Abstract

Predicting and understanding the phenomenon of surface subsidence caused by coal mining in working faces with faults are important issues for safe coal mining and efficient production. In numerical simulation experiments, it was found that the phenomenon of surface subsidence manifests when faults exist, and the degree of influence of faults with different dip angles on surface subsidence varies. This phenomenon is attributed to fault activation. According to the experimental results, the impact of faults with different dip angles on surface subsidence falls into three levels: level I for 35° faults, level II for 45° and 55° faults, and level III for 65° and 75° faults. Similarly, the relationship between the difficulty of fault activation and the dip angle of faults can be categorized as 35° faults prone to activation, 45° and 55° faults difficult to activate, and 65° and 75° faults not prone to activation. The probability integral correction model for fault mining, which integrates the surface subsidence values caused by fault-induced attenuation and the subsidence arising from separation spaces, was introduced, thereby constructing a surface subsidence prediction model. This proposed prediction model can accurately predict surface subsidence, with a root mean square error of 10.74 mm between the predicted and measured values, as validated using DInSAR results from the III 6301 working face in the Jincheng mining area.

Similar content being viewed by others

Introduction

Surface subsidence, being the most prevalent environmental geological issue stemming from coal seam mining, has garnered widespread attention1,2,3. Subsidence caused by coal mining can inflict severe impacts on both the local ecological environment and human settlements, encompassing the destruction of farmland, soil erosion, and the tilting of buildings4,5. Consequently, accurately predicting ground subsidence during coal mining has emerged as a top priority in mitigating surface subsidence effects. Numerous studies have revealed that the geological conditions conducive to subsidence zones are often diverse and do not conform to a single, conventional pattern, but rather encompass a myriad of complex geological factors that interact with each other6. In light of this, investigating coal seam mining under fault conditions holds significant value in comprehensively understanding the surface subsidence patterns across different geological settings.

Surface subsidence caused by underground mining is an extremely complex process that varies significantly with mining time and space. In order to comprehend the laws governing surface subsidence resulting from coal seam mining, numerous scholars have conducted a series of studies7,8,9,10,11,12,13. In the realm of field monitoring, traditional geodetic methods (including level instruments, total stations, and global navigation satellite systems (GNSS)) as well as non-contact remote sensing techniques (such as unmanned aerial vehicles (UAVs) and interferometric synthetic aperture radar (InSAR)) have been extensively utilized to monitor surface subsidence14,15. To accurately forecast surface subsidence, the influence function method has been widely adopted in prediction models. The integration of the probability integration method with remote sensing data has facilitated the monitoring of surface subsidence16, and similarly, the combination of the probability integration method with 3D laser scanning technology has also achieved effective monitoring of surface subsidence17. However, when utilizing conventional probability integration methods for predicting surface subsidence, special geological conditions, particularly the influence of faults on surface subsidence, are often overlooked.

Faults, as a common geological phenomenon, have long been a focal point of research in the field of geological engineering for their impact on the laws of surface subsidence. Utilizing FLAC3D software, the dynamic response of geological models containing faults can be precisely simulated18, thereby allowing for an in-depth analysis of the mechanism of fault activation and slip on surface subsidence. In the case of fault activation, surface subsidence no longer follows the traditional pattern of uniform subsidence, but may exhibit a phenomenon of biased subsidence, which has been verified in the FLAC3D numerical simulation experiments conducted by Luo et al.19. Sainoki et al.20 conducted further research by considering various factors that may lead to fault slip, establishing corresponding fault models, and conducting dynamic numerical simulation analyses. Their results indicated that during the mining process, faults are prone to sliding, which increases the risk of coal mine safety accidents. Wang et al.21 constructed a FLAC3D numerical model based on the actual geological conditions of the 6303 working face at Jisan Coal Mine of Yankuang Group and conducted detailed computational analyses. They found that faults have significant blocking effects on vertical stress, horizontal stress, and shear stress, providing a new perspective for understanding the interaction between faults and mining stress fields. The research of Cai et al.22 focused on the mechanism of the impact of the superposition of static and dynamic stresses during mining on fault activation and earthquake induction, further revealing the interaction between fault activities and mining activities. In summary, the impact of faults on the laws of surface subsidence has been widely studied and confirmed. However, there is still a lack of an efficient and precise method to predict surface subsidence caused by mining at faulted working faces. Therefore, future research needs to further explore and develop new prediction methods and techniques based on these studies, aiming to improve the accuracy and reliability of surface subsidence predictions.

As the scale of coal seam mining increases, the geomechanical environment becomes increasingly complex, and special geologic formations such as faults have a significant impact on rock damage and surface subsidence23. Faults can develop in areas where joint surfaces have shifted and where joint surfaces are densely packed. Faults are characterized by weak rock, low strength, susceptibility to deformation, as well as permeability24,25. Compared with mining coal seams under conventional geological conditions, conditions with faults often result in stress transfer and rock movement becoming more complex. Stresses around faults can be redistributed, leading to large amounts of energy accumulating. Coal mining operations can induce movement of faults, which can lead to significant rock and surface subsidence, or even a risk of rock burst26. Consequently, the study of surface subsidence is particularly necessary when mining coal seams under conditions with faults to ensure the safety of underground coal mine production as well as surface buildings.

Fault activation model

Mechanical modeling of fault activation in coal seam mining

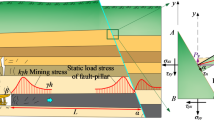

Since faults appear in rock as discontinuous structures, they tend to control the deformation, damage, and mechanical properties of rocks27. When there are faults in the rock layers overlying the working face, the mechanical connection between the rock bodies will be cut off, and the mechanical state of the key layers will also be changed, furthermore, the mining the coal seam in the footwall of a fault will form a ‘masonry beam’ structure at the key layers. The movement of the key layer due to mining the coal seam in the footwall of a fault and the forces is shown in Fig. 128.

