Abstract

The controlled shock wave (CSW) fracturing is an effective method for enhancing permeability of coal seam to promote gas extraction. Based on Fick’s law, Darcy’s law, the ideal gas law and the Langmuir equation, a damage-seepage-deformation coupling mathematical model of CSW fracturing in coal seam combined with the maximum tensile stress and the Mohr-Coulomb criterion is established. This model is implemented into COMSOL Multiphysics to simulate the coal seam CSW fracturing and subsequent gas extraction. When the shock wave and isotropic in-situ stress are applied on the borehole wall, the coal damage zone is an annular shape, and the permeability in the damage zone increases sharply. The CSW can effectively increase the efficiency of gas extraction and reduce the gas pressure and gas content in coal seam. With the increase of CSW action times, the damage in coal mass reaches a threshold and tends to be stable after several shocks. The damage area and the gas extraction efficiency are positively correlated with the shock intensity. Under the anisotropic ground stress, the larger diversity of the stress in different directions is, the more obvious damage extension in the fractured coal along the maximum stress direction is. Ground stress can inhibit the extension of cracks in the CSW fractured coal seam. This inhibition effect becomes more obvious with the increase of in-situ stress. Parameters are substantiated of controlled shock wave impact on the coal seam, which ensures increased methane extraction from low-permeability reservoirs, are substantiated.

Similar content being viewed by others

Introduction

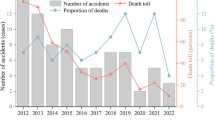

Coalbed methane is a by-product of coal mining, and the rational utilization of coalbed methane can effectively maintain the energy supply in China1. With the increase of mining depth, coal mines appear characteristics of great ground stress, large gas pressure, high temperature and low permeability2,3. The permeability of coal seam can be increased effectively by fracturing4. At present, coal permeability enhancement technologies include protective layer mining5, deep hole pre-cleavage blasting6, hydraulic fracturing7,8 and liquid CO2 fracturing9,10. However, these means have certain limitations, such as water blocking, complex operation processes and poor economic benefits, et al.11,12. It is urgent to find a more environmentally-effective means for increasing coal permeability13.

A powerful shock wave is generated when high-energy material explodes motivated by high voltage discharge in water as electrical energy transfers to mechanical energy14. This technology is initially applied to the exploitation of oil wells to expand the original cracks in the reservoir, create new micro-cracks, and remove the sediment in the reservoir channels, so as to achieve the purpose of permeability enhancement15,16. This CSW fracturing technology is applied to gas disaster prevention in high-gas and low-permeability coal seams17,18. In order to generate strong shock waves sufficient to fracture coal and rock, the technology has been developed from the early electric breakdown in water to the metal wire explosion. So far, this technology has been improved from electric explosion plasma of metal wire to drive energetic mixture to produce shock wave. The intensity of the shock wave can be controlled by quantitatively exciting energetic materials. The CSW fracturing coal is preliminarily explored. Compared with the traditional hydraulic fracturing method, the CSW technology is water-saving with high efficiency, good fracture connectivity, complex fracture network, and repeatable fracturing19,20. At present, the effectiveness of CSW in fracturing coal has been verified by experiments21. Many scholars have studied the initiation and propagation mechanism of coal cracks under the impact load22. It is found that the initiation coal cracks follows the maximum tensile stress criterion23, and the damage propagation in coal is related to the times of impact24. The intensity of CSW depends on the energy of exciting energetic materials. As the energy of the shock wave increases, the number of cracks in coal mass increases, and the length, width and distribution of cracks increase25,26. Under the in-situ stress, the damage of coal mass is inhibited, and the crack propagation varies with the coal strength and stress direction27. Based on the basic principles of fluid mechanics, solid mechanics and damage mechanics, models such as fluid-solid coupling, damage-seepage coupling and stress-damage-seepage coupling are formed28, which can effectively predict and analyze the damage, deformation and gas migration of coal seams. The above research has made a foundation for the application of CSW in gas extraction. However, the effect and law of CSW fracturing coal seam under different parameters of shock wave and impact strength need to be further studied.

In this study, a damage-seepage-deformation coupling model for CSW fracturing coal seam will be established. The damage variation in coal mass under the shock wave is simulated, and the effects of different impact times, impact load and geo-stress conditions on the damage expansion and the effect of enhanced gas extraction are analyzed. This will provide a reference for the industrial application of CSW enhanced gas extraction technology.

Mathematical modelling of CSW enhanced gas extraction

To simplify the process of CSW enhanced gas extraction and establish the damage-seepage-deformation coupling model, the following assumptions are proposed:

(1) In the process of CSW fracturing coal seam29:

-

The coal mass is regarded as an elastic-plastic medium, and the volume force is zero. The coupling effect of heat and stress is not considered.

