Abstract

Today, there is a significant concern in the industry regarding the disposal of wastewater containing dyes into the environment, so the management and appropriate disposal of these wastes in the environment are considerable. The main aim of this study is to assess the efficiency of activated carbon (AC) prepared from sesame shells to remove direct dyes from aqueous solutions. According to the results, AC prepared from sesame shell had a high specific surface area (525 m2/g) and porous structure. The results demonstrated that the adsorbent had high potential to remove direct dyes as 84.5% of direct brown 103 (DB103), 93.08% of direct red 80 (DR80), 93.37% of direct blue 21 (DB21) and 98.39% of direct blue 199 (DB199) under the optimal conditions of adsorbent dose 4.8 g/L, contact time 19 min, pH 3 and initial dye concentration 12 mg/L. The experimental results showed that kinetic data were best described by the pseudo-second-order model (R2 = 0.989) while isotherm data were best fitted by the Freundlich model (R2 = 0.994). In the present study, not only was the produced waste used as a useful and economically valuable material, but it was also applied as an effective adsorbent to remove direct dyes from industrial effluents and reduce environmental pollution.

Similar content being viewed by others

Introduction

Nowadays, some industries such as pulp manufacturing, cosmetics printing, plasticizing factories, petroleum products, pharmaceuticals, food processing industries, tanning and leather have a significant consumption of dye and water, therefore represent a potential source of colored wastewater production1,2,3,4. Dyes are classified into two groups of natural and synthetic. Synthetic dyes have three categories, including anionic, cationic, and non-ionic dyes5,6.

Actually, 17% of dye consumption refers to direct dyes in the textile industry related to the printing and dyeing of cotton, viscose, silk, wool and leather7. Direct dyes are in the group of anionic dyes. These dyes have one or more azo functional groups (N = N-) and are completely soluble in water. Discharge of direct dyes into water resources can cause damage to the ecosystem and is unpleasant aesthetically8,9,10,11. Furthermore, the nature of wastewater containing dye is characterized by its strong color, high concentration of organic matter, high amount of chemicals and auxiliaries, and poor biodegradability. Hence, it can cause pollution of water sources and affect human health12. Some of these adverse effects include skin sensitivity and irritation, cancer, genetic mutations, dysfunction of the kidneys, nausea, sweating, vomiting, confusion and headache13,14.

The use of common wastewater treatment methods to remove dyes is not effective due to their complex chemical structure and poor biodegradability15. Several physical, chemical and biological processes have been proposed to remove dyes from aquatic environments16. Some of these methods include membrane filtration, ozonation, advanced oxidation, reverse osmosis, coagulation and flocculation, ion exchange and adsorption17,18. Among these methods, adsorption has been considered due to its ease of operation, cost-effectiveness, no formation of by-products, insensitivity to toxic substances, fast process, high efficiency and high possibility of regenerating spent adsorbent19,20. One of the most common adsorbents used to remove various dyes and other pollutants is activated carbon (AC). Due to its high surface area, high porosity and low cost, this adsorbent is proposed for the removal of organic dyes from textile industry wastewater21,22.

Using expensive natural material such as coal or wood to prepare AC is not economical. AC made from agricultural residues or biomass and industrial wastes such as leaves, shells, seeds, and straw, due to its good chemical stability and ability to be used on a large scale, can be a suitable alternative to expensive adsorbents to adsorb different types of pollutants from aquatic media23. Recently, various types of agricultural waste such as straw (wheat and corn), plant peel (pistachio and almond), bamboo plant, rice shell, sawdust, fruit peel (orange peel, banana, coconut, kiwi and potato) and palm residues have been used to prepare AC24,25,26.

Sesame seed is an agricultural product that has been utilized in the confectionery, edible oil, cake and flour industries since ancient times. Various sesame processing industries are active in Yazd, Iran. Sesame seed processing produces a large volume of waste, especially in the peeling stage. These wastes are usually disposed of as useless solid waste in the environment, which in turn causes environmental pollution. Therefore, it is necessary to manage and, if possible, use these wastes optimally. The transformation of sesame waste into a cheap bio-adsorbent leads to economically valuable materials17. The sesame seeds processing industry is one of the most common industries in Yazd, and the waste of sesame shell created big problems for the environmental in terms of disposal and management. Therefore, the aim of the present study was to apply the waste sesame shell provided sesame seeds-processing companies from local factory, Yazd, Iran, and uses them to produce AC. In addition, the efficiency of AC produced from sesame shell was assessed to remove direct brown 103 (DB103) dye, which is one of the most conventional dyes used in the textile industry. According to the research, there is no literature that assesses AC prepared from sesame shell for direct dye removal from aqueous solution. Response surface methodology-Box-Behnken design (RSM-BBD) was applied to design experiments and optimize process parameters such as pH, contact time, initial dye concentration and adsorbent dose. Also, the kinetics, adsorption isotherm and thermodynamics of the dye adsorption process on the AC prepared from sesame shell were evaluated.

Materials and methods

Materials

Direct dyes were the products of BEZEMA, CHT, Germany. Sesame shells were obtained from a local sesame processing company in Yazd, Iran. Also, Na2SO4, NaCl, Na2HPO4, CaCl2, phosphoric acid (H3PO4), hydrochloric acid (HCl, 37%), and sodium hydroxide (NaOH) were purchased from Merck Company (Germany).

Synthesis of AC from sesame shell

At first, sesame shells were washed with distilled water for dust removal and dried at 100 °C for 24 h in the oven. Then, sesame shells were sieved through a 45 mesh to make the sesame shell particles uniform. Sesame shells were immersed in phosphoric acid with a weight ratio of 1:1 for the chemical activation, and then the samples were dried in an oven at 100 °C. The dried sesame shells obtained from the previous process were placed inside a muffle furnace (TEF1200-30–9 H and V, Aspeng co, Iran) under a flow of nitrogen gas for 2 h at a temperature of 500 °C to carbonize. The pyrolyzed sample was boiled in HCl solution for 20 min and washed several times with 0.1 M HCl solution and distilled water until to reached a neutral pH. At the end, samples were dried at 120 °C for 12 h27.