In Fig. 1, h represents the thickness of the overlying rock layer, H represents the thickness of the key layer, h1 represents the height of the collapse zone, and M represents the thickness of the coal seam, θ is the dip angle of the fault, q is the pressure of the overlying strata, F is the rebound force below the key layer, T is the horizontal stress, F1(x) and F2(x) are stress functions.

Analyze the small units on the fault plane and combine FN and T along the fault direction as shown in Eq. (1).

In the equation, FN is the support force of the fault face on block A. T is the horizontally squeezing force on the fault face of block A. Fx, Fy are combined forces in the x, y direction at the fault plane.

According to force analysis of the tiny unit of the fault, it is known that slip may occur at the contact surface between the fault and the rock layer. If it is the case that no activation slip occurs at the fault, then the condition \(F_{x} \tan \varphi \ge F_{y}\) needs to be satisfied, in which φ is the internal friction angle of the fault zone.

No activation at the fault should also satisfy Eq. (2), otherwise, delamination will occur at the critical layer and the fault.

The relationship between the positive stresses σ and shear stresses τ in the tiny cells on the fault and the dip angle θ of the fault is shown in Eq. (3), σ1 represents the maximum principal stress, σ2 represents the intermediate principal stress, σ3 represents the minimum principal stress.

Coal seam mining fault activation modeling

Faults, as a weak surface in the rock, under the additional stress of underground mining, have three main aspects in their activation process, as shown in Fig. 2. (a) When mining the coal seams in the footwall of a fault, where the rock move towards the side of the mining area, the fault is subjected to a tensile stress T in the rock. The fault surface is pulled apart when the tensile stress T exceeds the tensile strength of the fault, and a tension crack is formed at the junction of the fault and the rock. (b) Under the action of shear stress τ, when the shear stress τ exceeds the shear strength of the fault, it causes the fault to slip and form a stepwise movement at the fault outcrop. (c) The fault surface is structurally soft, and its strength is much less than the rock on both sides. The fault zone is filled with a certain amount of soft, loose, and crumbly structural material, and it undergoes changes in raw rock stresses due to coal seam mining. Under the action of compressive stress Fm, the filling materials in the fault zone are compressed, leading to the formation of small mobile basins at the fault outcrops.

The three processes of fault “activation” depend on the location of the fault relative to the mining and the corresponding mining conditions. Numerous studies have shown that in the presence of a fault, it becomes a mobile interface, causing anomalous surface movement and deformation. However, the three processes of fault “activation” are not independent but interrelated. Based on the three conceptual models of fault “activation” in Fig. 2, and in conjunction with the mining situation of the coal seam, we can find that there are also corresponding links between the three models. The “activation” model can be described as: In the early stages of mining, the coal mining face is away from the fault, and the coal seam mining does not directly affect the fault. After the coal seam is mined, the rock mass gradually shifts towards the goaf side, and at this time, the fault is subjected to tensile stress T. When T exceeds the tensile strength of the fault, open cracks will form at the fault. As the working face continues to advance, the “activation” forms of faults can be divided into two types: (1) When the shear stress τ exceeds the shear strength of the fault, the fault experiences sliding. (2) When the shear stress τ does not exceed the shear strength of the fault, the fault does not slip. At this time, as the coal seam mining gradually approaches the fault, the fault is subjected to compressive stress Fm from the upper and lower rock masses. The open cracks and the basic structure of the fault generated in the early stage of mining will be compressed.

By establishing a theoretical model of fault zones, this section clarifies that fault activation during coal mining can lead to different movement patterns of overlying rock compared to conventional geological conditions. Next, this article will employ numerical simulation methods to simulate the movement and deformation patterns of overlying rock and the surface when faults are present, and further analyze the impact of faults on the movement and deformation of overlying rock.

Numerical simulation analysis of surface subsidence anomalies

Numerical simulation establishment

The existence of faults in the coal seam mining process makes the surface subsidence pattern significantly different from that in the absence of faults. To study the relationship between the difference in the surface subsidence pattern and the fault dip angle, the following is an example of the change in fault dip angle, FLAC3D numerical simulation is employed to investigate the anomalous characteristics of surface subsidence caused by fault dip changes. Based on our previous research, we have discovered that when the fault dip angle is between 35° to 75°, the surface subsidence caused by coal mining exhibits patterns that differ from conventional surface subsidence. Therefore, this article focuses on studying fault dip angles ranging from 35° to 75°. Of course, coal mining under other dip angles is also noteworthy, and we will conduct experiments on other scenarios in subsequent research.

This study establishes a numerical simulation model based on the geological conditions of a mine’s mining area, and the geological parameters of the mining area are presented in Table 1. The model has a length of 1200 m, a width of 1200 m, and a working face size of 390 m × 400 m. The mean thickness of the coal seam is 5 m, the average burial depth is 280 m, and the coal seam is horizontal. The working face area is located in the center of the model, and a certain area of coal pillars is left in the strike and dip directions of the model to avoid boundary effects. The coal seam is mined in 13 separate operations, with each mining operation covering an area of 30 m × 400 m. The thickness of the fault zone is 5 m, the fault dip is 35° to 75°, and it is a reverse fault. Fault joints and mechanical parameters are assigned using the weakening assignment method29, and the mining method is footwall mining. The bottom and surrounding boundaries of the model constrain the boundary displacements and velocities, while the top is a free boundary. The original state of the model is self-weight balanced. The Mohr–Coulomb model is adopted30. For the convenience of the study, corresponding surface subsidence monitoring points are set on the surface. The models without and with faults are shown in Fig. 3. The surface subsidence monitoring points are laid out as shown in Fig. 4.