-

The fracture of coal under shock wave satisfies the Mohr-Coulomb criterion and the maximum tensile stress criterion.

-

The complex physical process acting on the solid is simplified as the stress boundary treatment of pressure changing with time.

(2) In the process of gas extraction from coal seam30:

-

Coal is a porous elastic medium including pores and fractures.

-

The gas migration in the matrix is driven by the concentration gradient and satisfies the Fick ‘s law; the gas migration in the fracture is driven by the pressure gradient and satisfies the Darcy ‘s law.

-

Water in coal only exists and migrates in fractures.

-

CH4 is regarded as an ideal gas, ignoring the gas gravity and considering the gas slippage effect.

-

The whole process is carried out at a constant temperature.

Governing equation of coal seam deformation field

The total strain of coal seam is the sum of the strain caused by the common action of controllable shock wave and in-situ stress, the strain caused by the fluid pressure in matrix pores and coal fractures, and the strain caused by gas adsorption and desorption. According to the Navier stress-strain relationship, the governing equation of stress field in the process of coal seam CSW fracturing is obtained31:

where G is the shear modulus of coal, GPa. ei, ij are in tensor form (e can be displacement u, pressure p, or strain ε).The first subscript represents the i-direction component of variable e. The second subscript represents the partial derivative of ei in the i-direction. The third subscript represents the partial derivative of ei, i in the j direction. ν is Poisson ratio; αm is matrix pores Biot coefficient; αf is the Biot coefficient; pm is gas pressure in the matrix, Pa; pf is gas pressure in the fracture, Pa; K is the bulk modulus, GPa. The calculation formulas are:

where E is the elastic modulus of coal, GPa; Ks is the skeleton bulk modulus, GPa; Es is the skeleton elastic modulus, GPa; Kn is fracture stiffness, GPa/m; sw and sg are the saturation of water and gas respectively, satisfying sw+sg = 1; pfw and pfg are fracture liquid and gas pressure respectively, Pa. Coal seam is simplified as a regularly-arranged cuboid with equal coal matrix intervals, namely representing element volume (REV). a0 is the width of equivalent matrix, m; b0 is the width of equivalent fracture, m. The values of a0 and b0 are calculated from the initial fracture porosity φf0 and the initial permeability k0 in the free state:

Evolution equation of coal seam damage field

Coal is a heterogeneous material, and the mechanical parameters of REV obey Weibull distribution. The probability density function is defined as32:

where u is the mechanical parameters of the unit (uniaxial tensile strength σt, uniaxial compressive strength σc and elastic modulus E); u0 is the average value of the mechanical parameters of the element; m is the homogeneity index. The larger the value of m, the better the uniformity of the mechanical parameters. In this paper, the influence of heterogeneity on the simulation is not considered, and m is taken as the fixed value 9.

When the stress state satisfies the maximum tensile failure criterion and the Mohr–Coulomb criterion, the coal seam produces tensile and shear damage33:

where θ is the internal friction angle of coal, °; F1 and F2 are the threshold functions of damage, respectively.

The damage variable can be defined as:

where εt0 and εc0 are the maximum tensile principal strain and the maximum compressive principal strain, respectively; n is a constant, and the value is 233; Tensile damage is often preceded by shear damage. The maximum tensile stress criterion is used to determine the tensile damage of the unit body. When the unit body is not damaged, the Mohr-Coulomb criterion is used to determine the shear damage. According to the elastic damage theory, the elastic modulus of the element decreases linearly with the damage variable:

where E0 and E are the elastic modulus of coal rock before and after damage, GPa, respectively.

Governing equation of fluid seepage field

In the process of gas extraction, the effect of temperature on the deformation of coal skeleton is ignored, and only the effect of physical fields such as stress and seepage on the coal skeleton is considered, so that the deformation and porosity change. The equation of porosity is34:

where Kf = b0·Kn is the equivalent fracture stiffness, GPa; εν is the volumetric strain of coal; εa is the adsorbed gas strain of coal skeleton, the subscript ‘0’ is the initial value of the parameter.

The relationship between porosity and permeability is:

Under the condition of damage, the sudden increase coefficient of coal permeability increases exponentially with the damage variable, which can be expressed as35:

where αD is the damage coefficient, and the value is 1035.

Considering the pore pressure and damage evolution, the permeability model of coal damage stage can be obtained:

According to the ideal gas state equation, the CH4 density ρg under standard conditions is:

where Mg is the molar mass of CH4, g/mol; pa is standard atmospheric pressure, 101.325 kPa; R is gas molar constant, 8.3143 J/(mol K); T is the temperature in the coal seam, K.

