Abstract

The CO2 displacement of coal seam gas can simultaneously promote gas extraction and CO2 sequestration, with gas injection pressure being a key factor influencing both efficiency and safety. This study examined the impact of varying CO2 injection pressure on gas extraction and sequestration. The findings indicated that higher CO2 injection pressures reduced the gas injection and extraction time costs, increased the equilibrium pressure and coal seam temperature, and decreased carbon sequestration efficiency. As the CO2 injection pressure increased, the CH4 cumulative desorption capacity and desorption rate rose by 4.98%, the time to reach the residual gas content critical value (TLV of 2 m3/t) shortened by 62.04 min, and the maximum CO2 storage per unit mass of coal increases by 3.6 m3/t. Increasing the injection pressure enhanced gas desorption and CO2 sequestration. A higher CO2 injection pressure resulted in a higher CH4 yield rate and a reduced CO2 injection rate in the later stages. Therefore, it is advisable to reduce the CO2 injection pressure during the low efficiency desorption stage.

Similar content being viewed by others

Introduction

In China, over 40% of coal seams are high gas, and more than 95% of mines have low permeability1, which significantly increases the risk of gas accidents, such as coal and gas outbursts and explosions during coal mining, posing serious threats to mine safety2,3,4. Between 2015 and 2022, 152 coal mine gas accidents resulted in 757 deaths5. Additionally, the emission and leakage of mine gas during coal production are major contributors to anthropogenic CH4 emissions in the atmosphere. The scale of atmospheric emission of coal mine gas reaches billions of tons of CO2 equivalent in China6,7. As a conventional method for controlling coal mine gas, gas extraction can effectively reduce coal seam gas pressure, gas content, and methane emissions, making it crucial for preventing gas disasters and ensuring safe production. However, the complexity of the coal seam structure in China, with most outburst seams being low-permeability8,9,10 and having permeability coefficients often below 0.1 m2/(MPa2·d), makes it difficult to achieve effective pre-drainage only through extraction boreholes or adjustments to borehole layout and parameters. To enhance the permeability and promote gas extraction in low-permeability coal seams, scholars have explored various measures, including deep-hole blasting11,12,13 and hydraulic techniques14. Although these methods have improved gas extraction rates to some extent, they have notable drawbacks. For instance, deep-hole blasting poses the risk of triggering coal and gas outbursts and hydraulic methods consume significant amounts of water and may cause a “water lock effect”15.

Inspired by “gas drive oil” technology in the oil industry, the United States conducted the first CO2- enhanced coalbed methane (CO2-ECBM) field test in the San Juan Basin in 1995, resulting in a 1.5-fold increase in enhanced coalbed methane (CBM) production and a recovery rate of 95%16. Since then, CO2-ECBM tests have been performed in Canada, the European Union17, Japan18, Poland19,20, India21, and China22, confirming the technical and economic feasibility of using CO2 injection to displace coalbed methane. Extensive studies have been carried out in the field of CO2-ECBM, including the injection of gas-phase CO223,24,25, supercritical CO226,27,28, and liquid CO2 into coal seams29,30,31. For coal seams, the burial depth is generally shallow, the bottom pressure is low, and the injection condition of the well head is difficult to achieve the injection of supercritical CO2, so it is generally injected in the form of liquid CO219,20. After the liquid CO2 is injected into the coal seam, the CO2 phase state is transformed under the action of cold shock and phase change pressure, and finally migrates in the coal seam in the form of gas-phase CO2. Therefore, the study of gas-phase CO2-ECBM project is of great significance to explain the mechanism of CO2 flooding of coal seam gas.

For the study of the gas-phase CO2-ECBM project, including experiments and simulations. Bai et al32,33. suggested that compared to natural desorption, CO2-ECBM increased the final CH4 desorption rate by 12.43%, with a higher CO2 injection pressure enhancing the CH4 diffusion coefficient and reducing the diffusion equilibrium time. Zhang et al.34 observed that increasing the CO2 injection pressure from 1.0 to 1.6 MPa decreased the CO2 sequestration efficiency from 67.89 to 43.98%. Zhang et al.35 demonstrated that the methane displacement efficiency of CO2 injection exceeded 90%, with the complete methane displacement from coal samples at high injection pressures above 8 MPa. Niu et al.36 discovered that increasing the CO2 saturation pressure, extending the CO2 saturation time, and increasing the water content contributed to coal softening. It has been widely confirmed that a higher CO2 injection pressure can enhance CH4 production37,38,39. Researchers have analyzed this mechanism through simulations. Li et al.40 established a hydraulic-mechanical-thermal coupling numerical model considering gas flow, competitive adsorption, temperature, and coal deformation, showing that the output increases with injection pressure. Perera et al.41 using the COMET 3 reservoir simulator concluded that the CO2 injection pressure could play a more significant role than lowering the CO2 injection temperature in CO2-ECBM projects. Hou et al.42 suggested that a higher CO2 injection pressure accelerates gas seepage velocity, leading to increased CO2 storage and CH4 production. Liu et al.43 reported that increasing the CO2 injection pressure expanded the range of CO2 in coal reservoirs and reduced the time needed for CO2 to displace CH4. Fan et al.44 demonstrated that a higher CO2 injection pressure enhanced the fluid migration rate within the reservoir. Liu et al.45 further showed that when the CO2 injection rate was below 10 t/d and the injection time did not exceed 8000 d, the impact on ground safety was minimal. After CO2 injection, the CH4 adsorption capacity significantly decreased, leading to a notable increase in the CH4 yield46,47.