Surface subsidence anomaly analysis

According to the previously mentioned conceptual model of “activation”, fault “activation” can be primarily divided into three situations: fault opening, fault sliding, and fault compression. Anomalies in surface subsidence occur primarily due to the presence of faults, which can alter the propagation of mining stresses through the formation. Secondly, the “activation” of the faults varies as the coal face advances, leading to anomalous surface subsidence. The change in fault dip angle will alter the form of fault “activation”, the timing of the start of "activation," and the location of "activation." Therefore, when faults are present in the rock, anomalies in surface subsidence occur as a result of the superposition of multiple factors. The surface subsidence under different fault dip angles obtained through numerical simulation is analyzed to determine the anomalous pattern of surface subsidence as the fault dip angle changes.

Characterization of anomalous changes in surface subsidence

The reverse faults, both without faults and with fault dips ranging from 35° to 75°, were selected, and the coal seams were excavated under these six geological conditions. The change characteristics of rock movement and the location of surface subsidence anomalies were simulated for different fault dip angles. Figure 5 shows the modeled rock subsidence cloud for excavation with varying fault dip angles. The rock subsidence cloud map is selected as the object of analysis when the excavation length is 120 m, 240 m, and 360 m. It can be seen from Fig. 5.

(1) When there is no fault mining, the rock subsidence above the mining area is symmetrical about the center of the mining area. As the mining length increases, the amount of rock subsidence gradually increases, and the trend of rock subsidence gradually extends from the basic roof to the surface.

(2) When the fault dip is 35°, at 120 m of excavation, the subsidence of the rock above the hollow area has been obviously shifted to the side of the open cut. The fault has the tendency to prevent the rock from subsiding to the surface. When excavating to 240 m, the sinking pattern of the basic roof is not affected by the fault, but the shallowly buried roc still undergoes biased sinking, biased towards the side of the open-cut. The degree of rock deviation subsidence diminishes at an excavation length of 360 m.

(3) When the fault dip angle increases from 45° to 75°, the tendency of the rock to sink to the side of the open cut in excavations up to 120 m gradually weakens. As the dip angle of the fault increases, the working face of the coal seam at the early stage of mining is farther away from the fault, and the effect of the fault on the movement of the rock is smaller. When the excavation reaches 240 m, the rock subsidence maps of 45° and 55° faults show an obvious deviated subsidence phenomenon, while only a small deviated subsidence phenomenon occurs when mining under 65° and 75° faults close to the surface. When the excavation reaches 360 m, the rock subsidence phenomenon of 45° and 55° faults increases, and the rock subsidence phenomenon of 65° and 75° faults appears near the stoping line.

Figure 6 shows the position of the maximum surface subsidence caused by coal seam excavation under different fault dip angles and the variation of the maximum subsidence with the excavation length. From the figure, it can be seen that when the excavation length is the same as in the case of faults, the location of the maximum surface subsidence lags behind that of the excavation without faults. The lag degree of 35° to 55° faults is higher than that of the faults at 65° and 75°, and the lag degree of 35° faults is the largest when the length of the excavation is 120 m. The location of the point where the maximum surface subsidence occurs is located near the eye of the open cut. This is very different from the subsidence law of conventional geological mining conditions. With the increase of fault dip angle, the change in the position of the maximum surface subsidence is first shown as moving closer to the eye of the open cut and then gradually returning to the center of the idle zone. The dip angle of a fault has a certain impact on the maximum subsidence position on the surface.

The following conclusions can be drawn from the changes in maximum surface subsidence:(1) For without fault mining, the maximum surface subsidence increased from 832 to 3920 mm. On the 35° fault, the maximum surface subsidence increased from 596 to 3181 mm, and the fault obstruction decreased from 28.3% to 18.8%. (2) For 45° and 55° faults, the maximum surface subsidence increased from 760 to 3300 mm and from 783 to 3525 mm, respectively. The fault obstruction increased from 8.4% to 15.8% and from 5.8% to 10.1%, respectively. (3) For 65° and 75° faults, the maximum surface subsidence increased from 813 to 3774 mm and from 828 to 3823 mm, respectively. The fault obstruction increased from 2.4% to 3.7% and from 0.5% to 2.5%, respectively.

The maximum surface subsidence of small-dip faults is smaller than that of non-faulted and large-dip faults. Small dip faults hinder the process of rock subsidence to the surface. With the increase in dip angle, the obstruction to the movement of the rock layer is gradually weakened, and the maximum subsidence of the surface gradually approaches the level of restoration seen in the absence of faults. According to the change in maximum surface subsidence, the degree of influence of different dip faults on surface subsidence can be categorized into three grades: level I for the high influence of 35° faults, level II for the medium influence of 45° and 55° faults, and level III for the low influence of 65° and 75° faults.

Fault activation analysis

Based on the analysis of abnormal surface subsidence, it can be seen that faults play a decisive role in the surface subsidence. Moreover, the occurrence of abnormal surface subsidence under the condition of fault existence is closely related to the fault activation during the coal mining process. In order to study the influence of fault activation on surface subsidence, the maximum principal stress and minimum principal stress in the fault zone at 55 m from the surface were monitored. The positive stress σ and shear stress τ were then calculated using Eq. (3), and subsequently, the activation of the fault zone was analyzed during the mining process.

Combined with the Mohr–Coulomb shear damage criterion31, the tangential force Fsmax for a slip to occur at the nodes of the fault contact surface is shown in Eq. (4).

where C is the cohesive force, φ is the angle of internal friction, A is the nodal surface area, and Fn is the nodal normal force.