Generalized Langmuir equation of gas adsorption equilibrium in coal seam is:

where cp is the content of CH4 in coal, kg/m3; ρc is true density of coal seam, kg/m3; pmg is the pressure of CH4 in coal matrix, MPa; ρg is the density of CH4 under standard conditions, kg/m3; a1 is the limit adsorption capacity of CH4, m3/kg; b1 is the Langmuir constant for CH4, MPa− 1.

The CH4 content per unit volume of coal matrix is equal to the sum of free gas content and adsorbed gas content. According to the mass conservation equation:

where φm is the porosity of the matrix; It is mainly controlled by the strain of the matrix and the initial matrix porosity, and its mathematical model can be expressed as36:

where φm0 is the initial matrix porosity; ΔS = S-S0 is the variation of matrix pore strain; S0 is the initial matrix pore strain variable; S is the matrix pore strain variable; The calculation formulas of S and S0 are as follows:

Coal seam gas extraction will break the original gas balance, resulting in gas migration under the action of pressure gradient or concentration gradient. The gas in the coal matrix is driven by the concentration gradient to exchange material with the fissure gas by diffusion. According to Fick’s law, the conservation of gas mass in the matrix can be derived as37:

where τ is the desorption time of CH4, d.

Combining Eqs. (12)–(17), the gas transport equation in the matrix can be obtained as:

In the fracture, according to the generalized Darcy ‘s law of gas-water two-phase flow, the seepage rates of gas and water are38,39:

where b is the Klinkenberg factor, Pa; µg is the dynamic viscosity of CH4, Pa·s; µw is the dynamic viscosity of water, Pa·s. Considering the effect of water on gas migration in fractures, the relative permeability models of gas and water phases are40:

where krg0 is the endpoint relative permeability of gas phase, m2; swr is the irreducible water saturation; sgr is the residual gas saturation fraction; krw0 is the endpoint relative permeability of water phase, m2.

In the unit volume of coal, the change of free gas in the fracture is equal to the sum of the gas flowing out (into) the fracture and the gas diffusing into (out) the fracture. The CH4 first desorbs from the matrix pore surface into the pore space, then diffuses from the pore space to the fracture space, and finally seeps from the fracture space to the drainage borehole. According to the mass conservation law, the governing equation of gas transport in the fracture is:

The governing equation of water seepage in fracture can be :

where ρw is the density of water, kg/m3.

Numerical solution method of mathematical model

The damage-seepage-deformation coupling model of CSW enhanced gas extraction is composed of governing Eqs. (1), (6), (19), (21) and (22). In this paper, the solid mechanics module and PDE module in COMSOL Mutiphysics software are used to realize numerical solution. Under the combined action of in-situ stress and shock wave, the stress field of coal mass is solved by Eq. (1), and the stress and strain distribution at each time step is obtained. Whether the coal mass is damaged after impact is judged by Eq. (5) and Eq. (6).

The specific calculation steps are shown in Fig. 1. The whole process can be divided into two steps:

-

The solid mechanics module is used to numerically calculate the process of CSW fracturing coal mass, obtain the damage variable, update the key physical and mechanical parameters of coal mass, and calculate the change in stress and permeability as fractured until the damage area reaches the stable maximum.

-

After updating the coal seam permeability to the previous calculation results, the gas extraction simulation calculation is carried out, and finally the effect of CSW fracturing coal seam enhanced gas extraction is obtained.

Simulation scheme and parameters setting of CSW enhanced gas extraction

Research background

Wuyang Coal Mine, which is located in the north of Changzhi City, Shanxi Province, belongs to Shanxi Lu ‘an Chemical Group Co., Ltd. The southern part of the minefield is bounded by the normal fault of Wenwangshan, and the north is bounded by the Xichuan normal fault. The north-south length is 12.97km, the east-west width is 10km, the well field covers an area of 74.011 km2. The basic structure of the field is a broad and gentle fold dipping to the southwest, accompanied by large or medium-sized, high-angle normal faults and secondary small faults, without magmatic intrusions having been found. The main mineable coal seams in the field are 3# coal seam of Shanxi Formation and 15# coal seam of Taiyuan Formation.

The 8002 working face is located in the 80 mining area of the minefiel with a strike length of 1480 m and an inclined length of 290 m. The recovery rate of the working face is designed as 93%. The mining object of this working face is 3# coal seam, whose structure is in a primary state. The coal type is mainly bright coal, followed by dark coal. The coal seam is stable with a buried depth of 421–586 m, and a thickness of 5.40 ~ 6.15 m, containing two layers of dirt band. The occurrence is flat and nearly horizontal, with a dip angle of 2°~8°. The coal seam with complex stress conditions in the working face is controlled by fold and fault structure, which is in the middle and high-stress area. The permeability of coal seam is relatively low, ~ 2.56 × 10− 17 m2, and the maximum gas content of raw coal is 23.32 m3/t.