Characterization of the adsorbent

In order to determine the characteristics and morphology of AC, various methods were employed. Fourier transform-infrared (FTIR) spectroscopy (AVATAR, Thermo, USA) was applied to identify the functional groups of the adsorbent; a scanning electron microscope (SEM) (MIRA III, TESCAN, Czech Republic) was used to analyze the structure and chemical composition of the AC. Also, the Sear method was used to measure the specific surface area of the adsorbent28. 0.5 g AC and 10 g NaCl were poured into 50 ml of 0.1 M HCl. Then the solution was mixed with a magnetic stirrer. Titration of the resulting mixture was carried out in a water bath at 298 K by standard 0.1 M NaOH to pH 4, and then it was continued to pH 9. The specific surface area was calculated by the following equation:

where S (m2/g) and V (mL) are the specific surface area and the volume of NaOH required to raise the pH from 4 to 9, respectively.

Preparation of stock solution of Direct Brown 103

In this study, direct brown 103 (DB 103) dye was used to evaluate the efficiency of activated carbon prepared from sesame shell. For this purpose, a certain amount of dye powder was dissolved in distilled water and its stock solution was obtained. The stock solution was diluted to different concentrations for use in other steps of the experiments. The molecular formula of direct brown 103 (DB103) dye is C26H15ClN5Na3O13S3 and the molecular weight of the dye is 806.04 g/mol.

Adsorption experiments

The impact of independent variables including pH, contact time, initial dye concentration, adsorbent dose, ionic strength and reusability on DB103 dye adsorption was assessed.

The adsorption experiments of DB103 dye onto AC prepared from sesame shell was carried out under Box–Behnken design. Firstly, the adsorbent with a predetermined dose (1–5 g/L) was added to a 50 mL Erlenmeyer flask containing 25 mL of DB103 dye solution (5-100 mg/L). The pH of the dye solution was adjusted by NaOH (0.1 M) and HCl (0.1 M) in the range of 3–8. A shaker (Teif Azma Teb, TAT 2138, Iran) was employed to mix the solution at 200 rpm with a duration time between 2 and 30 min. The concentration of DB103 dye before and after adsorption was measured through the colorimetric method by UV-VIS spectrophotometer (HACH, DR 6000, USA) at 438 nm wavelength. The removal efficiency and the adsorption capacity of the DB103 dye were determined by Eqs. (2,3).

where, Co (mg/L) and Ce (mg/L) are the concentrations of the dye at initial and equilibrium, respectively.

where, V (L) is the volume of dye solution; and m (g) is the mass of AC29.

After determining the optimal conditions by the model, the effect of other variables such as temperature, competitor ion and reusability on the amount of dye adsorption was investigated. Also, the effectiveness of AC adsorbent prepared from sesame shell in removing other direct dyes was evaluated. Kinetics and isotherms of the adsorption process were studied at various times and concentrations.

Experimental design

The response surface methodology30 was used to design the experiments by Design-Expert software (version 7, trial, Stat-Ease). In this study, the effect of factors including the adsorbent dose (1–5 g/L), the initial DB103 dye concentration (5-100 mg/L), contact time (2–30 min) and pH (3–8) by Box-Behnken design, which is one of the standard RSM methods, was evaluated. The operational ranges and codes of each factor is presented in Table S1.

Mathematical model Eq. (4) demonstrates the optimum value and effect of each factor during the adsorption process of DB103 dye on AC prepared from sesame shell:

where, Y (%), β, and k are the calculated response value, the model coefficient constant and the number of independent factors, respectively. Xi and Xj are coded independent factor values. Bi, Bii and Bij are linear, quadratic, and interactive coefficient terms, respectively. ε is the value of the error random term. All four variables were optimized based on the Box-Behnken design. In addition, the data were analyzed by analysis of variance. The significance of expressions was determined by p-value assessment (p-value < 0.05).

Results and discussion

Characterization of the adsorbent

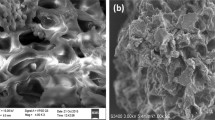

Activated carbon was prepared from sesame shell (Fig. 1. a and b) and its characteristics were investigated. SEM analysis was carried out to get information about the morphology and distribution of the main elements in the sesame shell and the prepared AC. By comparing the SEM images (Fig. 1. c and d), it is clear that the AC prepared from the sesame shell has a porous surface, which confirms the sesame shell was successfully activated by phosphoric acid. The atomic percentage of the C (65.88%) element in AC is higher than that of raw sesame shell (C = 55.17%), which demonstrated that the AC was successfully synthesized. The distribution of elements on the surface of AC and raw sesame shell was illustrated in Figs. 131,32. It clarifies that elements were homogeneously distributed on the adsorbent surface. The specific surface area of AC prepared from sesame shell was 525 m2/g, indicating the prepared natural adsorbent has a relatively high specific surface area and is useful for adsorbing DB103 dye molecules.

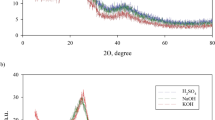

The functional groups on the surface of the adsorbent had been assessed by FTIR analysis. The identification of functional groups is based on the information given in Fig. 1 (i). The peak at 3431 cm− 1 and 3460 cm− 1 could be related to OH groups derived from interlayer crystal water. The peaks of 2918 cm− 1 and 2851 cm− 1 were associated with C-H stretching vibration. Peaks of 1653 cm− 1 and 1617 cm− 1 were connected to C = C vibrational stretching. Also, the stretching bands at 1435 cm− 1 and 1371 cm− 1 confirmed the C-O, O-H and C-H vibrations, respectively. The peak of 1054 cm− 1 was related to the OCH3 groups, which may be attributed to the lignin aromatic groups. The band around 1015 cm− 1 can be assigned to C-O-C groups. The stronger peak at 1576 cm− 1 was assigned to the C = C group, which it manifested sesame shell was activated favorably33,34.