When the fault zone is close to being destroyed, shear stress (τ) and normal stress (σ) on the fault should satisfy Eq. (5).

When \(\tan \varphi < \frac{\tau }{\sigma }\) it can be determined that the node on the fault zone has been destroyed and the fault has been activated. Note that the value \(\frac{\tau }{\sigma }\) is τσ.

The stress on the fault zone is monitored to get the τσ values in the fault zone when the working face advances 60 m, 120 m, 180 m, 240 m, 300 m, and 360 m. The τσ values under the faults with different dipping angles are shown in Fig. 7. According to Eq. (5), it can be seen that tanφ = 0.62. That is, when \(\frac{\tau }{\sigma }\) is greater than 0.62, it can be judged that fault damage has occurred and activation has taken place. From Fig. 7, it can be seen that the 35° fault is the first one to be activated when the mining length reaches 128 m, and has remained activated since then. When the mining length reaches 200 m, the 45° fault starts to activate. When the mining length reaches 240 m, the 55° fault starts to activate, while the 65° and 75° faults remain stable and do not activate during the entire mining process. Combining the relationship between fault activation benchmarks and fault dip, the difficulty of fault activation can be classified into three categories: 35° faults that are prone to activation, 45° and 55° faults where activation is less likely to occur, and 65° and 75° faults where no activation occurs.

In this paper, taking the 35° dipping fault as an example, it is divided into a non-activated zone, an activation intensified zone, and an activation smoothed zone, based on the relationship between fault activation and mining length. The division of the activation zone is closely related to the mining length. When the mining distance is less than 128 m, the fault is in the non-activation zone. In this stage, the fault will not be affected by mining activities, and the fault stability is better. When the mining length increases from 128 to 240 m, the fault is in the activation intensification zone, and the increasing trend of τσ intensifies from 0.62 to 1.04. At this time, the fault is more affected by mining. Activation of the fault has already occurred at this stage, and the degree of activation increases with the length of mining. When the mining length exceeds 240 m, the fault enters the activation smooth zone, and the fault remains activated at this stage.

Surface subsidence attenuation analysis

When the dip of a fault changes, the degree of surface subsidence anomaly also changes. There will be a marked difference between surface subsidence under conventional geologic conditions and surface subsidence in the fault. Based on the experimental results, the surface subsidence under these different working conditions is compared, and the surface subsidence attenuation coefficient ζ is introduced to characterize the extent to which the surface subsidence is affected by the fault. The Knothe time function is often used to characterize surface subsidence32,33. The introduced surface subsidence attenuation coefficient ζ is a parameter that changes dynamically with the mining length and surface location, which is determined by combining the relevant theoretical knowledge of the probabilistic integral method to find out the value of the time influence coefficient c at any surface point and any moment34.

Assuming the value of surface subsidence that varies with the location of the surface point in the absence of faults is Wi (i is the serial number represented by different surface locations, i.e., i = 1,2,3,––), and the surface subsidence value that varies with the location of the surface point in the presence of the fault is Wk (k is the serial number represented by different surface locations, i.e., k = 1,2,3,––), ζ is computed as shown in Eq. (6).

When ζ > 0, it means that the surface subsidence in the fault condition is smaller than that in the no-fault condition. When ζ < 0, it does not mean that the fault promotes surface subsidence. From the experimental results, it can be seen that the location of the maximum surface subsidence point occurred earlier than the fault-free condition, and the surface subsidence was biased.

It should be pointed out that the main influence radius of the numerical simulation model is calculated by Eq. (7). In Eq. (7), tanβ is the major influence angle tangent mainly related to the nature of the overlying rock layer, generally 1.5 ~ 2.5. Due to the specificity of the deformation pattern of surface movement in the presence of faults35 as well as the boundary effect of the numerical simulation36, the point 270 m away from the eye of the open cut is taken as the starting point of the attenuation coefficient.

The surface subsidence attenuation process at a fault dip of 65° was selected for analysis. The variation of ζ for different mining lengths and different surface locations is shown in Fig. 8. There are three main parts of the surface subsidence attenuation process that can be seen in the figure: the left side of the open-cut eye, the area from the open-cut eye to the fault outcrop, and the right side of the fault. On the left side of the open-cut eye, ζ decreases as the location of the surface point approaches the open-cut eye, but it still maintains a tendency to impede surface subsidence. ζ is greater than 0 from the open-cut eye to the fault outcrop, and the closer to the fault outcrop, the greater the degree of surface subsidence attenuation. As the mining distance increases, the surface subsidence attenuation at the same point will be lagged to a certain extent. When the point of surface subsidence is located to the right of the fault, the attenuation of surface subsidence increases dramatically. At the same point, the extent of surface subsidence attenuation increases with the increase in mining length. At different points, the attenuation of the surface subsidence decreases at points far from the fault.

Probability integral method

The difference between surface mobile deformation in the presence of faults and in their absence lies in the concentration of deformation at fault outcrops, manifesting as biased surface mobile deformation. There is also a distinction between surface mobile deformation within the zone of influence of faults and that occurring in areas devoid of faults. Therefore, the calculation of surface movement deformation can be segmented into two components: the surface movement deformation in the absence of faults, and the biased surface deformation resulting from the presence of faults. However, when faults exist, the surface subsidence pattern undergoes significant alterations. The activation of faults during coal seam mining and the occurrence of biased subsidence under their influence will impact the accuracy of traditional surface subsidence models. Therefore, the existing surface subsidence model needs to be modified to allow for the calculation of surface subsidence under faulted geological conditions.