The above analyses indicate that the CO2 injection pressure can be a critical factor in determining the effectiveness of gas extraction (mining), whether through surface gas injection to increase coalbed methane or underground gas injection to enhance the gas extraction. However, research on how the CO2 injection pressure affects coal seam parameters during extraction remains incomplete. To address this, we utilized a self-developed multiparameter synchronous test system to investigate the changes in gas concentration, pore pressure, coal seam temperature, CO2 injection rate, gas desorption rate, and CO2 storage capacity at gas-phase CO2 injection pressures of 0.6, 0.8, and 1.0 MPa. This study analyzed the impact of CO2 injection pressure on gas extraction and CO2 storage efficiency and examined the characteristics and injectability of synergistic CO2 storage. These findings could be crucial for advancing the understanding and application of CO2-ECBM technology.

Experimental methodology

Sample collection and preparation

Coal samples were collected from the contact lane #13,122 of the Zhao Zhuang coal mine in the #3 coal seam, located in the southeast of the Qinshui Basin, China (Fig. 1). The investigations revealed a gas content of 14–18 m3/t and an original gas pressure of 0.44–0.47 MPa in this coal seam, with a moisture content ranging from 0.8 to 7.5% at a depth of 690 m. After collection, vacuum-sealed samples were transported to the laboratory for testing. An experimental coal sample measuring Φ210 × 330 mm was prepared by layered compaction of 60–80 mesh pulverized coal, as detailed in previous studies32,33,48. Two samples were selected for proximate analysis and adsorption constant tests, and the results are shown in Table 1.

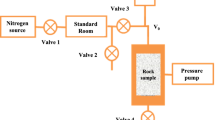

Experimental apparatus

Experiments were conducted using a self-developed CO2-displacement CH4 multiparameter dynamic test system. Different CO2 injection pressures are controlled by pressure reducing valves. The outlet pressure is controlled at 0.104 MPa by the back pressure valve. The mass flow meter is set after the back pressure valve to measure the desorption amount of CH4 directly. The coal sample tank is wrapped with heating belt, and the temperature control device keeps the temperature of the coal body constant. The coal sample tank is 210 mm in diameter and 400 mm in height. The detailed experimental procedure for CH4 desorption metering has been described in detail in previous articles32,33. Figure 2 shows the schematic of the experimental setup used in this study.

Experimental design and procedures

The test followed these steps, which were essentially the same as those described in a previous study. For a comprehensive description of the procedures, please refer to32 and33.

-

(1)

Stratified compaction of the coal samples. The crushed 60–80 mesh coal sample was placed in a coal sample tank, where axial pressure was applied using an electro-hydraulic servo testing machine, with the pressure controlled at 315 kN. During the application of the axial stress, three pressure and temperature sensors pre-embedded at 8, 18, and 28 cm from the gas injection port were used to monitor the pressure and temperature.

-

(2)

Sealing inspection. The system temperature was maintained at 30 °C, and helium gas was supplied at a specific pressure to verify the tightness of the circuit and the coal sample tank.

-

(3)

Vacuum. The coal sample tank was connected to a vacuum pump. Vacuuming was considered complete when the absolute pressure on the three pressure gauges on the side of the tank reached 0.004 MPa and remained stable at this level for 3 h. Typically, the vacuuming process lasted for 12 h.

-

(4)

CH4 adsorption saturation. The high-pressure cylinder was opened, and the output pressure of the pressure-reducing valve was set to 0.448 MPa. The volume of CH4 in the coal sample tank was measured using a CH4 mass-flow meter. When the three lateral pressures in the cylinder stabilized at 0.448 MPa for 4 h, indicating that adsorption was balanced, CH4 adsorption was saturated, and the high-pressure cylinder valve was closed. Typically, the saturation time for CH4 adsorption was 24 h.

-

(5)

Injection of CO2 gas. The CO2 high-pressure cylinder was opened, and the output pressure of the pressure-reducing valve was adjusted to 0.60 MPa. The CO2 volume in the coal sample tank was measured using a CO2 intake mass flow meter. During the displacement test, the CO2 intake valve was opened, and the outlet of the coal sample tank was connected to the atmosphere with a constant absolute pressure of 0.104 MPa. The computer recorded the dynamic test data in real time, including pore pressure, gas component concentration, coal body temperature, instantaneous flow rate from the mass flow meter, and cumulative amount. The test was concluded when the CH4 concentration at the outlet fell below 1% and the instantaneous flow rate was less than 20 mL/min, at which point both the CO2 inlet and outlet valves were closed and gas injection ceased. The experimental process is illustrated in Fig. 3, and the experimental conditions are listed in Table 2.

Results and discussion

Variation of outlet gas concentration

The volume fractions of CH4 and CO2 at the outlet varied with the CO2 injection time under different CO2 injection pressures (Fig. 4).

