lett.705, 50–58 (2018).

Leyland, A. & Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear. 246, 1–11 (2000).

Johnson, K. L. Contact Mechanics (Cambridge University Press, 1987).

Yazdani, B. et al. Tribological performance of graphene/carbon nanotube hybrid reinforced Al2O3 composites. Sci. Rep.5, 11579 (2015).

Bai, M. et al. Mechanical and tribological properties of Si and W doped diamond like carbon (DLC) under dry reciprocating sliding conditions. Wear484, 204046 (2021).

Wang, L., Bai, L., Lu, Z., Zhang, G. & Wu, Z. G. Influence of load on the tribological behavior of a-C films: Experiment and calculation coupling. Tribol Lett.52, 469–475 (2013).

Hu, X., Sundararajan, S. & Martini, A. The effects of adhesive strength and load on material transfer in nanoscale wear. Comput. Mater. Sci.95, 464–469 (2014).

Samyn, P., Schoukens, G., Verpoort, F., Van Craenenbroeck, J. & De Baets, P. Friction and wear mechanisms of sintered and thermoplastic polyimides under adhesive sliding. Macromol. Mater. Eng.292, 523–556 (2007).

Tekdir, H. & Yetim, A. F. Additive manufacturing of multiple layered materials (Ti6Al4V/316L) and improving their tribological properties with glow discharge surface modification. Vacuum184, 109893 (2021).

Yetim, A. F., Tekdir, H., Turalioglu, K., Taftali, M. & Yetim, T. Tribological behavior of plasma-sprayed Yttria-stabilized zirconia thermal barrier coatings on 316L stainless steel under high-temperature conditions. Mater. Lett.336, 133873 (2023).

Acknowledgements

The authors thank Dr. Azizollah Shafikhani for his guidance during this research.

Author information

Authors and Affiliations

Contributions

The authors confirm contribution to the paper as follows: study conception and design: Mohsen Samiee, data collection: Zahra Sadat Seyedraoufi; analysis and interpretation of results: Mehrdad Abbasi, Mohammad Javad Eshraghi; draft manuscript preparation: Vahid Abouei, Mohsen Samiee. All authors reviewed the results and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Samiee, M., Seyedraoufi, Z.S., Abbasi, M. et al. Optimizing gas pressure for enhanced tribological properties of DLC-coated graphite. Sci Rep 14, 22925 (2024). https://doi.org/10.1038/s41598-024-74038-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-74038-8