Principles of the probability product method

The probabilistic integral method is based on the theory of stochastic media and is a method for calculating surface movement deformation and prediction37. Its calculation principle is based on a total of four assumptions: (1) The rock mass is a homogeneous, discontinuous medium. (2) The principle of linear superposition applies. (3) The rock mass in the bending zone only undergoes deformation and does not change in volume. (4) At the end of mining, the volume of surface subsidence is equal to the volume of minerals extracted from the mining area.

Stochastic medium modeling involves regarding the rock as fine particles stratified according to different burial depths. When mining activities are carried out, the fine particles with shallow burial depths move toward the mining area, thereby enabling the prediction of the movement pattern of the particles in each stratification. The distribution of particles and their movement probabilities are shown in Fig. 9.

Probabilistic integral model modification

Basic assumptions

To establish a prediction model for mining-induced subsidence under fault geological conditions, the surface subsidence model under fault conditions is divided into two parts: coal seam mining subsidence and fault-induced subsidence. The following assumptions are made.

(1) It is assumed that the subsidence caused by coal seam mining conforms to the traditional probability integral subsidence model.

(2) It is assumed that the fault will not undergo any volumetric changes during the excavation process.

(3) The surface subsidence caused by the fault overlaps with the horizontal projection of the surface subsidence center caused by coal seam mining on the ground surface.

Based on the assumptions of the model, the surface movement model under the combined effect of coal mining and fault is established as shown in Fig. 10. The surface subsidence caused by coal mining is superimposed with the surface subsidence caused by the separation layer. Taking the surface point O directly above the mining boundary as the origin of the coordinates for coal mining-induced surface movement, the positive direction of the x-axis is defined as pointing horizontally towards the strike direction, and the surface subsidence value WC(x) represents the downward direction of the surface subsidence. Taking the surface point O3 directly above the fault outcrop as the origin of the coordinates for surface movement caused by the separation layer, the positive direction of the x-axis is defined as pointing horizontally towards the strike direction, and the surface subsidence value WF(x) represents the downward direction of the surface subsidence.

The surface subsidence caused by coal mining and the separation layer is a linear superposition of two subsidence events, namely, as shown in Eq. (8).

Correction for attenuation of surface subsidence due to faults

A certain degree of attenuation of surface subsidence occurs under the influence of faults. The surface subsidence attenuation coefficient ζc is introduced in the probabilistic integral model of the surface subsidence from coal mining.

Analyzing Fig. 10, the B(α0) subsidence caused by unit mining with Abscissa α0 (mining area 1 × dα0) is as follows:

According to the superposition principle, when the mining area is W0dm, the subsidence of point A (m) is as follows:

By integrating the Eq. (10), it can be obtained that the subsidence of the point with coordinate x on the limited mining main fault plane is:

The coordinate system of the three-dimensional surface subsidence from coal mining is shown in Fig. 10. The surface subsidence WC (x0, y0) at any point A (x0, y0) of the primary section of the surface trend caused by mining of the unit coal seam B (α, β) is as shown in Eq. (12).

Modification of the model for surface subsidence due to off-grading

The spatial distribution of surface subsidence caused by faults can be divided into mining space and separation space in the fault plane. The separation space caused by the fault plane can be regarded as an equivalent goaf, and the existence of the separation space will also disrupt the stress balance state of the rocks, leading to stress redistribution and achieving a new equilibrium, causing surface deformation38. When mining under the hanging wall of a fault, the “mining thickness” d of the equivalent goaf will change with the location of the fault, as shown in Fig. 11, which illustrates the changes in the equivalent goaf and the stress distribution on the micro-elements.

When the surface point K moves to K', a fault separation space will be generated at the fault location. According to Fig. 11, the change in mining thickness d during mining under the hanging wall can be expressed as shown in Eq. (13).

where w(x) and u(x) are the values of surface subsidence and horizontal movement of the surface point K, and θ is the fault dip.

By differentiating the equivalent goaf, the fault dip angle is equal to the coal seam dip angle, and d = (di + di+1)/2. The surface subsidence caused by the equivalent goaf can be calculated using the same method as for mining in inclined coal seams. A schematic diagram of the calculation of surface subsidence caused by the equivalent goaf is shown in Fig. 12. According to the calculation methodology for mining in inclined coal seams, the surface subsidence caused by the equivalent goaf is the superposition of the subsidence from coal seam C'F and coal seam D'E. From this, the surface subsidence value of the equivalent goaf can be obtained.

According to the calculation idea when mining inclined coal seams, the surface subsidence caused by equivalent mining airspace is formed by the superposition of coal seams C'F and coal seams D'E. From this, the surface subsidence value of the equivalent mining void area can be obtained as shown in Eq. (14).

where L is the transverse length of the calculated working face. r1 = H1/tanβ1, r2 = H2/tanβ2.

In summary, the surface subsidence value WC(x0,y0) caused by attenuation caused by faults and the surface subsidence WF(x1,y1) caused by interlayer space are shown in Eq. (15).

The surface subside value under fault conditions is shown in Eq. (16).

Projected surface subsidence under fault action

Research area and data

III 6301 working face is located in Jincheng City, Shanxi Province. The strike length of the working face is 833.77 m, the inclination length is 294.2 m, and the working face area is 245,295.134 m2. The SF456 fault above the working face is exposed at the retreat mining section up to 258 m, and the fault inclination angle is 65°. The topographic map of the study area is shown in Fig. 13. The vegetation coverage in this area is relatively low, and the maximum subsidence area along the road passing through the working face facilitates the selection of characteristic subsidence points. Moreover, the dry vegetation in this area in winter will not affect the DInSAR results. The location of the working face and the fault is shown in Fig. 14, and 45 monitoring points are arranged in the direction of the strike, with a spacing of 30 m between the monitoring points.