The 8002 working face of Wuyang Coal Mine is affected by the buried depth and geological structure. It belongs to the typical low permeability, high stress and high gas coal mine. The high ground stress and low permeability result in difficult gas extraction from the coal seam. Hence, this paper studies the feasibility of CSW fracturing to enhance gas extraction from the coal seam.

Research program settings

The CSW is to excite quantitative energetic materials through the formation of plasma channels by high-voltage discharge to achieve controllable energy of shock wave. In this paper, it is considered that the stress change of CSW accords with the stress change rule of high voltage electric pulse. The stress change of high voltage electric pulse monitored by previous experiments fits the stress curve of CSW on coal seam as the dynamic loading boundary condition of the fracturing hole, as shown in Fig. 2. Figure 2a shows the change curves of voltage, current and coal stress of high voltage electric pulse with a breakdown voltage of 25 kV monitored by predecessors in the experiment. According to the stress change curve of a high voltage electric pulse on coal seam, it can be seen that the stress rises rapidly to the peak value in a very short time and then decreases exponentially, with an overall duration of about 100 µs. On this basis, the CSW excites the energetic material to increase the shock wave energy, so the stress value of the shock wave is reasonably amplified (about equivalent to an increase of 5 g energetic material). The stress-time curve of coal caused by CSW is shown in Fig. 2b. It is applied as a dynamic load to the boundary of the fracturing borehole to study the coal damage and the evolution of permeability under the action of CSW.

Based on the above settings, the research on the process of CSW enhanced gas extraction is carried out:

-

(1)

The simulation of CSW fracturing coal under isotropic conditions of in-situ stress is conducted with the purpose of studying the propagation and attenuation law of shock wave in the coal seam, analyzing patterns of change in permeability as affected by damage, and then clarifying the effect of enhanced gas extraction.

-

(2)

The key parameters of CSW and in-situ stress are changed to study the influence of different factors on the CSW enhanced gas extraction. The simulation scheme is shown in Table 1. The parameters in the table are the values in the simulation of CSW fracturing coal under the isotropic condition of in-situ stress, serving as the reference value of this factor.

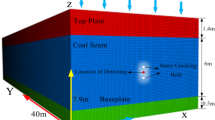

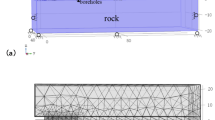

Geometric model and parameter setting

In the numerical simulation, the actual three-dimensional model is simplified to a plane strain problem to reduce the amount of simulation calculation. In order to enlarge the fracturing effect of the coal seam, a two-dimensional geometric model of 5 m × 5 m is established, which is selected on the section perpendicular to the borehole along the coal seam. A borehole with a large diameter of 113 mm is set in the center of the model as a CSW fracturing hole and a gas extraction hole, with the line AB as the monitoring line of the simulation effect, as shown in Fig. 3. The heterogeneity and anisotropy of coal lead to the complexity of its mechanical properties. The physical and mechanical parameters of numerical samples are specified according to the Weibull distribution shown in Eq. (4). The initial mechanical parameters of coal for REV are randomly generated by Matlab. The distribution of the initial elastic modulus of the coal seam is shown in Fig. 4. The average friction angle and Poisson’s ratio are 30 ° and 0.3, respectively. The initial gas pressure of the coal seam is 0.8 MPa, where the negative pressure of the extraction hole is 20 kPa, with the extraction time of 20d.

The left and lower boundaries of the geometric model are set as roller supports. The coal seam depth of the coal sample measured by the parameters is 434 m, and the overburden rock bulk weight is 23 kN/m3, so the vertical stress value is about 10 MPa. The vertical stress σH = 10 MPa is applied to the upper boundary, and the horizontal stress σh is applied to the right boundary, σh = λσH. In the process of cracking coal by controlled shock wave, the borehole wall is used as the loading boundary of shock stress.In order to better simulate the damage extension of coal seam under natural conditions during the process of CSW fracturing coal seam, low reflection boundary conditions are set around the geometric model to prevent stress concentrations by the reflection of shock wave at the boundary. In the process of gas extraction, the surroundings are set to have no flow boundary, the extraction negative pressure is set at the boundary of the borehole. The basic mechanical parameters of the coal seam and the related parameters used in the simulation are set in Table 2.

Analysis of simulation results of CSW enhanced gas extraction

In order to facilitate the study of the damage evolution process of low permeability coal seam under the action of CSW, the numerical simulation of fracturing coal and gas extraction under a single CSW was carried out under the isotropic condition of in-situ stress (σH = σh = 10 MPa).