Figure 4 demonstrates that after CO2 injection into the gas-containing coal, the volume fraction of CH4 decreased and the volume fraction of CO2 increased with longer injection time, exhibiting a three-stage change characteristic at different CO2 injection pressures. The CO2 volume fraction changed inversely. In Stage I, the volume fraction of CH4 in the outlet mixed gas remained at 100% without CO2. The injected CO2 was retained in the coal body as free and adsorbed CO2. In Stage II, as the CO2 injection volume increased, CH4 continuously desorbed, diffused, and flowed out of the chamber. Once the volume of injected CO2 reached saturation, excess CO2 flowed out of the coal body, with a sharp decrease in the CH4 volume fraction and a sharp increase in the CO2 volume fraction in the outlet mixed gas. In stage III, The volume fraction of CH4 in the exit gas mixture is close to 0%, and the CO2 in the exit gas mixture is close to 100%.The CO2 export exhibited a notable lag, referred to as the CO2 breakthrough time, which varied with CO2 injection pressure. As the injection pressure increased from 0.6 to 0.8 and 1.0 MPa, the CO2 breakthrough time decreased from 83.40 to 77.83 and 68.10 min, respectively. Concurrently, the outlet methane concentration decreased from 30.58 to 21.46% and then to 0.414% after 122 min of displacement. Thus, a higher CO2 injection pressure was observed with earlier CO2 breakthrough. This was primarily because increasing the gas injection pressure while keeping the original gas pressure of the reservoir unchanged effectively increased the pressure gradient between the gas injection well and the coal seam. This resulted in a higher flow rate of carbon dioxide and a reduced CO2 breakthrough time. Once CO2 breakthrough occurred, it indicated the formation of a circulation channel between the inlet and outlet, thereby reducing the displacement effect. At the injection pressure of 0.6 MPa, it spent 186.14 min for the CH4 concentration to decrease from 100 to 0.4%. At 0.8 MPa, this reduction cost 159.30 min, and at 1.0 MPa, it took 122 min. Thus, higher CO2 injection pressures led to lower extraction time costs.

With the increasing application of gas as a renewable energy source and China’s focus on greenhouse gas emissions, stepped utilization of coal mine gas has been developed. According to the “Coal Mine Safety Regulations”, gases with a concentration of less than 30% cannot be directly burned. Simultaneously, the influence of the CO2 injection pressure on the gas injection time was analyzed according to the varying requirements for the CH4 concentration in the gas generator sets. This analysis involved comparing the effects of CO2 injection pressure on gas injection time for two different scenarios: 30% high-concentration gas used for industrial and civil fuels and 6% concentration for internal combustion engine power generation, with methane volume fractions ranging from 6 to 30% (Table 3). At the gas injection pressures of 0.6, 0.8, and 1.0 MPa, the time required to achieve the CH4 concentration of 30% were 122.32, 111.54, and 92.29 min, respectively, and for the CH4 concentration of 6%, the time included 155.72, 143.87, and 114.48 min, respectively. In summary, higher gas injection pressures resulted in shorter CO2 breakthrough time and reduced the durations to achieve both civil CH4 concentrations and internal combustion engine CH4 concentrations, thereby effectively reducing the gas injection costs.

Variation of coal seam pore pressure

Figure 5 illustrates the variation in pore pressure with time at distances of 8, 18, and 28 cm from the injection port under different CO2 injection pressures. Figure 6 presents the partial pressure changes in CH4 and CO2 at a distance of 18 cm from the injection port at various CO2 injection pressures.

Figure 5 shows that after CO2 injection, the pore pressure in the coal was lower than that after CO2 gas injection. This was because CO2 first filled the free space in the coal and was then adsorbed onto the coal matrix. For the same CO2 injection pressure, the pore pressure changes were consistent across different monitoring points. However, the pore pressure was higher closer to the injection port, with the pore pressure at 8 cm from the injection port being greater than that at 18 cm, which was greater than that at 28 cm. This was due to the shorter transport path for CO2 gas and the rapid replenishment of desorbed gas at points closer to the injection port. Thus, the CO2 displacement process followed the “hierarchical displacement” law.

The pore pressure distribution is complicated under different CO2 injection pressure. When the injection pressure is 0.6 MPa, the pore pressure presents a change of “decreasing and then increasing”. While when the injection pressure is 0.8 and 1.0 MPa, the pore pressure presents a change of “single increasing”, which is mainly manifested by the inconsistency before the CO2 breakthrough. The difference before CO2 breakthrough was mainly due to the CH4 partial pressure (Fig. 6), CH4 discharge rate and CH4 desorption rate at 0.6 MPa. When the injection pressure is 0.6 MPa, the CH4 desorption rate is less than the CH4 discharge rate, and the CH4 partial pressure decreases, resulting in the CH4 discharge from the coal seam being greater than the CH4 adsorption state desorption amount. The coal seam is dominated by the free CH4 free state desorption emission, and the coal pore pressure decreases.

Comparing the pore pressure changes under different CO2 injection pressures, as shown in Fig. 5(a), (b), and (c), the pore pressure balance time included 250, 180, and 154 min for the CO2 injection pressures of 0.6, 0.8, and 1.0 MPa, respectively. This indicated that higher CO2 injection pressures resulted in a shorter equilibrium time. Additionally, at the same monitoring position, the pore pressure was consistently higher at greater injection pressures than lower ones, with the pressures at 0.8 and 1.0 MPa always exceeding the original coal seam pore pressure (Table 2). For instance, at the 100 min of injection, the pore pressures at the P1 monitoring position were 0.38, 0.72, and 0.89 MPa for the injection pressures of 0.6, 0.8, and 1.0 MPa, respectively. Consequently, the higher CO2 injection pressures led to higher equilibrium pressures and shorter time, which benefited coalbed methane extraction.