Due to the lack of level monitoring data in the area, complete surface subsidence values could not be obtained. In this research, DInSAR technology was used to monitor the surface subsidence since mining. A total of 13 image data acquired from December 6, 2022, to April 29, 2023, at an interval of 12 days were selected for processing. The DEM data used in this paper is the STRM-30 m DEM data (http://gdex.cr.usgs.gov/gdex/), which is topographic data collected by NASA. Utilizing the Shuttle Radar Topography Mission (SRTM) radar system on board the Space Shuttle, high-resolution radar altimetry measurements were conducted on the Earth’s surface to generate a global digital elevation model (DEM), providing more detailed topographic information. The STRM-30 data covers a global scale, including both land and ocean areas, and it is used in various fields such as cartography, terrain analysis, natural disaster monitoring, resource management, and more.

InSAR monitoring principles

The basic principle of monitoring mining subsidence by DInSAR technology is to carry out interference processing on the radar images acquired before and after mining, obtain interferograms containing terrain phase and deformation phase, eliminate the influence factors such as terrain, atmosphere, noise, etc. through differential technology, and then obtain the surface deformation39,40.

In the equation: φflat is the flat phase related to the distance direction. φtopo is the terrain phase. φdef is the phase of surface deformation along the satellite’s line of sight during two observation periods. φatmo is the atmospheric delay phase caused by atmospheric fluctuations. φnoise refers to the noise phase caused by temporal decoherence, spatial decoherence, and thermal noise. K is the phase integer ambiguity.

Analysis of results

Cumulative subsidence values for workface III6301 obtained using Sentinel-1A data from December 6, 2022, to April 29, 2023, are shown in Fig. 15.

The surface subsidence calculation model constructed in this study is used to predict the surface subsidence generated by the mining of the III6301 working face. Based on the comprehensive mining geological data and corresponding mine borehole histograms, we have obtained the corresponding probability integral model parameters. Specifically, the subsidence coefficient under the influence of faults is set to 0.64, the tangent of the main influence angle is set to 1.41, the offset distance of the inflection point is set to 23 m, the subsidence coefficient under the influence of bed separation is set to 0.75, the tangent of the main influence angle is set to 1.57, and the offset distance of the inflection point is set to 28 m.

The predicted subsidence values for each measuring point are obtained, and the predicted values are compared with the actual values, as shown in Fig. 16a. The predicted subsidence values of each measuring point obtained by the conventional surface subsidence calculation model are compared with the measured values, as shown in Fig. 16b.

From Fig. 16a, it can be seen that at each measurement point on the strike observation line, a large subsidence value of 232 mm is expected using the proposed superposition model, and the measured maximum subsidence value is 246 mm. The predicted results are in overall good agreement with the measured data, and the RMSE between the predicted and measured values is 10.74 mm. From Fig. 16b, it can be seen that the conventional surface subsidence prediction model performs worse than the modified model at faults, while the prediction at locations without faults is comparable to the modified model. The root-mean-square error between the predicted value and the measured value is 15.43 mm. It can be seen that the constructed modified model for the surface subsidence can well realize the prediction of inhomogeneity of surface subsidence caused by the activation of faults.

Discussions

This paper investigates the phenomenon of abnormal surface subsidence under the influence of faults, analyzes the ease of fault activation when the fault dip angle changes, and constructs a prediction model for surface subsidence under the influence of faults. The research content of this paper can analyze the characteristics of ground movement and deformation under fault conditions, allowing for advance planning to prevent safety accidents. Based on the research in this paper, further studies can be conducted on the evaluation of ground movement and deformation, as well as protective measures for ground movement and deformation in the presence of faults.

However, this paper also has its limitations. Firstly, the range of fault dip angle variation should be expanded. This paper only analyzes the impact of faults with dip angles ranging from 35° to 75°, and the corresponding changes in surface subsidence are unclear when the dip angle exceeds this range. Secondly, the model constructed in this paper is only applicable to conditions where faults exist, and the fault location and fault dip angle need to be obtained through geological exploration. When geological data is lacking or geological exploration conditions are not available, the model will be difficult to apply.

Conclusion

This study explores the abnormal patterns of surface subsidence caused by coal mining under fault conditions, revealing the characteristics of the effects of faults with different dip angles on surface subsidence. A prediction model for estimating surface subsidence under fault conditions is proposed. The main conclusions drawn from this study are as follows.

(1) Fault dip plays a major role in determining the location of maximum surface subsidence. According to the change of maximum surface subsidence, the influence of different inclination faults on surface subsidence can be categorized into three grades: 35°faults with high influence is grade I, 45°and 55°faults with medium influence is grade II and 65°and 75°faults with low influence is grade III.

(2) The activation of faults in the process of mining has obvious segmentation with the change of dip angle. Combined with the relationship between the fault activation benchmark and the fault dip angle, the relationship between the difficulty of fault activation and the fault dip angle can be divided into three categories. 35° faults that are easy to activate, 45° and 55° faults that are difficult to activate, and 65° and 75° faults that are not activated. Among them, the activated faults will go through the non-activation stage, activation intensification stage, and activation stabilization stage respectively with the increase of mining length.

(3) The revised prediction model that has been constructed can effectively solve the problem of skewed subsidence that occurs when the probability integration model is used to predict surface subsidence under fault conditions, and it has achieved good results in engineering practice. The constructed subsidence model provides a theoretical basis for coal mining in similar mines and technical guidance for coal mining in similar mines.

Data availability

The datasets generated and analyzed during the current study are available on request from the corresponding author. The multi-scene Sentinel-1A data research selected in this paper can be downloaded from https://search.asf.alaska.edu/. In the experiment, the external digital elevation model (Diital Elevation Model, DEM) selects the earth electronic terrain data ASTER GDEMV3 30 m jointly launched by NASA and METI to remove the terrain phase, the download website is https://www.usgs.gov/.