Box-Behnken design

The adsorption experiments were designed based on the Box-Behnken model. At first, similar studies were reviewed, and then the variable ranges were determined by conducting experiments and preliminary studies35,36,37. In Table S2, 29 experiments were performed and the results of each were presented. The relationship between the actual and predicted response values for DB103 dye adsorption by the adsorbent is shown in Fig. 2(a). The accuracy of the model is desirable and guaranteed when the experimental results are very close to the values calculated by the model, which is well shown by the plot of the actual and predicted values. Figure 2(b) shows the normal probability of the residuals for DB103 dye removal efficiency. It clearly indicates that the error terms are normal, and the selected regression model was appropriate because the residual points are close to a straight line38.

Analysis of variance

In this study, analysis of variance was used to assess the significance of the model parameters. The ANOVA and multiple regression coefficients of the adsorption of DB103 dye are presented in Table 1. For each significant model term, the higher F-value and lower P-value were considered indexes of the models significance. The quadratic model was further confirmed by a p-value less than 0.0001 and F-value of 91.79. Also, the lack of fit F-value of 3.40 does not depend on pure error significantly, and the 12.50% chance of a lack of fit F-value cannot cause disruption. In other words, the value of lack of fit was not significant, and it would be admissible. R² value (0.9892) was larger than 0.90 which implies the high correlation of the model. The predicted R² value was 0.9427, and the adjusted R² was 0.9784. The difference between these two quantities is less than 0.2, hence, there is reasonable compatibility between the predicted and adjusted R² values. Adeq precision, measuring the signal-to-noise ratio, was 39.382, which illustrated that a ratio greater than 4 and it was an adequate signal.

Evaluation of regression coefficients was carried out by polynomial regression model. The regression model is presented as Eq. (5):

The synergistic and antagonistic effects were shown by positive and negative signs, respectively. Generally, contact time and adsorbent dose had a synergistic effect on DB103 dye adsorption, while pH and DB103 dye concentration had an adverse effect.

Interactive effect of parameters

The contact time plays a very important role in the adsorption process. The dye removal efficiency according to the changes in different variables is exhibited in Fig. 3, indicating that the adsorption of DB103 by AC prepared from raw sesame shell increased as the contact time (2–30 min) increased. This phenomenon may be related to the increased probability of DB103 dye molecules interacting with vacant sites on the surface of the adsorbent39. Baloo et al. evaluated the efficiency of AC produced from empty fruit bunches and mesocarp fibers of oil palm in methylene blue and acid orange 10 dye removal. Results indicated that the removal efficiency of the studied dyes increased with increasing contact time9. Also, Feng et al., in a similar study, concluded that the dye removal efficiency increases with rising time40. Another important controlling parameter in the adsorption process is the pH value of the solution.

As shown in Fig. 3 (a), (b), (c), the dye removal percentage decreased with increasing pH from 3 to 8. Two possible mechanisms for dye adsorption onto the adsorbent may be considered: (a) an electrostatic interaction between the adsorbent and the dye molecule, (b) a chemical reaction between the dye and the adsorbent. At pH 3, due to the acidity of the solution, the concentration of \(\:{\text{H}}^{+}\)ions increase, so the positive charge on the AC surface enhances. It should be noted that when the pH increases, the number of negatively charged sites on the surface of AC increases and the number of positively charged sites decreases, and due to electrostatic repulsion, it prevents the adsorption of negatively charged DB103 dye. The reason can be due to the existence of additional \(\:{\text{O}\text{H}}^{-}\:\)ions, which causes competition with anionic dyes for adsorption on the adsorbent surface41.

In the similar studies, Thinakaran et al. worked on removing acid red 114 as an anionic dye from wastewater using AC prepared from seeds shell. Results of experiments illustrated that dye adsorption at pH 3 had the highest removal efficiency34. Also, Amin et al. found that dye removal was more efficient at low pH42. Based on the findings shown in Fig. 3 (b), (d) and (e), the variation in removal efficiency is such that as the dye concentration rises from 10 to 100 mg/L, the efficiency of AC to remove DB103 dye decreases. It can be claimed that each adsorbent can adsorb a certain amount of dye after a specified time due to the occupation of the active sites of the adsorbent surface. With increasing the initial dye concentration, the available surface for adsorbing DB103 dye molecules is severely limited, and the dye removal declines33. The findings reported by Srinivasan et al.43 and Raji et al.44 show that the relationship between dye concentration and adsorption efficiency is inverse. Increasing the adsorbent dose from 1 to 5 g/L provides the active surfaces available for the adsorption of DB103 dye (Fig. 3 (a), (d) and (f)). It can be asserted that, despite the low contact time, a high adsorbent dosage has a notable effect on the dye removal efficiency45. Zayed et al. investigated removing methyl orange via AC which was synthesized by leaves of sugar beet. According to the experiments, the removal percentage of methyl orange increased from 76.9 to 98.5% with the rise in the studied adsorbent mass in the range of 20 to 30 g46. The results presented in a similar study conducted by Tahir et al.47 and Ramutshatsha-Makhwedzha et al.48 show that the percentage of pollutant removal enhanced with the raising of the adsorbent dose.