Propagation law of shock wave in coal seam

Figure 5a is the stress change cloud diagram of the coal seam in the process of shock wave propagation. When the shock wave begins to act on the coal body, the stress around the borehole increases rapidly, and the impact propagates outward in a circular wave. With the increase of the propagation distance of the shock wave, the peak stress decreases gradually. Figure 5b shows the curve of the peak stress of the shock wave and the distance from the center of the borehole with time. The propagation velocity of the shock wave in the coal body tends to be stable, and the peak stress of the shock wave decreases with time in an inverse proportional function. The coal seam is broken by the high stress of the shock wave and absorbs a large amount of shock wave energy, resulting in a continuous decrease in the peak stress generated by the shock wave in the coal seam.

Evolution law of coal damage

Figure 6 is a schematic diagram of the coal seam damage change under the CSW. When the shock wave begins to act on the coal seam, the coal body near the borehole is severely damaged due to high stress impact and absorbs a large amount of energy from the shock wave, forming a circular coal crushing zone with an equal radius. In the process of shock wave transmitting outward, when the diameter of the broken zone reaches 0.3 m, the damage of the coal seam extends outward in the form of radial cracks. This phenomenon is caused by the continuous attenuation of energy during the propagation of shock waves through the coal seam.

Efficiency of enhanced gas extraction

The CSW pulses are used to crush the coal seam to increase permeability. The permeability of fractured coal increases greatly, as shown in Fig. 7. Due to the most serious impact around the borehole, the degree of coal fragmentation is high, and the permeability improvement effect is the largest. The permeability is 2172 times that of the unbroken area. The farther the distance from the borehole, the lower the multiple of permeability increase. During the gas extraction, it will reduce the gas pressure in the coal cracks around the extraction borehole, thereby promoting the gas desorption in the matrix, so as to achieve the purpose of reducing the gas content of the coal seam. Because the research area is small, the extraction time is set to be 20 days. Comparative analysis of gas pressure changes before and after fracturing coal seam is conducted, finding that without CSW enhanced gas extraction, the gas pressure around the extraction borehole decreases rapidly. Before fracturing the coal seam, the gas pressure decreases more slowly due to the farther away from the borehole. After fracturing the coal seam, due to the increase of permeability in the coal damage area, the gas pressure in the damage area around the borehole decreases sharply in the same extraction time, which is consistent with the gas pressure around the borehole. The gas in the study area migrates rapidly to the broken area, which accelerates the gas extraction rate in the coal seam, resulting in a more obvious gas extraction effect, as shown in Fig. 8.

Figure 9 is the gas pressure change curve of different extraction time on the monitoring line AB before and after the CSW enhanced gas extraction. When the CSW is not used to fracture the coal seam, the gas pressure in the fracture decreases with the extraction time. The gas pressure difference between the matrix and the fracture becomes larger, which promotes gas desorption in the matrix. As the extraction time increases, the decreasing rate of the gas pressure in fracture gradually slows down. The maximum gas pressure on the monitoring line is 0.69 MPa after 20 d of extraction. After the CSW fracturing the coal seam, the permeability of the damaged zone of the coal seam is higher than that of the undamaged one, and a large area of gas pressure is reduced near the extraction hole, which is equivalent to expanding the radius of the extraction hole and increasing the efficiency of gas extraction. The maximum gas pressure on the monitoring line is 0.61 MPa after 20 d of extraction.

Figure 10 is the change curve of the proportion of residual gas in coal before and after CSW enhanced gas extraction, under different extraction time. In the same extraction time, the proportion of residual gas after fracturing is lower. When the coal is not fractured, the proportion of residual gas is 85% after 20d of extraction. After fracturing, it can be reduced to 73%, improving that the gas extraction efficiency is increased by 12%. The permeability in the fracture zone increases after the CSW fracturing coal seam, which can effectively increase the gas extraction efficiency and reduce the CH4 content of the coal seam.

CSW as an emerging coal seam fracturing technology, have demonstrated the ability to effectively fracture coal seams and enhance the efficiency of gas extraction based on numerical simulation analysis of real-field data. When applying this technology for enhanced permeability in coal seams, a more detailed analysis of technical parameters and geological adaptability is required to ensure the safety and effectiveness of the technology application. This includes a comprehensive consideration of factors such as in-situ stress conditions and fracture propagation patterns to optimize construction parameters and improve the development efficiency of coal seam.

Influence of different factors on the CSW enhanced gas extraction

Different impact times

When the CSW technology is applied in the field, multiple discharges will be carried out to fracture the coal seam. In order to study the influence of different impact times on coal damage, the peak stress of CSW is set to 50 MPa for simulation. In the numerical calculation, the stress load condition of the CSW is applied again after inheriting the previous impact fracturing simulation results, and the calculation of multiple controllable shock wave fracturing coal body is realized. Figure 11 shows the cloud diagram of the damaged change in coal seam under multiple shock waves. After multiple impact cracking, the area of the damaged zone of the coal seam is further increased.