References

Ammirati, L., Mondillo, N., Rodas, R. A., Sellers, C. & Di Martire, D. Monitoring land surface deformation associated with gold artisanal mining in the Zaruma City (Ecuador). Remote Sensing 12(13), 2135. https://doi.org/10.3390/rs12132135 (2020).

Tajduś, K. et al. Analysis of mining-induced delayed surface subsidence. Minerals 11(11), 1187. https://doi.org/10.3390/min11111187 (2021).

El Kamali, M. et al. Monitoring of land surface subsidence using persistent scatterer interferometry techniques and ground truth data in arid and semi-arid regions, the case of Remah, UAE. Sci. Total Environ. 776, 145946. https://doi.org/10.1016/j.scitotenv.2021.145946 (2021).

Wang, L. et al. A novel evaluation method for the stability of construction sites on an abandoned goaf: A case study. KSCE J. Civil Eng. 26(6), 2835–2845. https://doi.org/10.1007/12205-022-1431-4 (2022).

Islam, N., Rabha, S., Subramanyam, K. S. V. & Saikia, B. K. Geochemistry and mineralogy of coal mine overburden (waste): A study towards their environmental implications. Chemosphere 274, 129736. https://doi.org/10.1016/j.chemosphere.2021.129736 (2021).

Ma, J., Yin, D., Jiang, N., Wang, S. & Yao, D. Application of a superposition model to evaluate surface asymmetric settlement in a mining area with thick bedrock and thin loose layer. J. Clean. Prod. 314, 128075. https://doi.org/10.1016/j.jclepro.2021.128075 (2021).

Guo, Q., Li, Y., Meng, X., Guo, G. & Lv, X. Instability risk assessment of expressway construction site above an abandoned goaf: a case study in China. Environ. Earth Sci. 78, 1–14 (2019).

Taghipour, M., Ghafoori, M., Lashkaripour, G. R., Hafezi Moghaddas, N. & Molaghab, A. A geomechanical evaluation of fault reactivation using analytical methods and numerical simulation. Rock Mech. Rock Eng. 54, 695–719. https://doi.org/10.1007/s00603-020-02309-7 (2021).

Ding, Q. et al. Monitoring, analyzing and predicting urban surface subsidence: A case study of Wuhan City, China. Int. J. Appl. Earth Obs. Geoinf. 102, 102422. https://doi.org/10.1016/j.jag.2021.102422 (2021).

Yuan, M. et al. Subsidence monitoring base on SBAS-InSAR and slope stability analysis method for damage analysis in mountainous mining subsidence regions. Remote Sens. 13(16), 3107. https://doi.org/10.3390/rs13163107 (2021).

Argyrakis, P. et al. Anthropogenically induced subsidence in Thessaly, central Greece: new evidence from GNSS data. Nat. Hazards 102, 179–200. https://doi.org/10.1007/s11069-020-03917-w (2020).

Wei, L., Wang, F., Tolomei, C., Liu, S., Bignami, C., Li, B., & Pan, X. Displacements of Fushun west opencast coal mine revealed by multi-temporal InSAR technology. Geo-spatial Inf. Sci. 1–17 (2023). https://doi.org/10.1080/10095020.2023.2239285

Jiang, H., Balz, T., Cigna, F., Tapete, D., Li, J., Han, Y. Multi-sensor InSAR time series fusion for long-term land subsidence monitoring. Geo-spatial Inf. Sci. 1–17 (2023). https://doi.org/10.1080/10095020.2023.2178337

Tang, F. et al. Improvement of mining subsidence modeling method based on UAV LiDAR in Yushen mining area. J. China Coal Soc. 45(7), 2655–2666 (2020).

Wang, Y. Research progress and prospect on ecological dis-turbance monitoring in mining area. Acta Geod. Et. Cartogr. Sin. 46(10), 1705–1716 (2017).

Wang, R. et al. A novel method of monitoring surface subsidence law based on probability integral model combined with active and passive remote sensing data. Remote Sens. 14(2), 299. https://doi.org/10.3390/rs14020299 (2022).

Wang, L. et al. Research on 3D laser scanning monitoring method for mining subsidence based on the auxiliary for probability integral method. KSCE J. Civil Eng. 25, 4403–4416. https://doi.org/10.1007/s12205-021-0053-6 (2021).

Wang, H. et al. Characteristic of stress evolution on fault surface and coal bursts mechanism during the extraction of longwall face in Yima mining area China. J. Struct. Geol. 136, 104071. https://doi.org/10.1016/j.jsg.2020.104071 (2020).

Luo, J. et al. Experimental simulation study on abnormal response of surface subsidence caused by mining in footwall of reverse fault. Prog. Geophys. 37(3), 1280–1291 (2022).

Sainoki, A. & Mitri, H. S. Dynamic behaviour of mining-induced fault slip. Int. J. Rock Mech. Min. Sci. 66, 19–29. https://doi.org/10.1016/j.ijrmms.2013.12.003 (2014).

Wang, X. B., Guo, C. S. & Deng, C. Q. Numerical modeling of fault bar-rier effects on three kinds of stresses: A case of footwall mining on the normal fault. Prog. Geophys. 35(4), 1605–1611 (2020).

Cai, W., Dou, L., Si, G. & Hu, Y. Fault-induced coal burst mechanism under mining-induced static and dynamic stresses. Engineering 7(5), 687–700. https://doi.org/10.1016/j.eng.2020.03.017 (2021).