Variation of coal seam temperature

The temperature change of the coal seam is crucial for analyzing the behavior of CO2 within the seam and understanding the energy mechanisms of CO2 displacing CH4. During the CO2 displacement of CH4, the temperature of the adsorbed CO2 increased, and the temperature of CH4 desorption decreased. This competitive adsorption between CO2 and CH4 can be monitored by observing the temperature variations throughout the displacement process. In our experiment, temperature changes were tracked at three monitoring points (8, 18, and 28 cm from the injection port) in real time. To account for any errors caused by the CO2 injection temperature, we continuously monitored the CO2 injection temperature (T0). For comparative analysis, we used the temperature variation (ΔT = T-T0). The temperature changes at different monitored positions are illustrated in Fig. 7.

Figure 7 demonstrates that when the gas injection pressure was 0.6 MPa, the coal seam temperature exhibited the change of “slow decrease - rapid increase - slow decrease.” At the injection pressures of 0.8 and 1.0 MPa, the coal seam temperature followed a pattern of “slow increase-rapid increase-slow decrease”. The difference is the pre-CO2 breakthrough stage. Before CO2 broke through the coal body, the coal seam temperature exhibited a downward trend, indicating that CH4 desorption was predominant at this stage. When the gas injection pressure was 0.8 or 1.0 MPa, the coal seam temperature consistently increased. This indicated that as the amount of CO2 injected increased, the competitive adsorption between CO2 and CH4 in the coal seam became more pronounced, with a higher amount of CO2 absorption. The time taken during the previous stage of the rapid rise in coal seam temperature varied at different monitoring points (Table 4). For instance, at a pressure of 0.8 MPa, the time at 8 cm, 18 cm, and 28 cm from the injection port to enter the rapid ascent stage were 0.42, 21.42, and 47.42 min, respectively. This variation indicated that as the distance from the gas injection port increased, there was a more pronounced time lag in the coal seam temperature, reaching the rapid rise stage. This observation reflects the “hierarchical displacement” phenomenon of CO2 in coal seam gas, moving “from near to far”, which aligns with the pore pressure changes observed at different monitoring positions discussed in Sect. 3.2. Under various CO2 injection pressures, the coal seam temperature exhibited a period of rapid heating. This phenomenon occurred because CO2 has a higher adsorption capacity and adsorption heat than CH4. The rapid increase in coal seam temperature indicated that CO2 adsorption was the predominant factor at this stage. Once the temperature peaked, it began to decline owing to a reduction in the CO2 adsorption rate and the heat exchange between the coal and the external environment. To further investigate the impact of the gas injection pressure on the coal seam temperature, a comparative analysis was conducted using a coal seam temperature 18 cm from the CO2 gas injection point (Fig. 8).

Figure 8 illustrates that as the gas injection pressure increased, the time required for the same temperature monitoring point to enter the rapid rise stage decreased. Specifically, at CO2 injection pressures of 0.6, 0.8, and 1.0 MPa, the time to reach the rapid rise stage were 32.98, 25.42, and 24.83 min, respectively. This trend indicated that a higher gas injection pressure enhanced the CO2 migration rate, facilitating its movement. Additionally, at these pressures, the maximum temperatures at 18 cm from the CO2 injection point were 8.5, 9.3, and 12.3 °C, respectively, indicating that the increased injection pressure increased the heat release from the coal seam. This heat release likely reduced CH4 adsorption on the active sites, thereby increasing the gas desorption rates. Consequently, the higher injection pressure accelerated CO2 migration and enhanced the heat release and temperature in the coal seam, thereby promoting gas desorption.

Variation of CH4 desorption

Improving the recovery rate of CH4 was the primary objective of the CO2 displacement coal seam gas test. The recovery rate (η) was defined as the percentage of the desorbed volume relative to the initial saturated adsorption volume of CH4, as calculated using Eq. (1). Figure 9 illustrates the relationship between CH4 cumulative desorption, CH4 recovery rate, and time.

where η is the recovery rate; Vde is the CH4 desorption volume, L; and V0 is the initial saturated adsorption volume of CH4, L.

Figure 9 illustrates that as the displacement time increased, both the cumulative desorption amount and the recovery rate of CH4 gradually increased. Additionally, higher CO2 injection pressures resulted in greater cumulative desorption amounts and recovery rates. The displacement equilibrium time varied with the CO2 injection pressure. Higher pressures resulted in shorter displacement equilibrium time. This also confirms that higher CO2 injection pressures reduce the time cost of the gas injection. To compare and analyze changes in desorption capacity and recovery rate, the displacement equilibrium time at an injection pressure of 1.0 MPa (166 min) was selected as the critical time, and we found that with the increase of displacement pressure from 0.6 MPa to 0.8 MPa and 1.0 MPa, the cumulative desorption capacity of CH4 increased from 89.28 L to 94.11 L and 97.24 L, and the recovery rate increased from 76.12 to 78.95% and 81.10%.