Figure 12 is the damaged area change curve of the coal seam under multiple shock waves. The change of coal damage area under different shock times can be divided into three stages: rapid growth stage (0 ~ 5 times), slow growth stage (5 ~ 17 times) and stable stage (after 17 times). At the beginning of the shock wave, the coal around the borehole absorbs a lot of energy and breaks rapidly. The broken coal absorbs shock wave energy and inhibits shock wave propagation to the outside. When the number of impact times is small, the damaged area of coal will increase rapidly. With the increase of the number of shock wave action, the damaged area of the coal body is expanded, the energy of the shock wave absorbed by the broken coal body is increased. The decrease in shock wave propagation efficiency inhibits fragmentation zone expansion. When the damaged zone reaches a certain extent, the shock wave energy cannot be effectively propagated to the undamaged zone due to the influence of the fractured coal, and the coal seam damage tends to be stable.

Different CSW intensities

In order to study the variation law of coal damage zone under different CSW intensities, the CSW with peak intensitiies of 10, 30, 50, 70, 90, 110, 130, 150, 170 and 200 MPa were set to simulate the different fracturing effects of coal. Figure 13 shows the cloud map of the damaged distribution in the coal seam caused by multiple shock waves with a peak strength of 50 MPa, 100 MPa, 150 MPa and 200 MPa (Tt = 10). Under the same impact times, the higher the peak strength is, the more obvious the outward extension trend of coal damage can be, and the larger the damage area.

Figure 14 shows the variation curves of the damaged area of the fractured coal with different CSW intensities and the proportion of residual gas content after extraction. With the increase of the peak stress of the CSW, the damaged area of the coal seam increases continuously, while the residual gas content of the coal decreases continuously. The effect of CSW enhanced gas extraction is proportional to the damaged area of the coal seam.

The shock wave intensity represents the sum of the energy of the shock wave, which produces a variety of mechanical effects including tensile, compressive and shear force, resulting in a complex fracture network in the coal seam. In this process, the coal body needs to consume and absorb the shock wave energy, resulting in the gradual attenuation of the shock wave intensity. The larger the impact energy, the more energy the coal needs to absorb, resulting in the larger the crushing damage area of the coal.

Different lateral pressure coefficients

In order to investigate the influence of different lateral pressure coefficients on the damage evolution, the peak pressure and impact times of CSW are kept constant (Tt = 10, Ts = 50 MPa). The vertical stress σH is set to be 10 MPa, and the horizontal stress σh is applied on the right boundary, σh = λσH. The values of λ are 0.3, 0.5, 0.8, 1, 1.3, 1.5, 1.8 and 2. Figure 15 is the cloud diagram of the damage distribution of CSW fracturing coal seam under the condition of lateral pressure coefficient of 0.3, 0.5, 0.8, 1, 1.5 and 2. With the increase of horizontal stress, the damaged area gradually decreases, and the shape and distribution of the damage zone have a change accordingly. When λ < 1, the damaged coal body extends along the vertical direction while the damage in the horizontal direction is suppressed. The crack length in the vertical direction increases with the increase of the difference between horizontal stress and vertical stress. When λ > 1, the coal body is more prone to damage in the horizontal direction. The crack length in the horizontal direction increases with the increase of the difference between horizontal stress and vertical stress. The extension length ratio in the horizontal and vertical directions is used to represent the extension direction of the damage zone, and the ratio is expressed by Tr. The value of Tr increases with the increase of the value of λ, as shown in Fig. 16, indicating that the coal seam is more likely to be destroyed along the horizontal direction.

Under the condition of different lateral stress coefficients, the cloud map of the gas pressure change after gas drainage for 20 days after fracturing the coal body is shown in Fig. 17. The decrease of gas pressure is similar to the shape of the damage zone, and there is obvious directivity. The reduction effect along the direction of the maximum principal stress is obvious. The stress in the vertical direction remains unchanged. The greater the pressure coefficient is, the stronger the in-situ stress suppression effect of coal damage is. In the same extraction time, the proportion of residual gas content in the coal seam is higher, as shown in Fig. 18.

Under the condition of high ground stress, coal cracking caused by shock wave has to overcome the compaction effect of ground stress on coal, and the higher the ground stress is, the faster the attenuation rate of shock wave propagation, thus inhibiting the expansion of blasting cracks. Under the condition of non-hydrostatic ground stress, the original ground stress state is disturbed, and the redistribution of stress in the rock will cause the stress concentration in the direction of greater principal stress, while the stress in the orthogonal direction is relatively low, so the fracture is more inclined to expand in the direction of higher ground stress.

Conclusions

(1) In this paper, the maximum tensile stress and the Mohr-Coulomb criterion are used to judge the damage expansion and evolution of coal under the action of CSW. Based on the fracture-pore dual pore structure of coal, the damage-seepage-deformation coupling model of coal gas extraction after impact fracturing is established by Fick’s law, Darcy’s law, the ideal gas state equation and the Langmuir equation.