Optimization

Optimization reveals the optimal conditions of the factors of the adsorption system in order to achieve the highest removal efficiency in the design of the adsorption process. In this study, according to the statistical model, the optimal values of variables were adsorbent dose 4.8 g/L, contact time 19 min, initial dye concentration 12 mg/L and the pH 3. Under optimal conditions, the experimental DB103 dye removal efficiency of 84.85% was very close to the predicted value (84.4%), which indicates the validity of the selected model. Furthermore, by comparing the pollutant removal percentage results between AC and raw sesame shell, it can be concluded that AC had a better performance than raw sesame shell (32.32%) for adsorbing DB103 dye. Figure S1 illustrated the images of dye solution before and after DB103 dye adsorption on the AC in the optimal condition.

Adsorption kinetic studies

The kinetic models were used in order to investigate the variables that affect the adsorption and interaction between AC and DB103 dye molecules. The adsorption pathway of DB103 dye was studied using pseudo-first-order, pseudo-second-order and intra-particle diffusion kinetic models. The pseudo-first-order kinetic is presented by Eq. (6):

where, qe (mg/g) and qt (mg/g) are the amounts of dye adsorbed by AC at equilibrium and at time t, respectively. K1 (1/min) is the rate constant of the pseudo-first-order model. The pseudo-second order kinetic calculation is shown in the Eq. (7):

where, K2 (g/mg/min) is the pseudo-second-order rate constant, and other symbols have the same meaning as it is mentioned in pseudo-first-order equations. The intra-particle diffusion (IPD) model presented by Weber and Morris is as follows to identify the diffusion process38,49:

where, Kp and C are the IPD rate constant (mg/g, 1/min1/2) and the intercept (mg/g) respectively. Also, the results of kinetic constants are presented in Table 2.

Among the three presented models, the pseudo-second-order model can be applied to the entire adsorption process due to its high correlation coefficient (R2 = 0.989) and this model is better than the other two models to describe DB103 dye adsorption on the AC prepared from sesame shell. The control of the adsorption process is provided by chemical interactions in the pseudo-second-order model, due to its alignment with the kinetic parameters50 which means electron exchange occurred via involvement of valence force between the direct dye and AC48. In similar study by Hudaverdi et al. reported that adsorption of malachite green dye on the sesame shell follows pseudo-second-order kinetic model17.

Adsorption isotherm studies

The adsorption isotherm examines the adsorption mechanism at the active sites of the adsorbent surface, and its results provide useful information51. It shows how much pollutant has been removed by a unit of adsorbent mass (equilibrium state) and how much is left52. The Langmuir adsorption isotherm theory states that the adsorbent surface has a limited number of identical sites, and the adsorption of a solute from a liquid solution takes place as a monolayer adsorption. Several assumptions are considered in the Langmuir model, which include: (i) adsorption of pollutants in certain homogeneous places inside the adsorbent; (ii) adsorption of a dye molecule in one place on the surface of the adsorbent (iii); limitation of the capacity of the adsorbent to adsorption (at equilibrium) (iv); equal energy of all the adsorbent sites. The Langmuir isotherm model calculates the maximum adsorption capacity related to the complete monolayer coverage on the adsorbent surface because the adsorption phenomenon occurs when the energies are uniform on the surface and the transmigration of adsorbate does not take place in the plane of the surface41. The linear form of this model is presented as follows53:

where, Ce (mg/L) is DB103 dye equilibrium concentration, qe (mg/g) and qmax (mg/g) are the adsorption capacity at equilibrium conditions and the maximum DB103 dye adsorption, respectively. b is the Langmuir constant and is related to the affinity of the adsorption site. The hypothesis of dye adsorption on a heterogeneous surface is defined by the Freundlich isotherm model, and its linear form is shown below:

where, Kf is the adsorption capacity and 1/n is the adsorption intensity. Dubinin–Radushkevich model has also been used to estimate free energy and determine the properties of the adsorbent54. The linear form of this model is presented as follows53:

where, β (mol2/J2) is the isotherm constant and E (kJ/mol) is the free energy of adsorption, and the rest of the symbols are mentioned in the previous equation55.

According to the results shown in Table 3 and Figure S3, among the three isotherm models that were examined, the value of the correlation coefficient (R2 = 0.994) in the Freundlich isotherm model is higher than two other models. Hence, the adsorption of DB103 dye on the AC follows the Freundlich isotherm model, so it manifested that adsorption was multi-layered on the heterogeneous surface of the adsorbent39. Since the calculated value of n (Table 3) is in the range of 1 and 10, it proves that the adsorption phenomenon has been carried out ideally. Also, the lower value of 1/n (higher n), signifies that there are high energy sites on the surface of the AC and the interaction of the adsorbent is stronger. It should be considered that the closer value of 1/n to zero indicates that the adsorbent surface is more heterogeneous, while the higher value of 1/n indicates that the adsorbent surface is homogeneous and the pollutant is adsorbed as a monolayer56. The results presented in Table 3 show that the value of 1/n is 0.5, indicating heterogeneous adsorption of DB103 dye. Bao et al. found that the best isotherm model of anionic dye adsorption on AC prepared from pulping by products of rice straw was the Freundlich model57. The findings reported by Li et al.58 and Thabede et al.59 manifested that the Freundlich isotherm model better described the adsorption of congo red and methylene blue using activated carbon produced from walnut shell and black cumin seeds, respectively.

Thermodynamics studies

Thermodynamics describes the behavior of processes, or, in other words, the relationship between temperature and dye adsorption in the system. Gibbs free energy change (ΔG), enthalpy change (ΔH) and entropy change (ΔS) are the main thermodynamic parameters that are given in the following equations60,61:

where, T (K) is temperature, and KL(L/g) and R (8.314 J/mol K) are equilibrium and universal gas constants, respectively.