Li, Z. L. et al. Mechanical analysis of static stress within fault-pillars based on a voussoir beam structure. Rock Mech. Rock Eng. 49, 1097–1105. https://doi.org/10.1007/s00603-015-0754-6 (2016).

Huang, N., Liu, R., Jiang, Y., Cheng, Y. & Li, B. Shear-flow coupling characteristics of a three-dimensional discrete fracture network-fault model considering stress-induced aperture variations. J. Hydrol. 571, 416–424. https://doi.org/10.1016/j.jhydrol.2019.01.068 (2019).

Hu, F., Oglesby, D. D. & Chen, X. The near-fault ground motion characteristics of sustained and unsustained free surface-induced supershear rupture on strike-slip faults. J. Geophys. Res. Solid Earth 125(5), e2019JB019039. https://doi.org/10.1029/2019JB019039 (2020).

Jiang, Y., Zhao, Y., Wang, H. & Zhu, J. A review of mechanism and prevention technologies of coal bumps in China. J. Rock Mech. Geotech. Eng. 9(1), 180–194. https://doi.org/10.1016/j.jrmge.2016.05.008 (2017).

Cai, W., Dou, L., Wang, G. & Hu, Y. Mechanical mechanism and induced thrust mechanism of fault activation caused by coal seam mining activities. J. Min. Safety Eng. 36(06), 1193–1202 (2019).

Han, K. M., Yu, Q. H., Zhang, H. X. & Li, F. M. Mechanism of fault activation when mining on hanging-wall and foot-wall. J. Chin. Coal Soc 45, 1327–1335 (2020).

Chrzanowskia, Szostk-Chrzanowski A. Finite element modelling of ground movements over a steeply inclined coal seam. In 6th ISM Conference on Developing Science and Art of Minerals Surveying.Harrogate 709–718 (1985).

Zhao, G., Guo, W., Lou, G. & Ma, Z. Numerical simulation of movement of both rock mass and surface under thick loose layer high-intensity mining condition. China Saf. Sci. J. 8(1), 130 (2018).

Ren, Z., Zhang, S. & Jiang, Y. Research on response of stress field in working face during thrustfault activation process under mining disturbance. Coal Sci. Technol. 49(09), 61–68 (2021).

Hu, Q. et al. Quantitative and dynamic predictive model for mining-induced movement and deformation of overlying strata. Eng. Geol. 311, 106876. https://doi.org/10.1016/j.enggeo.2022.106876 (2022).

Modeste, G., Doubre, C. & Masson, F. Time evolution of mining-related residual subsidence monitored over a 24-year period using InSAR in southern Alsace, France. Int. J. Appl. Earth Observ. Geoinf. 102, 102392. https://doi.org/10.1016/j.jag.2021.102392 (2021).

Cui, X., Miao, X., Zhao, Y. & Jin, R. Discussion on the time function of time dependent surface movement. J. China Coal Soc. 05, 453–456 (1999).

Cigna, F. & Tapete, D. Urban growth and land subsidence: Multi-decadal investigation using human settlement data and satellite InSAR in Morelia, Mexico. Sci. Total Environ. 811, 152211. https://doi.org/10.1016/j.scitotenv.2021.152211 (2022).

Gong, Y. Q., Guo, G. L., Wang, L. P., Li, H. Z., Zhang, G. X. & Fang, Z. A data-intensive numerical modeling method for large-scale rock strata and its application in mining subsidence prediction. Rock Mech. Rock Eng. 1–17 (2022). https://doi.org/10.1007/s00603-021-02745-z

Yang, J., Liu, C. & Wang, B. BFGS method based inversion of parameters in probability integral model 537. J. China Coal Soc. 44(10), 3058–3068 (2019).

Wu, K., Cai, L. & Chen, R. Study of mining subsidence prediction with the influence of fault. J. Hunan Univ. Sci. Technol. (Nat. Sci. Ed.) 23(04), 10–13 (2008).

Alam, M. S., Kumar, D. & Chatterjee, R. S. Improving the capability of integrated DInSAR and PSI approach for better detection, monitoring, and analysis of land surface deformation in underground mining environment. Geocarto Int. 37(12), 3607–3641. https://doi.org/10.1080/10106049.2020.1864028 (2022).

Niraj, K. C., Gupta, S. K. & Shukla, D. P. Kotrupi landslide deformation study in non-urban area using DInSAR and MTInSAR techniques on Sentinel-1 SAR data. Adv. Space Res. 70(12), 3878–3891. https://doi.org/10.1016/j.asr.2021.11.042 (2022).

Acknowledgements

This work is supported by the Natural Science Foundation of China (Grant Numbers 52274164 and 52174102), the Anhui Province Key Research and Development Plan Project (Grant Numbers 2022m07020007).

Author information

Authors and Affiliations

Contributions

L.J. performed literature search, conducted all the experiments, and drafed the manuscript; L.Y.M. performed experiments and assisted in manuscript writing; G.Q.B. and M.X.R.performed the homology modeling and assisted in manuscript writing; W.L. critically reviewed and revised the manuscript; and Z.G.M. conceptualized the idea and critically analyzed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Luo, J., Li, Y., Guo, Q. et al. Research on the surface subsidence characteristics and prediction models caused by coal mining under the reverse fault. Sci Rep 14, 25316 (2024). https://doi.org/10.1038/s41598-024-75182-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-75182-x

Keywords

This article is cited by

-

Development and application of advanced learning models for predicting the land subsidence due to coal mining

Scientific Reports (2025)

-

Evolution mechanisms of mining-induced overlying strata structures: a case study in the Qinshui coalfield

Scientific Reports (2025)

-

Mining-Induced Subsidence Predicting and Monitoring: A Comprehensive Review of Methods and Technologies

Geotechnical and Geological Engineering (2025)