(2) Under the action of single impact fracturing of isotropic ground stress, the coal around the borehole is subjected to strong impact to form a damage zone, and the damage zone diffuses outward from the borehole in a ring. As impulse action spreads deeper into the coal seam, its intensity weakens. In area where stress concentration exceeds the rock strength, a radial crack is formed. The permeability in the damaged zone increases after the CSW fracturing the coal seam, which can significantly improve gas extraction efficiency and reduce the CH4 pressure and the content of the coal seam.

(3) With the increase of impact times, the damage of coal tends to be stable after reaching a certain threshold after several impacts. The damage threshold caused by different CSW intensities is different, and the intensity determines the size of the damage area. The effect of the enhanced gas extraction after fracturing is proportional to the area of artificially created rocks damage zone.

(4) When the pressure coefficient deviates from 1, the damage caused by the fractured coal body has obvious directivity: extending along the direction parallel to the maximum principal stress. Under the action of in-situ stress, the effect of the CSW fracturing coal is inhibited, showing that the higher the in-situ stress is, the more obvious the inhibition effect is.

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Yang, Y. et al. Status and challenges of applications and industry chain technologies of hydrogen in the context of carbon neutrality. J. Clean. Prod. 134347 (2022).

He, X. et al. Permeability enhancement and gas drainage effect in deep high gassy coal seams via long-distance pressure relief mining: A case study. Adv. Civ. Eng. 2021, 1–13 (2021).

Xiao, B. et al. Late ordovician-early silurian extension of the northern margin of the Upper Yangtze platform (South China) and its impact on organic matter accumulation. J. Petrol. Sci. Eng. 220, 111238 (2023).

Бригида, В. С. et al. Использование разгрузочного бурения для обеспечения безопасности отработки газоносных угольных пластов Донбасса. Безопасность труда в промышленности 3, 7–11 (2019).

Yao, B. et al. Effect of protective coal seam mining and gas extraction on gas transport in a coal seam. Int. J. Min. Sci. Technol. 26(4), 637–643 (2016).

Li, P., Zhang, X. & Li, H. Technology of coupled permeability enhancement of hydraulic punching and deep-hole pre-splitting blasting in a three-soft coal seam. Mater. Technol. 55(1), 89–96 (2021).

Chen, B. et al. A review of hydraulic fracturing simulation. Arch. Comput. Methods Eng. 1–58. (2021).

Yang, L. et al. An improved gas–liquid–solid coupling model with plastic failure for hydraulic flushing in gassy coal seam and application in borehole arrangement. Phys. Fluids 35, 036603 (2023).

Fan, S. et al. Enhancing coalbed methane recovery with liquid CO2 fracturing in underground coal mine: From experiment to field application. Fuel 290, 119793 (2021).

Fan, C. et al. Recent advances and perspectives of CO2-enhanced coalbed methane: Experimental, modelling, and technological development. Energy Fuels 37(5), 3371–3412 (2023).

Zhao, P. et al. Greenhouse gas protection and control based upon the evolution of overburden fractures under coal mining: A review of methods, influencing factors, and techniques. Energy 129158 (2023).

Ni, G., Li, Z. & Xie, H. The mechanism and relief method of the coal seam water blocking effect (WBE) based on the surfactants. Powder Technol. 323, 60–68 (2018).

Chen, W. et al. Experimental study on an alternative oil stimulation technique for tight gas reservoirs based on dynamic shock waves generated by pulsed arc electrohydraulic discharges. J. Petrol. Sci. Eng. 88, 67–74 (2012).

Yutkin, L. A. Electrohydraulic Effect (Armed Services Technical Information Agency, 1955).

Wesley, R. H. Process and apparatus for electrohydraulic recovery of crude oil: U.S. patent 4,345,650[P]. 1982-8-24.

Sun, Y. et al. The development of the electric pulse oil-mining technology. High. Voltage Eng. 28(1), 41–44 (2002).

Wang, Y. Experiment and application of electric pulse treatment technology in coalbed methane reservoir. Public. Commun. Sci. Technol. 9, 125 (2011).

Zhang, Y., Qiu, A. & Qin, Y. Principle and engineering practices on coal reservoir permeability improved with electric pulse controllable shock waves. Coal Sci. Technol. 45(9), 79–85 (2017).

Jia, S. et al. Study on time variation of water shock front of coal based on high voltage electrical pulse reflection enhancement. J. Taiyuan Univ. Technol. 46(06), 680–684 (2015).

Li, C. et al. Effect of prefabricated cracks on high voltage electric pulse fracturing coal and rock mass in water. Coal Mine Saf. 52(07), 27–32 (2021).