The effect of temperature on the DB103 dye removal efficiency on the AC was assessed (Figure S4a). The values of thermodynamic parameters were calculated from the plot of ln KL versus 1/T (Figure S4b) and the results are presented in Table 4. According to the information given in the Table 4, the negative value of ΔG indicates that the adsorption process is spontaneous. The values of ΔH and ΔS, in the temperature range of 298–328 K were 24.590 kJ/mol and 83.431 J/mol.k. So, the positive value of ΔH manifested that the adsorption mechanism with increasing temperature works better and the adsorption mechanism is endothermic. The positive value of ΔS indicates the phenomenon that the disorder of the solid/liquid interface is increased throughout the DB103 dye adsorption process62.

Mechanism of DB103 dye adsorption

In this study, two physical and chemical interactions have been suggested for the mechanism of DB103 dye adsorption from the aqueous solution. The porosity of the AC surface had a significant effect on the adsorption of the DB103 dye on the adsorbent and improved the physical adsorption. Also, the pH parameter has an important impact on the surface binding site of the adsorbent and the ionization of dye molecules. In other words, decreasing pH causes an increase in the hydrogen ions (H+) on the surface of the adsorbent, which leads to the protonation of functional groups on the adsorbent surface. Threfore, an electrostatic interaction between AC prepared from sesame shell and anionic DB103 dye occurs.

Effect of competing ions on DB103 removal

In this work, the effect of competing ions on the dye removal efficiency was examined by employing four salts, including Na2SO4, NaCl, Na2HPO4 and CaCl2, in the concentrations of 50, 100, 250, 500 and 1000 mg/L under optimal conditions. The data displayed in Fig. 4 indicates that the adsorption efficiency has increased by increasing the dose of salt in the solution. The reason for this phenomenon can be attributed to the increase in the dimerization of dyes by increasing the amount of salt in the solution. All the selected salts in the dye solution increase the number of intermolecular forces between dye molecules. Hence, it leads to an improvement in the dye adsorption process on the AC surface63.

Reusability

The study of the reuse of the adsorbent is important in terms of the potential for successive use of the adsorbent and its cost-effectiveness for use on a real scale47. The regeneration of the adsorbent includes the desorption of the dye adsorbed on the adsorbent and then washing after each cycle. For this purpose, a 0.1 M NaOH solution and distilled water were used64. Then, the rinsed AC was subjected to DB103 dye removal again. According to the results shown in Fig. 5, the adsorption efficiency decreased from 84.85 to 42.58% after four cycles. It was found that the AC prepared from sesame shell has good reusability to adsorb DB103 dye even after four consecutive cycles.

Comparison of ACs based on different sources for dye removal

Three dyes, including DR80, DB21 and DB199 dyes, have also been adsorbed by AC prepared from sesame shell (Table 5). The removal percentages of DR80, DB21 and DB199 dyes were 93.08, 93.37 and 98.39%, respectively. The results showed that the synthesized adsorbent had a high efficiency in removing different direct dyes. Furthermore, Table 5 shows the comparison of direct dye adsorption efficiency by different AC adsorbents. AC have been produced from various waste agriculture sources, like the shells of Macor fruit and the comparison of efficiency of them with AC produced from sesame shell clarified that the adsorbent in the present study had high efficiency, could provide a suitable adsorption surface and be applied as an efficient adsorbent in the removal of different dyes.

Conclusion

This study aimed to produce AC from sesame shells, which were waste from a sesame processing company. The optimal values of operational variables were achieved according to the Box-Behnken model, which were the adsorbent dose of 4.8 g/L, contact time of 19 min, pH of 3 and initial dye concentration of 12 mg/L. In this condition, the adsorption of DB103 was 84.5% and was close to the predicted value by the model. The analysis of the kinetic model illustrated that control of the adsorption process is provided by chemical interactions in the pseudo-second-order model. The adsorption phenomenon was endothermic and spontaneous. The Freundlich isotherm model was the best fit for the adsorption process. Reusability of the adsorbent was investigated in four cycles, which showed that AC is cost-effective to apply on a large scale. Besides, the efficiency of AC prepared from sesame shell was evaluated to remove other direct dyes such as DR80, DB21 and DB199 and confirmed high removal percentages of different direct dyes. Overall, AC prepared from sesame shell, due to its environmental compatibility, having potential for high percentage removal of direct dyes, availability and reusibility is a suitable suggestion for the treatment of textile wastewater.

Data availability

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

References

Wang, H. et al. Effective adsorption of dyes on an activated carbon prepared from carboxymethyl cellulose: experiments, characterization and advanced modelling. Chem. Eng. J. 417, 128116. https://doi.org/10.1016/j.cej.2020 (2021).

Banerjee, S. & Chattopadhyaya, M. Adsorption characteristics for the removal of a toxic dye, tartrazine from aqueous solutions by a low cost agricultural by-product. Arab. J. Chem. 10, 1629–1638 (2017).

Archin, S., Sharifi, S. H. & Asadpour, G. Optimization and modeling of simultaneous ultrasound-assisted adsorption of binary dyes using activated carbon from tobacco residues: response surface methodology. J. Clean. Prod. 239, 118136. https://doi.org/10.1016/j.jclepro.2019.118136 (2019).

Djilani, C. et al. Adsorption of dyes on activated carbon prepared from apricot stones and commercial activated carbon. J. Taiwan. Inst. Chem. Eng. 53, 112–121 (2015).

Prajapati, A. K. & Mondal, M. K. Comprehensive kinetic and mass transfer modeling for methylene blue dye adsorption onto CuO nanoparticles loaded on nanoporous activated carbon prepared from waste coconut shell. J. Mol. Liq. 307, 112949. https://doi.org/10.1016/j.molliq.2020.112949 (2020).

Huang, Z. et al. Modified bentonite adsorption of organic pollutants of dye wastewater. Mater. Chem. Phys. 202, 266–276 (2017).