The cumulative gas desorption amount and displacement time exhibited a nonlinear relationship with varying gas desorption rates (curve slopes) at different time. Based on the characteristics of CO2 breakthrough time and gas desorption rate, the cumulative gas desorption amount was categorized into three stages: high efficiency, slow efficiency, and low efficiency. Table 5 shows that the CH4 desorption capacity was the highest in the high-efficiency desorption stage, and CH4 extraction was concentrated before CO2 breakthrough. During this stage, CH4 was primarily in the free state, with the injected CO2 primarily driving the CH4 output, which was largely affected by permeability. The high-efficiency desorption stage significantly contributed to the gas extraction and was highly efficient. After the CO2 breakthrough, free CH4 was gradually driven out, and the extraction entered the slow-efficiency desorption stage, where the gas injection displacement effect became more prominent. Here, the recovery rate increased from 13.09% at 0.6 MPa to 17.65% at 1.0 MPa. This stage was characterized by enhanced displacement, with pressurization promoting the production of adsorbed CH4. By the end of the experiment, the CH4 output was less affected by displacement effects, along with minimal contribution to gas extraction, thus marking the low-efficiency extraction stage.

Residual CH4 content

As the gas extraction progressed, the pressure within the coal seam gradually decreased, which reduced the pressure gradient between the extracted coal body and extraction borehole. This diminished pressure gradient may result in an insufficient “gas flow driving force” during the later stages of extraction, which could further decrease the pure gas flow rate while a large amount of gas remained in the coal seam. Improper management of this residual gas can increase the risk of coal and gas outbursts. The residual gas content of the coal seam was defined as the original gas content minus the CH4 desorption amount during the CO2 injection process when CH4 adsorption equilibrium was reached before CO2 injection. This could be a crucial indicator for evaluating the extraction effectiveness and the risk of outburst accidents. Figure 10 illustrates the residual gas content in the coal seam under different gas injection pressures.

Figure 10 shows that the residual gas content of the coal seam gradually decreased with increasing injection pressure. By the end of the experiment, as the injection pressure rose from 0.6 to 1.0 MPa, the residual gas content in the coal seam fell from 1.654 to 1.382 m3/t, and the displacement time decreased from 276 to 184 and 175.8 min. Compared with the original coal seam gas content, the gas injection pressure increase led to reductions of 76.99%, 78.94%, and 81.19%, respectively (Table 6). This trend was attributed to the fact that higher injection pressures increased the CO2 adsorption capacity, facilitating CO2 migration into the smaller pores of the coal seam and replacing adsorbed CH4 with free CH4. According to the extended Langmuir equation, CO2 injection lowered the partial pressure ratio of CH4, with higher injection pressures resulting in a lower partial pressure of CH4 in the coal body, thereby promoting CH4 desorption. Simultaneously, the higher injection pressures accelerated the gas seepage rate and enhanced the movement of free CH4.

As the displacement time increased, the residual gas content of the coal seam gradually decreased, and the reduction rate progressively diminished. This is because CH4 mainly comes from macropores in the early stage, and CH4 desorption is mainly controlled by pores and micropores in the later stage. The diffusion coefficient of large holes is larger than that of small holes and microholes, so the residual gas content of coal seam is gradually reduced in time. Under varying injection pressures, the residual gas content of the coal seams changed over time but ultimately stabilized. This was because for the same coal quality, the specific surface area, pore volume, and other pore structure parameters of the coal body remained relatively constant, preserving the characteristics of coal seam gas storage. Consequently, regardless of the changes in injection pressure, the quantity of gas trapped in the partially closed and poorly connected tiny pore spaces remained fixed. Based on the observed changes in the residual gas content, we hypothesized (indicated by the hollow circle in Fig. 10) that the residual gas content could decrease to 1.376 m3/t when the displacement time reached 400 min, regardless of whether the gas injection pressure was 0.6, 0.8, or 1.0 MPa. According to the “Detailed Rules for the Prevention and Control of Coal and Gas Outbursts”, the recommended critical values were a gas pressure (P) of 0.74 MPa and a gas content (W) of 8 m3/t (or 6 m3/t in the structural zone). In field implementation, the critical gas pressure was typically set at 0.74 MPa. However, owing to the variability of geological conditions in coal seams, the critical gas content values can differ between seams. For example, on November 25, 2019, a coal and gas outburst occurred at the Guizhou Sanjia Coal Mine. At that time, the mine was at a depth of 891 m, with the M16 coal seam’s original gas content at 7.57 m3/t and the gas pressure at 0.52 MPa, both below the recommended critical values, whereas an outburst still occurred. Consequently, a residual gas content of 2 m3/t was set as the threshold limit value (TLV), which was influenced by the initial gas adsorption amount and geological conditions. As shown in Fig. 10, the methane content decreased below the TLV after 145.64, 98.44, and 83.60 min of expulsion at injection pressures of 0.6, 0.8, and 1.0 MPa, respectively. This indicated that higher CO2 injection pressures effectively reduced the pre-extraction time and improved the coal seam gas pre-extraction rate.

Synergistic CO2 sequestration characteristics

The primary objective of CO2-ECBM is to increase the methane gas production from wells and sequester carbon dioxide in coal seams. Based on a study by Perera et al.41, the CO2 injection pressure is crucial in CO2-ECBM engineering, as the optimal injection pressure significantly improves the CO2 storage. To enable a more detailed comparison and analysis of how pressure affects the CO2 storage efficiency (SE), the CO2 SE was calculated, as outlined in Eqs. (2) and (3), respectively. Figure 11(a) and 11(b) illustrate the changes in CO2 storage capacity and SE over time under various injection pressures.