Yong, Q. I. N., Ai-ci Q I, U. & Yong-min, Z. Experiment and Discovery on Permeability Improved Technology of Coal Reservoir Based on Repeated Strong Pulse Waves of High Energy Accumulation (Coal Science & Technology, 2014).

Li, C. et al. Experimental study of the structural damage to coal treated by a high-voltage electric pulse discharge in water. Energy Fuels 36(12), 6280–6291 (2022).

Bao, X. et al. Damage characteristics and laws of micro-crack of underwater electric pulse fracturing coal-rock mass. Theoret. Appl. Fract. Mech. 111, 102853 (2021).

Zhang, X. et al. Petrophysical variation of coal treated by cyclic high-voltage electrical pulse for coalbed methane recovery. J. Petrol. Sci. Eng. 178, 795–804 (2019).

Yan, F. et al. Structural evolution characteristics of middle–high rank coal samples subjected to high-voltage electrical pulse. Energy Fuels 32(3), 3263–3271 (2018).

Yan, F. et al. Experimental investigation on anthracite coal fragmentation by high-voltage electrical pulses in the air condition: Effect of breakdown voltage. Fuel 183, 583–592 (2016).

Jia, L. et al. Novel multi-field coupling high-voltage electric pulse fracturing coal–rock permeability enhancement test system. Int. J. Rock Mech. Min. Sci. 158, 105180 (2022).

Fan, C. J. et al. Investigation on coal skeleton deformation in CO2 injection enhanced CH4 drainage from underground coal seam. Front. Earth Sci. 9 (2021).

Deng, J. et al. CH4 transport in micro–nano porous media associated with supercritical CO2 flooding. Phys. Fluids 34(7) (2022).

Luo, M. et al. Numerical optimization of drilling parameters for gas predrainage and excavating-drainage collaboration on roadway head. Geofluids (2022).

Li, S. et al. A fully coupled thermal-hydraulic-mechanical model with two-phase flow for coalbed methane extraction. J. Nat. Gas Sci. Eng. 33, 324–336 (2016).

Qiaorui, S. et al. Numerical study on gas–liquid two phase flow characteristic of multistage electrical submersible pump by using a novel multiple-size group (MUSIG) model. Phys. Fluids 34(6) (2022).

Fan, C. et al. Spatial–Temporal Evolution and Countermeasures for Coal and Gas Outbursts Represented as a Dynamic System 566855–6877 (Rock Mechanics and Rock Engineering, 2023).

Xu, H. et al. Modeling of diffusion kinetics during gas adsorption in a coal seam with a dimensionless inversion method. Fuel 326, 125068 (2022).

Zhu, W. C. et al. High-pressure air blasting experiments on concrete and implications for enhanced coal gas drainage. J. Nat. Gas Sci. Eng. 36, 1253–1263 (2016).

Chao-jun, F. A. N. et al. Numerical simulation of deep coalbed methane extraction based on fluid-solid-thermal coupling. J. China coal Soc. 41(12), 3076–3085 (2016).

Zhang, D. et al. A novel fluid–solid coupling model for the oil–water flow in the natural fractured reservoirs. Phys. Fluids 33(3) (2021).

Fan, C. et al. Numerical simulation of hydraulic fracturing in coal seam for enhancing underground gas drainage. Energy Explor. Exploit. 37(1), 166–193 (2019).

Shen, W. et al. Fully coupled modeling of two-phase fluid flow and geomechanics in ultra-deep natural gas reservoirs. Phys. Fluids 34(4) (2022).

Xu, H. et al. A dynamic prediction model for gas–water effective permeability based on coalbed methane production data. Int. J. Coal Geol. 121, 44–52 (2014).

Liu, S. W. et al. Characteristic analysis of plasma channel and shock wave in electrohydraulic pulsed discharge. Phys. Plasmas 26(9) (2019).

Engineeringtoolbox. https://www.engineeringtoolbox.com/.s

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant Nos. 52004117, 52174117 and 52074146), the Postdoctoral Science Foundation of China (Grant Nos. 2021T140290 and 2020M680975), the Discipline Innovation Team of Liaoning Technical University (Grant No. LNTU20TD-03).

Author information

Authors and Affiliations

Contributions

C. F. and H. S. put forward the main concepts of the paper.L. Y. and C. F. put forward the research methodology.H. S. designed and calculated the numerical simulation.M. L. and B. X. provided on-site information.H. S. and C. F. analyzed the research results.L. W., L. Y. and M. L. process data.C. F. and H. S. wrote the main manuscript text.H. S. and L. Z. prepared all figures.C. F. and M. L. supervised the research process of the paper.C. F. provided research funding.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, H., Fan, C., Yang, L. et al. Modelling of enhanced gas extraction in low permeability coal seam by controllable shock wave fracturing. Sci Rep 14, 24155 (2024). https://doi.org/10.1038/s41598-024-74259-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-74259-x