Irshad, S. et al. Solubilization of direct dyes in single and mixed surfactant system: a comparative study. J. Mol. Liq. 321, 114201. https://doi.org/10.1016/j.molliq.2020.114201 (2021).

Jawad, A. H. et al. High surface area and mesoporous activated carbon from KOH-activated dragon fruit peels for methylene blue dye adsorption: optimization and mechanism study. Chin. J. Chem. Eng. 32, 281–290 (2021).

Baloo, L. et al. Adsorptive removal of methylene blue and acid orange 10 dyes from aqueous solutions using oil palm wastes-derived activated carbons. Alex Eng. J. 60, 5611–5629 (2021).

He, X., Du, M., Li, H. & Zhou, T. Removal of direct dyes from aqueous solution by oxidized starch cross-linked chitosan/silica hybrid membrane. Int. J. Biol. Macromol. 82, 174–181 (2016).

Dalvand, A. et al. Application of chemical coagulation process for direct dye removal from textile wastewater. J. Environ. Health Sustain. Dev. 2, 333–339 (2017).

Kuang, Y., Zhang, X. & Zhou, S. Adsorption of methylene blue in water onto activated carbon by surfactant modification. Water. 12, 587 (2020).

Kadhom, M., Albayati, N., Alalwan, H. & Al-Furaiji, M. Removal of dyes by agricultural waste. Sustain. Chem. Pharm. 16, 100259. https://doi.org/10.1016/j.scp.2020.100259 (2020).

Xiao, W. et al. Preparation and evaluation of an effective activated carbon from white sugar for the adsorption of rhodamine B dye. J. Clean. Prod. 253, 119989. https://doi.org/10.1016/j.jclepro.2020.119989 (2020).

Naushad, M. et al. Adsorption kinetics, isotherm and reusability studies for the removal of cationic dye from aqueous medium using arginine modified activated carbon. J. Mol. Liq. 293, 111442. https://doi.org/10.1016/j.molliq.2019.111442 (2019).

Lafi, R., Montasser, I. & Hafiane, A. Adsorption of Congo red dye from aqueous solutions by prepared activated carbon with oxygen-containing functional groups and its regeneration. Adsorp Sci. Technol. 37, 160–181 (2019).

Arslan, H. & Alkan, E. Investigation the removal of malachite green dye from aqueous solution by using sesame shell. Int. J. Environ. Trends. 5, 79–99 (2021).

Nizam, N. U. M., Hanafiah, M. M., Mahmoudi, E., Halim, A. A. & Mohammad, A. W. The removal of anionic and cationic dyes from an aqueous solution using biomass-based activated carbon. Sci. Rep. 11, 1–17 (2021).

Patra, C., Gupta, R., Bedadeep, D. & Narayanasamy, S. Surface treated acid-activated carbon for adsorption of anionic azo dyes from single and binary adsorptive systems: a detail insight. Environ. Pollut. 266, 115102. https://doi.org/10.1016/j.envpol.2020.115102 (2020).

Achour, Y. et al. Insight into adsorption mechanism of Congo red dye onto Bombax Buonopozense bark activated-carbon using Central composite design and DFT studies. Surf. Interfaces. 23, 100977. https://doi.org/10.1016/j.surfin.2021.100977 (2021).

Hasanzadeh, M., Simchi, A. & Far, H. S. Nanoporous composites of activated carbon-metal organic frameworks for organic dye adsorption: synthesis, adsorption mechanism and kinetics studies. J. Ind. Eng. Chem. 81, 405–414 (2020).

Gupta, V. K., Agarwal, S., Ahmad, R., Mirza, A. & Mittal, J. Sequestration of toxic Congo red dye from aqueous solution using ecofriendly guar gum/activated carbon nanocomposite. Int. J. Biol. Macromol. 158, 1310–1318 (2020).

Chiang, C-H., Chen, J. & Lin, J-H. Preparation of pore-size tunable activated carbon derived from waste coffee grounds for high adsorption capacities of organic dyes. J. Environ. Chem. Eng. 8, 103929. https://doi.org/10.1016/j.jece.2020.103929 (2020).

Wang, Q. et al. Honeycomb-like activated carbon with microporous nanosheets structure prepared from waste biomass cork for highly efficient dye wastewater treatment. J. Hazard. Mater. 416, 125896. https://doi.org/10.1016/j.jhazmat.2021.125896 (2021).

Ferreira, G. M. D. et al. Adsorption of red azo dyes on multi-walled carbon nanotubes and activated carbon: a thermodynamic study. Colloids Surf. Physicochem Eng. Asp. 529, 531–540 (2017).

Han, Q., Wang, J., Goodman, B. A., Xie, J. & Liu, Z. High adsorption of methylene blue by activated carbon prepared from phosphoric acid treated eucalyptus residue. Powder Technol. 366, 239–248 (2020).

Hosseinzehi, M., Ehrampoush, M. H., Tamaddon, F., Mokhtari, M. & Dalvand, A. Eco-environmental preparation of magnetic activated carbon modified with 3-aminopropyltrimethoxysilane (APTMS) from sawdust waste as a novel efficient adsorbent for humic acid removal: Characterisation, modelling, optimisation and equilibrium studies. I Int. J. Environ. Anal. Chem. 1–21 (2021).

Mahvi, A. H. & Dalvand, A. Kinetic and equilibrium studies on the adsorption of Direct Red 23 dye from aqueous solution using montmorillonite nanoclay. Water Qual. Res. J. 55, 132–144 (2020).

Karami, M. A., Darvish Motevalli, M., Hyedarimanesh, Z. & Kamarehie, B. Effectiveness of Derived Oka activated Carbon coated with magnesium oxide in removal of Bromocresol Green. Isotherms Kinetics. 14, 42–51 (2019).