Figure 11(a) illustrates that the cumulative CO2 sequestration volume increased with displacement time under various injection pressures. To achieve the same cumulative CO2 sequestration volume, the longest time was required at an injection pressure of 0.6 MPa, while the shortest time was needed at 1.0 MPa. As the injection pressure increased, the amount of CO2 sequestered also increased, with the maximum CO2 storage per unit mass rising from 16.483 m3/t at 0.6 MPa to 19.907 m3/t at 1.0 MPa. Based on the CO2 storage per unit mass of coal, it was speculated (indicated by the hollow shape in Fig. 11(a)) that the CO2 storage per unit mass could reach its capacity limit at different pressures after 300 min of displacement. At injection pressures of 0.6, 0.8, and 1.0 MPa, the limit CO2 storage per unit mass of coal stabilized at 16.64, 17.40, and 20.20 m3/t, respectively, with the increase of 3.6 m3/t when the pressure rose from 0.6 to 1.0 MPa. However, higher CO2 injection pressures resulted in lower carbon sequestration efficiency. For instance, at the displacement time of 150 min, the carbon sequestration efficiency decreased from 92.61% at 0.6 MPa to 91.01% at 0.8 MPa and 88.39% at 1.0 MPa (Fig. 11(b)). These results indicated that as the CO2 injection pressure increased, a larger proportion of injected CO2 flowed out rather than remaining in the coal seam.

The CO2 injection rate and CH4 desorption rate are essential parameters for evaluating the CO2 injectability and the effectiveness of gas extraction and play a crucial role in assessing the efficiency of gas injection for gas replacement. Figures 12 and 13 illustrate the variation in the CO2 injection rate and changes in the outlet CH4 desorption rate under different CO2 injection pressures, respectively.

Figures 12 and 13 illustrate that both the outlet CH4 desorption rate and CO2 injection rate exhibited three stages: “slow decline-rapid decline-stability”. These stages corresponded to the high-efficiency, slow, and low-efficiency desorption stages, respectively, as detailed in Section 3.4. During the high-efficiency desorption stage, both the CO2 injection rate and the CH4 desorption rate increased with increasing CO2 injection pressure. The CO2 injection rate increased from 2133.69–1730.18 mL/min at 0.6 MPa to 3578.45–3045.96 mL/min at 1.0 MPa, and the CH4 desorption rate increased from 935.06–841.08 mL/min at 0.6 MPa to 1287.96–1081.65 mL/min at 1.0 MPa. During the low-efficiency desorption stage, as the CO2 injection pressure increased, the CO2 injection rate decreased. The difference in CH4 desorption rates changed little. The CO2 injection rate decreased from 860.15 mL/min at 0.6 MPa to 769.49 mL/min at 1.0 MPa, while the CH4 desorption rate stabilized at 10–20 mL/min during the terminal stage. Higher CO2 injection pressures facilitated initial CH4 desorption and accelerated CO2 injection into the coal seam. Concurrently, the higher CO2 injection pressures increased the initial coal seam pore pressure (Figure 5), reduced the CH4 partial pressure, accelerated plastic deformation and potential failure in the vulnerable areas of coal, and promoted the penetration and regeneration of the pore fracture network, thereby enhancing the initial CH4 desorption. Thus, from a gas extraction perspective, the increased gas injection pressure improved the early-stage displacement effectiveness but had little impact on the later-stage displacement. From the CO2 injectability perspective, a higher injection pressure resulted in a higher initial gas injection rate but a more significant decrease in the later gas injection rate, primarily owing to the greater CO2 adsorption expansion deformation. Therefore, it is advisable to reduce the CO2 injection pressure once the CO2 output rate reaches the maximum to alleviate the decrease in the CO2 injection rate and increase the CH4 output rate.

Conclusion

-

1.

As the CO2 injection pressure increased from 0.6 to 1.0 MPa, the time required to achieve 30% of the high-concentration gas for industrial and domestic fuels decreased from 122.32 to 92.29 min, and the time to reach 6% of the utilization concentration for internal combustion engine power generation gas decreased from 155.72 to 114.48 min. This increase in the injection pressure effectively reduced the cost of the injection time. Additionally, with higher CO2 injection pressures, the equilibrium pressure increased with greater heat release from the coal seam.

-

2.

As the CO2 injection pressure increased from 0.6 to 1.0 MPa, the cumulative desorption volume of CH₄ increased from 89.28 to 97.24 L, and the recovery rate increased from 76.12 to 81.10%. The residual gas content of the coal seam decreased to 1.376 m3/t at the injection pressures of 0.6, 0.8, and 1.0 MPa after 400 min of displacement. With the residual gas content of 2 m3/t as the Threshold Limit Value (TLV), the increasing injection pressure from 0.6 to 1.0 MPa reduced the displacement time from 145.64 to 83.60 min. Therefore, a higher CO2 injection pressure effectively shortened the pre-pumping time and enhanced the pre-pumping rate of the coal seam gas.

-

3.

Increasing the CO2 injection pressure from 0.6 to 1.0 MPa raised the ultimate CO2 storage capacity per unit mass of coal by 3.6 m3/t, demonstrating that a higher gas injection pressure effectively enhanced the CO2 storage capacity. However, this increase in pressure also contributed to a 4.22% decrease in CO2 sequestration efficiency.

-

4.

The initial perturbation caused by the high CO2 injection pressure during the high-efficiency desorption stage resulted in high initial injection and CH4 desorption rates. However, in the low-efficiency desorption stage, the CO2 injection rate decreased with increasing injection pressure. From the gas extraction perspective, although a higher gas injection pressure improved the displacement effectiveness during the high-efficiency desorption stage, it was less effective during the low-efficiency desorption stage. Additionally, the increased injection pressure significantly reduced the coal gas permeability during the low-efficiency desorption stage. In practical applications, it is advisable not to increase the CO2 injection pressure indiscriminately. Instead, reducing the CO2 injection pressure in the low-efficiency desorption stage could decelerate CO2 migration within the coal, extend the gas migration time, mitigate the decrease in CO2 injection efficiency, and simultaneously enhance the CH4 output.