Ragnebro, O. et al. Chloroform exposure in air and water in Swedish indoor swimming pools—urine as a biomarker of occupational exposure. Ann. Work Expo Health. 67, 876–885 (2023).

Kim, S-H. & Choi, P-P. Enhanced Congo red dye removal from aqueous solutions using iron nanoparticles: adsorption, kinetics, and equilibrium studies. Dalton Trans. 46, 15470–15479 (2017).

Espinoza-Montero, P. J., Alulema-Pullupaxi, P., Frontana-Uribe, B. A. & Barrera-Diaz, C. E. Electrochemical production of hydrogen peroxide on Boron-Doped diamond (BDD) electrode. Curr. Opin. Solid State Mater. Sci. 26, 100988. https://doi.org/10.1016/j.cossms.2022.100988 (2022).

Ofgea, N. M., Tura, A. M. & Fanta, G. M. Activated carbon from H3PO4-activated Moringa stenopetale seed husk for removal of methylene blue: optimization using the response surface method (RSM). Environ. Sustain. Indic. 16, 100214. https://doi.org/10.1016/j.indic.2022.100214 (2022).

Thinakaran, N., Panneerselvam, P., Baskaralingam, P., Elango, D. & Sivanesan, S. Equilibrium and kinetic studies on the removal of Acid Red 114 from aqueous solutions using activated carbons prepared from seed shells. J. Hazard. Mater. 158, 142–150 (2008).

Boumyaa, W. et al. Box–Behnken design for understanding of adsorption behaviors of cationic and anionic dyes by activated carbon. Molecules. 15, 17–19 (2021).

Azeez, S. et al. Box Behnken Design in the optimization of rhodamine B adsorption onto activated Carbon prepared from Delonix regia seeds and pods. J. Turk. Chem. Soc. A: Chem. 9, 209–226 (2022).

Azeez, S. O. et al. Optimization by Box Behnken design for eosin yellow dye removal from aqueous medium using date palm seeds-porous carbon@ TiO2 blend. J. Niger. Soc. Phys. Sci. 183 – 92 (2022).

Pormazar, S. M. & Dalvand, A. Adsorption of reactive black 5 azo dye from aqueous solution by using amine-functioned Fe3O4 nanoparticles with L-arginine: process optimisation using RSM. Int. J. Environ. Anal. Chem. 102, 1764–1783 (2022).

Ciğeroğlu, Z. et al. Remediation of tetracycline from aqueous solution through adsorption on g-C3N4-ZnO-BaTiO3 nanocomposite: optimization, modeling, and theoretical calculation. J. Mol. Liq. 369, 120866. https://doi.org/10.1016/j.molliq.2022.120866 (2023).

Feng, Y. et al. Basic dye adsorption onto an agro-based waste material–Sesame hull (Sesamum indicum L). Bioresource Technol. 102, 10280–10285 (2011).

Khaled, A., El Nemr, A., El-Sikaily, A. & Abdelwahab, O. Removal of Direct N Blue-106 from artificial textile dye effluent using activated carbon from orange peel: adsorption isotherm and kinetic studies. J. Hazard. Mater. 165, 100–110 (2009).

Amin, N. K. Removal of direct blue-106 dye from aqueous solution using new activated carbons developed from pomegranate peel: adsorption equilibrium and kinetics. J. Hazard. Mater. 165, 52–62 (2009).

Srinivasan, P., Bosco, A. J., Kalaivizhi, R., Selvi, J. A. & Sivakumar, P. Adsorption isotherm and kinetic study of direct Orange 102 dyes on TNJ activated carbon. Mater. Today Proc. 34, 389–394 (2021).

Raji, Y. et al. High adsorption capacities of crystal violet dye by low-cost activated carbon prepared from Moroccan Moringa oleifera wastes: characterization, adsorption and mechanism study. Diam. Relat. Mater. 135, 109834. https://doi.org/10.1016/j.diamond.2023.109834 (2023).

Mahmoodi, N. M., Taghizadeh, M. & Taghizadeh, A. Activated carbon/metal-organic framework composite as a bio-based novel green adsorbent: Preparation and mathematical pollutant removal modeling. J. Mol. Liq. 277, 310–322 (2019).

Zayed, A. M. et al. Facile synthesis of eco-friendly activated carbon from leaves of sugar beet waste as a superior nonconventional adsorbent for anionic and cationic dyes from aqueous solutions. Arab. J. Chem. 16, 104900 (2023).

Tahir, M. A., Bhatti, H. N. & Iqbal, M. Solar Red and Brittle Blue direct dyes adsorption onto Eucalyptus Angophoroides bark: equilibrium, kinetics and thermodynamic studies. J. Environ. Chem. Eng. 4, 2431–2439 (2016).

Ramutshatsha-Makhwedzha, D., Mavhungu, A., Moropeng, M. L. & Mbaya, R. Activated carbon derived from waste orange and lemon peels for the adsorption of methyl orange and methylene blue dyes from wastewater. Heliyon. 8, 09930. https://doi.org/10.1016/j.heliyon.2022.e09930 (2022).

Arni, L. A. et al. Design of separable magnetic chitosan grafted-benzaldehyde for azo dye removal via a response surface methodology: characterization and adsorption mechanism. Int. J. Biol. Macromol. 125086 (2023).

Roy, H., Prantika, T. R., Riyad, M., Paul, S. & Islam, M. S. Synthesis, characterizations, and RSM analysis of Citrus macroptera peel derived biochar for textile dye treatment. S Afr. J. Chem. Eng. 41, 129–139 (2022).

Jawad, A. H., Abd Malek, N. N., Khadiran, T., ALOthman, Z. A. & Yaseen, Z. M. Mesoporous high-surface-area activated carbon from biomass waste via microwave-assisted-H3PO4 activation for methylene blue dye adsorption: an optimized process. Diam. Relat. Mater. 128, 109288. https://doi.org/10.1016/j.diamond.2022.109288 (2022).

Onu, C. E. et al. Decolourization of bromocresol green dye solution by acid functionalized rice husk: artificial intelligence modeling, GA optimization, and adsorption studies. J. Hazard. Mater. Adv. 9, 100224. https://doi.org/10.1016/j.hazadv.2022.100224 (2023).

Pormazar, S. M. & Dalvand, A. Adsorption of Direct Red 23 dye from aqueous solution by means of modified montmorillonite nanoclay as a superadsorbent: mechanism, kinetic and isotherm studies. Korean J. Chem. Eng. 37, 2192–2201 (2020).

Nekouei, F., Nekouei, S., Tyagi, I. & Gupta, V. K. Kinetic, thermodynamic and isotherm studies for acid blue 129 removal from liquids using copper oxide nanoparticle-modified activated carbon as a novel adsorbent. J. Mol. Liq. 201, 124–133 (2015).

Dehghan Banadaki, M., Dalvand, A., Pormazar, S. M., Teimouri, F. & Shiri-Yekta, Z. Feasibility and recyclability study of magnetic activated carbon derived from palm tree fibres (AC/Fe3O4) in thorium (IV) removal from aqueous solution. Int. J. Environ. Anal. Chem. 1–18 (2024).

Putranto, A. et al. Effects of pyrolysis temperature and impregnation ratio on adsorption kinetics and isotherm of methylene blue on corn cobs activated carbons. S Afr. J. Chem. Eng. 42, 91–97 (2022).

Bao, Z., Lotfy, V. F., Zhou, X., Fu, S. & Basta, A. H. Assessment of porous carbon from rice straw residues with potassium ferrate-assisted activation as cationic and anionic dye adsorbents. Ind. Crops Prod. 212, 118298 (2024).

Li, Z. et al. Adsorption of Congo red and methylene blue dyes on an ashitaba waste and a walnut shell-based activated carbon from aqueous solutions: experiments, characterization and physical interpretations. Chem. Eng. J. 388, 124263. https://doi.org/10.1016/j.cej.2020.124263 (2020).

Thabede, P. M., Shooto, N. D. & Naidoo, E. B. Removal of methylene blue dye and lead ions from aqueous solution using activated carbon from black cumin seeds. S Afr. J. Chem. Eng. 33, 39–50 (2020).

Pormazar, S. M. et al. Application of amine-functioned Fe3O4 nanoparticles with HPEI for effective humic acid removal from aqueous solution: modeling and optimization. Korean. J. Chem. Eng. 37, 93–104 (2020).

Boulahbal, M. et al. Removal of the industrial azo dye crystal violet using a natural clay: Characterization, kinetic modeling, and RSM optimization. Chemosphere 306, 135516. https://doi.org/10.1016/j.chemosphere.2022.135516 (2022).

Elias, K. D., Ejidike, I. P., Mtunzi, F. M. & Pakade, V. E. Endocrine Disruptors-(estrone and β-estradiol) removal from water by Nutshell activated carbon: Kinetic, Isotherms and Thermodynamic studies. Chem. Thermodyn. Therm. Anal. 3, 100013. https://doi.org/10.1016/j.ctta.2021.100013 (2021).

Al-Degs, Y. S., El-Barghouthi, M. I., El-Sheikh, A. H. & Walker, G. M. Effect of solution pH, ionic strength, and temperature on adsorption behavior of reactive dyes on activated carbon. Dyes. Pigm. 77, 16–23 (2008).

Pormazar, S. M., Ehrampoush, M. H. & Dalvand, A. Removal of humic acid from aqueous solution by Fe3O4@L-arginine magnetic nanoparticle: kinetic and equilibrium studies. Int. J. Environ. Anal. Chem. 102, 3286–3301 (2022).

Aboua, K. N., Yobouet, Y. A., Yao, K. B., Gone, D. L. & Trokourey, A. Investigation of dye adsorption onto activated carbon from the shells of Macoré fruit. J. Environ. Manage. 156, 10–14 (2015).

Malik, P. Dye removal from wastewater using activated carbon developed from sawdust: adsorption equilibrium and kinetics. J. Hazard. Mater. 113, 81–88 (2004).

Acknowledgements

This study was financially supported by Shahid Sadoughi University of Medical Sciences (Grant no: 13947).

Author information

Authors and Affiliations

Contributions

S.S: Investigation, Methodology, Resources; S.MP: Methodology, Software, Formal analysis, Writing – original draft; M.T.G and M.HE: Data curation and validation; A. D: Supervision, Methodology, Data curation, Validation, Writing – review & editing, Funding acquisition.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sadeghy, S., Pormazar, S.M., Ghaneian, M.T. et al. Modeling and optimization of direct dyes removal from aqueous solutions using activated carbon produced from sesame shell waste. Sci Rep 14, 24867 (2024). https://doi.org/10.1038/s41598-024-76081-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-76081-x

Keywords

This article is cited by

-

Recent advances in polymer nanocomposites for the adsorptive removal of toxic azo dyes from water

Discover Water (2025)

-

Comparing Carbon Footprint and Environmental Impact of Local and Imported Raw Materials in Black Tea Latte and Sesame Ice Cream Production Using Life Cycle Assessment: A Case Study in Taiwan

Food and Bioprocess Technology (2025)

-

Preparation of activated carbon from Ziziphus jujuba stones by H3PO4-assisted thermo-chemical activation: application in the removal of anionic diazo dye from synthetic water

Biomass Conversion and Biorefinery (2025)

-

Empirical Modelling based Optimization of Azo-dye Adsorption by Polyurethane Sponge Containing Sodium Alginate-TiO2-NPs for Small Scale Industry

Water, Air, & Soil Pollution (2025)