Data availability

All data generated or analysed during this study are included in this published article.

References

Liu, J. S. et al. Evaluation of stress-controlled coal swelling processes. Int. J. Coal Geol. 83, 446–455 (2010).

Chen, D., Pan, Z. J., Liu, J. S. & Connell, L. D. An improved relative permeability model for coal reservoirs. Int. J. Coal Geol. 109, 45–57 (2013).

Zhang, H. B., Liu, J. S. & Elsworth, D. How sorption-induced matrix deformation affects gas flow in coal seams: a new FE model. Int. J. Rock Mech. Min. 45, 1226–1236 (2008).

Zhang, K. Z. et al. Geological control of fold structure on gas occurrence and its implication for Coalbed Gas Outburst: Case Study in the Qinan Coal Mine, Huaibei Coalfield, China. Nat. Resour. Res. 29, 1375–1395 (2020).

Li, X. D. et al. Multidimensional attribute statistics and characteristic analysis of unsafe actions in coal mine gas explosion accidents. Saf. Coal Mins. 55, 233–240 (2024). (in Chinese).

Guo, W. & Shi, Y. Remote sensing inversion of CO2 emissions from super-large coal-fired power plants in China based on OCO-2/ 3 satellite. J. Univ. Chin. Acad. Sci. 41 (04), 490–502 (2024).

Le, Q. C. et al. Global Carbon Budget 2016. Earth Syst. Sci. Data. 8, 605–649 (2016).

Cui, X., Zhang, J. Y., Guo, L. W. & Gong, X. M. Experimental investigation of the use of expansive materials to increase permeability in coal seams through expansive fracturing. Shock Vib. 2020, 7925724 (2020).

Huang, Q. M., Li, M. Y., Yan, M. Y., Ni, G. H. & Guo, Z. G. Influence mechanism of inorganic salts on coal permeability during foam fracturing. Energy. 276, 127561 (2023).

Zhao, Z. D. et al. Evaluating coal pore structure and gas sorption-diffusion behavior alteration induced by ultrasound stimulation using sorbing tests and matrix diffusion modeling. Geoenergy Sci. Eng. 234, 212642 (2024).

Li, H. et al. Effect of cyclic thermal stimulation on the pore structure and fluid space of coal and inspiration for coalbed methane production. Energy. 289, 129994 (2024).

Liu, C., Yang, X. & Yu, B. Rock-breaking mechanism and experimental analysis of confined blasting of borehole surrounding rock. Int. J. Min. Sci. Technol. 27, 795–801 (2017).

Dai, L, P. et al. Parameter Design Method for Destressing Boreholes to Mitigate Roadway Coal Bursts: Theory and Verification. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-024-04042-x (2024).

Xie, J. N. et al. Effects of pulse wave on the variation of coal pore structure in pulsating hydraulic fracturing process of coal seam. Fuel. 264, 116906 (2019).

Su, X. et al. Experimental study of water blocking damage on coal. J. Petrol. Sci. Eng. 156, 654–661 (2017).

Mavor, M. J., Gunter, W. D. & Robinson, J. R. Alberta multi-well micro-pilot testing for CBM properties, enhanced methane recovery and CO2 storage potential. SPE Annual Technical Conference and Exhibition. SPE-90256-MS (2004).

Olajossy, A. Some parameters of coal methane system that cause very slow release of methane from virgin coal beds (CBM). Int. J. Min. Sci. Technol. 27, 321–326 (2017).

Fujioka, M., Yamaguchi, S. & Nako, M. CO2-ECBM field tests in the Ishikari coal basin of Japan. Int. J. Coal Geol. 2010. 82 (3–4), 287–298 (2010).

Pagnier, H. et al. Field experiment of ECBM-CO2 in the upper Silesian basin of Poland (RECOPOL). Greenhouse Gas Control Technol. 7 (II-Part 1), 1391–1397 (2005).

Van Bergen, F. et al. Production of gas from coal seams in the Upper Silesian Coal Basin in Poland in the post-injection period of an ECBM pilot site. Int. J. Coal Geol. 77, 175–187 (2009).

Vishal, V., Ranjith, P. G. & Singh, T. N. CO2 permeability of Indian bituminous coals: implications for carbon sequestration. Int. J. Coal Geol. 105, 36–47 (2013).

Wong, S. et al. Enhanced coalbed methane and CO2 storage in anthracitic coals-Micro-pilot test at South Qinshui, Shanxi, China. Int. J. Greenhouse Gas Control. 1 (2), 215–222 (2007).

Aziz, N. I. & Ming-Li, W. The effect of sorbed gas on the strength of coal-an experimental study. Geotech. Geol. Eng. 17 (3), 387–402 (1999).

Larsen, J. W. The effects of dissolved CO2 on coal structure and properties. Int. J. Coal Geol. 57 (1), 63–70 (2004).

Bagga, P., Roy, D. G. & Singh, T. N. Effect of carbon dioxide sequestration on the mechanical properties of Indian coal. Eurock & Geomechanics Colloquium-future Development of Rock Mechanics, Schubert, W & Kluckner, A, (2015).

Jia, J. et al. An experimental study on the damage characteristics of mechanical properties of anthracite induced by supercritical CO2 injection. Environ. Earth Sci. 79 (1), 1–15 (2020).

Liu, J. et al. Evolution characteristics of coal microstructure before and after supercritical CO2 treatment based on the L-weighing-LNMR method. Energy Fuels. 37 (13), 9347–9358 (2023).

Perera, M. S. A., Ranjith, P. G. & Viete, D. R. Effects of gaseous and super-critical carbon dioxide saturation on the mechanical properties of bituminous coal from the Southern Sydney Basin. Appl. Energy. 110, 73–81 (2013).

Vishal, V., Ranjith, P. G. & Singh, T. N. An experimental investigation on behaviour of coal under fluid saturation, using acoustic emission. J. Nat. Gas Sci. Eng. 22, 428–436 (2015).

Bai, G. et al. Experimental study on damage law of liquid CO2 cyclic freeze-thaw coal. Energy. 284, 128532 (2023).

Li, Z. F., Xu, H. F. & Zhang, C. Y. Liquid nitrogen gasification fracturing technology for shale gas development. J. Petrol. Sci. Eng. 138, 253–256 (2016).

Bai, G. et al. Effect of CO2 injection on CH4 desorption rate in poor permeability coal seams: An experimental study. Energy. 238, 121674 (2022).

Bai, G., Su, J., Fu, S. G., Li, X. M. & Zhou, X. H. Effect of CO2 injection on the gas desorption and diffusion kinetics: An experimental study. Energy. 288, 129921 (2024).

Zhang, C. et al. Laboratory experiments of CO2-enhanced coalbed methane recovery considering CO2 sequestration in a coal seam. Energy. 262, 125473 (2023).

Zhang, X. & Ranjith, P. G. Experimental investigation of effects of CO2 injection on enhanced methane recovery in coal seam reservoirs. J. CO2 Utilization. 33, 394–404 (2019).

Niu, Q. et al. Experimental study on the softening effect and mechanism of anthracite with CO2 injection. Int. J. Rock Mech. Min. Sci. 138, 104614 (2021).

Li, Z. W., Yu, H. J. & Bai, Y. S. Numerical Simulation of CO2-ECBM Based on Multi-Physical Field Coupling Model. Sustainability. 14, 11789 (2022).

Lin, J., Ren, T., Cheng, Y. P. & Jan, N. et al. Laboratory quantification of coal permeability reduction effect during carbon dioxide injection process. Process Saf. Environ. Prot. 148, 638–649 (2021).

Hou, J. et al. Log evaluation of a coalbed methane (CBM) reservoir: a case study in the southern Qinshui basin, China. J. Geophys. Eng. 11 (1), 1–13 (2014)

Li, Z. et al. Analysis of permeability evolution mechanism during CO2 enhanced coalbed methane recovery based on impact factor method. Fuel. 304, 121389 (2021).

Perera, M. S. A. et al. Optimization of enhanced coal-bed methane recovery using numerical simulation. J. Geophys. Eng. 12 (1), 90–107 (2015).

Hou, Y. et al. Numerical simulation of the effect of injected CO2 temperature and pressure on CO2-enhanced coalbed methane. Appl. Sciences-Basel. 10 (4), 1385 (2020).

Liu, S. Q. et al. CO2 injectability and CH4 recovery of the engineering test in qinshui Basin, China based on numerical simulation. Int. J. Greenhouse Gas Control. 95, 102980 (2020).

Fan, C. J. et al. Thermo-hydro-mechanical-chemical couplings controlling CH4 production and CO2 sequestration in enhanced coalbed methane recovery. Energy. 173, 1054–1077 (2019).

Liu, X. D. et al. Modelling of geomechanical response for coal and ground induced by CO2-ECBM recovery. Gas Sci. Eng. 113, 204953 (2023).

Liu, X. d., Sang, S. X., Zhou, X. Z. & Wang, Z. L. Coupled adsorption-hydro-thermo-mechanical-chemical modeling for CO2 sequestration and well production during CO2-ECBM. Energy. 262, 125306 (2023).

Fang, H. H. et al. Coupling Mechanism of THMC Fields in Crushed Soft Coal with Low Permeability after CO2 Injection and Its Application in CO2-ECBM Technology. Energy Fuels. 38, 6891–6911 (2024).

Cheng, M, X. et al. Prediction Model of Lean Coal Adsorption of Power Plant Flue Gas. ACS Omega. 9 (10), 12101–12115 (2024).

Acknowledgements

This work was financially supported by the Scientific Research Funding project of National Natural Science Foundation of China (52104195, 52274204), China Association for Science and Technology ‘Young Talent Promotion Project’(2022QNRC001), and Liaoning Provincial Natural Science Foundation Outstanding Youth Fund Project (2024JH3/10200042).

Author information

Authors and Affiliations

Contributions

Gang Bai: Conceptualization, Methodology, Investigation, Writing-original draft. Jun Su: Investigation, Writing-original draft. Yadong Wang: Investigation. Mufeng Xiao: Resources. Xihua Zhou: Resources. Jundian Chen: Resources.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bai, G., Su, J., Wang, Y. et al. Effect of CO2 injection pressure on enhanced coal seam gas extraction. Sci Rep 14, 25735 (2024). https://doi.org/10.1038/s41598-024-76154-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-76154-x